Construction and Demolition Waste (CDW) Recycling—As Both Binder and Aggregates—In Alkali-Activated Materials: A Novel Re-Use Concept

Abstract

:1. Introduction

2. Materials and Methods

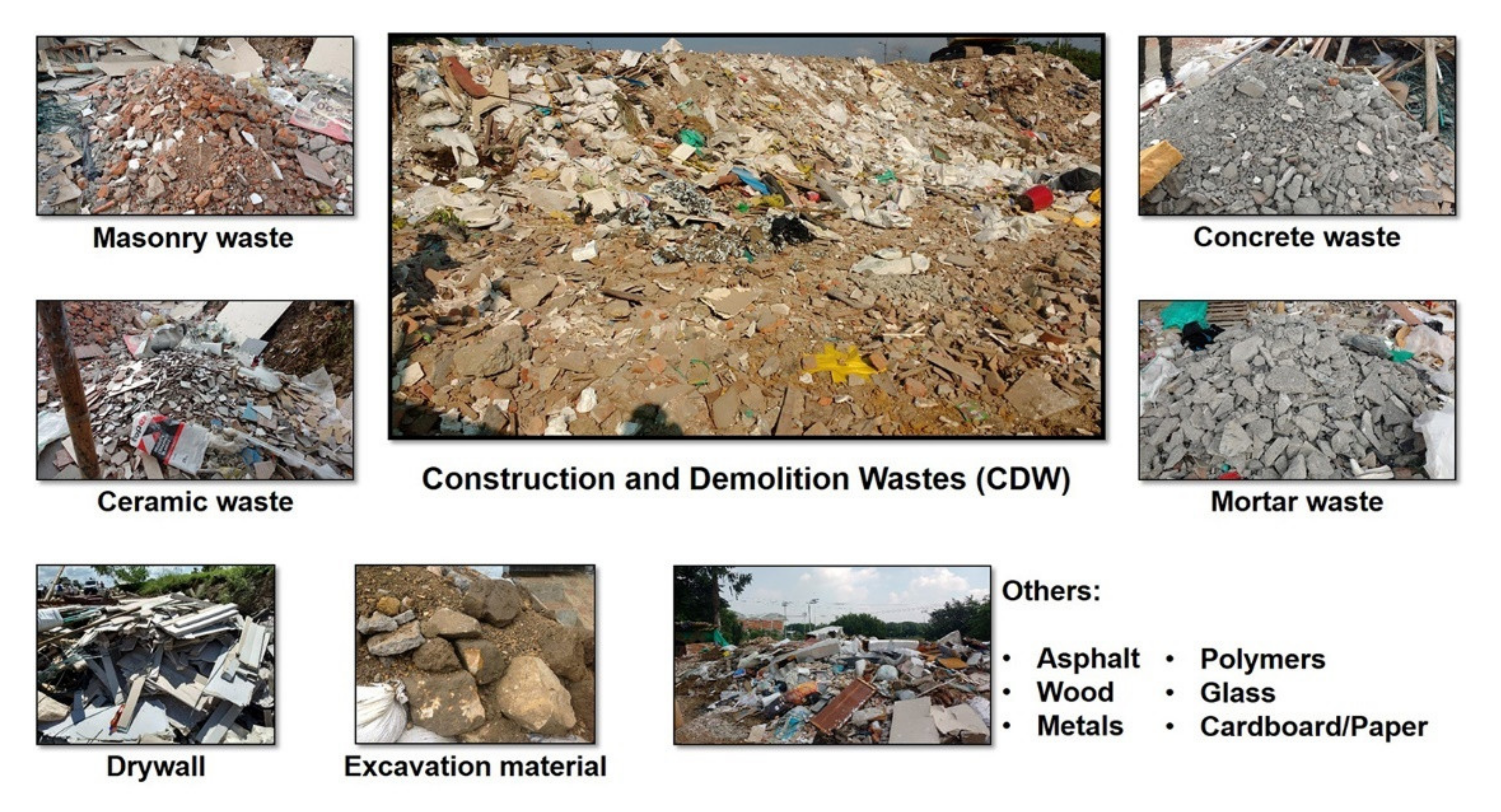

2.1. Construction and Demolition Wastes (CDW)

2.2. Characterization of Raw Materials

2.3. Design of Mixture and Production of Alkali-Activated Materials

2.3.1. Binder Optimization

2.3.2. Characterization of the Recycled Aggregates

2.3.3. Concretes and Blocks: Production and Characterization

3. Results and Discussion

3.1. Characterization of the CDW-Based Hybrid Cement (Binder)

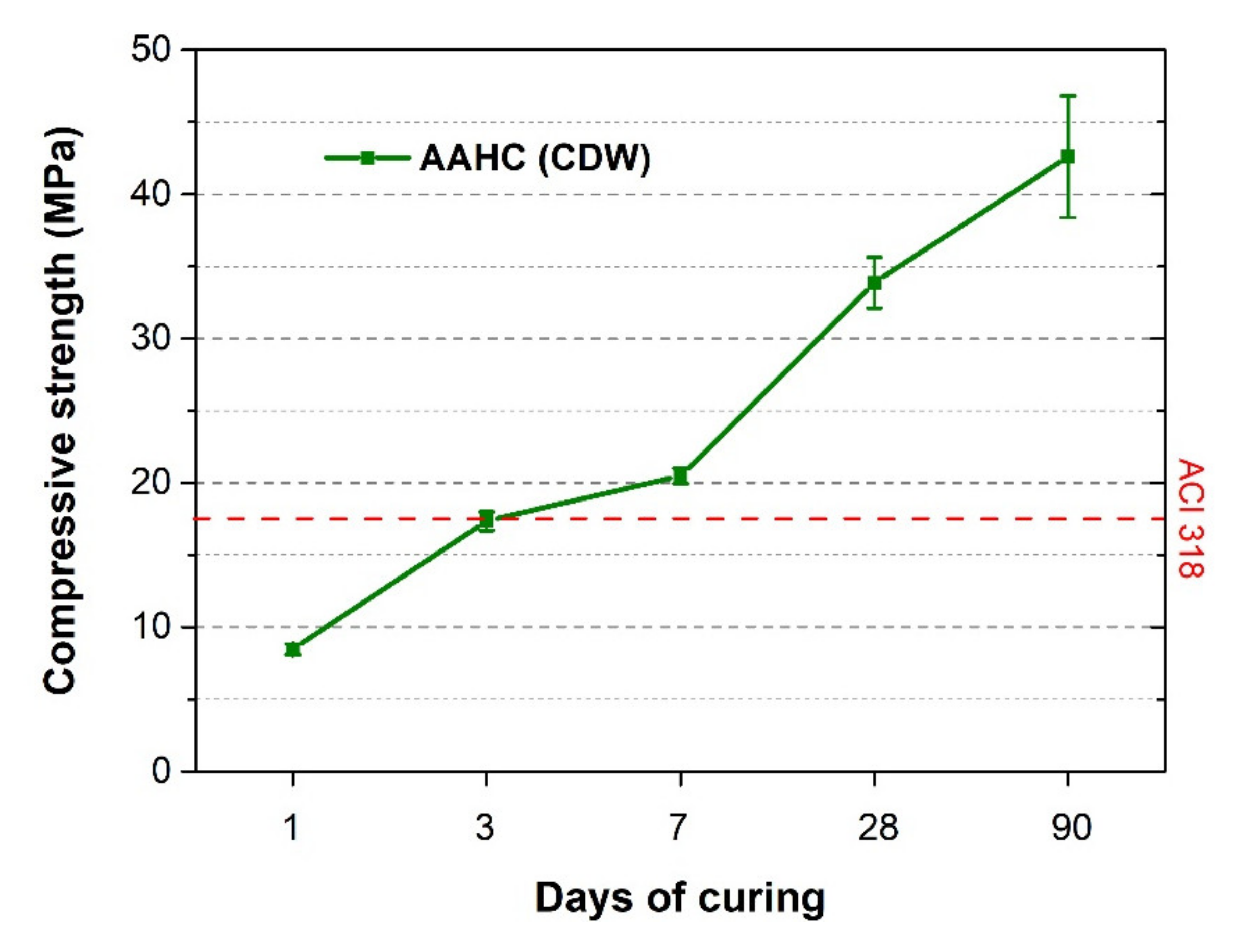

3.2. Characterization of CDW-Based Hybrid Concrete (AAHC) (As Both Precursor and Aggregates)

3.3. Production and Characterization of a Building Element (Solid Block Type) from the AAHC

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- European Commission, Construction and Demolition Waste (CDW). 2016. Available online: http://ec.europa.eu/environment/waste/construction_demolition.htm (accessed on 13 March 2018).

