A Three Methods Proactive Improvement Model for Buildings Construction Processes

Abstract

1. Introduction

- To create an innovative model that helps stakeholders reduce the environmental impacts of the built environment preceding to the construction phase;

- To help decrease the overall environmental impact of the construction sector.

- To enhance the knowledge of the green initiative and applications in the construction industry.

2. Research Methodology

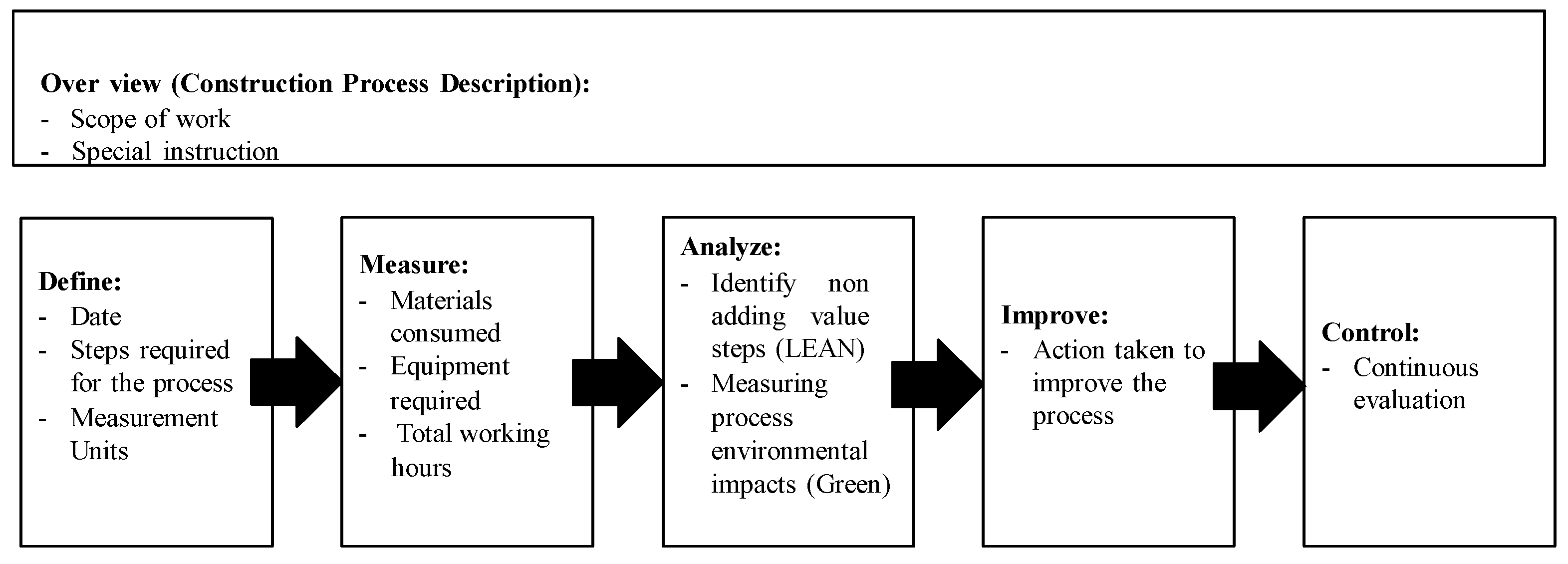

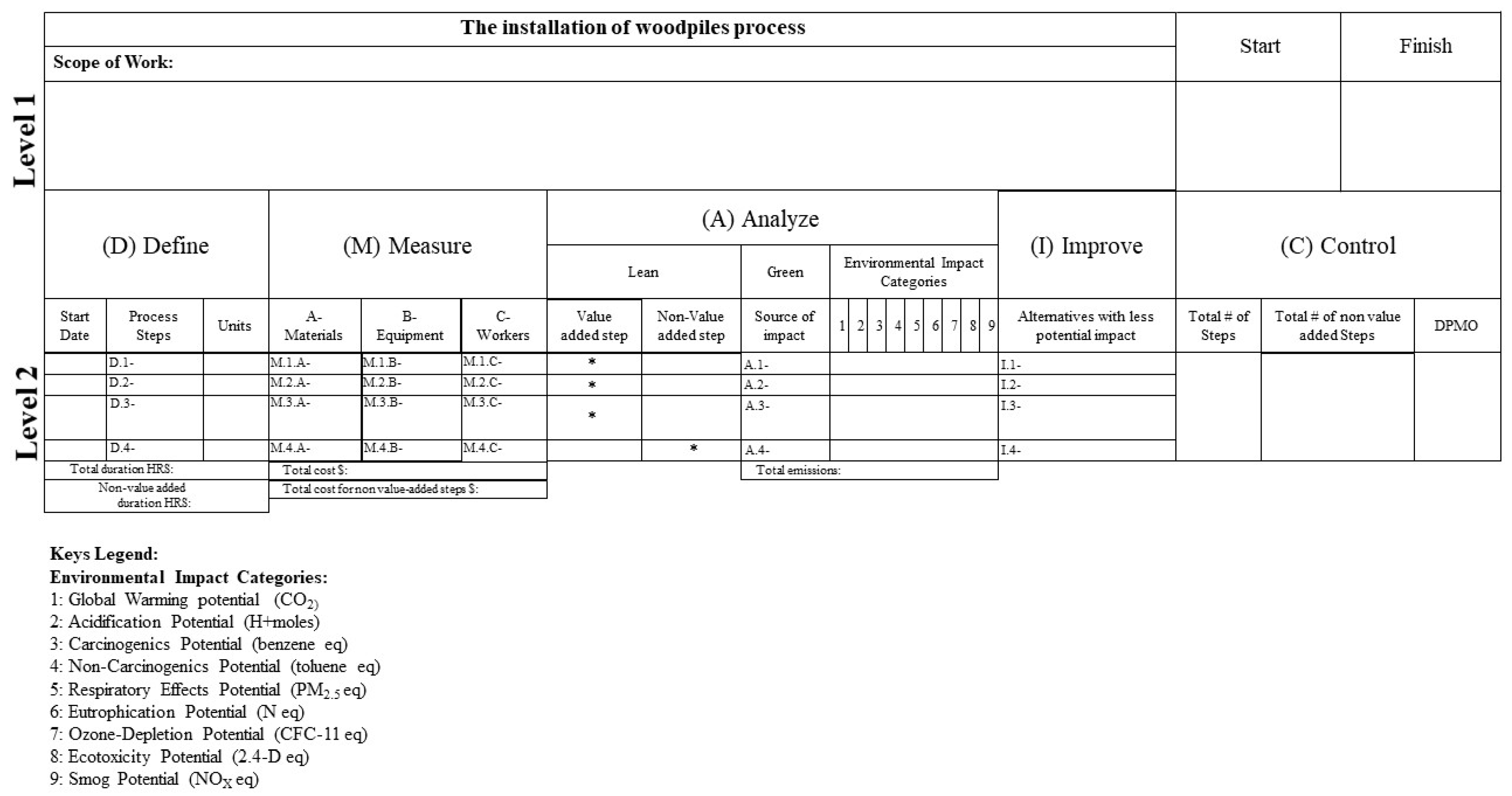

2.1. Lean Green Six-Sigma Model (LG6)

2.1.1. Define

2.1.2. Measure

2.1.3. Analyze

- The use of the Lean concept, to guide the contractor to identify the steps at his construction project, which use resources without adding any value so that they can be removed or modified;

- The use of the LG6 model analyzes the environmental impact generated at each task performed, as each step we do produces CO2 emissions. To minimize this emission, LG6 features limited inventory containing most of the common materials that are used in construction, such as concrete, steel, and blocks. Along with their environmental impact. Becoming an excellent tool for the user. The absolute amount of environmental impact for one single unit can be calculated using this inventory; for example, the quantity entered for steel to be analyzed is impact per 1 kg. All data are generated using SimaPro7 software. This software implements the concept of LCA, which systematically assesses and manages the environmental impact of a product, process, or service through its entire life cycle.

