Virtual Reality-Based Ergonomic Modeling and Evaluation Framework for Nuclear Power Plant Operation and Control

Abstract

1. Introduction

2. Background and Literature Reviews

2.1. Main Control Room in a Nuclear Power Plant

2.2. Virtual Model-Based Applications in a Nuclear Power Plant

3. Human Factor Guidelines and Ergonomic Issues for the MCR

3.1. Human Factor Guidelines for the MCR and its Console Design

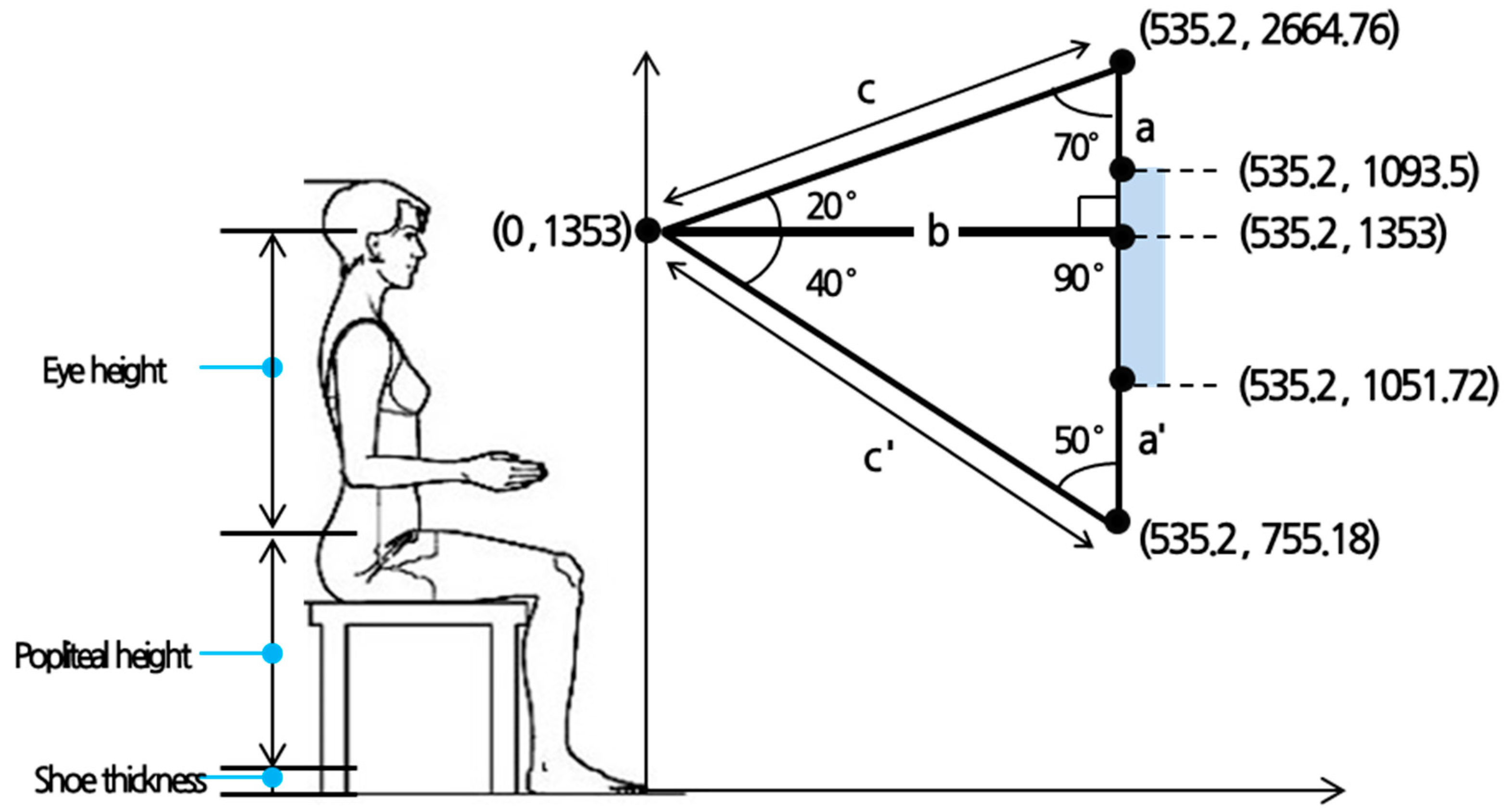

3.2. Anthropometric Data for Console Design and Ergonomic Issues in an MCR

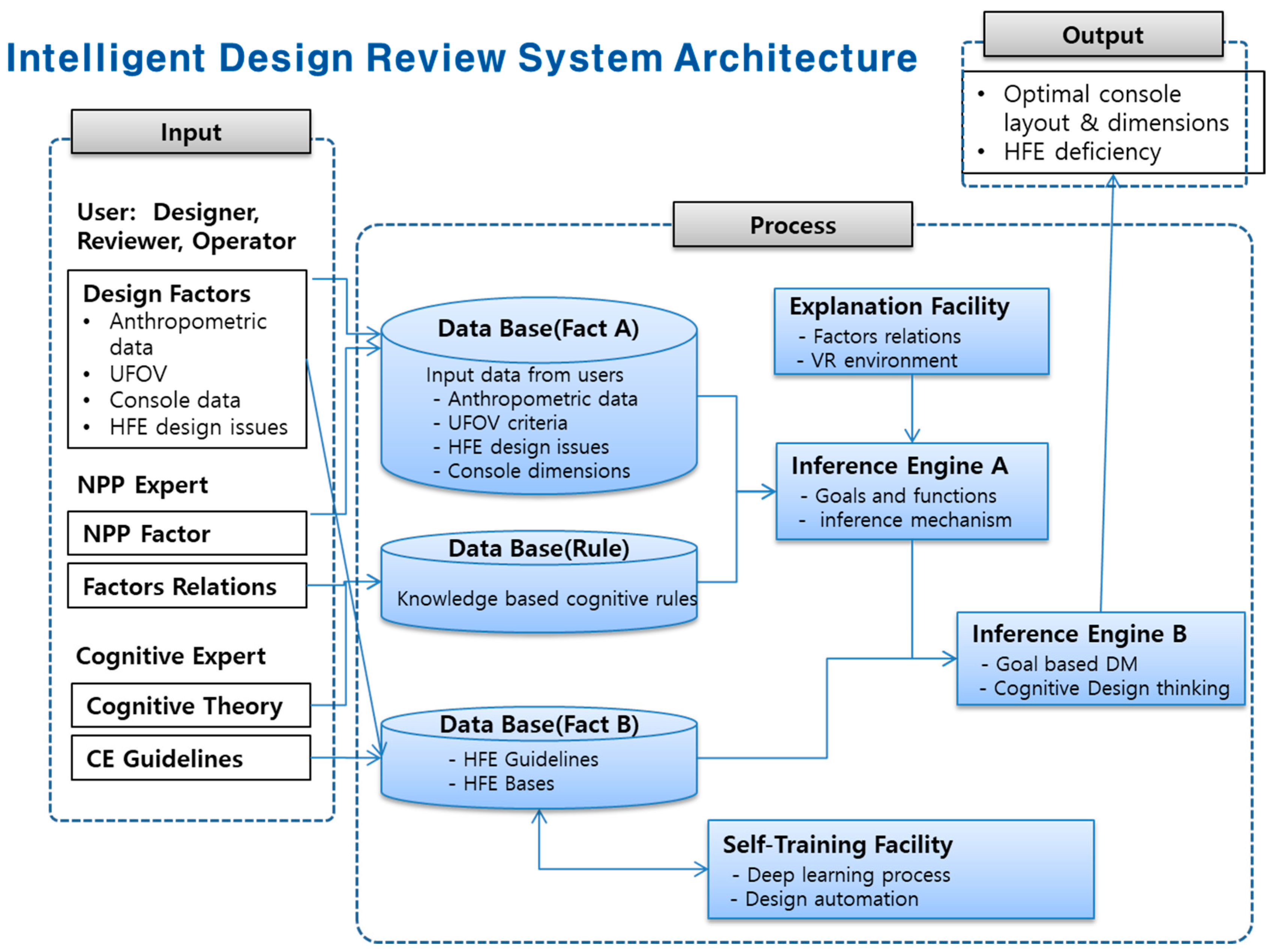

4. Intelligent MCR Design Review Framework using the Virtual Model

4.1. IDRS Building Blocks

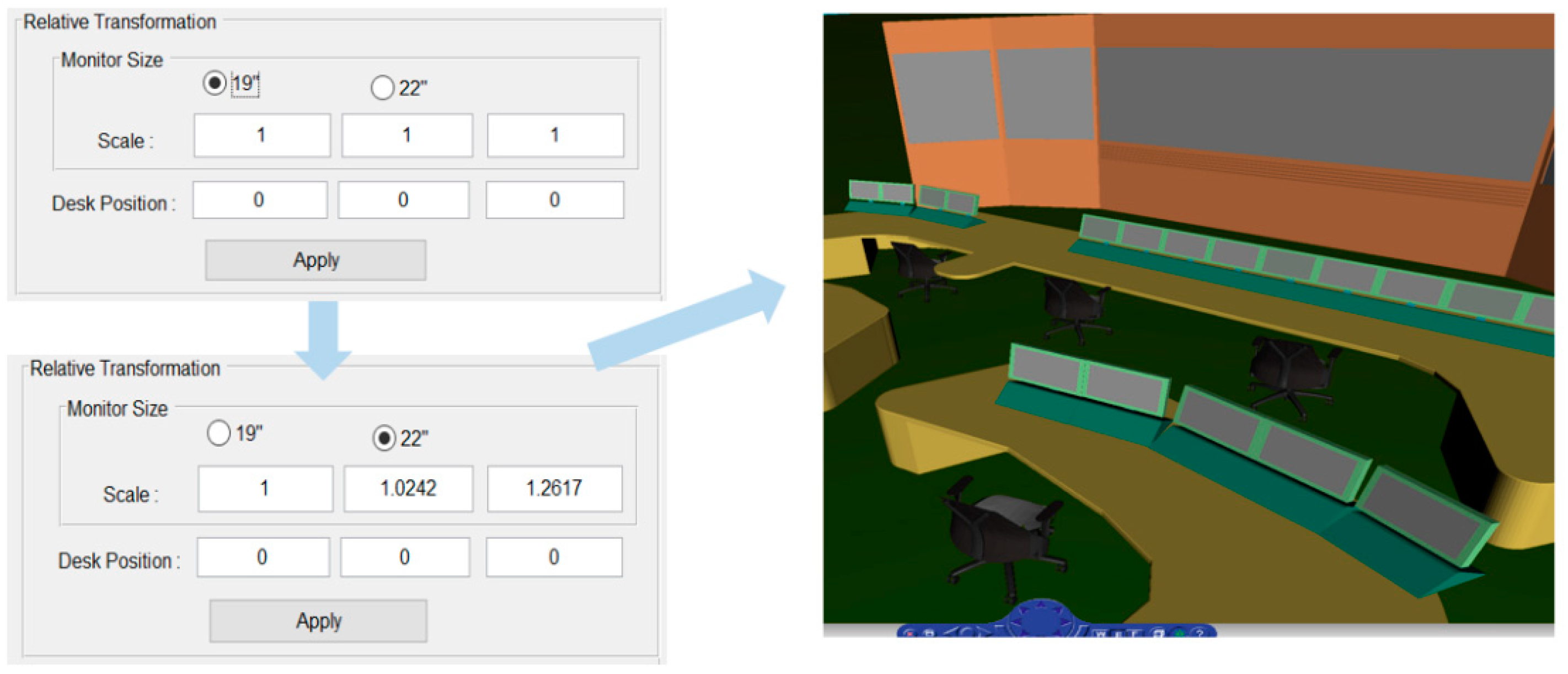

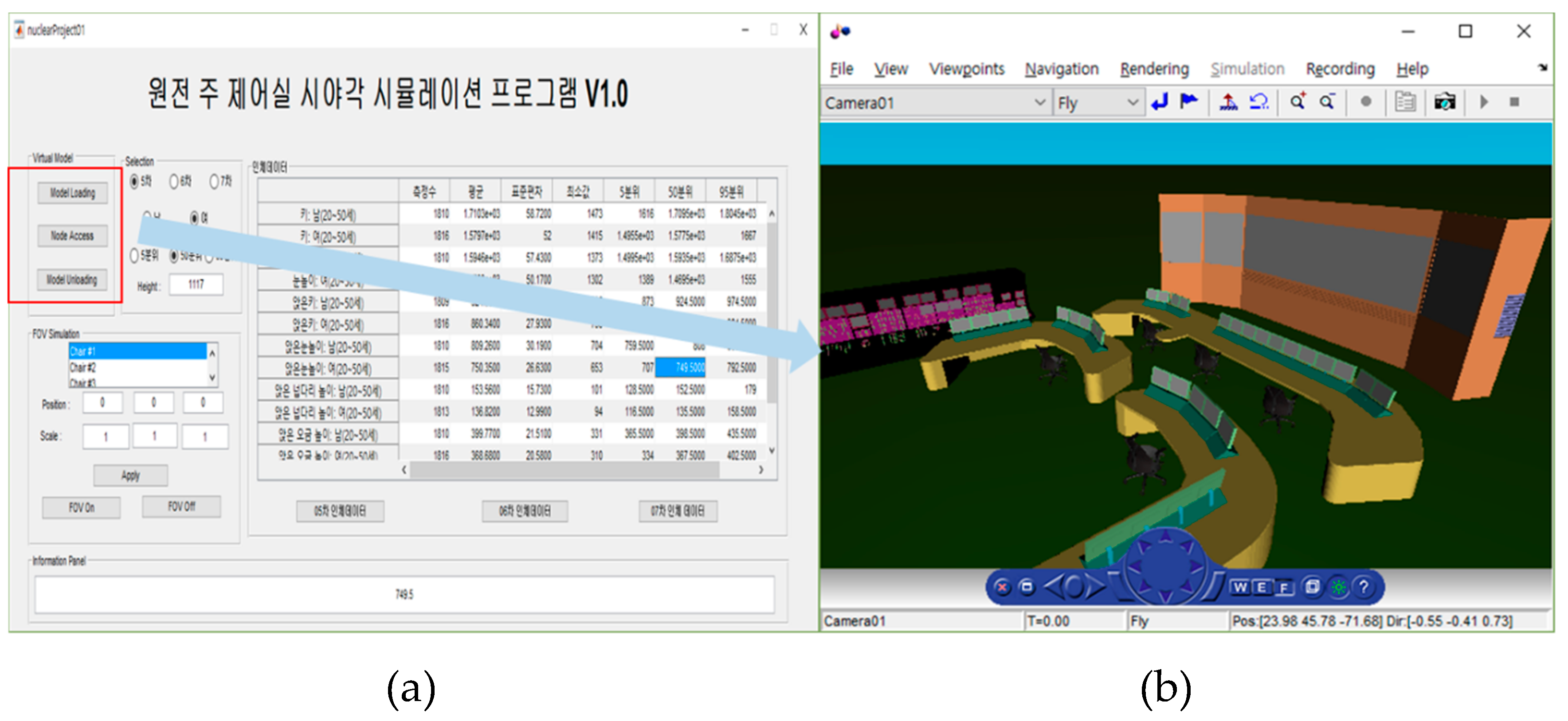