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Naciones Unidas CEPAL, Agenda 2030 y los Objetivos de Desarrollo Sostenible. Una oportunidad Para America Latina y el Caribe. Available online: http://www.sela.org/media/2262361/agenda-2030-y-los-objetivos-de-desarrollo-sostenible.pdf (accessed on 18 January 2018).

- Akcil, A.; Agcasulu, I.; Swain, B. Valorization of waste LCD and recovery of critical raw material for circular economy: A review. Resour. Conserv. Recycl. 2019, 149, 622–637. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Vieira, C.S.; Pereira, P.M. Use of recycled construction and demolition materials in geotechnical applications: A review. Resour. Conserv. Recycl. 2015, 103, 192–204. [Google Scholar] [CrossRef]

- Wu, Y.; Lu, B.; Bai, T.; Wang, H.; Du, F.; Zhang, Y.; Cai, L.; Jiang, C.; Wang, W. Geopolymer, green alkali activated cementitious material: Synthesis, applications and challenges. Constr. Build. Mater. 2019, 224, 930–949. [Google Scholar] [CrossRef]

- RILEM Technical Committee 247-DTA, 247-DTA: Durability Testing of Alkali-Activated Materials. Available online: https://www.rilem.net/groupe/247-dta-durability-testing-of-alkali-activated-materials-290 (accessed on 18 January 2018).

