Least Cost Analysis for Biocorrosion Mitigation Strategies in Concrete Sewers

Abstract

:1. Introduction

2. Materials and Methods

2.1. MIC Mitigation Methods

2.1.1. Flushing with High-Pressure Water

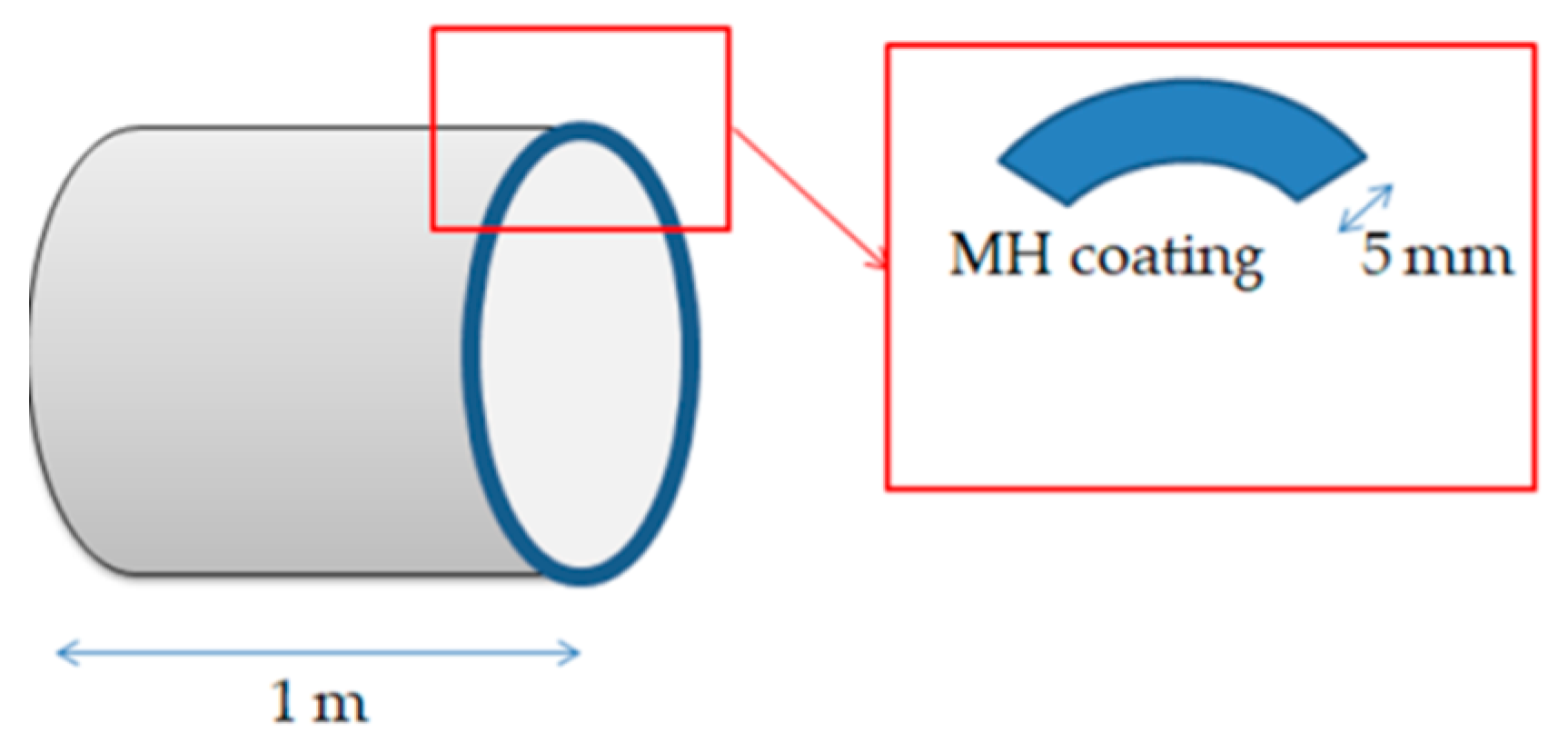

2.1.2. MHS Spraying

2.2. Cost-Comparative Analysis

2.2.1. Goal and Scope Definition

2.2.2. Inventory Analysis

2.2.3. Economic Assessment Formulas

3. Results

4. Limitations of This Study

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Islander, R.L.; Devinny, J.S.; Mansfeld, F.; Postyn, A.; Shih, H. Microbial Ecology of Crown Corrosion in Sewers. J. Environ. Eng. 1991, 117, 751–770. [Google Scholar] [CrossRef]

