1. Introduction

Waste generation is an unavoidable by-product of human activities. Approximately 3.5 million tonnes of municipal solid waste (MSW) are generated daily on a global scale [

1]. According to the United Nation’s estimates, the current world population of 7.3 billion is expected to reach 9.7 billion by 2050 and 11.2 billion by 2100 [

2]. An additional 2.5 billion people will add further pressure on the already fragile Earth’s eco-system. Despite preventive measures of recovery, recycling and re-use of materials, waste generation is expected to increase. The magnitude of waste production in Australia was 2.2 tonnes per capita in 2010–2011 alone. Moreover, 60% of this generated waste was either recovered or recycled, with the remaining 40% sent for disposal in landfills [

3].

Landfills emit gases and leachate into the environment and waterways as the waste is degraded over time. This will have adverse effect on the ecological system. It is estimated that landfills contribute to about 20% of the global greenhouse gas (methane and carbon dioxide) emissions and leaching of toxic chemicals, such as mercury, arsenic, beryllium, boron, cadmium, lead, thallium and hydrocarbon compounds, into the environment [

1,

2]. These emissions pose harmful threats to both human health and the environment [

3,

4]. Furthermore, landfills cause nuisances, such as flies, odours, smoke and noise, while the increase in vermin surrounding landfills becomes an issue with other adverse health effects, such as birth defects, respiratory illnesses and even cancer [

5,

6].

1.1. Issues Related to Waste-to-Energy Treatment

Waste-to-energy (WTE) is a commonly adopted approach, which refers to the recovery of heat and power from waste (non-recyclable waste) through combustion-based processes [

4]. Despite being an attractive option for the management of MSW, it is the subject of argument and concerns [

5,

6]. The main issues relate to the absence of standard controls and the emission of harmful pollutants into the air, land and water, which in turn cause human health and environmental issues [

7]. There are many recently published reports around the world discussing the results of life-cycle assessments of air pollution control, energy recovery in waste incineration and approaches to reduce their environmental impact [

8,

9,

10,

11,

12,

13]. It mostly acknowledges that the incineration of the unrecyclable part of MSW is the preferred management option when compared with landfilling even when waste incinerator systems produce toxic ash and other residues that need to be managed.

WTE or waste volume reduction results in the generation of mostly inorganic ash residues, which contain heavy metals, acids and other toxic compounds [

14]. Environmental pollution from particulate and gaseous discharges can occur if safe ash disposal methods are not in place [

15,

16]. It is a costly practice to store large volumes of toxic ash in a landfill. Some studies have even suggested that it is important to prevent heavy metal-rich wastes from being incinerated to reduce the content of toxic metals in the fly ash [

15]. The current disposal cost of MSW “tip fee” per tonne of waste in a United States (U.S.) landfill is about

$55 [

17]. However, this figure does not account for the long-term cost to the environment. The major impacts of ash disposal on terrestrial ecosystems include the leaching of toxic substances into soils and groundwater, reductions in plant establishment and growth due to adverse chemical characteristics of the ash, changes in the elemental composition of vegetation growing on the ash and increased mobility and accumulation of potentially toxic elements throughout the food chain [

18].

In view of the points raised above, we propose that MSW be used as a cheap and widely available raw ingredient in construction materials. In doing so, waste must be treated to a level of consistency that makes it possible to be used as a construction material. A detailed description of the MSW ‘treatment process’ to direct MSW to construction is provided in this paper. A holistic approach to the waste problem would consider the entire cycle of material use, which includes production, distribution and consumption, as well as waste collection and disposal [

19,

20]. Here, MSW intended for ‘disposal’ is diverted from a landfill or WTE and is used as the starting materials. Critics of MSW-to-construction would point to the variability in source and the difficulty in achieving consistency in the material composition. The proposed ‘treatment process’, however, will bring the waste product to a near-uniform consistency in terms of particle shape, size and moisture level. With regard to the variability in material composition, other products such as MSW incineration bottom ash with equally variable source materials have successfully been considered for inclusion in concrete [

21,

22,

23].

