1. Introduction

The refinery industry produces a large amount of sludge during crude oil exploration, production, storage, and the refining process [

1,

2,

3]. Oil sludge usually contains a high content of petroleum hydrocarbons (PHCs) [

4], heavy metals, and solid particles. The petroleum hydrocarbons from oil sludge contain a variety of aromatic hydrocarbons which are carcinogens, such as BTEX (benzene, toluene, ethylbenzene, xylene) and polycyclic aromatics hydrocarbons (PAHs) [

5,

6]. Therefore, petroleum sludge is considered harmful in many countries and improper treatment may pose a serious threat to the environment [

2,

7,

8]. However, due to the high content of petroleum hydrocarbon in the sludge, it is also considered a potential recoverable resource.

The extensive development of oily sludge treatment now focuses on environmental impact and renewable resource technologies including combustion, pyrolysis, chemical treatment, froth flotation, and microwave irradiation [

1,

6,

9]. Pyrolysis has excellent adaptability and fluidity of crude sludge to recycle valuable chemical raw materials and coke, and the process almost has no secondary pollution [

7,

9,

10]. The disadvantage is that a large amount of external energy is required for the endothermic reaction to occur, resulting in a high cost. The thermochemical conversion process also involves an extremely complex reaction path [

7,

9]. Combustion produces energy to drive steam boilers to generate electricity, or to provide valuable thermal energy for pyrolysis or refinery endothermic processes. However, the resulting pollutant emissions may pose a great threat to the environment [

9]. Chemical treatment processes require a large quantity of organic solvents, resulting in a large amount of secondary wastes, and further adequate treatment is required [

11,

12]. Application of microwave heating used for oil sludge treatment has been reported in recent years. There are many advantages to using microwave heating. The dielectric material could absorb the microwaves and raise its internal energy [

13], resulting in a faster heating rate [

14], shorter reaction time and higher efficiency of electric energy conversion (80–85%) [

15]. Akbari et al. (2016) used microwave to treat crude oil in water emulsion. When emulsion samples (40–60% W/O) were treated with microwave irradiation under 360 W microwave power for 3 min, demulsification reached 100% [

16].

The electric field interacts with polar materials whereas the magnetic field reacts with charged material. Through the interaction between the medium molecules and the MW electromagnetic field, the electromagnetic energy can be converted directly into heat energy [

17,

18,

19]. Microwave heating is the result of absorption of microwave energy by a dielectric medium exposed to the electromagnetic field [

20]. The rate of medium temperature increase caused by absorption of microwave energy is given by Equation (1) [

18]:

where

Pabs is the power conversion in one unit volume (W/m

3),

f is the frequency of the radiation in Hz,

is the permittivity of free space (8.854 × 10

−12 F/m),

is the complex component of the relative permittivity of the dielectric (it is also known as the effective relative dielectric loss factor),

Cp is the specific heat of the material in J/kg °C,

is the density of the material in kg m

−3,

E is the electric field in V/m, Δ

t is the time duration in seconds, and Δ

T is the temperature rise in the material in °C. The density and heat capacity of crude oil are derived from the (2), (3) and (4) [

21].

In this study, through the characteristics of microwaves coupling with high dielectric constant substances in oil sludge, the medium (moisture) in the sludge converts the absorbed microwave energy into heat energy which is enough for the removal of BTEX substances in the sludge. In this way, the value of oil resource recovery after microwave treatment is promoted. Furthermore, by combining with the membrane recovery technique, the high value tail gas could be produced in the process of sludge treatment.

