Historic Building Energy Audit and Retrofit Simulation with Hemp-Lime Plaster—A Case Study

Abstract

:1. Introduction

2. Challenges and Benefits of Hemp Use in AEC Sector

2.1. Technical Standpoint

2.2. Commercial Standpoint

2.3. Knowledge Standpoint

2.4. Regulatory Standpoint

2.5. Psychological Standpoint

2.6. Invisible Standpoint

3. Materials and Methods

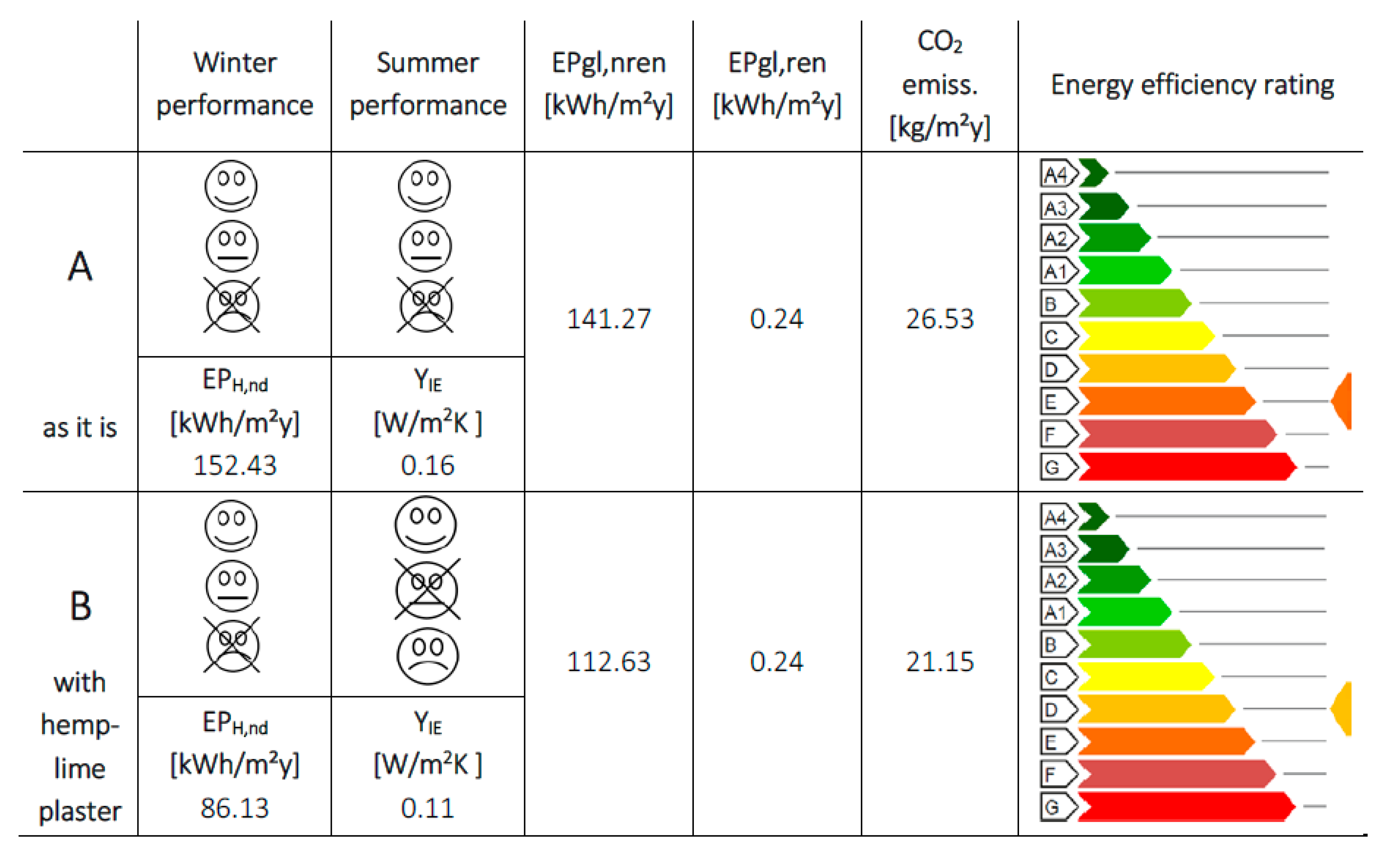

- Winter and summer performances are qualitative indexes of the energy requirement needed to meet the indoor comfort, regardless the type and performance of the MEP system. They give an indication of the building (or housing unit) thermal insulation capacity in summer and winter, on a qualitative assessment scale, “high” (

), “medium” (

), “low” (

). In particular, EPH,nd is a general requirement on the building envelope measuring the heating thermal performance and depending on the thermal insulation of the envelope (opaque and transparent), on the performance of a possible ventilation system and on the internal and solar intake. YIE is the Dynamic thermal admittance averaged on the whole building.

- EPgl,nren is the “non-renewable energy performance index”, indicating the amount of energy consumed for the building to reach the comfort conditions. It takes into account the need for non-renewable primary energy for (a) winter and summer air conditioning, (b) production of domestic hot water and (c) ventilation. It is calculated on the basis of the ratio between the energy required to bring an environment to the comfort temperature and its net walkable area. It directly determines the building energy class. The smaller, the better.

- EPgl,ren is the “renewable energy performance index”, same as the previous index but applying only to energy produced from renewable sources. The higher, the better.

- CO2 emiss is a measure of the building impact on the environment in terms of estimated carbon dioxide (CO2) emissions per year. The lower the value, the less the impact.

