Measurement of Permeability in Horizontal Direction of Open-Graded Friction Course with Rutting

Abstract

:1. Introduction

2. Materials

3. Test Equipment and Method

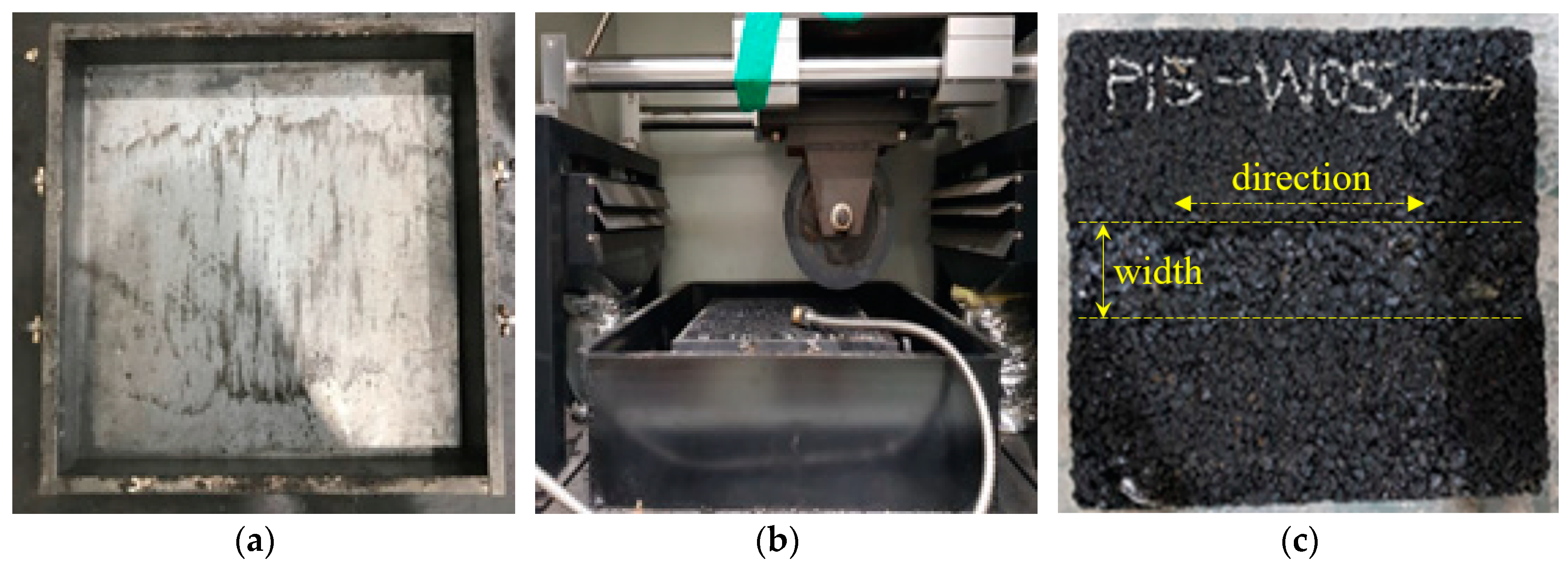

3.1. Wheel Tracking Test

3.1.1. Test Equipment

3.1.2. Specimen Preparation

- (1)

- Preparation of the WT specimen mold (Figure 5a);

- (2)

- Preparation of the OGFC specimen; shape: square, length of one side: 300 ± 5 mm, and thickness: 50 mm;

- (3)

- (4)

- Curing the compacted specimen at room temperature for 12 h;

- (5)

- Curing the specimen at a constant temperature of 60 ± 0.5 °C for 5 h before beginning the test. Maximum curing time should be 24 h;

- (6)

- Positioning a testing wheel (width: 50 mm) at the center of the specimen and applying a parallel reciprocating wheel load of 686 N in the vehicle travel direction with a frequency of 42 times per minute at the center of the specimen (Figure 5b); and

- (7)

- Measuring and recording the depth of rutting at 1, 5, 10, 15, 30, 45, and 60 min. Complete the test when 4, 8, and 12 mm ruts have been generated in the specimens with porosities of 10.3%, 15.6%, and 19.6%, respectively (Figure 5c).