4.2. Virtual Model-Based Implementation of 2D–3D Design

4.3. Virtual Model-Based Simulation and Evaluation for MCR Design Suitability

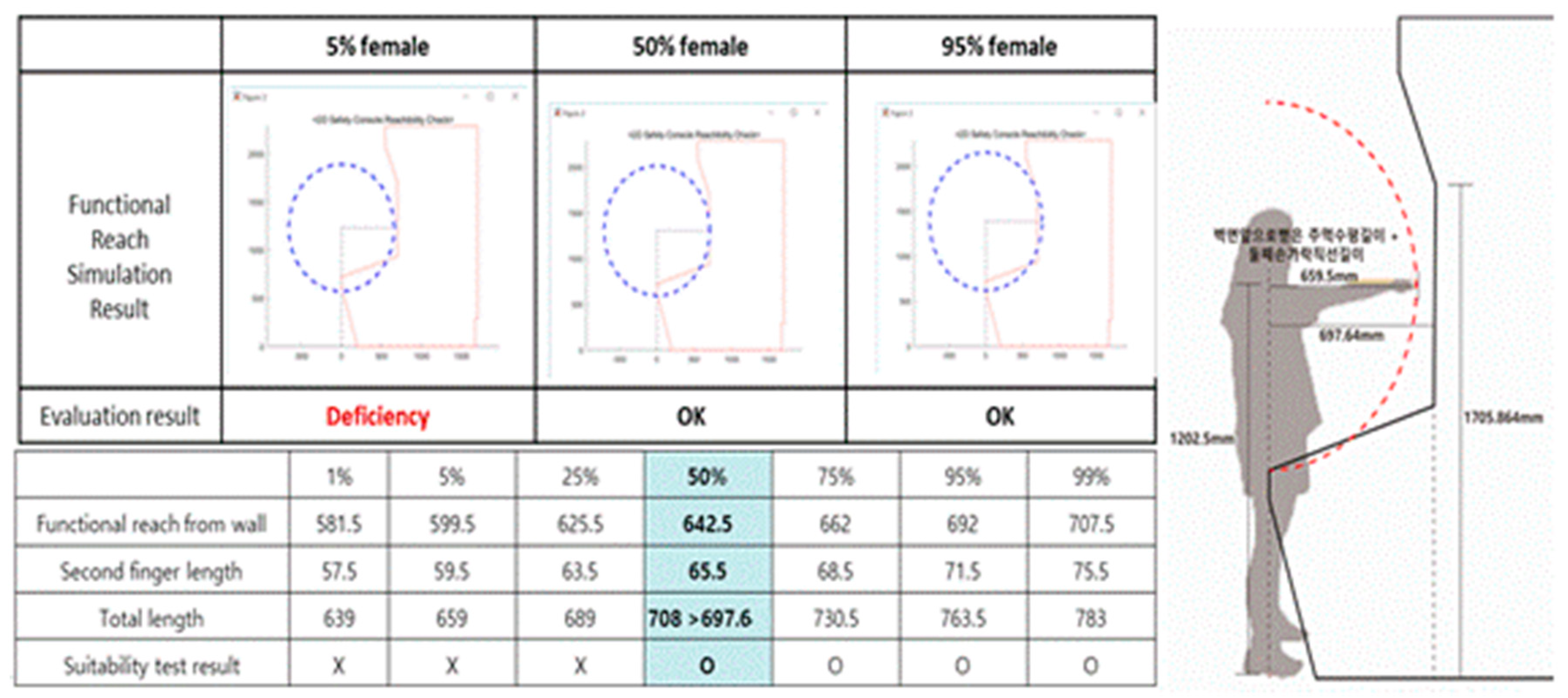

5. Design Improvement Results and Recommendations

6. Conclusions and Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- International Atomic Energy Agency (IAEA). Accident Analysis for Nuclear Power Plants. Available online: https://nucleus.iaea.org/sites/gsan/lib/Safety%20Assessment%20Safety%20Series/Accident%20Analysis%20for%20Nuclear%20Power%20Plants-SRS-23.pdf?Mobile=1&Source=%2Fsites%2Fgsan%2Flib%2F_layouts%2Fmobile%2Fview%2Easpx%3FList%3D2f739bb0%252D85b9%252D4fba%252Db5c3%252D6c457b2661b8%26View%3Dcf24c949%252D7312%252D4eda%252Db1a4%252Ded6747731de9%26CurrentPage%3D1 (accessed on 5 May 2019).