2. Materials and Methods

2.1. Experimental Equipment

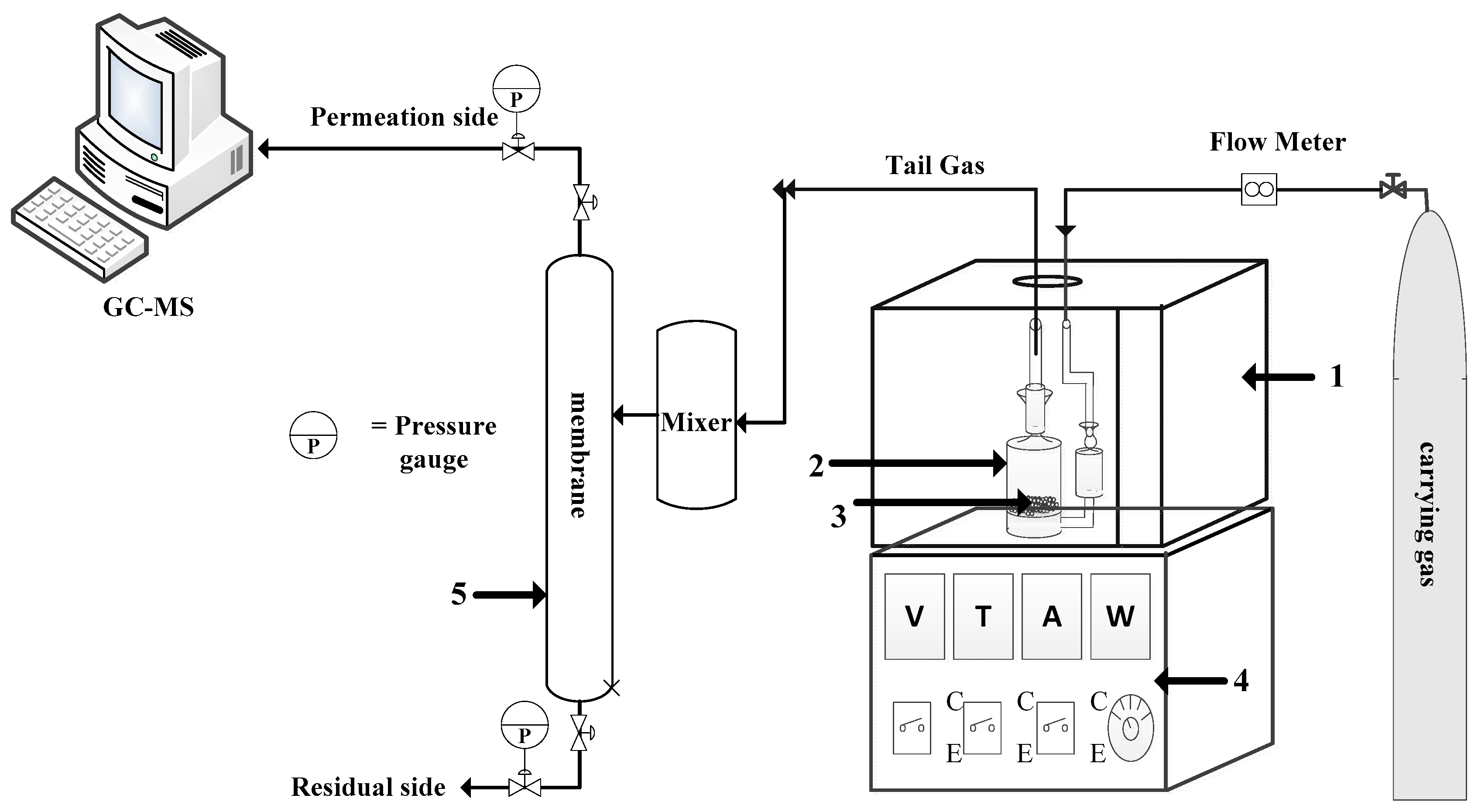

The microwave oven (SAMPO Co.) was equipped with a (Proportional-Integral-Derivative) (PID) to control the output power. The microwave frequency was 2.45 GHz and the maximum output power was 750 W. A 50 mL quartz reactor with 20 holes at the bottom was also used. The sludge samples were taken from the crude oil storage tank in the refinery. The sludge sample (10 g, semi-liquid, water content 18 wt%, heat value 10,968 cal/g) was placed in the reactor then put into the microwave oven. Carrier gas (N

2) was introduced from the bottom of the reactor. The tail gas was evaporated from top of the reactor, then entered a membrane separator (

Figure 1).

The hollow fiber tubing inside of the membrane separator (Dalian Eurofilm Industrial Ltd.) was made of a polyimide material coated with silicone rubber. The outside diameter of the hollow fiber tubing was between 300 and 450 μm with an inner diameter of 150 to 200 μm. 1 µL of the tail gas sample was taken every 10 s and the composition was analyzed by gas chromatography-mass spectrometry (GC-MS) quantitatively and qualitatively. The gas samples were also collected at the inlet and outlet of the membrane separator by a 1 L cylinder and then analyzed by GC-MS.

