Assessment Model of End-of-Life Costs and Waste Quantification in Selective Demolitions: Case Studies of Nearly Zero-Energy Buildings

Abstract

1. Introduction

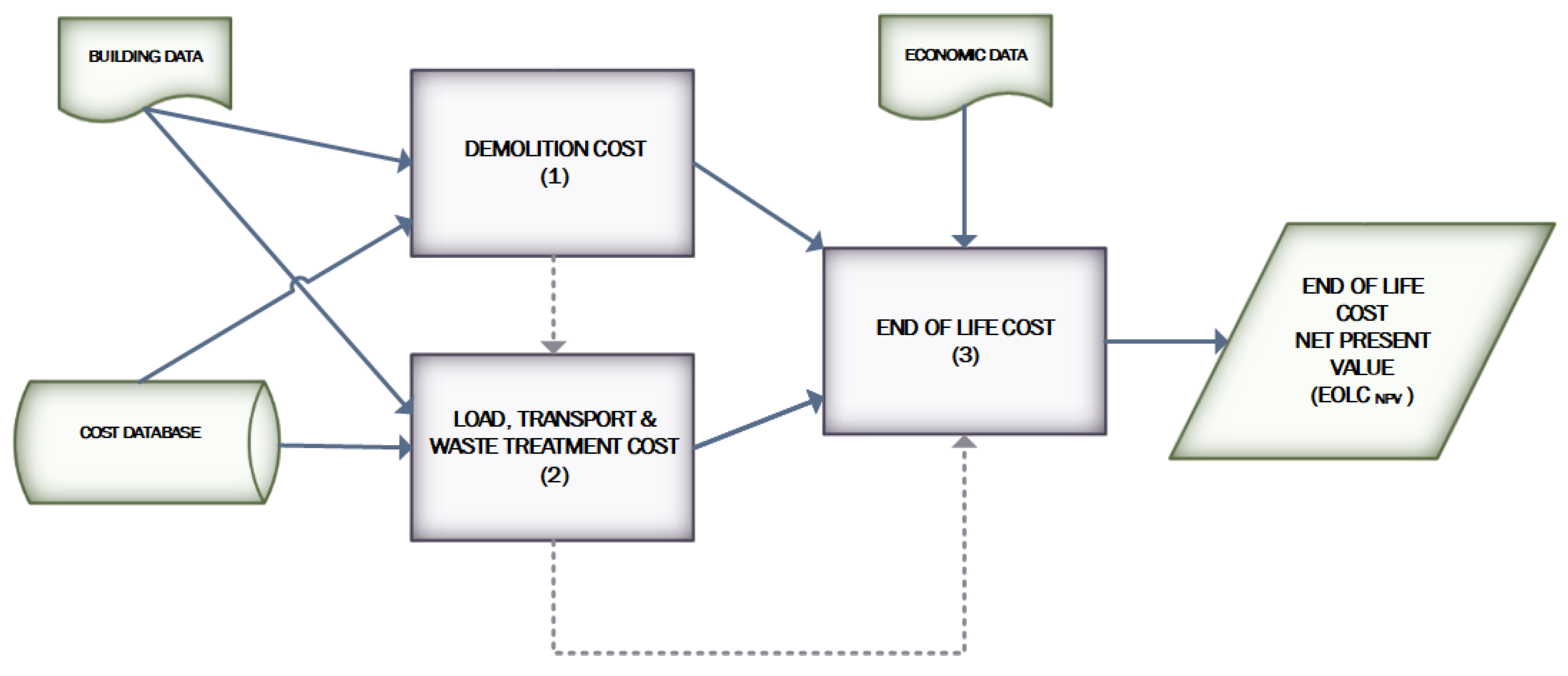

2. Methodology

2.1. Demolition Costs

2.2. Load, Transport, and Waste Management Costs

2.3. EOLC

2.4. Cost Normalization

2.5. Sensitivity Analysis

2.6. LCC CRAVEzero Calculation

3. Case Studies Description, Scenario

3.1. Case Studies Description

3.2. Scenario

4. Results and Discussions

4.1. EOLC Results

4.2. Waste Streams and EOLC

4.3. Sensitivity Analysis

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| Equation Parameter List | |