- Lampris, C.; Lupo, R.; Cheeseman, C. Geopolymerisation of silt generated from construction and demolition waste washing plants. Waste Manag. 2009, 29, 368–373. [Google Scholar] [CrossRef]

- Reig, L.; Tashima, M.; Borrachero, M.; Monzó, J.; Cheeseman, C.; Payá, J. Properties and microstructure of alkali-activated red clay brick waste. Constr. Build. Mater. 2013, 43, 98–106. [Google Scholar] [CrossRef] [Green Version]

- Komnitsas, K.; Zaharaki, D.; Vlachou, A.; Bartzas, G.; Galetakis, M. Effect of synthesis parameters on the quality of construction and demolition wastes (CDW) geopolymers. Adv. Powder Technol. 2015, 26, 368–376. [Google Scholar] [CrossRef] [Green Version]

- Robayo, R.A.; Mulford, A.; Munera, J.; De Gutiérrez, R.M. Alternative cements based on alkali-activated red clay brick waste. Constr. Build. Mater. 2016, 128, 163–169. [Google Scholar] [CrossRef]

- Vásquez, A.; Cárdenas, V.; Robayo, R.A.; De Gutiérrez, R.M. Geopolymer based on concrete demolition waste. Adv. Powder Technol. 2016, 27, 1173–1179. [Google Scholar] [CrossRef]

- Zaharaki, D.; Galetakis, M.; Komnitsas, K. Valorization of construction and demolition (C&D) and industrial wastes through alkali activation. Constr. Build. Mater. 2016, 121, 686–693. [Google Scholar] [CrossRef]