- O’Dea, V. Understanding biogenic sulfide corrosion. Mater. Perform. 2007, 46, 11. [Google Scholar]

- Wang, T.; Wu, K.; Kan, L.; Wu, M. Current understanding on microbiologically induced corrosion of concrete in sewer structures: A review of the evaluation methods and mitigation measures. Constr. Build. Mater. 2020, 247, 118539. [Google Scholar] [CrossRef]

- Grengg, C.; Mittermayr, F.; Ukrainczyk, N.; Koraimann, G.; Kienesberger, S.; Dietzel, M. Advances in concrete materials for sewer systems affected by microbial induced concrete corrosion: A review. Water Res. 2018, 134, 341–352. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; De Schryver, P.; De Gusseme, B.; De Muynck, W.; Boon, N.; Verstraete, W. Chemical and biological technologies for hydrogen sulfide emission control in sewer systems: A review. Water Res. 2008, 42, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Roghanian, N.; Banthia, N. Development of a sustainable coating and repair material to prevent bio-corrosion in concrete sewer and waste-water pipes. Cem. Concr. Compos. 2019, 100, 99–107. [Google Scholar] [CrossRef]

- Fytianos, G.; Baltikas, V.; Loukovitis, D.; Banti, D.; Sfikas, A.; Papastergiadis, E.; Samaras, P. Biocorrosion of Concrete Sewers in Greece: Current Practices and Challenges. Sustainability 2020, 12, 2638. [Google Scholar] [CrossRef] [Green Version]

- Karageorgos, P.; Latos, M.; Kotsifaki, C.; Lazaridis, M.; Kalogerakis, N. Treatment of unpleasant odors in municipal wastewater treatment plants. Water Sci. Technol. 2010, 61, 2635–2644. [Google Scholar] [CrossRef]

- Bravo, L.; Ferrer, I. Life Cycle Assessment of an intensive sewage treatment plant in Barcelona (Spain) with focus on energy aspects. Water Sci. Technol. 2011, 64, 440–447. [Google Scholar] [CrossRef]

- Gaterell, M.; Griffin, P.; Lester, J. Evaluation of Environmental Burdens Associated with Sewage Treatment Processes Using Life Cycle Assessment Techniques. Environ. Technol. 2005, 26, 231–250. [Google Scholar] [CrossRef]

- Gallego, A.; Hospido, A.; Moreira, M.T.; Feijoo, G. Environmental performance of wastewater treatment plants for small populations. Resour. Conserv. Recycl. 2008, 52, 931–940. [Google Scholar] [CrossRef]

- Hospido, A.; Moreira, M.T.; Feijoo, G. A comparison of municipal wastewater treatment plants for big centres of population in Galicia (Spain). Int. J. Life Cycle Assess. 2007, 13, 57. [Google Scholar] [CrossRef]

- Ortiz, M.; Raluy, R.G.; Serra, L.M. Life cycle assessment of water treatment technologies: Wastewater and water-reuse in a small town. Desalination 2007, 204, 121–131. [Google Scholar] [CrossRef]

- Sustainable Solutions Corporation, Life Cycle Assessment of PVC Water and Sewer Pipe and Comparative Sustainability Analysis of Pipe Materials Royersford, USA. 2017. Available online: https://www.uni-bell.org/files/Reports/Life_Cycle_Assessment_of_PVC_Water_and_Sewer_Pipe_and_Comparative_Sustainability_Analysis_of_Pipe_Materials.pdf (accessed on 16 March 2020).