2.1.4. Improve

2.1.5. Control

2.2. Case Study

3. Research Findings and Results

3.1. Define (D)

3.2. Measure (M)

3.3. Analyze (A)

3.4. Improve (I)

3.5. Control (C)

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- U.S. Environmental Protection Agency. Advancing Sustainable Materials Management: 2017 Fact Sheet; U.S. Environmental Protection Agency: Washington, DC, USA, 2019.

- Fuertes, A.; Casals, M.; Gangolells, M.; Forcada, N.; Macarulla, M.; Roca, X. An environmental impact causal model for improving the environmental performance of construction processes. J. Clean. Prod. 2013, 52, 425–437. [Google Scholar] [CrossRef]

- Albliwi, S.A.; Antony, J.; Arshed, N.; Ghadge, A. Implementation of lean six sigma in Saudi Arabian organisations. Int. J. Qual. Reliab. Manag. 2017, 34, 508–529. [Google Scholar] [CrossRef]

- US Green Building Council. LEED (Leadership in Energy and Environmental Design) Green building Rating System. Available online: http://www.usgbc.org/leed/leed_main.asp (accessed on 18 June 2017).

- Banawi, A.; Bilec, M.M. A framework to improve construction processes: Integrating Lean, Green and Six Sigma. Int. J. Constr. Manag. 2014, 14, 45–55. [Google Scholar] [CrossRef]

- Banawi, A.-A.; Bilec, M. Applying Lean, Green, and Six-Sigma Framework to Improve Exterior Construction Process in Saudi Arabia. J. Constr. Eng. Proj. Manag. 2014, 4, 12–22. [Google Scholar] [CrossRef]

- Hussain, K.; He, Z.; Ahmad, N.; Iqbal, M. Green, lean, six sigma barriers at a glance: A case from the construction sector of Pakistan. Build. Environ. 2019, 161, 106225. [Google Scholar] [CrossRef]

- Howell, G.A. What is lean construction-1999. Proc. IGLC 1999, 7, 1. [Google Scholar]

- Osmani, M.; Glass, J.; Price, A.D. Architects’ perspectives on construction waste reduction by design. Waste Manag. 2008, 28, 1147–1158. [Google Scholar] [CrossRef]

- Ohno, T. Toyota Production System: Beyond Large-Scale Production; CRC Press: Boca Raton, FL, USA, 1988. [Google Scholar]

- Pasqualini, F.; Zawislak, P.A. Value stream mapping in construction: A case study in a Brazilian construction company. In Proceedings of the 13th International Group for Lean Construction Conference: Proceedings, Sydney, Australia, 19–21 July 2005; p. 117. [Google Scholar]

- Lapinski, A.R.; Horman, M.J.; Riley, D.R. Lean processes for sustainable project delivery. J. Constr. Eng. Manag. 2006, 132, 1083–1091. [Google Scholar] [CrossRef]

- Salem, O.; Solomon, J.; Genaidy, A.; Minkarah, I. Lean construction: From theory to implementation. J. Manag. Eng. 2006, 22, 168–175. [Google Scholar] [CrossRef]

- Klotz, L.E.; Horman, M.; Bodenschatz, M. A lean modeling protocol for evaluating green project delivery. Lean Constr. J. 2007, 3. [Google Scholar]

- Yu, H.; Tweed, T.; Al-Hussein, M.; Nasseri, R. Development of lean model for house construction using value stream mapping. J. Constr. Eng. Manag. 2009, 135, 782–790. [Google Scholar] [CrossRef]

- Van den Bos, A.; Kemper, B.; de Waal, V. A study on how to improve the throughput time of Lean Six Sigma projects in a construction company. Int. J. Lean Six Sigma 2014, 5, 212–226. [Google Scholar] [CrossRef]