- Wheatley, S.; Sovacool, B.; Sornette, D. Of disasters and dragon kings: A statistical analysis of nuclear power incidents and accidents. Risk Anal. 2017, 37, 99–115. [Google Scholar] [CrossRef] [PubMed]

- United States Nuclear Regulatory Commission. NRC Regulatory Guides. Available online: https://www.nrc.gov/reading-rm/doc-collections/reg-guides/ (accessed on 5 May 2019).

- Cipollaro, A.; Lomonaco, G. Contributing to the nuclear 3S’s via a methodology aiming at enhancing the synergies between nuclear security and safety. Prog. Nucl. Energy 2016, 86, 31–39. [Google Scholar] [CrossRef]

- United States Nuclear Regulatory Commission. Control Room. Available online: https://www.nrc.gov/reading-rm/basic-ref/glossary/control-room.html (accessed on 5 May 2019).

- United States Nuclear Regulatory Commission. Highly Integrated Control Rooms-human Factors. Available online: https://www.nrc.gov/about-nrc/regulatory/research/digital/key-issues/control-room-human.html (accessed on 5 May 2019).

- United States Nuclear Regulatory Commission. Design Practices for Communications and Workstations in Highly Integrated Control Rooms. Available online: https://www.nrc.gov/reading-rm/doc-collections/nuregs/contract/cr6991/ (accessed on 5 May 2019).

- Cha, W.; Choi, E. A case study on designing a console design review system considering operators’ viewing range and anthropometric data. J. Ergon Soc Korea. 2017, 36, 373–383. [Google Scholar]

- Zheng, Z. Cognitive Load Measurement and Application; Routledge: New York, NY, USA, 2018. [Google Scholar]

- U.S. Nuclear Regulatory Commission. Cognitive Skill Training for Nuclear Power Plant Operational Decision Making (NUREC/CR-6126); Westinghouse Electric Corporation: Pittsburgh, PA, USA, 1994.

- Ra, D.W.; Cha, W.C. Development of Design Aiding System for the application of the Cognitive Interface for Information Displays. In Proceedings of the Ergonomics Society of Korea, UNIST, Ulsan, Korea, 23 May 2013. [Google Scholar]

- Boring, R.L.; Joe, J.C.; Ulrich, T.A.; Lew, R.T. Early-stage designed and evaluation for nuclear power plant control upgrades. In Proceedings of the Human Factors and Ergonomics Society 58th Annual Meeting, San Diego, CA, USA, 27–31 October 2014. [Google Scholar]

- Mu, Z.; Huang, R.; Liu, M. A study on the application of virtual reality technology in the field of nuclear power. In Proceedings of the 2017 International Conference on Smart Grid and Electrical Automation (ICSGEA), Changsha, China, 27–28 May 2017. [Google Scholar]

- Yan, G.; Li, M. Path planning and visualizing for maintenance simulation of nuclear power plant. Int. J. Online Eng. 2013, 9, 17–22. [Google Scholar] [CrossRef][Green Version]

- Rodenas, J.; Zarza, I.; Burgos, M.C.; Felipe, A. Developing a virtual reality application for training nuclear power plant operators: Setting up a database containing dose rates in the refueling plant. Radiat. Prot. Dosim. 2004, 111, 173–780. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y. Development and application of virtual nuclear power plant in digital society environment. Int. J. Energy Res. 2018, 43, 1521–1533. [Google Scholar] [CrossRef]

- Onitsuka, S.; Iijima, T.; Yamada, T.; Yoshimura, S. Seismic analysis of nuclear power plants by using three-dimensional finite element models: A review. J. Nucl. Sci. Technol. 2019, 56, 1–16. [Google Scholar] [CrossRef]

- Yoshimura, S.; Kobayashi, K.; Akiba, H.; Suzuki, S.; Ogino, M. Seismic response analysis of full-scale boiling water reactor using three-dimensional finite element method. J. Nucl. Sci. Technol. 2015, 4, 546–567. [Google Scholar]

- Jorge, C.; Mol, A.; Couto, P.; Pereira, C. Nuclear Power-Section 18 Nuclear plants and emergency virtual simulations based on a low-cost engine reuse, Nuclear Power, 1st ed.; Sciyo: Shanghai, China, 2010. [Google Scholar]

- Machado, D.M.; Cotelli, A.; Galvao, D.; Mol, A.C.A.; Carvalho, P.V.R.; Vidal, M. Use dosimetry virtual tool for security studies physics and nuclear. Procedia Manuf. 2015, 3, 1765–1771. [Google Scholar] [CrossRef]

- Xue, F.; Zhao, B.; Zhou, W.; Chen, L.; Wong, H. Computational egress and analysis for nuclear reactor building. In Proceedings of the 2018 International Conference on Computer Science and Application Engineering, Hohhot, China, 22–24 October 2018. [Google Scholar]

- Shen, Y.; Shen, H. The application of virtual reality technology to the conical roof lifting for the AP100 nuclear power plant. In Proceedings of the 2013 21st International Conference on Nuclear Engineering, Chengdu, China, 29–2 August 2013. [Google Scholar]

- Cao, Y.; Mo, Z.; Xiao, L.; Wang, H.; Ai, Z.; Zhang, Z. Efficient visualization of high-resolution virtual nuclear reactor. J. Vis. 2018, 21, 857–871. [Google Scholar] [CrossRef]

- Cha, W. Cognitive Interface; Kaos Book: Seoul, Korea, 2016. [Google Scholar]

- KEPCO E&C. Technical Report: Environment Design for Shingori 5&6; KEPCO E&C: Gimcheon, Korea, 2016; pp. 1–150. [Google Scholar]

- Nuclear Regulatory Commission. Human System Interface Design Review Guideline (NUREG-0700, Revision 2). Available online: https://www.nrc.gov/reading-rm/doc-collections/nuregs/staff/sr0700/ (accessed on 5 May 2019).