- Energy efficiency rating is a score, ranging from G to A4, directly deriving from the “non-renewable energy performance index” (EPgl,nren) by comparing the latter to a predefined scale, in which each step is an energy performance level. The efficiency class scale is based on the value of the “non-renewable energy performance index” of a reference building (EPgl,nren,standard), corresponding to the threshold between classes A1 and B. All other performance levels are obtained by multiplying the asset value (EPgl,nren,standard) by reduction (classes from B to G) or increase (classes from A1 to A4) coefficients.

4. Results and Discussion

) indicates that the test gave positive results and the wall was verified against the applied condition. In particular, for the interstitial test, it means that the structure was not subject to interstitial condensation phenomena; for the mould test, it means that the structure was not subject to mould formation. However, in this second test, for both YES and NO outcomes, the software indicated the most critical month, which is also reported in Figure 4.

) indicates that the test gave positive results and the wall was verified against the applied condition. In particular, for the interstitial test, it means that the structure was not subject to interstitial condensation phenomena; for the mould test, it means that the structure was not subject to mould formation. However, in this second test, for both YES and NO outcomes, the software indicated the most critical month, which is also reported in Figure 4.5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Marino, A.; Pariso, P. Comparing European countries’ performances in the transition towards the Circular Economy. Sci. Total Environ. 2020. [Google Scholar] [CrossRef] [PubMed]

- Marino, A.; Pariso, P. E-Government and its Impact on National Economic Development: A Case Study Concerning Southern Italy International. In Proceedings of the 3rd International Conference on E-Commerce, E-Business and E-Government, ICEEG, Lyon, France, 18–21 June 2019. [Google Scholar]

- Chang, R.D.; Zuo, J.; Soebarto, V.; Zhao, Z.Y.; Zillante, G.; Gan, X.L. Discovering the transition pathways toward sustainability for construction enterprises: Importance-performance analysis. J. Constr. Eng. Manag. 2017, 143, 04017013. [Google Scholar] [CrossRef] [Green Version]

- Hsiao, T.Y.; Huang, Y.T.; Yu, Y.H.; Wernick, I.K. Modeling materials flow of waste concrete from construction and demolition wastes in Taiwan. Resour. Policy 2002, 28, 39–47. [Google Scholar] [CrossRef]

