The Role of Structural Context in Making Business Sense of Investments for Sustainability–A Case Study

Abstract

1. Introduction

2. Theoretical Background

2.1. The Activities and Procedures of the Investment Process

2.2. The Role of Information

3. Materials and Methods

3.1. Sampling: The Case Investment and the Case Company

“The Company Board of Alpha has made the decision to undertake an environmental and energy investment at Alpha Mill. The aim is to strengthen the mill for the future by improving environmental performance and energy efficiency as well as enabling for future expansion. The expected investment amount is €90 million.”(Press release for the case investment, 2011. The quote has been somewhat modified to ensure anonymity of the case firm.)

3.2. Data Collection and Analysis

4. Results

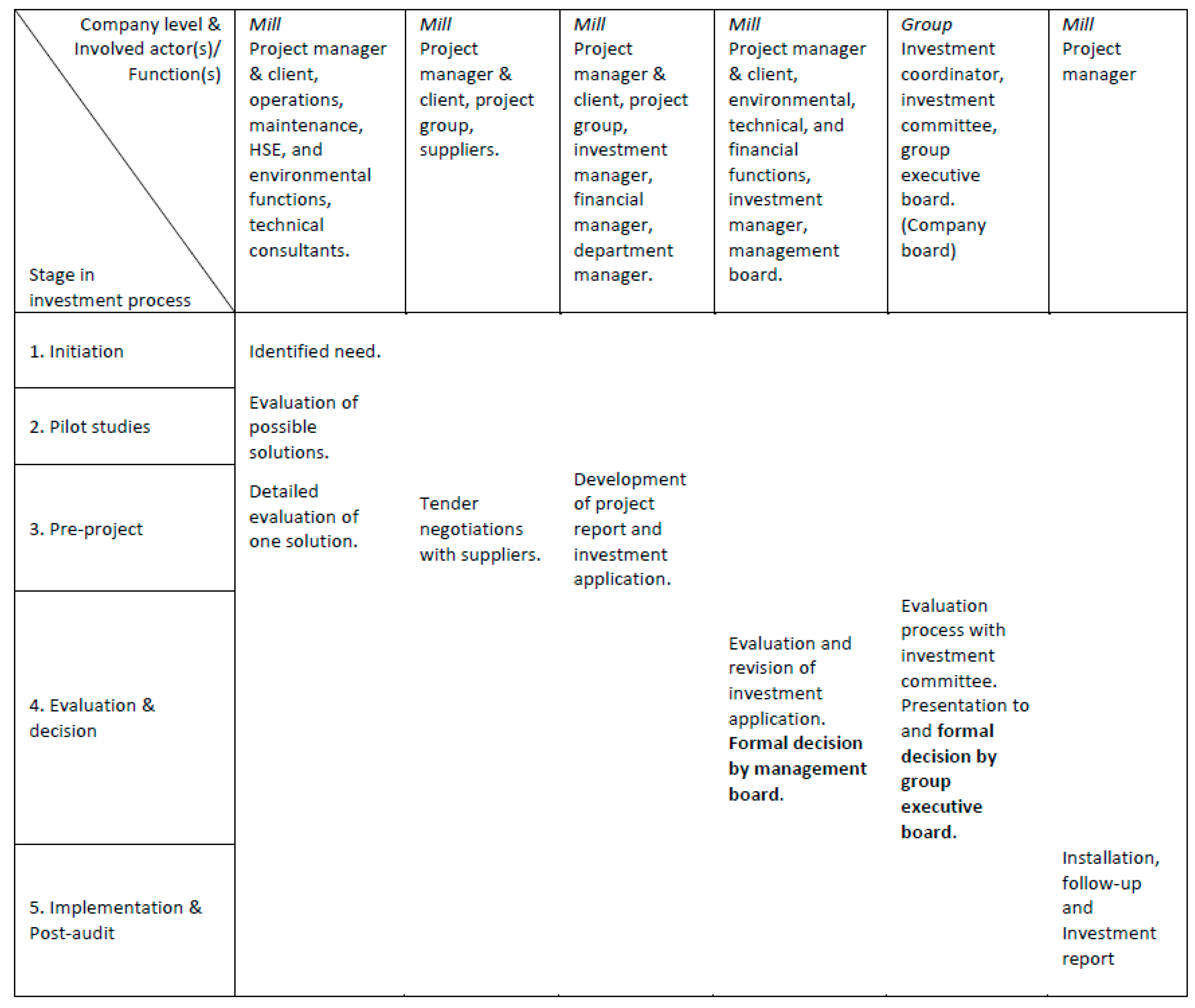

4.1. Activities

“No, we have a standardized method for how this should be done. Whether it is environmentally related, production or energy…”(Technical Controller, Alpha Mill)