2.2. Experimental Methods

A layer of insulation cotton (about 2 mm thick) was laid on the bottom of the reaction apparatus to avoid blockage of the air venting from the oil sludge. Sludge (10 g) was evenly spread on the insulating cotton, and the reactor was placed in the microwave oven. The experimental parameters were as follows: (1) the microwave output power (in W) was controlled at 200, 250 or 300; (2) the microwave irradiation time (in seconds) was set to 0, 10, 20, 30, and 60 s; (3) absorbed energy and electric field intensity were used; (4) under a microwave power of 300 W, each cycle consisted of 10 s irradiation time followed by 10 sec intermission interval. Up to 90 cycles, for a total of 900 s multi-interval irradiation, were tested in the experiment.

The gas generated from the microwave treatment was introduced into a mixer before it entered the membrane device where the gas pressure stabilized. The inlet gas flow rate at the membrane device was adjusted by the gas permeation pressure at the outlet.

2.3. Analyses

An HP 6890 gas chromatography (GC) equipped with a capillary column (HP-5MS) and coupled with an HP 5973 mass selective detector (MSD) was used for identifying and quantifying intermediates and final products of the tail gas. The carrying gas (He) flow rate was maintained at a constant of 10 mL/min. The oven temperature was programmed to increase from 100 °C to 280 °C at a gradient rate of 20 °C/min. It was then held at 280 °C for 10 min. A thermocouple, K-Type with error 0.3% of full scale, was used for temperature measurement.

The analysis method used was the National Institute of Environmental Analysis (NIEA) W785.54B and United States Environmental Protection Agency (USEPA) method 8260B, which can detect a total of 60 volatile organic compounds. The heat value of the petro-sludge was carried out according to the standard methods (e.g., National Institute of Environmental Analysis (NIEA) R214.01C for heat value). The data analysis of the heavy metal content for petroleum sludge was based on the use of aqua regia (nitric acid: hydrochloric acid = 1:3) as the acid solution of heavy metal leaching followed by the use of inductively coupled plasma optical emission spectrometry (ICP-OES) to conduct the heavy metal total analysis after microwave digestion, using the NIEA R317.11C method. The data analysis was also based on the use of nitric acid as the heavy metal extraction solution, which was put into a bottle extraction vessel and performed a 30 ± 2 RPM selection device for 18 ± 2 h of extraction. The extracted acid solution was subjected to heavy metal dissolution analysis with toxicity characteristic leaching procedure (TCLP), using NIEA R201.15C.

3. Results and Discussion

3.1. Effect of Energy Absorption and Electric Field Strength at Different Microwave Power

The characteristics of microwave radiation heating rely on dipole rotation and ionic conduction. The dipole rotation changes with the direction of the alternating microwave radiation field [

22]. When a solvent is used as a media in the microwave radiation field, the solvent changes from polarization to polarized state and the electric energy is stored. The degree of polarization depends on the composition and morphology of the solvent and the frequency of the electric field applied.

Figure 2 shows the sludge temperature in the microwave oven when the oil sludge is irradiated inside the microwave oven at different microwave power with varied radiation durations. The oil sludge temperatures 66.5 °C, 79.6 °C, and 96.5 °C correspond to the microwave power at 200, 250, and 300 W with the treatment time for 60 s.

The water has a higher dielectric constant and dielectric loss constant (25 °C,

= 78 F/M and 25 °C,

= 12.5 F/M, respectively) at 2.45 GHz microwave frequency. On the other hand, the dielectric constant (

) and dielectric loss tangent (

) of the crude oil sludge can be calculated with the Equations (5) and (6) under different microwave power and irradiation time [

17]:

