The Impact Assessment of Campus Buildings Based on a Life Cycle Assessment–Life Cycle Cost Integrated Model

Abstract

:1. Introduction

2. Method

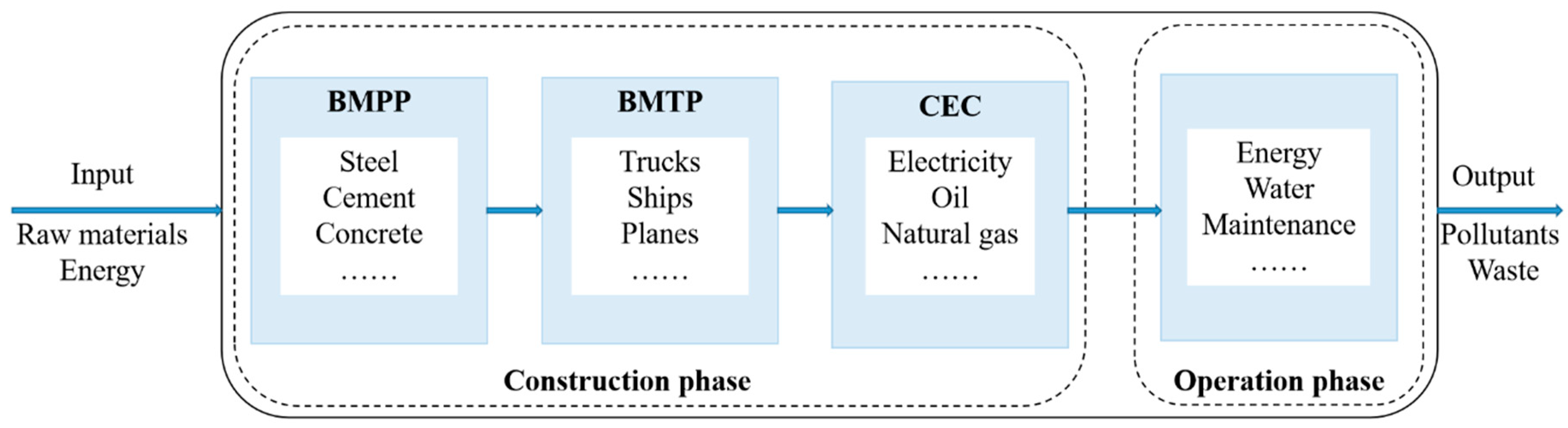

2.1. Establishment of LCA and LCC Models for Campus Buildings

2.1.1. Goal and Scope Definition

- Due to the large-scale and complex materials used to construct university buildings in China, it is difficult to obtain all the data on buildings and to perform an accurate evaluation of their life cycle. Therefore, this study focuses on the main raw materials in buildings.

- We consider only the consumption of energy, water, and building maintenance in the operation phase of buildings. The average annual consumption data are taken as the consumption of energy, water, and maintenance materials during the operation phase, and it is assumed that the level of consumption remains unchanged during the operation phase.

- We assume that buildings can operate for 50 years and that building technology will not change during these 50 years.

- Given the long operating life of a building, the time span of the construction phase can be neglected.

- Due to the lack of basic data in China, it is difficult to determine the currency factors of some evaluation indexes. Therefore, at this stage, it is infeasible to evaluate all LCA indexes in the integrated model. In this regard, we analyzed some building LCA cases, building materials LCA cases and some related studies and found that the indexes related to greenhouse gases, sulfur oxides, nitrogen oxides, photochemical oxidants, and resource consumption were concerned in the construction field [48,49,50,51]. Considering the limitations of actual conditions, at present, the selection of LCA indexes in the integrated model would focus on the environmental impact brought by the above substances. With the development of future construction technology and the improvement of relevant studies on currency factors, the LCA indexes can be further adjusted to improve the integrated model.

