Quality Control of the Thermal Properties of Superstructures in Accommodation Spaces in Naval Constructions

Abstract

:1. Introduction

2. Methods to Characterize the Thermal Transmittance in Vertical Elements

2.1. The Heat Flow Meter Method and Temperature Measurement Methods

2.2. Expressions for the Convective Term

3. Methodology

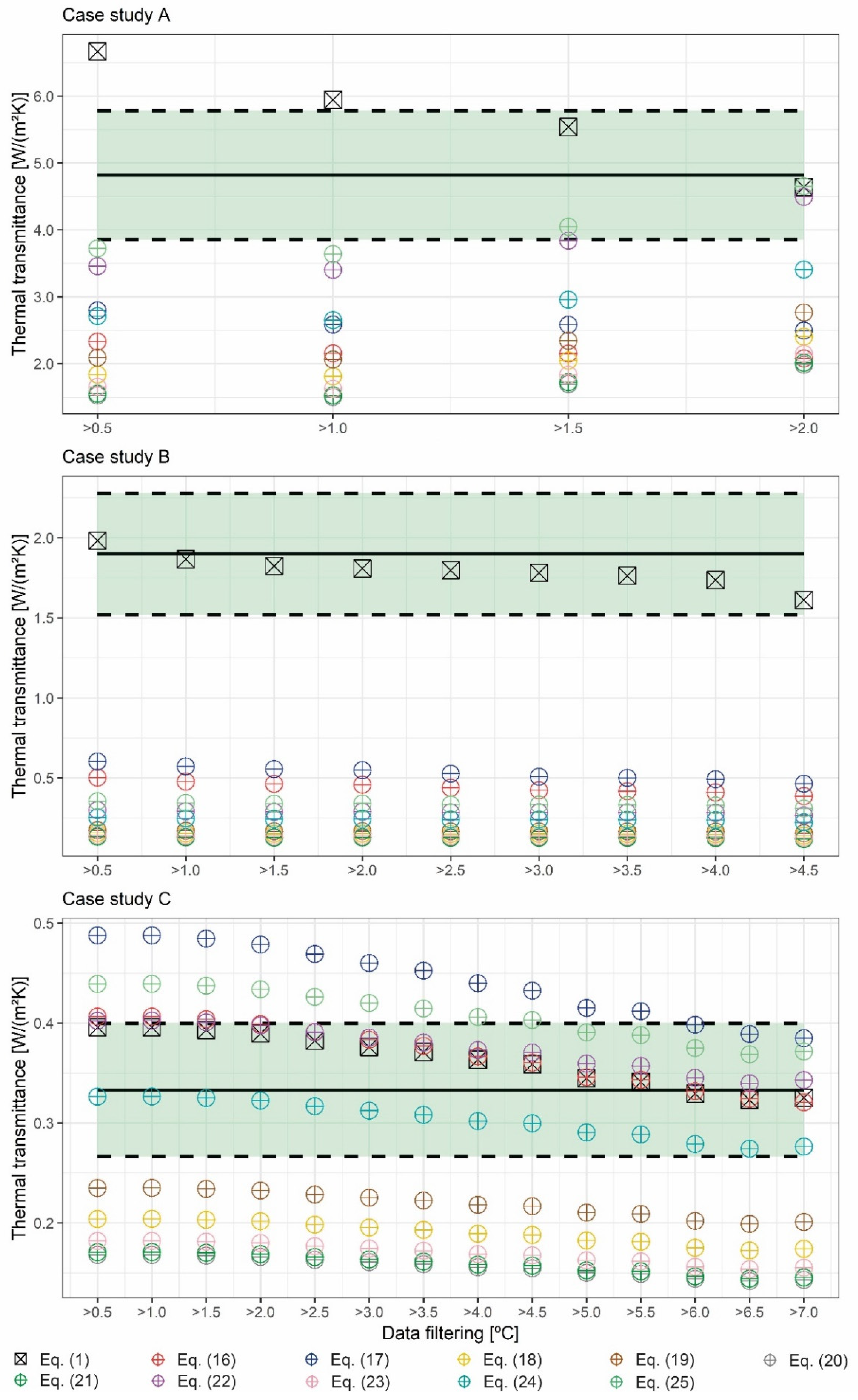

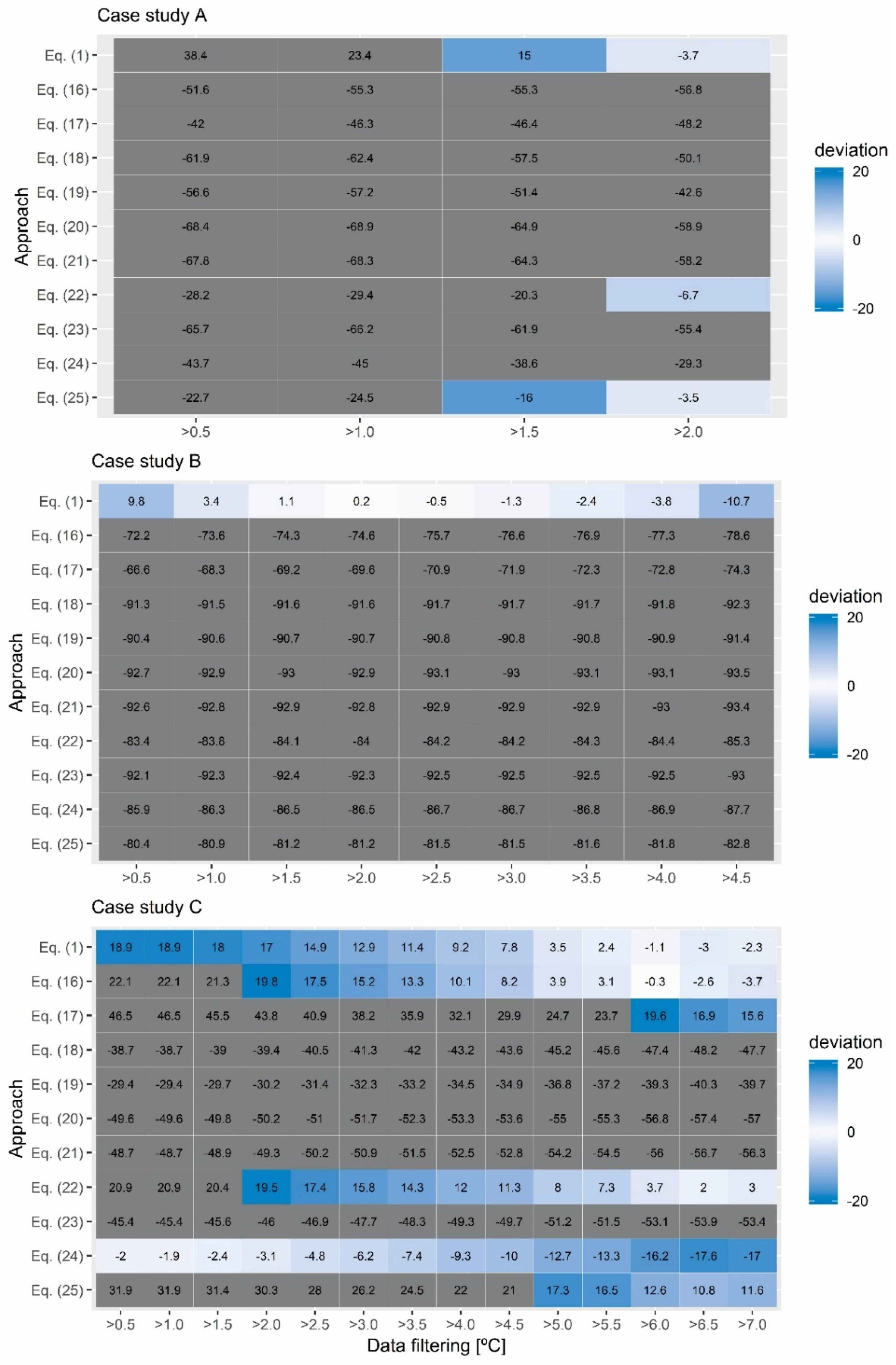

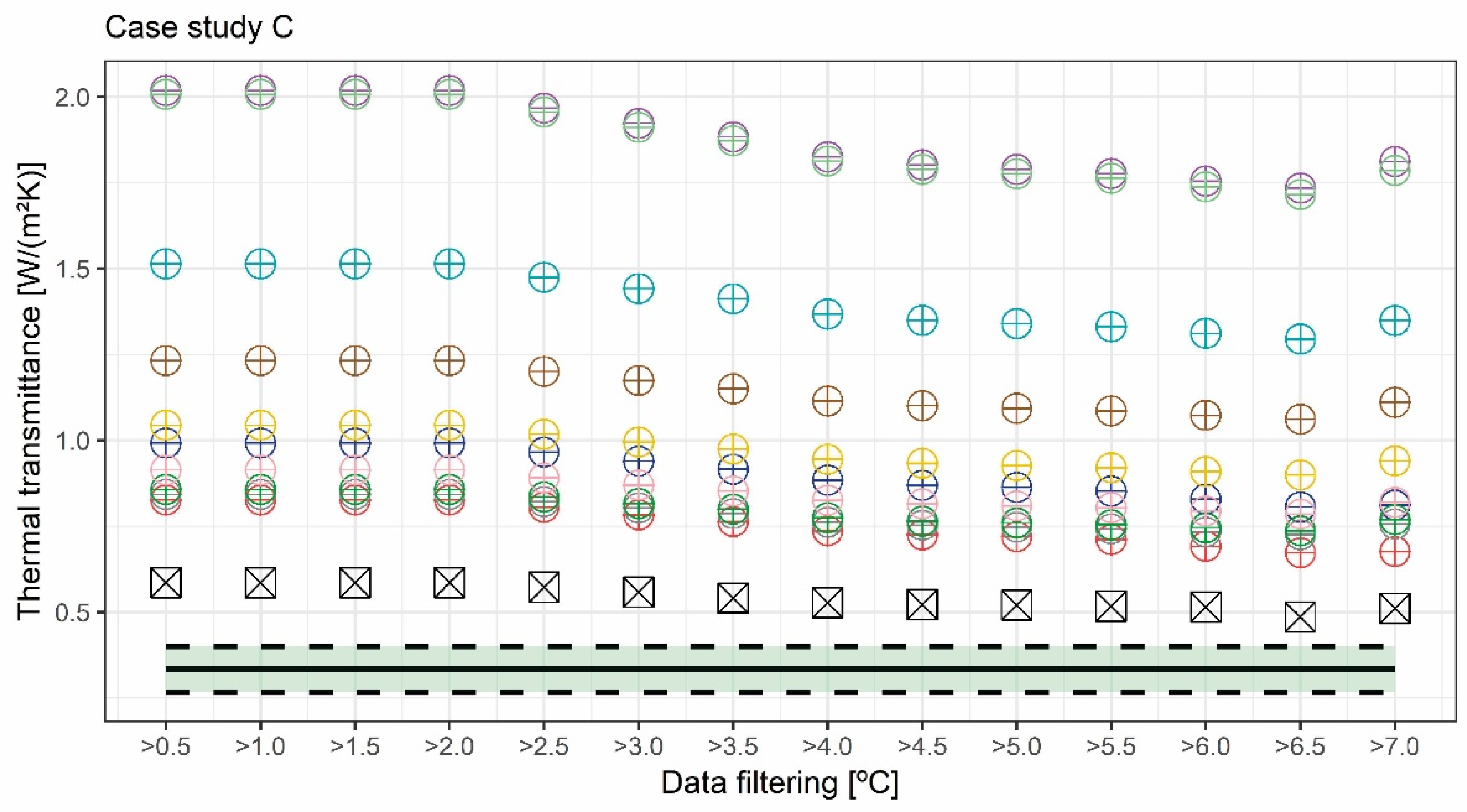

4. Results and Discussion

- (1)