| CCi | Volume conversion ratio of building element {m3a/umBEi} |

| CCk | Volume conversion ratio of material {m3a/umMk} |

| CRij | Unit conversion ratio. {umDCj /umBEi} |

| CTi | Bulk volume ratio {m3b/ m3a} |

| DCi | Demolition cost of building element {€} |

| TDC | Total demolition cost {€} |

| dak | Apparent density of material {t/m3a} |

| dbki | Bulk density of material {t/m3b} |

| dr | Discount rate {dimensionless} |

| DBVi | Demolished bulk volume of building element {m3b}. |

| DBVki | Quantity of demolished bulk volume for each material {m3b}. |

| DCj | unit demolition cost {€/umDCj} |

| DWki | Quantity of demolished weight for each material {t} |

| DWUk | Demolition waste reuse {t} |

| DWYk | Demolition waste recycle {t} |

| DWDk | Demolition waste disposal {t} |

| EOLC | End-of-life cost {€} |

| EOLCNPV | End-of-life cost net present value {€} |

| (EOLCNPV)n | End-of-life costs net present value and normalized. {€} |

| i | Inflation rate {dimensionless} |

| icd | Cost index {dimensionless} |

| Pok | Treatment option percentage {dimensionless} |

| PUk | Reuse percentage {dimensionless} |

| PYk | Recycle percentage {dimensionless} |

| PDk | Disposal percentage {dimensionless} |

| Qi | Quantity of building element {umBEi}. |

| qki | Quantity of the material included in the BE {umMk/umBEi}. |

| TLC | Total Load costs {€} |

| TTC | Total Transport cost {€} |

| LC | Unitary load cost {€/t} |

| TC | Unitary transport cost {€/t·km} |

| TWC | Total Waste treatment cost {€} |

| Vki | Volume percentage of material k in building element i. {dimensionless} |

| WCok | Unitary waste treatment cost {€/t} |

| WTDok | Waste treatment distance {km} |

| y | Period of time {years} |

| Measure Unit List | |

| m3a | Apparent volume. |

| m3b | Bulk volume. |

| umBEi | Unit of measurement of building elements {m, m2, m3…} |

| umDCj | Unit of measurement of demolition work unit {m, m2, m3…} |

| umMk | Unit of measurement material {m, m2, m3, t…} |

| t | tonns |

References

- Rosselló-Batle, B.; Moià, A.; Cladera, A.; Martínez, V. Energy use, CO2 emissions and waste throughout the life cycle of a sample of hotels in the Balearic Islands. Energy Build. 2010, 42, 547–558. [Google Scholar] [CrossRef]

- Radhi, H.; Sharples, S. Global warming implications of facade parameters: A life cycle assessment of residential buildings in Bahrain. Environ. Impact Assess. Rev. 2013, 38, 99–108. [Google Scholar] [CrossRef]

- Nematchoua, M.K.; Teller, J.; Reiter, S. Statistical life cycle assessment of residential buildings in a temperate climate of northern part of Europe. J. Clean. Prod. 2019, 229, 621–631. [Google Scholar] [CrossRef]

- Asif, M.; Muneer, T.; Kelley, R. Life cycle assessment: A case study of a dwelling home in Scotland. Build. Environ. 2007, 42, 1391–1394. [Google Scholar] [CrossRef]

- Dimoudi, A.; Tompa, C. Energy and environmental indicators related to construction of office buildings. Resour. Conserv. Recycl. 2008, 53, 86–95. [Google Scholar] [CrossRef]

- Du, P.; Wood, A.; Stephens, B.; Song, X. Life-Cycle Energy Implications of Downtown High-Rise vs. Suburban Low-Rise Living: An Overview and Quantitative Case Study for Chicago. Buildings 2015, 5, 1003–1024. [Google Scholar] [CrossRef]