- Kim, S.; Vyas, R.; Bito, J.; Niotaki, K.; Collado, A.; Georgiadis, A.; Tentzeris, M.M. Ambient RF Energy-Harvesting Technologies for Self-Sustainable Standalone Wireless Sensor Platforms. Proc. IEEE 2014, 102, 1649–1666. [Google Scholar] [CrossRef]

- Tatari, O.; Kucukvar, M. Eco-efficiency of construction materials: Data envelopment analysis. J. Constr. Eng. Manag. 2011, 138, 733–741. [Google Scholar] [CrossRef]

- Muller, M.F.; Esmanioto, F.; Huber, N.; Loures, E.R.; Junior, O.C. A systematic literature review of interoperability in the green Building Information Modeling lifecycle. J. Clean. Prod. 2019, 223, 397–412. [Google Scholar] [CrossRef]

- Sinka, M.; Radina, L.; Sahmenko, G.; Korjakins, A.; Bajare, D. Enhancement of Lime-Hemp Concrete Properties Using Different Manufacturing Technologies. In Proceedings of the First International Conference on Bio-Based Building Materials, Clermont-Ferrand, France, 22–24 June 2015; pp. 1–8. [Google Scholar]

- Liobikienė, G.; Butkus, M. The European Union possibilities to achieve targets of Europe 2020 and Paris agreement climate policy. Renew. Energy 2017, 106, 298–309. [Google Scholar] [CrossRef]

- 10. European Parliament, Council of the European Union. Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the energy performance of buildings and Subsequent Amendments and Additions. Off. J. Eur. 2010, 3, 124–146.

- European Council (23 and 24 October 2014)—Conclusions, Energy and Climate Framework 2030. Available online: https://ec.europa.eu/clima/policies/strategies/2030_en#tab-00– (accessed on 10 February 2020).

- Adamczyk, J.; Dylewski, R. The impact of thermal insulation investments on sustainability in the construction sector. Renew. Sustain. Energy Rev. 2017, 80, 421–429. [Google Scholar] [CrossRef]

- Bevan, R.; Woolley, T. Hemp Lime Construction. A Guide to Building with Hemp Lime Composites; BRE Electronic Publications: Bracknell, UK, 2008. [Google Scholar]

- Martabid, J.E.; Mourgues, C. Criteria used for selecting envelope wall systems in Chilean residential projects. J. Constr. Eng. Manag. 2015, 141, 05015011. [Google Scholar] [CrossRef]

- Arroyo, P.; Tommelein, I.D.; Ballard, G. Selecting globally sustainable materials: A case study using choosing by advantages. J. Constr. Eng. Manag. 2015, 142, 05015015. [Google Scholar] [CrossRef]

- Energy Efficiency for EU Historic Districts Sustainability (EFFESUS). Available online: https://www.effesus.eu (accessed on 21 May 2020).

- Robust Internal Thermal Insulation of Historic Buildings (RiBuild). Available online: https://www.ribuild.eu (accessed on 21 May 2020).

- Lucchi, E.; Roberti, F.; Alexandra, T. Definition of an experimental procedure with the hot box method for the thermal performance evaluation of inhomogeneous walls. Energy Build. 2018, 179, 99–111. [Google Scholar] [CrossRef]

- Lucchi, E.; Becherini, F.; Di Tuccio, M.C.; Troi, A.; Frick, J.; Roberti, F.; Bernardi, A. Thermal performance evaluation and comfort assessment of advanced aerogel as blown-in insulation for historic buildings. Energy Build. 2017, 122, 258–268. [Google Scholar] [CrossRef]

- Lucchi, E.; Tabak, M.; Troi, A. The “cost optimality” approach for the internal insulation of historic buildings. Energy Procedia 2017, 133, 412–423. [Google Scholar] [CrossRef]

- Di Giuseppe, E.; D’Orazio, M.; Du, G.; Favi, C.; Lasvaux, S.; Maracchini, G.; Padey, P. A stochastic approach to LCA of internal insulation solutions for historic buildings. Sustainability 2020, 12, 1535. [Google Scholar] [CrossRef] [Green Version]

- Brostrom, T.; Bernardi, A.; Egusquiza, A.; Frick, J.; Kahn, M. A Method for Categorization of European Historic Districts and a Multiscale Data Model for the Assessment of Energy Interventions. 2013. Available online: https://www.effesus.eu/wp-content/uploads/2016/02/EWCHP-2013-Effesus-final.pdf (accessed on 18 May 2020).