- Sassoni, E.; Pahlavan, P.; Franzoni, E.; Bignozzi, M.C. Valorization of brick waste by alkali-activation: A study on the possible use for masonry repointing. Ceram. Int. 2016, 42, 14685–14694. [Google Scholar] [CrossRef]

- Murillo, L.M.; Delvasto, S.; Suárez, M.G. A study of a hybrid binder based on alkali-activated ceramic tile wastes and portland cement. In Sustainable and Nonconventional Construction Materials Using Inorganic Bonded Fiber Composites; Elsevier BV: Amsterdam, The Netherlands, 2017; pp. 291–311. [Google Scholar]

- Reig, L.; Sanz, M.; Borrachero, M.; Monzó, J.; Soriano, L.; Payá, J. Compressive strength and microstructure of alkali-activated mortars with high ceramic waste content. Ceram. Int. 2017, 43, 13622–13634. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.; Rivera, J.F.; De Gutiérrez, R.M. Alkali-activated building materials made with recycled construction and demolition wastes. Constr. Build. Mater. 2017, 149, 130–138. [Google Scholar] [CrossRef]

- Tuyan, M.; Andiç-Çakir, Ö.; Ramyar, K. Effect of alkali activator concentration and curing condition on strength and microstructure of waste clay brick powder-based geopolymer. Compos. Part B Eng. 2018, 135, 242–252. [Google Scholar] [CrossRef]

- Fort, J.; Vejmelková, E.; Koňáková, D.; Alblová, N.; Čáchová, M.; Keppert, M.; Rovnaníková, P.; Černý, R. Application of waste brick powder in alkali activated aluminosilicates: Functional and environmental aspects. J. Clean. Prod. 2018, 194, 714–725. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Yehualaw, M.D.; Vo, D.-H.; Huynh, T.-P. Development of high-strength alkali-activated pastes containing high volumes of waste brick and ceramic powders. Constr. Build. Mater. 2019, 218, 519–529. [Google Scholar] [CrossRef]

- Olivia, M.; Nikraz, H. Properties of fly ash geopolymer concrete designed by Taguchi method. Mater. Des. 2012, 36, 191–198. [Google Scholar] [CrossRef] [Green Version]

- Reig, L.; Soriano, L.; Borrachero, M.; Monzó, J.; Payá, J. Influence of the activator concentration and calcium hydroxide addition on the properties of alkali-activated porcelain stoneware. Constr. Build. Mater. 2014, 63, 214–222. [Google Scholar] [CrossRef]

- Puertas, F.; Barba, A.; Gazulla, M.F.; Gómez, M.P.; Palacios, M.; Martinez-Ramirez, S. Residuos cerámicos para su posible uso como materia prima en la fabricación de clínker de cemento Portland: Caracterización y activación alcalina. Mater. Constr. 2006, 56, 73–84. [Google Scholar] [CrossRef] [Green Version]

- De Gutiérrez, R.M.; Mejía, J.M.; Puertas, F. Ceniza de cascarilla de arroz como fuente de sílice en sistemas cementicios de ceniza volante y escoria activados alcalinamente. Mater. Constr. 2013, 63, 361–375. [Google Scholar] [CrossRef] [Green Version]

- Puertas, F.; Martínez-Ramírez, S.; Alonso, S.; Vázquez, T. Alkali-activated fly ash/slag cements. Cem. Concr. Res. 2000, 30, 1625–1632. [Google Scholar] [CrossRef]

- Phoo-Ngernkham, T.; Chindaprasirt, P.; Sata, V.; Pangdaeng, S.; Sinsiri, T. Properties of high calcium fly ash geopolymer pastes with Portland cement as an additive. Int. J. Miner. Met. Mater. 2013, 20, 214–220. [Google Scholar] [CrossRef]