- Ko, C.-H.; Kuo, J.-D. Making formwork construction lean. J. Civ. Eng. Manag. 2015, 21, 444–458. [Google Scholar] [CrossRef]

- Xu, G.; Li, M.; Chen, C.-H.; Wei, Y. Cloud asset-enabled integrated IoT platform for lean prefabricated construction. Autom. Constr. 2018, 93, 123–134. [Google Scholar] [CrossRef]

- Garrett, D.F.; Lee, J. Lean construction submittal process—A case study. Qual. Eng. 2014, 23, 84–93. [Google Scholar] [CrossRef]

- Rosenbaum, S.; Toledo, M.; González, V. Improving environmental and production performance in construction projects using value-stream mapping: Case study. J. Constr. Eng. Manag. 2014, 140, 04013045. [Google Scholar] [CrossRef]

- Hill, R.C.; Bowen, P.A. Sustainable construction: Principles and a framework for attainment. Constr. Manag. Econ. 1997, 15, 223–239. [Google Scholar] [CrossRef]

- Guggemos, A.A.; Horvath, A. Decision support tool for environmental analysis of commercial building structures. In Proceedings of the Construction Research Congress 2005: Broadening Perspectives, San Diego, CA, USA, 5–7 April 2005; pp. 1–11. [Google Scholar]

- Ortiz, O.; Castells, F.; Sonnemann, G. Sustainability in the construction industry: A review of recent developments based on LCA. Constr. Build. Mater. 2009, 23, 28–39. [Google Scholar] [CrossRef]

- Rajagopalan, N.; Bilec, M.M.; Landis, A.E. Residential life cycle assessment modeling: Comparative case study of insulating concrete forms and traditional building materials. J. Green Build. 2010, 5, 95–106. [Google Scholar] [CrossRef]

- Sabnis, A.; Pranesh, M. Sustainability evaluation of buildings in pre-use phase using figure of merit as a new tool. Energy Build. 2017, 145, 121–129. [Google Scholar] [CrossRef]

- Al-Nuaimi, S.; Banawi, A.-A.A.; Al-Ghamdi, S.G. Environmental and Economic Life Cycle Analysis of Primary Construction Materials Sourcing under Geopolitical Uncertainties: A Case Study of Qatar. Sustainability 2019, 11, 6000. [Google Scholar] [CrossRef]

- Gardner, H.; Garcia, J.; Hasik, V.; Olinzock, M.; Banawi, A.; Bilec, M.M. Materials life cycle assessment of a living building. Procedia Cirp 2019, 80, 458–463. [Google Scholar] [CrossRef]

- Sabbagh, M.J.; Mansour, O.E.; Banawi, A.A. Grease the Green Wheels: A Framework for Expediting the Green Building Movement in the Arab World. Sustainability 2019, 11, 5545. [Google Scholar] [CrossRef]

- Bilec, M.; Ries, R.; Matthews, H.S.; Sharrard, A.L. Example of a hybrid life-cycle assessment of construction processes. J. Infrastruct. Syst. 2006, 12, 207–215. [Google Scholar] [CrossRef]

- Bilec, M.M.; Ries, R.J.; Matthews, H.S. Life-cycle assessment modeling of construction processes for buildings. J. Infrastruct. Syst. 2009, 16, 199–205. [Google Scholar] [CrossRef]

- Liu, C.; Ahn, C.R.; An, X.; Lee, S. Life-cycle assessment of concrete dam construction: Comparison of environmental impact of rock-filled and conventional concrete. J. Constr. Eng. Manag. 2013, 139, A4013009. [Google Scholar] [CrossRef]

- Sharrard, A.L.; Matthews, H.S.; Ries, R.J. Estimating construction project environmental effects using an input-output-based hybrid life-cycle assessment model. J. Infrastruct. Syst. 2008, 14, 327–336. [Google Scholar] [CrossRef]