- Bianco, L.; Serra, V.; Fantucci, S.; Dutto, M.; Massolino, M. Thermal insulating plaster as a solution for refurbishing historic building envelopes: First experimental results. Energy Build. 2015, 95, 86–91. [Google Scholar] [CrossRef]

- Walker, R.; Pavía, S. Thermal performance of a selection of insulation materials suitable for historic buildings. Build. Environ. 2015, 94, 155–165. [Google Scholar] [CrossRef]

- Moretti, E.; Belloni, E.; Agosti, F. Innovative mineral fiber insulation panels for buildings: Thermal and acoustic characterization. Appl. Energy 2016, 169, 421–432. [Google Scholar] [CrossRef]

- Pineda, P.; García-Martínez, A.; Castizo-Morales, D. Environmental and structural analysis of cement-based vs. natural material-based grouting mortars. Results from the assessment of strengthening works. Constr. Build. Mater. 2017, 138, 528–547. [Google Scholar] [CrossRef]

- Blumberga, A.; Kass, K.; Kamendere, E.; Žogla, G.; Kamenders, A.; Blumberga, D.; Grāvelsiņš, A.; Purviņš, R.; Rošā, M.; Timma, L.; et al. Robust Internal Thermal Insulation of Historic Buildings-State of the Art on Historic Building Insulation Materials and Retrofit Strategies; RiBuild Project; pp. 1–87. Available online: https://lirias.kuleuven.be/retrieve/550350 (accessed on 18 May 2020).

- Dario, B.-L.; Marco, L.; Daniel, H.-A.; Franziska, H.; Alexandra, T. Evaluation of natural-based internal insulation systems in historic buildings through a holistic approach. Energy 2019, 181, 521–531. [Google Scholar]

- Eriksson, P.; Hermann, C.; Hrabovszky-Horvath, S.; Rodwell, D. EFFESUS Methodology for Assessing the Impacts of Energy-Related Retrofit Measures on Heritage Significance. 2014. Available online: https://www.effesus.eu/dissemination/publications (accessed on 19 May 2020).

- Nowotna, A.; Pietruszka, B.; Lisowski, P. Eco-Friendly Building Materials. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 290, p. 012024. [Google Scholar]

- Stapulionienė, R.; Vaitkus, S.; Vėjelis, S.; Sankauskaitė, A. Investigation of thermal conductivity of natural fibres processed by different mechanical methods. Int. J. Precis. Eng. Manuf. 2016, 17, 1371–1381. [Google Scholar] [CrossRef]

- Yılmaz, M.; Bakış, A. Sustainability in construction sector. Procedia Soc. Behav. Sci. 2015, 195, 2253–2262. [Google Scholar] [CrossRef] [Green Version]

- Khodeir, L.M.; Othman, R. Examining the interaction between lean and sustainability principles in the management process of AEC industry. Ain Shams Eng. J. 2018, 9, 1627–1634. [Google Scholar] [CrossRef]

- Kidalova, L.; Stevulova, N.; Terpakova, E.; Helcman, M. Effective utilization of alternative materials in lightweight composites. Chem. Eng. Trans. 2011, 25, 1079–1084. [Google Scholar]

- Kidalova, L.; Stevulova, N.; Terpakova, E.; Sicakova, A. Utilization of alternative materials in lightweight composites. J. Clean. Prod. 2012, 34, 116–119. [Google Scholar] [CrossRef]

- Pergamo, R.; Briamonte, L.; Cerrato, D. The textile hemp chain: Value analysis, economic and environmental benefits. Calitatea 2018, 19, 375–378. [Google Scholar]

- European Commission. 2019. Available online: https://ec.europa.eu/info/news/new-rules-greener-and-smarter-buildings-will-increase-quality-life-all-europeans-2019-apr-15_en] (accessed on 18 May 2020).

