A Multi-Criteria Evaluation Method of Product-Level Circularity Strategies

Abstract

1. Introduction

- RQ: How to evaluate circularity strategies for a product and/or service using a decision method to help a company select a suitable strategy at EoL stage?

- What are the relevant criteria and sub-criteria/indicators to be used to evaluate circularity strategies?

- How to evaluate circularity strategies using a decision-making method that incorporates the criteria and sub-criteria/indicators?

2. Literature Review

2.1. The Circular Economy and Product Circularity Strategies

- repair aims to recover a used product to “working order” by fixing/replacing specified faults using service and spare parts [41];

- refurbish involves returning products to a specific quality level, usually less than that of a new product [42];

- recondition involves returning the quality of a product to a satisfactory level (typically less than a virgin standard or new product) giving the resultant product a warranty less than that of a newly manufactured equivalent [41,43]. Reconditioned products have gone through more extensive testing and repair than refurbished products [42];

- cannibalization is an activity of recovering parts from returned products. Recovered parts are used in repair, refurbishing, reconditioning, and remanufacturing of other products [49]; and

2.2. Circularity Strategies’ Evaluation Methods

2.3. Multi-Criteria Evaluation Methods of Circularity Strategies

3. Materials and Methods

3.1. Initial Method Selection

3.2. Selection of Decision Criteria, Sub-Criteria and Indicators

3.3. Method Development

3.4. Verification of the Method

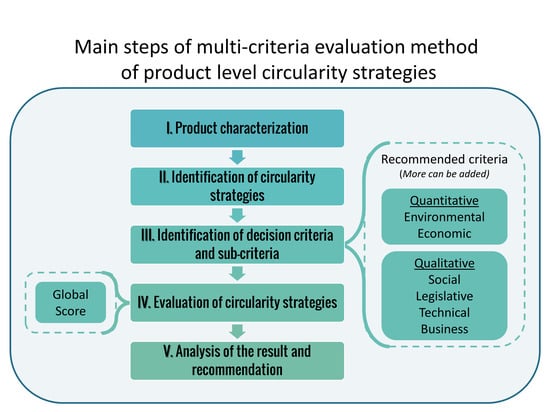

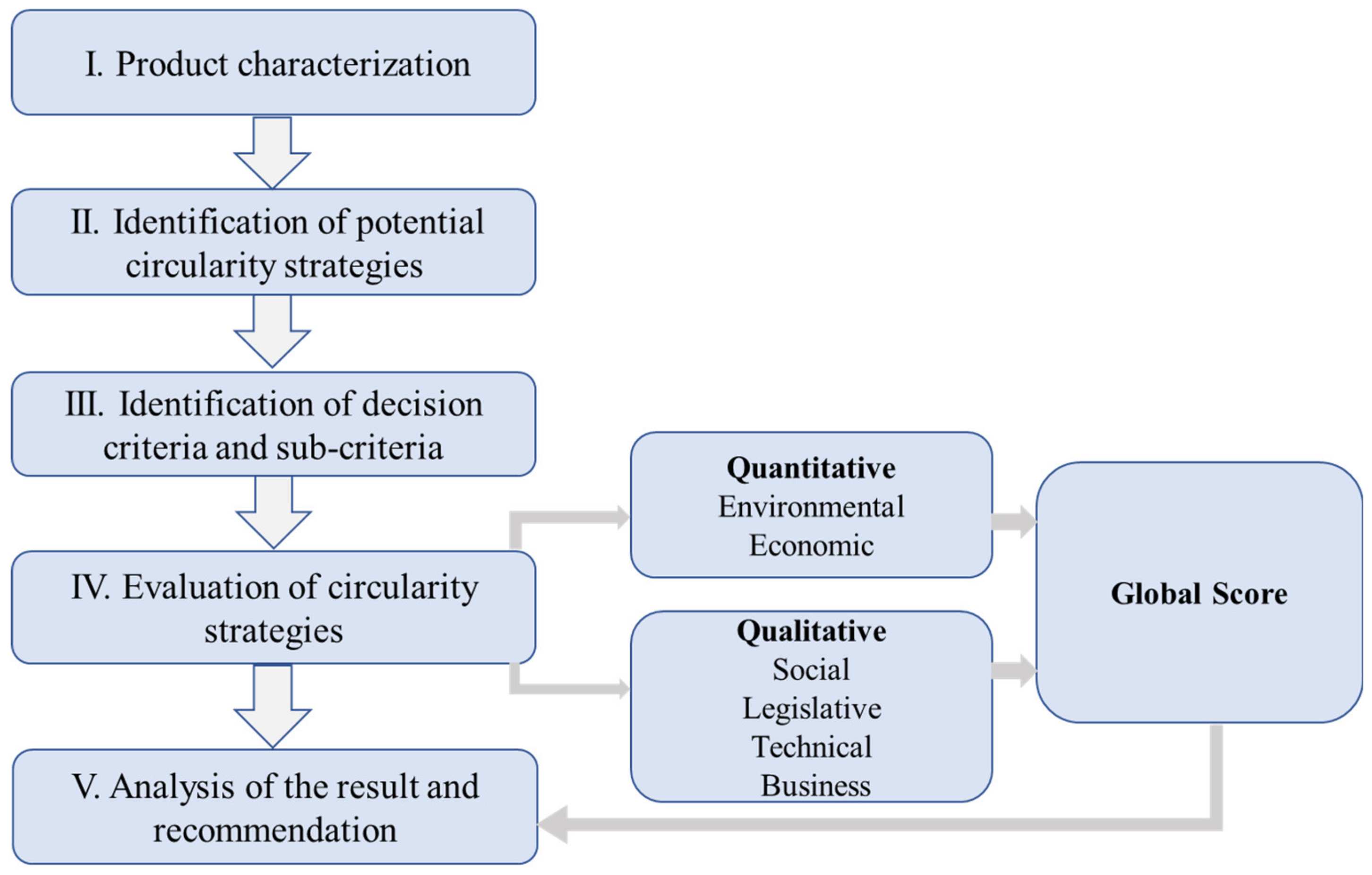

4. Multi-Criteria Evaluation Method of Product-Level Circularity Strategies Description

4.1. Product Characterization

4.2. Identification of Circularity Strategies

4.3. Identification of Decision Criteria, Sub-Criteria and Indicators

4.4. Evaluation of Circularity Strategies

- Wj is the weighted value of j of m criteria

- Xi(j) is the value of i of criterion j

- M(Ai) is total evaluation result for each strategy.