“It is the same template regardless of what it is.”(Department Manager, Alpha Mill)

“Most investment projects are connected to availability and what needs to be fixed in order to maintain or improve the availability.”(Maintenance Manager, Alpha Mill)

“At the mill level, there are few improvements you can do. You have to prioritize between the opportunities you have and the necessary investments you have to go through with.”(Investment Coordinator, Alpha Group)

“There is probably no investment with a payback period of more than 2 years that is approved within the mill’s investment budget.”(Department Manager, Alpha Mill)

“It can be to take the decision to make the pre-study, and should we proceed and also do a pre-project and feasibility study? Should we develop an investment application? Then I am also part of the management board which acts as a tollgate, where we decide whether we should make an investment.”(Department Manager, Alpha Mill)

“We had already negotiated with the suppliers so the day we got the authorization we could sign the contracts and start.”(Investment Manager, Alpha Mill)

4.2. Procedures

“It was a mandatory investment, but we chose to be proactive.”(Investment Manager, Alpha Mill)

“It really has to go by the technical department so that they can sign. If it is estimated to have an environmental impact, be it air, water, chemicals, etc., then the environmental department must comment as well, and then it should pass the financial department and I should put my signature on it.—It is governed through an instruction exactly the way in which it should proceed.—It should be a project manager and so forth. It doesn’t matter (what it is), it is still money that is going out.”(Financial Manager, Alpha Mill)

“You have to have a process where it is fundamental that those responsible for the company’s finances say yes or no.”(Sustainability Director, Alpha Group)

“It is a somewhat iterative process. It starts with an idea and the closer you get with the pre-studies and pre-project, you start to see ‘will this make it?’ Once you have the final numbers in your hand it is rarely a no.”(Investment Coordinator, Alpha Group)

4.3. The Role of Information

“Since you ensure you have certain standard processes and standard documents, it forces you to reflect.”(Financial Manager, Alpha Mill)

“Those who make the decision need to know why you want to do this.—So, it is the motive. It rarely fails based on technology and the level of detail.”(Investment Manager, Alpha Mill)

“This was a typical case of ‘we mention it but we don’t bother pushing for it’—But work environment is a considerable change.”(Investment Manager, Alpha Mill)

4.4. A Note on Energy Efficiency and Non-Energy Benefits

“Maybe you install new equipment to increase production and then you end up improving energy efficiency as well. So it is not always that you aim to save energy and increase production, it is more often the other way around.”(Technical Controller, Alpha Mill)

“Increased productivity, improved quality, reliability in production… This is why we wish to make certain investments.”(Financial Manager, Alpha Mill)

“An energy efficiency investment is an environmental action that pays off.”(Investment Manager, Alpha Mill)

“Energy is such a big question for us. It’s a lot bigger than environment and sustainability. For us, energy is such a large cost, so there is a driving force for that (energy) work.”(Environmental Manager, Alpha Mill)

“Energy is one of the resources we use but then it also costs a lot of money too—it happens to go hand in hand.”(Sustainability Director, Alpha Group)

“The most critical issues need to be prioritized within the mill’s investment budget, which often implies investments in production, availability or maintenance.—energy efficiency is ‘just money,’ whereas for example investments in production have a shorter payback period and an operational focus.”(Division Manager, Alpha Mill)

5. Discussion

6. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Abdul-Rashid, S.H.; Sakundarini, N.; Ghazilla, R.A.R.; Thurasamy, R. The impact of sustainable manufacturing practices on sustainability performance. Empirical evidence form Malaysia. Int. J. Oper. Prod. Manag. 2016, 37, 182–204. [Google Scholar] [CrossRef]

- Cagno, E.; Neri, A.; Trianni, A. Broadening to sustainability the perspective of industrial decision-makers on the energy efficiency measures adoption: Some empirical evidence. Energy Effic. 2018, 11, 1193–1210. [Google Scholar] [CrossRef]

- Porter, M.; van der Linde, C. Green and competitive: Ending the stalemate. Harv Bus Rev. 1995, 73, 120–134. [Google Scholar]