- Amann, M.; Holland, M.; Maas, R.; Vandyck, T.; Saveyn, B. Costs, Benefits and Economic Impacts of the EU Clean Air Strategy and their Implications on Innovation and Competitiveness; IIASA Report; International Institute for Applied Systems Analysis (IIASA): Laxenburg, Austria, 2017. [Google Scholar]

- European Commission. 2017. Available online: https://ec.europa.eu/eurostat/news/themes-in-the-spotlight/household-expenditure-2017 (accessed on 18 May 2020).

- European Commission. 2016. Available online: https://ec.europa.eu/commission/presscorner/detail/en/MEMO_16_3986 (accessed on 18 May 2020).

- European Commission. 2016. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52016DC0860from=EN (accessed on 18 May 2020).

- Sassoni, E.; Manzi, S.; Motori, A.; Montecchi, M.; Canti, M. Novel sustainable hemp-based composites for application in the building industry: Physical, thermal and mechanical characterization. Energy Build. 2014, 77, 219–226. [Google Scholar] [CrossRef]

- Hussain, A.; Calabria-Holley, J.; Lawrence, M.; Ansell, M.P.; Jiang, Y.; Schorr, D.; Blanchet, P. Development of novel building composites based on hemp and multi-functional silica matrix. Compos. Part B Eng. 2019, 156, 266–273. [Google Scholar] [CrossRef]

- Costantine, G.; Maalouf, C.; Moussa, T.; Polidori, G. Experimental and numerical investigations of thermal performance of a Hemp Lime external building insulation. Build. Environ. 2018, 2018 131, 140–153. [Google Scholar] [CrossRef]

- Awwad, E.; Mabsout, M.; Hamad, B.; Farran, M.T.; Khatib, H. Studies on fiber-reinforced concrete using industrial hemp fibers. Constr. Build. Mater. 2012, 35, 710–717. [Google Scholar] [CrossRef]

- Jami, T.; Karade, S.; Singh, L.P. Hemp Concrete-A traditional and novel green building material. In Proceedings of the International Conference on Advances in Construction Materials and Structures, IIT Roorkee, Roorkee, Uttarakhand, India, 7–8 March 2018; p. 8. [Google Scholar]

- Walker, R.; Pavía, S. Thermal and moisture monitoring of an internally insulated historic brick wall. Build. Environ. 2018, 133, 178–186. [Google Scholar] [CrossRef]

- Maalouf, C.; Ingrao, C.; Scrucca, F.; Moussa, T.; Bourdot, A.; Tricase, C.; Asdrubali, F. An energy and carbon footprint assessment upon the usage of hemp-lime concrete and recycled-PET façades for office facilities in France and Italy. J. Clean. Prod. 2018, 170, 1640–1653. [Google Scholar] [CrossRef]

- Agliata, R.; Gianoglio, S.; Mollo, L. Hemp-lime composite for buildings insulation: Material properties and regulatory framework. Vitr. Int. J. Archit. Technol. Sustain. 2018, 4, 48–57. [Google Scholar] [CrossRef] [Green Version]

- Arrigoni, A.; Pelosato, R.; Melia, P.; Ruggieri, G.; Sabbadini, S.; Dotelli, G. Life cycle assessment of natural building materials: The role of carbonation, mixture components and transport in the environmental impacts of hempcrete blocks. J. Clean. Prod. 2017, 149, 1051–1061. [Google Scholar] [CrossRef]

- Busbridge, R.; Rhydwen, R. An investigation of the thermal properties of hemp and clay monolithic walls. In Proceedings of the Advances in Computing and Technology, (AC&T) The School of Computing and Technology 5th Annual Conference, London, UK, 14 September 2010. [Google Scholar]