- Rivera, J.F.; Mejia, J.M.; De Gutiérrez, R.M.; Suárez, M.G. Hybrid cement based on the alkali activation of by-products of coal. Rev. Constr. 2014, 13, 31–39. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Lodeiro, I.; Fernández-Jiménez, A.; Palomo, A. Variation in hybrid cements over time. Alkaline activation of fly ash–portland cement blends. Cem. Concr. Res. 2013, 52, 112–122. [Google Scholar] [CrossRef]

- Bernal, S.A.; Rodriguez, E.D.; De Gutiérrez, R.M.; Provis, J.L.; Delvasto, S. Activation of Metakaolin/Slag Blends Using Alkaline Solutions Based on Chemically Modified Silica Fume and Rice Husk Ash. Waste Biomass Valoriz. 2011, 3, 99–108. [Google Scholar] [CrossRef]

- Mejia, J.; Rodriguez, E.D.; De Gutiérrez, R.M. Utilización potencial de una ceniza volante de baja calidad como fuente de aluminosilicatos en la producción de geopolímeros. Ing. Univ. 2014, 18, 309. [Google Scholar] [CrossRef] [Green Version]

- De Gutiérrez, R.M.; Robayo, R.A.; Gordillo, M. Natural pozzolan—And granulated blast furnace slag-based binary geopolymers. Mater. Constr. 2016, 66. [Google Scholar] [CrossRef] [Green Version]

- Robayo-Salazar, R.; De Gutiérrez, R.M.; Puertas, F. Study of synergy between a natural volcanic pozzolan and a granulated blast furnace slag in the production of geopolymeric pastes and mortars. Constr. Build. Mater. 2017, 157, 151–160. [Google Scholar] [CrossRef]

- Lodeiro, I.G.; Fernandez-Jiménez, A.; Palomo, A. Hydration kinetics in hybrid binders: Early reaction stages. Cem. Concr. Compos. 2013, 39, 82–92. [Google Scholar] [CrossRef]

- Gruyaert, E.; Robeyst, N.; De Belie, N. Study of the hydration of Portland cement blended with blast-furnace slag by calorimetry and thermogravimetry. J. Therm. Anal. Calorim. 2010, 102, 941–951. [Google Scholar] [CrossRef]

- Xu, H.; Gong, W.; Syltebo, L.; Lutze, W.; Pegg, I.L. DuraLith geopolymer waste form for Hanford secondary waste: Correlating setting behavior to hydration heat evolution. J. Hazard. Mater. 2014, 278, 34–39. [Google Scholar] [CrossRef] [PubMed]

- Xu, Q.; Hu, J.; Ruiz, J.M.; Wang, K.; Ge, Z. Isothermal calorimetry tests and modeling of cement hydration parameters. Thermochim. Acta 2010, 499, 91–99. [Google Scholar] [CrossRef]

- López, A.; Guzmán, G.A.; Di Sarli, A.R. Color stability in mortars and concretes. Part 2: Study on architectural concretes. Constr. Build. Mater. 2016, 123, 248–253. [Google Scholar] [CrossRef]

- Levinson, R.; Akbari, H.; Berdahl, P.; Wood, K.; Skilton, W.; Petersheim, J. A novel technique for the production of cool colored concrete tile and asphalt shingle roofing products. Sol. Energy Mater. Sol. Cells 2010, 94, 946–954. [Google Scholar] [CrossRef] [Green Version]

- Ortega, E.A.; Cheeseman, C.; Knight, J.; Loizidou, M. Properties of alkali-activated clinoptilolite. Cem. Concr. Res. 2000, 30, 1641–1646. [Google Scholar] [CrossRef]

- Lodeiro, I.G.; Macphee, D.; Palomo, A.; Fernandez-Jiménez, A. Effect of alkalis on fresh C–S–H gels. FTIR analysis. Cem. Concr. Res. 2009, 39, 147–153. [Google Scholar] [CrossRef]

