Life Cycle Sustainability Assessment of Alternative Energy Sources for the Western Australian Transport Sector

Abstract

:1. Introduction

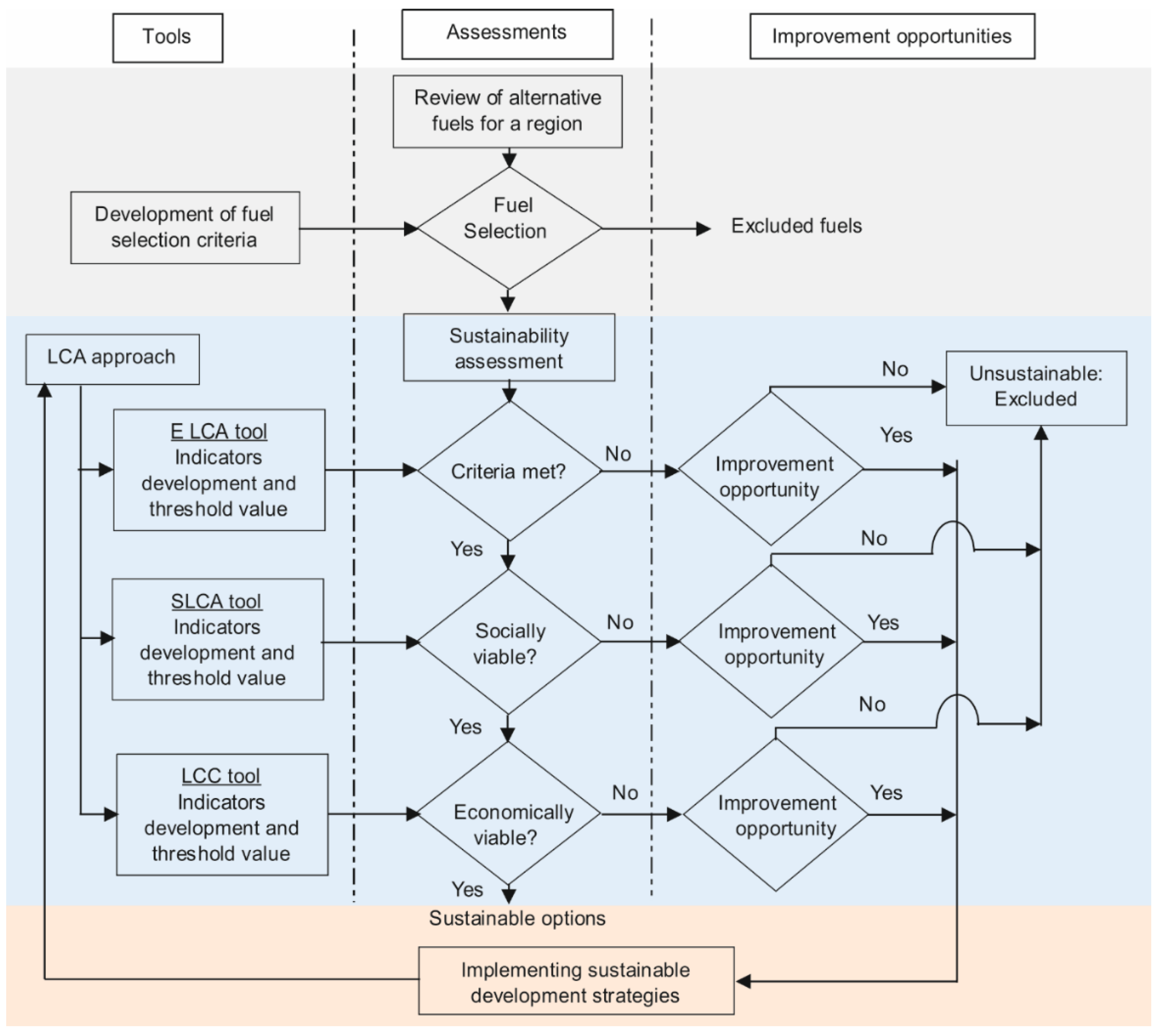

2. Implementation of the Framework

2.1. The Framework

2.2. Goal and Scope of the Study

2.3. Fuel Selection

2.4. Selection of Indicators

2.5. Data Collection and Assessment Procedures

2.5.1. Environmental Indicators

- Based on the average wheat yield in the state, a medium yield of 1.9 tonnes/ha in a farm in WA was considered for the production of wheat [45]. The ethanol conversion plant was considered to be located in the Kwinana Industrial Area (KIA) adjacent to the BP refinery. Local emission factors for WA soil were sourced from Hoque et al. [2].

- The ethanol production plant from straw was considered to be situated in the Northam area as it was one of the eight promising locations for straw-based ethanol production in WA. As wheat was the dominant cereal (around 70%) in WA, wheat-based straw was assumed as an input in the analysis. The estimated amount of straw that remained on the paddock after providing 1.5 tonnes per ha retention was 1.92 tonnes/ha [2]. As cereal was produced in WA solely for food production purposes, and the current straw mostly remains unused, no environmental burden was attributed to straw production [46]. The straw was considered to be transported to the plant from within a 70 km radius of the plant [47].

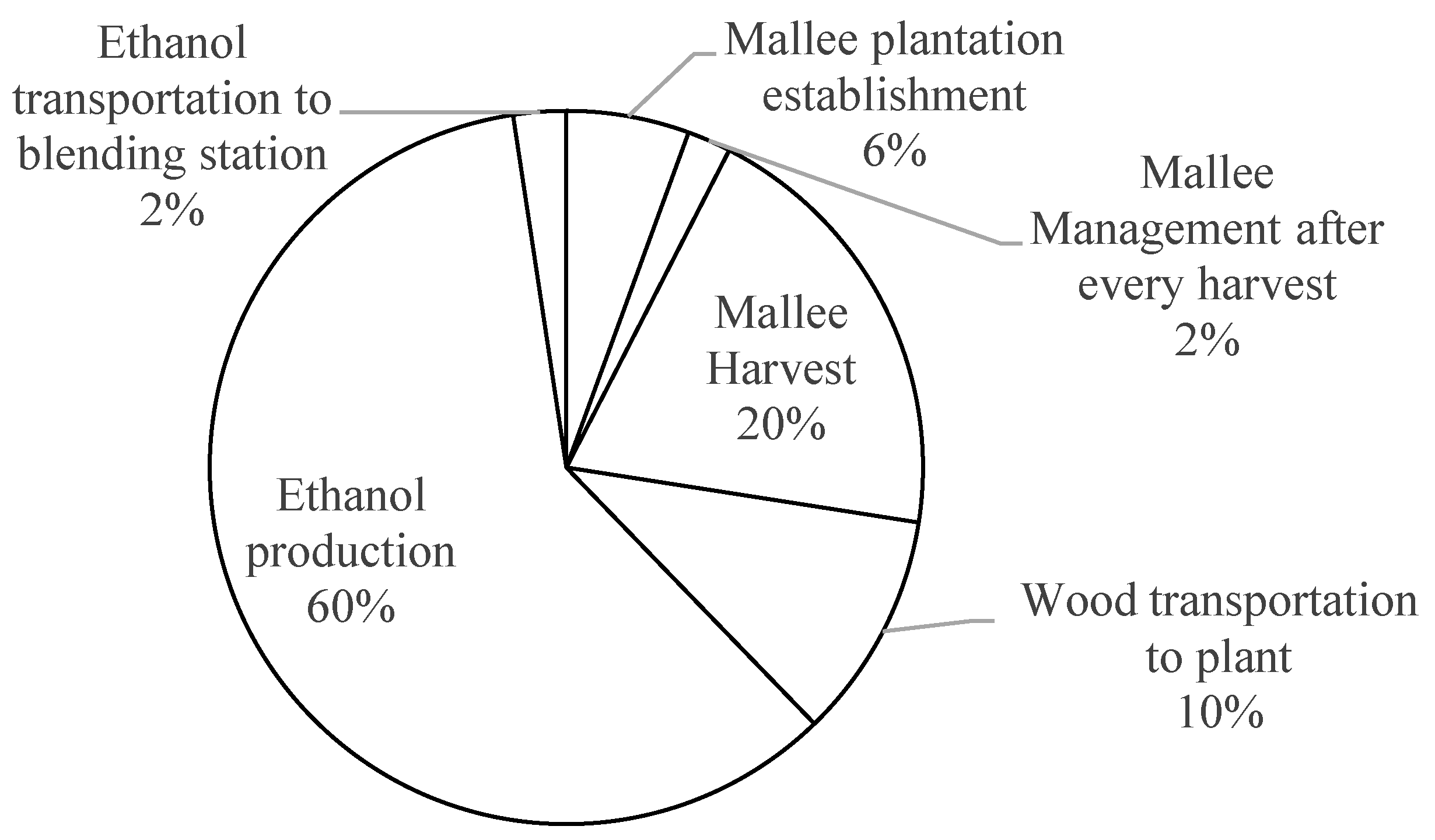

- Katanning, a mallee-rich area of WA, was chosen for mallee-based ethanol. Mallee biomass was estimated to be transported 100 km to a processing farm [48]. The total life of the mallee tree was considered to be 30 years. The first harvest was considered to be after six years, and the following 6 harvests were done at 4-year intervals (16 metric tonne/harvest/ha) [48]. All ethanol was considered to be transported to the BP refinery, KIA, for blending with gasoline.

- Water electrolysis has been considered for this study for hydrogen production. It employs the proton exchange membrane (PEM) electrolyzer, which requires 54 kWh per kg of hydrogen [2,49]. The hydrogen production plant at KIA was assumed to receive water from a renewable-based desalination plant. This option was chosen because these plants supply around 50% of WA water [50]. The Perth desalination plant in WA [51] is currently completely powered by wind electricity.

- The ethanol and hydrogen were estimated to be transported an average distance of 138.39 km [2] from the final processing plants to the end user. This was calculated based on the mean distance of BP refueling stations from the Kwinana refinery in WA.

- EVs and PHEVs were assumed to be charged overnight at home using grid electricity due to the suitability of home charging in WA [2].