1.2. Waste Composition

In Australia, construction and demolition waste (masonry material), organic wastes and fly ash are the largest waste streams, representing nearly two-thirds of waste generated in 2014–2015 [

24]. Organic waste constitutes more than 45% of the average composition of MSW in more than 110 countries surveyed worldwide. If one excludes recyclable waste materials, such as paper (16.7%), plastic (10.1%), glass (4.7%) and metals (4.2%), organic waste, together with other “unidentified” waste (17.7%), constitutes more than two-thirds of MSW by composition. Other countries have similar numbers. For instance, the organic matter content of China’s MSW exceeds 60%, and the water content is about 50% [

25]. In India, analysis of MSW samples collected from a dumpsite consisted of 36% (by weight) bio-waste (food waste, yard waste, coconut waste) and around 30% recyclable materials (plastics, paper, cardboard and metals) [

26]. The analysis of old MSW samples collected from the same site but different depths (3–4 m and 6–7 m) showed the dominance of plastics (25%–33%) and mixed ‘organic’ residue (28%–55%) [

26]. In neighbouring Bangladesh, food and vegetable wastes are the main components (79% on average) of MSW [

27]. An investigation of a total number of 160 Egyptian MSW samples indicated an average percentage composition of 54.4% food waste (organic) waste [

28]. Biodegradable waste in European Union member states ranges from 19% in the United Kingdom (UK) to 49% in Greece [

29]. Therefore, clearly, more than half of MSW in most countries can be classified as semi-organic, which is, at this time, either incinerated or dumped into landfills.

In the following sections, we will firstly review the published works on the use of waste in construction materials (WTC). As it will be noted, industrial waste with highly variable composition has already been used as a raw material for construction materials. Secondly, we will describe a ‘treatment process’ to achieve the level of consistency needed for use as a part of construction materials. In sum, the treatment process includes a sanitising procedure and an automatic separation process of different types of recyclable materials. The appropriate waste product is then subjected to vortex-oscillation technology that will offer new physical effects in the form of dehydration, grinding and mixing via an efficient and cost-effective manner [

30]. Lastly, to demonstrate the feasibility of using the non-recyclable MSW (referred to as ‘biomass’), a random ‘treated’ sample of the material is characterised and then used as a part replacement for binder in a cement paste. Calorimetry of the mixes is then carried out, followed by compressive strength testing of the cement-based biomass samples.

2. Review of Waste to Construction: State of the Art

The principle of waste valorisation, circular economy and recycling organic waste is relevant to both developing and advanced economies with respect to answering their current waste management issues [

31]. It is expected that, with the growing population and increased rate of agricultural productivity [

32], the organic waste supply will be ever more present. The interest in turning agricultural by-products (organic waste) into construction material is, however, nothing new [

33,

34,

35,

36,

37]. There are many agri-waste-based building products that have successfully made their way into the construction industry [

35,

37,

38,

39], and the research and development in the area are continuing [

39]. A comprehensive review of supplementary cementitious materials originating from agricultural waste is reported in [

35]. Further, Akhtar and Patel [

39] present a pertinent review of agro-industrial discards and invasive weed-based lignocelluloses as green building materials. Madurwar et al. [

40] has equally presented a thorough review of the application of agro-waste in sustainable construction materials. The reader is encouraged to refer these recently published review papers for a detailed report on the status of research conducted on solid waste (including organic waste) intended as a construction material.

2.1. Typical Waste Materials Investigated

Progress in structural design and materials technology along with serious environmental concerns necessitate the use of composite materials that are lightweight, eco-friendly, cost effective and meet construction material requirements [

40,

41]. These include material workability, strength, durability, thermal properties and acoustic insulation properties. Typical waste materials that have been investigated include rice husk [

37], ground coffee waste [

42], banana skin [

34], coconut shell [

38], coconut (

Cocos nucifera) and durian (

Durio zibethinus) fibres [

43], wood fibre waste [

44,

45], cellulose primary sludge generated on paper and pulp mills [

46], lignocellulite waste [

47], sisal fibres [

48], wool fibres [

49] and carpet fibre [

50]. Some investigators have considered human hair fibre [

51] as additive cement-based products to improve the engineering properties of construction materials [

51,

52].

