Assessment of Mechanical Property Variation of As-Processed Bast Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Equipment

2.2. Fiber Treatment

2.3. Fiber Characterization

2.3.1. Preselection and Selection

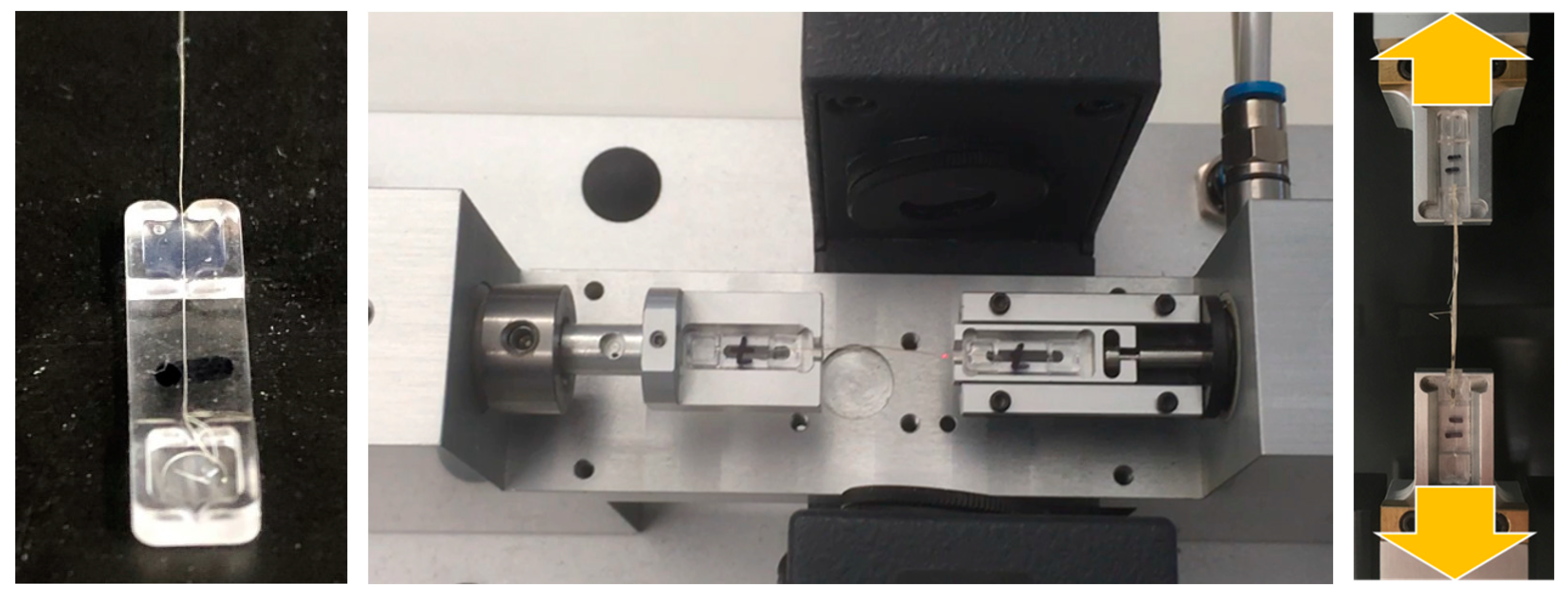

2.3.2. Mounting

2.3.3. Fiber Dimensional Analysis

2.3.4. Fiber Tensile Testing

2.3.5. Confocal Microscopy and Image Processing

3. Results and Discussion

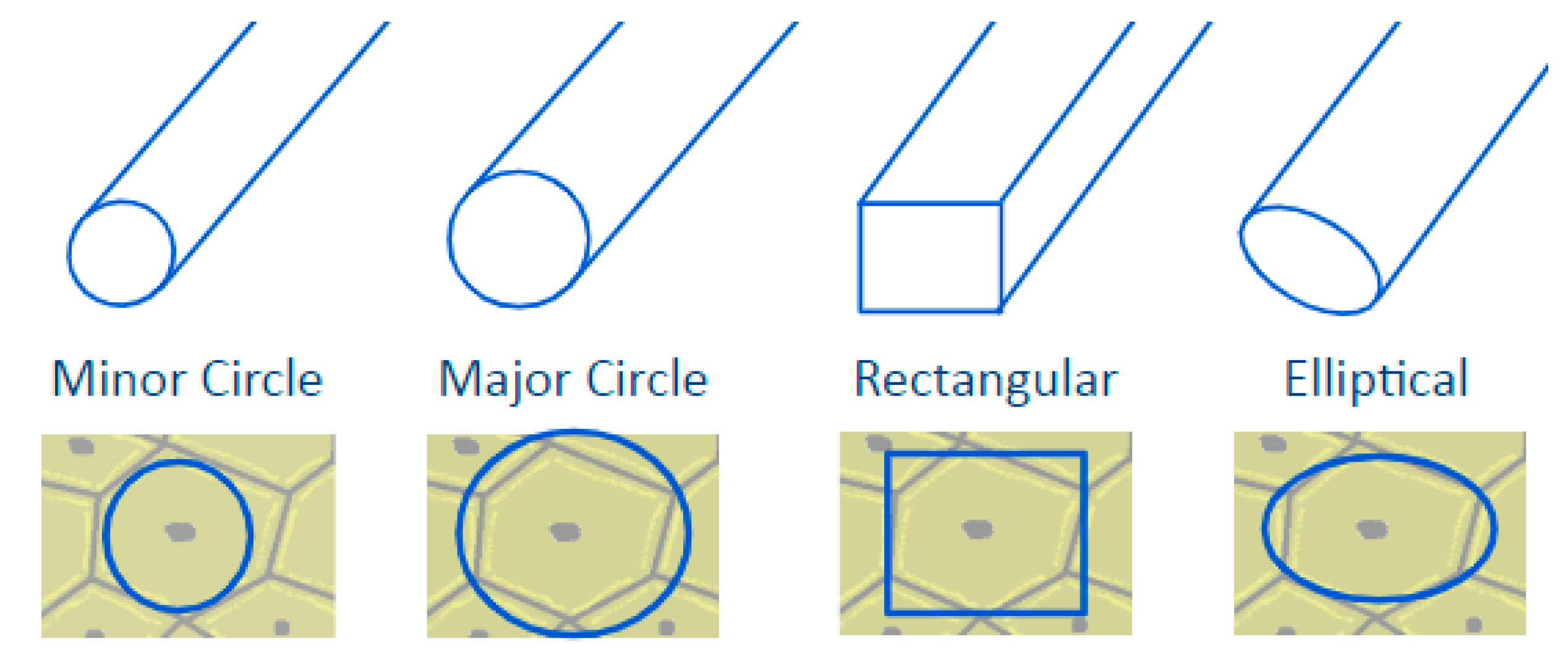

3.1. Cross-Sectional Approximation

3.2. Observed Physical Defects

3.3. Stem Diameter and Fiber Color

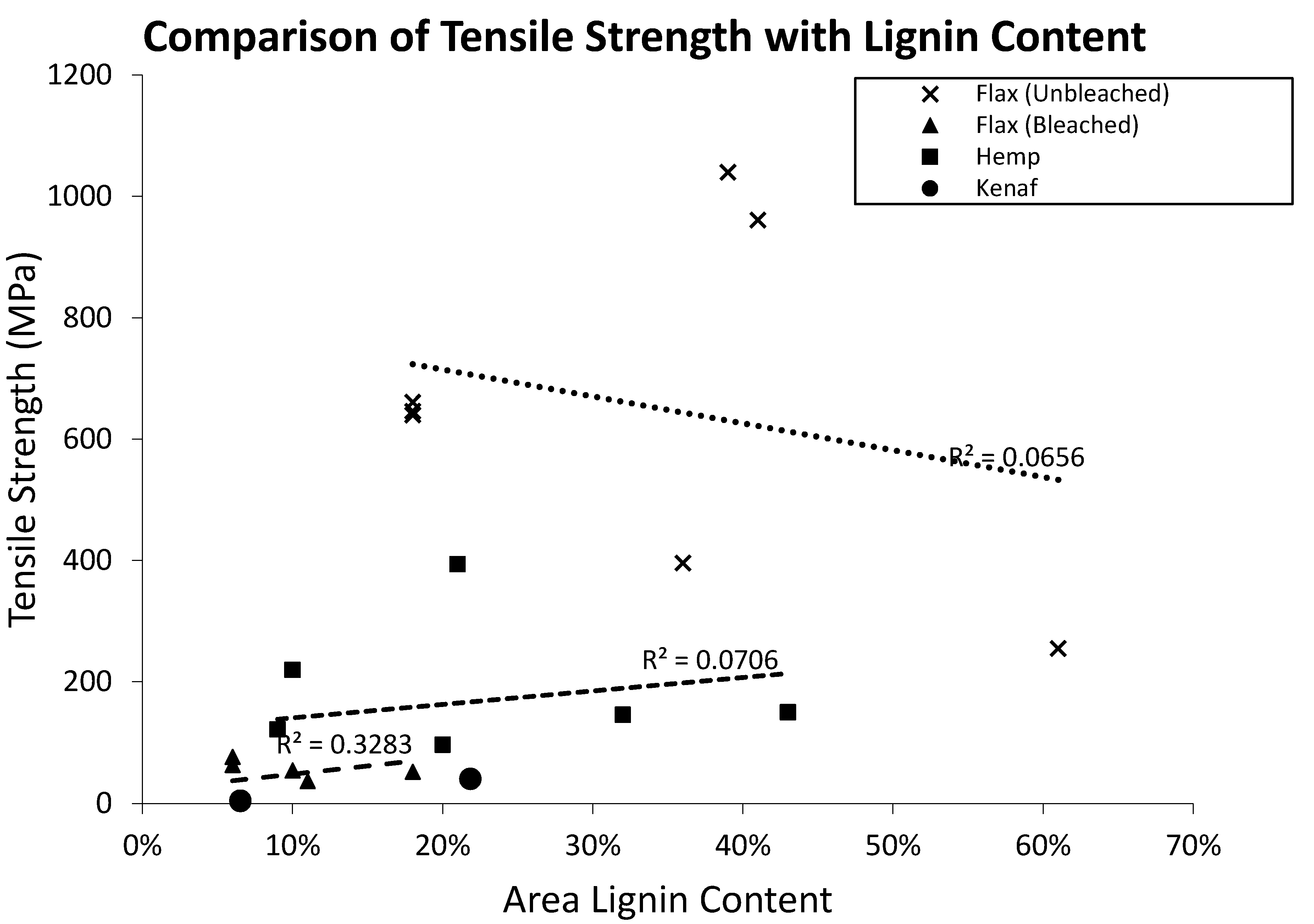

3.4. Fiber Composition

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hill, C.; Hughes, M. Natural fibre reinforced composites opportunities and challenges. J. Biobased Mater. Bioenergy 2010, 4, 148–158. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef] [Green Version]