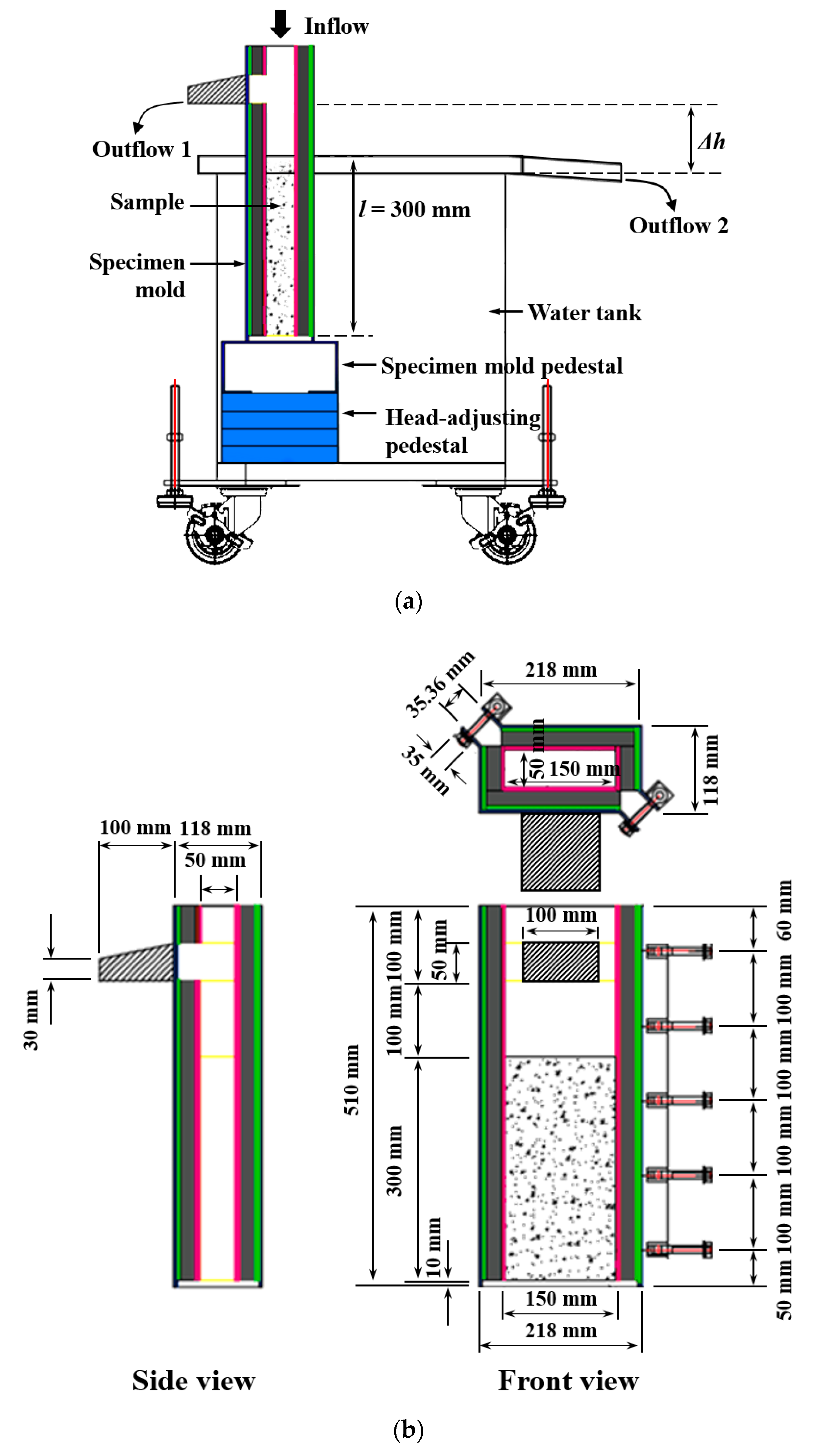

3.2. Horizontal Permeability Test

3.2.1. Equipment Development

- (1)

- Specimen Mold Fixture

- (2)

- Water Tank

- (3)