2.2. Typical Dosage of Waste as a Part Replacement of Raw Aggregates in Cementitious Mixes

The dosage of organic/semi-organic product into the cementitious matrix depends on the chemical and material characteristics of the waste product. It also depends on the construction material to be produced and its desired properties. Wolfe and Gjinolli [

46] verify the possibility of producing fibre-cement sheets by replacing 25% of the conventional used virgin long fibre by primary effluent treatment cellulose sludge. Some researchers pre-treat the fibre wastes, mechanically and/or chemically, before mixing them with cement and the appropriate amount of water [

47]. The waste treatment is done to reduce the tendency of fibres to absorb water and consequently overcome the side effects of exposing the composite end-product to humidity. Different chemical treating agents, based on organic and inorganic materials, are used, e.g., gelatine–hexamine mixture, sodium silicate and linseed oil [

47].

2.3. Effect of Addition of Waste into Binder

Experimental findings show that, in general, the addition of semi-organic or organic materials results in the decrease of workability and density of cement-based products [

50]. Consequently, their mechanical properties, such as modulus of elasticity and compressive strength decrease with the increased dosage of waste content [

53,

54,

55]. The decrease in strength with the increase in fibre content is due to the fact that fibres have a comparatively lower density, and some can appear as voids in comparison with the parent material [

55]. Depending on the binder material and intended use, some authors have reported that some fibres increase the strength and stiffness of the mixture, thus making it a good material for construction [

51].

Waste fibres, however, significantly improve the splitting tensile strength, fracture energy and cracking behaviour [

48]. The reason for the improved tensile strength is the bonding interaction between the fibre and the binder matrix. When enough fibres are present in the matrix, the level of ductility and the post-cracking performance of the material is expected to improve. It is demonstrated that the peak strength may exceed the strength at first cracking by a factor of two or more, depending on the volume fraction of fibres and their strength [

48]. Some explanation of the bonding and microstructural behaviour (under load) of wood fibre-reinforced cement products and their performance in service is presented in [

56]. It is also commonly known that adding organic fibres improve other material properties, such as thermal properties and acoustics.

3. Proposed MSW Treatment Process

A method for stabilising physically unstable organic wastes comprised of non-biological, organic, water insoluble compounds, usually dispersed in water, was proposed a while back [

57]. The intention was to form environmentally acceptable, impermeable, load-bearing materials [

58,

59]. However, the progress in this area has been slow because of the labour-intensive nature of the work and the cost associated with its treatment. The variability in the material quality, difficulty of using established manufacturing practices [

59] and the odour due to volatile sulfuric compounds [

60,

61] have been some of the hurdles. The construction industry finds it difficult to uptake raw materials with variability in their compositions and material contamination [

62,

63]. Naturally, the variability in the composition of the material brings about uncertainty and increases the level of risk in successfully completing the construction work. This clearly becomes a management issue, which the builders and contractor would like to avoid. Therefore, it is less troublesome to deal with organic waste by landfilling and composting [

64] rather than recycling and re-use.

There are two stages of the treatment process: the first stage essentially consists of cutting, sterilising and sorting, and the second one is composed of the grinding, mixing and drying processes.