- As for case study A, a total of four different filtering was applied with the following limit values: 0.5, 1.0, 1.5, and 2.0 °C;

- (2)

- As for case study B, a total of nine different filtering was applied with the following limit values: 0.5, 1.0, 1.5, 2.0, 2.5, 3.0, 3.5, 4.0, and 4.5 °C;

- (3)

- As for case study C, a total of 14 different filtering was applied with the following limit values: 0.5, 1.0, 1.5, 2.0, 2.5, 3.0, 3.5, 4.0, 4.5, 5.0, 5.5, 6.0, 6.5, and 7.0 °C.

5. Conclusions

- (1)

- The heat flow meter method was the approach presenting a greater potential of use in ships as it obtained results within the limits of acceptability in the three case studies monitored;

- (2)

- The temperature measurement methods had a variable behavior in the tests, although some case studies obtained representative results. In this regard, case study A obtained a low percentage deviation with respect to the reference value. Although these methods are not a methodology, such as the heat flow meter method, they could be an optional methodology for engineers responsible for assessing the thermal properties of ship superstructures. Given the influence of the equation used for the internal convective heat transfer coefficient, new studies should be conducted to determine the expression which is best adapted to this approach. In this regard, the approach through dimensionless numbers should be analyzed similarly to what has been done in the quantitative infrared thermography method in buildings [62];

- (3)

- The progressive increase in the data filtering in the post-processing led to a decrease in the thermal transmittance value obtained, thus achieving more adjusted results in the heat flow meter method. It was also found that the criterion of data filtering could vary according to the layers of the superstructure, so that superstructures with a high thermal transmittance require a lower thermal gradient (greater than 2 °C), and those with a low thermal transmittance require a higher thermal gradient (greater than 5 °C);

- (4)

- The effect of placing the probes in zones affected by the thermal bridge could lead to obtaining non-representative results. In this regard, the results obtained in this research have shown that placing the probes in the zone influenced by the thermal bridge of the junction of the bulkhead with the floor were not representative with any approach. There was an increase in the percentage deviation greater than 50% with respect to that obtained in the zone not influenced by the thermal bridge. Likewise, this effect influenced the temperature measurement methods more than the heat flow meter method, although the results were not valid in none of them. Therefore, a fundamental requirement to use these methods in ship superstructures is that probes are not placed in zones affected by thermal bridges. For this purpose, the infrared thermography could be an effective technique to find the most adequate zone to place probes, similarly to this research.

Author Contributions

Funding

Conflicts of Interest

References

- International Maritime Organization. Maritime Facts and Figures. Available online: https://imo.libguides.com/c.php?g=659460&p=4655523 (accessed on 20 May 2020).

- Riola, J.M.; de Arboleya, M.G. Habitability and personal space in seakeeping behaviour. J. Marit. Res. 2006, 3, 41–54. [Google Scholar]

- International Maritime Organisation. Third International Maritime Organisation Greenhouse Gases Study; Technical Report; International Maritime Organisation: London, UK, 2014.

- Vergara, J.; McKesson, C.; Walczak, M. Sustainable energy for the marine sector. Energy Policy 2012, 49, 333–345. [Google Scholar] [CrossRef]

- Olivier, J.G.J.; Janssens-Maenhout, G.; Muntean, M.; Peters, J. Trends in Global CO2 Emissions; PBL Netherlands Environmental Assessment Agency: The Hague, The Netherlands, 2015. [Google Scholar]

- Armellini, A.; Daniotti, S.; Pinamonti, P.; Reini, M. Evaluation of gas turbines as alternative energy production systems for a large cruise ship to meet new maritime regulations. Appl. Energy 2018, 211, 306–317. [Google Scholar] [CrossRef] [Green Version]