- Gebregziabiher, B.S.; Thomas, R.J.; Peethamparan, S. Temperature and activator effect on early—Age reaction kinetics of alkali-activated slag binders. Constr. Build. Mater. 2016, 113, 783–793. [Google Scholar] [CrossRef] [Green Version]

- Herrero, M.J.S.; Fernandez-Jiménez, A.; Palomo, A. Alkaline Hydration of C2S and C3S. J. Am. Ceram. Soc. 2015, 99, 604–611. [Google Scholar] [CrossRef]

- Djobo, J.N.Y.; Tchakouté, H.K.; Ranjbar, N.; Elimbi, A.; Tchadjié, L.N.; Njopwouo, D. Gel Composition and Strength Properties of Alkali-Activated Oyster Shell-Volcanic Ash: Effect of Synthesis Conditions. J. Am. Ceram. Soc. 2016, 99, 3159–3166. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.; De Gutiérrez, R.M.; Puertas, F. Alkali-activated binary concrete based on a natural pozzolan: Physical, mechanical and microstructural characterization. Mater. Constr. 2019, 69, 191. [Google Scholar] [CrossRef]

| Waste | Addition | Optimal Synthesis Conditions | Application | Ref. | Year | Country | ||

|---|---|---|---|---|---|---|---|---|

| Activator | Cured | C.S. | ||||||

| Concrete | 20% MK | NaOH + Na2SiO3 | 60 °C (3d) | 33 MPa | Paste | [9] | 2009 | UK |

| Masonry | --- | NaOH + Na2SiO3 | 60 °C (7d) | 50 MPa | PasteMortar | [10] | 2013 | Spain |

| Concrete | --- | NaOH + Na2SiO3 | 90 °C (7d) | 13 MPa | Paste | [11] | 2015 | Greece |

| Masonry | 58 MPa | |||||||

| Tile | 50 MPa | |||||||

| Masonry | 0% | NaOH + Na2SiO3 | 25 °C | 54 MPa | Paste | [12] | 2016 | Colombia |

| 20% OPC | 103 MPa | |||||||

| Concrete | 0% | NaOH + Na2SiO3 | 25 °C | 26 MPa | Paste | [13] | 2016 | Colombia |

| 30% OPC | 34 MPa | |||||||

| 10% MK | 46 MPa | |||||||

| Concrete | --- | NaOH + Na2SiO3 | 80 °C (1d) | 8 MPa | Paste | [14] | 2016 | Greece |

| Masonry | 39 MPa | |||||||

| Tile | 58 MPa | |||||||

| Masonry | --- | NaOH + Na2SiO3 | 50 °C (1d) | --- | Coating | [15] | 2016 | Italy |

| Ceramic | 15% OPC | NaOH + Na2SiO3 | 25 °C | 58 MPa | Paste | [16] | 2017 | Colombia |

| 25 MPa | Mortar | |||||||

| Ceramic | 5% Ca(OH)2 | NaOH + Na2SiO3 | 65 °C (3d) | 43 MPa | Mortar | [17] | 2017 | Spain |

| Masonry | 0% | NaOH | 25 °C | 7 MPa | Paste | [18] | 2017 | Colombia |

| 10% OPC | 41 MPa | |||||||

| 0% | NaOH + Na2SiO3 | 54 MPa | ||||||

| 20% OPC | 103 MPa | |||||||

| Concrete | 0% | NaOH | 7 MPa | |||||

| 30% OPC | 10 MPa | |||||||

| 0% | NaOH + Na2SiO3 | 26 MPa | ||||||

| 30% OPC | 34 MPa | |||||||

| Masonry | --- | NaOH + Na2SiO3 | 90 °C (5d) | 36 MPa | Mortar | [19] | 2018 | Turkey |

| Masonry | --- | NaOH + Na2SiO3 | 25 °C | 42 MPa | Paste | [20] | 2018 | R. Czech |