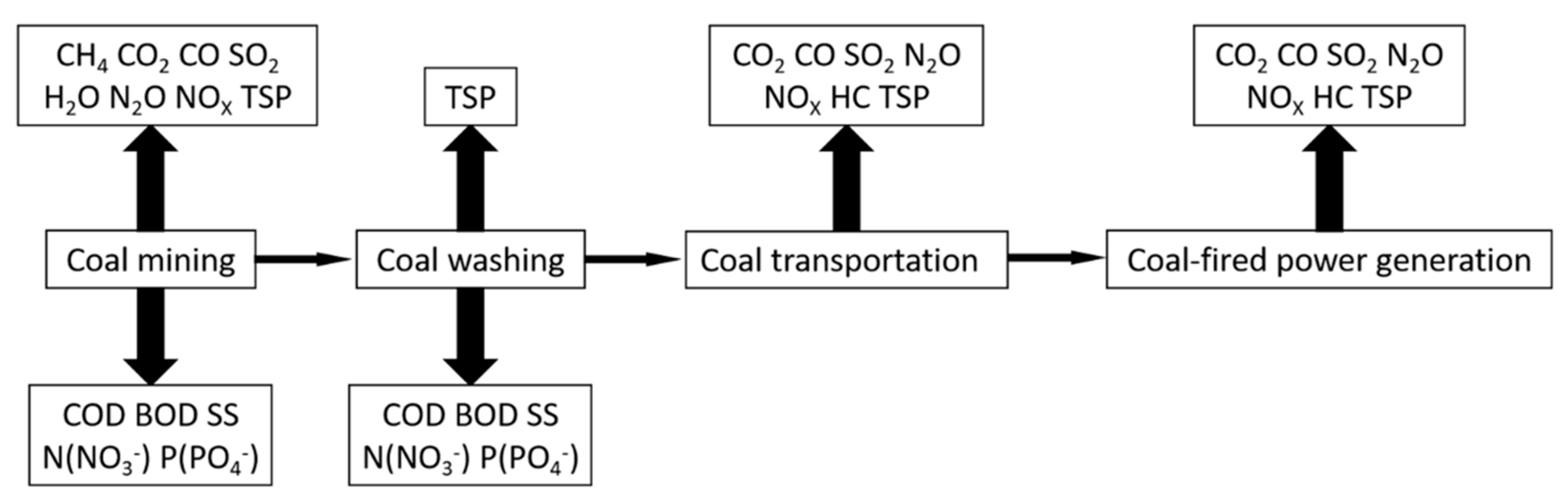

2.1.2. Inventory Analysis

2.1.3. Impact Assessment

2.2. Establishment of a Comprehensive Index for Campus Building Assessment

3. Case Study

3.1. Case Overview

3.2. Inventory Analysis

3.3. Results and Interpretation

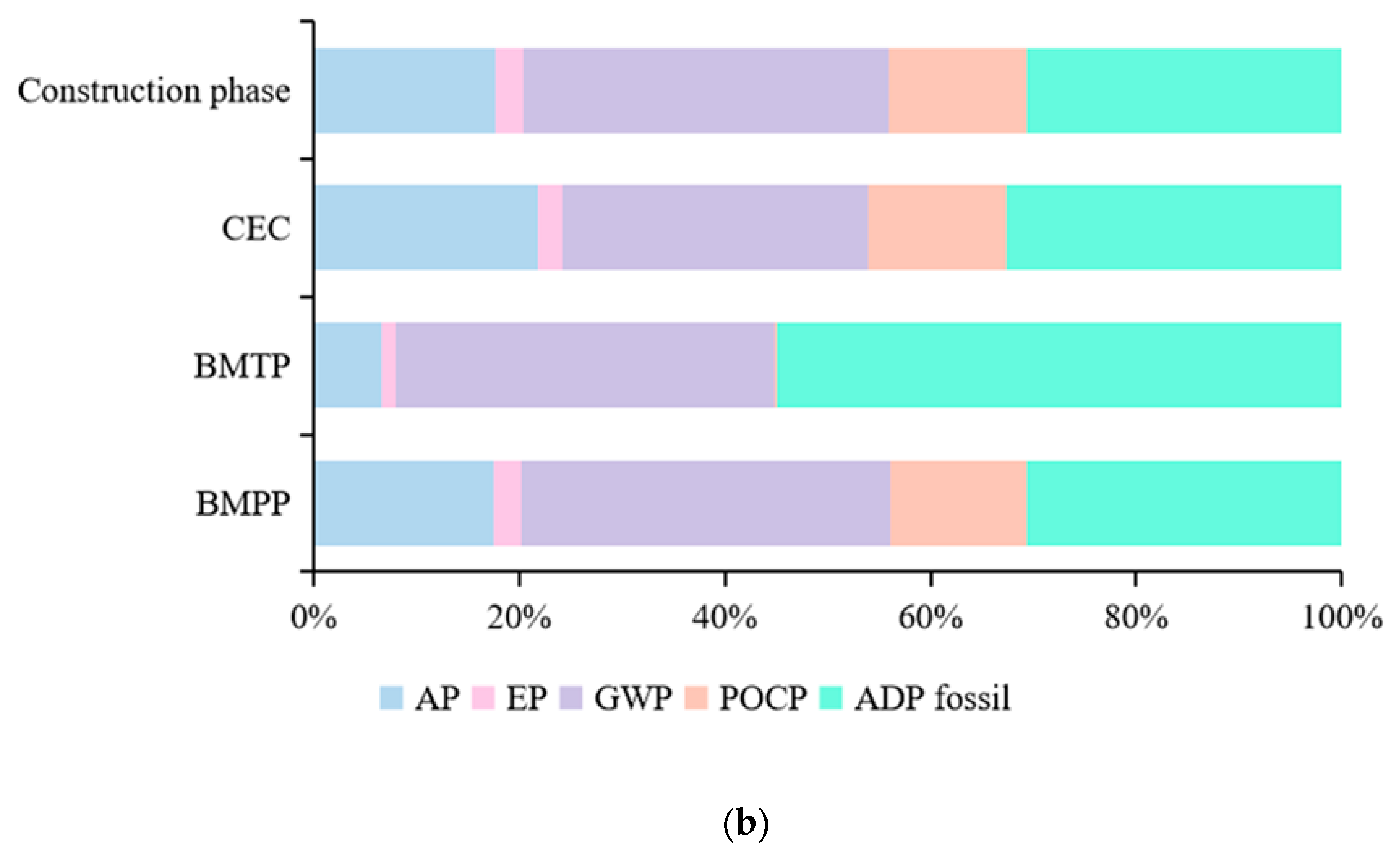

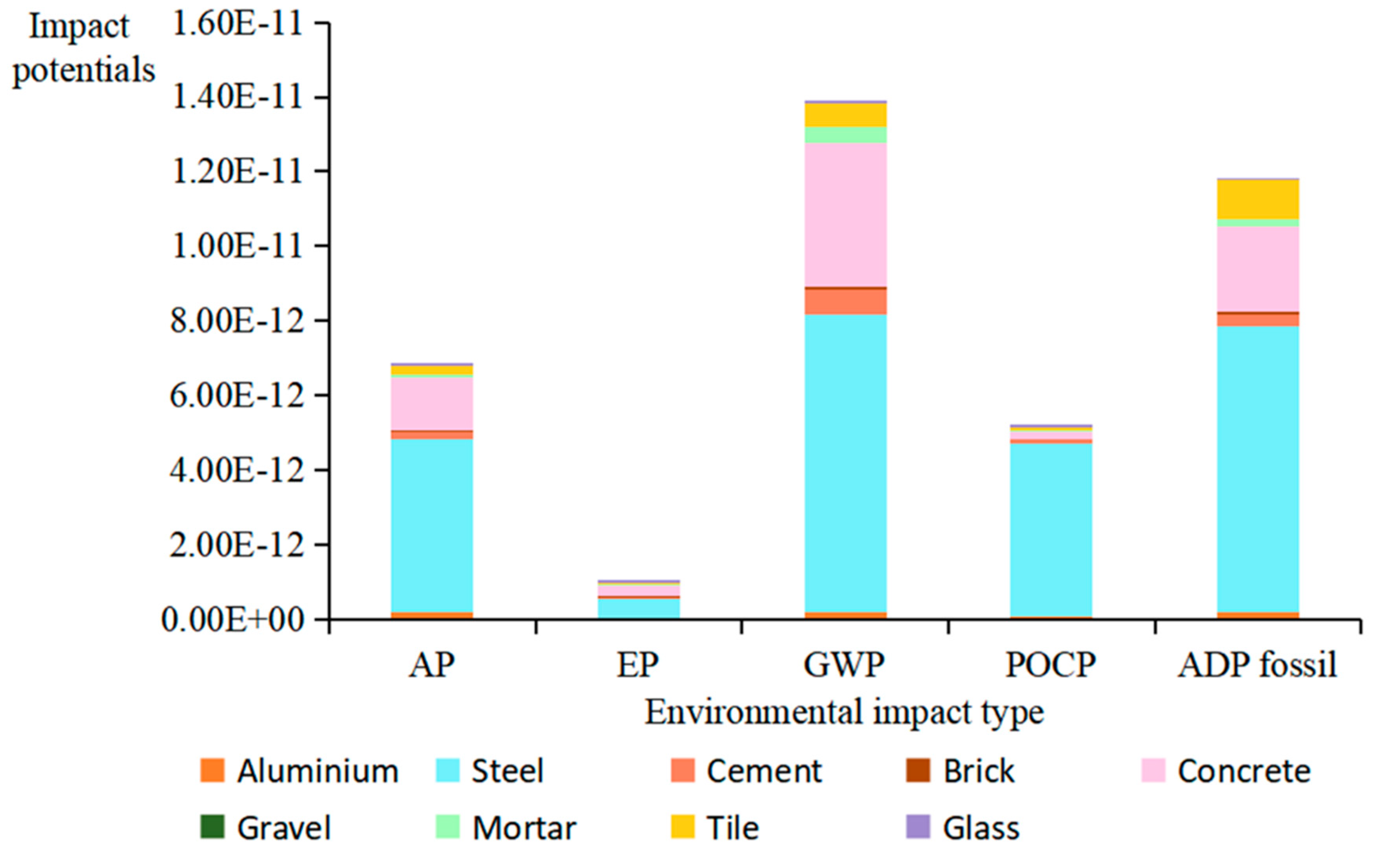

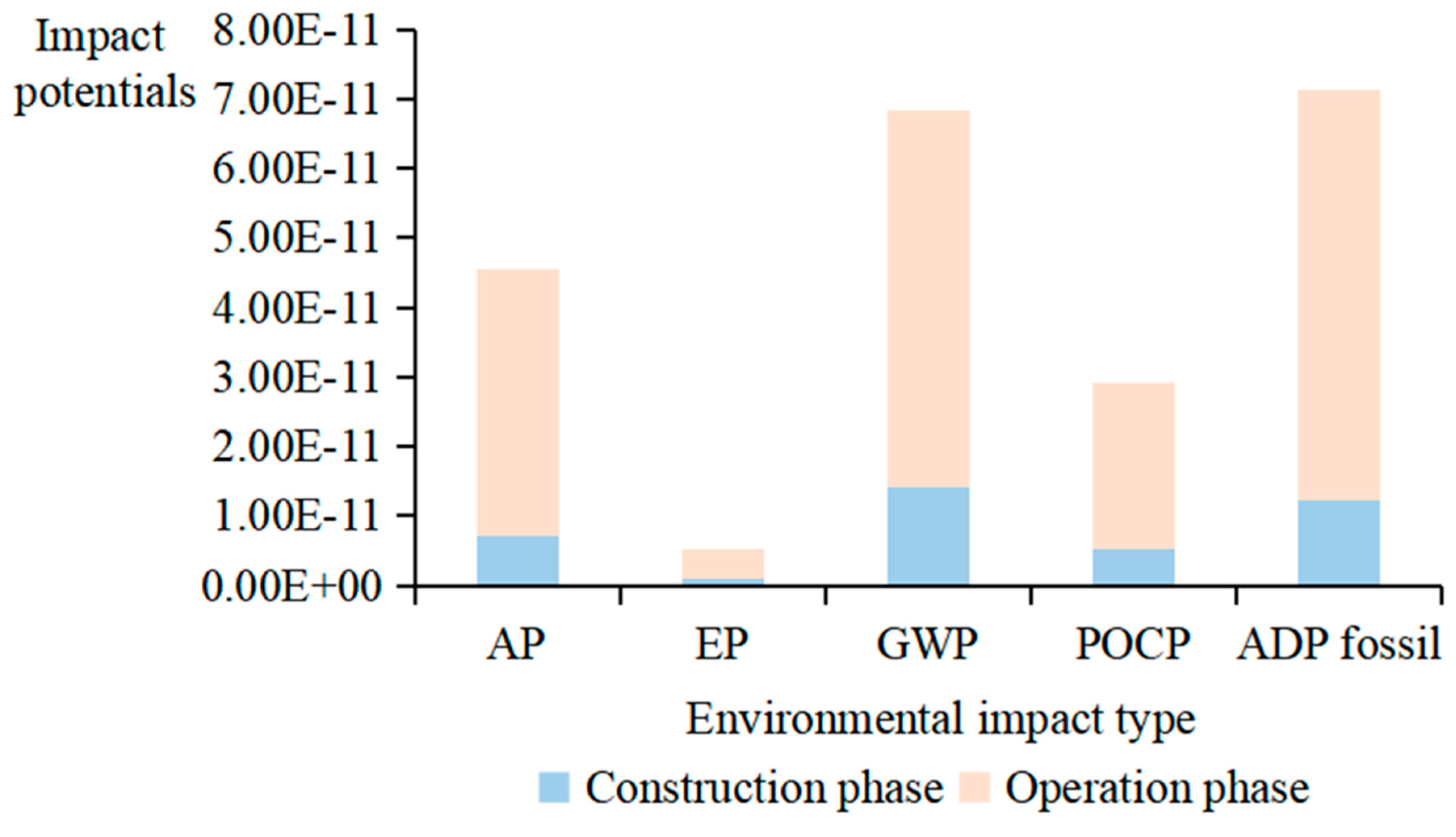

3.3.1. Construction Phase

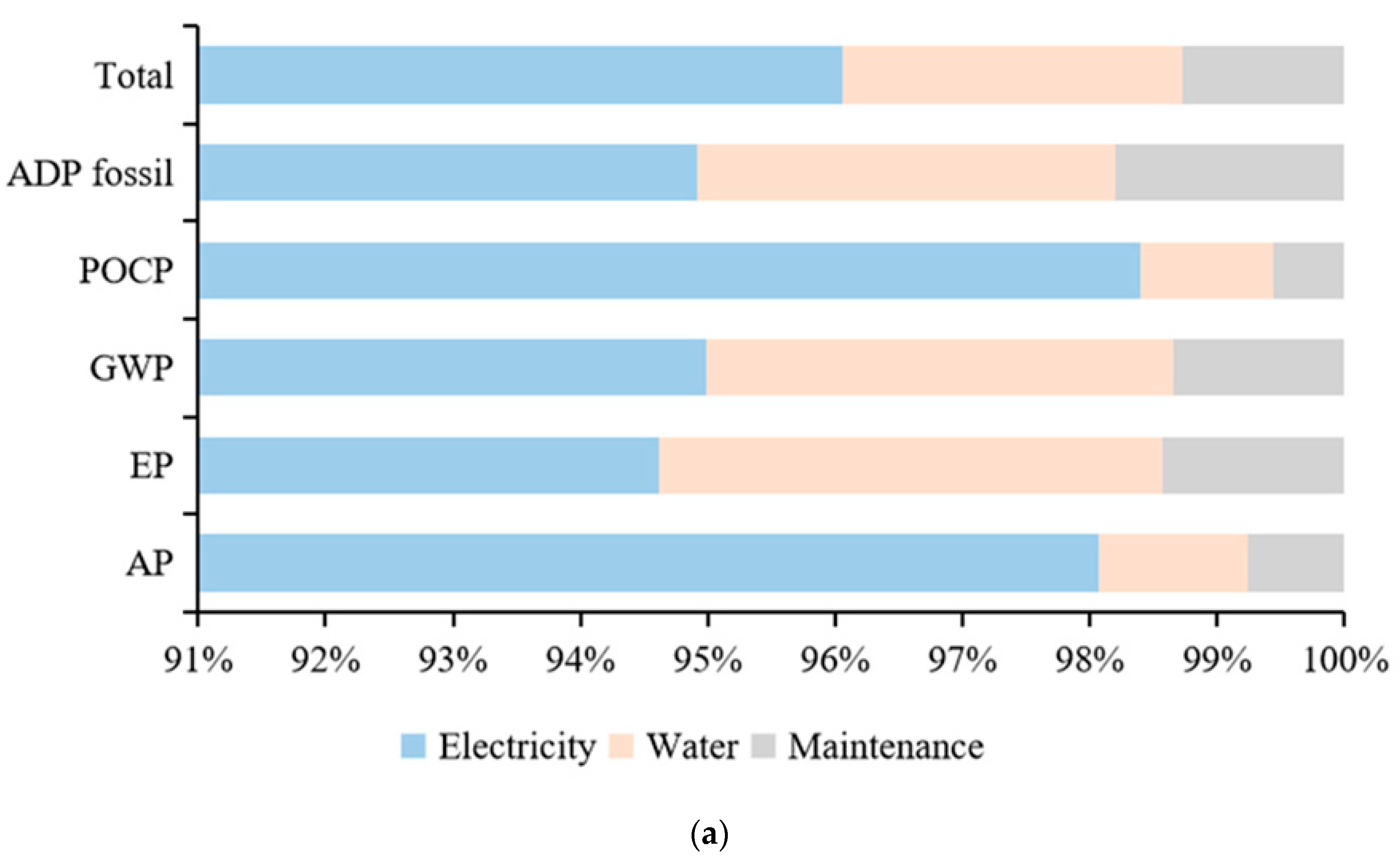

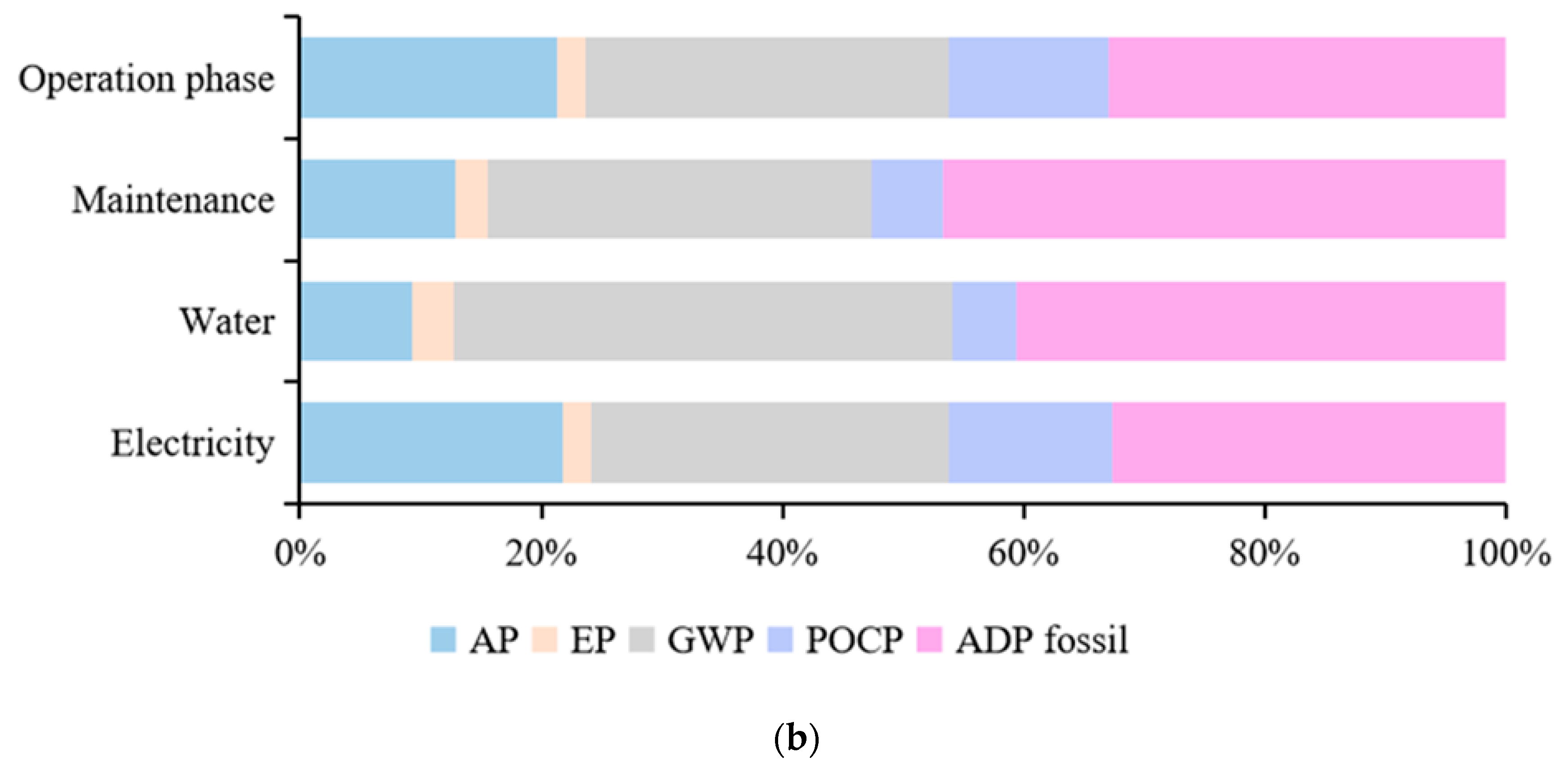

3.3.2. Operation Phase

3.3.3. Full Life Cycle Impact and Integration Results

3.4. Improvement Suggestions

3.4.1. Suggestions for the Proposed Buildings

- Select suitable building materials. For the selection of building materials, environmentally friendly building materials are preferable. At the same time, regional characteristics should be considered in the selection of building materials to avoid transferring the environmental impact of the construction phase to the construction operation phase. Some scholars have compared building materials [26,57,58,59,60,61,62,63,64,65], and some scholars have considered the influence of the external environment when evaluating building materials [13,20,21,66] These studies can provide a reference for building designers to choose building materials.

