Gob-Side Entry Retaining Involving Bag Filling Material for Support Wall Construction

Abstract

:1. Introduction

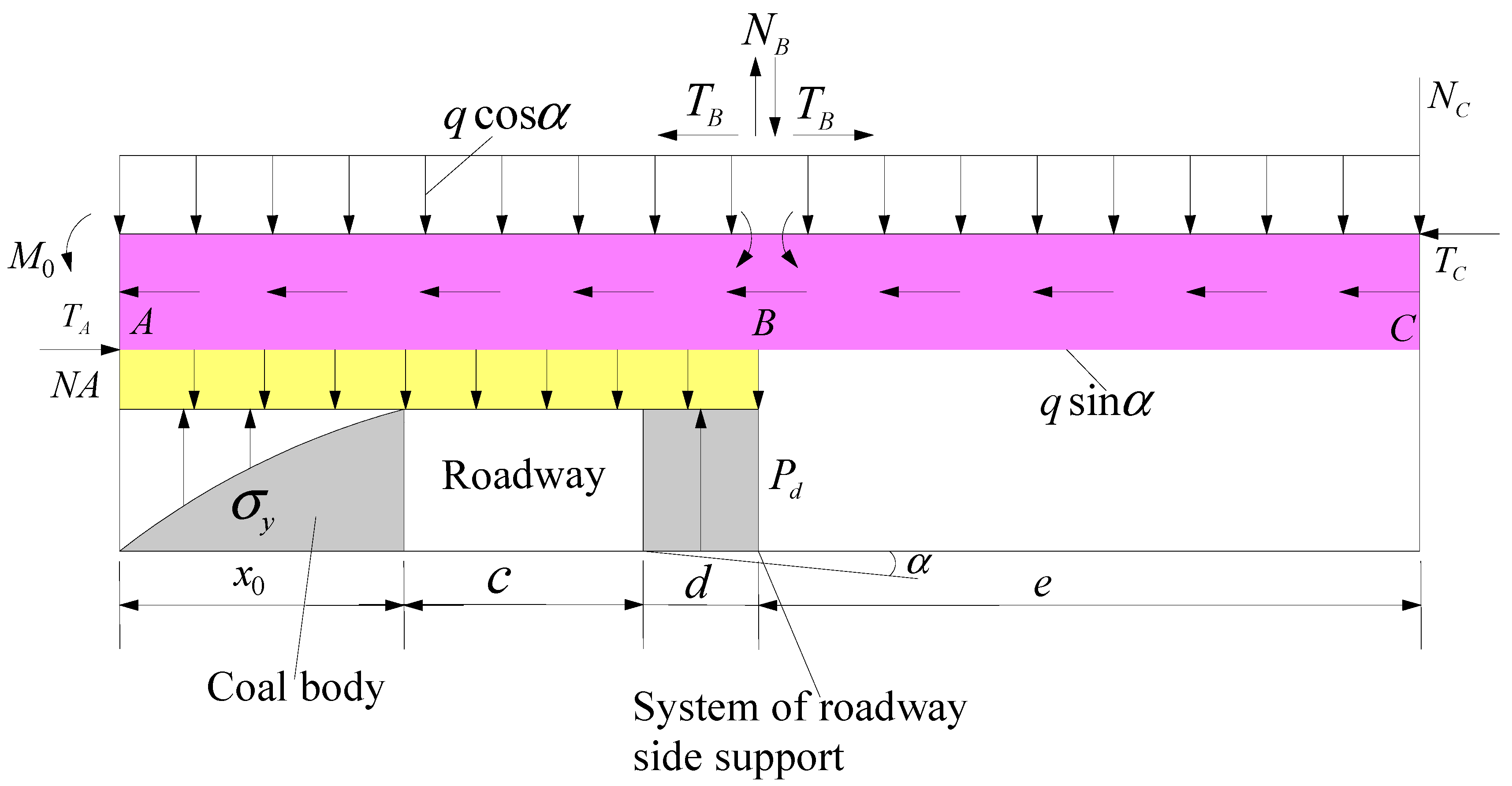

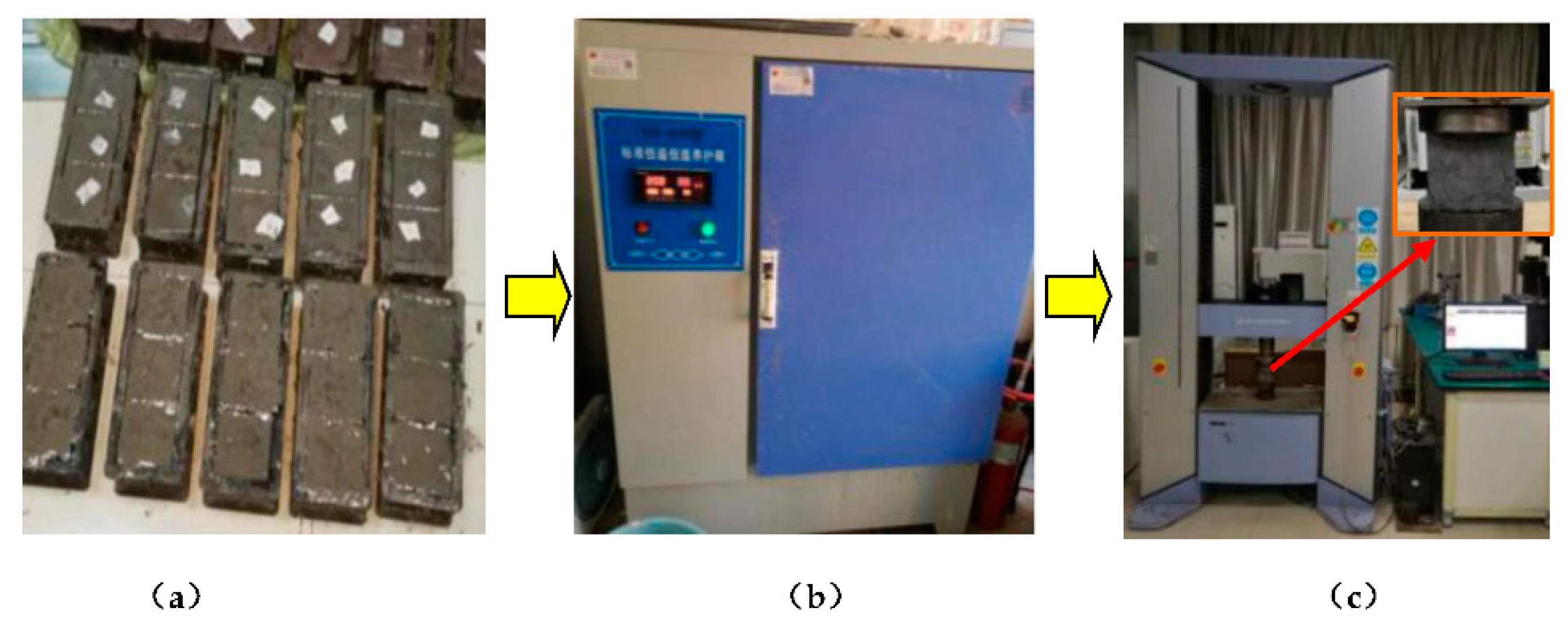

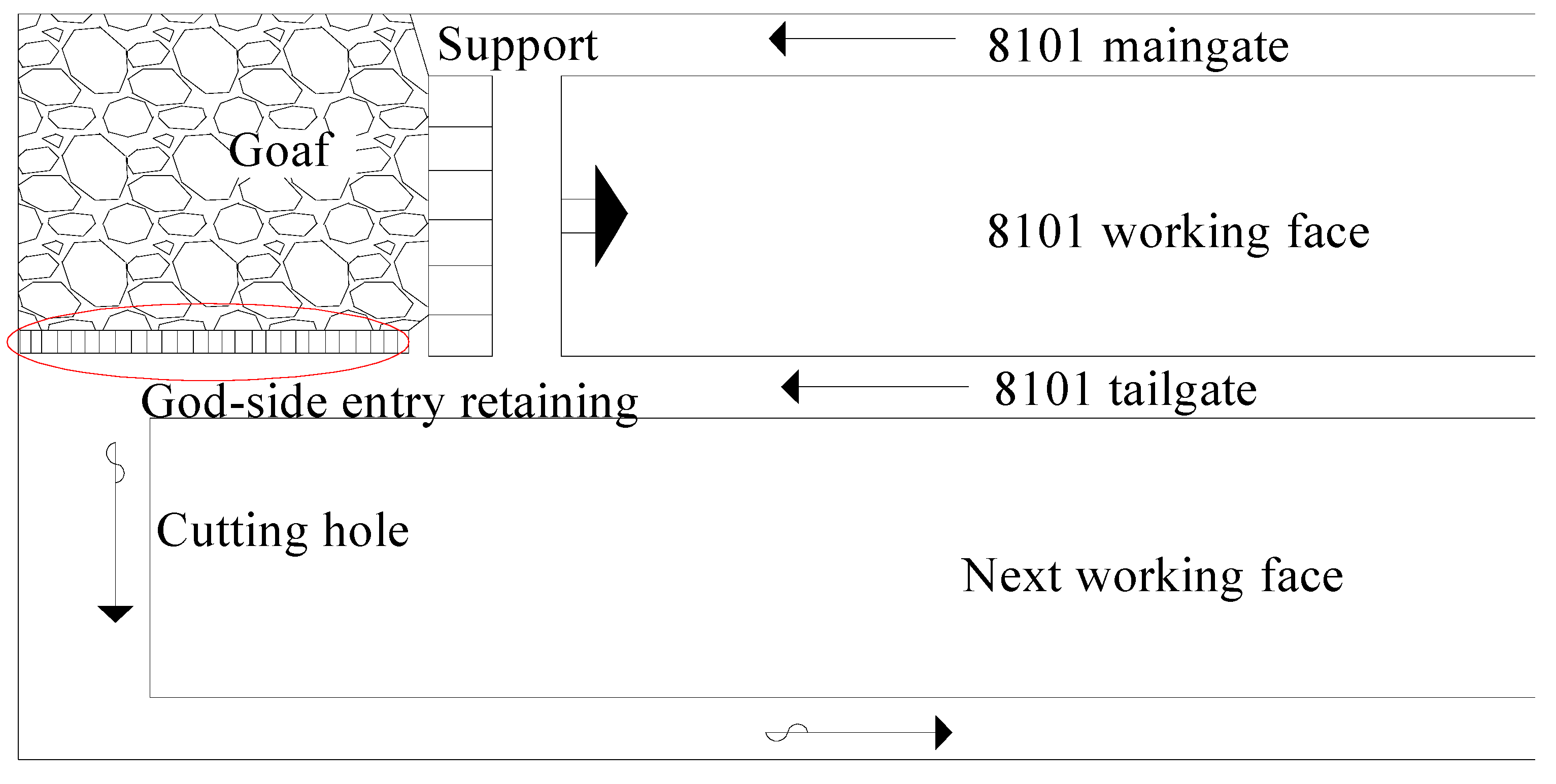

2. Gob-Side Entry Support Resistance Calculation

3. Gob-Side Entry Retaining Mining Technology with Bag Filling Material for Wall Construction

3.1. Bag Preparation

3.1.1. Raw Materials

- Cement—It is the most important material for gob-side entry retaining. It hydrates immediately on encountering water and initially forms a plastic paste, with the paste gradually losing its plasticity. The cement paste then hardens, thereby forming , and the strength increases until it attains a desired condensate value.

- Putty powder—It is mainly a binder that enables aggregation and firm bonding of concrete particles. It also prevents hollowing, micro expansion, and cracking when the filling material encounters water. It is characterized by small and cohesive particles.

- Sand—This contains mainly SiO2, representing an inert material of high strength and good durability. It is a good low-cost fine aggregate that acts as “bone”, and improves the overall strength of the mixed material.

- Fly ash—It comprises particles with sizes of 1–100 μm from coal combustion. Its characteristics involve specific corrosion resistance and high early strength. In the mixed material used for gob-side entry retaining, it helps to increase the workability and overall strength of the mixed material.

- Additive—The accelerator is a high efficiency additive commonly used in coal mine enterprises. It is an admixture that increases the initial speed of the reaction between cement and water, and promotes the quick setting and hardening of the concrete.