- Xij is the assigned value of Ai for the sub-criteria Cjk

- Xij max; Xij min are the maximum and minimum assigned value Ai for the sub-criteria Cj respectively.

- Wj is the weighted value of j of m criteria

- Xi(j) is the value of i of criterion j

- M(Ai) is total evaluation result for each strategy.

4.5. Analysis of the Result and Recommendation

5. Verification of the Multi-Criteria Evaluation Method of Product-Level Circularity Strategies

5.1. Case Study for Company A

5.2. Case Study for Company B

6. Discussion and Conclusions

6.1. Discussion

- It guides the decision-makers through the whole process of identifying and evaluating various potential circularity strategies against each other and business-as-usual.

- It helps companies identify potential circular offerings and strategies.

- It suggests a list of criteria and sub-criteria/indicators which are relevant for evaluating circular strategies, but also allows for flexibility so that the decision-maker can modify these criteria and provides insights on how to approach such modifications.

- It can be used to evaluate and compare a large number of circular strategies.

- It is a flexible method that can easily be scaled up or down to meet the needs of the decision-makers.

6.2. Conclusions and Future Research

Author Contributions

Funding

Conflicts of Interest

References

- Niskanen, J.; Anshelm, J.; McLaren, D. Local conflicts and national consensus: The strange case of circular economy in Sweden. J. Clean. Prod. 2020, 261, 121117. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Rosa, P.; Sassanelli, C.; Urbinati, A.; Chiaroni, D.; Terzi, S. Assessing relations between Circular Economy and Industry 4.0: A systematic literature review. Int. J. Prod. Res. 2020, 58, 1662–1687. [Google Scholar] [CrossRef]

- Fellner, J.; Lederer, J.; Scharff, C.; Laner, D. Present potentials and limitations of a circular economy with respect to primary raw material demand. J. Ind. Ecol. 2017, 21, 494–496. [Google Scholar] [CrossRef]

- EMF. Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition; EMF: Cowes, UK, 2013. [Google Scholar]