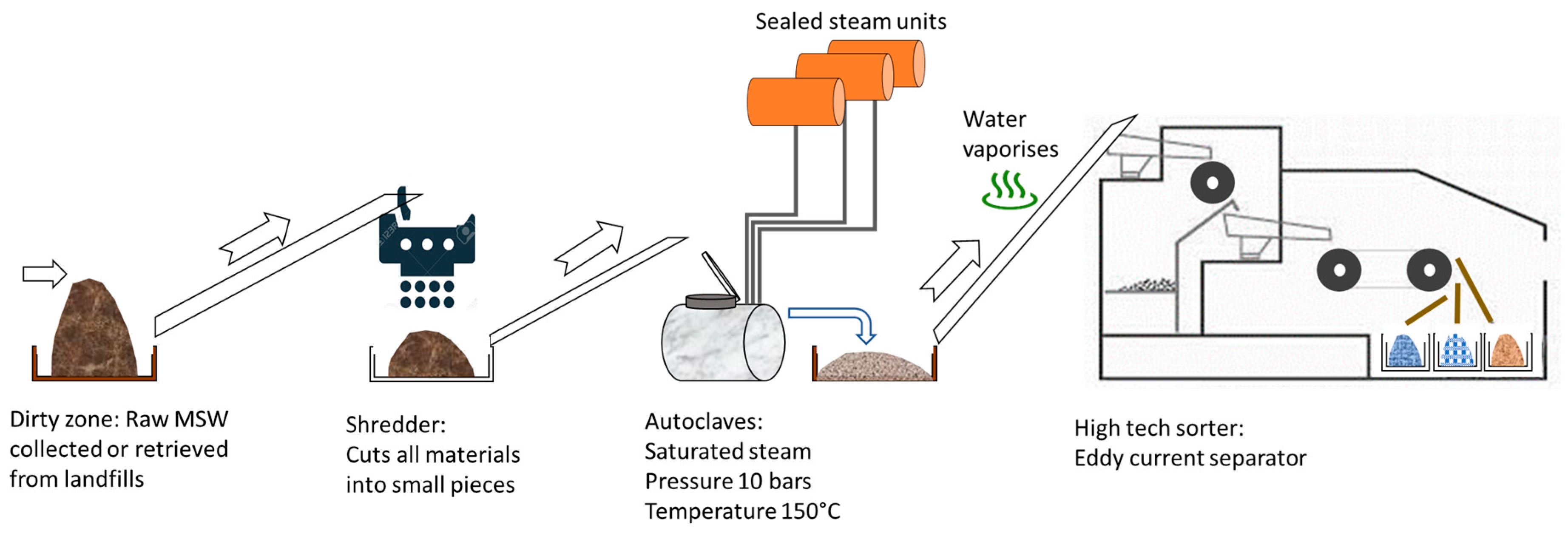

Stage 1: Cutting, Sterilising and Sorting

Figure 1 presents the innovative processes involved in stage 1. Essentially, MSW is transferred to a ‘dirty zone’ using waste collection trucks. The reader should note that the process for treatment of waste retrieved from landfills is essentially the same. An example of an established process as described in stage 1 has recently been published on Australian Broadcasting Corporation (ABC) news’ website [

64].

MSW is transferred via conveyor belts to a shredder, which cuts the materials to smaller size for easier manipulation and further processing. The shredded material is then transferred to steam autoclave router machines. The purpose of autoclaving MSW is to physically treat it before processing. The autoclave system operates under conditions of saturated steam with the pressure reaching 5 bars or 0.5 MPa and temperatures up to 150 °C. Under these conditions, the microorganisms or their spores are eliminated. Background to the autoclave process is provided in [

65,

66]. The invention of the autoclave steriliser is attributed to Charles Chamberland in 1879. The process described here is similar to that used to sterilise and sort medical waste [

67]. For sterilisation purposes, the steam is generated in separate steam units that are completely sealed. This means that no water is released into the environment at this stage. Because the material’s biodegradable fraction undergoes physical changes, it becomes easier for various elements to separate. In addition, because sludge is separated in the process settling down, the final volume of MSW is significantly reduced. Once out of the autoclaving process, MSW is still hotter than the surrounding environment and while it is transferred to other units for further sorting, the sterile water evaporates, leaving the material semi-dry. Thereafter, MSW is transferred through the feeder to technologically advanced separators. These separators use advanced sensing technology and optics to identify different materials. The metals, plastics and glass are separated, respectively, for recycling. The end-product, which is a semi-organic mixture referred to as the ‘biomass’, is collected. Therefore, the separation of the recyclable part of MSW leaves the mostly organic or semi-organic portion of the waste to be treated.