- Li, X.; Zhu, Y.; Zhang, Z. An LCA-based environmental impact assessment model for construction processes. Build. Environ. 2010, 45, 766–775. [Google Scholar] [CrossRef]

- Setijono, D.; Al-Aomar, R. A lean construction framework with Six Sigma rating. Int. J. Lean Six Sigma 2012, 3, 299–314. [Google Scholar]

- Tchidi, M.F.; He, Z.; Li, Y.B. Process and quality improvement using Six Sigma in construction industry. J. Civ. Eng. Manag. 2012, 18, 158–172. [Google Scholar] [CrossRef]

- Lee, K.-L.; Su, Y. Applying six sigma to quality improvement in construction. J. Manag. Eng. 2012, 29, 464–470. [Google Scholar] [CrossRef]

- Taner, M.T. Critical success factors for six sigma implementation in large-scale Turkish construction companies. Int. Rev. Manag. Mark. 2013, 3, 212–225. [Google Scholar]

- Siddiqui, S.Q.; Ullah, F.; Thaheem, M.J.; Gabriel, H.F. Six Sigma in construction: A review of critical success factors. Int. J. Lean Six Sigma 2016, 7, 171–186. [Google Scholar] [CrossRef]

- Karakhan, A. Six sigma & construction safety: Using the DMAIC cycle to improve incident investigations. Prof. Saf. 2017, 62, 38. [Google Scholar]

- Negi, P.S.; Mandaliya, A.; Mahida, A.; Patel, A.; Patyal, V.S. Six Sigma in construction industry: A review. Int. J. Product. Qual. Manag. 2017, 22, 451–465. [Google Scholar] [CrossRef]

- Fernández-Solís, J.L.; Gadhok, N. Comparative Analysis of Lean and Six Sigma in Building Construction: Benefits, Obstacles and Opportunities; Texas A&M University Libraries: Killeen, TX, USA, 2018. [Google Scholar]

- Han, S.H.; Chae, M.J.; Im, K.S.; Ryu, H.D. Six sigma-based approach to improve performance in construction operations. J. Manag. Eng. 2008, 24, 21–31. [Google Scholar] [CrossRef]

- Pheng, L.S.; Hui, M.S. Implementing and applying Six Sigma in construction. J. Constr. Eng. Manag. 2004, 130, 482–489. [Google Scholar] [CrossRef]

- Stewart, R.A.; Spencer, C.A. Six-sigma as a strategy for process improvement on construction projects: A case study. Constr. Manag. Econ. 2006, 24, 339–348. [Google Scholar] [CrossRef]

- Hallam, C.; Contreras, C. Integrating lean and green management. Manag. Decis. 2016, 54, 2157–2187. [Google Scholar] [CrossRef]

- Cherrafi, A.; Elfezazi, S.; Govindan, K.; Garza-Reyes, J.A.; Benhida, K.; Mokhlis, A. A framework for the integration of Green and Lean Six Sigma for superior sustainability performance. Int. J. Prod. Res. 2017, 55, 4481–4515. [Google Scholar] [CrossRef]

- Beary, T.M.; Abdelhamid, T.S. Production planning process in residential construction using lean construction and six sigma principles. In Proceedings of the Construction Research Congress 2005: Broadening Perspectives, San Diego, CA, USA, 5–7 April 2005; pp. 1–10. [Google Scholar]

- Clough, R.H.; Sears, G.A.; Sears, S.K.; Segner, R.O.; Rounds, J.L. Construction Contracting: A practical Guide to Company Management; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Linoff, G.S. Data Analysis Using SQL and Excel; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Yassine, T.; Bacha, M.B.S.; Fayek, F.; Hamzeh, F. Implementing takt-time planning in construction to improve work flow. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction, Oslo, Norway, 25–27 June 2014; pp. 23–27. [Google Scholar]

