Energy, Exergy, and Sustainability Analyses of the Agricultural Sector in Bangladesh

Abstract

:1. Introduction

2. Methodology and Data Sources

2.1. Basic Relations for Exergy Analysis

2.1.1. Chemical Exergy

2.1.2. Energy and Exergy Efficiencies

2.2. Sustainability Index and Depletion Number

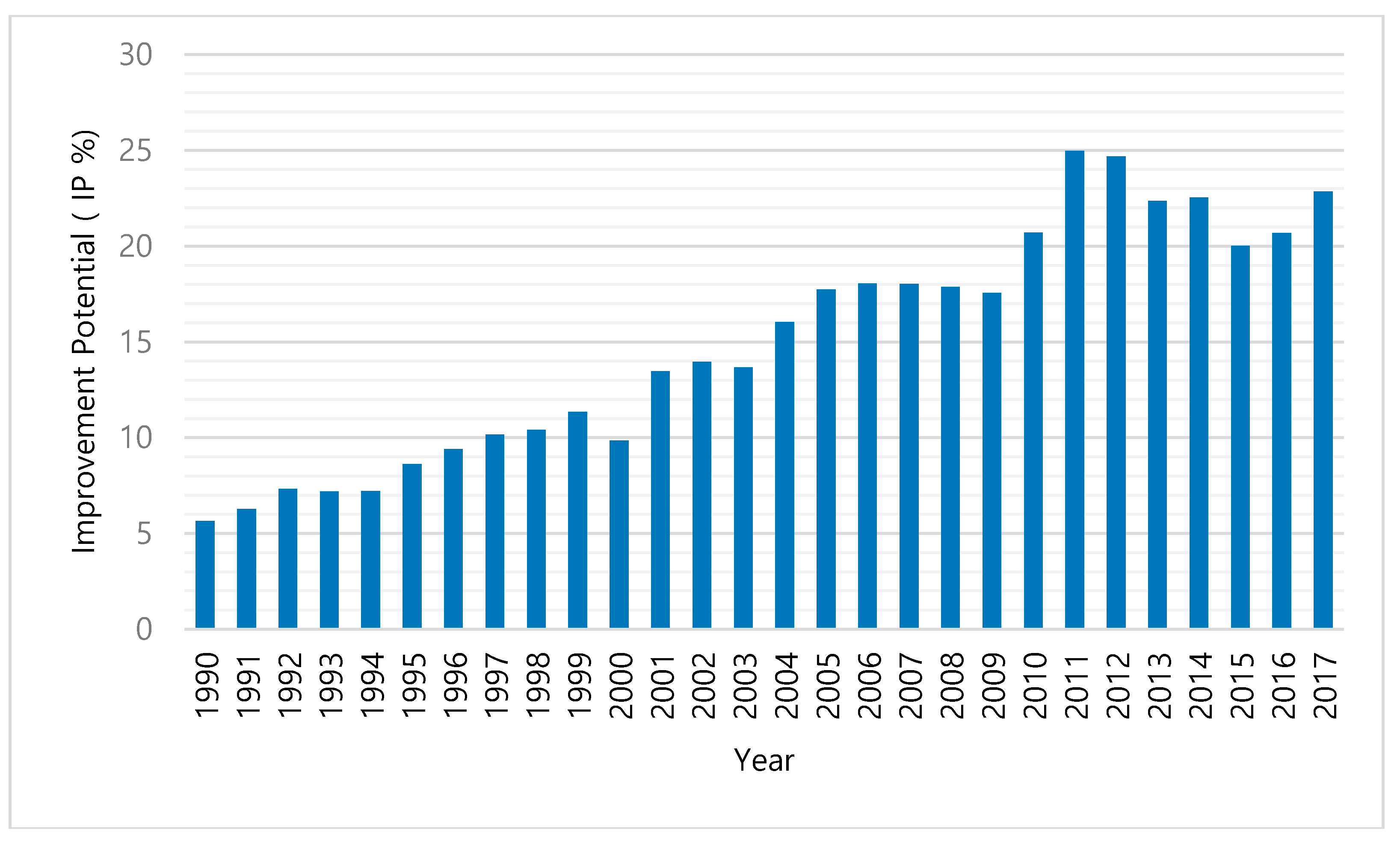