- Michailidou, A.V.; Vlachokostas, C.; Moussiopoulos, N.; Maleka, D. Life Cycle Thinking used for assessing the environmental impacts of tourism activity for a Greek tourism destination. J. Clean. Prod. 2016, 111, 499–510. [Google Scholar] [CrossRef]

- Marrero, M.; Rivero-Camacho, C.; Alba-Rodríguez, M.D. What are we discarding during the life cycle of a building? Case studies of social housing in Andalusia, Spain. Waste Manag. 2020, 102, 391–403. [Google Scholar] [CrossRef]

- EN-15643-1. Sustainability of Construction Works—Sustainability Assessment of Buildings—Part 1: General Framework; Comite Europeen de Normalisation: Geneva, Switzerland, 2010. [Google Scholar]

- ISO 15686-5. Buildings and Constructed Assets—Service Life Planning—Part 5: Life-Cycle Costing; International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

- EN-16627. Sustainability of Construction Works—Assessment of Economic Performance of Buildings—Calculation Methods; Comite Europeen de Normalisation: Geneva, Switzerland, 2015. [Google Scholar]

- Alba-Rodríguez, M.D.; Martínez-Rocamora, A.; González-Vallejo, P.; Ferreira-Sánchez, A.; Marrero, M. Building rehabilitation versus demolition and new construction: Economic and environmental assessment. Environ. Impact Assess. Rev. 2017, 66, 115–126. [Google Scholar] [CrossRef]

- Islam, H.; Jollands, M.; Setunge, S. Life cycle assessment and life cycle cost implication of residential buildings—A review. Renew. Sustain. Energy Rev. 2015, 42, 129–140. [Google Scholar] [CrossRef]

- Dwaikat, L.N.; Ali, K.N. Green buildings life cycle cost analysis and life cycle budget development: Practical applications. J. Build. Eng. 2018, 18, 303–311. [Google Scholar] [CrossRef]

- Pelzeter, A. Building optimisation with life cycle costs—The influence of calculation methods. J. Facil. Manag. 2007, 5, 115–128. [Google Scholar] [CrossRef]

- European Commission. Report from the Commission to the European Parliament on the Implementation of the Circular Economy Action Plan COM/2019/190 Final; European Union: Brussels, Belgium, 2019. [Google Scholar]

- European Commission. EU Construction & Demolition Waste Management Protocol; Dublin, 22 June 2017; European Union: Brussels, Belgium, 2016; Volume 62, ISBN 1866505041. [Google Scholar]

- European Parliament. Directive 2014/24/EU of The European Parliament and of The Council of 26 February 2014 on Public Procurement and Repealing Directive 2004/18/EC (Text with EEA Relevance); European Parliament: Brussels, Belgium, 2014; Volume 94. [Google Scholar]

- Kofoworola, O.F.; Gheewala, S.H. Estimation of construction waste generation and management in Thailand. Waste Manag. 2009, 29, 731–738. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Yuan, H.; Kang, X.; Lu, W. Critical success factors for on-site sorting of construction waste: A china study. Resour. Conserv. Recycl. 2010, 54, 931–936. [Google Scholar] [CrossRef]

- Yuan, H.; Shen, L. Trend of the research on construction and demolition waste management. Waste Manag. 2011, 31, 670–679. [Google Scholar] [CrossRef]

- Wu, Z.; Yu, A.T.W.; Shen, L.; Liu, G. Quantifying construction and demolition waste: An analytical review. Waste Manag. 2014, 34, 1683–1692. [Google Scholar] [CrossRef]

- Mália, M.; De Brito, J.; Pinheiro, M.D.; Bravo, M. Construction and demolition waste indicators. Waste Manag. Res. 2013, 31, 241–255. [Google Scholar] [CrossRef]

- Coelho, A.; De Brito, J. Generation of construction and demolition waste in Portugal. Waste Manag. Res. 2011, 29, 739–750. [Google Scholar] [CrossRef]