Stage 2: Grinding, Mixing and Drying

The second stage consists of subjecting the appropriate waste material to vortex-oscillation technology, which offers additional physical effects, such as dehydration, grinding and mixing through an efficient and cost-effective manner. The technology is currently in demand in most manufacturing industries that require making products to a uniform consistency. Attempting to turn any waste materials and industrial by-products into a raw construction material requires consistency in material composition, particle size distribution and moisture content [

27]. There are already automated systems in place for drying, mixing and grinding products in different industries, such as in cement manufacturing and agribusiness. However, advanced vortex-oscillation technology is a device that mechanically generates powerful vortices, acoustic shock, cavitation and pressure differentials in new generation equipment that is highly-efficient with low energy input, proven commercial reliability and relatively inexpensive costs [

68].

The system is based on the effect of a wavy flow on the motion of a particle (waste) in air. The flow waviness decreases the hydrodynamic or aerodynamic drag and generates a forward thrust. The physics of this phenomenon are reported by Platzer and Sorokodum [

69]. The apparatus for granulating materials without any grinding is well known. The working principle for this is well described in [

70]. In such an apparatus, the air stream at high pressure, together with the material to be granulated, is fed into a cyclone chamber. A vortex formed within the chamber entraps the material and subjects it to violent turbulence, thereby causing it to break up through collision and self-abrasion. However, the apparatus as described in [

68] is capable of processing very hard materials efficiently whilst minimising wear of the fan and the walls of the conduit. It creates a cyclone in air stream passing through a conduit of circular section. The centripetal forces created by the motion of the air stream pull any particulate material entrained in the air stream away from the walls of the conduit. With a wide range of sonic frequencies within the conduit, a pattern of powerful vortices is created in the air stream. The formation of regions of space with high vorticity is characterised by a high dissipation of kinetic energy. Due to the conversion, potential-to-kinetic energy stresses are created within the cyclone at the particle level, which causes minute explosions. The vortices of the cyclone take the form of implosions, which can break the material up further into smaller particles.