- Boring, R.L.; Dudenhoeffer, D.D.; Halbert, B.P.; Gore, B.F. Virtual power plant control room and crew modeling using MIDAS. In Proceedings of the workshop on future control station designs and human performance issues in nuclear power plants, Moulineaux, France, 15 October 2007. [Google Scholar]

- Korea Agency for Technology and Standard. 7th Korean Anthropometric Data Survey Report. Available online: http://www.sizekorea.kr (accessed on 5 May 2019).

- KEPCO E&C. Technical Report: Environment Design for Shingori 3&4; KEPCO E&C: Gimcheon, Korea, 2008; pp. 1–120.

- Lagari, P.L.; Nasiakou, A.; Alamaniotis, M. Evaluation of human machine interface (HMI) on a digital and analog control room in nuclear power plants using a fuzzy logic approach. Int. J. Monit. Surveill. Technol. Res. 2016, 4, 50–68. [Google Scholar] [CrossRef]

- Nasiakou, A.; Bean, R.; Alamaniotis, M. Development of human machine interface for digital control rooms in nuclear power plants. In Proceedings of the NPIC & HMIT, San Francisco, CA, USA, 11–15 June 2017. [Google Scholar]

- Lee, H.; Banerjee, A. A self-configurable large-scale virtual manufacturing environment for collaborative designers. Virtual Real. 2011, 15, 21–40. [Google Scholar] [CrossRef]

| Virtual Model Application Area | Research Studies and Systems |

|---|---|

| Operation guides for NPP controls | Virtual operator training [13]; Path planning and maintenance guiding simulation [14]; Refueling plant training [15]; Virtual roaming simulation and organ dose evaluation [16] |

| Emergency handling in an NPP | Seismic analysis of an NPP [17,18]; Emergency path planning [19]; Security simulation [20]; Egress simulation [21] |

| Reference models for NPP construction | Conical roof lifting for an NPP [22]; Reactor modeling [23] |

| Classification | Horizontal Visual Field | Vertical Visual Field | ||

|---|---|---|---|---|

| General range | The visual field range through which a subject can be viewed is 1° (to the left and right) when a central vertical axis is set up between the left and right eyes. | In the vertical direction, the visual field tilts downwards more; The direction of the visual field is usually placed at 10° downwards. | ||

| Range in deciphering letters | Same visual field axis | 5–10° (left and right from the central axis) | Centered on visual height horizon | Desirable upward visual field limit is 15° |

| Range by which a symbol can be seen | 5–30° (left and right from the central axis) | Upper limit: 20° Lower limit: 30° | ||

| Range by which colors can be distinguished | 30–60° (left and right from the central axis) | Upper limit: 30° Lower limit: 40° | ||