- Rogelj, J.; Shindell, D.; Jiang, K.; Fifita, S.; Forster, P.; Ginzburg, V.; Handa, C.; Kheshgi, H.; Kobayashi, S.; Kriegler, E.; et al. Mitigation pathways compatible with 1.5 °C in the context of sustainable development. In Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change, Sustainable Development, and Efforts to Eradicate Poverty; Masson-Delmotte, V., Zhai, P., Pörtner, H.-O., Roberts, D., Skea, J., Shukla, P.R., Pirani, A., Moufouma-Okia, W., Péan, C., Pidcock, R., et al., Eds.; IPCC: Geneva, Switzerland, 2018. [Google Scholar]

- UN. United Nations Sustainable Development Goals. The Sustainable Development Goals Report; 2018. Available online: https://unstats.un.org/sdgs/files/report/2018/TheSustainableDevelopmentGoalsReport2018-EN.pdf (accessed on 8 January 2020).

- Fonseca, L.M.; Domingues, J.P.; Dima, A.M. Mapping the sustainable development goals relationships. Sustainability 2020, 12, 3359. [Google Scholar] [CrossRef]

- Gimenez, C.; Sierra, V.; Rodon, J. Sustainable operations: Their impact on the triple bottom line. Int. J. Prod. Econ. 2012, 140, 149–159. [Google Scholar] [CrossRef]

- Albino, V.; Balice, A.; Rosa Maria Dangelico, R.M. Environmental strategies and green product development: An overview on sustainability-driven companies. Bus. Strateg. Environ. 2009, 18, 83–96. [Google Scholar] [CrossRef]

- Epstein, M.J.; Yuthas, K. Analyzing sustainability impacts. Strateg. Finance 2012, 93, 27–33. [Google Scholar]

- Brunke, J.-C.; Johansson, M.; Thollander, P. Empirical investigation of barriers and drivers to the adoption of energy conservation measures, energy management practices and energy services in the Swedish iron and steel industry. J. Clean. Prod. 2014, 84, 509–525. [Google Scholar] [CrossRef]

- Haraldsson, J.; Johansson, M.T. Barriers to and drivers for improved energy efficiency in the Swedish aluminium industry and aluminium casting foundries. Sustainability 2019, 11, 2043. [Google Scholar] [CrossRef]

- Solnørdal, M.T.; Foss, L. Closing the energy efficiency gap—A systematic review of empirical articles on drivers to energy efficiency in manufacturing firms. Energies 2018, 11, 518. [Google Scholar] [CrossRef]

- Thollander, P.; Ottosson, M. An energy efficient Swedish pulp and paper industry—Exploring barriers to and driving forces for cost-effective energy efficiency investments. Energy Effic. 2008, 1, 21–34. [Google Scholar] [CrossRef]

- Del Río González, P. Analysing the factors influencing clean technology adoption: A study of the spanish pulp and paper industry. Bus. Strateg. Environ. 2005, 14, 20–37. [Google Scholar] [CrossRef]

- Sardianou, E. Barriers to industrial energy efficiency investments in Greece. J. Clean. Prod. 2008, 16, 1416–1423. [Google Scholar] [CrossRef]

- Cagno, E.; Trianni, A. Evaluating the barriers to specific industrial energy efficiency measures: An exploratory study in small and medium-sized enterprises. J. Clean. Prod. 2014, 82, 70–83. [Google Scholar] [CrossRef]

- De Groot, H.L.F.; Verhoef, E.T.; Nijkamp, P. Energy saving by firms: Decision-making, barriers and policies. Energy Econ. 2001, 23, 717–740. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Thollander, P.; Backlund, S. Barriers to industrial energy efficiency in foundries: A European comparison. J. Clean. Prod. 2013, 40, 161–176. [Google Scholar] [CrossRef]

- Venmans, F. Triggers and barriers to energy efficiency measures in the ceramic, cement and lime sectors. J. Clean. Prod. 2014, 69, 133–142. [Google Scholar] [CrossRef]

- Sullivan, R.; Gouldson, A. The governance of corporate responses to climate change: An international comparison. Bus. Strateg. Environ. 2017, 26, 413–425. [Google Scholar] [CrossRef]

- Paramonova, S.; Thollander, P.; Ottosson, M. Quantifying the extended energy efficiency gap—Evidence from Swedish electricity-intensive industries. Renew. Sust. Energ. Rev. 2015, 51, 472–483. [Google Scholar] [CrossRef]

- Vesty, G.; Brooks, A.; Oliver, J. Contemporary Capital Investment Appraisal from a Management Accounting and Integrated Thinking Perspective: Case Study Evidence. CPA. Australia. 2015. Available online: https://www.cpaaustralia.com.au/~/media/corporate/allfiles/document/professional-resources/sustainability/sustainability-and-capital-investment-case-studies.pdf (accessed on 2 July 2019).