- Solís-Guzmán, J.; Marrero, M.; Montes-Delgado, M.V.; Ramírez-de-Arellano, A. A Spanish model for quantification and management of construction waste. Waste Manag. 2009, 29, 2542–2548. [Google Scholar] [CrossRef]

- Akinade, O.O.; Oyedele, L.O.; Omoteso, K.; Ajayi, S.O.; Bilal, M.; Owolabi, H.A.; Alaka, H.A.; Ayris, L.; Henry Looney, J. BIM-based deconstruction tool: Towards essential functionalities. Int. J. Sustain. Built Environ. 2017, 6, 260–271. [Google Scholar] [CrossRef]

- NIST BEES Online. Available online: https://ws680.nist.gov/bees/(A(YRWmdd3E1QEkAAAAZWE1NmE3MzUtMWM4Zi00OTA1LWI0MTctN2RkODkzOWYyNGMzu9uo8zgO971rP3Ett3WWtXZwV6A1))/AnalysisParametersBuildingProds.aspx (accessed on 7 July 2020).

- BIONOVA Ltd. One Click LCA. Available online: https://www.oneclicklca.com/ (accessed on 7 July 2020).

- Cheng, J.C.P.; Ma, L.Y.H. A BIM-based system for demolition and renovation waste estimation and planning. Waste Manag. 2013. [Google Scholar] [CrossRef] [PubMed]

- BRE Group. IMPACT. Available online: https://www.bregroup.com/impact/ (accessed on 7 July 2020).

- Garzia, F.; Pernetti, R.; Weiss, T.; Venus, D.; Knotzer, A.; Thouvenot, M.; Berggren, B. D2.1: Report on EU Implementation of nZEBs; EURAC research: Bolzano, Italy, 2018. [Google Scholar]

- Pernetti, R.; Garzia, F.; Paoletti, G. D2.2: Spreadsheet with LCCs A Database for Benchmarking Actual NZEB Life-Cycle Costs of the Case Studies; EURAC research: Bolzano, Italy, 2018. [Google Scholar]

- European Parliament. Directive 2010/31/EU, of european parliament and of the council of 19 May 2010 on the energy performance of building (recast). Off. J. Eur. Union 2010, 153, 13–35. [Google Scholar]

- European Commission. Guidelines accompanying Commission Delegated Regulation (EU) No 244/2012 of 16 January supplementing Directive 2010/31/EU of the European Parliament and of the Council. Off. J. Eur. Union 2012, 115, 1–28. [Google Scholar]

- European Commission. Commission recommendation (EU) 2016/1318, on guidelines for the promotion of nearly zero-energy buildings and best practices to ensure that, by 2020, all new buildings are nearly zero-energy buildings. Off. J. Eur. Union 2016, 208, 46–57. [Google Scholar]

- IDAE. Escala de calificación energética—Edificios de nueva construcción. Labelling schemes for new buildings; IDAE—Instituto para la Diversificación y Ahorro de la Energía: Madrid, Spain, 2009. [Google Scholar]

- D’Agostino, D.; Mazzarella, L. What is a Nearly zero energy building? Overview, implementation and comparison of definitions. J. Build. Eng. 2019, 21, 200–212. [Google Scholar] [CrossRef]

- Karlessi, T.; Kampelis, N.; Kolokotsa, D.; Santamouris, M.; Standardi, L.; Isidori, D.; Cristalli, C. The Concept of Smart and NZEB Buildings and the Integrated Design Approach. Proc. Eng. 2017, 180, 1316–1325. [Google Scholar] [CrossRef]

- ACCD—Andalusia Construction Cost Database. 2017. Available online: http://www.juntadeandalucia.es/organismos/fomentoyvivienda/areas/vivienda-rehabilitacion/planes-instrumentos/paginas/bcca-sept-2017.html (accessed on 7 July 2020).