| Classification | Useful Guidelines for Design Configuration |

|---|---|

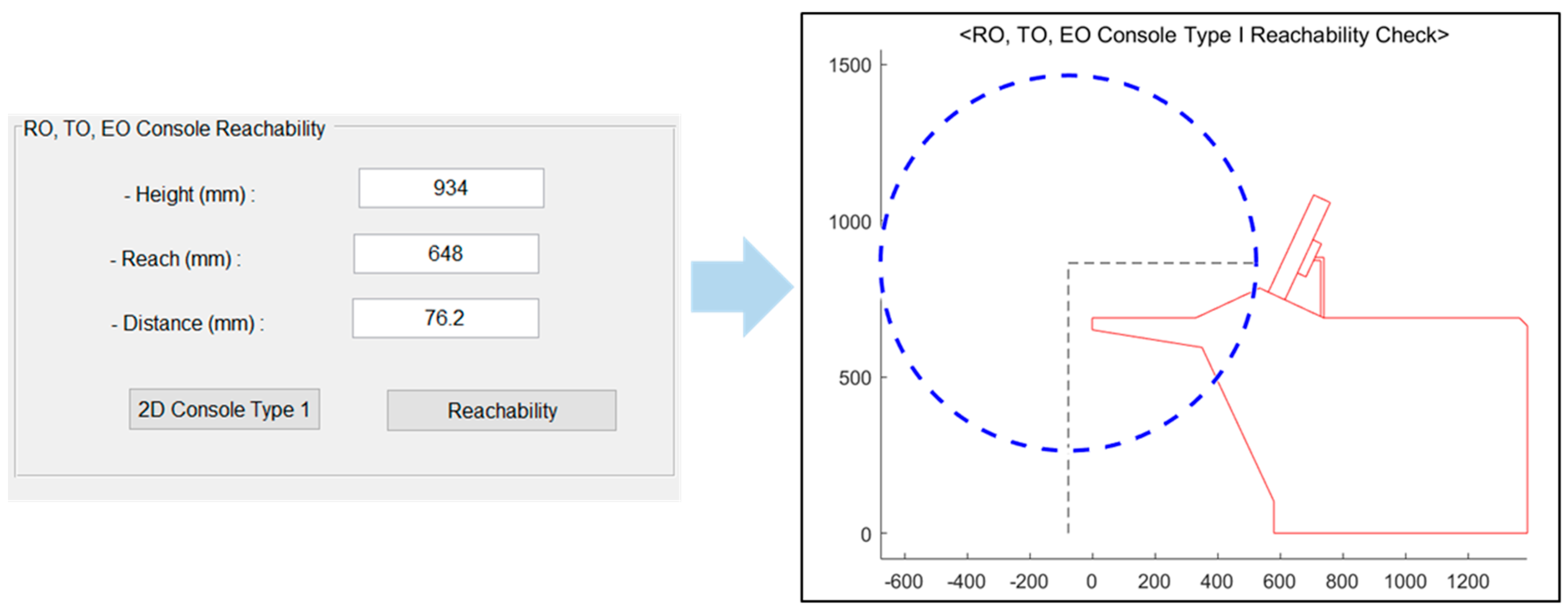

| Horizontal space standard of the control and display devices | All the control and information display units used for the main jobs of a sit-down console should be placed within the maximum values of viewing range and extended reach of a user in the sitting-down position [26]. |

| Standard of console visual display unit (VDU)’s vertical useful field of view (UFOV) | In stand-up and sit-down consoles, all information display units, including an alarm indicator, need to be offered within the 5th percentile of a female’s field of view measurement (75° from horizontal field of view) [26]. The angle that the field of view and a visual display unit (VDU) forms needs to be maintained higher than 45° [26]. |

| Actual layout range standard of VDU information | When main information display units were placed in a sit-down console, horizontal layout range was within 35° (to the left and right) centered on the line of sight (LOS) by using actual console shape data, with a vertical layout range designed to make the LOS 40° downwards [25,26,27]. The bench board slope, in conjunction with its depth, should be such that all controls are within the functional reach radius of the 5th percentile of females [25,26,27]. Controls should be set back a minimum of 3 inches from the front edge to protect against accidental contact [26]. |

| No. | Console Design Evaluation Item | 5% | 50% | 95% |

|---|---|---|---|---|

| 1 | Stature | 161.4 | 170.5 | 179.9 |

| 2 | Eye height | 149.8 | 159.0 | 168.1 |

| 3 | Acromial height | 129.7 | 138.2 | 146.6 |

| 4 | Biacromial height | 36.3 | 39.9 | 43.2 |

| 5 | Finger height | 58.0 | 63.8 | 68.8 |

| 6 | Wall–finger distance | 75.9 | 82.6 | 88.7 |

| 7 | Sitting height | 87.3 | 92.4 | 97.4 |

| 8 | Eye height, sitting | 76.0 | 80.7 | 85.8 |

| 9 | Shoulder height, sitting | 55.5 | 59.8 | 64.2 |

| 10 | Elbow height, sitting | 22.4 | 26.2 | 30.0 |

| 11 | Forearm–fingertip length, sitting | 41.6 | 44.8 | 48.0 |

| 12 | Height of upper thigh when seated | 46.3 | 55.0 | 61.0 |

| 13 | Popliteal height | 36.5 | 39.7 | 43.3 |

| 14 | Buttock–knee length | 53.0 | 56.7 | 61.2 |

| 15 | Buttock–popliteal length | 42.3 | 46.5 | 51.0 |

| 16 | Hip breadth, sitting | 31.6 | 34.8 | 38.3 |

| 17 | Thigh clearance | 12.8 | 15.3 | 17.7 |

| 18 | Knee height | 39.8 | 43.8 | 47.7 |

| Stage | Model Format | Used Software | System O.S.*** | Other Notes |

|---|---|---|---|---|

| 2D drawing error check | PDF viewer | - | PDF documents are given due to the security issue | |

| 3D CAD* conversion | dwg/dxf/max | AutoDesk© /Rhino© | - | - |

| Conversion to interoperable format | wrl | 3D Builder | - | Virtual reality modeling language (VRML) [32] format conversion |

| Integrated GUI docking | m/Java | Octav /Matlab /Java | Windows 10 | Java-based GUI** and Matlab-based calculation modules |

| 3D simulation model | wrl/m/Java | Java | Windows 10 | Integrated IDRS framework |