3.1.2. Material Ratio and Bag Preparation

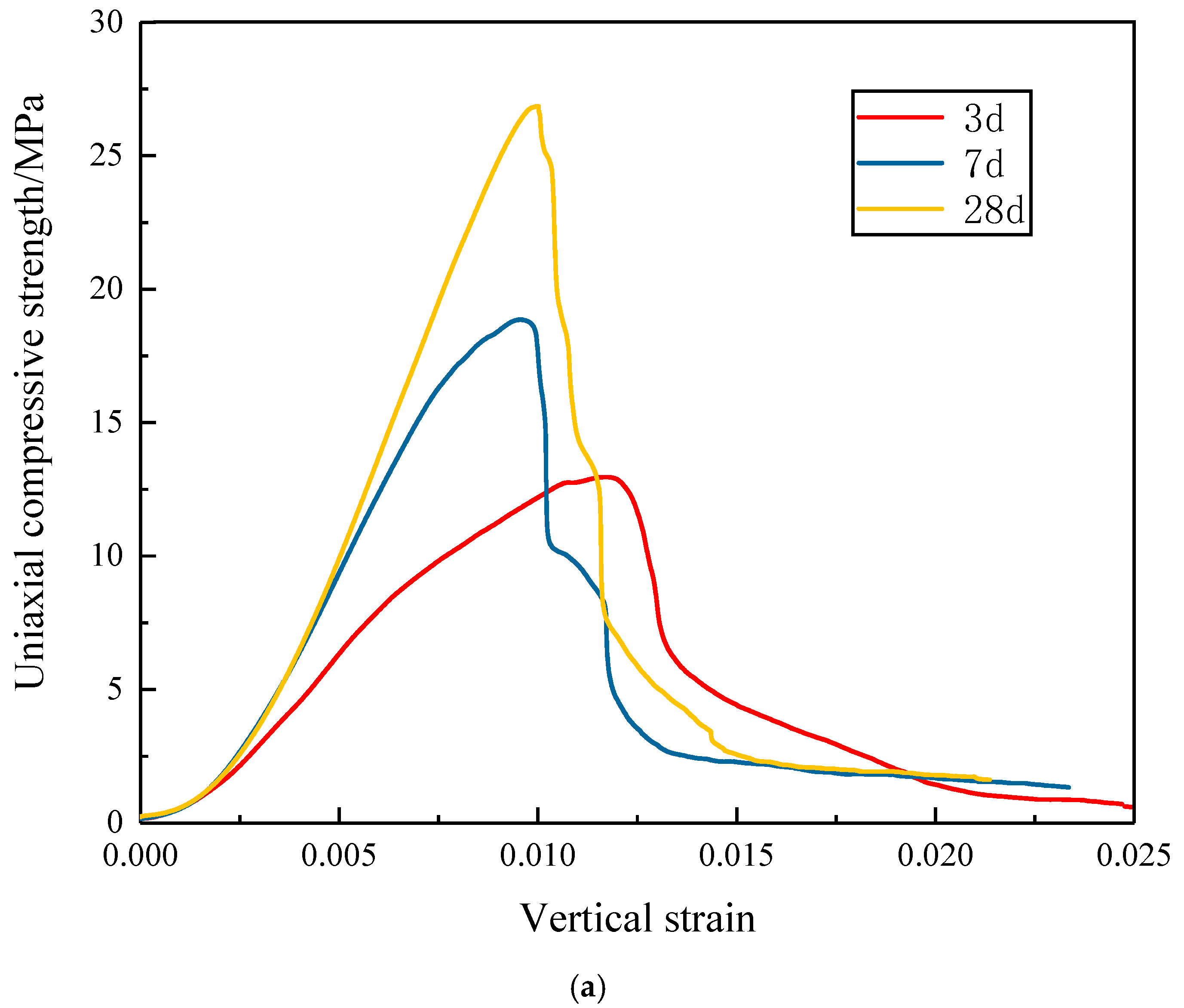

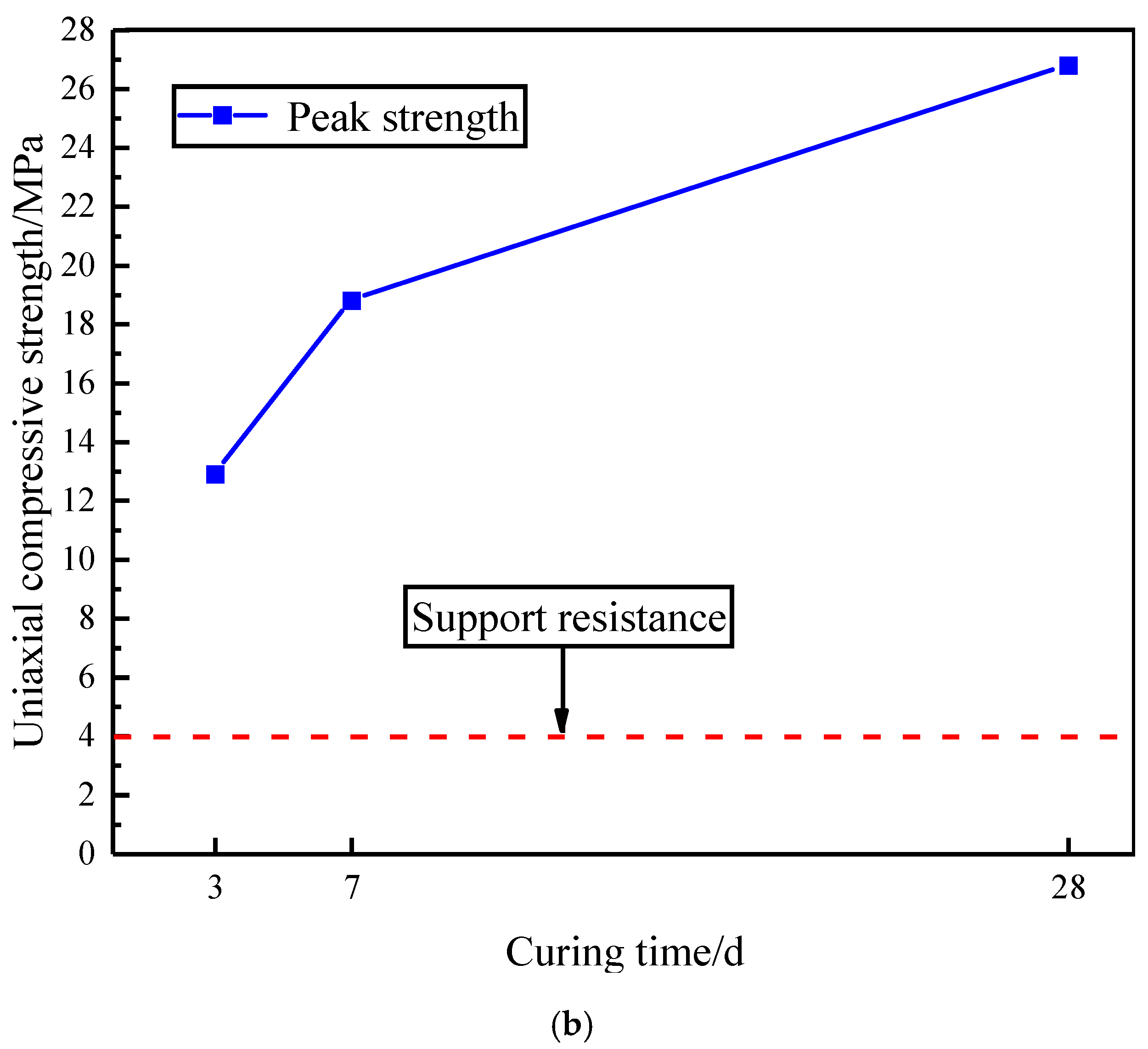

3.1.3. Mechanical Properties of the Materials

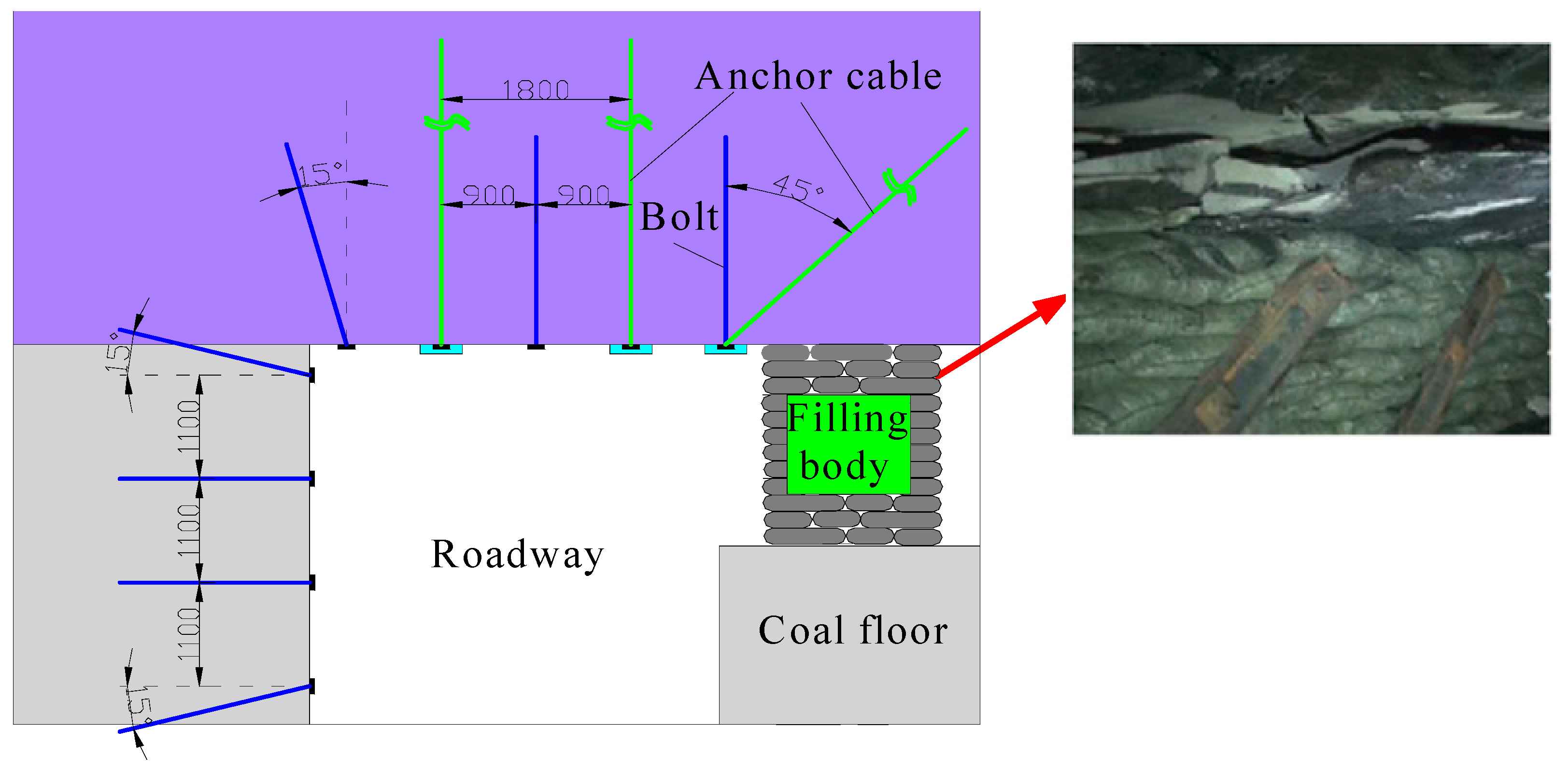

3.2. Wall Construction

4. Numerical Simulation and Field Monitoring