- Head-Adjusting Part

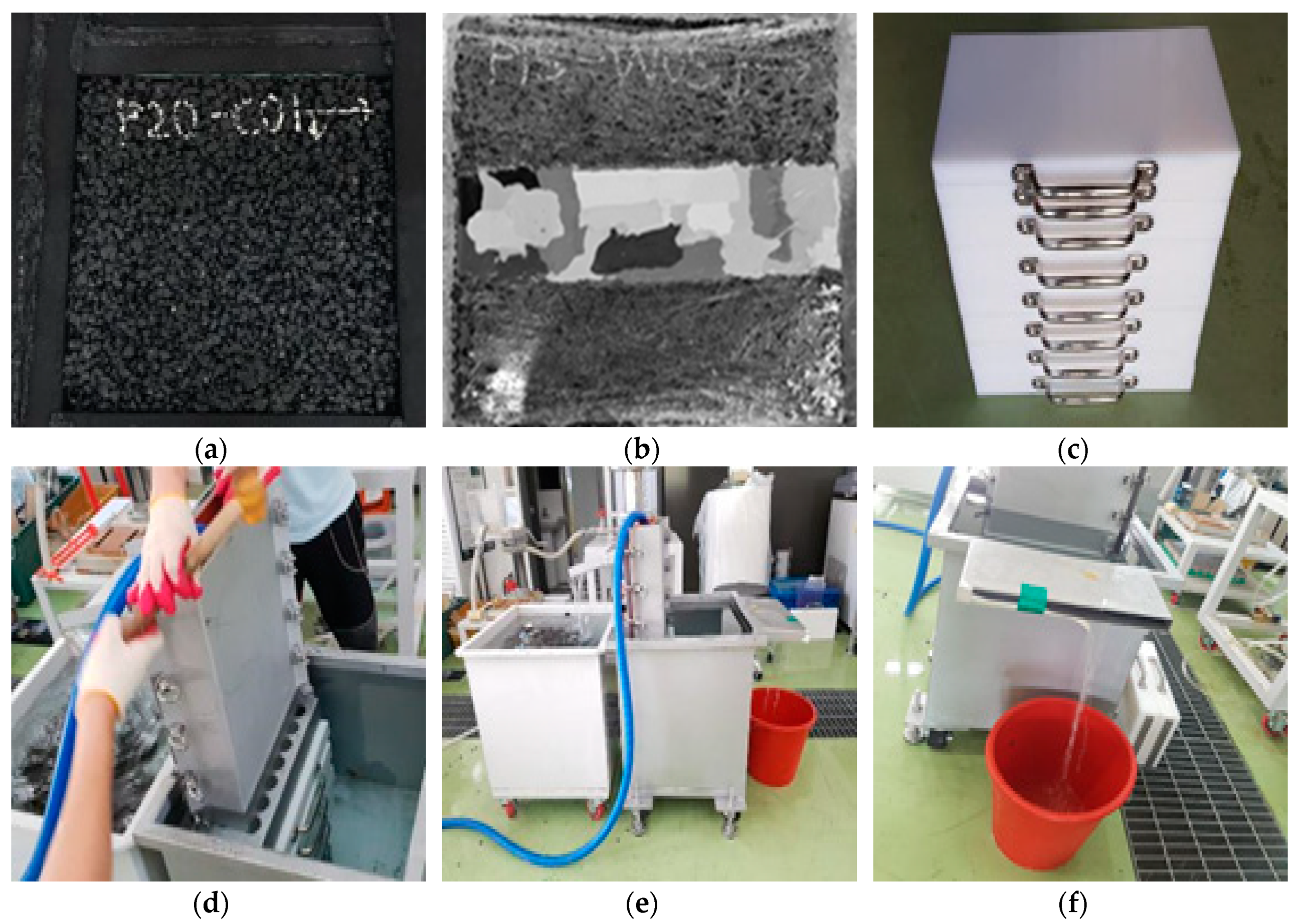

3.2.2. General Procedures

- (1)

- Mark the direction in which the horizontal permeability will be evaluated in the test specimen (Figure 7a).

- (2)

- (3)

- Commence water penetration and saturating of the test specimen by injecting water at the top of the specimen mold fixture and discharge excess water to the water tank (Figure 7e).

- (4)

- Measure the amount of overflow per hour and evaluate the horizontal permeability if water accumulates and the water level becomes uniform, based on the overflow (Figure 7f).

- (5)

- Rotate the test specimen by 90° and repeat the test procedure shown in Figure 7d–f.