- Summerscales, J.; Dissanayake, N.; Virk, A.; Hall, W. A review of bast fibres and their composites. Part 1—Fibres as reinforcements. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1329–1335. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Morreale, M. Green composites: A brief review. Compos. Part A Appl. Sci. Manuf. 2011, 42, 579–588. [Google Scholar] [CrossRef]

- Malkapuram, R.; Kumar, V.; Negi, Y.S. Recent development in natural fiber reinforced polypropylene composites. J. Reinf. Plast. Compos. 2009, 28, 1169–1189. [Google Scholar] [CrossRef]

- Wang, B.; Panigrahi, S.; Tabil, L.; Crerar, W. Effects of chemical treatments on mechanical and physical properties of flax fiber-reinforced rotationally molded composites. In 2004 ASAE Annual Meeting; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2004. [Google Scholar]

- Huo, S.; Thapa, A.; Ulven, C.A. Effect of surface treatments on interfacial properties of flax fiber-reinforced composites. Adv. Compos. Mater. 2013, 22, 109–121. [Google Scholar] [CrossRef]

- Reux, F.; Verpoest, I. Flax and Hemp Fibres: A Natural Solution for the Composite Industry; JEC Composites Publications: Springfield, MO, USA, 2014. [Google Scholar]

- Thomas, L.; Mishra, S.; Bismarck, A. Plant Fibers as Reinforcement for Green Composites. In Natural Fibers, Biopolymers, and Biocomposites; CRC Press: Boca Raton, FL, USA, 2005; pp. 52–128. [Google Scholar]

- Lefeuvre, A.; Bourmaud, A.; Morvan, C.; Baley, C. Elementary flax fibre tensile properties: Correlation between stress–strain behaviour and fibre composition. Ind. Crops Prod. 2014, 52, 762–769. [Google Scholar] [CrossRef]