The density (

ρ0) and thermal capacity (Cp) of oil sludge changes when exposed to different microwave power and irradiation time. These values can be calculated by Formulas (2)–(4). Finally, the calculated results from Formulas (2)–(6) are used in Formula (1) to determine the average absorbed energy of sludge material volume. By using a different microwave power (200, 250 and 300 W) with the same microwave irradiation time of 60 s, the electric field produced by oil sludge under the microwave electromagnetic field were 12.1, 13.2, and 13.8 V/m, respectively. This increased with higher microwave power and oil sludge temperatures. According to the results from Formulas (5) and (6), dielectric loss increased along with the rises of the oil sludge temperature. At the same time, dielectric loss indicates the ability of the material absorbing microwave energy to convert it into heat energy. Therefore, the oil sludge absorbs more MW energy in the initial stage and makes the temperature rise faster. However, with the increase of oil sludge temperature, the impacts on the dielectric loss also increase and the intensity of the microwave energy absorption by oil sludge gradually declines [

23].

In addition, the temperature rise causes the volume of sludge to expand and the density to decrease, which further affects the heat capacity of the sludge material after being continuously microwaved. Therefore, according to the microwave power and irradiation time, the sludge mass density (

ρ0) and the substance heat capacity (Cp) change. The calculation results of Formulas (2)–(4) are used in Formula (1) to calculate the average microwave energy of the sludge absorption electric field. The results in

Figure 3 show that whether the microwave power was 200, 250, or 300 W, the average microwave energy of the sludge absorption electric field decreased along with the temperature of the sludge.

3.2. Recovering of the Tail Gas by Memberane Separator Following the Microwave Process

During the microwave treatment process, the temperature of the oil sludge increased and enabled volatile organic compounds (VOCs) be released. These VOCs were separated and recovered via a membrane separator device.

Gases with high solubility and small molecules pass through the membrane quicker than less soluble gases with larger molecules which need to permeate the membrane. In addition, different membrane materials have different separation capacities. The driving force needed to separate gases is achieved by means of a partial pressure gradient that is caused by the pressure difference between the residual side and the permeate side. The greater the difference, the more gas permeates through the membrane. To maintain the permeation pressure at 2.0 kg/cm (g), the permeate flow rate was adjusted for testing at 0.7, 0.9, 1.1, 1.3, and 1.5 L/min. The results are shown in

Figure 4, when the permeate flow rate increased from 0.7 to 1.5 L/min. The VOCs recovery rates also increased dramatically from 23.3% to 71.9% for C

3, 21.9% to 71.3% for C

4, 17.6% to 71.0% for C

5, and 14.3% to 78.2% for C

6.

3.3. Effect of Microwave Radiation on BTEX Removal from Oil Sludge

The crude oil sludge absorbed MW energy under microwave irradiation and resulted in rising the temperature to decomposed heavy hydrocarbons into light hydrocarbons (such as alkanes and aromatics hydrocarbons). Subsequently, the cracking reactions occurred when alkyl side chains of alkanes and aromatic hydrocarbons were destroyed in heated zones generated by microwave energy, and the resulting compositions were physically volatilized. Among them, polar substances (heavy chain molecules) absorbed the higher microwave energy, which in turn destroyed the structure of the low energy chain (C–H). The degree of cracking depended on the heat generated by the microwave process.

The results show that when the oily sludge sample had a total irradiation of 60 s in 6 cycles (10 s of irradiation with 10 s of interval per cycle) under a microwave power ranging from 200–300 W, the BTEX removal rates increased from 15.6% to 38.3% for benzene, 16.8% to 29.8% for toluene, 24.1% to 29.4% for ethyl benzene, and 15.8% to 24.2 % for xylene. Meanwhile, when increasing total irradiation to 900 s in 90 cycles (

Table 1) the removal rates for benzene, toluene, ethylbenzene, and xylene were 98.5%. The residual concentration was 0.4% mg/L, 62.0% mg/L, 51.6% mg/L, and 29.9% mg/L respectively.

In addition, the experimental results show that the viscosity of oil sludge can be reduced by microwave irradiation. The oil sludge was actually water in oil emulsion (W/O), which was formed by vigorous mixing under extremely high external pressure. The microwave increased the temperature of the emulsion, resulting in the decrease of the alkane content leading to decrease in viscosity [

24].