- Kim, D.; Yi, S.; Lee, W. Life cycle assessment of sewer system: Comparison of pipe materials. In Proceedings of the 2012 World Congress on Advances in Civil, Environmental, and Materials Research (ACEN’ 12), Seoul, Korea, 26–30 August 2012. [Google Scholar]

- Gjorv, O.E.; Sakai, K. Concrete Technology for a Sustainable Development in the 21st Century; CRC Press: Boca Raton, FL, USA, 2003; pp. 332–340. [Google Scholar]

- Æsøy, A.; Østerhus, S.; Bentzen, G. Controlled treatment with nitrate in sewers to prevent concrete corrosion. Water Supply 2002, 2, 137–144. [Google Scholar] [CrossRef]

- Saleh, M.Y.; EL-Zahar, M.M.H.; Ashour, N.M.M. Application of Life Cycle Cost Analysis Method on Wastewater Treatment Plants In Egypt. In Proceedings of the Twenty-first International Water Technology Conference, IWTC21, Ismailia, Egypt, 28–30 June 2018. [Google Scholar]

- Stein, D. Rehabilitation and Maintenance of Drains and Sewers; Ernst & Sohn Wiley: Berlin, Germany, 2001; 804p. [Google Scholar]

- UN-Habitat. State of the World’s Cities 2008/2009–Harmonious Cities; UN-Habitat: Nairobi, Kenya, 2008. [Google Scholar]

- XYLEM. WHITE PAPER Life Cycle Costs for Wastewater Pumping Systems June 2015. Available online: https://www.xylem.com/siteassets/support/tekniska-rapporter/white-papers-pdf/life-cycle-costs-lcc-for-wastewater-pumping-systems.pdf (accessed on 17 March 2020).

- Concrete Pipe Associationof Australasia. Life Cycle Cost Analysis in Drainage Projects. Technical Brief. 2015. Available online: https://www.cpaa.asn.au/images/publications/technical_briefs/life%20cycle%20drainage.pdf (accessed on 17 March 2020).

- Yoshida, H.; Christensen, T.H.; Scheutz, C. Life cycle assessment of sewage sludge management: A review. Waste Manag. Res. 2013, 31, 1083–1101. [Google Scholar] [CrossRef]

- Abraham, D.M. Life Cycle Cost Integration for the Rehabilitation of Wastewater Infrastructure. Constr. Res. Congr. 2003, 1–9. [Google Scholar] [CrossRef]

- Årskog, V.; Fossdal, S. Life-Cycle Assessment of Repair and Maintenance Systems For Concrete Structures. In Proceedings of the International Workshop on Sustainable Development and Concrete Technology, Beijing, China, 20–21 May 2014. [Google Scholar]

- Tsagarakis, K.P.; Mara, D.; Angelakis, A.N. Application of Cost Criteria for Selection of Municipal Wastewater Treatment Systems. Water Air Soil Pollut. 2003, 142, 187–210. [Google Scholar] [CrossRef]

- Wu, L.; Hu, C.; Liu, W.V. The Sustainability of Concrete in Sewer Tunnel—A Narrative Review of Acid Corrosion in the City of Edmonton, Canada. Sustainability 2018, 10, 517. [Google Scholar] [CrossRef] [Green Version]

- Noeiaghaei, T.; Mukherjee, A.; Mistri, A.; Chae, S.-R. Biogenic deterioration of concrete and its mitigation technologies. Constr. Build. Mater. 2017, 149, 575–586. [Google Scholar] [CrossRef]

- Sydney, R.; Esfandi, E.; Surapaneni, S. Control concrete sewer corrosion via the crown spray process. Water Environ. Res. 1996, 68, 338–347. [Google Scholar] [CrossRef]

- Nielsen, A.H.; Vollertsen, J.; Jensen, H.S.; Wium-Andersen, T.; Hvitved-Jacobsen, T. Influence of pipe material and surfaces on sulfide related odor and corrosion in sewers. Water Res. 2008, 42, 4206–4214. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Jiang, G.; Chiu, T.H.; Zhou, M.; Keller, J.; Bond, P.L. Effects of surface washing on the mitigation of concrete corrosion under sewer conditions. Cem. Concr. Compos. 2016, 68, 88–95. [Google Scholar] [CrossRef] [Green Version]

- Crownmag. Innovative Coating Materials for Corrosion Protection of Sewer Network Pipes. Available online: http://crownmag.gr/en/ (accessed on 23 March 2020).

- American Concrete Pipe Assocation. Least Cost Analysis. Resource 07-130 (06/07) 5M 2007. Available online: https://www.concretepipe.org/wp-content/uploads/2015/05/LCA-Brochure.pdf (accessed on 23 March 2020).

