1.1. Research Problem

Poor urban and rural areas throughout the United States have increasingly seen large groceries and supermarkets go out of business or move. Created in the aftermath of these closings are what has been termed food deserts, where people in large sections of cities do not have access to healthier food. According to the United States Department of Agriculture (USDA), 23.5 million Americans live in communities where access to fresh produce and meat is inadequate [

1]. The social disparity in health is extreme, as has been remarkably seen during the COVID-19 pandemic, where the urban poor death rate is substantially greater than the population at large due to the higher preponderance of pre-existing conditions in these communities. For example, the death rate from COVID-19 in food deserts account for more than 70% of coronavirus deaths in the city of Chicago [

2]. In Chicago, the death rate from diabetes in a food desert is twice that of regions with access to healthier food [

3].

Corner stores of various varieties have moved into these food deserts to offset the food gaps which have resulted from the grocery departures or closures. These stores include dollar stores, mini-marts, and gas station connected food marts. These stores are located to be accessible to nearly all residents and ideally within walking distance. However, they in general have not provided access to healthier foods, e.g., fresh produce and meat.

Over the years, there have been continuous initiatives, both from local and national organizations, to encourage corner markets to sell healthy foods [

4]. However, there have also been challenges to fully implement said initiatives. For one, it has been difficult to establish a healthy food corner market in areas where a generation or more of people have not been exposed to healthy diets or lack awareness of how to prepare healthy meals. Often corner store customers are not open to the purchase of healthier foods [

5]. This trend is also observed in food pantries where fresh produce free for the taking is left to remain on the shelves.

A second barrier, and the sole focus of this paper, is the cost for businesses to purchase healthier foods and sell them at an affordable price. The small volume of sales dissuades interest by healthy food distributors in selling to corner markets. Often corner market owners who sell fresh produce purchase their food from the groceries they can access. Collectively, these two barriers virtually prohibit healthy food sells in corner markets.

In general, corner store markets have very slim profit margins [

6]. Any additional cost burden such as the inclusion of fresh produce and meat likely is enough to push them into the red. This study is predicated on the idea that if the economic position of corner markets can be improved, then there at least is a possibility of adding healthier food to their product inventories. Therefore, this study aims to assess opportunities for corner stores to increase their profit margin through affordable investments aimed at reduced energy costs.

1.2. Previous Research in Grocery Store Energy Consumption

Many reported studies have investigated the performance of typical supermarket refrigerated display cases relative to the indoor store environment. For example, Howell and Adams developed a model to predict the energy consumption of (i) medium temperature, single shelf, (ii) medium temperature, multi shelf, and (iii) low temperature reach-in (open) storage cabinets in a 4656

food store in Tampa, Florida, US [

7]. Their results showed a savings of 10% in annual display case operating costs with a 5% reduction in store relative humidity. Another study explored experimentally the effect of reducing the internal store environmental relative humidity on annual energy consumption of eight supermarkets in Florida, US [

8]. Controls were set in place to maintain a minimum relative humidity value in all stores which reached as low of a value of 37% in the month of March. The estimated annual food refrigeration energy savings for all of stores from this intervention was 45%. In Sweden, field measurement of temperature variations in refrigerated display case cabinets was conducted in three supermarkets. The study found that the energy consumption of the display case cabinets was influenced by the outdoor climate condition. They observed that electrical consumption by the display cabinets increased 55% during summer because of an increase in the store ambient humidity [

9].

A number of studies have investigated the energy savings of closed relative to open refrigerated display cases [

10]. For example, an experimental investigation of the effects of operating conditions including door opening frequency, ambient air temperature, and refrigerated case temperature distributions was performed [

11]. This study found that closed display cabinets achieve better thermal homogeneity and less energy consumption than open display cabinet regardless of the door opening frequency.

Additionally, many studies have assessed the benefit of air curtains used in open display cases on energy consumption [

12]. The variation of the thickness, width, height, and velocity of the air curtain along with its pressure and temperature difference on the performance of the display case refrigerated was investigated by Ge and Tassou [

13].

Last of all, a few studies considered investigated phase change material (PCM) integration into refrigerated display cases to buffer transient impacts which often require the case to be maintained colder than needed. Potential energy savings have been documented. One study demonstrated a 6% reduction in energy for display cabinets outfitted with this technology for store environmental conditions of 25 °C and 60% RH [

14].

Nearly all of the previous studies have mainly focused on large supermarkets. Corner stores with an area of 500

or less have received very little attention, despite the fact that they are deemed to be the worst performing building type from an energy perspective [

15]. There do exist a few benchmarks for corner market energy intensity. These are summarized in

Table 1 below. Energy intensities in the range of 346 kWh/m

2-year for what has been termed a sustainable corner markets to as high as 1172.3 kWh/m

2-year have been documented. Most interesting are the findings from the Minnesota Department of Commerce [

16]. Their comprehensive study of corner markets in Minnesota revealed a significant difference in energy intensity for chain owned (1173.3 kWh/m

2-year) versus local owned (764.2 kWh/m

2-year). The benchmark energy intensity associated with typical corner stores are shown in

Table 1.