- Kim, Y.-C.; Hong, W.-H.; Park, J.-W.; Cha, G.-W. An estimation framework for building information modeling (BIM)-based demolition waste by type. Waste Manag. Res. 2017, 35, 1285–1295. [Google Scholar] [CrossRef]

- Ramirez de Arellano Agudo, A.; Llatas-Oliver, C.; García-Torres, I. Retirada Selectiva de Residuos: Modelo de Presupuestacion; Coleccion Nivel 6; Fundacion Cultural del Colegio Oficial de Aparejadores y Arquitectos Tecnicos: Sevilla, Spain, 2002. [Google Scholar]

- Marrero, M.; Ramirez-De-Arellano, A. The building cost system in andalusia: Application to construction and demolition waste management. Constr. Manag. Econ. 2010, 28, 495–507. [Google Scholar] [CrossRef]

- González-Vallejo, P.; Muñoz-Sanguinetti, C.; Marrero, M. Environmental and economic assessment of dwelling construction in Spain and Chile. A comparative analysis of two representative case studies. J. Clean. Prod. 2019, 208, 621–635. [Google Scholar] [CrossRef]

- ASTM E917. Stardard Practice for Measuring Life-Cycle Costs of Buildings and Building Systems; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- EN-15643-4. Sustainability of Construction Works. Assessment of Buildings. Framework for the Assessment of Economic Performance; Comite Europeen de Normalisation: Geneva, Switzerland, 2012. [Google Scholar]

- European Parliament. Directive 2008/98/EC, On Waste and Repealing Centain Directives. Off. J. Eur. Union 2008, 312, 3–30. [Google Scholar]

- Dantata, N.; Touran, A.; Wang, J. An analysis of cost and duration for deconstruction and demolition of residential buildings in Massachusetts. Resour. Conserv. Recycl. 2005, 44, 1–15. [Google Scholar] [CrossRef]

- Solís-Guzmán, J.; Marrero, M.; Guisado García, D. Model for the quantification and budgeting of the construction and demolition waste. Application to roads|Modelo de cuantificación y presupuestación en la gestión de residuos de construcción y demolición. Aplicación a viales. Carreteras 2014, 4, 6–18. [Google Scholar]

- Pun, S.K.; Liu, C.; Langston, C. Case study of demolition costs of residential buildings. Constr. Manag. Econ. 2006, 24, 967–976. [Google Scholar] [CrossRef]

- Freire-Guerrero, A.; Alba-Rodríguez, M.D.; Marrero, M. A budget for the ecological footprint of buildings is possible: A case study using the dwelling construction cost database of Andalusia. Sustain. Cities Soc. 2019, 51. [Google Scholar] [CrossRef]

- European Commission. 2000/532/EC European waste catalogue. Off. J. Eur. Communities 2000, 226, 3–24. [Google Scholar]

- European Constructions Costsd Ltd. European Cost Index. Available online: http://constructioncosts.eu/cost-index/ (accessed on 7 July 2020).

- Langdon, D. Life Cycle Costing (LCC) as a contribution to sustainable construction: A common methodology. Literature review. Davis Langdon Manag. Consult. 2007, 1, 1–113. [Google Scholar]

- Heiselberg, P.; Brohus, H.; Hesselholt, A.; Rasmussen, H.; Seinre, E.; Thomas, S. Application of sensitivity analysis in design of sustainable buildings. Renew. Energy 2009, 34, 2030–2036. [Google Scholar] [CrossRef]

- Tian, W. A review of sensitivity analysis methods in building energy analysis. Renew. Sustain. Energy Rev. 2013, 20, 411–419. [Google Scholar] [CrossRef]

- Weiss, T.; Moser, C.; Venus, D.; Garzia, F.; Pernetti, R.; Köhler, G.; Stöcker, T. D6.1: Parametric Models for Buildings and Building Clusters: Building Features and Boundaries; EURAC research: Bolzano, Italy, 2019. [Google Scholar]

- Marenjak, S.; Krstić, H. Sensitivity analysis of facilities life cycle costs. Teh. Vjesn. 2010, 17, 481–487. [Google Scholar]

- Federal Reserve Bank of St. Louis Interest Rates, Discount Rate for Euro Area (INTDSREZQ193N)|FRED|St. Louis Fed. Available online: https://fred.stlouisfed.org/series/INTDSREZQ193N (accessed on 7 July 2020).