2.5.2. Social Indicators

- Person-hours required per unit of inputs (e.g., production of herbicides, fertilizers, etc.) were calculated by collecting data from local plants/organizations. For example, fertilizer was required during the cultivation of ethanol feedstocks. The number of staff required to produce each unit of fertilizer was collected from Perdaman Industries located in Karratha, WA. To produce 2 million tonnes of fertilizer per annum, the producer would require around 200 permanent staff [56]. Therefore, the calculated man-hours for this input were 1.79 × 10−4 for per kg of fertilizer by considering standard working hours of 34.4 per week for Australia [57]. Job creations through plant construction (e.g., plants to produce fertilizers, electricity, etc.) were not considered as these plants were not solely constructed to produce inputs for alternative fuels.

- Job creation related to other activities, such as seeding, spraying, and harvesting during the farming stage of ethanol (Supplementary Materials Section C: Table S1), were calculated based on local data published in various studies [42,43,58,59] and information received from the Department of Primary Industries and Regional Development [60]. Staff requirements for the ethanol production plant (e.g., 1.17 × 10−3 man-hours/L for cellulosic ethanol) were taken from AECOM Australia [61], whereas the data for the hydrogen production plant (e.g., 4.48 × 10−3 man-hours/kg H2) were based on American industries [62] due to the unavailability of local data.

- The measurement of job creation per kWh of electricity generation is quite complex because the electricity is produced from a number of fuel sources. For locally inaccessible information, Equation (9) in the Supplementary Materials: Section B [20,63] was used to generate the data by using the electricity mix of WA. Job creation during the fuel extraction and plant operation phases were taken into account because of the direct influences of these phases on the local job market. The job creation per kWh was calculated as 1.90 × 10−4 man-hours/kWh. Distribution phases of all fuels were assumed to create the same number of jobs based on the estimation by Garrett-Peltier et al. [64].

- The Altona vehicle assembly plant in Australia employed 4000 staff for the assembly of 61,000 cars per year [65]. Based on this information and the average life of 112,567 km for a passenger vehicle in WA [2], the job creation through vehicle assembly per km has been calculated. Assembly of an EV would require 30% less time compared to gasoline due to there being less moving parts in the drive train [66]. A hydrogen fuel cell vehicle (HFCV), on the other hand, requires more time to assemble due to the use of complex technologies (i.e., fuel cells and safety devices). However, the assembly time is expected to reduce with mass production and improvements in automation, as has occurred with the gasoline engine [67,68]. The time required for assembly also varies with the size of the plant, number of cars produced per year, and vehicle model [69]. The job creation through vehicle assembly was thus assumed to be the same for all vehicles to provide a fair comparison.

2.5.3. Economic Indicators

- Assumptions regarding the cost per unit of corresponding traditional fuel is one of the deciding factors for the sustainability assessment of alternative fuels. The gasoline price was close to 150 cents/L in 2013 and decreased afterwards but started to increase again in 2018 [70]. To capture this variation, the average gasoline price (135.42 cents/L) for the last 7 years was considered [70].

- Zero economic allocation was provided to cereal straw during the environmental assessment [2]. This was done because the cereals were solely cultivated for food production in WA and, therefore, no cost was allocated for straw production. However, costs associated with straw harvesting, handling, nutrient replacement, and transportation of straw to the processing plant were considered. Additionally, a nominal profit margin of around 11 AUD/tonne of straw was considered for the farmers for their contribution to bioenergy [43].

- The cost relating to different activities for growing mallee in WA was based on the studies by Wu et al. [58] and Stucley et al. [43]. This is shown in Section C of the Supplementary Materials (Table S2). The estimated cost of mallee production was around 53.45 AUD/green metric tonne.

- A 50,000 kg/day hydrogen production plant (approximately equivalent to ethanol plant capacity) with a project life of 35 years was considered [62,71]. An initial capital cost of around 144 M AUD for the hydrogen plant was assumed based on an estimation by the Commonwealth Scientific and Industrial Research Organization Australia [71]. With the initial investment, a 15% replacement cost was assumed every 7 years due to the fuel cell stack [62]. All the capital costs were based on 100% debt with 7% interest rate over the life cycle of the project [71].

- The costs of utilities, such as electricity, water, and gas, for different purposes are shown in Table 3. Water price for non-residential customers varies in WA due to the associated cost of supplying water in different regional locations [72]. The electricity costs of hydrogen and ethanol plants were based on the price for industrial customers received from a local supplier, Synergy [73].

- Hydrogen delivery through tube tankers was modelled by calculating the costs associated with the price of the truck, tube tankers, the required amount of diesel, and the driver’s wage [76]. The calculated cost was found to be 2.30 AUD/kg. This cost of hydrogen distribution was found to be very close to 2.24 AUD/kg, which was the estimate received from a local transportation and logistics company [77].

- All the cost values were inflated by 3% every year [78] until the end of the project life (e.g., 20 years for ethanol and 35 years for hydrogen). The discounted cash flow analysis was used to determine the present value of the future costs associated with fuel production using Equation (11) [78]. LCC per VKT of fuel was then calculated using a capital recovery [79] factor as shown in Equations (12)–(14) in Supplementary Materials: Section B.

- The producer margin of locally produced liquid fuel (i.e., ethanol in this study) was considered to be 0.10 AUD/L [80], which was around 10% of the production cost. A similar profit margin (i.e., 10% of production cost) was also assumed for hydrogen fuel.

- An excise rate of 26.21% for ethanol in Australia was incorporated in the analysis. It has been assumed that there would not be any excise on hydrogen as both the Australian federal government and WA state governments were ready to support the penetration of hydrogen in different settings within the country [81]. A GST (goods and service tax) of 10%, however, was applied to both the fuels for base case analysis as it was usually added to fuel costs in Australia [82].

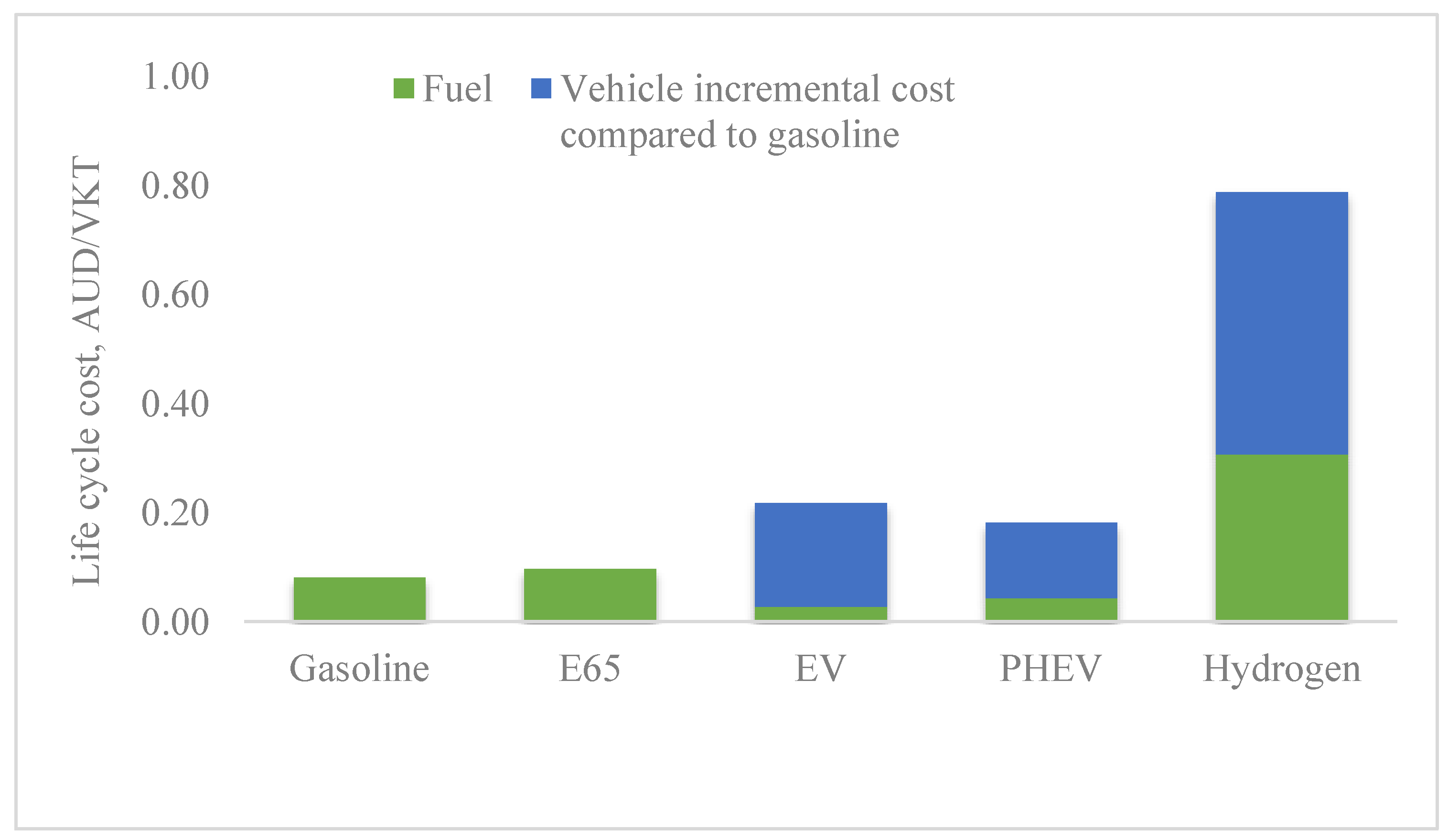

- The cost of an ethanol-blended gasoline vehicle was assumed to be the same as for the gasoline vehicle [73,83]. Costs of AUD 44,037, 39,326 and 70,650 were calculated for EV, PHEV, and hydrogen fuel cell vehicles, respectively, based on a study by Miotti et al. [26]. The price of the gasoline vehicle (i.e., AUD 26,709) was based on the market price in WA [84]. The additional vehicle cost for alternative fuel vehicles compared to the gasoline vehicle due to the changes in powertrain was considered to be paid upfront during the vehicle purchase and subjected to discounted cash flow analysis with the same inflation and discount rate as like fuel [85]. The life of a new passenger vehicle in WA was 10.23 years [2].