3.4. Thermal Value Analysis for Oil Sludge

The demulsification of oil sludge was achieved after microwave irradiation, which can separate the water phase and oil phase in the sludge. The longer the microwave irradiation time, the deeper the microwave penetration depth. When the microwave power was set at 300 W and the total irradiation was 300, 600, and 900 s with 10 s of irradiation and 10 sec of interval per cycle, the calorific value (higher heating value, dry) of the dried sludge was determined under each condition. The calorific value of the sludge was 10,012, 10,284, and 10,423 cal/g corresponding to a total irradiation time of 300, 600, and 900 s, respectively.

In addition, the water content in the sludge will affect the power required for subsequent microwave heating. When the water content is higher, using higher power for the test will cause the temperature of the sludge to rise too fast and cause liquefaction. The boiling of the water phase leads to the separation of the oil phase and the solid phase. Therefore, when the total irradiation time increased, the calorific value increased due to water loss in the oil sludge. In the meantime, the lighter hydrocarbons in the oil sludge decreased along with the increase in temperature of the sludge.

The utilization of microwave energy could efficiently reduce the viscosity of the oily sludge. The heavy hydrocarbons contained in the oil sludge were able to absorb microwave energy immensely; hence, the high temperature generated by the microwave power could effectively reduce the high carbon number of hydrocarbons [

25]. In fact, the heavy molecule hydrocarbons were destroyed, thus reducing the viscosity of the oil sludge.

After high temperature (800 °C) combustion on microwave-treated sludge, the residual ash content of heavy metals was analyzed as follows: iron (Fe): 92,347.08 mg/L zinc (Zn): 1792.86 mg/L; manganese (Mn): 1609.34 mg/L; lead (Pb): 66.74 mg/L; copper (Cu): 312.21 mg/L; barium (Ba): 28.89 mg/L; nickel (Ni): 131.64 mg/L; chromium (Cr): 62.51 mg/L; cadmium (Cd): 40.2 mg/L. In addition, toxicity characteristic leaching procedure (TCLP) testing was performed on the bottom residue of oil sludge for heavy metal content determination. The heavy metal contents were 0.034 mg/L Ba, 0.047 mg/L As, 0.011 mg/L Hg, and 0.041 mg/L Se. Elements of Cr, Pb, Cd, Cu, and Cr

6+ were not detected (N.D.). These results are similar to the results obtained by Shie et al. (2000) which detected heavy metals in trace levels or not at all [

5].

In light of the above results, after the process of microwave treatment, the benzene content was reduced to 0.4 mg/L in the oil sludge. This is lower than the regulatory standard of 0.5 mg/L set by the Environmental Protection Administration (EPA) in Taiwan. In addition, the concentration of heavy metals is less than the regulated standards, and the heat value reached 10,423 cal/g. In the future, it would be beneficial to mix the microwave-treated oil sludge into rice husks, wood chips or other crop wastes and convert it into refuse-derived fuel, so as to enhance the value of oil sludge resource recovery.

4. Conclusions

In this study, the microwave irradiation technique was able to remove BTEX from sediment of crude oil sludge. The results showed that the benzene removal rate was 98.5% and the residual concentration was below the regulatory standard of 0.5 mg/L when 10 g of oil sludge was treated with 900 s (90 cycles) of interval irradiation under 300 W microwave power. In the meantime, the removal rates of toluene, ethyl-benzene, and xylene were 62.8%, 51.6%, and 29.9%, respectively.

With only 60 s of microwave irradiation at 200, 250, and 300 W, the oil sludge temperature increased from room temperature to 66.5 °C, 79.6 °C and 96.5 °C, respectively. The electric fields of the sludge were 12.1, 13.2 and 13.8 V/m, respectively. However, with the increase of oil sludge temperature, the dielectric loss of oil sludge decreased gradually and the average microwave energy of the oil sludge absorbing the electric field increased from 0.17 to 0.24 and 0.31 W/cm. In addition, the VOCs in the oil sludge evaporated when the temperature increased in the microwave process, which could be recovered by a membrane separator device. When the permeate flowrate increased from 0.7 to 1.5 L/min, the VOCs recovery rates increased dramatically from 23.3% to 71.9% for C3; 21.9% to 71.3% for C4, 17.6% to 71.0% for C5; and 14.3% to 78.2% for C6.

This study shows it is feasible to use this innovative microwave treatment technology not only to reduce the harmful substances in oil sludge waste but also to enhance the renewable resource value of oil sludge.