- Feist, W.; Pfluger, R.; Schneieders, J.; Kah, O.; Kaufman, B.; Krick, B. Passive House Planning Package Version 7; Passive House Institute: Darmstadt, Germany, 2012. [Google Scholar]

- Eurostat Electricity Prices for Households in the European Union 2010–2017, Semmi-Annually. Available online: http://epp.eurostat.ec.europa.eu (accessed on 7 July 2020).

- EN15459-1:2017. Energy Performance of Buildings—Economic Evaluation Procedure for Energy Systems in Buildings—Part 1: Calculation Procedures, Modules M1-M14; Comite Europeen de Normalisation: Geneva, Switzerland, 2017. [Google Scholar]

- SGC. Tarifa de Precios de Reciclaje de Residuos de la Construcción; SGC: Fresno de la Ribera, Spain, 2016. [Google Scholar]

- RESIDUALIA. Tarifas—Centro de Gestión Medioambiental Sierra Segura. Available online: http://www.residualia.net/tarifas/ (accessed on 8 November 2019).

- BRE; Deloitte; FCT; ICEDD; RPS; VTT, D.-G. Resource Efficient Use of Mixed Wastes Improving Management of Construction and Demolition Waste; Final report; European Commission: Brussels, Belgium, 2017. [Google Scholar]

- ICE. Demolition Protocol; Institution of Civil Engineeres: London, UK, 2008. [Google Scholar]

- Banias, G.; Achillas, C.; Vlachokostas, C.; Moussiopoulos, N.; Papaioannou, I. A web-based Decision Support System for the optimal management of construction and demolition waste. Waste Manag. 2011, 31, 2497–2502. [Google Scholar] [CrossRef]

| Description | Qi | umBE | ||

| Roof with cold attic | 1541 | m2 | ||

| Components | Height (cm) | |||

| Gypsum board | 1.30 | |||

| Wood/air | 2.80 | |||

| Plastic foil | 0.02 | |||

| Isolation + Wood frames | 60.00 | |||

| Wood | 2.20 | |||

| Bituminous sheet | 3.25 | |||

| TOTAL height | 69.57 | |||

| Breakdown cost calculation | ||||

| umDCj | Concept | CRij | €/umDCj | €/umBE |

| m2 | Selective demolition wood roof | 1.00 m2/m2 | 7.46 €/m2 | 7.46 €/m2 |

| m2 | Selective demolition wood frames | 1.00 m2/m2 | 14.72 €/m2 | 14.72 €/m2 |

| m2 | Selective demolition suspended ceiling | 1.00 m2/m2 | 2.24 €/m2 | 2.24 €/m2 |

| m3 | Selective demolition isolation panels | 0.60 m3/m2 | 15.42 €/m2 | 9.20 €/m2 |

| TOTAL | 33.67 €/m2 | |||

|  |  | |

| Name | Residence Alizari | Solallén | Väla Gård |

| Year | 2015 | 2015 | 2012 |

| Location | Malaunay (France) | Växjö (Sweden) | Helsingborg (Sweden) |

| GFA {m2} | 2825 | 2100 | 1815 |

| Building typology | Residential | Residential | Office building |

| Floors | 5 | 1 | 3 |

| Construction features | Concrete structure. Triple glazing, internal and external insulation | Wood structure. Well insulated and airtight | Concrete structure except wood roof. Well insulated and airtight |

| Equipment features | Balanced ventilation with heat recovery, centralized wood boiler, photovoltaics | Balanced ventilation with HR, GSHP, photovoltaics | Balanced ventilation with HR, GSHP, photovoltaics |

| Net final energy consumption | 63.90 kWh/m2.yr | 28.18 kWh/m2.yr | 12.58 kWh/m2.yr |

| GFA = gross floor area, HR = heat recovery, GSHP = Ground source heat pump | |||