- For carbon reduction credits (Equation (15) in Supplementary Materials: Section B), an average value of 40 AUD/tonne of GHG emission was assumed based on Wang et al. [86]. The assumed value was consistent with the guidelines from the International Monetary Fund and the United States Environmental Protection Agency [87]. The indicator net benefit was calculated based on the difference between the costs per km of using gasoline and an alternative fuel option.

2.6. Determination of Threshold Value

3. Interpretation of Base Case Results

3.1. Environmental Life Cycle Assessment

3.2. Social Life Cycle Assessment

3.3. Life Cycle Costing

4. Improvement Strategies

4.1. Environmental Strategies

4.2. Social Strategies

- Sophisticated engine calibration: Previous studies explain that the higher ethanol blends lean out the air-fuel mixture, which results in an increase in NOx emission [143]. Thus, the engine control module of the vehicle needs to be able to adjust the air–fuel ratio with the amount of ethanol content in the blend [143].

- After-treatment devices: The use of exhaust gas recirculation (EGR) as an after-treatment device can also help to meet the vehicle exhaust emission standard [147,148]. It has been found that clean and cooled EGR in the gasoline engine with the aid of gasoline particulate filters (GPFs) could reduce HC, CO, NOx, and PM without compromising fuel economy [148]. The cooled clean EGR technique decreases knocking, which enables a higher compression ratio for fuel economy although some engine power is required for cooling [148].

4.3. Economic Strategies

- Long-term soft loan for the capital cost at the rate of 3% interest rate over the project life;

- The removal of GST on vehicle purchases would provide savings of around AUD 4000 on EV and AUD 3575 on PHEV.

- A fifty percent subsidy on vehicle registration can generate around AUD 4000 benefit over the life of the vehicle. This subsidy comprises the license fee, recording fee, insurance duty, and GST but will not include insurance because injury cover is required for driver and passenger wellbeing [162].

- Currently, there is no import duty on passenger vehicles in Australia from some countries, including Japan and the USA, under the free trade agreement. Inclusion of an import duty of around 10% on gasoline vehicles can reduce the difference in cost between gasoline and alternative fuel vehicles to AUD 1000.

- The remaining amount of around AUD 4200 for EV and AUD 1100 for PHEV can be covered either by direct subsidy and/or tax benefits for the EV owner.

4.4. Summary Results of the LCSA Framework for Western Australian Transport Fuel

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AUD | Australian Dollar |

| BP | British Petroleum |

| CFF | Conservation of fossil fuel |

| CRC | Carbon reduction credit |

| E2 | Ethanol-blended gasoline (2% ethanol and 98% gasoline) |

| E55 | Ethanol-blended gasoline (55% ethanol and 45% gasoline) |

| E65 | Ethanol-blended gasoline (65% ethanol and 35% gasoline) |

| ELCA | Environmental life cycle assessment |

| EU | European Union |

| EV | Electric vehicle |

| FFD | Fossil fuel depletion |

| GHG | Greenhouse gas |

| GST | Goods and service tax |

| GV | Gasoline vehicle |

| GWP | Global warming potential |

| ha | Hectare |

| HFCV | Hydrogen fuel cell vehicle |

| HHVEE | Human health based on vehicle exhaust emission |

| ISO | International Organization for Standardization |

| kg | Kilogram |

| KIA | Kwinana Industrial Area |

| L | Litre |

| LCA | Life cycle assessment |

| LCC | Life cycle costing |

| LCSA | Life cycle sustainability assessment |

| MJ | Megajoule |

| ML | Megalitre |

| Mt | Megatonne |

| OHAS | Occupational health and safety |

| PEM | Proton exchange membrane |

| PHEV | Plug-in hybrid electric vehicle |

| PJ | Petajoule |

| PPA | Power purchase agreement |

| SLCA | Social life cycle assessment |

| TBL | Triple bottom line |

| tkm | Tonne-kilometre |

| VKT | Vehicle kilometre travel |

| WA | Western Australia |

| WC | Water consumption |

References

- Roy, P.; Dutta, A. Life cycle assessment of ethanol derived from sawdust. Bioresour. Technol. 2013, 150, 407–411. [Google Scholar] [CrossRef] [PubMed]

- Hoque, N.; Biswas, W.; Mazhar, I.; Howard, I. Environmental Life Cycle Assessment of Alternative Fuels for Western Australia’s Transport Sector. Atmosphere 2019, 10, 398. [Google Scholar] [CrossRef] [Green Version]

- Roy, P.; Orikasa, T.; Tokuyasu, K.; Nakamura, N.; Shiina, T. Evaluation of the life cycle of bioethanol produced from rice straws. Bioresour. Technol. 2012, 110, 239–244. [Google Scholar] [CrossRef] [PubMed]

- Tucki, K.; Orynycz, O.; Murk, R.; Świć, A.; Botwińska, K. Modeling of Biofuel’s Emissivity for Fuel Choice Management. Sustainability 2019, 11, 6842. [Google Scholar] [CrossRef] [Green Version]

- Hoque, N.; Biswas, W.; Mazhar, I.; Howard, I. LCSA Framewrok for Assessing Sustainability of Alternative Fuel for Transport Sector. Chem. Eng. Trans. 2019, 72, 103–108. [Google Scholar]

- Department of Industry and Science. Australian Energy Update 2015; Department of Industry and Science, Commonwealth of Australia: Canberra, Australia, 2015.

- John, B.A. Australia’s Liquid Fuel Security Part-2 2014. A Report for NRMA Motoring & Services; National Road and Motorists’ Association: Sydney, Australia, 2014. [Google Scholar]

- Commonwealth of Australia. Liquid Fuel Security Rev.; Department of the Environment and Energy: Canberra, Australia, 2019.

- Government of Western Australia. Perth Air Emissions Study 2011–2012; Government of Western Australia: Perth, Australia, 2018.

- Biswas, W.K.; Thompson, B.C.; Islam, M.N. Environmental life cycle feasibility assessment of hydrogen as an automotive fuel in Western Australia. Int. J. Hydrog. Energy 2013, 38, 246–254. [Google Scholar] [CrossRef]

- Wynne, E. Perth Public Transport Use Falls for Fifth Year in a row, with Many Preferring Traffic to Trains. 2017. Available online: https://www.abc.net.au/news/2017-09-12/why-are-people-avoiding-public-transport-in-perth/8893648 (accessed on 21 February 2020).

- Chapple, R. Western Australian Greenhouse Gas Estimates 2012; Government of Western Australia: Perth, WA, Australia, 2012.

- Renouf, M. Best Practice Guide for Life Cycle Impact Assessment (LCIA) in Australia. In Australian Life Cycle Assessment Society; Life Cycle Assessment Society: Melbourne, Australia, 2015. [Google Scholar]

- Roger, H. New Diesel and Petrol Vehicles to be Banned from 2040 in UK. BBC News. 2017. Available online: https://www.bbc.com/news/uk-40723581 (accessed on 12 September 2019).

- Chrisafis, A.; Vaughan, A. France to ban sales of petrol and diesel cars by 2040. The Guardian. 2017. Available online: https://www.theguardian.com/business/2017/jul/06/france-ban-petrol-diesel-cars-2040-emmanuel-macron-volvo (accessed on 12 February 2020).

- Bureau of Transport and Regional Economics. Health Impacts of Transport Emissions in Australia: Economic Costs: Working Paper 63; Department of Transport and Regional Services, Commonwealth of Australia: Canberra, Australia, 2005.

- Hoque, N.; Mazhar, I.; Biswas, W. Application of Life Cycle Assessment for Sustainability Evaluation of Transportation Fuels. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Lim, C.I.; Biswas, W. Sustainability assessment for crude palm oil production in Malaysia using the palm oil sustainability assessment framework. Sustain. Dev. 2019, 27, 253–269. [Google Scholar] [CrossRef]

- Hasan, U.; Whyte, A.; Al Jassmi, H. Life cycle assessment of roadworks in United Arab Emirates: Recycled construction waste, reclaimed asphalt pavement, warm-mix asphalt and blast furnace slag use against traditional approach. J. Clean. Prod. 2020, 257, 120531. [Google Scholar] [CrossRef]

- Akber, M.Z.; Thaheem, M.J.; Arshad, H. Life cycle sustainability assessment of electricity generation in Pakistan: Policy regime for a sustainable energy mix. Energy Policy 2017, 111, 111–126. [Google Scholar] [CrossRef]

- Santoyo-Castelazo, E.; Azapagic, A. Sustainability assessment of energy systems: Integrating environmental, economic and social aspects. J. Clean. Prod. 2014, 80, 119–138. [Google Scholar] [CrossRef]

- Osorio-Tejada, J.L.; Llera-Sastresa, E.; Scarpellini, S. A multi-criteria sustainability assessment for biodiesel and liquefied natural gas as alternative fuels in transport systems. J. Nat. Gas Sci. Eng. 2017, 42, 169–186. [Google Scholar] [CrossRef] [Green Version]

- Li, T.; Roskilly, A.P.; Wang, Y. A Regional Life Cycle Sustainability Assessment Approach and its Application on Solar Photovoltaic. Energy Procedia 2017, 105 (Suppl. C), 3320–3325. [Google Scholar] [CrossRef]

- Keller, H.; Rettenmaier, N.; Reinhardt, G.A. Integrated life cycle sustainability assessment—A practical approach applied to biorefineries. Appl. Energy 2015, 154, 1072–1081. [Google Scholar] [CrossRef]

- Guinée, J. Life Cycle Sustainability Assessment: What Is It and What Are Its Challenges? In Taking Stock of Industrial Ecology; Clift, R., Druckman, A., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 45–68. [Google Scholar]

- Miotti, M.; Hofer, J.; Bauer, C. Integrated environmental and economic assessment of current and future fuel cell vehicles. Int. J. Life Cycle Assess. 2017, 22, 94–110. [Google Scholar] [CrossRef] [Green Version]

- Sharma, R.; Manzie, C.; Bessede, M.; Crawford, R.H.; Bear, M.J. Conventional, hybrid and electric vehicles for Australian driving conditions. Part 2: Life cycle CO2-e emissions. Transp. Res. Part C Emerg. Technol. 2013, 28, 63–73. [Google Scholar] [CrossRef]

- Notter, D.A.; Gauch, M.; Widmer, R.; Wager, P.; Stamp, A.; Zah, R.; Althaus, H.J. Contribution of Li-ion batteries to the environmental impact of electric vehicles. ACS Publ. 2010, 44, 6550–6556. [Google Scholar]

- Stasinopoulos, P.; Shiwakoti, N.; McDonald, S. Life-cycle greenhouse gas emissions of electric and conventional vehicles in Australia. In ITS-Enhancing Liveable Cities and Communities; Intelligent Transport Systems Australia (ITS Australia): Melbourne, Australia, 2016; pp. 1–10. [Google Scholar]

- Lim, C.I.; Biswas, W. An evaluation of holistic sustainability assessment framework for palm oil production in Malaysia. Sustainability 2015, 7, 16561–16587. [Google Scholar] [CrossRef] [Green Version]

- Lim, C.I.; Biswas, W.K. Development of triple bottom line indicators for sustainability assessment framework of Malaysian palm oil industry. Clean Technol. Environ. Policy 2018, 20, 539–560. [Google Scholar] [CrossRef]

- Australian Renewable Energy Agency. Life Cycle Assessment (LCA) of Bioenergy Products and Projects; Australian Government: Canberra, Australia, 2016.