2.3. Improvement Potential

2.4. Data Sources

2.5. Methodology

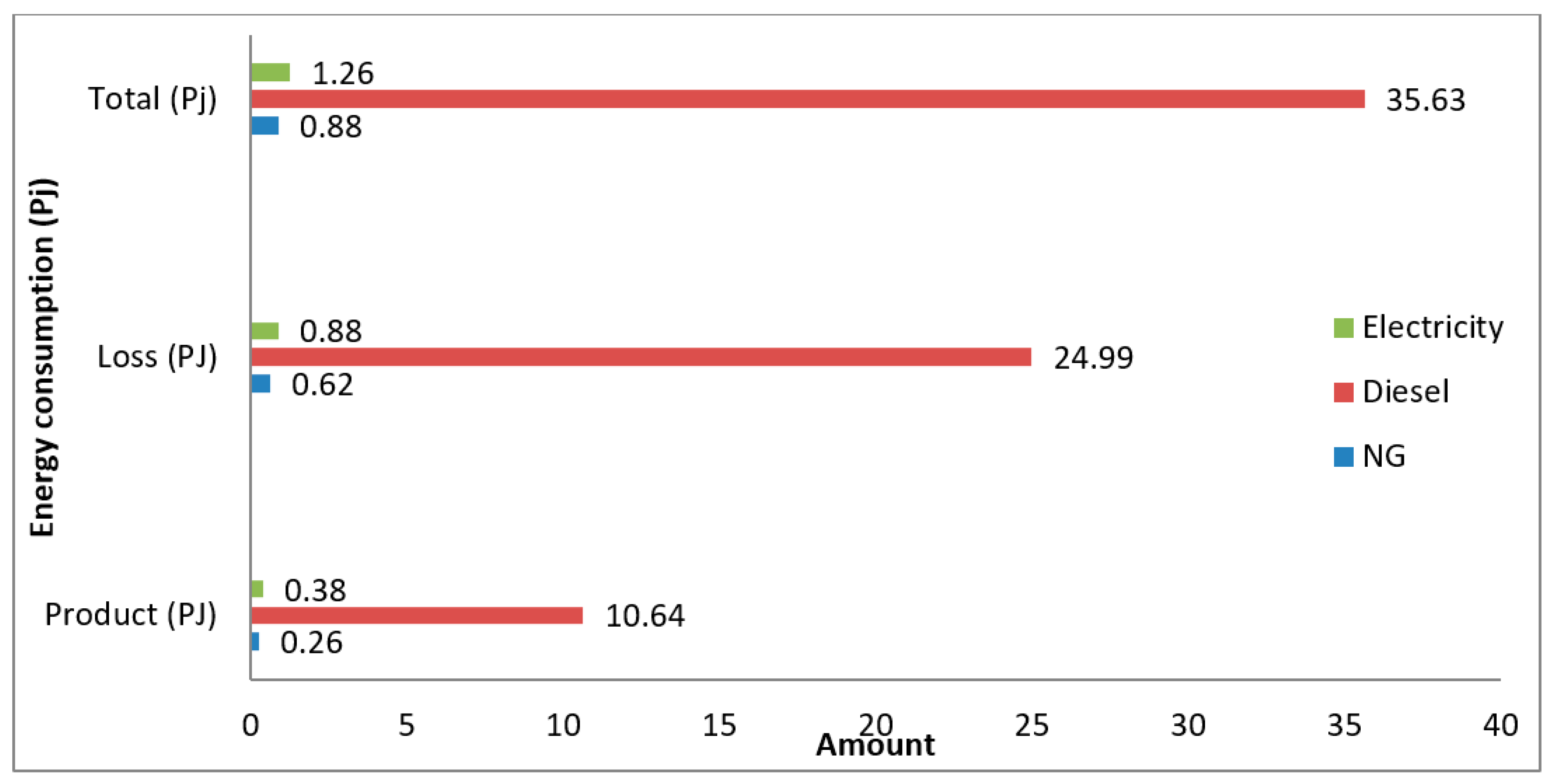

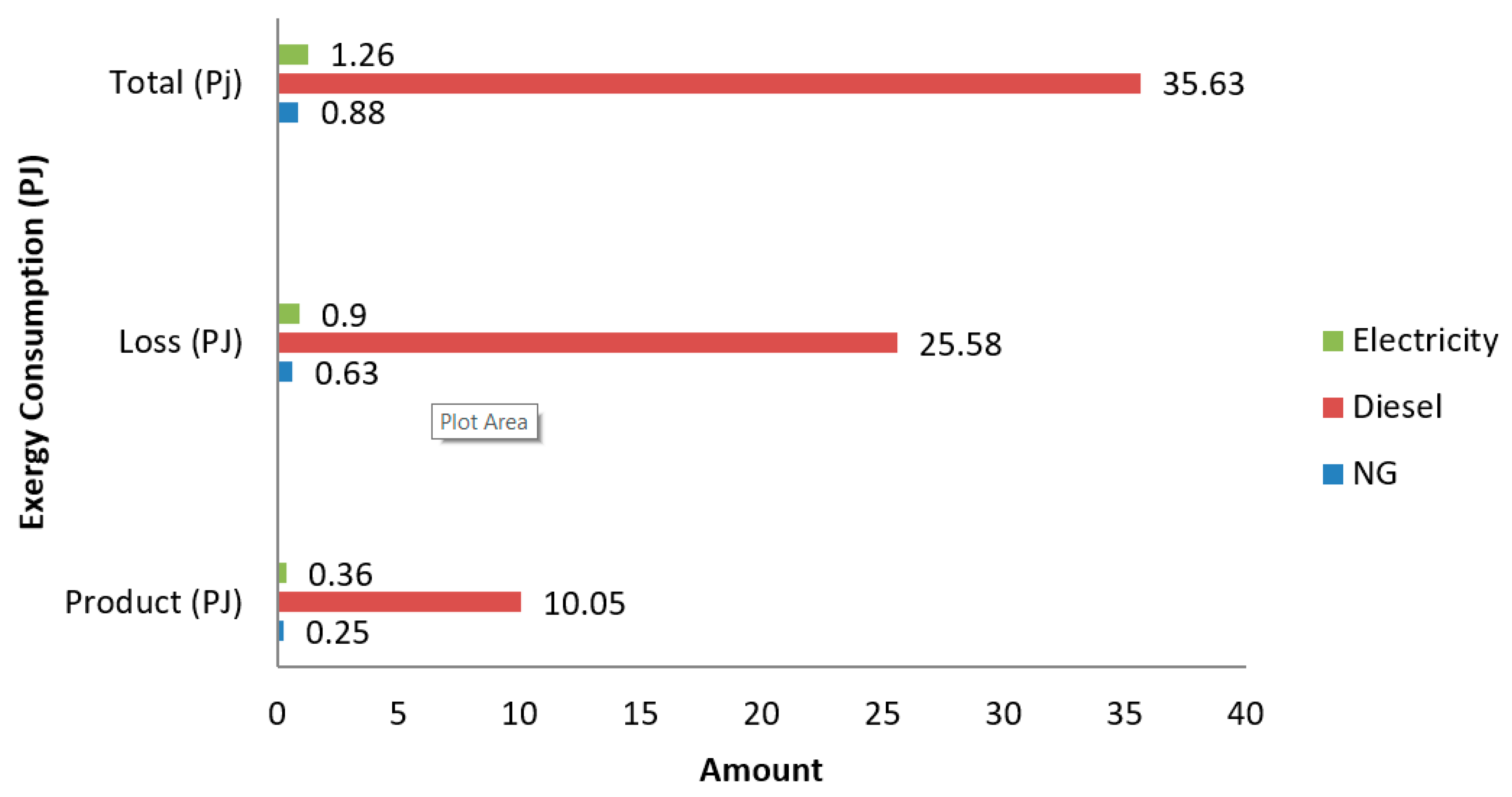

3. Results and Discussion

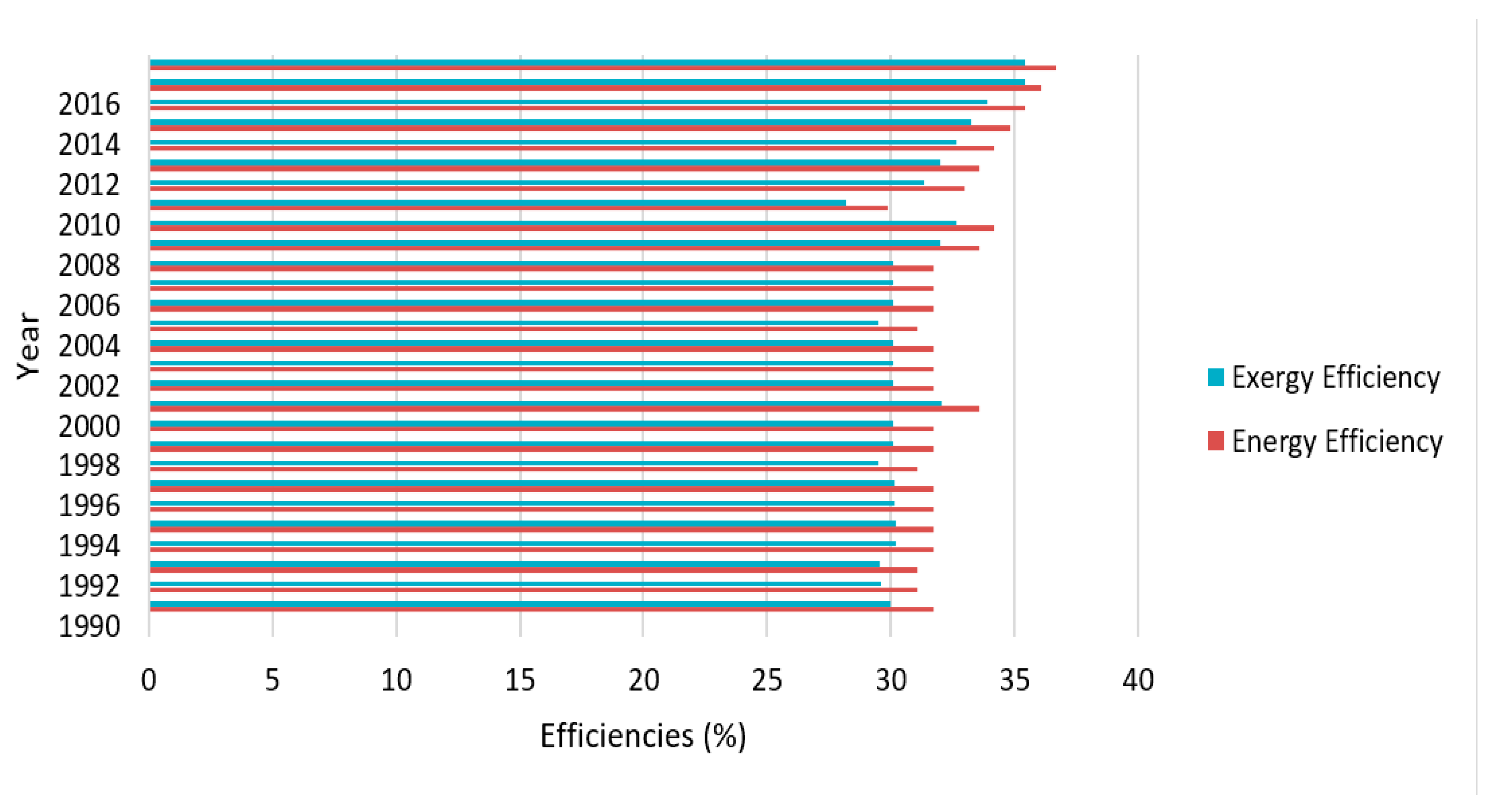

3.1. Overall Energy and Exergy Efficiencies

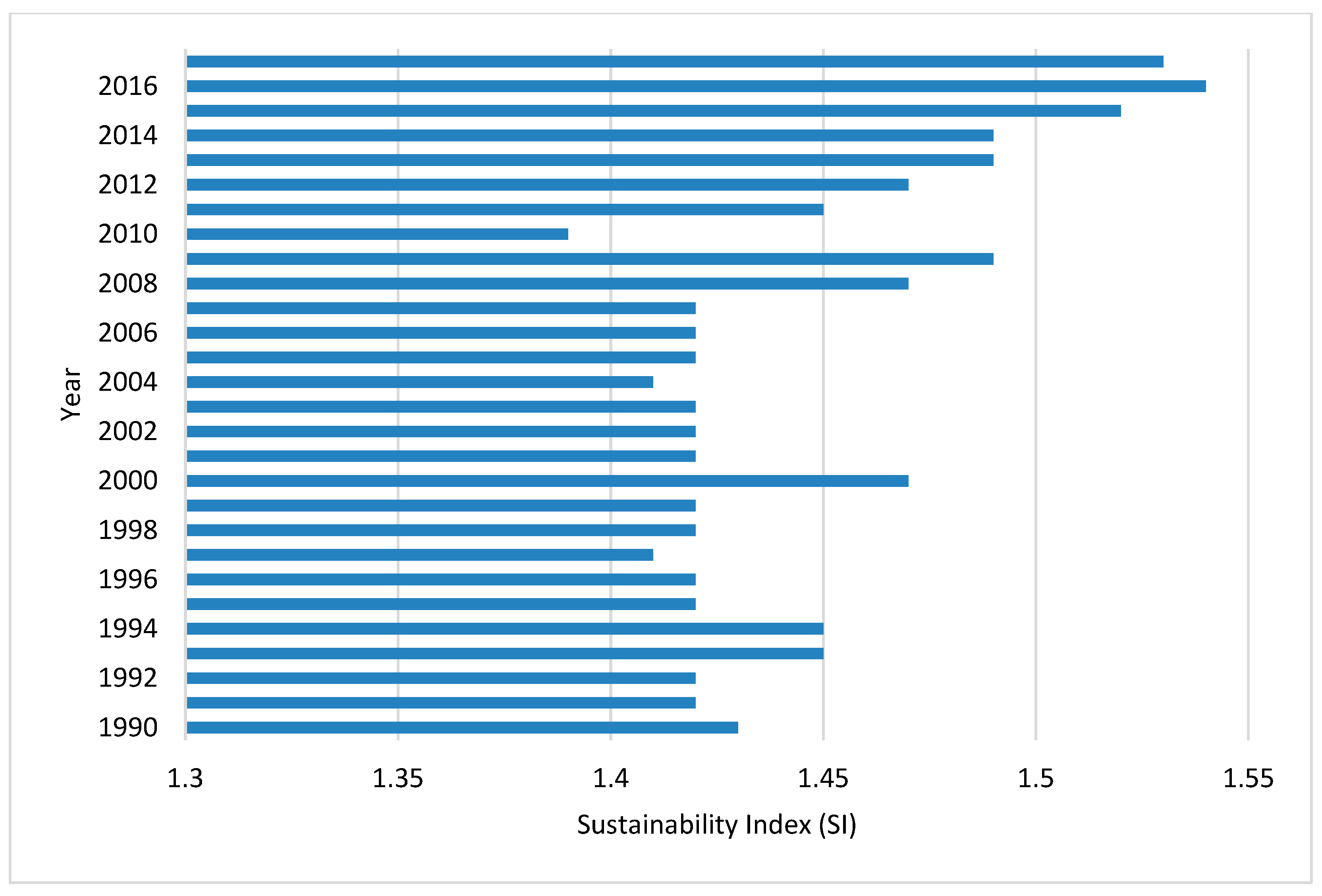

3.2. Calculation of Sustainability Indicators