- Anderson, K.; Bows, A. Executing a Scharnow turn: Reconciling shipping emissions with international commitments on climate change. Carbon Manag. 2012, 3, 615–628. [Google Scholar] [CrossRef]

- Adland, R.; Cariou, P.; Wolff, F.C. Does energy efficiency affect ship values in the second-hand market? Transp. Res. Part A Policy Pract. 2018, 111, 347–359. [Google Scholar] [CrossRef] [Green Version]

- Ancona, M.A.; Baldi, F.; Bianchi, M.; Branchini, L.; Melino, F.; Peretto, A.; Rosati, J. Efficiency improvement on a cruise ship: Load allocation optimization. Energy Convers. Manag. 2018, 164, 42–58. [Google Scholar] [CrossRef]

- Poulsen, R.T.; Sornn-Friese, H. Achieving energy efficient ship operations under third party management: How do ship management models influence energy efficiency? Res. Transp. Bus. Manag. 2015, 17, 41–52. [Google Scholar] [CrossRef] [Green Version]

- Yan, Y.; Zhang, H.; Long, Y.; Wang, Y.; Liang, Y.; Song, X.; Yu, J.J.Q. Multi-objective design optimization of combined cooling, heating and power system for cruise ship application. J. Clean. Prod. 2019, 233, 264–279. [Google Scholar] [CrossRef]

- Trivyza, N.L.; Rentizelas, A.; Theotokatos, G. Impact of carbon pricing on the cruise ship energy systems optimal configuration. Energy 2019, 175, 952–966. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Lian, Z.; Gong, Z.; Wang, Y.; Yu, G. Thermal comfort, vibration, and noise in Chinese ship cabin environment in winter time. Build. Environ. 2018, 135, 104–111. [Google Scholar] [CrossRef]

- Ng, A.K.; Ölçer, A.I. A new human comfort model onboard a vessel based on Sugeno type fuzzy inference system. Ocean Eng. 2012, 55, 116–124. [Google Scholar] [CrossRef]

- Palella, B.I.; Quaranta, F.; Riccio, G. On the management and prevention of heat stress for crews onboard ships. Ocean Eng. 2016, 112, 277–286. [Google Scholar] [CrossRef]

- Karmann, C.; Schiavon, S.; Arens, E. Percentage of commercial buildings showing at least 80% occupant satisfied with their thermal comfort. In Proceedings of the 10th Windsor Conference: Rethinking Comfort, Windsor, UK, 12–15 April 2018. [Google Scholar]

- Salata, F.; Golasi, I.; Petitti, D.; de Lieto Vollaro, E.; Coppi, M.; de Lieto Vollaro, A. Relating microclimate, human thermal comfort and health during heat waves: An analysis of heat island mitigation strategies through a case study in an urban outdoor environment. Sustain. Cities Soc. 2017, 30, 79–96. [Google Scholar] [CrossRef]

- Tham, K.W.; Willem, H.C. Room air temperature affects occupants’ physiology, perceptions and mental alertness. Build. Environ. 2010, 45, 40–44. [Google Scholar] [CrossRef]

- Jang, M.S.; Koh, C.D.; Moon, I.S. Review of thermal comfort design based on PMV/PPD in cabins of Korean maritime patrol vessels. Build. Environ. 2007, 42, 55–61. [Google Scholar] [CrossRef]

- Bienvenido-Huertas, D.; Oliveira, M.; Rubio-Bellido, C.; Mar, D. A comparative analysis of the international regulation of thermal properties in building envelope. Sustainability 2019, 11, 5574. [Google Scholar] [CrossRef] [Green Version]

- Taylor, T.; Counsell, J.; Gill, S. Energy efficiency is more than skin deep: Improving construction quality control in new-build housing using thermography. Energy Build. 2013, 66, 222–231. [Google Scholar] [CrossRef]