- Carre, A. A Comparative Life Cycle Assessment of Alternative Constructions of a Typical Australian House Design; Forest and Wood Products Australia: Melbourne, Australia, 2011; p. 147-0809. [Google Scholar]

- O’Connell, D.; Batten, D.; O’Connor, M.H.; May, B.; Raison, R.J.; Keating, B.A.; Beer, T.; Braid, A.L.; Haritos, V.; Begley, C. Biofuels in Australia: Issues and Prospects: A Report for the Rural Industries Research and Development Corporation; Rural Industries Research and Development Corporation: Canberra, Australia, 2007. [Google Scholar]

- Ekener-Petersen, E.; Höglund, J.; Finnveden, G. Screening potential social impacts of fossil fuels and biofuels for vehicles. Energy Policy 2014, 73 (Suppl. C), 416–426. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M.; Tatari, O. Towards life cycle sustainability assessment of alternative passenger vehicles. Sustainability 2014, 6, 9305–9342. [Google Scholar] [CrossRef] [Green Version]

- Souza, A.; Watanabe, M.D.B.; Cavalett, O.; Ugaya, C.M.L.; Bonomi, A. Social life cycle assessment of first and second-generation ethanol production technologies in Brazil. Int. J. Life Cycle Assess. 2018, 23, 617–628. [Google Scholar] [CrossRef]

- Yu, M.; Halog, A. Solar photovoltaic development in Australia—A life cycle sustainability assessment study. Sustainability 2015, 7, 1213–1247. [Google Scholar] [CrossRef] [Green Version]

- OECD. Society at a Glance 2016: OECD Social Indicators; OECD Publishing: Paris, France, 2016. [Google Scholar]

- Food and Agriculture Organization of the United Nations (FAO). The Global Bioenergy Partnership Sustainability Indicators for Bioenergy; FAO: Rome, Italy, 2011. [Google Scholar]

- Osorio-Tejada, J.L.; Llera-Sastresa, E.; Scarpellini, S. Liquefied natural gas: Could it be a reliable option for road freight transport in the EU? Renew. Sustain. Energy Rev. 2017, 71, 785–795. [Google Scholar] [CrossRef] [Green Version]

- Weldegiorgis, F.S.; Franks, D.M. Social dimensions of energy supply alternatives in steelmaking: Comparison of biomass and coal production scenarios in Australia. J. Clean. Prod. 2014, 84, 281–288. [Google Scholar] [CrossRef]

- Stucley, C.; Schuck, S.; Sims, R.; Bland, J.; Marino, B.; Borowitzka, M.; Abadi, A.; Bartle, J.; Giles, R.; Thomas, Q. Bioenergy in Australia: Status and Opportunities; Bioenergy Australia: New South Wales, Australia, 2012. [Google Scholar]

- United Petroleum. Ethanol Production. 2018. Available online: https://www.unitedpetroleum.com.au/about/ethanol-production/ (accessed on 3 May 2018).

- Wilkinson, I. Western Australian Wheat Industry. 2018. Available online: https://www.agric.wa.gov.au/grains-research-development/western-australian-wheat-industry (accessed on 1 January 2018).

- Grant, T.F. Greenhouse Gas and Sustainability Footprints of Emerging Biofuels for Queensland; Department of Environment and Science: Queensland, Australia, 2018.

- Brooksbank, K.; Lever, M.; Paterson, H.; Weybury, M. Biomass Scoping Study: Opportunities for Agriculture in Western Australia; Department of Agriculture and Food: Perth, WA, Australia, 2014.

- Crossin, E. Life cycle assessment of a mallee eucalypt jet fuel. Biomass Bioenergy 2017, 96, 162–171. [Google Scholar] [CrossRef]

- Hinkley, J.; Hayward, j.; McNaughton, R.; Gillespie, R.; Matsumoto, A.; Watt, M.; Lovegrove, K. Cost Assessment of Hydrogen Production from PV and Electrolysis; Commonwealth Scientific and Industrial Research Organization: Canberra, Australia, 2016.

- Water Corporation. Desalination. 2019. Available online: https://www.watercorporation.com.au/water-supply/our-water-sources/desalination (accessed on 11 January 2011).

- Water Technology. Perth Seawater Desalination Plant. 2019. Available online: https://www.water-technology.net/projects/perth/ (accessed on 16 May 2019).

- Japan Electric Power Corporation Center. The Electric Power Industry in Japan 2019; Japan Electric Power Corporation Center: Tokyo, Japan, 2019. [Google Scholar]

- Government of Western Australia. Future Battery Industry Strategy Western Australia; Government of Western Australia: Perth, WA, Australia, 2019.

- Hastie, H. Train Builds Return to Midland after Historic Railcar ‘Super-Contract’ Signing. WA Today. 2019. Available online: https://www.watoday.com.au/national/western-australia/train-builds-return-to-midland-after-historic-railcar-super-contract-signing-20191210-p53im7.html (accessed on 7 January 2020).

- Energy Matters. Australian Electric Vehicle Maker ACE-EV Could Produce 15,000 Cars by 2025. 2019. Available online: https://www.energymatters.com.au/renewable-news/electric-vehicle-maker-plans-15000-evs/ (accessed on 7 January 2020).

- Perdaman Industries (Chemical and Fertilizers). Job Creation by Perdaman Industries (Chemical and Fertilizers) at Karratha, Western Australia. 2017. Available online: https://perdaman.com.au/perdaman-industries-chemicals-fertilisers/ (accessed on 22 November 2019).

- Rustandi, F.; Wu, H. Biodiesel production from canola in Western Australia: Energy and carbon footprints and land, water, and labour requirements. Ind. Eng. Chem. Res. 2010, 49, 11785–11796. [Google Scholar] [CrossRef]

- Wu, H.; Fu, Q.; Giles, R.; Bartle, J. Production of mallee biomass in Western Australia: Energy balance analysis. Energy Fuels 2007, 22, 190–198. [Google Scholar] [CrossRef]

- Biswas, W.K.; Barton, L.; Carter, D. Global warming potential of wheat production in Western Australia: A life cycle assessment. Water Environ. J. 2008, 22, 206–216. [Google Scholar] [CrossRef]

- Pathan, S.; (Department of Primary Industries and Regional Development, Perth, Western Australia). Personal Communication, 2018.

- AECOM Australia. Efficient Costs of New Entrant Ethanol Producers; AECOM Australia: Perth, WA, Australia, 2016. [Google Scholar]

- Miller, M.; Raju, A.S.; Roy, P.S. The Development of Lifecycle Data for Hydrogen Fuel Production and Delivery. UC Davis National Center for Sustainable Transportation. Available online: https://escholarship.org/uc/item/3pn8s961 (accessed on 19 December 2019).

- Rutovitz, J.; Dominish, E.; Downes, J. Calculating Global Energy Sector Jobs: 2015 Methodology; Institute for Sustainable Futures: Sydney, Australia, 2015. [Google Scholar]

- Garrett-Peltier, H. The Employment Impacts of a Low-Carbon Fuel Standard for Minnesota; University of Massachusetts: Amherst, MA, USA, 2012. [Google Scholar]

- ABC News. Toyota Workers out of Jobs as Car Manufacturer Closes Altona Plant. 2017. Available online: https://www.abc.net.au/news/2017-10-03/toyota-car-production-ends-altona-after-50-years-manufacturing/9007624 (accessed on 24 November 2019).

- Gustafson, S. Shift to Electric Vehicles Weighs Heavy on UAW-GM Talks. 2019. Available online: https://www.autoblog.com/2019/09/27/uaw-gm-strike-ev-job-fears/ (accessed on 17 December 2019).

- Sørensen, B. Social Implications. In Hydrogen and Fuel Cells, 2nd ed.; Academic Press: Boston, MA, USA, 2012; Chapter 6; pp. 361–402. [Google Scholar]

- Harding, R.; Inagaki, K. Japan Gambles on Toyota’s Hydrogen Powered Car. 2017. Available online: https://www.ft.com/content/328df346-10cb-11e7-a88c-50ba212dce4d (accessed on 17 December 2019).

- Toyota. How Long Does it Actually Take to Make a Car? 2019. Available online: https://www.toyota.co.jp/en/kids/faq/b/01/06/ (accessed on 17 December 2019).

- Fuel Watch Western Australia. Fuel Watch Historical Price Search. 2020. Available online: https://www.fuelwatch.wa.gov.au/fuelwatch/pages/public/historicalPriceSearch.jspx (accessed on 13 February 2020).

- Bruce, S.; Temminghoff, M.; Hayward, J.; Schmidt, E.; Munnings, C.; Palfreyman, D.; Hartley, P. National Hydrogen Roadmap: Pathways to an Economically Sustainable Hydrogen Industry in Australia; CSIRO Australia: Canberra, Australia, 2018.

- WA Water Corporation. Regional Non-Residential Water Use Steps. 2019. Available online: https://www.watercorporation.com.au/home/business/my-account/your-bill-and-charges (accessed on 12 May 2019).

- He, Y. Impacts of Flexible-Fuel Vehicles on Brazil’s Fuel Markets; Rutgers University-Graduate School-New Brunswick: New Brunswick, NJ, USA, 2013. [Google Scholar]

- Synergy. Standard Electricity Prices and Charges; Synergy: Perth, WA, Australia, 2019. [Google Scholar]

- Department of Industry Innovation and Science Australia. Gas Price Trends Review; Department of Industry Innovation and Science Australia: Canberra, Australia, 2017.