3.3. Comparison Based on Exergy Efficiency

3.4. Comparison in Terms of Sustainability Index

3.5. Improvement Potential

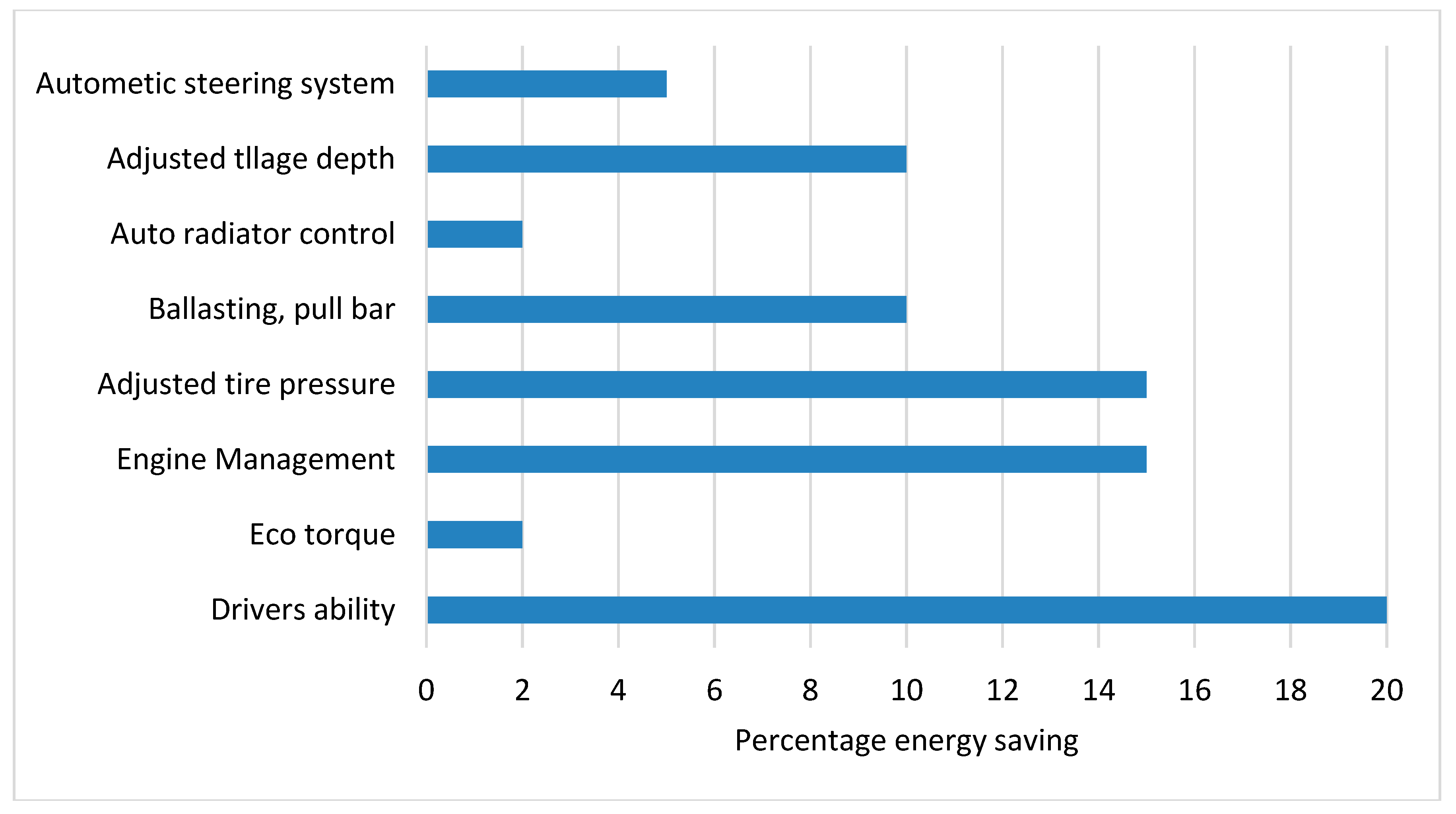

3.6. Strategies for Energy or Exergy Saving

4. Conclusions

- Overall energy efficiencies differ from 29.86% to 36.68%, and overall exergy efficiencies differ from 28.2% to 35.4% from 1990 to 2017.

- SI values vary between 1.39 and 1.54 within this period.

- Bangladesh’s agricultural sector is more sustainable than that of Iran, Jordan, Malaysia, or Saudi Arabia.

- The RI and LOP from diesel fuel are much higher than that of other fuel types. Maximum RI is 0.95 and the maximum LOP is 2.50.