- Gitelman, L.; Magaril, E.; Kozhevnikov, M.; Rada, E.C. Rational behavior of an enterprise in the energy market in a circular economy. Resources 2019, 8, 73. [Google Scholar] [CrossRef]

- Webster, K. The Circular Economy: A Wealth of Flows; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Bocken, N.M.P.; Olivetti, E.A.; Cullen, J.M.; Potting, J.; Lifset, R. Taking the Circularity to the Next Level: A Special Issue on the Circular Economy. J. Ind. Ecol. 2017, 21, 476–482. [Google Scholar] [CrossRef]

- Elia, V.; Gnoni, M.G.; Tornese, F. Measuring circular economy strategies through index methods: A critical analysis. J. Clean. Prod. 2017, 142, 2741–2751. [Google Scholar] [CrossRef]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F.; Kendall, A. A taxonomy of circular economy indicators. J. Clean. Prod. 2019, 207, 542–559. [Google Scholar] [CrossRef]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the circular economy: Evidence from the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef]

- Rizos, V.; Behrens, A.; van der Gaast, W.; Hofman, E.; Ioannou, A.; Kafyeke, T.; Flamos, A.; Rinaldi, R.; Papadelis, S.; Hirschnitz-Garbers, M.; et al. Implementation of circular economy business models by small and medium-sized enterprises (SMEs): Barriers and enablers. Sustainability 2016, 8, 1212. [Google Scholar] [CrossRef]

- Kristensen, H.S.; Mosgaard, M.A. A review of micro level indicators for a circular economy—Moving away from the three dimensions of sustainability? J. Clean. Prod. 2020, 243, 118531. [Google Scholar] [CrossRef]

- Bianchini, A.; Rossi, J.; Pellegrini, M. Overcoming the main barriers of circular economy implementation through a new visualization tool for circular business models. Sustainability 2019, 11, 6614. [Google Scholar] [CrossRef]

- Geng, Y.; Fu, J.; Sarkis, J.; Xue, B. Towards a national circular economy indicator system in China: An evaluation and critical analysis. J. Clean. Prod. 2012, 23, 216–224. [Google Scholar] [CrossRef]

- Linder, M.; Sarasini, S.; Loon, P. Van A metric for quantifying product-level circularity. J. Ind. Ecol. 2017, 21, 545–558. [Google Scholar] [CrossRef]

- Cayzer, S.; Griffiths, P.; Beghetto, V. Design of indicators for measuring product performance in the circular economy. Int. J. Sustain. Eng. 2017, 7038, 289–298. [Google Scholar] [CrossRef]

- Huysman, S.; Schaepmeester, J.D.; Ragaert, K.; Dewulf, J.; Meester, S. De Resources, conservation and recycling performance indicators for a circular economy: A case study on post-industrial plastic waste. Resour. Conserv. Recycl. 2017, 120, 46–54. [Google Scholar] [CrossRef]

- Parchomenko, A.; Nelen, D.; Gillabel, J.; Rechberger, H. Measuring the circular economy—A multiple correspondence analysis. J. Clean. Prod. 2019, 210, 200–216. [Google Scholar] [CrossRef]

- Sassanelli, C.; Rosa, P.; Rocca, R.; Terzi, S. Circular economy performance assessment methods: A systematic literature review. J. Clean. Prod. 2019, 229, 440–453. [Google Scholar] [CrossRef]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F. How to assess product performance in the circular economy? Proposed requirements for the design of a circularity measurement framework. Recycling 2017, 2, 6. [Google Scholar] [CrossRef]

- Lindfors, A.; Feiz, R.; Eklund, M.; Ammenberg, J. Assessing the potential, performance and feasibility of urban solutions: Methodological considerations and learnings from biogas solutions. Sustainability 2019, 11, 3756. [Google Scholar] [CrossRef]

- Ali, M.; Kennedy, C.M.; Kiesecker, J.; Geng, Y. Integrating biodiversity offsets within circular economy policy in China. J. Clean. Prod. 2018, 185, 32–43. [Google Scholar] [CrossRef]

- Pesce, M.; Tamai, I.; Guo, D.; Critto, A.; Brombal, D.; Wang, X.; Cheng, H.; Marcomini, A. Circular Economy in China: Translating Principles into Practice. Sustainability 2020, 12, 832. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation and Granta Design. An Approach to Measuring Circularity; Ellen MacArthur Foundation and Granta Design: Cowes, UK, 2015. [Google Scholar]