- US Department of Energy. Fuel Cell Technologies Office Multi-Year Research, Development, and Demonstration Plan: Planned Program Activities for 2011–2020; DOE, U.S.: Washington, DC, USA, 2012.

- Ruhul, A.; (Centurion Logistics & Transport Services, Perth, Western Australia). Personal Communication, 2018.

- Lawania, K.K.; Biswas, W.K. Cost-effective GHG mitigation strategies for Western Australia’s housing sector: A life cycle management approach. Clean Technol. Environ. Policy 2016, 18, 2419–2428. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Yoo, M.; Cha, K.; Lim, T.; Hur, T. Life cycle cost analysis to examine the economical feasibility of hydrogen as an alternative fuel. Int. J. Hydrog. Energy 2009, 34, 4243–4255. [Google Scholar] [CrossRef]

- Department of Agriculture and Food Western Australia. Ethanol Production from Grain; Department of Agriculture and Food Western Australia: Perth, WA, Australia, 2006.

- Government of Western Australia. Western Australian Renewable Hydrogen Strategy; Government of Western Australia: Perth, WA, Australia, 2019.

- United Petroleum. List Pricing (Wholesale). 2017. Available online: https://www.unitedpetroleum.com.au/wholesale/list-pricing/ (accessed on 10 April 2020).

- Shirk, M. History of Significant Vehicle and Fuel Introductions in the United States; Oak Ridge National Lab. (ORNL): Oak Ridge, TN, USA, 2017.

- Toyota. Toyota Corolla Hatch Price. 2020. Available online: https://www.toyota.com.au/corolla/hatch/prices (accessed on 20 January 2020).

- NSW Government. Management Standrad for Life Cycle Costing; NSW Government: Sydney, Australia, 2014.

- Wang, P.; Deng, X.; Zhou, H.; Yu, S. Estimates of the social cost of carbon: A review based on meta-analysis. J. Clean. Prod. 2019, 209, 1494–1507. [Google Scholar] [CrossRef]

- Kember, O.; Jackson, E.; Connor, J. Counting All The Costs: Recognising the Carbon Subsidy to Polluting Energy; Policy Brief; The Climate Institute: Sydney, Australia, 2014. [Google Scholar]

- Fatimah, Y.A.; Biswas, W.K. Remanufacturing as a means for achieving low-carbon SMEs in Indonesia. Clean Technol. Environ. Policy 2016, 18, 2363–2379. [Google Scholar] [CrossRef] [Green Version]

- Climate Council. Australia’s Rising Greenhouse Gas Emissions; Climate Council of Australia Ltd.: Sydney, Australia, 2018. [Google Scholar]

- Clean Energy Council. Clean Energy Australia: Report 2019; Clean Energy Council: Melbourne, Australia, 2019. [Google Scholar]

- Zucaro, A.; Forte, A.; Fierro, A. Life cycle assessment of wheat straw lignocellulosic bio-ethanol fuel in a local biorefinery prospective. J. Clean. Prod. 2018, 194, 138–149. [Google Scholar] [CrossRef]

- Hawkins, T.R.; Singh, B.; Majeau-Bettez, G.; Strømman, A.H. Comparative Environmental Life Cycle Assessment of Conventional and Electric Vehicles. J. Ind. Ecol. 2013, 17, 53–64. [Google Scholar] [CrossRef]

- Evangelisti, S.; Tagliaferri, C.; Brett, D.J.L.; lettieri, P. Life cycle assessment of a polymer electrolyte membrane fuel cell system for passenger vehicles. J. Clean. Prod. 2017, 142, 4339–4355. [Google Scholar] [CrossRef]

- Tagliaferri, C.; Evangelisti, S.; Acconcia, F.; Domenech, T.; Ekins, P.; Barletta, D.; Lettieri, P. Life cycle assessment of future electric and hybrid vehicles: A cradle-to-grave systems engineering approach. Chem. Eng. Res. Des. 2016, 112, 298–309. [Google Scholar] [CrossRef]

- Helmers, E.; Dietz, J.; Hartard, S. Electric car life cycle assessment based on real-world mileage and the electric conversion scenario. Int. J. Life Cycle Assess. 2017, 22, 15–30. [Google Scholar] [CrossRef]

- Lombardi, L.; Tribioli, L.; Cozzolion, R.; Bella, G. Comparative environmental assessment of conventional, electric, hybrid, and fuel cell powertrains based on LCA. Int. J. Life Cycle Assess. 2017, 22, 1989–2006. [Google Scholar] [CrossRef]

- Mehmeti, A.; Angelis-Dimakis, A.; Arampatzis, G.; McPhail, S.; Ulgiati, S. Life cycle assessment and water footprint of hydrogen production methods: From conventional to emerging technologies. Environments 2018, 5, 24. [Google Scholar] [CrossRef] [Green Version]

- Rapier, R. Energy Balance For Ethanol Better Than For Gasoline? 2019. Available online: http://www.energytrendsinsider.com/2006/04/08/energy-balance-for-ethanol-better-than-for-gasoline/ (accessed on 24 June 2019).

- Paul, W.; Winnie, C.; Harry, S. 2015 Energy Balance for the Corn-Ethanol Industry; United States Department of Agriculture Office of the Chief Economist, Office of Energy Policy and New Uses: Washington, DC, USA, 2016.

- Sharma, A.; Strezov, V. Life cycle environmental and economic impact assessment of alternative transport fuels and power-train technologies. Energy 2017, 133, 1132–1141. [Google Scholar] [CrossRef]

- Patyk, A.; Bachmann, T.M.; Brisse, A. Life cycle assessment of H2 generation with high temperature electrolysis. Int. J. Hydrog. Energy 2013, 38, 3865–3880. [Google Scholar] [CrossRef]

- Harto, C.; Meyers, R.; Williams, E. Life cycle water use of low-carbon transport fuels. Energy Policy 2010, 38, 4933–4944. [Google Scholar] [CrossRef]

- Elgowainy, A.; Wu, M.; Lampert, D.; Cai, H.; Han, J.; Wang, M. Life-Cycle Analysis of Water Consumption for Hydrogen Production: 2016 DOE Hydrogen and Fuel Cells Program Annual Merit Review; Argonne National Laboratory: Lemont, IL, USA, 2016.

- Pontau, P.; Hou, Y.; Cai, H.; Zhen, Y.; Jia, X.; Chiu, A.; Xu, M. Assessing land-use impacts by clean vehicle systems. Resour. Conserv. Recycl. 2015, 95, 112–119. [Google Scholar] [CrossRef] [Green Version]

- Luo, L.; van der Voet, E.; Huppes, G. Life cycle assessment and life cycle costing of bioethanol from sugarcane in Brazil. Renew. Sustain. Energy Rev. 2009, 13, 1613–1619. [Google Scholar] [CrossRef]

- Sengupta, S.; Cohan, D.S. Fuel cycle emissions and life cycle costs of alternative fuel vehicle policy options for the City of Houston municipal fleet. Transp. Res. D 2017, 54, 160–171. [Google Scholar] [CrossRef] [Green Version]

- Shahraeeni, M.; Ahmed, S.; Malek, K.; Van Drimmelen, B.; Kjeang, E. Life cycle emissions and cost of transportation systems: Case study on diesel and natural gas for light duty trucks in municipal fleet operations. J. Nat. Gas Sci. Eng. 2015, 24, 26–34. [Google Scholar] [CrossRef]

- Zhou, T.; Roodra, M.J.; Maclean, H.L.; Luk, J. Life cycle GHG emissions and lifetime costs of medium-duty diesel and battery electric trucks in Toronto, Canada. Transp. Res. D 2017, 55, 91–98. [Google Scholar] [CrossRef]

- Daylan, B.; Ciliz, N. Life cycle assessment and environmental life cycle costing analysis of lignocellulosic bioethanol as an alternative transportation fuel. Renew. Energy 2016, 89, 578–587. [Google Scholar] [CrossRef]

- ISO14040. Environmental Mangament—Life Cycle Assessment—Principles and Frame Work; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization. ISO14044. Environemnental Management-Life Cycle Assessments-Requirements and Guidelines; International Standard Organization (ISO): Geneva, Switzerland, 2006. [Google Scholar]

- Barton, L.; Thamo, T.; Engelbrecht, D.; Biswas, W. Does growing grain legumes or applying lime cost effectively lower greenhouse gas emissions from wheat production in a semi-arid climate? J. Clean. Prod. 2014, 83, 194–203. [Google Scholar] [CrossRef] [Green Version]

- Mekonnen, M.M.; Gerbens-Leenes, P.; Hoekstra, A.Y. The consumptive water footprint of electricity and heat: A global assessment. Environ. Sci. Water Res. Technol. 2015, 1, 285–297. [Google Scholar] [CrossRef]

- Allison, E.; Mandler, B. Health and Safety in Oil and Gas Extraction: Reducing the Exposure of Oil and Gas Workers to Health and Safety Hazards; American Geosciences Institute: Alexandria, VA, USA, 2018. [Google Scholar]

- Jansen, J.; Rong, Y.; Markit, I. Safety Is Paramount; PV Magazine Australia: Canberra, Australia, 2019. [Google Scholar]

- Kong, L.; Li, C.; Jiang, J.; Pecht, M.G. Li-ion battery fire hazards and safety strategies. Energies 2018, 11, 2191. [Google Scholar] [CrossRef] [Green Version]

- Bisschop, R.; Willstrand, O.; Amon, F.; Rosenggren, M. Fire Safety of Lithium-Ion Batteries in Road Vehicles; RISE Research Institute of Sweden: Gothenburg, Sweden, 2019. [Google Scholar]

- Hydrogen Strategy Group. Hydrogen for Australia’s Future; Hydrogen for Australia’s Future: Canberra, Australia, 2018.

- DSDMIP Queensland. Queensland Hydrogen Industry Strategy 2019–2024; The Department of State Development, Manufacturing, Infrastructure and Planning: City East, QLD, Australia, 2019.

- COAG Energy Council Hydrogen Working Group. Australia’s National Hydrogen Strategy; Department of Industry, Science, Energy and Resources: Canberra, Australia, 2019.