- Baldwin, A.; Bordoli, D. Handbook for Construction Planning and Scheduling; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Zhang, S.; Boukamp, F.; Teizer, J. Ontology-based semantic modeling of construction safety knowledge: Towards automated safety planning for job hazard analysis (JHA). Autom. Constr. 2015, 52, 29–41. [Google Scholar] [CrossRef]

- Kozhevnikov, D. Building a system for efficient use of resources in construction. MATEC Web Conf. 2018, 193, 05014. [Google Scholar] [CrossRef][Green Version]

- Raitu, C.; Anderson, B.B.; Sfakianaki, E. Resource-efficient construction: Rethinking construction towards sustainability. World J. Sci. Technol. Sustain. Dev. 2015, 12, 233–242. [Google Scholar]

- Shrestha, P.P.; Pradhananga, N.; Mani, N. Correlating the quantity and bid cost of unit price items for public road projects. Ksce J. Civ. Eng. 2014, 18, 1590–1598. [Google Scholar] [CrossRef]

- Ni, P.; Mangalathu, S.; Mei, G.; Zhao, Y. Permeable piles: An alternative to improve the performance of driven piles. Comput. Geotech. 2017, 84, 78–87. [Google Scholar] [CrossRef]

| Define (D): | |||

|---|---|---|---|

| Date Start | Process Steps | Process Description | Units |

| 06/01 | D.1 | Delivering the woodpiles and the piles points to the job site. | 50 Mile |

| 06/01 | D.2 | Driving the equipment to the job site. | 30 Mile |

| 06/02 | D.3 | Setting up the equipment. | 4 Hrs. |

| 06/02 | D.4 | Taking down the equipment. | 4 Hrs. |

| 06/02,03 | D.5 | Moving out the equipment. | 4 Hrs. |

| 06/04 | D.6 | Driving the piles | 56 Hrs. |

| 06/12 | D.7 | Cutting to length | 16 Hrs. |

| 06/14 | D.8 | Cleaning up the site | 4 Hrs. |

| Total Process Duration in Hours | 85 | ||

| Non-Value-added Total Duration in Hours | 28 | ||

| Measure (M): | ||||

|---|---|---|---|---|

| Process Steps | A- Materials | Quantities | Unit Cost $ | Total Cost $ |

| M.1.A | 1. 168 wooden piles (40 lin. ft.) | 6720 ft. | 11 | 72,912 |

| 2. Pile points. | 168 pieces | 65 | 10,884 | |

| M.2.A | NA | |||

| M.3.A | NA | |||

| M.4.A | NA | |||

| M.5.A | NA | |||

| M.6.A | NA | |||

| M.7.A | NA | |||

| M.8.A | NA | |||

| Total Materials Cost | 83,795 | |||

| Total Materials Cost for Non-Value-Added Steps | 0 | |||

| B- Equipment | Fuel Usage in Gal. | Cost of Equipment Usage | ||

| Unit Cost $ | Total Cost $ | |||

| M.1.B | 1. NA | |||

| 2. NA | ||||

| 3. A truck for materials transportation. | Include with materials cost | |||

| M.2.B | 1. A truck for equipment transportation. | Include with equipment cost | ||

| M.3.B | NA | |||

| M.4.B | NA | |||

| M.5.B | NA | |||

| M.6.B | 1. Crane 800 HP, Diesel | 2688 | 82.4 | 4614.4 |

| 2. Leads for hummer | NA | 14.63 | 819.28 | |

| 3. Pile hummer 600 HP., Diesel | 2016 | 10.8 | 604.8 | |

| 4. Air compressor 3.0 HP., Gasoline | 6.72 | 14.65 | 820.4 | |

| M.7.B | 1. Concrete Saw, Gasoline 5.6 HP. | 5.4 | 9.35 | 523.6 |

| M.8.B | 1. Construction cleaning tools (brushes, brooms, etc.) | NA | NA | NA |