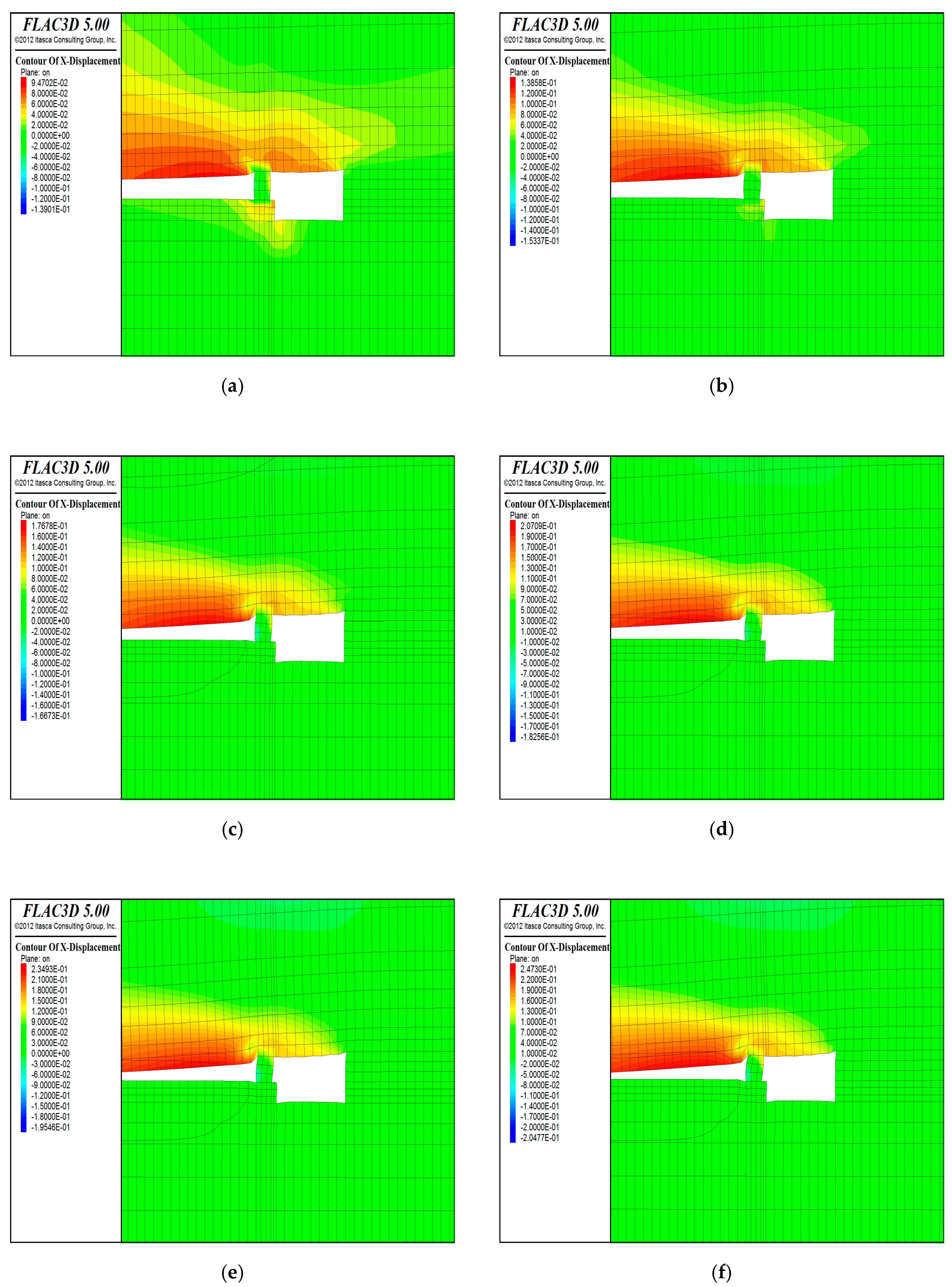

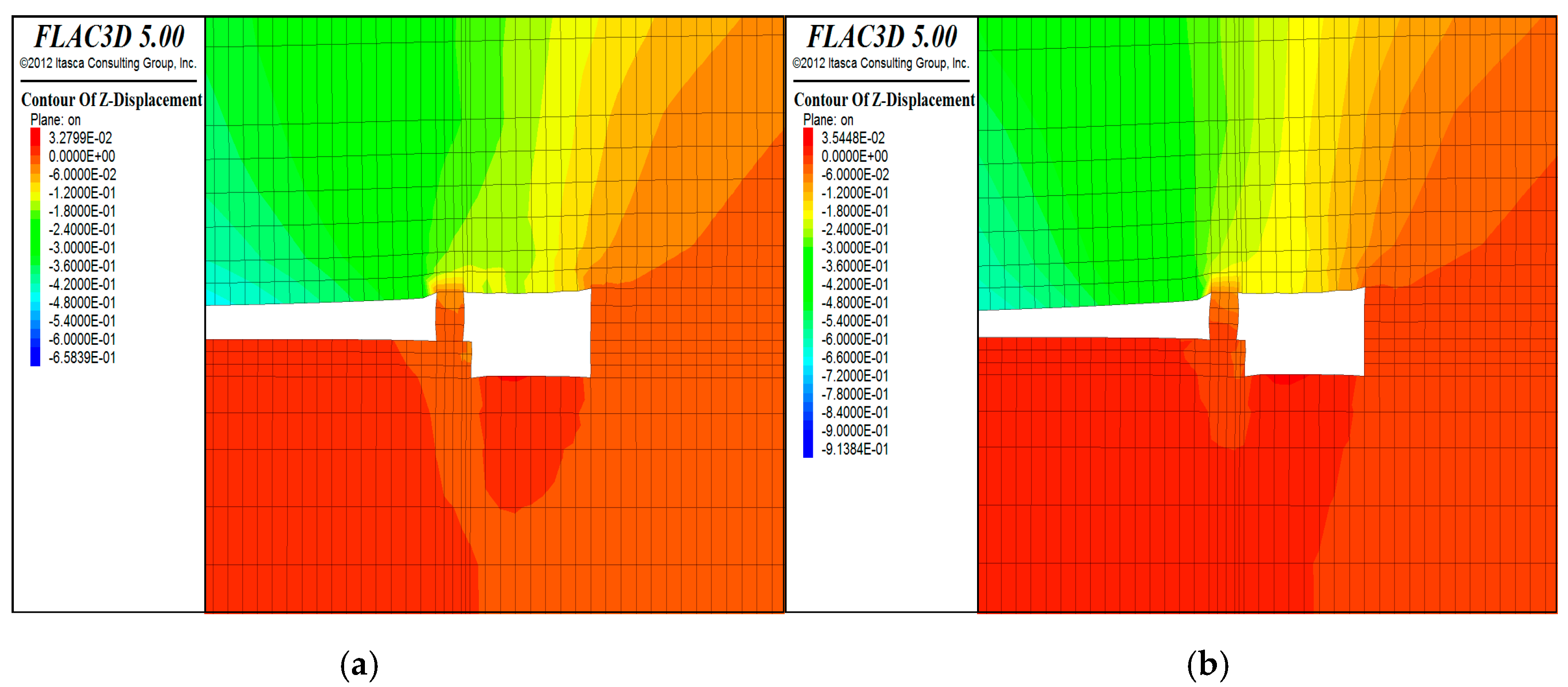

4.1. Numerical Simulation

4.1.1. Displacement along the Two Sides of the Roadway

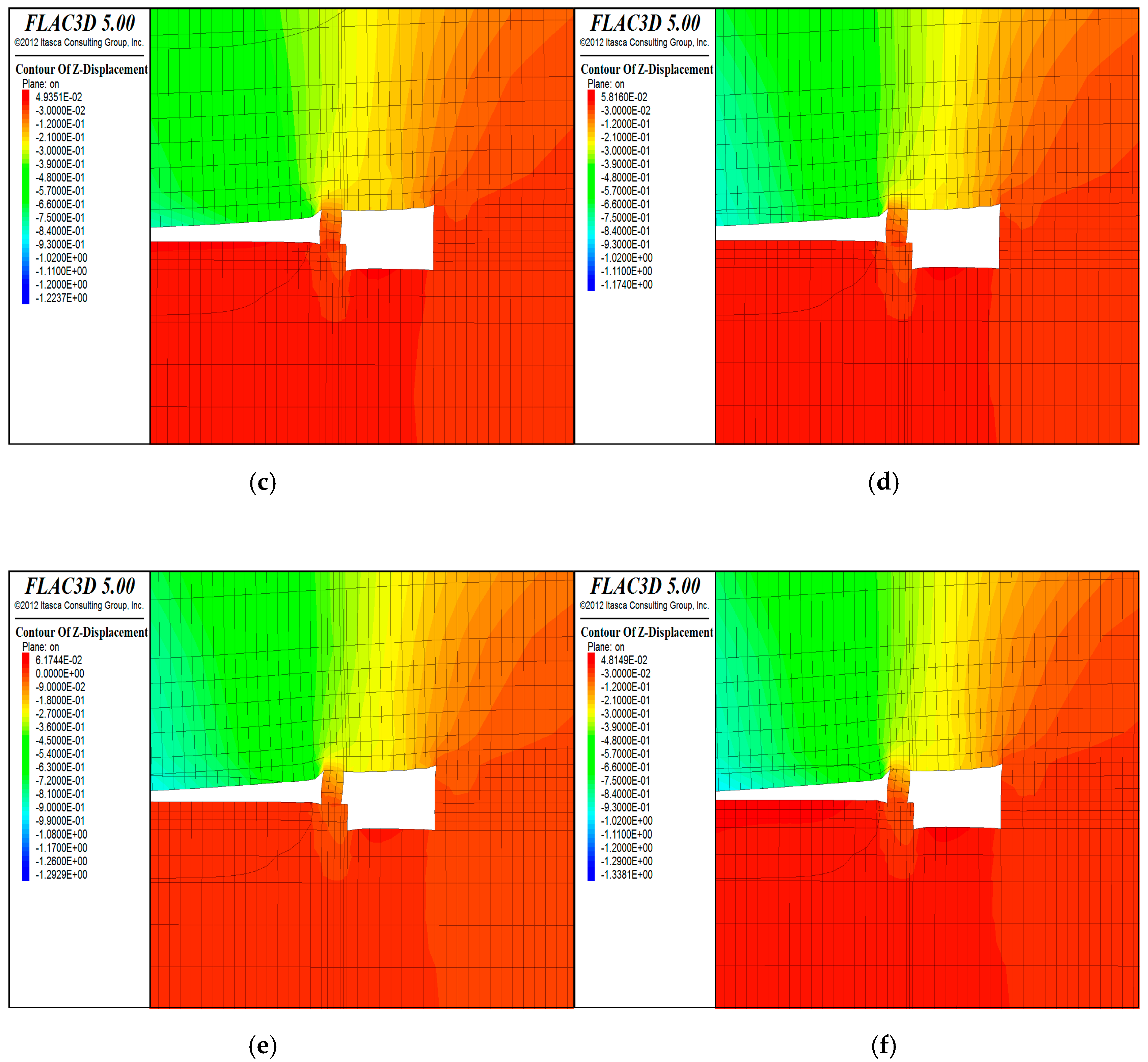

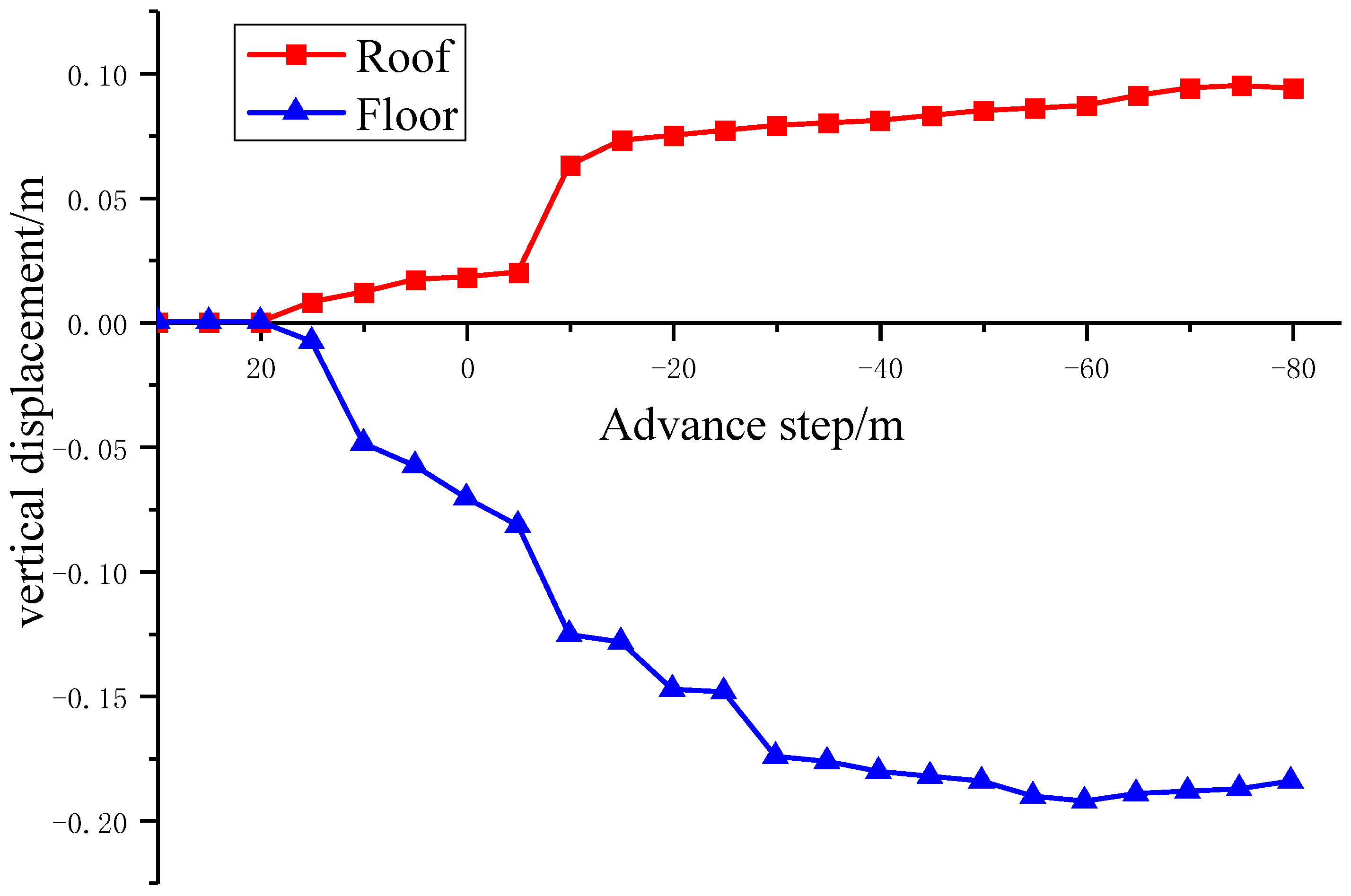

4.1.2. Vertical Displacement