- Baley, C. Analysis of the flax fibres tensile behaviour and analysis of the tensile stiffness increase. Compos. Part A Appl. Sci. Manuf. 2002, 33, 939–948. [Google Scholar] [CrossRef]

- Shah, D.U.; Nag, R.K.; Clifford, M.J. Why do we observe significant differences between measured and ‘back-calculated’ properties of natural fibres? Cellulose 2016, 23, 1481–1490. [Google Scholar] [CrossRef] [Green Version]

- Andersons, J.; Poriķe, E.; Spārniņš, E. Ultimate strain and deformability of elementary flax fibres. J. Strain Anal. Eng. Des. 2011, 46, 428–435. [Google Scholar] [CrossRef]

- Hornsby, P.R.; Hinrichsen, E.; Tarverdi, K. Preparation and properties of polypropylene composites reinforced with wheat and flax straw fibres: Part I fibre characterization. J. Mater. Sci. 1997, 32, 443–449. [Google Scholar] [CrossRef]

- Barkoula, N.M.; Garkhail, S.K.; Peijs, T. Effect of compounding and injection molding on the mechanical properties of flax fiber polypropylene composites. J. Reinf. Plast. Compos. 2010, 29, 1366–1385. [Google Scholar] [CrossRef]

- Kessler, R.W.; Becker, U.; Kohler, R.; Goth, B. Steam explosion of flax—A superior technique for upgrading fibre value. Biomass Bioenergy 1998, 14, 237–249. [Google Scholar] [CrossRef]

- Stamboulis, A.; Baillie, C.A.; Peijs, T. Effects of environmental conditions on mechanical and physical properties of flax fibers. Compos. Part A Appl. Sci. Manuf. 2001, 32, 1105–1115. [Google Scholar] [CrossRef]

- Graupner, N.; Herrmann, A.S.; Müssig, J. Natural and man-made cellulose fibre-reinforced poly (lactic acid)(PLA) composites: An overview about mechanical characteristics and application areas. Compos. Part A Appl. Sci. Manuf. 2009, 40, 810–821. [Google Scholar] [CrossRef]

- Shibata, S.; Cao, Y.; Fukumoto, I. Press forming of short natural fiber-reinforced biodegradable resin: Effects of fiber volume and length on flexural properties. Polym. Test. 2005, 24, 1005–1011. [Google Scholar] [CrossRef]

- Goda, K.; Sreekala, M.S.; Gomes, A.; Kaji, T.; Ohgi, J. Improvement of plant based natural fibers for toughening green composites—Effect of load application during mercerization of ramie fibers. Compos. Part A Appl. Sci. Manuf. 2006, 37, 2213–2220. [Google Scholar] [CrossRef]

- Angelini, L.G.; Lazzeri, A.; Levita, G.; Fontanelli, D.; Bozzi, C. Ramie (Boehmeria nivea (L.) Gaud.) and Spanish Broom (Spartium junceum L.) fibres for composite materials: Agronomical aspects, morphology and mechanical properties. Ind. Crops Prod. 2000, 11, 145–161. [Google Scholar] [CrossRef]

- Alcock, M.; Ahmed, S.; DuCharme, S.; Ulven, C.A. Influence of Stem Diameter on Fiber Diameter and the Mechanical Properties of Technical Flax Fibers from Linseed Flax. Fibers 2018, 6, 10. [Google Scholar] [CrossRef]

- Lefeuvre, A.; Bourmaud, A.; Lebrun, L.; Morvan, C.; Baley, C. A study of the yearly reproducibility of flax fiber tensile properties. Ind. Crops Prod. 2013, 50, 400–407. [Google Scholar] [CrossRef]

- Duval, A.; Alain, B.; Laurent, A.; Christophe, B. Influence of the sampling area of the stem on the mechanical properties of hemp fibers. Mater. Lett. 2011, 65, 797–800. [Google Scholar] [CrossRef]

- Charlet, K.; Baley, C.; Morvan, C.; Jernot, J.P.; Gomina, M.; Bréard, J. Characteristics of Hermès flax fibres as a function of their location in the stem and properties of the derived unidirectional composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1912–1921. [Google Scholar] [CrossRef]