| Masonry | 30% GBFS + 10% FA | NaOH + Na2SiO3 | 25 °C | 70 MPa | Paste | [21] | 2019 | Taiwan |

| Ceramic | 30% GBFS + 10% FA | NaOH + Na2SiO3 | 25 °C | 60 MPa | ||||

| Material | SiO2 | Al2O3 | CaO | Fe2O3 | Na2O | K2O | MgO | Others | LOI |

|---|---|---|---|---|---|---|---|---|---|

| CDW precursor | 47.6 | 11.2 | 21.2 | 5.9 | 0.6 | 1.1 | 1.1 | 2.3 | 9.1 |

| OPC | 17.9 | 3.9 | 62.3 | 4.8 | 0.2 | 0.3 | 1.8 | 4.7 | 4.1 |

| Characteristics | Fine Recycled Aggregate (FRA) | Coarse Recycled Aggregate (CRA) | ||

|---|---|---|---|---|

| Standard | Result | Standard | Result | |

| Bulk density (kg/m3) | ASTM C128 | 2029 | ASTM C127 | 2326 |

| Absorption (%) | ASTM C128 | 12.12 | ASTM C127 | 9.17 |

| Unit weight (kg/m3) | ASTM C29 | 1240 | ASTM C29 | 1211 |

| Maximum size (mm) | N/A | ASTM C136 | 25.4 | |

| Fineness modulus | ASTM C136 | 3.04 | N/A | |

| Organic impurities | ASTM C40 | Organic plate No. 1 | N/A | |

| Resistance to degradation (%) | N/A | ASTM C131 | 33.65 | |

| Material | Dry Weight (kg) | Density (kg/m3) | Volume (m3) |

|---|---|---|---|

| CDW precursor | 450 | 2690 | 0.167 |

| OPC | 50 | 3100 | 0.016 |

| Alkaline activator solution * | 326 | 1259 | 0.259 |

| Coarse recycled aggregate (CRA) | 605 | 2326 | 0.260 |

| Fine recycled aggregate (FRA) | 605 | 2029 | 0.298 |

| Total | 2036 | N/A | 1 |

| CDW Concrete Block | Properties and Characteristics | Result |

|---|---|---|

| Dimensions (length × width × height) | 200 × 100 × 80 mm |

| Curing temperature | 25 °C | |

| Compressive strength (28 days) | 26.1 MPa | |

| Rupture modulus (28 days) | 3.6 MPa | |

| Density | 1926 kg/m3 | |

| Water absorption | 14.4% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Robayo-Salazar, R.A.; Valencia-Saavedra, W.; Mejía de Gutiérrez, R. Construction and Demolition Waste (CDW) Recycling—As Both Binder and Aggregates—In Alkali-Activated Materials: A Novel Re-Use Concept. Sustainability 2020, 12, 5775. https://doi.org/10.3390/su12145775

Robayo-Salazar RA, Valencia-Saavedra W, Mejía de Gutiérrez R. Construction and Demolition Waste (CDW) Recycling—As Both Binder and Aggregates—In Alkali-Activated Materials: A Novel Re-Use Concept. Sustainability. 2020; 12(14):5775. https://doi.org/10.3390/su12145775

Chicago/Turabian StyleRobayo-Salazar, Rafael A., William Valencia-Saavedra, and Ruby Mejía de Gutiérrez. 2020. "Construction and Demolition Waste (CDW) Recycling—As Both Binder and Aggregates—In Alkali-Activated Materials: A Novel Re-Use Concept" Sustainability 12, no. 14: 5775. https://doi.org/10.3390/su12145775

APA StyleRobayo-Salazar, R. A., Valencia-Saavedra, W., & Mejía de Gutiérrez, R. (2020). Construction and Demolition Waste (CDW) Recycling—As Both Binder and Aggregates—In Alkali-Activated Materials: A Novel Re-Use Concept. Sustainability, 12(14), 5775. https://doi.org/10.3390/su12145775