- Rebitzer, G.; Hunkeler, D. Life cycle costing in LCM: Ambitions, opportunities, and limitations. Int. J. Life Cycle Assess. 2003, 8, 253–256. [Google Scholar] [CrossRef]

- Mitsakis, E.; Stamos, I.; Grau, J.M.S.; Chrysochoou, E.; Iordanopoulos, P.; Aifadopoulou, G. Urban Mobility Indicators for Thessaloniki. J. Traffic Logist. Eng. 2013, 1, 148–152. [Google Scholar] [CrossRef] [Green Version]

- Lemer, A. Life Cycle Costing: For the Analysis, Management and Maintenance of Civil Engineering Infrastructure. Constr. Manag. Econ. 2015, 33, 689–691. [Google Scholar] [CrossRef]

- Wastewater Treatment Plants. Monitoring Database. Special Secretariat for Water. Ministry of Environment and Energy. Available online: http://astikalimata.ypeka.gr/Services/Pages/WtpViewApp.aspx (accessed on 24 March 2020).

- Smol, M.; Adam, C.; Preisner, M. Circular economy model framework in the European water and wastewater sector. J. Mater. Cycles Waste Manag. 2020, 22, 682–697. [Google Scholar] [CrossRef] [Green Version]

| Assumptions | Unit | Values | Remarks |

|---|---|---|---|

| Area radius | km | 20–50 | Different scenarios based on city size |

| Expected economic life | yr | 50 | [19] |

| Inputs | |||

| Labour | €/h | 6.33 | National payscale |

| Water consumption | €/m3 | 0.95–1.11 | Based on the selling price of each MWSE |

| Mg(OH)2 Slurry | €/m | 2.65–10.60 | Based on the sewer diameter |

| Diesel | €/l | 1.5 | |

| Lubricants | €/l | 3.275 | 7% of diesel |

| Energy | €/kWh | 0.13001 | National electricity price |

| Outputs | |||

| NPV for each corrosion mitigation strategy | €/km | Figure 3, Figure 4 and Figure 5 | |

| PVC replacement | €/km | 361,567–569,320 | Based on the Concrete Pipe Size |

| Equipment depreciation | |||

| Sprayer | €/h | 1.26 | ABC software http://www.abc.aua.gr/ |

| Lorry 2 T | €/h | 10.86 | ABC software http://www.abc.aua.gr/ |

| Disturbance (Indirect impacts) | |||

| Annual daily traffic | Vehicles/day | 236–4128 | [35] |

| Time delay | h | 0.15–0.5 | Based on the controlling method |

| Days of each project | days | - | Based on the duration |

| Person labor hour | €/h | 6.33 | National payscale |

| Freight delay | €/h | 17.97 | National payscale |

| Vehicle passenger traffic | % | 97 | [33] |

| Vehicle freight traffic | % | 3 | [33] |

| Occupancy of vehicle | Persons | 1.2 | [33] |

| Town | Town Number on Map | Peak Population Equivalent | Type of System | Concrete Pipe Size |

|---|---|---|---|---|

| Thessaloniki | 1 | 900,000 | Combined | 1000 mm |

| Serres | 2 | 79,000 | Combined | 800 mm |

| Kozani | 3 | 46,000 | Combined | 250 mm |

| Florina | 4 | 20,000 | Separate | 400 mm |

| Controlling Method | Kozani | Thessaloniki | Serres | Florina |

|---|---|---|---|---|

| Water flushing | 2,121,665 € | 15,667,682 € | 2,379,757 € | 895,730 € |

| MHS/year | 108,735 € | 802,969 € | 121,963 € | 45,906 € |

| PVC installation | 265,208 € | 1,468,845 € | 223,102 € | 83,975 € |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fytianos, G.; Tziolas, E.; Papastergiadis, E.; Samaras, P. Least Cost Analysis for Biocorrosion Mitigation Strategies in Concrete Sewers. Sustainability 2020, 12, 4578. https://doi.org/10.3390/su12114578

Fytianos G, Tziolas E, Papastergiadis E, Samaras P. Least Cost Analysis for Biocorrosion Mitigation Strategies in Concrete Sewers. Sustainability. 2020; 12(11):4578. https://doi.org/10.3390/su12114578

Chicago/Turabian StyleFytianos, Georgios, Emmanouil Tziolas, Efthimios Papastergiadis, and Petros Samaras. 2020. "Least Cost Analysis for Biocorrosion Mitigation Strategies in Concrete Sewers" Sustainability 12, no. 11: 4578. https://doi.org/10.3390/su12114578