- Rotilio, M.; Cucchiella, F.; De Berardinis, P.; Stornelli, V. Thermal transmittance measurements of the historical masonries: Some case studies. Energies 2018, 11, 2987. [Google Scholar] [CrossRef] [Green Version]

- Lucchi, E. Thermal transmittance of historical stone masonries: A comparison among standard, calculated and measured data. Energy Build. 2017, 151, 393–405. [Google Scholar] [CrossRef]

- International Organization for Standardization. Part 1: Heat flow meter method. In ISO 9869-1: 2014—Thermal Insulation—Building Elements–In Situ Measurement of Thermal Resistance and Thermal Transmittance; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- McIntyre, D.A. In situ measurement of U-values. Build. Serv. Eng. Res. Technol. 1985, 6, 1–6. [Google Scholar] [CrossRef]

- Siviour, J.B.; Mcintyre, D.A. U-value meters in theory and practice. Build. Serv. Eng. Res. Technol. 1982, 3, 61–69. [Google Scholar] [CrossRef]

- Modera, M.P.; Sherman, M.H.; Sonderegger, R.C. Determining the U-Value of a Wall from Field Measurements of Heat Flux and Surface Temperatures. In Building Applications of Heat Flux Transducers; Bales, E., Bomberg, M., Courville, G.E., Eds.; ASTM International: West Conshohocken, PA, USA, 1985; pp. 203–219. ISBN 978-0-8031-4949-6. [Google Scholar]

- Bienvenido-Huertas, D.; Rubio-Bellido, C.; Pérez-Ordóñez, J.L.; Moyano, J. Optimizing the evaluation of thermal transmittance with the thermometric method using multilayer perceptrons. Energy Build. 2019, 198, 395–411. [Google Scholar] [CrossRef]

- Grubeša, I.N.; Teni, M.; Krstić, H.; Vračević, M. Influence of freeze/thaw cycles on mechanical and thermal properties of masonry wall and masonry wall materials. Energies 2019, 12, 1464. [Google Scholar] [CrossRef] [Green Version]

- Nardi, I.; Paoletti, D.; Ambrosini, D.; De Rubeis, T.; Sfarra, S. U-value assessment by infrared thermography: A comparison of different calculation methods in a Guarded Hot Box. Energy Build. 2016, 122, 211–221. [Google Scholar] [CrossRef]

- Ficco, G.; Iannetta, F.; Ianniello, E.; D’Ambrosio Alfano, F.R.; Dell’Isola, M. U-value in situ measurement for energy diagnosis of existing buildings. Energy Build. 2015, 104, 108–121. [Google Scholar] [CrossRef]

- Bienvenido-Huertas, D.; Moyano, J.; Marín, D.; Fresco-Contreras, R. Review of in situ methods for assessing the thermal transmittance of walls. Renew. Sustain. Energy Rev. 2019, 102, 356–371. [Google Scholar] [CrossRef]

- Teni, M.; Krstić, H.; Kosiński, P. Review and comparison of current experimental approaches for in-situ measurements of building walls thermal transmittance. Energy Build. 2019, 203, 109417. [Google Scholar] [CrossRef]

- Trethowen, H. Measurement errors with surface-mounted heat flux sensors. Build. Environ. 1986, 21, 41–56. [Google Scholar] [CrossRef]

- Desogus, G.; Mura, S.; Ricciu, R. Comparing different approaches to in situ measurement of building components thermal resistance. Energy Build. 2011, 43, 2613–2620. [Google Scholar] [CrossRef]

- Cesaratto, P.G.; De Carli, M.; Marinetti, S. Effect of different parameters on the in situ thermal conductance evaluation. Energy Build. 2011, 43, 1792–1801. [Google Scholar] [CrossRef]

- Cucumo, M.; De Rosa, A.; Ferraro, V.; Kaliakatsos, D.; Marinelli, V. A method for the experimental evaluation in situ of the wall conductance. Energy Build. 2006, 38, 238–244. [Google Scholar] [CrossRef]