| Main Categories | Detailed Functions |

|---|---|

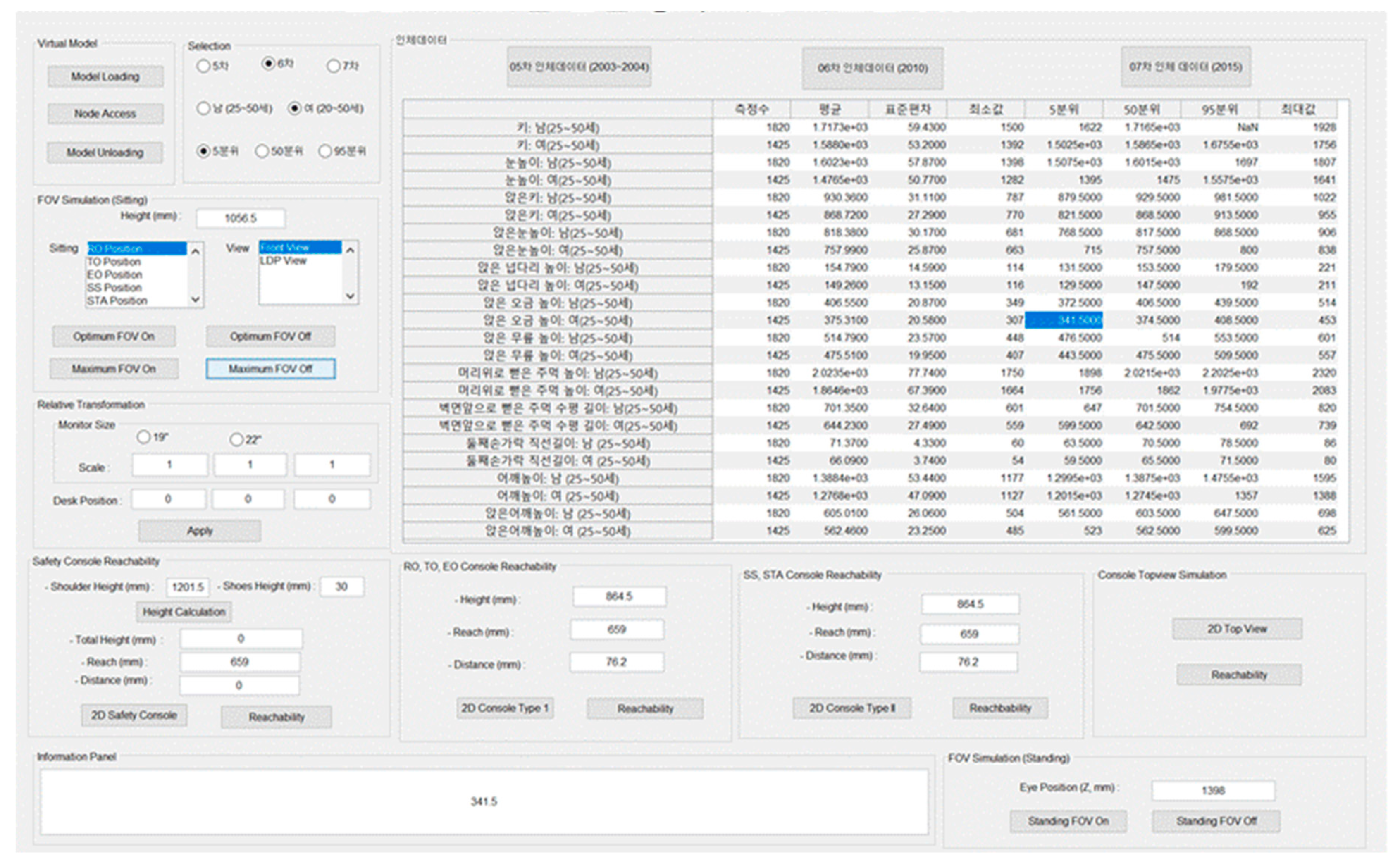

| Anthropometric data interface | Anthropometric database implementation (5th/6th/7th Korean Anthropometric Data Survey Reports); comparisons between both anthropometric data types; automatic calculation of ergonomic parameters (considering shoes and other factors) |

| Simulation | FOV simulation per each position (RO/TO/EO/SO/SS/STA); estimation of optimal view and maximum views; control range (reachability) calculation for Type I consoles (RO, TO, EO); control range (reachability) calculation for Type II consoles (SS, STA) |

| User interface (UI) changes and Transformation | UI integrations/separations; parametric transformation for each component in the MCR |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.; Cha, W.C. Virtual Reality-Based Ergonomic Modeling and Evaluation Framework for Nuclear Power Plant Operation and Control. Sustainability 2019, 11, 2630. https://doi.org/10.3390/su11092630

Lee H, Cha WC. Virtual Reality-Based Ergonomic Modeling and Evaluation Framework for Nuclear Power Plant Operation and Control. Sustainability. 2019; 11(9):2630. https://doi.org/10.3390/su11092630

Chicago/Turabian StyleLee, Hyunsoo, and Woo Chang Cha. 2019. "Virtual Reality-Based Ergonomic Modeling and Evaluation Framework for Nuclear Power Plant Operation and Control" Sustainability 11, no. 9: 2630. https://doi.org/10.3390/su11092630

APA StyleLee, H., & Cha, W. C. (2019). Virtual Reality-Based Ergonomic Modeling and Evaluation Framework for Nuclear Power Plant Operation and Control. Sustainability, 11(9), 2630. https://doi.org/10.3390/su11092630