4.1.3. Stress Conditions at the Roof and Floor of the Support Body

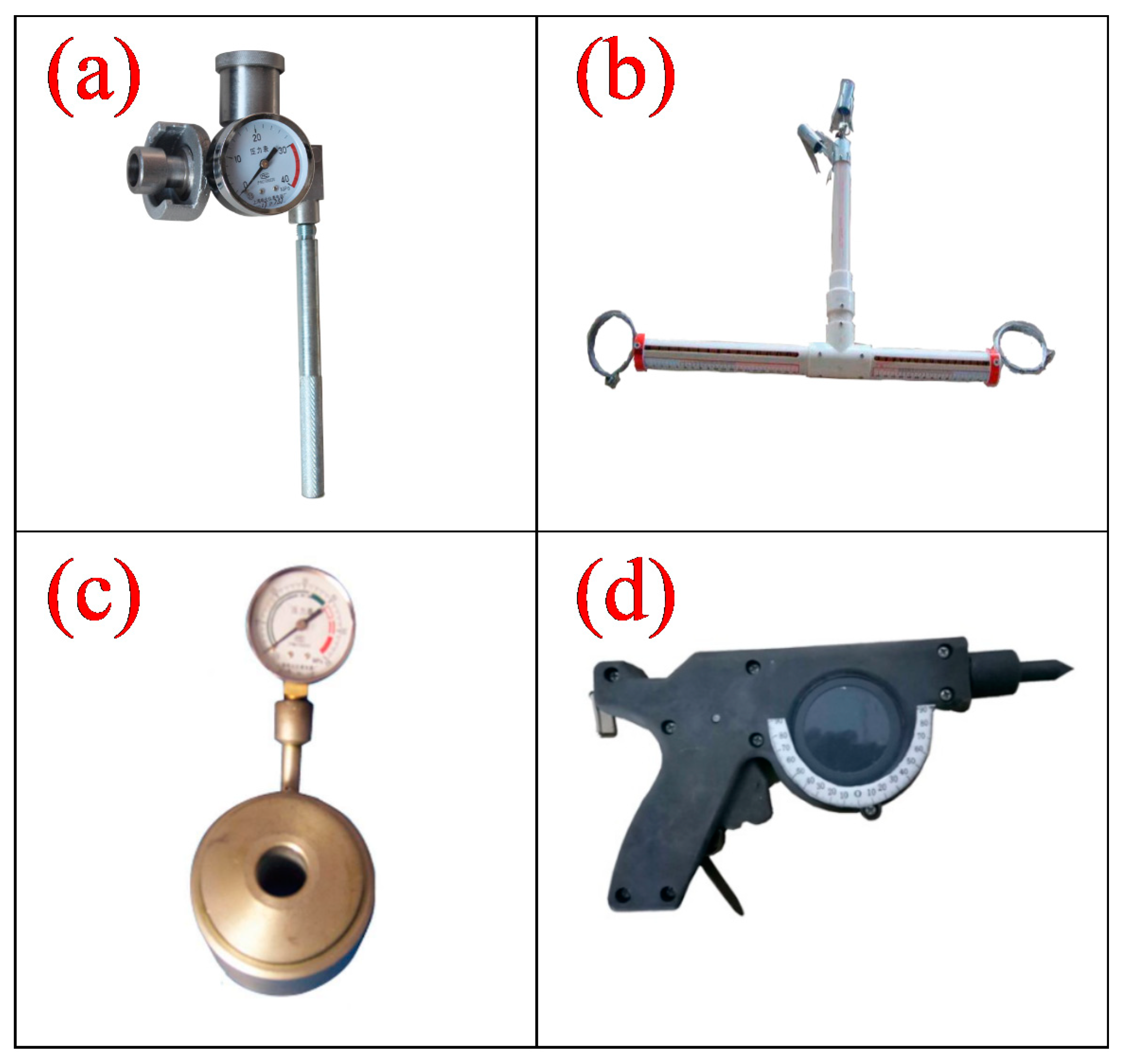

4.2. Field Monitoring

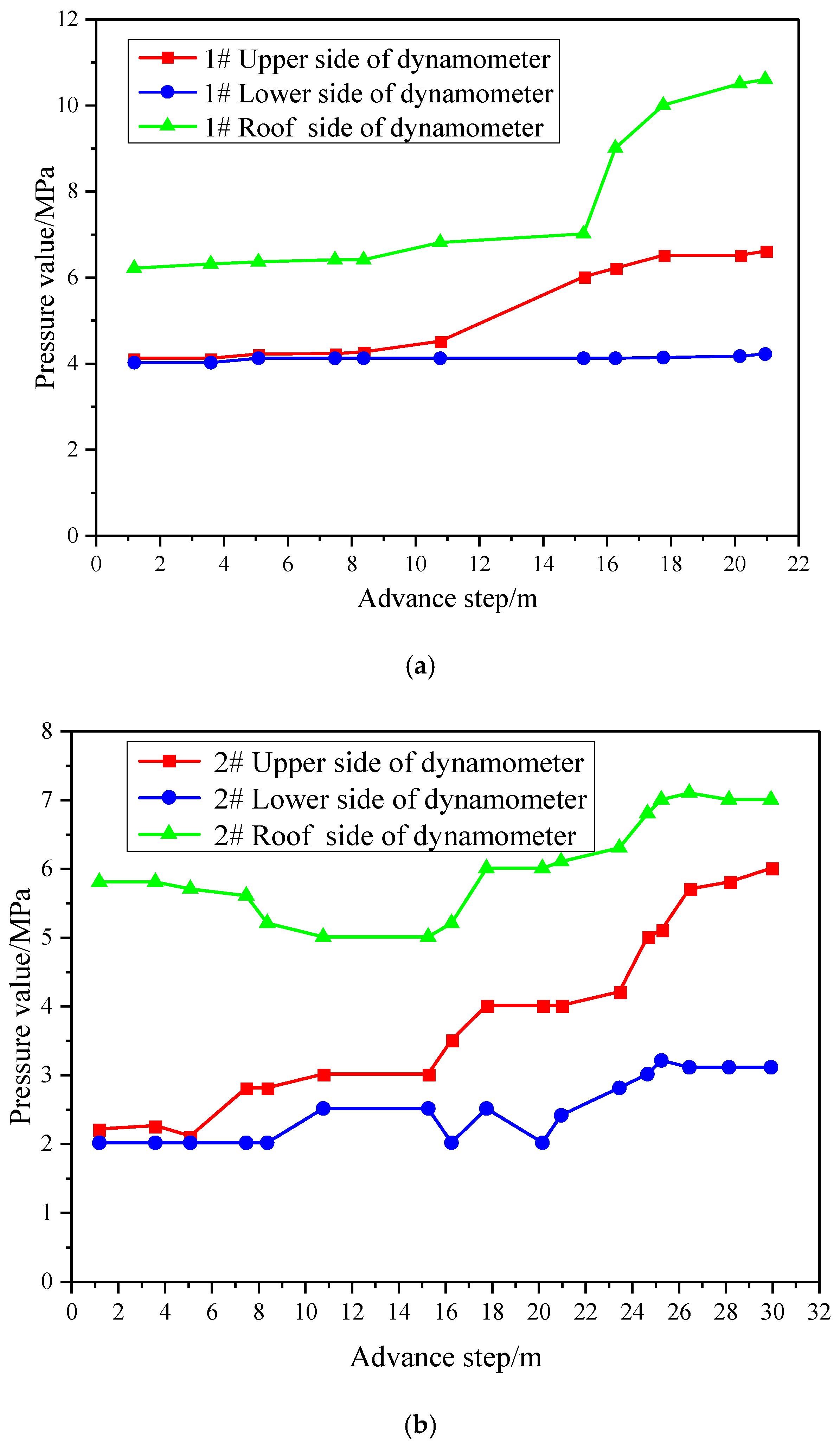

4.2.1. Single Hydraulic Prop Monitoring Analysis

4.2.2. Roof Separation Observation Results Analysis