- Peng, C.; Wu, Z. In situ measuring and evaluating the thermal resistance of building construction. Energy Build. 2008, 40, 2076–2082. [Google Scholar] [CrossRef]

- Cucumo, M.; Ferraro, V.; Kaliakatsos, D.; Mele, M. On the distortion of thermal flux and of surface temperature induced by heat flux sensors positioned on the inner surface of buildings. Energy Build. 2018, 158, 677–683. [Google Scholar] [CrossRef]

- Meng, X.; Yan, B.; Gao, Y.; Wang, J.; Zhang, W.; Long, E. Factors affecting the in situ measurement accuracy of the wall heat transfer coefficient using the heat flow meter method. Energy Build. 2015, 86, 754–765. [Google Scholar] [CrossRef]

- Lakatos, Á. Comprehensive thermal transmittance investigations carried out on opaque aerogel insulation blanket. Mater. Struct. 2016, 50, 50. [Google Scholar] [CrossRef]

- Albatici, R.; Tonelli, A.M. Infrared thermovision technique for the assessment of thermal transmittance value of opaque building elements on site. Energy Build. 2010, 42, 2177–2183. [Google Scholar] [CrossRef]

- Cesaratto, P.G.; De Carli, M. A measuring campaign of thermal conductance in situ and possible impacts on net energy demand in buildings. Energy Build. 2013, 59, 29–36. [Google Scholar] [CrossRef]

- Litti, G.; Khoshdel, S.; Audenaert, A.; Braet, J. Hygrothermal performance evaluation of traditional brick masonry in historic buildings. Energy Build. 2015, 105, 393–411. [Google Scholar] [CrossRef]

- Björk, F.; Enochsson, T. Properties of thermal insulation materials during extreme environment changes. Constr. Build. Mater. 2009, 23, 2189–2195. [Google Scholar] [CrossRef]

- Ahmad, A.; Maslehuddin, M.; Al-Hadhrami, L.M. In situ measurement of thermal transmittance and thermal resistance of hollow reinforced precast concrete walls. Energy Build. 2014, 84, 132–141. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 6946:2007—Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation Method; International Organization for Standardization: Geneva, Switzerland, 2007. [Google Scholar]

- Szodrai, F.; Lakatos, A. Effect of the air motion on the heat transport behaviour of wall structures. Int. Rev. Appl. Sci. Eng. 2017, 8, 67–73. [Google Scholar] [CrossRef] [Green Version]

- Alamdari, F.; Hammond, G.P. Improved data correlations for buoyancy-driven convection in rooms. Build. Serv. Eng. Res. Technol. 1983, 4, 106–112. [Google Scholar] [CrossRef]

- Churchill, S.W.; Chu, H.H.S. Correlating equations for laminar and turbulent free convection from a horizontal cylinder. Int. J. Heat Mass Transf. 1975, 18, 1049–1053. [Google Scholar] [CrossRef]

- Holman, J.P. Heat Transfer, 6th ed.; McGraw-Hill, Inc.: New York, NY, USA, 1986; ISBN 0-07-029620-0. [Google Scholar]

- Fohanno, S.; Polidori, G. Modelling of natural convective heat transfer at an internal surface. Energy Build. 2006, 38, 548–553. [Google Scholar] [CrossRef]

- Earle, R.L.; Earle, M.D. Unit Operations in Food Processing; Pergamon Press: Oxford, UK, 1983. [Google Scholar]

- Giesecke, F.E. Radiant heating and cooling. ASHVE J. Heat. Pipe. Air Cond. 1940, 12, 484–485. [Google Scholar]

- Khalifa, A.J.N.; Marshall, R.H. Validation of heat transfer coefficients on interior building surfaces using a real-sized indoor test cell. Int. J. Heat Mass Transf. 1990, 33, 2219–2236. [Google Scholar] [CrossRef]

- Wilkes, G.B.; Peterson, C.M.F. Radiation and convection from surfaces in various positions. Trans. ASHVE 1938, 44, 513–520. [Google Scholar]