- WER and EEF of diesel fuel are higher than that of the other fuels analyzed. The WER value is 0.74, and the EEF value is 2.47.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| H | Higher heating value (kJ/kg) |

| W | Shaft work (kJ) |

| Tr | Energy fraction or weighting factor |

| Fɳo | Overall weighted mean energy efficiency (%) |

| Fφo | Overall weighted mean exergy efficiency (%) |

| IP | Improvement potential (%) |

| DN | Depletion number |

| ∈ | Specific exergy (kJ/kg) |

| ɳ | Energy efficiency (%) |

| φ | Exergy efficiency (%) |

| γ | Exergy factor |

| ex | Output condition |

| ff | Fuel |

| in | Input condition |

| o | Overall system |

| Des | Destroyed |

| EEF | Environmental effect factor |

| Ex | Exergy |

| In | Input |

| LOP | Lack of productivity |

| RI | Relative irreversibility |

| SI | Sustainability index |

| WER | Waste exergy ratio |

References

- Ahmed, A.; Bakar, M.S.A.; Hamdani, R.; Park, Y.K.; Lam, S.S.; Sukri, R.S.; Hussain, M.; Majeed, K.; Phusunti, N.; Jamil, F.; et al. Valorization of underutilized waste biomass from invasive species to produce biochar for energy and other value-added applications. Environ. Res. 2020, 186, 109596. [Google Scholar] [CrossRef] [PubMed]

- Majeed, K.; Ahmed, A.; Bakar, M.S.A.; Mahlia, T.M.I.; Saba, N.; Hassan, A.; Jawaid, M.; Hussain, M.; Iqbal, J.; Ali, Z. Mechanical and Thermal Properties of Montmorillonite-Reinforced Polypropylene/Rice Husk Hybrid Nanocomposites. Polymers 2019, 11, 1557. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Radenahmad, N.; Morni, N.A.H.; Ahmed, A.; Bakar, M.S.A.; Zaini, J.; Azad, A.K. Characterization of Rice Husk as a Potential Renewable Energy Source. In Proceedings of the 7th Brunei International Conference on Engineering and Technology 2018, Bandar Seri Begawan, Brunei, 12–14 November 2018. [Google Scholar] [CrossRef]

- Ahamed, J.U.; Saidur, R.; Masjuki, H.H.; Mekhilef, S.; Ali, M.B.; Furqon, M.H. An application of energy and exergy analysis in agricultural sector of Malaysia. Energy Policy 2011, 39, 7922–7929. [Google Scholar] [CrossRef]

- Kanoǧlu, M.; Kazim Işik, S.; Abuşoǧlu, A. Performance characteristics of a Diesel engine power plant. Energy Convers. Manag. 2005, 46, 1692–1702. [Google Scholar] [CrossRef]

- Reistad, G.M. Available Energy Conversion and Utilization in the United States. J. Eng. Power 1975, 97, 429. [Google Scholar] [CrossRef]

- Zhang, B.; Jin, P.; Qiao, H.; Hayat, T.; Alsaedi, A.; Ahmad, B. Exergy analysis of Chinese agriculture. Ecol. Indic. 2017. [Google Scholar] [CrossRef]

- Yildizhan, H. Thermodynamics analysis for a new approach to agricultural practices: Case of potato production. J. Clean. Prod. 2017, 166, 660–667. [Google Scholar] [CrossRef]

- Yildizhan, H. Energy, exergy utilization and CO 2 emission of strawberry production in greenhouse and open field. Energy 2018, 143, 417–423. [Google Scholar] [CrossRef]

- Dincer, I.; Hussain, M.M.; Al-Zaharnah, I. Energy and exergy utilization in agricultural sector of Saudi Arabia. Energy Policy 2005, 33, 1461–1467. [Google Scholar] [CrossRef]

- Utlu, Z.; Hepbasli, A. Assessment of the energy and exergy utilization efficiencies in the Turkish agricultural sector. Int. J. Energy Res. 2006, 30, 659–670. [Google Scholar] [CrossRef]

- Al Ghandoor, A.; Jaber, J.O. Analysis of energy and exergy utilisation of Jordan’s agricultural sector. Int. J. Exergy 2009, 6, 491–508. [Google Scholar] [CrossRef]

- Avara, A.; Karami, M. Energy and exergy efficiencies in agricultural and utility sectors of Iran compared with other countries. In Proceedings of the 2010 International Conference on Mechanical and Electrical Technology, Singapore, 10–12 September 2010; pp. 6–10. [Google Scholar] [CrossRef]

- Bligh, D.C.; Ugursal, V.I. Exergy efficiency factors for transportation: Updated Reistad estimates. Int. J. Exergy 2013, 12, 273–277. [Google Scholar] [CrossRef]

- Ministry of Agriculture of Bangladesh (MOA). Available online: http://www.moa.gov.bd/site/page/4fb627c0-d806-4a7e-a1cdb67d4bc85159/Bangladesh-Agriculture-at-a-Glance (accessed on 20 February 2020).

- Employment in Agriculture, The World Bank. Available online: https://data.worldbank.org/indicator/SL.AGR.EMPL.ZS?name_desc=false (accessed on 20 February 2020).

- Energy Efficiency and Conservation Master Plan up to 2030-SREDA. Available online: http://sreda.gov.bd/files/EEC_Master_Plan_SREDA.pdf (accessed on 22 February 2020).

- Wall, G. A Useful Concept. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 1986. [Google Scholar]

- Chowdhury, T.; Chowdhury, H.; Thirugnanasambandam, M.; Hossain, S.; Barua, P.; Ahamed, J.U.; Saidur, R.; Sait, S.M. Is the commercial sector of Bangladesh sustainable?—Viewing via an exergetic approach. J. Clean. Prod. 2019, 228, 544–556. [Google Scholar] [CrossRef]

- Dincer, I.; Hussain, M.M.; Al-Zaharnah, I. Energy and exergy utilization in transportation sector of Saudi Arabia. Appl. Eng. 2004, 24, 525–538. [Google Scholar] [CrossRef]

- Rosen, M.A.; Dincer, I. Sectoral Energy and Exergy Modeling of Turkey. J. Energy Resour. Technol. 1997, 119, 200. [Google Scholar] [CrossRef]

- Rosen, M.A.; Dincer, I.; Kanoglu, M. Role of exergy in increasing efficiency and sustainability and reducing environmental impact. Energy Policy 2008, 36, 128–137. [Google Scholar] [CrossRef]

- Hossain, N. Characterization of Novel Moss Biomass, Bryum dichotomum Hedw. as Solid Fuel Feedstock. BioEnergy Res. 2019, 13, 50–60. [Google Scholar] [CrossRef]