3.2.3. Permeability after Rutting

- (1)

- Prepare the specimen with rutting via the WT test.

- (2)

- Seal the rutted portion with impermeable material (Figure 7b).

- (3)

- Perform the horizontal permeability test.

- (4)

- Measure the horizontal permeability.

4. Test Results

4.1. Horizontal Permeability

4.2. Horizontal Permeability after Rutting

5. Practical Implications

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Thorsten, S.; Lorenzo, C. Integrating decentralized rainwater management in urban planning and design: Flood resilient and sustainable water management using the example of coastal cities in The Netherlands and Taiwan. Water 2013, 5, 593–616. [Google Scholar] [CrossRef] [Green Version]

- Morgan, C.; Bevington, C.; Levin, D.; Robinson, P.; Davis, P.; Abbott, J.; Simkins, P. Water Sensitive Urban. Design in the UK; CIRIA, Classic House: London, UK, 2013; pp. 1–20. [Google Scholar]

- Collins, K.A.; Hunt, W.F.; Hathaway, J.M. Hydrologic comparison of four types of permeable pavement and standard asphalt in Eastern North Carolina. J. Hydrol. Eng. 2008, 13, 1146–1157. [Google Scholar] [CrossRef]

- Damodaram, C.; Giacomoni, M.H.; Khedun, C.P.; Holmes, H.; Ryan, A.; Saour, W.; Zechman, E.M. Simulation of combined best management practices and low impact development for sustainable stormwater management. J. Am. Water Resour. Assoc. 2010, 46, 907–918. [Google Scholar] [CrossRef]

- Fassman, E.A.; Blackbourn, S. Urban runoff mitigation by a permeable pavement system over impermeable soils. J. Hydrol. Eng. 2010, 15, 475–485. [Google Scholar] [CrossRef]

- Ahiablame, L.M.; Engel, B.A.; Chaubey, I. Effectiveness of low impact development practices: Literature review and suggestions for future research. Water Air Soil Pollut. 2012, 223, 4253–4273. [Google Scholar] [CrossRef]

- Hinman, C.; Wulkan, B. Low Impact Development: Technical Guidance Manual for Puget Sound; Washington State University Extension & Puget Sound Partnership: Tacoma, WA, USA, 2012; pp. 1–365. [Google Scholar]

- Brattebo, B.O.; Booth, D.B. Long-term stormwater quantity and quality performance of permeable pavement systems. Water Res. 2003, 37, 4369–4376. [Google Scholar] [CrossRef]

- Smith, R.D. Permeable Interlocking Concrete Pavements—Design, Specifications, Construction, Maintenance; Interlocking Concrete Pavement Institute: Washington, DC, USA, 2011; pp. 1–48. [Google Scholar]

- Kumar, K.; Kozak, J.; Hundal, L.; Cox, A.; Zhang, H.; Granato, T. In-situ infiltration performance of different permeable pavements in a employee used parking lot—A four-year study. J. Environ. Manag. 2016, 167, 8–14. [Google Scholar] [CrossRef]

- Tennis, P.; Leming, M.L.; Akers, D.J. Pervious Concrete Pavements; Engineering Bulletin 302.02; Portland Cement Association (PCA): Skokie, IL, USA; National Ready Mixed Concrete Association: Silver Spring, MD, USA, 2004; pp. 1–32. [Google Scholar]

- Fleming, P.R.; Frost, M.W.; Lambert, J.P. Review of lightweight deflectometer for routine in situ assessment of pavement material stiffness. Transp. Res. Rec. 2007, 2004, 80–87. [Google Scholar] [CrossRef] [Green Version]

- ACI. 522R-10 Report on Previous Concrete; American Concrete Institute (ACI): Farmington Hills, MI, USA, 2010; pp. 1–37. [Google Scholar]

- Montes, F.; Valavala, S.; Haselbach, L.M. A new test method for porosity measurements of portland cement pervious concrete. J. ASTM Int. 2005, 2, 1–13. [Google Scholar] [CrossRef]

- Neithalath, N.; Sumanasooriya, M.S.; Deo, O. Characterizing pore volume, sizes, and connectivity in pervious concretes for permeability prediction. Mater. Charact. 2010, 61, 802–813. [Google Scholar] [CrossRef]