- Government of Western Australia. Perth Fuel Cell Bus Trial Summary of Achievements 2004–2007; Department of Planning and Infrastructure, Government of Western Australia: Perth, WA, Australia, 2008.

- Jin, D.; Choi, K.; Myung, C.; Lim, Y.; Lee, J.; Park, S. The impact of various ethanol-gasoline blends on particulates and unregulated gaseous emissions characteristics from a spark ignition direct injection (SIDI) passenger vehicle. Fuel 2017, 209, 702–712. [Google Scholar] [CrossRef]

- Masum, B.M.; Masjuki, H.H.; Kalam, M.A.; Fattah, I.M.R.; Palash, S.M.; Abedin, M.J. Effect of ethanol–gasoline blend on NOx emission in SI engine. Renew. Sustain. Energy Rev. 2013, 24, 209–222. [Google Scholar] [CrossRef]

- D’Allegro, J. Powering the Future: Hydrogen Cars May yet Threaten Tesla. CNBC Newsletter. 2019. Available online: https://www.cnbc.com/2019/02/21/musk-calls-hydrogen-fuel-cells-stupid-but-tech-may-threaten-tesla.html (accessed on 25 December 2019).

- Elaine. Australia Has the Highest Manufacturing-Cost Structure Among Largest Goods-Exporting Countries: Study. 2014. Available online: https://www.australianmanufacturing.com.au/15915/australia-has-the-highest-manufacturing-cost-structure-among-largest-goods-exporting-countries-study (accessed on 23 March 2020).

- Lu, B.; Blakers, A.; Stocks, M. 90–100% renewable electricity for the South West Interconnected System of Western Australia. Energy 2017, 122, 663–674. [Google Scholar] [CrossRef]

- Laslett, D.; Careter, C.; Creagh, C.; Jennigs, P. A large-scale renewable electricity supply system by 2030: Solar, wind, energy efficiency, storage and inertia for the South West Interconnected System (SWIS) in Western Australia. Renew. Energy 2017, 113, 713–731. [Google Scholar] [CrossRef] [Green Version]

- The Climate Institute. Clean Energy Jobs in Regional Australia. 2009. Available online: http://www.climateinstitute.org.au/verve/_resources/cleanenergyjobssnapshot_westernaustralia.pdf (accessed on 17 September 2018).

- Dujmovic, J. Toyota’s Prius Is Testing a New Solar Look that Could Put it Back in the Lead for Hybrid Cars. 2019. Available online: https://www.marketwatch.com/story/toyotas-prius-is-testing-a-new-solar-look-that-could-put-it-back-in-the-lead-for-hybrid-cars-2019-07-11?fbclid=IwAR1ZAzaEU40l_rYo8pNBrbd5Ar66a1HZ72EnKuT7agH9dls2i1adrCWE0RA (accessed on 20 December 2019).

- Geoscience Australia, BREE. Australian Energy Resource Assessment; Australian Government: Canberra, Australia, 2014. [Google Scholar]

- Australian Bureau of Meteorology. Climate Information for Solar Energy; Commonwealth of Australia: Canberra, Australia, 2019.

- Hoque, N.; Kumar, S. Performance of photovoltaic micro utility systems. Energy Sustain. Dev. 2013, 17, 424–430. [Google Scholar] [CrossRef]

- Hochman, Z.; Horan, H. Causes of wheat yield gaps and opportunities to advance the water-limited yield frontier in Australia. Field Crops Res. 2018, 228, 20–30. [Google Scholar] [CrossRef]

- Robertson, M.; Kirkegaard, J.; Rebetzke, G.; Llewellyn, R.; Wark, T. Prospects for yield improvement in the Australian wheat industry: A perspective. Food Energy Secur. 2016, 5, 107–122. [Google Scholar] [CrossRef] [Green Version]

- Barton, L.; Hoyle, F.C.; Stefanova, K.T.; Murphy, D.V. Incorporating organic matter alters soil greenhouse gas emissions and increases grain yield in a semi-arid climate. Agric. Ecosyst. Environ. 2016, 231, 320–330. [Google Scholar] [CrossRef] [Green Version]

- Assainar, S.K.; Abbott, L.K.; Mickan, B.S.; Storer, P.J.; Whiteley, A.S.; Siddique, K.H.M.; Solaiman, Z.M. Polymer-coated rock mineral fertilizer has potential to substitute soluble fertilizer for increasing growth, nutrient uptake, and yield of wheat. Biol. Fertil. Soils 2020, 56, 1–14. [Google Scholar] [CrossRef]

- URS Asutralia. Oil mallee industry development plan for Western Australia. In Forest Products Commission; URS Australia: Perth, WA, Australia, 2008. [Google Scholar]

- RIRDC. Sustainable Production of Bioenergy: A Review of Global Bioenergy Sustainability Frameworks and Assessment Systems; RIRDC: Canberra, Australia, 2009. [Google Scholar]

- Kelly, G. Avenues to sustainable road transport energy in New Zealand. Int. J. Sustain. Transp. 2015, 10, 505–516. [Google Scholar] [CrossRef] [Green Version]

- Climate Council. Renewable Energy Jobs: Future Growth in Australia; The Climate Council of Australia Limited: Sydney, Australia, 2016. [Google Scholar]

- Commonwealth of Australia. The Lithium-Ion Battery Value Chain: New Economy Opportunities for Australia; Australian Trade and Investment Commission: Canberra, Australia, 2018.

- Karavalakis, G.; Short, D.; Russell, R.L.; Jung, H.; Johnson, K.C.; Asa-Awuku, A.; Durbin, T.D. Assessing the impacts of ethanol and isobutanol on gaseous and particulate emissions from flexible fuel vehicles. Environ. Sci. Technol. 2014, 48, 14016–14024. [Google Scholar] [CrossRef] [Green Version]

- Karavalakis, G.; Durbin, T.D.; Shrivastava, M.; Zheng, Z.; Villela, M.; Jung, H. Impacts of ethanol fuel level on emissions of regulated and unregulated pollutants from a fleet of gasoline light-duty vehicles. Fuel 2012, 93, 549–558. [Google Scholar] [CrossRef]

- Oh, C.; Cha, G. Impact of fuel, injection type and after-treatment system on particulate emissions of light-duty vehicles using different fuels on FTP-75 and HWFET test cycles. Int. J. Automot. Technol. 2015, 16, 895–901. [Google Scholar] [CrossRef]

- Doğan, B.; Erol, D.; Yaman, H.; Kodani, E. The effect of ethanol-gasoline blends on performance and exhaust emissions of a spark ignition engine through exergy analysis. Appl. Therm. Eng. 2017, 120, 433–443. [Google Scholar] [CrossRef]

- Delavarrafiee, M.; Frey, H.C. Real-world fuel use and gaseous emission rates for flex fuel vehicles operated on E85 versus gasoline. J. Air Waste Manag. Assoc. 2018, 68, 235–254. [Google Scholar] [CrossRef] [Green Version]

- Wei, H.; Zhu, T.; Shu, G.; Tan, L.; Wang, Y. Gasoline engine exhaust gas recirculation—A review. Appl. Energy 2012, 99, 534–544. [Google Scholar] [CrossRef]

- Fischer, M.; Kreutziger, P.; Sun, Y.; Kotrba, A. Clean EGR for Gasoline Engines–Innovative Approach to Efficiency Improvement and Emissions Reduction Simultaneously. SAE International, 2017; SAE Technical Paper 2017-01-0683; Available online: https://saemobilus.sae.org/content/2017-01-0683/ (accessed on 19 December 2019).

- Lauren, V.; (Australian Renewable Energy Agency, Canberra, Australia). Personal Communication, 2020.

- Parliament of Australia. Petrol, Excise and GST. 2020. Available online: https://www.aph.gov.au/Parliamentary_Business/Committees/Senate/Economics/Completed_inquiries/2004-07/petrol_price/report/c05 (accessed on 19 April 2020).

- Kato, T.; Kubota, M.; Kobayashi, N.; Suzuoki, Y. Effective utilization of by-product oxygen from electrolysis hydrogen production. Energy 2005, 30, 2580–2595. [Google Scholar] [CrossRef]

- Harvego, E.A.; O’Brien, J.E.; McKellar, M.G. System Evaluations and Life-Cycle Cost Analyses for High-Temperature Electrolysis Hydrogen Production Facilities; Idaho National Laboratory: Idaho Falls, ID, USA, 2012.

- Energetics; Norton Rose Fulbright; WWF-Australia. NSW Guide to Corporate Power Purchase Agreement; WWF-Australia: Sydney, Australia, 2018. [Google Scholar]

- WWF-Australia. Helping Business-Pathways to Purchase Renewable Energy; WWF-Australia: Sydney, Australia, 2016. [Google Scholar]

- Australian Government. Wholesale Statistics. 2020. Available online: https://www.aer.gov.au/wholesale-markets/wholesale-statistics/annual-volume-weighted-average-spot-prices-regions (accessed on 15 January 2020).

- Mzengrab, M. How the ACT’s 100% Renewable Electricity Target Is Saving Households Cash. 2019. Available online: https://reneweconomy.com.au/how-the-acts-100-renewable-electricity-target-is-saving-households-cash-22222/?fbclid=IwAR35z3qAV3ZRvAORZsfM03sRPKOG6hmOedPnDq15s1dZSJe_nZdKyMATWBM (accessed on 11 October 2019).

- Vorrath, S. City of Adelaide Seals Deal to Go 100% Renewable. July 2020. Available online: https://reneweconomy.com.au/city-of-adelaide-seals-deal-to-go-100-renewable-starting-july-44123/?fbclid=IwAR2aw9WWR4spwyyqDhUFwZaMxrEbMGQQtsCZaTazsDAx2CI-x8LToJcyE7Y (accessed on 6 February 2020).

- Arslan, R.; Ulusoy, Y.; Tekin, Y.; Sürmen, A. An evaluation of the alternative transport fuel policies for Turkey. Energy Policy 2010, 38, 3030–3037. [Google Scholar] [CrossRef]

- Holtsmark, B.; Skonhoft, A. The Norwegian support and subsidy policy of electric cars. Should it be adopted by other countries? Environ. Sci. Policy 2014, 42, 160–168. [Google Scholar] [CrossRef]

- RAC. EV Takeup: We Look at Incentives and EV Take up around the World. 2020. Available online: https://rac.com.au/car-motoring/info/future_ev-incentives (accessed on 20 January 2020).