- Design low-energy buildings. The “Design Standard for Energy Efficiency of Public Buildings” (GB50189-2015) should be strictly implemented during the process of building design. Appropriate heating and cooling methods should be determined based on local characteristics. Conditional areas can consider accessing the electricity generated by new energy, which can greatly reduce resource consumption and environmental pollution. However, the cost of some new energy generation methods is relatively high, so economic factors should be taken into consideration when making decisions. The LCA–LCC integrated model constructed in this study can be used for scheme comparison and selection.

- Improve the bidding scheme. In this study, we found that although the impact of the BMTP is small, the contributions of diesel production and vehicle transportation to the GWP during the BMTP are almost equal. The environmental impact and cost of vehicle transportation are directly related to the transportation distance. Therefore, it is necessary for managers to consider the distance between the supply point of building materials and the construction site during the bidding phase.

3.4.2. Suggestions for Existing Buildings

- Renovate the power supply system of the teaching building. Based on the survey, we propose two alternative scenarios. Scenario 1: The teaching building is located in a coastal city in North China, where solar energy resources are relatively abundant. In addition, the school building roof area is large. Distributed photovoltaic power can be designed in combination with architectural features, and a photovoltaic unit can be installed on the roof. Therefore, distributed photovoltaic power can be considered. Scenario 2: Relevant departments intend to develop wind power in the area, which would make the use of wind power at the university possible. However, it is undeniable that the above two power generation methods have higher cost than the original power generation method [67]. Therefore, it is advisable for decision makers to evaluate the above alternative scenarios with the LCA–LCC integrated model before making a decision.