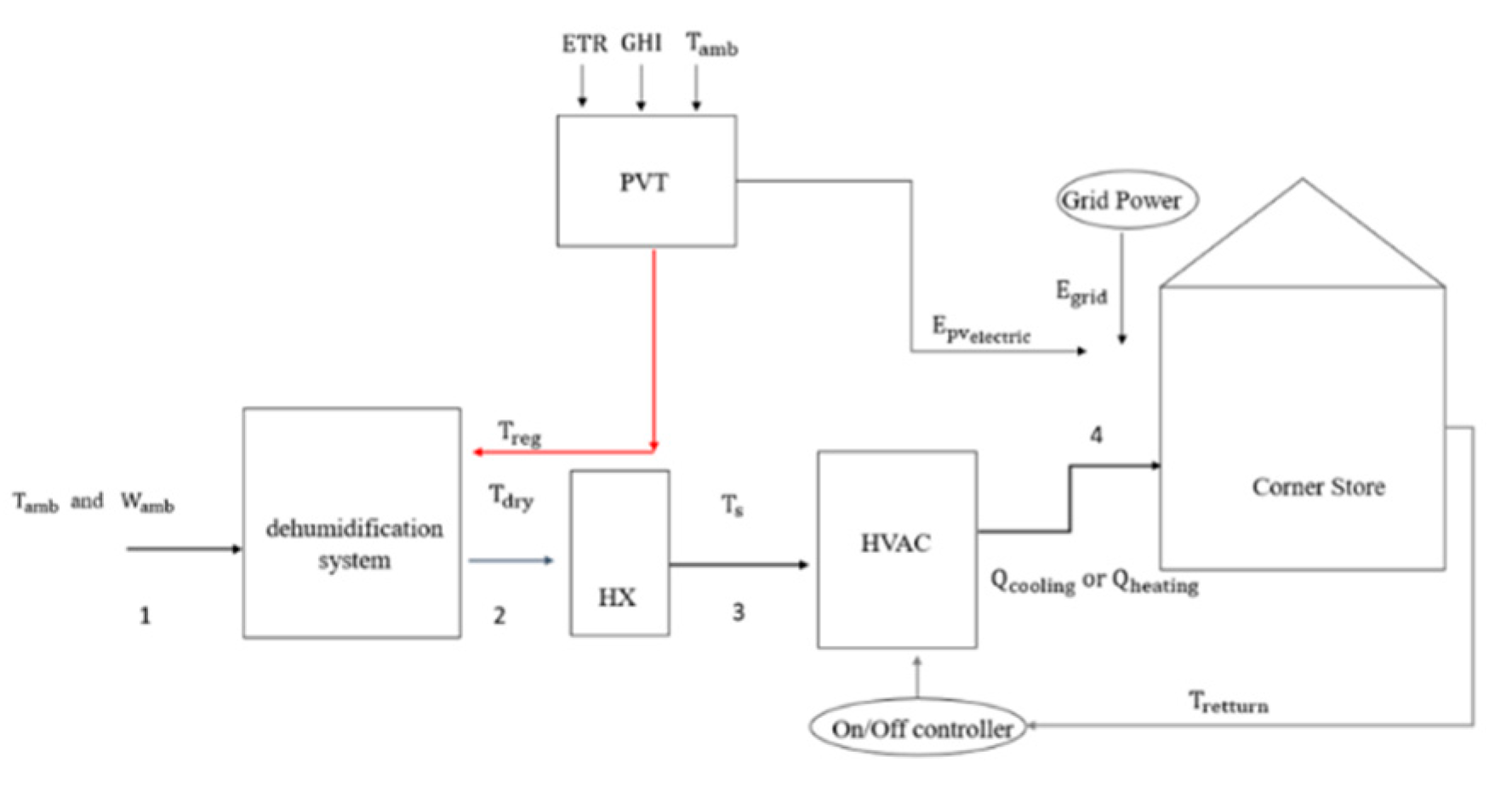

This research uniquely poses use of a solar dehumidification system integrated into a corner store heating, ventilation, and air conditioning (HVAC) systems. Several studies have considered use of these systems in commercial and residential buildings. However, no known study has addressed the problem of high energy consumption in corner markets. This study seeks to demonstrate the economic feasibility of this technology in three different cities in the United States. These cities (Dayton, OH, Pine Bluff, AR, and Phoenix, AZ) are representative of cooling dominated/relatively hot and humid summers; cooling dominated with extreme summer heat and humidity; and cooling dominated with extreme summer heat but moderate humidity.

The following describes the structure for this paper. First, in

Section 2 the model section describes the models required to estimate annual energy consumption in typical corner stores and in corner stores reliant about the posed solar dehumidification system. Included in both cases are models for estimating heat loss/gain to/from the external environment, refrigeration case models, and HVAC system models. The posed system also includes models for the solar dehumidification system.

Section 3 shows the predictions for the baseline and posed configurations for a typical corner store located in the three cities studied. The prediction results aim to elucidate the annual energy and cost savings.

Section 4 shows the economic analysis used to estimate payback from the capital investment of the posed solar dehumidification system.

Section 5 discusses the significance of the findings and the future work needed to validate results. Lastly,

Section 6 offers summary conclusions.