| Total Equipment Cost | 7382.5 | |||

| Total Equipment Cost for Non-Value-Added Steps | 523.6 | |||

| C- Workers | Working Hours | Unit Cost $/Hr. | Total Cost $ | |

| M.1.C | NA | |||

| M.2.C | NA | |||

| M.3.C | 1. (2) General laborers | 4 | 15.56 | 124.48 |

| M.4.C | 1. (2) General laborers | 4 | 15.56 | 124.48 |

| M.5.C | 1. (2) General laborers | 4 | 15.56 | 124.48 |

| M.6.C | 1. (1) Crane operator | 56 | 21.67 | 1386 |

| 2. (3) General laborers | 56 | 15.56 | 2987.52 | |

| M.7.C | 1. (2) General laborers | 7 | 15.56 | 497.92 |

| M.8.C | 1. (1) General laborers | 1 | 15.56 | 15.56 |

| Total Workers Cost | 5370.2 | |||

| Total Workers Cost for Non-Value Steps | 871.4 | |||

| Analyze (A): | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Lean | Green | ||||||||

| Process Steps | Value-Added Steps | Non-Value-Added Steps | Source of Potential Waste/Environmental Impact to be Analyzed by LCA | Inventories | |||||

| A.1 | A.1.1 Resources usage/wood | 6720 ft. | |||||||

| A.1.2 Resources usage/steel | 2016 kg | ||||||||

| A.1.3 Transportation/Diesel | 50 Mile | ||||||||

| A.2 | A.2 Transportation/Diesel | 30 Mile | |||||||

| A.3 | NA | ||||||||

| A.4 | NA | ||||||||

| A.5 | NA | ||||||||

| A.6 | A.6.1 Equipment usage/Diesel | 2688 Gal | |||||||

| NA | NA | ||||||||

| A.6.3 Equipment usage/Diesel | 2016 Gal | ||||||||

| A.6.4 Equipment usage/Diesel | 6.72 Gal | ||||||||

| A.7 | A.7 Equipment usage/Diesel | 5.4 Gal | |||||||

| A.8 | NA | ||||||||

| Green—Life Cycle Environmental Impact Categories | |||||||||

| Item | Global Warming (CO2 eq.) kg | Acidification Potential (H+moleseq.) kg | Carcinogenics Potential (Benzene eq.) kg | Non-Carcinogenics Potential (Toluene eq.) kg | Respiratory Effects Potential (PM2.5 eq.) kg | Eutrophication Potential (N eq.) kg | Ozone Depletion Potential (CFC-11eq.) kg | Eco Toxicity Potential (2.4-D eq.) kg | Smog Potential (NOX eq.) kg |

| A.1.1 | −1,065,098 | 93,808.84 | 98.9 | 97,0641.3 | 315 | 39.6 | 2.81 × 10−6 | 20,099.9 | 1279 |

| A.1.2 | 2116 | 1044 | 62 | 110,759 | 4 | 0.6 | 7.0825 × 10−6 | 249 | 10 |

| A.1.3 | 65 | 23 | 0.012 | 195 | 0.05 | 0.04 | 9.6911 × 10−6 | 9 | 0.5 |

| A.2 | 39 | 14 | 0.007 | 117 | 0.03 | 0.024 | 5.8146 × 10−6 | 5.4 | 0.3 |

| A.3 | NA | ||||||||

| A.4 | NA | ||||||||

| A.5 | NA | ||||||||

| A.6.1 | 4683 | 3227 | 11 | 239,336 | 5 | 2 | 1.3081 × 10−6 | 6646 | 32 |

| A.6.2 | NA | ||||||||

| A.6.3 | 3512 | 2420 | 9 | 179,502 | 4 | 1.7 | 9.8109 × 10−7 | 4985 | 24 |

| A.6.4 | 13 | 8.8 | 0.03 | 651 | 0.01 | 0.006 | 3.5594 × 10−9 | 18 | 0.09 |

| A.7 | 10 | 7 | 0.02 | 520 | 0.01 | 0.004 | 2.8444 × 10−9 | 14 | 0.07 |

| A.8 | NA | ||||||||

| TotalEmissions | (1,054,660.2) | 100,552.8 | 181.2 | 1,501,721.5 | 327.6 | 44 | 2.7696 × 10−5 | 32,027.3 | 1345.7 |