- Stahel, W.R. The circular economy. Nature 2016, 531, 435–438. [Google Scholar] [CrossRef]

- Bakker, C.; den Hollander, M.; Van Hinte, E.; Zljlstra, Y. Products That Last: Product Design for Circular Business Models; TU Delft Library: Delft, The Netherlands, 2014. [Google Scholar]

- Niu, S.; Zhuo, H.; Xue, K. DfRem-Driven closed-loop supply chain decision-making: A systematic framework for modeling research. Sustainability 2019, 11, 3299. [Google Scholar] [CrossRef]

- Hopkinson, P.; De Angelis, R.; Zils, M. Systemic building blocks for creating and capturing value from circular economy. Resour. Conserv. Recycl. 2020, 155, 104672. [Google Scholar] [CrossRef]

- Levänen, J.; Lyytinen, T.; Gatica, S. Modelling the Interplay Between Institutions and Circular Economy Business Models: A Case Study of Battery Recycling in Finland and Chile. Ecol. Econ. 2018, 154, 373–382. [Google Scholar] [CrossRef]

- Alamerew, Y.A.; Brissaud, D. Modelling reverse supply chain through system dynamics for realizing the transition towards the circular economy: A case study on electric vehicle batteries. J. Clean. Prod. 2020, 254, 120025. [Google Scholar] [CrossRef]

- Sangwan, K.S. Key activities, decision variables and performance indicators of reverse logistics. Procedia CIRP 2017, 61, 257–262. [Google Scholar] [CrossRef]

- Julianelli, V.; Caiado, R.G.G.; Scavarda, L.F.; Cruz, S.P.D.M.F. Interplay between reverse logistics and circular economy: Critical success factors-based taxonomy and framework. Resour. Conserv. Recycl. 2020, 158, 104784. [Google Scholar] [CrossRef]

- Korhonen, J.; Nuur, C.; Feldmann, A.; Seyoum Eshetu, B. Circular economy as an essentially contested concept. J. Clean. Prod. 2018, 175, 544–552. [Google Scholar] [CrossRef]

- Di Maio, F.; Rem, P.C. A Robust Indicator for Promoting Circular Economy through Recycling. J. Environ. Prot. 2015, 06, 1095–1104. [Google Scholar] [CrossRef]

- Brissaud, D.; Zwolinski, P. The Scientific Challenges for a Sustainable Consumption and Production Scenario: The Circular Reuse of Materials for the Upgrading and Repurposing of Components. Procedia CIRP 2017, 61, 663–666. [Google Scholar] [CrossRef]

- Richa, K.; Babbitt, C.W.; Gaustad, G.; Wang, X. A future perspective on lithium-ion battery waste flows from electric vehicles. Resour. Conserv. Recycl. 2014, 83, 63–76. [Google Scholar] [CrossRef]

- Burke, A. Performance, Charging, and Second-Use Considerations for Lithium Batteries for Plug-In Electric Vehicles; UC Davis Institute of Transportation Studies: Davis, CA, USA, 2009. [Google Scholar]

- Winslow, K.M.; Laux, S.J.; Townsend, T.G. A review on the growing concern and potential management strategies of waste lithium-ion batteries. Resour. Conserv. Recycl. 2018, 129, 263–277. [Google Scholar] [CrossRef]

- King, A.M.; Burgess, S.C.; Ijomah, W.; McMahon, C.A. Reducing waste: Repair, recondition, remanufacture or recycle? Sustain. Dev. 2006, 14, 257–267. [Google Scholar] [CrossRef]

- Krikke, H.R. Recovery Strategies and Reverse Logistic Network Design. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 1998. [Google Scholar]

- Paterson, D.A.P.; Ijomah, W.L.; Windmill, J.F.C. End-of-Life decision tool with emphasis on remanufacturing. J. Clean. Prod. 2017, 148, 653–664. [Google Scholar] [CrossRef]

- Ijomah, W.L. A Model-Based Definition of The Generic Remanufacturing Business Process; University of Plymouth: Plymouth, UK, 2002. [Google Scholar]

- Rose, C.M. Design for Environment: A Method for Formulating End-of-Life Strategies. Ph.D. Thesis, Stanford University, Stanford, CA, USA, 2000. [Google Scholar]