- Sankari, H.S. Comparison of bast fibre yield and mechanical fibre properties of hemp (Cannabis sativa L.) cultivars. Ind. Crops Prod. 2000, 11, 73–84. [Google Scholar] [CrossRef]

- Mediavilla, V.; Leupin, M.; Keller, A. Influence of the growth stage of industrial hemp on the yield formation in relation to certain fibre quality traits. Ind. Crops Prod. 2001, 13, 49–56. [Google Scholar] [CrossRef]

- Fuqua, M.A.; Huo, S.; Ulven, C.A. Natural fiber reinforced composites. Polym. Rev. 2012, 52, 259–320. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Van de Velde, K.; Kiekens, P. Effect of material and process parameters on the mechanical properties of unidirectional and multidirectional flax/polypropylene composites. Compos. Struct. 2003, 62, 443–448. [Google Scholar] [CrossRef]

- Cantero, G.; Arbelaiz, A.; Llano-Ponte, R.; Mondragon, I. Effects of fibre treatment on wettability and mechanical behaviour of flax/polypropylene composites. Compos. Sci. Technol. 2003, 63, 1247–1254. [Google Scholar] [CrossRef]

- Keener, T.J.; Stuart, R.K.; Brown, T.K. Maleated coupling agents for natural fibre composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 357–362. [Google Scholar] [CrossRef]

- Arbelaiz, A.; Fernandez, B.; Ramos, J.A.; Mondragon, I. Thermal and crystallization studies of short flax fibre reinforced polypropylene matrix composites: Effect of treatments. Thermochim. Acta 2006, 440, 111–121. [Google Scholar] [CrossRef]

- Bos, H.L.; Müssig, J.; van den Oever, M.J. Mechanical properties of short-flax-fibre reinforced compounds. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1591–1604. [Google Scholar] [CrossRef]

- Angelov, I.; Wiedmer, S.; Evstatiev, M.; Friedrich, K.; Mennig, G. Pultrusion of a flax/polypropylene yarn. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1431–1438. [Google Scholar] [CrossRef]

- Madsen, B.; Lilholt, H. Physical and mechanical properties of unidirectional plant fibre composites—An evaluation of the influence of porosity. Compos. Sci. Technol. 2003, 63, 1265–1272. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G.I. Biofibres, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 276, 1–24. [Google Scholar] [CrossRef]

- Lamy, B.; Baley, C. Stiffness prediction of flax fibers-epoxy composite materials. J. Mater. Sci. Lett. 2000, 19, 979–980. [Google Scholar] [CrossRef]

- Baley, C.; Busnel, F.; Grohens, Y.; Sire, O. Influence of chemical treatments on surface properties and adhesion of flax fibre–polyester resin. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1626–1637. [Google Scholar] [CrossRef]

- Zafeiropoulos, N.; Williams, D.; Baillie, C.; Matthews, F.L. Engineering and characterisation of the interface in flax fibre/polypropylene composite materials. Part I. Development and investigation of surface treatments. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1083–1093. [Google Scholar] [CrossRef]

- Joffe, R.; Andersons, J.; Wallström, L. Strength and adhesion characteristics of elementary flax fibres with different surface treatments. Compos. Part A Appl. Sci. Manuf. 2003, 34, 603–612. [Google Scholar] [CrossRef]

- Bessadok, A.; Langevin, D.; Gouanvé, F.; Chappey, C.; Roudesli, S.; Marais, S. Study of water sorption on modified Agave fibres. Carbohydr. Polym. 2009, 76, 74–85. [Google Scholar] [CrossRef]

- John, M.J.; Anandjiwala, R.D. Recent developments in chemical modification and characterization of natural fiber-reinforced composites. Polym. Compos. 2008, 29, 187–207. [Google Scholar] [CrossRef]

- Doherty, W.O.; Mousavioun, P.; Fellows, C.M. Value-adding to cellulosic ethanol: Lignin polymers. Ind. Crops Prod. 2011, 33, 259–276. [Google Scholar] [CrossRef] [Green Version]

- Coletta, V.C.; Rezende, C.A.; da Conceição, F.R.; Polikarpov, I.; Guimarães, F.E. Mapping the lignin distribution in pretreated sugarcane bagasse by confocal and fluorescence lifetime imaging microscopy. Biotechnol. Biofuels 2013, 6, 43. [Google Scholar] [CrossRef]