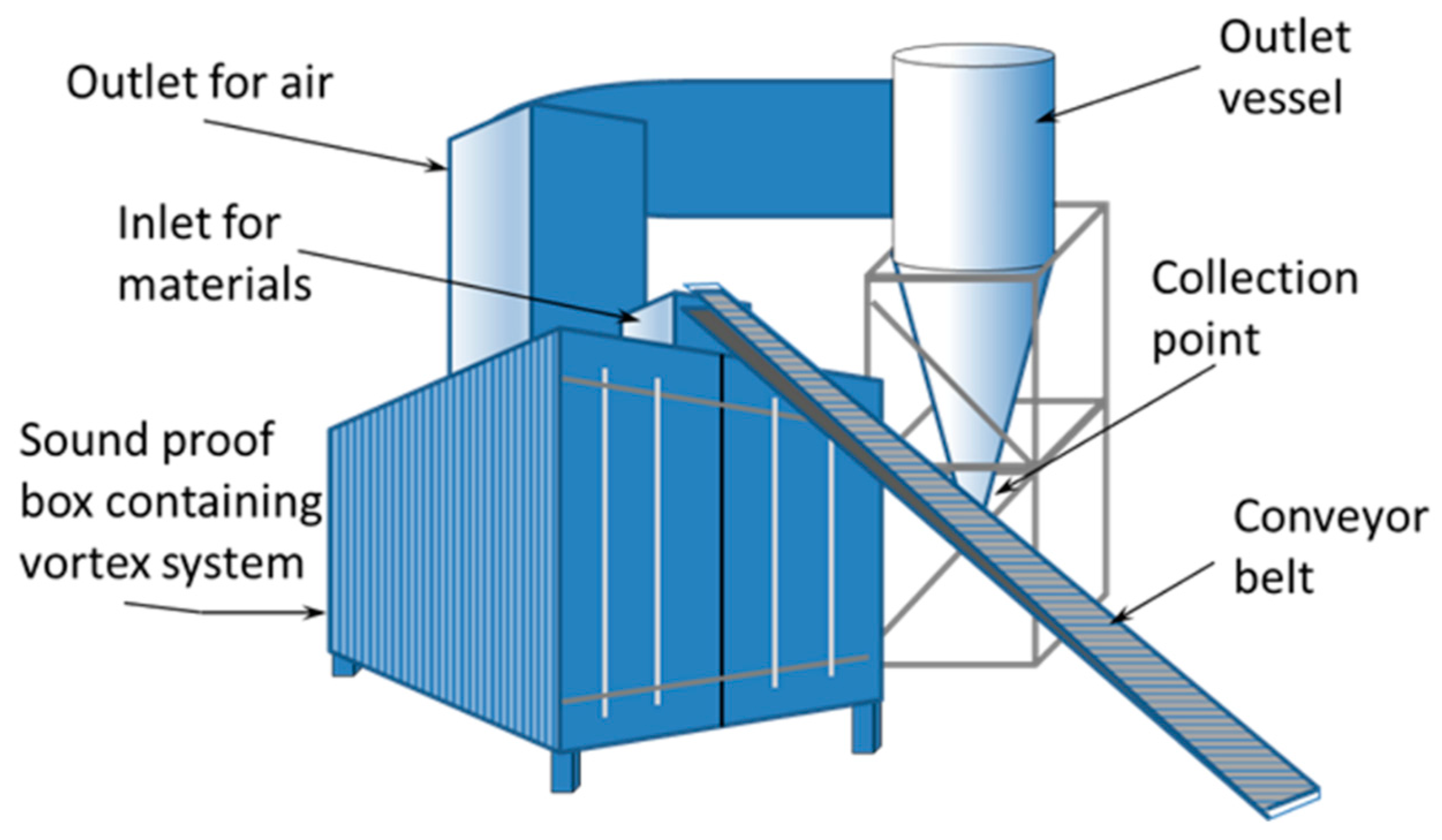

A schematic drawing of a typical vortex-oscillation system housed in a sound proof container box and other components are presented in

Figure 2. The nature of the machine is such that it produces significant noise that can be more than 120 dB. To enable the use of such a machine in general commercial applications and bring the noise level down to about 85 dB, it is housed in an aero-acoustic processing machine surrounded by at least one layer of noise attenuation materials [

71]. The housing is equipped with an air impeller to draw air and material to be processed through an axial inlet system, expelling the air and processed material through a transverse outlet or exhaust port for outputting processed product with air. The airflow paths that are required for the operation of the aero-acoustic processing machine are provided to enable airflow into the housing whilst significantly reducing the noise emission [

71]. The untreated/raw material is fed into the system through a conveyor belt to an inlet opening located at the top of the container. The pulverised material then falls under self-weight though a narrow opening where it is collected in boxes.

6. Implications of the Proposed Methodology and Challenges

The two-step method prescribed herein relies on the most advanced technologies in the field for the processing of MSW. The process turns MSW into biomass with a consistency that can be considered for use in value-added materials in the construction industry. The problem of MSW management, processing and re-use is common in countries with both advanced and developing economies. While most nations can readily afford the technologies described, any valuation of the proposed methodology must integrate the socio-economic context of the processes to be comprehensive. Ongoing health hazards due to environmental pollution and the social nuisance of the disposal of MSW are a burden to the global economy. Therefore, a radical approach, such as the one proposed in this paper, is needed to minimise the disposal burden of MSW. Successful use of biomass as a construction material will turn MSW into a commodity that is available everywhere in the world.

Similar to any other new technology, there will be numerous challenges ahead mostly associated with adopting the use of biomass as “raw” ingredient for construction products. For instance, seasonal changes in the type of produce will cause variability in the composition of biomass. Other issues will include variability in terms of socio-geographic and cultural contexts. All of these can be dealt with in due course, but certainly further research and development work will be necessary.