- Sundin, E. Product and Process Design for Successful Remanufacturing. Ph.D. Thesis, Linköping University, Linköping, Sweden, 2004. [Google Scholar]

- Bauer, T.; Brissaud, D.; Zwolinski, P. Design for High Added-Value End-of-Life Strategies. In Sustainable Manufacturing; Springer: Cham, Switzerland, 2017; ISBN 978-3-319-48513-3. [Google Scholar]

- Kurt, A.; Cung, V.; Mangione, F.; Cortes-Cornax, M.; Front, A. An extended circular supply chain model including repurposing activities. In Proceedings of the International Conference on Control, Automation and Diagnosis (ICCAD), Grenoble, France, 2–4 July 2019; pp. 1–6. [Google Scholar]

- Alamerew, Y.A.; Brissaud, D. Circular economy assessment tool for end of life product recovery strategies. J. Remanuf. 2018, 9, 169–185. [Google Scholar] [CrossRef]

- Jawahir, I.S.; Bradley, R. Technological elements of circular economy and the principles of 6R-based closed-loop material flow in sustainable manufacturing. Procedia Cirp 2016, 40, 103–108. [Google Scholar] [CrossRef]

- Widmer, T.; Tjahjono, B.; Bourlakis, M. Defining value creation in the context of circular PSS. Procedia CIRP 2018, 73, 142–147. [Google Scholar] [CrossRef]

- Kumar, V.; Shirodkar, P.S.; Camelio, J.A.; Sutherland, J.W. Value flow characterization during product lifecycle to assist in recovery decisions. Int. J. Prod. Res. 2007, 45, 18–19. [Google Scholar] [CrossRef]

- Thierry, M.; Salomon, M.; Vannunen, J.; Vanwassenhove, L. Strategic Issues in Product Recovery Management. Calif. Manag. Rev. 1995, 37, 114–135. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Kambanou, M.L.; Sakao, T. Using life cycle costing (LCC) to select circular measures: A discussion and practical approach. Resour. Conserv. Recycl. 2020, 155, 104650. [Google Scholar] [CrossRef]

- Mont, O.; Plepys, A.; Whalen, K.; Nußholz, J.L. Business Model Innovation For a Circular Economy: Drivers and Barriers for the Swedish Industry–the Voice of REES Companies; Lund University Publications: Lund, Sweden, 2017. [Google Scholar]

- Babbitt, C.W.; Gaustad, G.; Fisher, A.; Chen, W.-Q.; Liu, G. Closing the loop on circular economy research: From theory to practice and back again. Resour. Conserv. Recycl. 2018, 135, 1–2. [Google Scholar] [CrossRef]

- Pauliuk, S. Critical appraisal of the circular economy standard BS 8001:2017 and a dashboard of quantitative system indicators for its implementation in organizations. Resour. Conserv. Recycl. 2018, 129, 81–92. [Google Scholar] [CrossRef]

- Blomsma, F.; Pieroni, M.; Kravchenko, M.; Pigosso, D.C.A.; Hildenbrand, J.; Kristinsdottir, A.R.; Kristoffersen, E.; Shahbazi, S.; Nielsen, K.D.; Jönbrink, A.-K.; et al. Developing a circular strategies framework for manufacturing companies to support circular economy-oriented innovation. J. Clean. Prod. 2019, 241, 118271. [Google Scholar] [CrossRef]

- Saidani, M.; Yannou, B.; Leoroy, Y.; Cluzel, F. Hybrid top-down and bottom-up framework to measure products’ circularity performance. In Proceedings of the 21st International conference on engineering design, ICED17, Vancover, BC, Canada, 21–25 August, 2017; Volume 1, pp. 81–90. [Google Scholar]

- Doyle, K.; Ijomah, W.L.; Antony, J. Identifying the End of Life Decision Making Factors. In Design for Innovative Value Towards a Sustainable Society; Springer: Dordrecht, The Netherlands, 2012; pp. 530–534. [Google Scholar] [CrossRef]

- Dunmade, I. PLETS model: A sustainability concept based approach to product end-of-life management. In Proceedings of the Environmentally Conscious Manufacturing IV; Surendra, M.G., Ed.; International Society for Optics and Photonics: Bellingham, WA, USA, 2004; Volume 5583, pp. 118–126. [Google Scholar]