- Barua, P.; Chowdhury, T.; Chowdhury, H.; Islam, R.; Hossain, N. Potential of power generation from chicken waste-based biodiesel, economic and environmental analysis: Bangladesh’s perspective. SN Appl. Sci. 2020, 2, 330. [Google Scholar] [CrossRef] [Green Version]

- Cornelissen, R.L. Thermodynamics and Sustainable Development. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 1997. [Google Scholar]

- Connelly, L.; Koshland, C.P. Two aspects of consumption: using an exergy-based measure of degradation to advance the theory and implementation of industrial ecology. Resour. Conserv. Recycl. 1997, 19, 199–217. [Google Scholar] [CrossRef]

- Chowdhury, H.; Chowdhury, T.; Chowdhury, P.; Islam, M.; Saidur, R.; Sait, S.M. Integrating sustainability analysis with sectoral exergy analysis: A case study of rural residential sector of Bangladesh. Energy Build. 2019, 202, 109397. [Google Scholar] [CrossRef]

- Chowdhury, T.; Chowdhury, H.; Chowdhury, P.; Sait, M.S.; Paul, A.; Ahamed, J.U.; Saidur, R. A case study to application of exergy-based indicators to address the sustainability of Bangladesh residential sector. Sustain. Energy Technol. Assess. 2020, 37, 100615. [Google Scholar] [CrossRef]

- Van Gool, W. Energy policy: Fairly tales and factualities. In Innovation and Technology-Strategies and Policies; Soares, O.D.D., da Cruz, A.M., Costa Pereira, G., Soares, I.M.R.T., Reis, A.J.P.S., Eds.; Kluwer Academic Publisher: Dordrecht, The Netherlands, 1997; pp. 93–105. [Google Scholar]

- United Nations Energy Statistics Database for Bangladesh. Available online: https://knoema.com/UNSDESD2017/un-statistics-division-energy-statistics-database-1990-2014?location=1000170-bangladesh> (accessed on 23 February 2020).

- International Energy Agency Energy Statistics for Non Member Country. Available online: http://www.iea.org/countries/non-membercountries/bangladesh>/ (accessed on 22 February 2020).

- Mottaleb, K.A.; Krupnik, T.J.; Erenstein, O. Factors associated with small-scale agricultural machinery adoption in Bangladesh: Census findings. J. Rural Stud. 2016, 46, 155–168. [Google Scholar] [CrossRef] [Green Version]

- Grisso, R.; Perumpral, J.V.; Vaughan, D.; Roberson, G.T.; Pitman, R. Predicting Tractor Diesel Fuel Consumption; Virginia Cooperative Extension Publication: Petersburg, Russia, 2010; pp. 442–473. [Google Scholar]

- Koniuszy, A.; Kostencki, P.; Berger, A.; Golimowski, W. Power performance of farm tractor in field operations. Eksploat. I Niezawodn. Maint. Reliab. 2017, 19, 43–47. [Google Scholar] [CrossRef]

- Farias, M.S.; Schlosser, J.F.; Linares, P.; Barbieri, J.P.; Luis, G.M.N.; Oliveira, F.V.; Rüdell, I.I.P. Fuel consumption efficiency of an agricultural tractor equipped with continuously variable transmission. Ciênc. Rural 2017, 47. [Google Scholar] [CrossRef] [Green Version]

- Almaliki, S.; Alimardani, R.; Omid, M. Fuel consumption models of MF285 tractor under various field conditions. Agric. Eng. Int. CIGR J. 2016, 18, 147–158. Available online: http://www.cigrjournal.org (accessed on 20 March 2020).

- Ueka, Y.; Yamashita, J.; Sato, K.; Doi, Y. Study on the Development of the Electric Tractor—Specifications and Traveling and Tilling Performance of a Prototype Electric Tractor. Eng. Agric. Environ. Food 2013, 6, 160–164. [Google Scholar] [CrossRef]

- Ludwig, V.; Stephan, D.; Sandra, R. How to Increase Diesel Fuel Efficiency in Agriculture. Available online: https://www.landtechnik-online.eu/ojs-2.4.5/index.php/landtechnik/article/viewFile/2011-2-140-143/514 (accessed on 20 March 2020).

- Hossain, S.; Chowdhury, H.; Chowdhury, T.; Ahamed, J.U.; Saidur, R.; Sait, S.M.; Rosen, M.A. Energy, exergy and sustainability analyses of Bangladesh’s power generation sector. Energy Rep. 2020, 6, 868–878. [Google Scholar] [CrossRef]

- Galil, A.A.; Mostafa, M.M.; Elnono, A.M.; Mohamed, F.M. Biogas utilization for powering water irrigation pump. MISR J. Agric. Eng. 2008, 25, 1438–1453. [Google Scholar]

- Haque, M.M. Photovoltaic water pumping system for irrigation. In Proceedings of the 4th International Conference on Mechanical Engineering, Utrecht, The Netherlands, 14–17 October 2001; pp. 21–26. [Google Scholar]

| Fuel | Exergy Factor γff |

|---|---|

| Natural Gas | 0.93 |

| Diesel | 1.07 |

| Electricity | 1 |

| Year | Energy Input Data (PJ) | ||

|---|---|---|---|

| Diesel | Electricity | Natural gas | |

| 1990 | 10.17 | 0.61 | 0 |

| 1991 | 10.63 | 0.62 | 0.72 |

| 1992 | 12.48 | 0.75 | 0.73 |

| 1993 | 12.43 | 0.79 | 0.74 |

| 1994 | 12.43 | 0.81 | 0.75 |

| 1995 | 14.91 | 1.11 | 0.62 |

| 1996 | 16.37 | 1.09 | 0.74 |

| 1997 | 17.54 | 1.04 | 0.73 |

| 1998 | 18.21 | 1.11 | 0.77 |

| 1999 | 19.80 | 1.34 | 0.73 |

| 2000 | 17.71 | 1.75 | 0.66 |

| 2001 | 23.81 | 1.44 | 0.67 |

| 2002 | 24.62 | 1.50 | 0.75 |

| 2003 | 23.99 | 1.61 | 0.77 |

| 2004 | 27.80 | 1.77 | 0.83 |

| 2005 | 31.40 | 1.89 | 0.83 |

| 2006 | 31.86 | 2.06 | 0.83 |

| 2007 | 31.82 | 2.08 | 0.82 |

| 2008 | 32.36 | 3.32 | 0.77 |

| 2009 | 31.90 | 3.93 | 0.71 |

| 2010 | 35.63 | 1.26 | 0.88 |

| 2011 | 44.92 | 4.10 | 0.88 |

| 2012 | 44.92 | 4.56 | 0.84 |

| 2013 | 41.11 | 4.48 | 0.88 |

| 2014 | 41.45 | 5.45 | 0.88 |

| 2015 | 37.22 | 5.19 | 0.88 |

| 2016 | 39.52 | 6.06 | 0.99 |

| 2017 | 43.84 | 6.44 | 1.11 |

| Year | Diesel | Electricity | NG | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RI | LOP | WER | EEF | RI | LOP | WER | EEF | RI | LOP | WER | EEF | |