- Reduce the use of electrical energy. Reducing the use of electric energy can be achieved in the following three ways: a. Strengthening environmental education for students, b. formulating rules for the use of public resources on campus, and c. strengthening supervision and management. Ding et al. recently conducted a study on the behaviour of students in a Chinese university and proposed a strategy for reducing energy consumption via behavioural changes. The results of this study indicate that the improvement in energy-saving education for Chinese college students is imminent [68]. The teaching building is mainly open to college students. By strengthening students’ environmental education and cultivating energy-saving habits, the energy consumption of the teaching building can be reduced to some extent. In addition, relevant departments can formulate rules for the use of public resources on campus. For the teaching building, study lounges and other places, an appointment system can be adopted and an online point assessment system can be established. A user needs to turn off indoor electrical equipment after using it. If an administrator finds that the electrical equipment is not turned off, the user’s points will be deducted. After points are deducted to a certain point, the user will be restricted from using the public resources. Through this approach, administrators can strengthen supervision and effectively reduce the waste of electric energy.

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Questionnaire

| Comparative Indexes | Equal Importance | Between Equal Importance and Moderate Importance | Moderate Importance | Between Moderate Importance and Strong Importance | Strong Importance | Between Strong Importance and Very Strong Importance | Very Strong Importance | Between Very Strong Importance and Extreme Importance | Extreme Importance |

|---|---|---|---|---|---|---|---|---|---|

| A (Human health) B (Ecosystem quality) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Human health) B (Climate change) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Human health) B (Resource consumption) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Human health) B (Construction cost) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Human health) B (Operating cost) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Ecosystem quality) B (Climate change) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Ecosystem quality) B (Resource consumption) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Ecosystem quality) B (Construction cost) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Ecosystem quality) B (Operating cost) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Climate change) B (Resource consumption) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Climate change) B (Construction cost) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Climate change) B (Operating cost) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Resource consumption) B (Construction cost) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Resource consumption) B (Operating cost) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

| A (Construction cos) B (Operating cost) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) | ( ) |

Appendix B. The Environmental Impact Potentials at Various Phases in the Case Study

| Item | AP | EP | GWP | POCP | ADP Fossil | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Characterization (kg SO2 eq.) | Normalization | Characterization (kg Phosphate eq.) | Normalization | Characterization (kg CO2 eq.) | Normalization | Characterization (kg Ethene eq.) | Normalization | Characterization (MJ) | Normalization | |

| Building materials production | 1.63 | 6.81 × 10−12 | 0.157 | 9.94 × 10−13 | 5.80 × 102 | 1.39 × 10−11 | 0.19 | 5.17 × 10−12 | 4.50 × 103 | 1.18 × 10−11 |

| Building materials transportation | 9.65 × 10−4 | 4.04 × 10−15 | 1.28 × 10−4 | 8.11 × 10−16 | 0.952 | 2.27 × 10−14 | 2.81 × 10−6 | 7.62 × 10−17 | 12.8 | 3.38 × 10−14 |

| Construction energy consumption | 7.07 × 10−2 | 2.96 × 10−13 | 4.87 × 10−3 | 3.08 × 10−14 | 16.9 | 4.03 × 10−13 | 6.74 × 10−3 | 1.83 × 10−13 | 1.67 × 102 | 4.41 × 10−13 |

| Item | AP | EP | GWP | POCP | ADP Fossil | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Characterization (kg SO2 eq.) | Normalization | Characterization (kg Phosphate eq.) | Normalization | Characterization (kg CO2 eq.) | Normalization | Characterization (kg Ethene eq.) | Normalization | Characterization (MJ) | Normalization | |

| Electricity | 0.18 | 7.53 × 10−13 | 1.24 × 10−2 | 7.83 × 10−14 | 43 | 1.03 × 10−12 | 1.72 × 10−2 | 4.67 × 10−13 | 4.27 × 102 | 1.12 × 10−12 |

| Water | 2.14 × 10−3 | 8.97 × 10−15 | 5.19 × 10−4 | 3.28 × 10−15 | 1.66 | 3.97 × 10−14 | 1.83 × 10−4 | 4.97 × 10−15 | 14.8 | 3.90 × 10−14 |

| Maintenance | 1.40 × 10−3 | 5.88 × 10−15 | 1.88 × 10−4 | 1.19× 10−15 | 0.609 | 1.45 × 10−14 | 9.83 × 10−5 | 2.67 × 10−15 | 8.09 | 2.13 × 10−14 |

| Item | AP | EP | GWP | POCP | ADP Fossil | ADP Fossil | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Characterization (kg SO2 eq.) | Normalization | Characterization (kg Phosphate eq.) | Normalization | Characterization (kg CO2 eq.) | Normalization | Characterization (kg Ethene eq.) | Normalization | Characterization (MJ) | Normalization | |

| Construction phase | 1.70 | 7.11 × 10−12 | 0.162 | 1.03 × 10−12 | 5.98 × 102 | 1.42 × 10−11 | 0.197 | 5.36 × 10−12 | 4.68 × 103 | 1.23 × 10−11 |

| Operation phase | 9.18 | 3.84 × 10−11 | 0.655 | 4.14 × 10−12 | 2.26 × 103 | 5.42 × 10−11 | 0.874 | 2.37 × 10−11 | 2.25 × 104 | 5.90 × 10−11 |

| Grand total | 10.9 | 4.55 × 10−11 | 0.817 | 5.16 × 10−12 | 2.86 × 103 | 6.85 × 10−11 | 1.07 | 2.91 × 10−11 | 2.72 × 104 | 7.13 × 10−11 |

References

- Finlay, J.; Massey, J. Eco-Campus: Applying the Ecocity Model to Develop Green University and College Campuses. Int. J. Sustain. High. Educ. 2012, 13, 150–165. [Google Scholar] [CrossRef] [Green Version]

- Geng, Y.; Liu, K.; Xue, B.; Fujita, T. Creating a “Green University” in China: A Case of Shenyang University. J. Clean. Prod. 2013, 61, 13–19. [Google Scholar] [CrossRef]

- Findler, F.; Schönherr, N.; Lozano, R.; Stacherl, B. Assessing the Impacts of Higher Education Institutions on Sustainable Development—An Analysis of Tools and Indicators. Sustainability 2019, 11, 59. [Google Scholar] [CrossRef] [Green Version]

- Anand, C.K.; Bisaillon, V.; Webster, A.; Amor, B. Integration of Sustainable Development in Higher Education—A Regional Initiative in Quebec (Canada). J. Clean. Prod. 2015, 108, 916–923. [Google Scholar] [CrossRef]

- Alghamdi, A.; Haider, H.; Hewage, K.; Sadiq, R. Inter-University Sustainability Benchmarking for Canadian Higher Education Institutions: Water, Energy, and Carbon Flows for Technical-Level Decision-Making. Sustainability 2019, 11, 2599. [Google Scholar] [CrossRef] [Green Version]

- Akhanova, G.; Nadeem, A.; Kim, J.R.; Azhar, S.A. Framework of Building Sustainability Assessment System for the Commercial Buildings in Kazakhstan. Sustainability 2019, 11, 4759. [Google Scholar] [CrossRef] [Green Version]

- Alyami, S.H.; Rezgui, Y. Sustainable Building Assessment Tool Development Approach. Sustain. Cities Soc. 2012, 5, 52–62. [Google Scholar] [CrossRef]

- Lee, W.L.; Burnett, J. Benchmarking Energy Use Assessment of HK-BEAM, BREEAM and LEED. Build. Environ. 2008, 43, 1882–1891. [Google Scholar] [CrossRef]

- USGBC. Available online: http://www.usgbc.org/displaypage.aspx?cmspageid=220 (accessed on 10 September 2019).