- Shih, L.H.; Chang, Y.S.; Lin, Y.T. Intelligent evaluation approach for electronic product recycling via case-based reasoning. Adv. Eng. Informatics 2006, 20, 137–145. [Google Scholar] [CrossRef]

- Selmi, M.; Kormi, T.; Bel Hadj Ali, N. Comparison of multi-criteria decision methods through a ranking stability index. Int. J. Oper. Res. 2016, 27, 165. [Google Scholar] [CrossRef]

- Velasquez, M.; Hester, P.T. An analysis of multi-criteria decision making methods. Int. J. Oper. Res. 2013, 10, 56–66. [Google Scholar]

- ResCoM Resource Conservative Manufacturing Project. Available online: https://rescomd58.eurostep.com/idealco/pathfinder/ (accessed on 5 March 2020).

- Lee, H.M.; Lu, W.F.; Song, B. A framework for assessing product end-of-life performance: Reviewing the state of the art and proposing an innovative approach using an end-of-life index. J. Clean. Prod. 2014, 66, 355–371. [Google Scholar] [CrossRef]

- Evans, J.; Bocken, N.M.P. Circular Economy Toolkit. Available online: http://circulareconomytoolkit.org/index.html (accessed on 16 July 2019).

- Iakovou, E.; Moussiopoulos, N.; Xanthopoulos, A.; Achillas, C.; Michailidis, N.; Chatzipanagioti, M.; Koroneos, C.; Bouzakis, K.D.; Kikis, V. A methodological framework for end-of-life management of electronic products. Resour. Conserv. Recycl. 2009, 53, 329–339. [Google Scholar] [CrossRef]

- Mardani, A.; Jusoh, A.; Nor, K.M.D.; Khalifah, Z.; Zakwan, N.; Valipour, A. Multiple criteria decision-making techniques and their applications—A review of the literature from 2000 to 2014. Econ. Res. Istraz. 2015, 28, 516–571. [Google Scholar] [CrossRef]

- Macoun, P.; Prabhu, R. Guidelines for Applying Multi-Criteria Analysis to The Assessment of Criteria and Indicators; CIFOR: Bogor, Indonesia, 1999. [Google Scholar]

- Feiz, R.; Ammenberg, J. Assessment of feedstocks for biogas production, part I—A multi-criteria approach. Resour. Conserv. Recycl. 2017, 122, 373–387. [Google Scholar] [CrossRef]

- Dijk, M.; de Kraker, J.; van Zeijl-Rozema, A.; van Lente, H.; Beumer, C.; Beemsterboer, S.; Valkering, P. Sustainability assessment as problem structuring: Three typical ways. Sustain. Sci. 2017, 12, 305–317. [Google Scholar] [CrossRef]

- Siregar, D.; Arisandi, D.; Usman, A.; Irwan, D.; Rahim, R. Research of Simple Multi-Attribute Rating Technique for Decision Support. J. Phys. Conf. Ser. 2017, 930. [Google Scholar] [CrossRef]

- Risawandi, R.R. Study of the Simple Multi-Attribute Rating Technique For Decision Support. IJSRST 2016, 2, 491–494. [Google Scholar]

- Taylor, J.M.; Love, B.N. Simple multi-attribute rating technique for renewable energy deployment decisions (SMART REDD). J. Def. Model. Simul. Appl. Methodol. Technol. 2014, 11, 227–232. [Google Scholar] [CrossRef]

- Böckin, D.; Willskytt, S.; André, H.; Tillman, A.-M.; Ljunggren Söderman, M. How product characteristics can guide measures for resource efficiency—A synthesis of assessment studies. Resour. Conserv. Recycl. 2020, 154, 104582. [Google Scholar] [CrossRef]

- Roy, B. Multicriteria Methodology for Decision Aiding; Springer Science & Business Media: Berlin/Heideberg, Germany, 1996. [Google Scholar]

- Bocken, N.; Strupeit, L.; Whalen, K.; Nußholz, J. A review and evaluation of circular business model innovation tools. Sustainability 2019, 11, 2210. [Google Scholar] [CrossRef]

- Finnveden, G.; Moberg, Å. Environmental systems analysis tools—An overview. J. Clean. Prod. 2005, 13, 1165–1173. [Google Scholar] [CrossRef]