- Cerezo, V. Propriétés mécaniques, thermiques et acoustiques d’un matériau à base de particules végétales: Approche éxpérimentale et modélisation théorique. Inst. Natl. Des Sci. Appliquées De Lyon 2005, 1, 229–234. [Google Scholar]

- Ronchetti, P. Il Cemento di Canapa e Calce: Un Promettente Materiale e Metodo di Costruzione per L’edilizia Sostenibile. 2007. Available online: http://www.canapa-info.ch/info/pt/IMG/pdf/Cemento_di_canapa_e_calce_-_promettente_materiale_e_metodo_di_costruzione_per_l_edilizia_sostenibile.pdf (accessed on 15 May 2020).

- Walker, R.; Pavía, S. Moisture transfer and thermal properties of hemp–lime concretes. Constr. Build. Mater. 2014, 64, 270–276. [Google Scholar] [CrossRef]

- Campolongo, G.; Chiaravallotti, R.; Pinoni, M. La Svalutazione Dell’immobile per Difetto dei Requisiti Acustici; Maggioli Ed.: Rimini, Italy, 2011. [Google Scholar]

- Building Research Establishment. Fire Resistance Test in accordance with BS EN 1365-1:1999 on a Lime Technology 3 × 3 m Tradical-Hemcrete Loaded Wall; Test Report 250990; Environmental Protection Agency: Wexford, Ireland, 2009. [Google Scholar]

- Murphy, F.; Pavia, S. and Walker, R. An Assessment of the Physical Properties of Lime-Hemp Concrete. In Proceeding of the Bridge and Concrete Research in Ireland, Dublin, Ireland, 6–7 September 2012. [Google Scholar]

- Benfratello, S.; Capitano, C.; Peri, G.; Rizzo, G.; Scaccianoce, G.; Sorrentino, G. Thermal and structural properties of a hemp–lime biocomposite. Constr. Build. Mater. 2013, 48, 745–754. [Google Scholar] [CrossRef]

- Daly, P.; Ronchetti, P.; Woolley, T. Hemp Lime Bio-Composite as a Building Material Irish Construction; Environmental Protection Agency: Wexford, Ireland, 2012. [Google Scholar]

- Bouloc, P.; Allegret, S.; Arnaud, L. Hemp: Industrial Production and Uses; CABI: Wallingford, UK, 2013. [Google Scholar]

- Carus, M.; Sarmento, L. The European Hemp Industry: Cultivation, Processing and Applications for Fibres, Shivs, Seeds and Flowers; European Industrial Hemp Association (EIHA): Huerth, Germany, 2017; pp. 1–9. [Google Scholar]

- Sacilik, K.; Öztürk, R.; Keskin, R. Some physical properties of hemp seed. Biosyst. Eng. 2003, 86, 191–198. [Google Scholar] [CrossRef]

- Fortenbery, T.R.; Bennett, M. Opportunities for commercial hemp production. Rev. Agric. Econ. 2004, 26, 97–117. [Google Scholar] [CrossRef]

- Forlani, M.C.; Radogna, D.; Mastrolonardo, L. Hemp for a healthy and sustainable building in Abruzzo. In Intelligent Human System Integration, Proceedings of the 1st international Conference IHSINT, Dubai, UAE, 7–9 January 2018; Springer: Dubai, UAE, 2018. [Google Scholar]

- Smith, B.C. Hemp Testing Insanity. Cannabis Sci. Technol. 2019, 2, 10–13. [Google Scholar]

- Posani, M.; Veiga, M.D.R.; de Freitas, V.P. Towards Resilience and Sustainability for Historic Buildings: A Review of Envelope Retrofit Possibilities and a Discussion on Hygric Compatibility of Thermal Insulations. Int. J. Archit. Herit. 2019, 1–17. [Google Scholar] [CrossRef]

- Strandberg-de Bruijn, P.; Donarelli, A.; Balksten, K. Full-scale Studies of Improving Energy Performance by Renovating Historic Swedish Timber Buildings with Hemp-lime. Appl. Sci. 2019, 9, 2484. [Google Scholar] [CrossRef] [Green Version]

- Available online: http://agricoltura.regione.campania.it/canapa/canapa.html (accessed on 18 May 2020).