- Wei, Y.; Wang, S. German Building Sustainability Assessment System Based on Integrated Lca Methodology. Arch. J. 2014, 11, 92–96. (In Chinese) [Google Scholar]

- Konig, H.; De Cristofaro, M.L. Benchmarks for Life Cycle Costs and Life Cycle Assessment of Residential Buildings. Build. Res. Inf. 2012, 40, 558–580. [Google Scholar] [CrossRef]

- Tecchio, P.; Gregory, J.; Olivetti, E.; Ghattas, R.; Kirchain, R. Streamlining the Life Cycle Assessment of Buildings by Structured Under-Specification and Probabilistic Triage. J. Ind. Ecol. 2019, 23, 268–279. [Google Scholar] [CrossRef]

- Hennequin, T.; Dong, Y.; Arnbjerg-Nielsen, K.; Sørup, H. Life Cycle Assessment of a Typical European Single-Family Residence and its Flood Related Repairs. J. Clean. Prod. 2019, 228, 1334–1344. [Google Scholar] [CrossRef]

- Zabalza, I.; Scarpellini, S.; Aranda, A.; Llera, E.; Jáñez, A. Use of LCA as a Tool for Building Ecodesign. A Case Study of a Low Energy Building in Spain. Energies 2013, 6, 3901–3921. [Google Scholar] [CrossRef] [Green Version]

- Lessard, Y.; Anand, C.; Blanchet, P.; Frenette, C.; Amor, B. LEED v4: Where are we Now? Critical Assessment through the LCA of an Office Building Using a Low Impact Energy Consumption Mix. J. Ind. Ecol. 2018, 22, 1105–1116. [Google Scholar] [CrossRef]

- Vitale, P.; Arena, U. An Attributional Life Cycle Assessment for an Italian Residential Multifamily Building. Environ. Technol. 2017, 39, 3033–3045. [Google Scholar] [CrossRef] [PubMed]

- Kofoworola, O.F.; Gheewala, S.H. Environmental Life Cycle Assessment of a Commercial Office Building in Thailand. Int. J. Life Cycle Assess. 2008, 13, 498–511. [Google Scholar] [CrossRef]

- Marique, A.F.; Rossi, B. Cradle-To-Grave Life-Cycle Assessment within the Built Environment: Comparison between the Refurbishment and the Complete Reconstruction of an Office Building in Belgium. J. Environ. Manag. 2018, 224, 396–405. [Google Scholar] [CrossRef] [Green Version]

- Vitale, P.; Arena, N.; Di Gregorio, F. Life Cycle Assessment of the End-Of-Life Phase of a Residential Building. Waste Manag. 2017, 60, 311–321. [Google Scholar] [CrossRef]

- Chhabra, J.P.S.; Hasik, V.; Bilec, M.M.; Warn, G.P. Probabilistic Assessment of the Life-Cycle Environmental Performance and Functional Life of Buildings due to Seismic Events. J. Archit. Eng. 2018, 24, 04017035. [Google Scholar] [CrossRef]

- Welsh-Huggins, S.J.; Liel, A.B. A Life-Cycle Framework for Integrating Green Building and Hazard-Resistant Design: Examining the Seismic Impacts of Buildings with Green Roofs. Struct. Infrastruct. Eng. 2017, 13, 19–33. [Google Scholar] [CrossRef]

- Liu, X.L.; Wang, H.T.; Chen, J. Method and basic model for development of Chinese reference life cycle database. Acta Sci. Circumstantiae 2010, 30, 2136–2144. (In Chinese) [Google Scholar]

- Gong, X.; NIE, Z.; Wang, Z.; Zuo, T. Research and Development of Chinese LCA Database and LCA Software. Rare Met. 2006, 25, 101–104. [Google Scholar] [CrossRef]

- Ma, X.; Wang, H.T. Research and Application of Life Cycle Assessment in China. Chem. Eng. Equip. 2015, 2, 164–166. (In Chinese) [Google Scholar]

- Huang, L.; Liu, Y.; Krigsvoll, G.; Johansen, F. Life Cycle Assessment and Life Cycle Cost of University Dormitories in the Southeast China: Case Study of the University Town of Fuzhou. J. Clean. Prod. 2018, 173, 151–159. [Google Scholar] [CrossRef]

- Buyle, M.; Galle, W.; Debacker, W.; Audenaert, A. Sustainability Assessment of Circular Building Alternatives: Consequential LCA and LCC for Internal Wall Assemblies as a Case Study in a Belgian Context. J. Clean. Prod. 2019, 218, 141–156. [Google Scholar] [CrossRef]

- Li, Q.Y. BIM Enabled Life Cycle Environmental and Cost Analysis of a Prototype of Small Scalezero Energy House. Master’s Thesis, Tianjin University, Tianjin, China, 2017. (In Chinese). [Google Scholar]

- Liu, H.B.; Xue, Z.Y.; Fan, J.L.; Wang, J.X.; Wang, H.N.; Zhang, R.S. Application and Development of life cycle assessment (LCA) in the Field of Construction. J. Saf. Environ. Forthcoming.

- Campisi, D.; Gitto, S.; Morea, D. An Evaluation of Energy and Economic Efficiency in Residential. Int. J. Energy Econ. Policy 2018, 8, 185–196. [Google Scholar]

- Gong, X.; Michel, P.; Cantin, R. Multiple-Criteria Decision Analysis of BIM Influences in Building Energy Management. Build. Simul. 2019, 12, 641–652. [Google Scholar] [CrossRef]

- Tian, Z.W. The Research on Assessment of Environment and Economic Performance for Recycled Concrete Based on LCA–LCC. Master’s Thesis, Zhejiang University, Hangzhou, China, 2012. (In Chinese). [Google Scholar]

- Kim, S.H.; Choi, M.S. Environmental Impact Assessment and Eco-Friendly Decision-Making in Civil Structures. Environ. Manag. 2013, 126, 105–112. [Google Scholar] [CrossRef]

- Shi, J.; Wang, Y.; Fan, S.; Ma, Q.; Jin, H. An Integrated Environment and Cost Assessment Method Based on LCA and LCC for Mechanical Product Manufacturing. Int. J. Life Cycle Assess. 2019, 24, 64–77. [Google Scholar] [CrossRef]

- Opher, T.; Friedler, E.; Shapira, A. Life Cycle Sustainability Assessment of Urban Water Reuse at Various Centralization Scales. Int. J. Life Cycle Assess. 2018, 24, 1319–1332. [Google Scholar] [CrossRef]

- Kouloumpis, V.; Azapagic, A. Integrated Life Cycle Sustainability Assessment Using Fuzzy Inference: A Novel FELICITA Model. Sustain. Prod. Consum. 2018, 15, 25–34. [Google Scholar] [CrossRef] [Green Version]

- Li, X.D.; Wu, X.; Zhang, Z.H. Study on Social WTP for Environmental Impacts Based on the LCA Theory. J. Harbin Inst. Technol. 2005, 11, 51–54. (In Chinese) [Google Scholar]

- Soares, N.; Pereira, L.D.; Ferreira, J.; Conceicao, P.; da Silva, P.P. Energy Efficiency of Higher Education Buildings: A Case Study. Int. J. Sustain. High. Educ. 2015, 16, 669–691. [Google Scholar] [CrossRef] [Green Version]

- Xiong, H.B.; Zhang, C.; Yeo, J.T.; Zhao, Y. Environmental Impact Comparison of Different Structure Systems Based on Life Cycle Assessment Methodology. In Advanced Materials Research; Li, H., Liu, Y.F., Guo, M., Zhang, R., Du, J., Eds.; Trans Tech Publications Ltd.: Zurich, Switzerland, 2012; Volume 374, p. 405. [Google Scholar]

- Environmental Management—Life Cycle Assessment-Principles and Framework (ISO 14040); International Standardization Organization: Geneva, Switzerland, 2016.