- Hernández-Hernández, H.M.; Chanona-Pérez, J.J.; Vega, A.; Ligero, P.; Farrera-Rebollo, R.R.; Mendoza-Perez, J.A.; Calderón-Domínguez, G.; Vera, N.G. Spectroscopic and Microscopic Study of Peroxyformic Pulping of Agave Waste. Microsc. Microanal. 2016, 22, 1084–1097. [Google Scholar] [CrossRef]

- Virk, A.S.; Hall, W.; Summerscales, J. Modulus and strength prediction for natural fibre composites. Mater. Sci. Technol. 2012, 28, 864–871. [Google Scholar] [CrossRef]

- Virk, A.S.; Hall, W.; Summerscales, J. Physical characterization of jute technical fibers: Fiber dimensions. J. Nat. Fibers 2010, 7, 216–228. [Google Scholar] [CrossRef]

- Ji, Z.; Ma, J.F.; Zhang, Z.H.; Xu, F.; Sun, R.C. Distribution of lignin and cellulose in compression wood tracheids of Pinus yunnanensis determined by fluorescence microscopy and confocal Raman microscopy. Ind. Crops Prod. 2013, 47, 212–217. [Google Scholar] [CrossRef]

- Sunstrand, LLC. Available online: https://www.sunstrands.com/ (accessed on 29 March 2019).

- Diastron Limited. Available online: https://www.diastron.com/technical-fibre/ (accessed on 29 March 2019).

- Bourmaud, A.; Baley, C. Rigidity analysis of polypropylene/vegetal fibre composites after recycling. Polym. Degrad. Stab. 2009, 94, 297–305. [Google Scholar] [CrossRef]

- ASTM. ASTM C1557-14, Standard Test Method for Tensile Strength and Young’s Modulus of Fibers; ASTM International: West Conshohocken, PA, USA, 2014; Available online: www.astm.org (accessed on 23 May 2019).

- ImageJ: Image Processing and Analysis in Java. Available online: https://imagej.nih.gov/ij/ (accessed on 23 April 2019).

| Characteristics | Description | Image |

|---|---|---|

| Consistent | Uniform thickness along gage length |  |

| Fraying | Microfibrils peeling along length |  |

| Kink | Observable corner or sharp change in direction |  |

| Inconsistency | Observable variation in diameter along length |  |

| Minor Circle Approximation | Major Circle Approximation | Rectangular Approximation | Elliptical Approximation | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Fiber Type | Number of Valid Tests | Elastic Modulus (GPa) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Tensile Strength (MPa) |

| Hemp | 296 | 8 (6) | 139 (119) | 61 (109) | 937 (975) | 15 (7) | 249 (159) | 21 (9) | 337 (207) |

| Flax | 454 | 11 (11) | 212 (212) | 86 (71) | 1255 (1086) | 26 (15) | 391 (287) | 33 (19) | 523 (381) |

| Kenaf | 99 | 6 (5) | 64 (78) | 30 (29) | 284 (330) | 11 (10) | 108 (123) | 14 (13) | 138 (157) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feigel, B.; Robles, H.; Nelson, J.W.; Whaley, J.M.S.; Bright, L.J. Assessment of Mechanical Property Variation of As-Processed Bast Fibers. Sustainability 2019, 11, 2655. https://doi.org/10.3390/su11092655

Feigel B, Robles H, Nelson JW, Whaley JMS, Bright LJ. Assessment of Mechanical Property Variation of As-Processed Bast Fibers. Sustainability. 2019; 11(9):2655. https://doi.org/10.3390/su11092655

Chicago/Turabian StyleFeigel, Bryan, Hanami Robles, Jared W. Nelson, James M.S. Whaley, and Lydia J. Bright. 2019. "Assessment of Mechanical Property Variation of As-Processed Bast Fibers" Sustainability 11, no. 9: 2655. https://doi.org/10.3390/su11092655

APA StyleFeigel, B., Robles, H., Nelson, J. W., Whaley, J. M. S., & Bright, L. J. (2019). Assessment of Mechanical Property Variation of As-Processed Bast Fibers. Sustainability, 11(9), 2655. https://doi.org/10.3390/su11092655