- Mazhoud, B.; Collet, F.; Pretot, S.; Chamoin, J. Hygric and thermal properties of hemp-lime plasters. Build. Environ. 2016, 96, 206–216. [Google Scholar] [CrossRef]

- Italian Ministry of Economic Development. Decreto interministeriale 26 giugno 2015 “Applicazione delle metodologie di calcolo delle prestazioni energetiche e definizione delle prescrizioni e dei requisiti minimi degli edifici”, ai sensi dell’articolo articolo 4, comma 1, del decreto legislativo 19 agosto 2005, n. 192, con relativi allegati 1 (e rispettive appendici A e B) e 2; Italian Ministry of Economic Development: Rome, Italy, 2005. [Google Scholar]

- European Committee for Standardization. Hygrothermal Performance of Building Components and Building Elements–Internal Surface Temperature to Avoid Critical Surface Humidity and Interstitial Condensation–Calculation Methods; EN ISO 13788: 2012; European Committee for Standardization: Bruxelles, Belgium, 2012. [Google Scholar]

- Claude, S.; Ginestet, S.; Bonhomme, M.; Escadeillas, G.; Taylor, J.; Marincioni, V.; Altamirano, H. Evaluating retrofit options in a historical city center: Relevance of bio-based insulation and the need to consider complex urban form in decision-making. Energy Build. 2019, 182, 196–204. [Google Scholar] [CrossRef] [Green Version]

| Challenges | Primary Role of the AEC Sector | Sustainable AEC Sector Objectives |

|---|---|---|

| 1. Savings in the supply of power |

| Supply of raw materials:

|

| 2. Mitigation of climatic change |

| Use of resources:

|

| 3. Waste management and protection of resources |

| Dismantling, demolition in situ, recovery, disposal and transport:

|

| 4. Health and wellness economic growth |

| Improve workers’ health and safety on construction sites:

|

| 5. Financial resources availability |

| End-of-life costs:

|

| Technical | Commercial | Knowledge | Regulatory | Psychological | Invisible |

|---|---|---|---|---|---|

|

|

|

|

|

|

| Material | Thermal Conductivity λ [W/mK] | Surface Mass Density * s.m.d. [kg/m2] | Steam Permeab. (RH ≤ 50%) P [kg/msPa] | Specific Heat Cap. c [J/kgK] |

|---|---|---|---|---|

| Yellow Neapolitan Tuff | 1.70 | 23 | 0.02 | 1380 |

| Hollow bricks | 0.25 | 6 | 36.00 | 840 |

| Gypsum lime plaster | 0.70 | 14 | 18.00 | 1000 |

| Hemp-lime plaster | 0.12 | 5 | 43.00 | 1200 |

| Layout A1 | Layout A2 | Layout A3 | ||||||

| Layer no | Material | Thickness [mm] | Layer no | Material | Thickness [mm] | Layer no | Material | Thickness [mm] |