- Environmental Management—Life Cycle Assessment-Requirements and Guidelines (ISO 14044); International Standardization Organization: Geneva, Switzerland, 2016.

- Buildings and Constructed Assets—Service-Life Planning—Part 5: Life-Cycle Costing (ISO 15686-5); International Standardization Organization: Geneva, Switzerland, 2008.

- Sun, Y.F. The Research of Energy-Saving Buildings Cost Management Based on the Theory of Whole Life Cycle. Master’s Thesis, Shandong University of Technology, Qingdao, China, 2014. (In Chinese). [Google Scholar]

- Sharma, A.; Saxena, A.; Sethi, M.; Shree, V. Life Cycle Assessment of Buildings: A Review. Renew. Sustain. Energy Rev. 2011, 15, 871–875. [Google Scholar] [CrossRef]

- Robati, M.; Kokogiannakis, G.; McCarthy, T.J. Impact of Structural Design Solutions on the Energy and Thermal Performance of an Australian Office Building. Build. Environ. 2017, 124, 258–282. [Google Scholar] [CrossRef]

- Asdrubali, F.; Baldassarri, C.; Fthenakis, V. Life Cycle Analysis in the Construction Sector: Guiding the Optimization of Conventional Italian Buildings. Energy Build. 2013, 64, 73–89. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K.; Sadiq, R. Conventional Versus Modular Construction Methods: A Comparative Cradle-to-Gate LCA for Residential Buildings. J. Clean. Prod. 2019, 204, 109479. [Google Scholar] [CrossRef]

- Morales, M.; Moraga, G.; Kirchheim, A.P.; Passuello, A. Regionalized Inventory Data in LCA of Public Housing: A Comparison between Two Conventional Typologies in Southern Brazil. J. Clean. Prod. 2019, 238, 117869. [Google Scholar] [CrossRef]

- Petrovic, B.; Myhren, J.A.; Zhang, X.; Wallhagen, M.; Eriksson, O. Life Cycle Assessment of a Wooden Single-Family House in Sweden. Appl. Energy 2019, 251, 113253. [Google Scholar] [CrossRef]

- Laiblova, L.; Pesta, J.; Kumar, A.; Hajek, P.; Fiala, C.; Vlach, T.; Koci, V. Environmental Impact of Textile Reinforced Concrete Facades Compared to Conventional Solutions-LCA Case Study. Materials 2019, 12, 319419. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, W.; Yv, H.; Zhang, Z.Y. A Comparative Study on Life Cycle Environmental Impacts of Building Insulation Materials. New Build. Mater. 2017, 44, 101–105. (In Chinese) [Google Scholar]

- Sustainability of Construction Works. Environmental Product Declarations. Product Category Rules for Concrete and Concrete Elements (EN 16757: 2017); CEN: Brussels, Belgium, 2017.

- Sun, Y.F. The Research of Energy-Saving Buildings Cost Management Based on the Theory of Whole Life Cycle Cost-Taking High-Rise Residential Buildings as an Example. Master’s Thesis, Shandong University of Technology, Qingdao, China, 2014. [Google Scholar]

- Xu, S.B. Practical Decision Method: Analytic Hierarchy Process. Principle; Tianjin University Press: Tianjin, China, 1988. (In Chinese) [Google Scholar]

- Liu, X.; Gao, X. A Survey Analysis of Low Carbon Technology Diffusion in China’s Iron & Steel Industry. J. Clean. Prod. 2016, 129, 88–101. [Google Scholar]

- Zhang, Y.; Bo, X.; Zhao, Y.; Nielsen, C.P. Benefits of Current and Future Policies on Emissions of China’s Coal-Fired Power Sector Indicated by Continuous Emission Monitoring. Environ. Pollut. 2019, 251, 415–424. [Google Scholar] [CrossRef]

- Yu, P.; Luo, Z.Y.; Wang, Q.H.; Fang, M.X. Life Cycle Assessment of Transformation from a Sub-critical Power Plant into a Polygeneration Plant. Energy Convers. Manag. 2019, 198, 111801. [Google Scholar] [CrossRef]

- Paik, I.; Na, S.; Yoon, S. Assessment of CO2 Emissions by Replacing an Ordinary Reinforced Concrete Slab with the Void Slab System in a High-Rise Commercial Residential Complex Building in South Korea. Sustainability 2019, 11, 82. [Google Scholar] [CrossRef] [Green Version]

- Cuenca-Moyano, G.M.; Martin-Morales, M.; Bonoli, A. Environmental Assessment of Masonry Mortars Made with Natural and Devoted Aggregates. Int. J. Life Cycle Assess. 2019, 24, 191–210. [Google Scholar] [CrossRef]

- Talang, R.P.N.; Sirivithayapakorn, S. Comparing Environmental Burdens, Economic Costs and Thermal Resistance of Different Materials for Exterior Building Walls. J. Clean. Prod. 2018, 197, 1508–1520. [Google Scholar] [CrossRef]

- Zea Escamilla, E.; Habert, G.; Correal Daza, J.; Archilla, H.; Echeverry Fernández, J.; Trujillo, D. Industrial or Traditional Bamboo Construction? Comparative Life Cycle Assessment (LCA) of Bamboo-Based Buildings. Sustainability 2018, 10, 3096. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, I.M.; Tsavdaridis, K.D. Life Cycle Assessment (LCA) and Cost (LCC) Studies of Lightweight Composite Flooring Systems. J. Build. Eng. 2018, 20, 624–633. [Google Scholar] [CrossRef]

- Saleem, M.; Chhipi-Shrestha, G.; Andrade, M.; Dyck, R.; Ruparathna, R.; Hewage, K.; Sadiq, R. Life Cycle Thinking–Based Selection of Building Facades. J. Archit. Eng. 2018, 24, 04018029. [Google Scholar] [CrossRef]

- Hossain, Y.; Marsik, T. Conducting Life Cycle Assessments (LCAs) to Determine Carbon Payback: A Case Study of a Highly Energy-Efficient House in Rural Alaska. Energies 2019, 12, 1732. [Google Scholar] [CrossRef] [Green Version]