| Improve (I): | |

|---|---|

| Process Steps | Optional Alternatives (For Better Process Performance) |

| I.1.1 | |

| I.1.2 | |

| I.1.3 | Purchase materials a close providers (Less travel distance by) |

| I.2 | Purchase materials a close providers (Less travel distance by) |

| I.3 | |

| I.4 | |

| I.5 | |

| I.6 | |

| I.7 | Considered wood piles with same length |

| I.8 | |

| Control (C): | ||

|---|---|---|

| Total Number of Steps in The Process | Total Number of the Value-Added Steps in The Process | Defective Per Million Opportunities (DPMO) |

| 8 | 4 | 500,000 |

| Outputs for Installation OF Woodpiles Process | ||||

|---|---|---|---|---|

| Division | Foundation | Process | Installation of Woodpiles | |

| Total number of steps in the process | 8 | |||

| Total number of non-value added steps in the process | 4 | |||

| Defective per million opportunities | 500,000 | |||

| Sigma level out of 6 | 1.5 | |||

| Total process time Hrs. | 85 | |||

| Time that might be saved in the process Hrs./Percentage | 28/33% | |||

| Total process cost $ | 96,547.76 | |||

| Total Savings cost $/Percentage | 1394.96/1% | |||

| Total savings in materials cost $ | 0 | |||

| Total savings in equipment cost $ | 523.6 | |||

| Total savings in workers cost $ | 871.36 | |||

| Total Environmental Impact | ||||

| Impact Category | Unit | Original Process Value-added Steps + Non-value Steps | Modified Process Value-added Steps Only | Percentage Saving |

| Global Warming | (CO2 eq.) | (1,054,660.2) | (1,054,670.3) | 1 |

| Acidification | (H+moles eq.) | 100,552.8 | 100,545.8 | 0.99 |

| Carcinogenics | (Benzene eq.) | 181.2 | 181.1 | 0.99 |

| Non-carcinogenics | (Toluene eq.) | 1,501,721.5 | 1,501,201.1 | 0.99 |

| Respiratory effects | (PM2.5 eq.) | 327.6 | 327.5 | 0.99 |

| Eutrophication | (N eq.) | 44.05 | 44.04 | 0.99 |

| Ozone depletion | (CFC-11 eq.) | 2.7696 × 10−5 | 2.7693 × 10−5 | 0.99 |

| Eco toxicity | (2.4-D eq.) | 32,027.3 | 32,012.8 | 0.99 |

| Smog | (NOX eq.) | 1345.78 | 1345.71 | 0.99 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banawi, A.-A.; Besné, A.; Fonseca, D.; Ferrandiz, J. A Three Methods Proactive Improvement Model for Buildings Construction Processes. Sustainability 2020, 12, 4335. https://doi.org/10.3390/su12104335

Banawi A-A, Besné A, Fonseca D, Ferrandiz J. A Three Methods Proactive Improvement Model for Buildings Construction Processes. Sustainability. 2020; 12(10):4335. https://doi.org/10.3390/su12104335

Chicago/Turabian StyleBanawi, Abdul-Aziz, Alia Besné, David Fonseca, and Jose Ferrandiz. 2020. "A Three Methods Proactive Improvement Model for Buildings Construction Processes" Sustainability 12, no. 10: 4335. https://doi.org/10.3390/su12104335

APA StyleBanawi, A.-A., Besné, A., Fonseca, D., & Ferrandiz, J. (2020). A Three Methods Proactive Improvement Model for Buildings Construction Processes. Sustainability, 12(10), 4335. https://doi.org/10.3390/su12104335