| 1 | GL-P | 20 | 1 | GL-P | 20 | 1 | GL-P | 20 |

| 2 | YNT | 660 | 2 | YNT | 660 | 2 | YNT | 560 |

| 3 | GL-P | 20 | 3 | GL-P | 20 | 3 | GL-P | 20 |

| Total | 700 | Total | 700 | Total | 600 | |||

| envelope | partition | envelope | ||||||

| Layout A4 | Layout A5 | Layout A6 | ||||||

| 1 | GL-P | 20 | 1 | GL-P | 20 | 1 | GL-P | 20 |

| 2 | YNT | 560 | 2 | YNT | 510 | 2 | YNT | 460 |

| 3 | GL-P | 20 | 3 | GL-P | 20 | 3 | GL-P | 20 |

| Total | 600 | Total | 550 | Total | 500 | |||

| partition | partition | envelope | ||||||

| Layout A7 | Layout A8 | Layout A9 | ||||||

| 1 | GL-P | 20 | 1 | GL-P | 20 | 1 | GL-P | 10 |

| 2 | YNT | 460 | 2 | YNT | 360 | 2 | HB | 80 |

| 3 | GL-P | 20 | 3 | GL-P | 20 | 3 | GL-P | 10 |

| Total | 500 | Total | 400 | Total | 100 | |||

| partition | partition | envelope | ||||||

| Layout B1 | Layout B2 | Layout B3 | ||||||

| Layer no | Material | Thickness [mm] | Layer no | Material | Thickness [mm] | Layer no | Material | Thickness [mm] |

| 1 | HL-P | 50 | 1 | HL-P | 50 | 1 | HL-P | 50 |

| 2 | YNT | 660 | 2 | YNT | 660 | 2 | YNT | 560 |

| 3 | HL-P | 70 | 3 | HL-P | 70 | 3 | HL-P | 70 |

| Total | 780 | Total | 780 | Total | 680 | |||

| envelope | partition | envelope | ||||||

| Layout B4 | Layout B5 | Layout B6 | ||||||

| 1 | HL-P | 50 | 1 | HL-P | 50 | 1 | HL-P | 50 |

| 2 | YNT | 560 | 2 | YNT | 510 | 2 | YNT | 460 |

| 3 | HL-P | 70 | 3 | HL-P | 70 | 3 | HL-P | 70 |

| Total | 680 | Total | 630 | Total | 580 | |||

| partition | partition | envelope | ||||||

| Layout B7 | Layout B8 | Layout B9 | ||||||

| 1 | HL-P | 50 | 1 | HL-P | 50 | 1 | HL-P | 40 |

| 2 | YNT | 460 | 2 | YNT | 360 | 2 | HB | 80 |

| 3 | HL-P | 70 | 3 | HL-P | 70 | 3 | HL-P | 40 |

| Total | 580 | Total | 480 | Total | 160 | |||

| partition | partition | envelope | ||||||

| Parameter | Legislation | Reference Value | ||

|---|---|---|---|---|

| Thermal admittance | U | [W/m2K] | D.M. 26.06.2015 | U < 0.36 W/m2K—climate zone C (a warm Italian zone)—refurbishment interventions |

| Dynamic thermal admittance | Yie | [W/m2K] | D.M. 26.06.2015 | Ymn < 0.10 W/m2K (vertical and inclined walls, excluding those facing north) |

| Attenuation coefficient | Fa | |Yie|/U | D.M. 26.06.2009 | Fa > 0.60 inadequate Fa < 0.15 excellent |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Agliata, R.; Marino, A.; Mollo, L.; Pariso, P. Historic Building Energy Audit and Retrofit Simulation with Hemp-Lime Plaster—A Case Study. Sustainability 2020, 12, 4620. https://doi.org/10.3390/su12114620

Agliata R, Marino A, Mollo L, Pariso P. Historic Building Energy Audit and Retrofit Simulation with Hemp-Lime Plaster—A Case Study. Sustainability. 2020; 12(11):4620. https://doi.org/10.3390/su12114620

Chicago/Turabian StyleAgliata, Rosa, Alfonso Marino, Luigi Mollo, and Paolo Pariso. 2020. "Historic Building Energy Audit and Retrofit Simulation with Hemp-Lime Plaster—A Case Study" Sustainability 12, no. 11: 4620. https://doi.org/10.3390/su12114620

APA StyleAgliata, R., Marino, A., Mollo, L., & Pariso, P. (2020). Historic Building Energy Audit and Retrofit Simulation with Hemp-Lime Plaster—A Case Study. Sustainability, 12(11), 4620. https://doi.org/10.3390/su12114620