4.2.3. Bolt Stress Monitoring Analysis

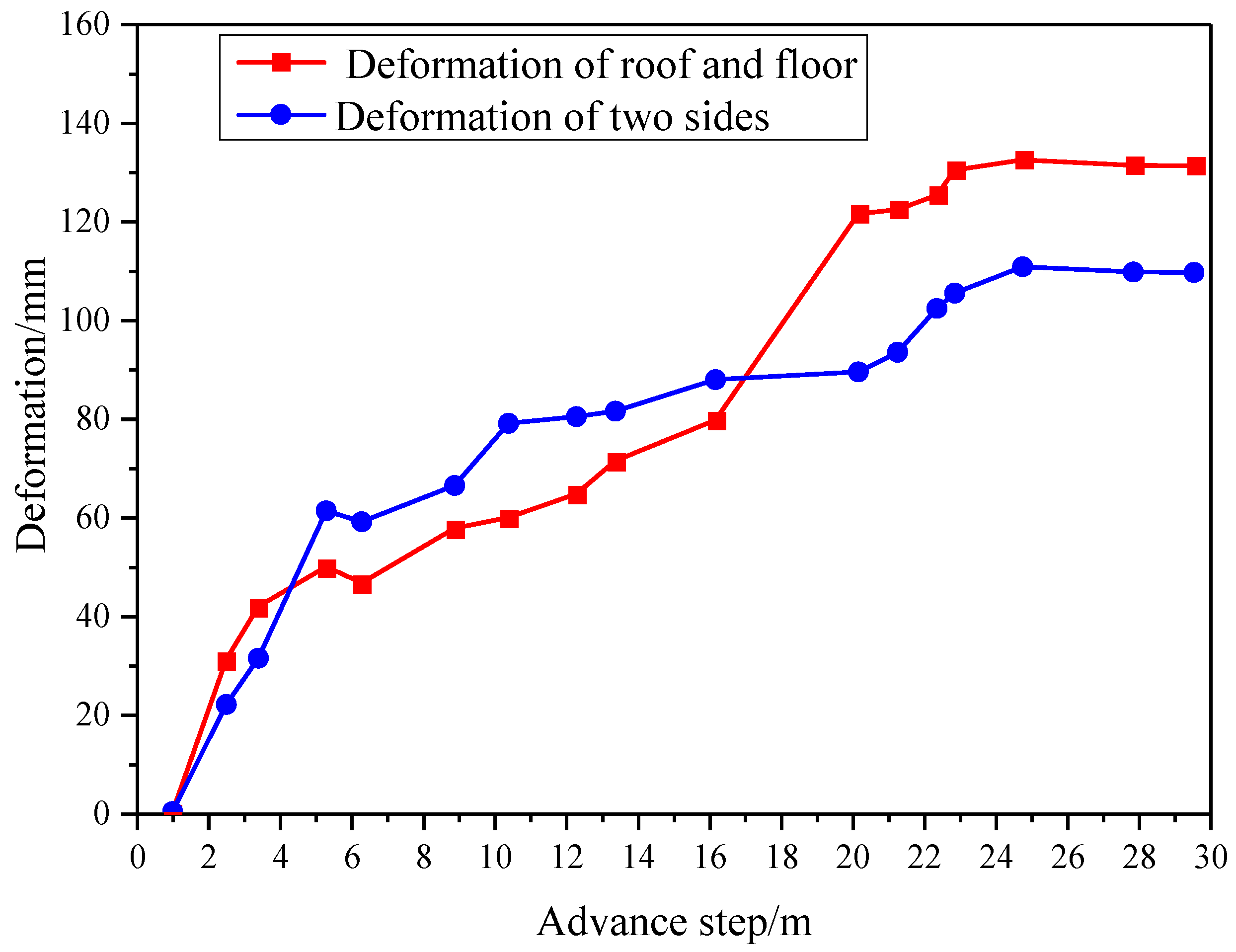

4.2.4. Analysis of Deformation on the Roadway Sides and Near the Roof and Floor

5. Conclusions

- (1)

- In coal mine gob-side entry-retaining practice, improving the production rate is a longstanding crucial issue requiring continuous and further attention from engineers and researchers. Based on this consideration, a new gob-side entry retaining approach including mixing materials, bagging and sealing, underground transportation, and staggered construction was proposed in this study.