- Kaddoura, M.; Kambanou, M.L.; Tillman, A.-M.; Sakao, T. Is prolonging the lifetime of passive durable products a low-hanging fruit of a circular economy? A multiple case study. Sustainability 2019, 11, 4819. [Google Scholar] [CrossRef]

- Martínez-Blanco, J.; Lehmann, A.; Muñoz, P.; Antón, A.; Traverso, M.; Rieradevall, J.; Finkbeiner, M. Application challenges for the social Life Cycle Assessment of fertilizers within life cycle sustainability assessment. J. Clean. Prod. 2014, 69, 34–48. [Google Scholar] [CrossRef]

- Ishizaka, A.; Labib, A. Analytic hierarchy process and expert choice: Benefits and limitations. OR Insight 2009, 22, 201–220. [Google Scholar] [CrossRef]

- Munshi, J. A method for constructing likert scales. SSRN Electron. J. 2014. [Google Scholar] [CrossRef]

- Nemoto, T.; Beglar, D. Developing likert-scale questionnaires. In Proceedings of the JALT Conference Proceedings, Tokyo, Japan, 25–28 October 2014; pp. 1–8. [Google Scholar]

- Kjaer, L.L.; Pigosso, D.C.A.; Niero, M.; Bech, N.M.; McAloone, T.C. Product/Service-Systems for a Circular Economy: The Route to Decoupling Economic Growth from Resource Consumption? J. Ind. Ecol. 2019, 23, 22–35. [Google Scholar] [CrossRef]

- Matschewsky, J. Unintended circularity?-Assessing a product-service system for its potential contribution to a circular economy. Sustainability 2019, 11, 2725. [Google Scholar] [CrossRef]

| Method | Description |

|---|---|

| Circular pathfinder (CP) | A web-based tool to identify a suitable strategy based on a survey of 10 product-related qualitative questions [66]. |

| End-of-life index (EoLI) | An EoL process cost-based index to evaluate circularity strategies including remanufacturing, recycling etc. [67]. |

| Product recovery multi-criteria decision tool (PR-MCDT) | A CE evaluation tool that evaluates circularity strategies (remanufacturing, recycling, repair, and reuse) at strategic level. The strategies are assessed according to relevant economic, environmental and social indicators [49]. |

| CE toolkit | A web-based tool to assess product/service throughout the entire life cycle. The proposed tool could be used by companies, distributers/retailers and consumers [68]. |

| CE assessment dashboard | A dashboard of new and established quantitative indicators is proposed for CE strategy assessment in organizations [58]. |

| Circularity potential indicator (CPI) | A circularity performance indicator to measure the performance of products in the early phases of a new or re-design product development [60]. |

| Multi-criteria matrix | A multi-criteria approach to assist decision-making for EoL management of electronic products [69]. |

| Criteria | Sub-Criteria/Indicator |

|---|---|

| Environmental | Life Cycle Assessment (LCA), EoL impact indicator (EOLI), Human health (HH), Ecosystem quality (EQ), Resources (R), |

| Economic | Life Cycle Costing (LCC), disassembly cost, net recoverable value, logistics cost, EoL treatment cost, |

| Social | Job creation opportunity, exposure of employees to hazardous materials, level of customer satisfaction, |

| Legislative | Effect of legislative pressure, compliance with new and existing legislation, |

| Technical | Technical state, availability of recovery facilities, separability of materials, advancement in technology, presence/removability of hazardous content, |

| Business | Market demand, competitive pressure, return core volume. |

| List of Strategies | Description |

|---|---|

| Business-as-usual (BAU) | The vacuum waste systems are installed based on contracts and remote control and regular maintenance is conducted during the use phase. When the inlet breaks, the whole door is replaced, and the post-used product is mostly recycled. |

| (Circular strategy 1) (Transformative strategy) (Repair) | Same as BAU but when the inlet breaks, broken parts of the door are repaired by service technicians (broken parts of the door are replaced with new parts and parts of the door that are not broken are reused). |

| (Circular strategy 2) (Future strategy) (Remanufacturing) | Same as circular strategy 1 but when the inlet breaks, parts of the door that are not broken are reused to make new doors in which the quality of the product is equivalent to a newly manufactured product. |

| Circularity Strategies | Business-as-Usual | Circular Strategy 1 | Circular Strategy 2 | ||