- Volkswagen, A.G. How Electric Car Incentives around the World Work. 2019. Available online: https://www.volkswagenag.com/en/news/stories/2019/05/how-electric-car-incentives-around-the-world-work.html (accessed on 20 January 2020).

- The Royal Automobile Club of WA. How Much Does Car Rego Cost in WA? Find Out Why Some Cars’ Registration Costs Are Cheaper than Others. 2020. Available online: https://rac.com.au/car-motoring/info/how-much-does-car-rego-cost-in-wa (accessed on 10 January 2020).

- Electric Vehicle Council Australia. State of Electric Vehicles; Electric Vehicle Council Australia: Sydney, Australia, 2019. [Google Scholar]

- Climate Works. The State of Electric Vehicles in Australia: Driving Momentum in Electric Mobility; ClimateWorks, Australia on Behalf of Electric Vehicle Council Australia: Melbourne, Australia, 2018. [Google Scholar]

- Parliament of Victoria. Inquiry into Electric Vehicles; Government of Australia: Melbourne, Australia, 2018.

- IEA. IEA Bioenergy Countries’ Report: Bioenergy Policies and Status of Implementation; IEA: Paris, France, 2016. [Google Scholar]

| Sustainability Dimension | Indicator | Unit | Percentage of Respondents that Considered it Important |

|---|---|---|---|

| Environmental | Global warming potential (GWP) | Kg CO2/VKT | 87% |

| Fossil fuel depletion (FFD) | MJ/VKT | 67% | |

| Water consumption (WC) | m3/VKT | 63% | |

| Land use (LU) | Ha.a/VKT | 53% | |

| Social | Local job creation * | man.hour/VKT | 67% |

| Conservation of fossil fuel (CFF) | MJ/VKT | 50% | |

| Occupational health and safety (OHAS) | Qualitative | 50% | |

| Human health based on vehicle exhaust emission (HHVEE) ** | gm/VKT | 86% | |

| Economic | Life cycle costing (LCC) | AUD/VKT | 83% |

| Carbon reduction credit (CRC) | AUD/VKT | 57% | |

| Net benefit | AUD/VKT | 70% |

| Options | Equivalent Vehicle | Description | Vehicle Inventory |

|---|---|---|---|

| Gasoline | Toyota Corolla | 0.06 L/km | Hoque et al. [2] |

| HFCV | Toyota Mirai | 0.01 kg/km 114 kW polymer electrolyte fuel cell 5 kg hydrogen tank | |

| EV | Nissan Leaf (2nd generation) | 40 kWh Li-ion battery 270 km per single charge | |

| PHEV | Toyota Prius Prime | 8.8 kWh Li-ion battery 155 Wh/km first 40 km 0.044 L gasoline/km in charge sustaining mode | |

| E 65 | Ethanol flex fuel vehicle | 0.075 L/km (modified fuel and injection system for the Toyota Corolla) |

| Items | Unit | Cost/Unit | Purpose | Reference |

|---|---|---|---|---|

| Electricity | AUD/kWh | 0.2011 * (of which the first 10 unit/month is free) | EV and PHEV home charging | [74] |

| Electricity | 0.5274 (peak) 0.1584 (off-peak) | Ethanol and hydrogen production plant | [74] | |

| Desalinated water | AUD/kL | 1.17 | Hydrogen plant at KIA | [51] |

| Water for business utility at Northam | 7.221 | Ethanol from cereal plant | [72] | |

| Water for business utility at Katanning | 8.562 | Ethanol from mallee plant | [72] | |

| Water for business utility at KIA | 3.653 | Ethanol from wheat | [72] | |

| Natural gas | AUD/GJ | 9.81 | Ethanol from wheat | [75] |

| Indicators | Thresholds | Source of Information | Description |

|---|---|---|---|

| GWP | Reduction ≥ 33% | Climate Council, Australia [89] | Alternative fuels should reduce at least 33% of GWP impact compared to gasoline in Australia. |

| FFD | Reduction ≥ 34% | Studies from regions socio-economically similar to WA [92,93,94,95,96,97,98,99,100]. | At least a 34% FFD reduction is required to meet the criteria compared to base case gasoline. |

| WC | ≤1.48 × 10−3 m3/VKT | Studies from similar regions to WA in terms of water stress and socio-economics [96,101,102,103]. | Water consumption of alternative fuel cannot exceed 1.48 × 10−3 m3/VKT |

| LU | ≤1.73 × 10−6 ha.a/VKT | Studies from similar regions to WA in terms of land availability and socio-economics [2,95,96,97,100,104]. | Land use of alternative fuels should be less than or equal to 1.73 × 10−6 ha.a/VKT |

| local job creation | ≥1.09 × 10−3 man-hours/km | O’Connell et al. [34] | The total job creation has to be ≥1.09 × 10−3 man-hours/km. |

| CFF | ≥1.00 × 100 MJ/VKT | Median value of studies from regions socio-economically similar to WA [92,93,94,95,96,97,98,99,100]. | Alternative fuels in WA should conserve equal to or more than 1.00 × 100 MJ/VKT of fossil fuel. |

| OHAS | 5 (100% agreement from the respondents) | Based on the methodology of Hoque et al. [5] | Acceptance levels were measured based on a 5-point Likert scale where 5 is the required level of acceptance. |

| HHVEE | alternative fuel vehicle’s emission < gasoline vehicle’s emission | Based on O’Connell et al. [34] | One of the reasons for choosing alternative fuel is to reduce tail pipe emissions, which should be lower than the existing option (gasoline in this instance). |

| LCC | ≤8.13 × 10−2 AUD/VKT | Based on the cost of local gasoline use [34] | The cost of alternative fuel should be compared with the existing option (gasoline in this study) to determine its financial viability. |

| CRC | ≥3.30 × 10−3 AUD/km | Based on Climate Council, Australia [89] and 40 AUD/tonne carbon price [86]. | With the CRC of 40 AUD/tonne, the credit should be at least 3.30 × 10−3 AUD/km based on the Climate Council of Australia. |

| Net benefit | Cost of using gasoline per VKT - Cost of using alternative fuel per VKT ≥ 0 | O’Connell et al. [34] | The cost of alternative fuel should be compared with the existing option (gasoline in this study) to determine its financial viability. |

| Indicators | Options | Results | Remarks |

|---|---|---|---|

| GWP | Hydrogen | 5.57 × 10−1 CO2/VKT | 120.00% higher than gasoline; fails to meet the criterion |

| E65 | 1.49 × 10−1 CO2/VKT | 41.03% lower than gasoline; meets the criterion | |

| EV | 1.80 × 10−1 CO2/VKT | 28.92% lower than gasoline; fails to meet the criterion | |

| PHEV | 2.17 × 10−1 CO2/VKT | 14.10% lower than gasoline fails to meet the criterion | |

| FFD | Hydrogen | 5.34 MJ/VKT | 83% higher than gasoline; fails to meet the criterion |

| E65 | 1.74 MJ/VKT | 40% lower than gasoline; meets the criterion | |

| EV | 1.77 MJ/VKT | 39.40% lower than gasoline; meets the criterion | |

| PHEV | 2 MJ/VKT | 31.36% lower than gasoline, fails to meet the criterion | |

| WC | Hydrogen | 1.49 × 10−3 m3/VKT | Fails to meet the criterion |

| E65 | 1.12 × 10−3 m3/VKT | meets the criterion | |

| EV | 4.89 × 10−4 m3/VKT | meets the criterion | |

| PHEV | 5.35 × 10−4 m3/VKT | meets the criterion | |

| LU | Hydrogen | 2.83 × 10−6 ha.a/VKT | Fails to meet the criterion |

| E65 | 5.72 × 10−6 ha.a/VKT | Fails to meet the criterion | |

| EV | 1.07 × 10−6 ha.a/VKT | meets the criterion | |

| PHEV | 6.23 × 10−7 ha.a/VKT | meets the criterion |

| Indicators | Options | Results | Remarks |

|---|---|---|---|

| local job creation | Hydrogen | 1.19 × 10−3 man-hours/VKT | Meets the criterion |

| E65 | 1.13 × 10−3 man-hours/VKT | Meets the criterion | |

| EV | 1.07 × 10−3 man-hours/VKT | Fails to meet the criterion | |

| PHEV | 1.06 × 10−3 man-hours/VKT | Fails to meet the criterion | |

| CFF | Hydrogen | −2.43 × 100 MJ/VKT | Fails to meet the criterion |

| E65 | 1.17 × 100 MJ/VKT | Meets the criterion | |

| EV | 1.15 × 100 MJ/VKT | Meets the criterion | |

| PHEV | 9.1 × 10−1 MJ/VKT | Fails to meet the criterion | |

| OHAS | Hydrogen | 5 | Meets the criterion |

| E65 | 5 | Meets the criterion | |

| EV | 5 | Meets the criterion | |

| PHEV | 5 | Meets the criterion | |

| HHVEE | Hydrogen | There is no tail pipe CO, PM, or NOx emission | Meets the criterion |

| E65 | CO ≈ 1.77 × 10−1 gm/VKT | Lower than gasoline (2.75 × 10−1 gm/VKT); meets the criterion | |

| NOx ≈ 3.57 × 10−3 gm/VKT | Higher than gasoline (2.00 × 10−3 gm/VKT); fails to meet the criterion | ||

| PM ≈ 6.58 × 10−4 gm/VKT | Lower than gasoline (1.85 × 10−3 gm/VKT); meets the criterion | ||

| EV | There is no tail pipe CO, PM, or NOx emission | Meets the criterion | |

| PHEV | At least a 50% reduction * of tail pipe CO, PM, and NOx emissions compared with gasoline | Meets the criterion | |

| Meets the criterion | |||

| Meets the criterion |

| Indicators | Options | Results, AUD/VKT | Remarks |

|---|---|---|---|

| CRC | Hydrogen | −1.21 × 10−2 | Fails to meet the criterion |

| E65 | 4.22 × 10−3 | Meets the criterion | |

| EV | 2.94 × 10−3 | Fails to meet the criterion | |

| PHEV | 1.43 × 10−3 | Fails to meet the criterion | |

| Net benefit | Hydrogen | Without CRC −7.06 × 10−1 | Fails to meet the criterion |