- (2)

- Test results showed that the uniaxial compressive strengths of the specimens comprising cement, putty powder, fly ash, sand, and accelerator prepared using a defined proportion and cured for 3, 7, and 28 days (12.91 MPa, 18.82 MPa, and 26.84 MPa, respectively) were all greater than the support wall resistance (4 MPa).

- (3)

- Using the 8101 working face as the background, the efficacy of the proposed method involving the use of bag filling material for wall construction was verified. Compared with the concrete grouted wall and paste filling methods, the gob-side entry retaining involving bag filling material for wall construction is a relatively simple technology characterized by rapid roadway formation.

- (4)

- The stress and deformation law simulated via numerical methods and monitored during field tests are basically consistent. The peak of stress and deformation obtained by field tests are slightly smaller than those obtained by numerical simulation. The monitoring results show that the deformation of roadway is small, which can meet the production demand of coal mine.

Author Contributions

Funding

Conflicts of Interest

References

- Yang, H.; Liu, Y.; Cao, S.; Pan, R.; Wang, H.; Li, Y.; Luo, F. A caving self-stabilization bearing structure of advancing cutting roof for gob-side entry retaining with hard roof stratum. Geomech. Eng. 2020, 21, 23–33. [Google Scholar]

- Luan, H.; Jiang, Y.-J.; Lin, H.; Li, G. Development of a New Gob-Side Entry-Retaining Approach and Its Application. Sustainability 2018, 10, 470. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.; Cao, S.; Wang, S.; Fan, Y.; Wang, S.; Chen, X. Adaptation assessment of gob-side entry retaining based on geological factors. Eng. Geol. 2016, 209, 143–151. [Google Scholar] [CrossRef]

- Mu, W.; Li, L.; Guo, Z.; Du, Z.; Wang, S. Novel Segmented Roadside Plugging-Filling Mining Method and Overlying Rock Mechanical Mechanism Analyses. Energies 2019, 12, 2073. [Google Scholar] [CrossRef] [Green Version]

- Zhang, N.; Yuan, L.; Han, C.; Xue, J.; Kan, J. Stability and deformation of surrounding rock in pillarless gob-side entry retaining. Saf. Sci. 2012, 50, 593–599. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, J.; Li, Z. A new research system for caving mechanism analysis and its application to sublevel top-coal caving mining. Int. J. Rock Mech. Min. Sci. 2016, 88, 273–285. [Google Scholar] [CrossRef]

- Cui, F.; Yang, Y.; Lai, X.; Jia, C.; Shan, P. Experimental Study on the Effect of Advancing Speed and Stoping Time on the Energy Release of Overburden in an Upward Mining Coal Working Face with a Hard Roof. Sustainability 2019, 12, 37. [Google Scholar] [CrossRef] [Green Version]

- Xie, Z.; Zhang, N.; Feng, X.; Liang, D.; Wei, Q.; Weng, M. Investigation on the evolution and control of surrounding rock fracture under different supporting conditions in deep roadway during excavation period. Int. J. Rock Mech. Min. Sci. 2019, 123, 104122. [Google Scholar] [CrossRef]

- Xie, Z.; Zhang, N.; Qian, D.; Han, C.; An, Y.; Wang, Y. Rapid Excavation and Stability Control of Deep Roadways for an Underground Coal Mine with High Production in Inner Mongolia. Sustainability 2018, 10, 1160. [Google Scholar] [CrossRef] [Green Version]

- Qiu, P.; Wang, J.; Ning, J.; Liu, X.; Hu, S.; Gu, Q. Rock burst criteria of deep residual coal pillars in an underground coal mine: A case study. Geomech. Eng. 2019, 19, 499–511. [Google Scholar]

- Tan, Y.; Ma, Q.; Zhao, Z.; Gu, Q.; Fan, D.; Song, S.; Huang, D. Cooperative bearing behaviors of roadside support and surrounding rocks along gob-side. Geomech. Eng. 2019, 18, 439–448. [Google Scholar]

- Anagnostopoulos, T.; Kyriakopoulos, G.L.; Ntanos, S.; Gkika, E.; Asonitou, S. Intelligent Predictive Analytics for Sustainable Business Investment in Renewable Energy Sources. Sustainability 2020, 12, 2817. [Google Scholar] [CrossRef] [Green Version]

- Gao, D.; Liu, Y.; Wang, T.; Wang, D. Experimental Investigation of the Impact of Coal Fines Migration on Coal Core Water Flooding. Sustainability 2018, 10, 4102. [Google Scholar] [CrossRef] [Green Version]

- Dong, S.; Wang, Z.; Li, Y.; Li, F.; Li, Z.; Chen, F.; Cheng, H. Assessment of Comprehensive Effects and Optimization of a Circular Economy System of Coal Power and Cement in Kongtong District, Pingliang City, Gansu Province, China. Sustainability 2017, 9, 787. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.; Yin, L.; Guo, W. Stress–Seepage Coupling of Cataclastic Rock Masses Based on Digital Image Technologies. Rock Mech. Rock Eng. 2018, 51, 2355–2372. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, X.; Jiang, N.; Yin, L.; Guo, W. Porosity zoning characteristics of fault floor under fluid-solid coupling. Bull. Int. Assoc. Eng. Geol. 2020, 79, 2529–2541. [Google Scholar] [CrossRef]

- Zhang, Y.; Tang, J.; Xiao, D.; Sun, L.; Zhang, W. Spontaneous caving and gob-side entry retaining of thin seam with large inclined angle. Int. J. Min. Sci. Technol. 2014, 24, 441–445. [Google Scholar] [CrossRef]

- Zhou, B.; Xu, J.; Zhao, M.; Zeng, Q. Stability study on naturally filling body in gob-side entry retaining. Int. J. Min. Sci. Technol. 2012, 22, 423–427. [Google Scholar] [CrossRef]

- Tan, Y.; Yu, F.; Ning, J.; Zhao, T. Design and construction of entry retaining wall along a gob side under hard roof stratum. Int. J. Rock Mech. Min. Sci. 2015, 77, 115–121. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, D.; Fan, G. Structural effect of a soft–hard backfill wall in a gob-side roadway. Min. Sci. Technol. (China) 2011, 21, 313–318. [Google Scholar] [CrossRef]

- Yuehua, D.; Jianxin, T.; Xiangke, Z.; Yong, F.U.; Zhangyin, D.A.I. Analysis and application in controlling surrounding rock of support reinforced roadway in gob-side entry with fully mechanized mining. Min. Sci. Technol. (China) 2010, 20, 839–845. [Google Scholar] [CrossRef]

- Su, H.; Bai, J.; Yan, S.; Chen, Y.; Zhang, Z. Study on gob-side entry retaining in fully-mechanized longwall with top-coal caving and its application. Int. J. Min. Sci. Technol. 2015, 25, 503–510. [Google Scholar] [CrossRef]

- Yang, J.; He, M.; Cao, C. Design principles and key technologies of gob side entry retaining by roof pre-fracturing. Tunn. Undergr. Space Technol. 2019, 90, 309–318. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, Y.; Yang, J.; Zhang, X.; He, M. Meso- and macroeffects of roof split blasting on the stability of gateroad surroundings in an innovative nonpillar mining method. Tunn. Undergr. Space Technol. 2019, 90, 99–118. [Google Scholar] [CrossRef]

- Wang, Q.; He, M.; Yang, J.; Gao, H.; Jiang, B.; Yu, H. Study of a no-pillar mining technique with automatically formed gob-side entry retaining for longwall mining in coal mines. Int. J. Rock Mech. Min. Sci. 2018, 110, 1–8. [Google Scholar] [CrossRef]