| 1990 | 0.95 | 2.21 | 0.66 | 2.2 | 0.05 | 0.12 | 0.04 | 0.13 | 0.00 | 0.00 | 0.00 | 0.00 |

| 1991 | 0.90 | 2.14 | 0.63 | 2.1 | 0.05 | 0.12 | 0.03 | 0.10 | 0.05 | 0.11 | 0.04 | 0.13 |

| 1992 | 0.90 | 1.83 | 0.64 | 2.13 | 0.05 | 0.12 | 0.04 | 0.13 | 0.05 | 0.11 | 0.03 | 0.10 |

| 1993 | 0.90 | 2.08 | 0.63 | 2.1 | 0.05 | 0.12 | 0.04 | 0.13 | 0.05 | 0.11 | 0.03 | 0.10 |

| 1994 | 0.90 | 2.08 | 0.63 | 2.1 | 0.05 | 0.13 | 0.04 | 0.13 | 0.05 | 0.11 | 0.03 | 0.10 |

| 1995 | 0.91 | 2.10 | 0.63 | 2.1 | 0.06 | 0.15 | 0.04 | 0.13 | 0.03 | 0.08 | 0.02 | 0.07 |

| 1996 | 0.91 | 2.10 | 0.63 | 2.1 | 0.06 | 0.13 | 0.04 | 0.13 | 0.03 | 0.08 | 0.02 | 0.07 |

| 1997 | 0.92 | 2.50 | 0.74 | 2.47 | 0.05 | 0.14 | 0.04 | 0.13 | 0.03 | 0.09 | 0.03 | 0.10 |

| 1998 | 0.92 | 2.12 | 0.64 | 2.13 | 0.05 | 0.12 | 0.04 | 0.13 | 0.03 | 0.07 | 0.02 | 0.07 |

| 1999 | 0.91 | 2.12 | 0.64 | 2.13 | 0.06 | 0.14 | 0.04 | 0.13 | 0.03 | 0.07 | 0.02 | 0.07 |

| 2000 | 0.89 | 1.89 | 0.60 | 1.88 | 0.08 | 0.18 | 0.06 | 0.19 | 0.03 | 0.06 | 0.02 | 0.06 |

| 2001 | 0.93 | 2.15 | 0.65 | 2.17 | 0.05 | 0.12 | 0.04 | 0.13 | 0.03 | 0.05 | 0.02 | 0.07 |

| 2002 | 0.92 | 2.14 | 0.65 | 2.17 | 0.05 | 0.12 | 0.04 | 0.13 | 0.02 | 0.06 | 0.02 | 0.07 |

| 2003 | 0.92 | 2.14 | 0.64 | 2.13 | 0.06 | 0.14 | 0.04 | 0.13 | 0.02 | 0.06 | 0.02 | 0.07 |

| 2004 | 0.92 | 2.20 | 0.65 | 2.17 | 0.05 | 0.13 | 0.04 | 0.13 | 0.03 | 0.06 | 0.02 | 0.07 |

| 2005 | 0.93 | 2.16 | 0.65 | 2.17 | 0.05 | 0.12 | 0.04 | 0.13 | 0.02 | 0.05 | 0.01 | 0.03 |

| 2006 | 0.92 | 2.15 | 0.65 | 2.17 | 0.06 | 0.13 | 0.04 | 0.13 | 0.02 | 0.05 | 0.01 | 0.03 |

| 2007 | 0.92 | 2.15 | 0.65 | 2.17 | 0.06 | 0.13 | 0.04 | 0.13 | 0.02 | 0.05 | 0.01 | 0.03 |

| 2008 | 0.90 | 1.91 | 0.61 | 1.91 | 0.09 | 0.18 | 0.06 | 0.19 | 0.01 | 0.04 | 0.01 | 0.03 |

| 2009 | 0.88 | 1.82 | 0.59 | 1.79 | 0.10 | 0.21 | 0.07 | 0.21 | 0.02 | 0.04 | 0.01 | 0.03 |

| 2010 | 0.95 | 2.41 | 0.68 | 2.43 | 0.03 | 0.08 | 0.02 | 0.07 | 0.02 | 0.05 | 0.01 | 0.04 |

| 2011 | 0.91 | 1.99 | 0.62 | 2.0 | 0.08 | 0.17 | 0.05 | 0.16 | 0.01 | 0.03 | 0.01 | 0.03 |

| 2012 | 0.90 | 1.91 | 0.61 | 1.91 | 0.09 | 0.18 | 0.06 | 0.19 | 0.01 | 0.03 | 0.001 | 0.003 |

| 2013 | 0.89 | 1.84 | 0.60 | 1.82 | 0.09 | 0.19 | 0.06 | 0.18 | 0.02 | 0.03 | 0.01 | 0.03 |

| 2014 | 0.88 | 1.76 | 0.58 | 1.76 | 0.10 | 0.22 | 0.07 | 0.21 | 0.02 | 0.03 | 0.01 | 0.03 |

| 2015 | 0.87 | 1.70 | 0.57 | 1.67 | 0.11 | 0.22 | 0.07 | 0.21 | 0.02 | 0.04 | 0.01 | 0.03 |

| 2016 | 0.86 | 1.59 | 0.56 | 1.6 | 0.12 | 0.23 | 0.08 | 0.23 | 0.02 | 0.03 | 0.02 | 0.06 |

| 2017 | 0.85 | 1.58 | 0.57 | 1.61 | 0.11 | 0.22 | 0.08 | 0.24 | 0.02 | 0.03 | 0.01 | 0.03 |