- Ahn, J.; Lee, Y.; Vaidya, S.; Kim, J.-H.; Lee, S.-W. Estimation the porosity of pervious concretes based on X-Ray CT and submerged weight. J. Korean Soc. Hazard Mitig. 2013, 13, 77–81. [Google Scholar] [CrossRef] [Green Version]

- Thelen, E.; Howe, L.F. Porous Pavement; The Franklin Institute Press: Philadelphia, PA, USA, 1978; pp. 1–98. [Google Scholar]

- ASTM. D 3203/D 3203M-11. In Standard Test Method for Percent Air Voids in Compacted Dense and Open Bituminous Paving Mixtures; ASTM: Philadelphia, PA, USA, 2011. [Google Scholar]

- AASHTO. T 305-14. In Standard Method of Test for Determination of Draindown Characteristics in Uncompacted Asphalt Mixtures; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2018. [Google Scholar]

- ASTM. D 6857/D 6857M-11. In Standard Test Method for Maximum Specific Gravity and Density of Bituminous Paving Mixtures Using Automatic Vacuum Sealing Method; ASTM: Philadelphia, PA, USA, 2017. [Google Scholar]

- ASTM. D 7064/D 7064M-08. In Standard Practice for Open-Graded Friction Course (OGFC) Mix Design; ASTM: Philadelphia, PA, USA, 2013. [Google Scholar]

- NAPA. Porous Asphalt Pavements for Storm Water Management: Design, Construction and Maintenance Guide; National Asphalt Pavement Association (NAPA): Greenbelt, MD, USA, 2008. [Google Scholar]

- Amirjani, M. Clogging of Permeable Pavements in Semi-Arid Areas. Master of Science; Delft University of Technology: Delft, The Netherlands, 2010. [Google Scholar]

- Marcaida, A.; Nguyen, T.; Ahn, J. Investigation of particle-related clogging of sustainable concrete pavements. Sustainability 2018, 10, 4845. [Google Scholar] [CrossRef] [Green Version]

- Suresha, S.N.; George, V.; Ravi Shankar, A.U. Effect of aggregate gradations on properties of porous friction course mixes. Mater. Struct. 2010, 43, 789–801. [Google Scholar] [CrossRef]

- Deo, O.; Sumanasooriya, M.; Neithalath, N. Permeability reduction in pervious concretes due to clogging: Experiments and modeling. J. Mater. Civ. Eng. 2010, 22, 741–751. [Google Scholar] [CrossRef]

- Fwa, T.F.; Tan, S.A.; Chuai, C.T. Permeability measurement of base materials using falling-head test apparatus. Transp. Res. Rec. 1998, 1615, 94–99. [Google Scholar] [CrossRef]

- Fwa, T.F.; Tan, S.A.; Guwe, Y.K. Laboratory evaluation of clogging potential of porous asphalt mixtures. Transp. Res. Rec. 1999, 1681, 43–49. [Google Scholar] [CrossRef]

- Ahn, J.; Marcaida, A.; Lee, Y.; Jung, J. Development of test equipment for evaluating hydraulic conductivity of permeable block pavements. Sustainability 2018, 10, 2549. [Google Scholar] [CrossRef] [Green Version]

- Andrés-Valeri, V.C.; Marchioni, M.; Sañudo-Fontaneda, L.A.; Giustozzi, F.; Becciu, G. Laboratory assessment of the infiltration capacity reduction in clogged porous mixture surfaces. Sustainability 2016, 8, 751. [Google Scholar] [CrossRef] [Green Version]

- Kennedy, T.W.; Huber, G.A.; Harrigan, E.T.; Cominsky, R.J.; Hughes, C.S.; Von Quintus, H.; Moulthrop, J.S. Superior performing asphalt pavements (Superpave); The product of the SHRP asphalt research program: Washington, DC, USA, 1994. [Google Scholar]

- Nguyen, T.H.; Ahn, J.; Lee, J.; Kim, J.-H. Dynamic Modulus of Porous Asphalt and the Effect of Moisture Conditioning. Materials 2019, 12, 1230. [Google Scholar] [CrossRef] [Green Version]

- Korean Agency for Technology and Standards. KS F 2374. In Standard Test Method for Wheel Tracking of Asphalt Mixtures; Korean Agency for Technology and Standards: Seoul, Korea, 2017. [Google Scholar]