- Yang, H.; Han, C.; Zhang, N.; Sun, C.; Pan, D.; Dong, M. Stability Control of a Goaf-Side Roadway under the Mining Disturbance of an Adjacent Coal Working Face in an Underground Mine. Sustainability 2019, 11, 6398. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Chen, L.; Gao, Y.; Hu, J.; Yang, J.; He, M. Study of An Innovative Approach of Roof Presplitting for Gob-Side Entry Retaining in Longwall Coal Mining. Energies 2019, 12, 3316. [Google Scholar] [CrossRef] [Green Version]

- Sun, Q.; Zhang, J.; Huang, Y.; Yin, W. Failure Mechanism and Deformation Characteristics of Gob-Side Entry Retaining in Solid Backfill Mining: A Case Study. Nat. Resour. Res. 2019, 29, 1–15. [Google Scholar] [CrossRef]

- Xie, Z.; Zhang, N.; Meng, F.; Han, C.; An, Y.; Zhu, R. Deformation Field Evolution and Failure Mechanisms of Coal–Rock Combination Based on the Digital Speckle Correlation Method. Energies 2019, 12, 2511. [Google Scholar] [CrossRef] [Green Version]

- Xie, Z.; Zhang, N.; Yuan, Y.; Xu, G.; Wei, Q. Study on Safety Control of Composite Roof in Deep Roadway Based on Energy Balance Theory. Sustainability 2019, 11, 3688. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.; Yin, D.; Jiang, N.; Wang, F.; Zhao, Z. Mechanical properties of oil shale-coal composite samples. Int. J. Rock Mech. Min. Sci. 2019, 123, 104120. [Google Scholar] [CrossRef]

- Chen, Y.; Bai, J.; Yan, S.; Xu, Y.; Wang, X.; Ma, S. Control mechanism and technique of floor heave with reinforcing solid coal side and floor corner in god-side coal entry retaining. Int. J. Min. Sci. Technol. 2012, 22, 841–845. [Google Scholar] [CrossRef]

- Liu, L.; Xin, J.; Huan, C.; Qi, C.; Zhou, W.; Song, K.-I. Pore and strength characteristics of cemented paste backfill using sulphide tailings: Effect of sulphur content. Constr. Build. Mater. 2020, 237, 117452. [Google Scholar] [CrossRef]

- Sun, Q.; Tian, S.; Sun, Q.; Li, B.; Xia, Y.; Wei, X.; Mu, Q. Preparation and microstructure of fly ash geopolymer paste backfill material. J. Clean. Prod. 2019, 225, 376–390. [Google Scholar] [CrossRef]

- Chen, S.; Du, Z.; Zhang, Z.; Zhang, H.; Xia, Z.; Feng, F. Effects of chloride on the early mechanical properties and microstructure of gangue-cemented paste backfill. Constr. Build. Mater. 2020, 235, 117504. [Google Scholar] [CrossRef]

- Chen, S.; Du, Z.; Zhang, Z.; Yin, D.; Feng, F.; Ma, J. Effects of red mud additions on gangue-cemented paste backfill properties. Powder Technol. 2020, 367, 833–840. [Google Scholar] [CrossRef]

- Zhang, C.; Jin, Z.; Feng, G.; Song, X.; Rui, G.; Yujiang, Z. Double Peaked Stress–Strain Behavior and Progressive Failure Mechanism of Encased Coal Pillars Under Uniaxial Compression. Rock Mech. Rock Eng. 2020, 1–14. [Google Scholar] [CrossRef]

- Feng, F.; Chen, S.; Li, D.; Huang, W.; Peng, K.; Zang, C. Excavation unloading-induced fracturing of hard rock containing different shapes of central holes affected by unloading rates and in situ stresses. Energy Sci. Eng. 2019, 8, 4–27. [Google Scholar] [CrossRef] [Green Version]

- Lin, G.; Teng, J.G. Advanced stress-strain model for FRP-confined concrete in square columns. Compos. Part. B Eng. 2020, 197, 108149. [Google Scholar] [CrossRef]

- Wu, F.; Deng, Y.; Wu, J.; Li, B.; Sha, P.; Guan, S.; Zhang, K.; He, K.; Liu, H.; Qiu, S. Stress–strain relationship in elastic stage of fractured rock mass. Eng. Geol. 2020, 268, 105498. [Google Scholar] [CrossRef]

- Fang, K.; Cui, L.; Fall, M. A coupled chemo-elastic cohesive zone model for backfill-rock interface. Comput. Geotech. 2020, 125, 103666. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, Z.; Jiang, B.; Gao, H.; Huang, Y.; Zhang, P. Research on an automatic roadway formation method in deep mining areas by roof cutting with high-strength bolt-grouting. Int. J. Rock Mech. Min. Sci. 2020, 128, 104264. [Google Scholar] [CrossRef]

- Sun, J. Mechanics criterion and factors affecting overburden stability in solid dense filling mining. Int. J. Min. Sci. Technol. 2017, 27, 407–413. [Google Scholar] [CrossRef]

- Yan, H.; He, F.; Yang, T.; Li, L.; Zhang, S.; Zhang, J. The mechanism of bedding separation in roof strata overlying a roadway within a thick coal seam: A case study from the Pingshuo Coalfield, China. Eng. Fail. Anal. 2016, 62, 75–92. [Google Scholar] [CrossRef]

- Wu, G.; Chen, W.; Jia, S.; Tan, X.; Zheng, P.; Tian, H.; Rong, C. Deformation characteristics of a roadway in steeply inclined formations and its improved support. Int. J. Rock Mech. Min. Sci. 2020, 130, 104324. [Google Scholar] [CrossRef]

- Zhao, X.; Li, H.; Zhang, S.; Yang, X. Stability Analyses and Cable Bolt Support Design for A Deep Large-Span Stope at the Hongtoushan Mine, China. Sustainability 2019, 11, 6134. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.; Han, C.; Zhang, N.; Sun, Y.; Pan, D.; Sun, C. Long High-Performance Sustainable Bolt Technology for the Deep Coal Roadway Roof: A Case Study. Sustainability 2020, 12, 1375. [Google Scholar] [CrossRef] [Green Version]

| Parameters | σ/MPa | k | α/° | σy/MPa |

|---|---|---|---|---|

| Value | 6 | 2.0 | 3 | 4.15 |

| Name | Bulk Density/kN/m3 | Shear Modulus/GPa | Bulk Modulus/GPa | Cohesion/MPa | Tensile Strength/MPa | Internal Friction Angle/° | |

|---|---|---|---|---|---|---|---|

| Roof | Siltstone | 27.1 | 0.35 | 0.77 | 7.8 | 9.3 | 32 |

| Sandy mudstone | 25.6 | 0.24 | 0.45 | 3.6 | 2.4 | 25 | |

| Medium sandstone | 26.2 | 0.29 | 0.49 | 5.2 | 5.1 | 28 | |

| Sandy mudstone | 25.3 | 0.24 | 0.45 | 3.6 | 2.4 | 25 | |

| Coal | Coal | 13.1 | 0.13 | 0.41 | 2.5 | 1.1 | 17 |

| Floor | Sandy mudstone | 25.3 | 0.24 | 0.45 | 3.6 | 2.4 | 25 |

| Medium sandstone | 26.2 | 0.29 | 0.49 | 5.2 | 5.1 | 28 | |

| Filling body | 25.0 | 0.95 | 0.71 | 4.4 | 3.5 | 50 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, Z.; Chen, S.; Ma, J.; Guo, Z.; Yin, D. Gob-Side Entry Retaining Involving Bag Filling Material for Support Wall Construction. Sustainability 2020, 12, 6353. https://doi.org/10.3390/su12166353

Du Z, Chen S, Ma J, Guo Z, Yin D. Gob-Side Entry Retaining Involving Bag Filling Material for Support Wall Construction. Sustainability. 2020; 12(16):6353. https://doi.org/10.3390/su12166353

Chicago/Turabian StyleDu, Zhaowen, Shaojie Chen, Junbiao Ma, Zhongping Guo, and Dawei Yin. 2020. "Gob-Side Entry Retaining Involving Bag Filling Material for Support Wall Construction" Sustainability 12, no. 16: 6353. https://doi.org/10.3390/su12166353

APA StyleDu, Z., Chen, S., Ma, J., Guo, Z., & Yin, D. (2020). Gob-Side Entry Retaining Involving Bag Filling Material for Support Wall Construction. Sustainability, 12(16), 6353. https://doi.org/10.3390/su12166353