| With CRC −7.18 × 10−1 | Fails to meet the criterion | ||

| E65 | Without CRC −1.51 × 10−2 | Fails to meet the criterion | |

| With CRC −1.08 × 10−2 | Fails to meet the criterion | ||

| EV | Without CRC −1.36 × 10−1 | Fails to meet the criterion | |

| With CRC −1.33 × 10−1 | Fails to meet the criterion | ||

| PHEV | Without CRC −1.00 × 10−1 | Fails to meet the criterion | |

| With CRC −9.87 × 10−2 | Fails to meet the criterion |

| Options | Strategies | Effect on Sustainability Performance |

|---|---|---|

| Hydrogen | Renewable electricity (wind and solar) [2,10] | GWP: 69.37% < gasoline; FFD: 65.28% < gasoline WC: 3.55 × 10−4 m3/km; LU: 1.64 × 10−7 ha.a/km |

| EV | Cleaner electricity for charging [2] | GWP: 49.86% < gasoline; FFD: 49.70% < gasoline WC: 4.80 × 10−4 m3/km; LU: 1.07 × 10−6 ha.a/km |

| PHEV | Use of E10 in place of gasoline [2] Cleaner electricity for charging [2] 180 Wp solar cells installed on the car [129] | GWP: 34.70% < gasoline; FFD: 43.57% < gasoline WC: 5.27 × 10−4 m3/km; LU: 6.67 × 10−7 ha.a/km |

| Ethanol | Ethanol blend E55 considered in place of E65 | GWP: 34.51% < gasoline; FFD: 34.01% < gasoline WC: 1.06 × 10−3 m3/km; LU: 1.69 × 10−6 ha.a/km |

| Options | Social Performance after Incorporating Environmental Strategies | Revised Results after Incorporating Social Strategies | |

|---|---|---|---|

| Environmental | Social | ||

| Hydrogen | local job creation: 1.43 × 10−3 man-hours/VKT CFF: 1.90 × 100 MJ/VKT OHAS: 5 HHVEE: Same as base case | GWP: 69.38% < gasoline FFD: 65.30% < gasoline WC: 3.55 × 10−4 m3/km LU: 1.64 × 10−7 ha.a/km | local job creation: 1.43 × 10−3 man-hours/VKT CFF:1.91 × 100 MJ/VKT OHAS: 5 HHVEE: Same as base case |

| EV | local job creation: 1.10 × 10−3 man-hours/VKT CFF: 1.45 × 100 MJ/VKT OHAS: 5 HHVEE: Same as base case | GWP: 50.10% < gasoline FFD: 50.04% < gasoline WC: 4.78 × 10−4 m3/km LU: 1.07 × 10−6 ha.a/km | local job creation: 1.19 × 10−3 man-hours/VKT CFF: 1.46 × 100 MJ/VKT OHAS: 5 HHVEE: Same as base case |

| PHEV | local job creation: 1.07 × 10−3 man-hours/VKT CFF: 1.31 × 100 MJ/VKT OHAS: 5 HHVEE: Further reduction * of tail pipe emission. Minimum reduction could be around 56.6% compared to gasoline. | GWP: 34.78% < gasoline FFD: 43.68% < gasoline WC: 5.26 × 10−4 m3/km LU: 6.67 × 10-7 ha.a/km | local job creation: 1.10 × 10−3 man-hours/VKT CFF: 1.31 × 100 MJ/VKT OHAS: 5 HHVEE: Social strategies have no effect on exhaust emission. |

| Ethanol (E55) | local job creation: 1.11 × 10−3 man-hours/VKT CFF: 1.00 × 100 MJ/VKT OHAS: 5 HHVEE: CO ≈ 1.92 × 10−1 gm/VKT; PM ≈ 8.18 × 10−4 gm/VKT; NOx emission (3.86 × 10−3 gm/km) still fails to meet the criterion due to the higher value compared to gasoline per km. | GWP: 35.61% < gasoline FFD: 34% < gasoline WC: 1.07 × 10−3 m3/km LU: 1.72 × 10-6 ha.a/km | local job creation: 1.11 × 10−3 man-hours/VKT CFF: 1.00 × 100 MJ/VKT OHAS: 5 HHVEE: To make this criterion sustainable, further engine calibration and/or after-treatment devices are required for the consistent reduction of NOx compared to gasoline. |

| Options | Description | Expected cost [71] |

|---|---|---|

| 1 | Hydrogen plants use electricity from the network, but low-emission electricity is still possible through power purchase agreements (PPAs). PPAs help buyers to secure low-priced renewable electricity from remote area power supply systems that are usually operated by wind and solar plants in Australia through long-term contracts [153,154]. The agreed price may vary up to a certain level based on the spot price in the national electricity market [153]. | Depending on the contract and government support, the average electricity price in Australia could be as low as 6 cents/kWh for generating electricity from renewable wind and solar. |

| 2 | Electricity is considered to be supplied from a renewable energy farm in the vicinity of hydrogen plants. | The estimated cost could be the same as option 1 (i.e., 6 cents/kWh). |

| 3 | Due to the increasing trend of renewable electricity, surplus renewable electricity from the grid will be available as “curtailed renewable energy” in the grid. | The price is estimated to be low (2 cents/kWh) for this curtailed electricity due to the low demand for this surplus electricity. |

| Options | Base Case Sustainability Issues | Sustainability Improvement Strategies | Implications of Improvement Strategies | Final Status of Sustainability | ||

|---|---|---|---|---|---|---|

| Environmental | Social | Economic | ||||

| Hydrogen + | Fails to meet all environmental, one social (CFF), and all economic indicators. |

| Meets all the criteria GWP: 69.38% < gasoline FFD: 65.30% < gasoline WC: 3.55 × 10−4 m3/km LU: 1.64 × 10−7 ha.a/km. | Meets all the criteria local job creation: 1.43 × 10−3 man-hours/VKT CFF: 1.91 × 100 MJ/VKT OHAS: 5 HHVEE: No tail pipe CO, PM, or NOx emission | Fails to meet LCC and net benefit criteria LCC: 5.62 × 10−1 AUD/VKT CRC: 7.02 × 10−3 AUD/VKT Net benefit without CRC: -4.80 × 10−1 AUD/VKT Net benefit with CRC: −4.73 × 10−1 AUD/VKT | Economic sustainability was not achieved due to the high cost of HFCV. |

| EV | Fails to meet one environmental (GWP), one social (local job creation criteria), and all economic indicators. |

| Meets all the criteria GWP: 50.10% < gasoline FFD: 50.04% < gasoline WC: 4.78 × 10−4 m3/km LU: 1.07 × 10−6 ha.a/km | Meets all the criteria local job creation: 1.19 × 10−3 man-hours/VKT CFF: 1.46 MJ/VKT OHAS: 5 HHVEE: No tail pipe CO, PM, or NOx emission | Meets all the criteria LCC: 8.13 × 10−2 AUD/VKT CRC: 5.07 × 10−3 AUD/VKT Net benefit without CRC: 0.00 × 100 AUD/VKT Net benefit with CRC: 5.07 × 10−3 AUD/VKT | All three dimensions of sustainability were achieved. |

| PHEV | Fails to meet two environmental (GWP and FFD), two social (local job creation and CFF), and all economic indicators. |

| Meets all the criteria GWP: 34.78% < gasoline FFD: 43.68% < gasoline WC: 5.26 × 10−4 m3/km LU: 6.67 × 10−7 ha.a/km | Meets all the criteria local job creation: 1.10 × 10−3 man-hours/VKT CFF: 1.31 × 100 MJ/VKT OHAS: 5 HHVEE: Vehicle exhaust emission (CO, PM, and NOx) lower than gasoline. Vehicle runs on electricity during 56.6% of its travel time after implementing the strategies. | Meets all the criteria LCC: 8.13 × 10−2 AUD/VKT CRC: 3.52 × 10−3 AUD/VKT Net benefit without CCR: 0.00 × 100 AUD/VKT Net benefit with CCR: 3.52 × 10−3 AUD/VKT | All three dimensions of sustainability were achieved. |

| E65 * | Fails to meet one environmental (land use), one social (HHVE: NOx emission for E65 was found to be higher than gasoline), and two economic (LCC and net benefit) indicators. |

| Meets all the criteria GWP: 35.61% < gasoline FFD: 34.00% < gasoline WC: 1.07 × 10−3 m3/km LU: 1.72 × 10-6 ha.a/km | Meets all the criteria local job creation: 1.11 × 10−3 man-hours/VKT CFF: 1.00 × 100 MJ/VKT OHAS: 5 HHVEE: Tail pipe CO and PM emissions are lower than gasoline. Consistent NOx emission reduction compared to gasoline is also possible with engine control strategies and after-treatment devices. | Meets all the criteria LCC: 8.13 × 10−2 AUD/VKT CRC: 3.61 × 10−3 AUD/VKT Net benefit without CCR: 0.00 × 100 AUD/VKT Net benefit with CCR: 3.61 × 10−3 AUD/VKT | E55 * meets all three dimensions of sustainability. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoque, N.; Biswas, W.; Mazhar, I.; Howard, I. Life Cycle Sustainability Assessment of Alternative Energy Sources for the Western Australian Transport Sector. Sustainability 2020, 12, 5565. https://doi.org/10.3390/su12145565

Hoque N, Biswas W, Mazhar I, Howard I. Life Cycle Sustainability Assessment of Alternative Energy Sources for the Western Australian Transport Sector. Sustainability. 2020; 12(14):5565. https://doi.org/10.3390/su12145565

Chicago/Turabian StyleHoque, Najmul, Wahidul Biswas, Ilyas Mazhar, and Ian Howard. 2020. "Life Cycle Sustainability Assessment of Alternative Energy Sources for the Western Australian Transport Sector" Sustainability 12, no. 14: 5565. https://doi.org/10.3390/su12145565

APA StyleHoque, N., Biswas, W., Mazhar, I., & Howard, I. (2020). Life Cycle Sustainability Assessment of Alternative Energy Sources for the Western Australian Transport Sector. Sustainability, 12(14), 5565. https://doi.org/10.3390/su12145565