- Korean Agency for Technology and Standards. KS F 2366. In Standard Test Method for Theoretical Maximum Specific Gravity of Asphalt Mixtures; Korean Agency for Technology and Standards: Seoul, Korea, 2017. [Google Scholar]

- AASHTO. T 209. In Standard Method of Test for Theoretical Maximum Specific Gravity (Gmm) and Density of Asphalt Mixtures; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2019. [Google Scholar]

- Korean Agency for Technology and Standards. KS F 2337. In Standard Test Method for Marshall Stability and Flow Of Asphalt Mixtures; Korean Agency for Technology and Standards: Seoul, Korea, 2017. [Google Scholar]

- Huang, B.; Wu, H.; Shu, X.; Burdette, E.G. Laboratory evaluation of permeability and strength of polymer-modified pervious concrete. Constr. Build. Mater. 2010, 24, 818–823. [Google Scholar] [CrossRef]

- Coleri, E.; Kayhanian, M.; Harvey, J.T.; Yang, K.; Boone, J.M. Clogging evaluation of open graded friction course pavements tested under rainfall and heavy vehicle simulators. J. Environ. Manag. 2013, 129, 164–172. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Liu, H.; Sha, F.; Yang, H.; Zhang, Q.; Shi, S.; Zheng, Z. Investigation of the porosity distribution, permeability, and mechanical performance of pervious concretes. Processes 2018, 6, 78. [Google Scholar] [CrossRef] [Green Version]

| Mixture | OGFC-19.6 | OGFC-15.6 | OGFC-10.3 |

|---|---|---|---|

| Measured density (g/cm3) | 1.936 | 2.020 | 2.128 |

| Theoretical density (g/cm3) | 2.407 | 2.393 | 2.373 |

| Air void content (%) | 19.6 | 15.6 | 10.3 |

| Asphalt content (%) | 5.9 | 6.0 | 6.1 |

| Draindown (%) | 0.10 | 0.13 | 0.13 |

| Cantabro loss (%) | 11.1 | 12.6 | 13.0 |

| Test | Value | Unit |

|---|---|---|

| Viscosity (135 °C) | 3.4 | Pa·s |

| G*/sinδ (original) (82 °C) | 1.27 | kPa |

| G*/sinδ (after RTFO) (82 °C) | 2.49 | kPa |

| G*·sinδ (after PAV) (28 °C) | 564 | kPa |

| Flash point | 342 | °C |

| Stiffness (−24 °C) | 194 | MPa |

| m-value (−24 °C) | 0.32 | °C |

| Head-adjusting pedestal thickness (mm) | 30 | 60 | 90 | 120 | 150 | 180 | 210 | 240 | 270 | 300 | 330 | 360 | 390 |

| Hydraulic gradient (i) | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1.0 | 1.1 | 1.2 | 1.3 |

| Urban Expressways | Main Arterial Roads | Minor Arterial Roads | Collector Roads | Local Roads | |

|---|---|---|---|---|---|

| Lane width (m) | 3.5 | 3.25–3.5 | 3.0–3.25 | 3.0 | 2.75–3.0 |

| Design speed (km/h) | 80–100 | 60–80 | 50–60 | 40–50 | 30–40 |

| Main function | Network arterial road connector | Urban arterial road network connector | Complementing the main arterial roads | Establishment of major road networks in urban areas | Road starting and ending points |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoo, J.; Nguyen, T.H.; Lee, E.; Lee, Y.; Ahn, J. Measurement of Permeability in Horizontal Direction of Open-Graded Friction Course with Rutting. Sustainability 2020, 12, 6428. https://doi.org/10.3390/su12166428

Yoo J, Nguyen TH, Lee E, Lee Y, Ahn J. Measurement of Permeability in Horizontal Direction of Open-Graded Friction Course with Rutting. Sustainability. 2020; 12(16):6428. https://doi.org/10.3390/su12166428

Chicago/Turabian StyleYoo, Jaewon, Tan Hung Nguyen, Eungu Lee, Yunje Lee, and Jaehun Ahn. 2020. "Measurement of Permeability in Horizontal Direction of Open-Graded Friction Course with Rutting" Sustainability 12, no. 16: 6428. https://doi.org/10.3390/su12166428