- Churchill, S.W.; Usagi, R. A general expression for the correlation of rates of transfer and other phenomena. AIChE J. 1972, 18, 1121–1128. [Google Scholar] [CrossRef]

- ASTM International. ASTM E1933-14, Standard Practice for Measuring and Compensating for Emissivity Using Infrared Imaging Radiometers; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Maroy, K.; Carbonez, K.; Steeman, M.; Van Den Bossche, N. Assessing the thermal performance of insulating glass units with infrared thermography: Potential and limitations. Energy Build. 2017, 138, 175–192. [Google Scholar] [CrossRef]

- Bienvenido-Huertas, D.; Rodríguez-Álvaro, R.; Moyano, J.J.; Rico, F.; Marín, D. Determining the U-Value of Façades Using the Thermometric Method: Potentials and Limitations. Energies 2018, 11, 360. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez-Jiménez, C.E.; Moyano, J.; Carretero-Ayuso, M.J.; Guillén-Lupiánez, M.I. Methodological proposal for on-site watertightness testing with wind pressure on facade windows. J. Perform. Constr. Facil. 2017, 32. [Google Scholar] [CrossRef]

- Bienvenido-Huertas, D.; Bermúdez, J.; Moyano, J.J.; Marín, D. Influence of ICHTC correlations on the thermal characterization of façades using the quantitative internal infrared thermography method. Build. Environ. 2019, 149, 512–525. [Google Scholar] [CrossRef]

| Equipment | Variable | Measurement Range | Resolution | Accuracy |

|---|---|---|---|---|

| Data logger ALMEMO 2590-4AS | ||||

| with thermocouples T 190-3 | Temperature | −10–105 °C | 0.1 K | ±0.05 K ±0.05% |

| with thermocouples T 190-10 | Temperature | −200–205 °C | 0.1 K | ±0.05 K ±0.05% |

| with plate FQA018C | Heat flux | ±2000 W/m2 | 5% | |

| Data logger TESTO 435-2 | ||||

| with thermocouples 0614 1635 | Temperature | −20–70 °C | 0.1 °C | ±0.1 °C |

| with thermocouples 0632 9735 | Temperature | −20–70 °C | 0.1 °C | ±0.3 °C |

| Infrared camera FLIR E60bx | FOV | 25° × 19° | ||

| Spectral range | 7.5–13 µm | |||

| Thermal sensitivity | <0.05–30 °C |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bienvenido-Huertas, D.; Moyano, J.; Rodríguez-Jiménez, C.E.; Muñoz-Rubio, A.; Bermúdez Rodríguez, F.J. Quality Control of the Thermal Properties of Superstructures in Accommodation Spaces in Naval Constructions. Sustainability 2020, 12, 4194. https://doi.org/10.3390/su12104194

Bienvenido-Huertas D, Moyano J, Rodríguez-Jiménez CE, Muñoz-Rubio A, Bermúdez Rodríguez FJ. Quality Control of the Thermal Properties of Superstructures in Accommodation Spaces in Naval Constructions. Sustainability. 2020; 12(10):4194. https://doi.org/10.3390/su12104194

Chicago/Turabian StyleBienvenido-Huertas, David, Juan Moyano, Carlos E. Rodríguez-Jiménez, Aurelio Muñoz-Rubio, and Francisco Javier Bermúdez Rodríguez. 2020. "Quality Control of the Thermal Properties of Superstructures in Accommodation Spaces in Naval Constructions" Sustainability 12, no. 10: 4194. https://doi.org/10.3390/su12104194

APA StyleBienvenido-Huertas, D., Moyano, J., Rodríguez-Jiménez, C. E., Muñoz-Rubio, A., & Bermúdez Rodríguez, F. J. (2020). Quality Control of the Thermal Properties of Superstructures in Accommodation Spaces in Naval Constructions. Sustainability, 12(10), 4194. https://doi.org/10.3390/su12104194