| Parameter | Value | Source | |

|---|---|---|---|

| Life cycle cost building | Various | [32] | |

| Time period | 40 years | [32] | |

| Inflation rate | 0 | - | |

| Discount rate | 1.51% | [58] | |

| Cost normalization index Spain | 70.52% | [52] | |

| Load Cost (LC) | 0.65 €/t | [39] | |

| Transport Cost (TC) | 0.69 €/t km | [39] | |

| Demolition Cost (DC) | Various | [39] | |

| Waste Treatment Cost (WC) Material(k) | Recycle (WCYk) | Disposal (WCDk) | [39,62,63] |

| Mix non-inert | - | 70.00 €/t | |

| Mix inert | 9.50 €/t | 30.00 €/t | |

| Concrete | 4.00 €/t | 30.00 €/t | |

| Ceramics | 6.00 €/t | 30.00 €/t | |

| Wood | 25.00 €/t | 70.00 €/t | |

| Glass | 30.00 €/t | 70.00 €/t | |

| Bituminous | 3.50 €/t | 70.00 €/t | |

| Metal | −80.00 €/t | 30.00 €/t | |

| Cable | −900.00 €/t | 70.00 €/t | |

| Soil | 3.00 €/t | 30.00 €/t | |

| Isolation | 60.00 €/t | 80.00 €/t | |

| Gypsum based | 60.00 €/t | 80.00 €/t | |

| Paper | 3.50 €/t | 70,00 €/t | |

| Hazardous | - | 80,00 €/t | |

| Waste Treatment Distance (WTD) | 15 km | - | |

| Recycle waste percentage | |||

| Mixed inert, concrete, ceramic | 75% | [65] | |

| Gypsum-based | 10% | [64] | |

| Wood | 57% | [65] | |

| Metal | 80% | [64] | |

| Soil, glass, paper | 50% | [64] | |

| Plastic, bituminous, isolation | 25% | [64] | |

| Waste | Alizari | Residential. Reinforced. Concrete * | Solallén | Residential. Wood * | Väla Gård | Non-Residential. Reinforced Concrete * |

|---|---|---|---|---|---|---|

| Concrete | 810.76 | 492–840 | 278.95 | 137–300 | 683.50 | 401–768 |

| Wood | 3.08 | 12–58 | 92.81 | 70–275 | 61.93 | 20–159 |

| Metal | 45.49 | 9.8–28.4 | 9.84 | 4.8–22.5 | 34.69 | 28.4–53 |

| Isolation | 9.69 | 0.1–2.2 | 47.32 | 0.1–2.2 | 19.58 | 0.1–2.2 |

| Gypsum | 27.57 | 10.8–64.3 | 40.61 | 10.9–105.4 | 12.67 | 10.8–75.7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vázquez-López, E.; Garzia, F.; Pernetti, R.; Solís-Guzmán, J.; Marrero, M. Assessment Model of End-of-Life Costs and Waste Quantification in Selective Demolitions: Case Studies of Nearly Zero-Energy Buildings. Sustainability 2020, 12, 6255. https://doi.org/10.3390/su12156255

Vázquez-López E, Garzia F, Pernetti R, Solís-Guzmán J, Marrero M. Assessment Model of End-of-Life Costs and Waste Quantification in Selective Demolitions: Case Studies of Nearly Zero-Energy Buildings. Sustainability. 2020; 12(15):6255. https://doi.org/10.3390/su12156255

Chicago/Turabian StyleVázquez-López, Eduardo, Federico Garzia, Roberta Pernetti, Jaime Solís-Guzmán, and Madelyn Marrero. 2020. "Assessment Model of End-of-Life Costs and Waste Quantification in Selective Demolitions: Case Studies of Nearly Zero-Energy Buildings" Sustainability 12, no. 15: 6255. https://doi.org/10.3390/su12156255

APA StyleVázquez-López, E., Garzia, F., Pernetti, R., Solís-Guzmán, J., & Marrero, M. (2020). Assessment Model of End-of-Life Costs and Waste Quantification in Selective Demolitions: Case Studies of Nearly Zero-Energy Buildings. Sustainability, 12(15), 6255. https://doi.org/10.3390/su12156255