|---|---|---|---|---|---|

| Criteria | Sub-Criteria/Indicator | Weight (Wj) | |||

| Environmental Normalization (N) | LCA (GWP100—kg CO2 eq.) | 0.15 | 1545 | 1545 | 1525 |

| 0.98 | 0.98 | 1 | |||

| (kg SO2 eq.) | 7.2 | 7 | 6.8 | ||

| 0.94 | 0.97 | 1 | |||

| (kg PO4 eq.) | 4.3 | 4.3 | 4.3 | ||

| 1 | 1 | 1 | |||

| Economic Normalization (N) | LCC (Provider’s profit (SEK)) 1 | 0.20 | 22,350 | 21,100 | 21,600 |

| 1 | 0.94 | 0.97 | |||

| Social Normalization (N) | Job creation opportunity (a) | 0.10 | 4 | 4 | 5 |

| 0.8 | 0.8 | 1 | |||

| Legislative Normalization (N) | Effect of legislative pressure (a) | 0.15 | 5 | 3 | 1 |

| 0.2 | 0.33 | 1 | |||

| Technical Normalization (N) | Technical feasibility e.g., disassembly (a) | 0.20 | 2 | 4 | 5 |

| 0.4 | 0.8 | 1 | |||

| Business Normalization (N) | Market demand (a) | 0.20 | 3 | 5 | 5 |

| 0.6 | 1 | 1 | |||

| Total (without Wi) Total (with Wi) | 1.00 | 3.97 | 4.85 | 5.97 | |

| 0.66 | 0.82 | 0.99 | |||

| List of Strategies | Description |

|---|---|

| Business-as-usual | The product is sold to the customer. The customer is responsible for disposal of the product when it reaches its EoL phase. |

| Circular strategy (upgrading) | The product is upgraded by refreshing products’ appearance and therefore, its operational life for the customer is doubled. The company is responsible for providing the intended service. |

| Circularity Strategies | Business-as-Usual | Circular Strategy | ||

|---|---|---|---|---|

| Criteria | Sub-Criteria | Weight (Wj) | ||

| Environmental Normalization (N) | LCA (GWP100—kg CO2 eq.) | 0.15 | 230 | 125 |

| (kg SO2 eq.) | 0.53 | 1.00 | ||

| 1.35 | 0.70 | |||

| 0.52 | 1.00 | |||

| (kg PO4 eq.) | 0.40 | 0.20 | ||

| 0.50 | 1.00 | |||

| Economic Normalization (N) | LCC (Provider’s profit (SEK)) 2 | 0.20 | 550 | 600 |

| 0.90 | 1.00 | |||

| Social Normalization (N) | Job creation opportunity (a) | 0.10 | 2 | 4 |

| 0.5 | 1 | |||

| Legislative Normalization (N) | Effect of legislative pressure (a) | 0.15 | 2 | 3 |

| 0.66 | 1 | |||

| Technical Normalization (N) | Technical feasibility e.g., disassembly (a) | 0.20 | 2 | 5 |

| 0.4 | 1 | |||

| Business Normalization (N) | Market demand (a) | 0.20 | 3 | 4 |

| 0.75 | 1 | |||

| Total (without Wi) Total (with Wi) | 1.00 | 3.73 | 6.00 | |

| 0.63 | 1.00 | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alamerew, Y.A.; Kambanou, M.L.; Sakao, T.; Brissaud, D. A Multi-Criteria Evaluation Method of Product-Level Circularity Strategies. Sustainability 2020, 12, 5129. https://doi.org/10.3390/su12125129

Alamerew YA, Kambanou ML, Sakao T, Brissaud D. A Multi-Criteria Evaluation Method of Product-Level Circularity Strategies. Sustainability. 2020; 12(12):5129. https://doi.org/10.3390/su12125129

Chicago/Turabian StyleAlamerew, Yohannes A., Marianna Lena Kambanou, Tomohiko Sakao, and Daniel Brissaud. 2020. "A Multi-Criteria Evaluation Method of Product-Level Circularity Strategies" Sustainability 12, no. 12: 5129. https://doi.org/10.3390/su12125129

APA StyleAlamerew, Y. A., Kambanou, M. L., Sakao, T., & Brissaud, D. (2020). A Multi-Criteria Evaluation Method of Product-Level Circularity Strategies. Sustainability, 12(12), 5129. https://doi.org/10.3390/su12125129