- Cruz Rios, F.; Grau, D.; Chong, W.K. Reusing Exterior Wall Framing Systems: A Cradle-To-Cradle Comparative Life Cycle Assessment. Waste Manag. 2019, 94, 120–135. [Google Scholar] [CrossRef] [PubMed]

- Yılmaz, E.; Arslan, H.; Bideci, A. Environmental Performance Analysis of Insulated Composite Facade Panels Using Life Cycle Assessment (LCA). Constr. Build. Mater. 2019, 202, 806–813. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Bin Marsono, A.K.; Gohari, A. Sustainable Materials Selection Based on Flood Damage Assessment for a Building Using LCA and LCC. J. Clean. Prod. 2019, 222, 844–855. [Google Scholar] [CrossRef]

- Cai, J. Research on Cost Control and Optimization of Power Generation Industry under the Background of Supply Side Reformation-Based on the Case of C Power Plant. Master’s Thesis, Anhui University, Hefei, China, 2018. (In Chinese). [Google Scholar]

- Ding, Z.K.; Hu, T.; Li, M.; Xu, X.X.; Zou, P.X.W. Agent-Based Model for Simulating Building Energy Management in Student Residences. Energy Build. 2019, 198, 11–27. [Google Scholar] [CrossRef]

| Topic | Indexes | Country | Integration Method | Source |

|---|---|---|---|---|

| The research on assessment of environment and economic performance for recycled concrete based on LCA–LCC | Climate change; Acidification; Water resource consumption; Mineral resource consumption; Solid waste; Photochemical pollution; Fossil energy consumption; Economic indexes. | China | Social willingness-to-pay (WTP) | [31] |

| Environmental impact assessment and eco-friendly decision-making in civil structures | Global warming; Ozone depletion; Acidification; Eutrophication; Photochemistry ozone creation; Economic indexes. | Korea | Analytic hierarchy process (AHP); CO2 conversion method | [32] |

| An integrated environment and cost assessment method based on LCA and LCC for mechanical product manufacturing | Chinese resource depletion potential; Global warming potential; Photochemical ozone creation potential; Eutrophication potential; Acidification potential; Economic indexes. | China | Social WTP | [33] |

| Comparative life cycle sustainability assessment of urban water reuse at various centralization scales | Human health; Ecosystems; Resources; Social indexes; Economic indexes. | Israel | AHP | [34] |

| Integrated life cycle sustainability assessment using fuzzy inference: A novel FELICITA model | Recyclability of power plant construction materials; Global warming potential; Ozone layer depletion potential; Acidification potential; Eutrophication potential; Photochemical ozone creation potential; Social indexes; Economic indexes. | England | Fuzzy inference | [35] |

| Life Cycle | Inventory Category | Comments | |

|---|---|---|---|

| LCA | LCC | ||

| Construction phase | Building materials inventory | Building materials cost inventory | Main building materials consumption and cost. |

| Energy consumption inventory | Energy charge inventory | Energy consumption and energy charge for on-site building construction. (Transportation energy consumption is not included). | |

| Building materials transport inventory | Building materials transportation cost inventory | Transportation distance and cost from building materials production site to construction site. | |

| Operation phase | Energy and water consumption inventory | Energy and water bills | Energy and water consumption quantities and charges during building operation. |

| Building maintenance inventory | Building maintenance cost inventory | The replacement quantity and cost of building materials in the process of building operation. | |

| Indexes Category | Evaluation Indexes |

|---|---|

| Human health | Ionizing radiation, ozone layer destruction, human toxicity, photochemical oxidant, inhalable particles, other special substances |

| Ecosystem quality | Acidification, ecotoxicity, eutrophication |

| Climate change | Global warming, CO2 emissions |

| Resource consumption | Land occupation, fossil energy consumption, mineral resource consumption, freshwater consumption |

| Environmental Influence | Currency Factor | Unit |

|---|---|---|

| GWP | 0.22 | RMB/kg CO2 eq. |

| AP | 0.71 | RMB/kg SO2 eq. |

| EP | 5.60 | RMB/kg Phosphate eq. |

| POCP | 3.41 | RMB/kg Ethene eq. |

| ADP fossil | 3.34 × 10−5 | RMB/MJ |

| Item | Quantity | Price (RMB/m2) | Distance (km) | Comments | |

|---|---|---|---|---|---|

| Unit | Amount | ||||

| Steel | kg/m2 | 146.56 | 583.75 | 25.00 | - |

| Cement | kg/m2 | 38.85 | 15.60 | 18.00 | - |

| Cement | kg/m2 | 1667.77 | 299.28 | 5.20 | - |

| Mortar | kg/m2 | 216.96 | 50.13 | 14.00 | - |

| Gravel | kg/m2 | 16.52 | 1.64 | 14.00 | - |

| Brick | kg/m2 | 33.23 | 8.55 | 3.80 | - |

| Glass | kg/m2 | 0.52 | 306.86 | 8.10 | - |

| Aluminium products | kg/m2 | 0.38 | 11.37 | 15.00 | - |

| Tile | kg/m2 | 76.30 | 32.60 | 18.00 | - |

| Diesel | kg/m2 | 0.50 | 3.32 | - | Mainly used for building materials transportation. |

| Electricity | kw·h/m2 | 15.52 | 11.66 | - | Mainly used for field construction. |

| Item | Quantity | Price (RMB/a·m2) | Comments | |

|---|---|---|---|---|

| Unit | Amount | |||

| Cement | kg/a·m2 | 0.13 | 0.05 | Since the wind speed of the location is high in winter and spring, the maintenance process mainly considers the replacement of glass and tile. |

| Glass | kg/a·m2 | 0.03 | 17.7 | |

| Tile | kg/a·m2 | 1.22 | 0.52 | |

| Water | m3/a·m2 | 2.88 | 15.98 | - |

| Electricity | kw·h/a·m2 | 39.55 | 48.87 | - |

| Construction Cost | Operating Cost | Total |

|---|---|---|

| 1324.76 | 1309.97 | 2634.73 |

| AP | EP | GWP | POCP | ADP Fossil |

|---|---|---|---|---|

| 3.26 | 2.06 | 288.48 | 1.61 | 0.39 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, Z.; Liu, H.; Zhang, Q.; Wang, J.; Fan, J.; Zhou, X. The Impact Assessment of Campus Buildings Based on a Life Cycle Assessment–Life Cycle Cost Integrated Model. Sustainability 2020, 12, 294. https://doi.org/10.3390/su12010294

Xue Z, Liu H, Zhang Q, Wang J, Fan J, Zhou X. The Impact Assessment of Campus Buildings Based on a Life Cycle Assessment–Life Cycle Cost Integrated Model. Sustainability. 2020; 12(1):294. https://doi.org/10.3390/su12010294

Chicago/Turabian StyleXue, Zhuyuan, Hongbo Liu, Qinxiao Zhang, Jingxin Wang, Jilin Fan, and Xia Zhou. 2020. "The Impact Assessment of Campus Buildings Based on a Life Cycle Assessment–Life Cycle Cost Integrated Model" Sustainability 12, no. 1: 294. https://doi.org/10.3390/su12010294