| Country | Energy Efficiency (%) | Exergy Efficiency (%) | Source |

|---|---|---|---|

| Bangladesh | 29.86–36.68 | 28.2–35.4 | This study |

| Iran | 29–41.7 | 16.9–20.2 | [13] |

| Malaysia | 22 | 20.728 | [4] |

| Turkey | 29.1–41.1 | 27.9–37.4 | [11] |

| Saudi Arabia | 27.25 | 20.65 | [10] |

| Jordan | 37.30 | 23.45 | [12] |

| Country | Sustainability Index (SI) |

|---|---|

| Bangladesh | 1.39–1.54 |

| Iran | 1.20–1.25 |

| Malaysia | 1.26 |

| Turkey | 1.39–1.60 |

| Saudi Arabia | 1.26 |

| Jordan | 1.31 |

| Year | Driver Ability | Eco-Torque | Engine Management | Adjusted Tire Pressure | Ballasting, Pull Bar | Automatic Radiator Control | Adjusted Tillage Depth | Automatic Steering System |

|---|---|---|---|---|---|---|---|---|

| 1990 | 1.52 | 0.15 | 1.14 | 1.14 | 0.76 | 0.15 | 0.76 | 0.38 |

| 1991 | 1.60 | 0.16 | 1.20 | 1.20 | 0.80 | 0.16 | 0.80 | 0.40 |

| 1992 | 1.88 | 0.19 | 1.41 | 1.41 | 0.94 | 0.19 | 0.94 | 0.47 |

| 1993 | 1.86 | 0.19 | 1.39 | 1.39 | 0.93 | 0.19 | 0.93 | 0.46 |

| 1994 | 1.86 | 0.19 | 1.39 | 1.39 | 0.93 | 0.19 | 0.93 | 0.46 |

| 1995 | 2.23 | 0.22 | 1.67 | 1.67 | 1.12 | 0.22 | 1.12 | 0.56 |

| 1996 | 2.45 | 0.24 | 1.84 | 1.84 | 1.22 | 0.24 | 1.22 | 0.61 |

| 1997 | 3.02 | 0.30 | 2.27 | 2.27 | 1.51 | 0.30 | 1.51 | 0.76 |

| 1998 | 2.72 | 0.27 | 2.04 | 2.04 | 1.36 | 0.27 | 1.36 | 0.68 |

| 1999 | 2.96 | 0.30 | 2.22 | 2.22 | 1.48 | 0.30 | 1.48 | 0.74 |

| 2000 | 2.58 | 0.26 | 1.93 | 1.93 | 1.29 | 0.26 | 1.29 | 0.64 |

| 2001 | 3.56 | 0.36 | 2.67 | 2.67 | 1.78 | 0.36 | 1.78 | 0.89 |

| 2002 | 3.68 | 0.37 | 2.76 | 2.76 | 1.81 | 0.37 | 1.81 | 0.92 |

| 2003 | 3.59 | 0.36 | 2.69 | 2.69 | 1.80 | 0.36 | 1.80 | 0.90 |

| 2004 | 4.20 | 0.42 | 3.15 | 3.15 | 2.01 | 0.42 | 2.01 | 1.05 |

| 2005 | 4.7 | 0.47 | 3.53 | 3.53 | 2.35 | 0.47 | 2.35 | 1.18 |

| 2006 | 4.77 | 0.48 | 3.58 | 3.58 | 2.38 | 0.48 | 2.38 | 1.19 |

| 2007 | 4.76 | 0.48 | 3.58 | 3.58 | 2.38 | 0.48 | 2.38 | 1.10 |

| 2008 | 4.71 | 0.47 | 3.53 | 3.53 | 2.36 | 0.47 | 2.36 | 1.18 |

| 2009 | 4.6 | 0.46 | 3.45 | 3.45 | 2.30 | 0.46 | 2.30 | 1.15 |

| 2010 | 5.47 | 0.55 | 4.11 | 4.11 | 2.74 | 0.55 | 2.74 | 1.37 |

| 2011 | 6.60 | 0.66 | 4.95 | 4.95 | 3.30 | 0.66 | 3.30 | 1.65 |

| 2012 | 6.54 | 0.65 | 4.90 | 4.90 | 3.27 | 0.65 | 3.27 | 1.63 |

| 2013 | 5.93 | 0.59 | 4.44 | 4.44 | 2.96 | 0.59 | 2.96 | 1.48 |

| 2014 | 5.92 | 0.59 | 4.44 | 4.44 | 2.96 | 0.59 | 2.96 | 1.48 |

| 2015 | 5.26 | 0.53 | 3.95 | 3.95 | 2.63 | 0.53 | 2.63 | 1.32 |

| 2016 | 5.47 | 0.55 | 4.10 | 4.10 | 2.76 | 0.55 | 2.76 | 1.37 |

| 2017 | 6.04 | 0.60 | 4.53 | 4.53 | 3.02 | 0.60 | 3.02 | 1.51 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chowdhury, T.; Chowdhury, H.; Ahmed, A.; Park, Y.-K.; Chowdhury, P.; Hossain, N.; Sait, S.M. Energy, Exergy, and Sustainability Analyses of the Agricultural Sector in Bangladesh. Sustainability 2020, 12, 4447. https://doi.org/10.3390/su12114447

Chowdhury T, Chowdhury H, Ahmed A, Park Y-K, Chowdhury P, Hossain N, Sait SM. Energy, Exergy, and Sustainability Analyses of the Agricultural Sector in Bangladesh. Sustainability. 2020; 12(11):4447. https://doi.org/10.3390/su12114447

Chicago/Turabian StyleChowdhury, Tamal, Hemal Chowdhury, Ashfaq Ahmed, Young-Kwon Park, Piyal Chowdhury, Nazia Hossain, and Sadiq M. Sait. 2020. "Energy, Exergy, and Sustainability Analyses of the Agricultural Sector in Bangladesh" Sustainability 12, no. 11: 4447. https://doi.org/10.3390/su12114447

APA StyleChowdhury, T., Chowdhury, H., Ahmed, A., Park, Y.-K., Chowdhury, P., Hossain, N., & Sait, S. M. (2020). Energy, Exergy, and Sustainability Analyses of the Agricultural Sector in Bangladesh. Sustainability, 12(11), 4447. https://doi.org/10.3390/su12114447