- Haka, S. A review of the literature on capital budgeting and investment appraisal: Past, present, and future musings. In Handbook of Management Accounting Research; Chapman, C.S., Hopwood, A.G., Shields, M.D., Eds.; Elsevier Ltd.: Amsterdam, The Netherlands, 2007; Volume 2, pp. 697–728. ISBN 9780080467566. [Google Scholar]

- Emmanuel, C.; Harris, E.; Komakech, S. Towards a better understanding of capital investment decisions. J. Account. Organ. Chang. 2010, 6, 477–504. [Google Scholar] [CrossRef]

- Maritan, C.A. Capital investment as investing in organizational capabilities: An empirically grounded process model. Acad. Manag. J. 2001, 44, 513–531. [Google Scholar] [CrossRef]

- Fleiter, T.; Hirzel, S.; Worrell, E. The characteristics of energy-efficiency measures—A neglected dimension. Energy Policy 2012, 51, 502–513. [Google Scholar] [CrossRef]

- Bower, J.L. Managing the Resource Allocation Process: A Study of Corporate Planning and Investment; HBS Press: Boston, MA, USA, 1970; ISBN 87584-083-3. [Google Scholar]

- Simons, R. Performance Measurement and Control Systems for Implementing Strategy; Prentice Hall: New Jersey, NJ, USA, 2000; ISBN 013-021945-2. [Google Scholar]

- Segelod, E. Corporate control of investments and management styles. Int. J. Prod. Econ. 1996, 43, 227–237. [Google Scholar] [CrossRef]

- Segelod, E. The content and role of the investment manual—A research note. Manag. Account. Res. 1997, 8, 221–231. [Google Scholar] [CrossRef]

- Strauch, M.; Pidun, U.; Knyphausen-Aufseß, D. Process matters—How strategic decision-making process characteristics impact capital allocation efficiency. Long Range Plann. 2019, 52, 202–220. [Google Scholar] [CrossRef]

- Harris, E.P.; El-Massri, M. Capital investment appraisal. In Review of Management Accounting Research; Abdel-Kader, M., Ed.; Palgrave: London, UK, 2011; pp. 343–377. ISBN 978-0-230-35327-5. [Google Scholar]

- Huikku, J.; Karjalainen, J.; Seppälä, T. The dynamism of pre-decision controls in the appraisal of strategic investments. Br. Account. Rev. 2018, 50, 516–538. [Google Scholar] [CrossRef]

- Anthony, R.N.; Govindarajan, V. Management Control Systems, 12th ed.; McGraw-Hill: Boston, MA, USA, 2007; ISBN 0071254102. [Google Scholar]

- Thollander, P.; Ottosson, M. Energy management practices in Swedish energy-intensive industries. J. Clean. Prod. 2010, 18, 1125–1133. [Google Scholar] [CrossRef]

- Nehler, T. A systematic literature review of methods for improved utilisation of the non-energy benefits of industrial energy efficiency. Energies 2018, 11, 3241. [Google Scholar] [CrossRef]

- Worrell, E.; Laitner, J.A.; Ruth, M.; Finman, H. Productivity benefits of industrial energy efficiency measures. Energy 2003, 28, 1081–1098. [Google Scholar] [CrossRef]

- Pye, M.; McKane, A. Making a stronger case for industrial energy efficiency by quantifying non-energy benefits. Resour. Conserv. Recycl. 2000, 28, 171–183. [Google Scholar] [CrossRef]

- Nehler, T.; Rasmussen, J. How do firms consider non-energy benefits? Empirical findings from energy-efficiency investments in Swedish industry. J. Clean. Prod. 2016, 113, 472–482. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Neri, A. Modelling barriers to the adoption of industrial sustainability. J. Clean. Prod. 2017, 168, 1482–1504. [Google Scholar] [CrossRef]

- Rosen, M.A.; Kishawy, H.A. Sustainable manufacturing and design: Concepts, practices and needs. Sustainability 2012, 4, 154–174. [Google Scholar] [CrossRef]

- Harris, E. Project risk assessment: A European field study. Br. Account. Rev. 1999, 31, 347–371. [Google Scholar] [CrossRef]

- Gond, J.-P.; Grubnic, S.; Herzig, C.; Moon, J. Configuring management control systems: Theorizing the integration of strategy and sustainability. Manag. Account. Res. 2012, 23, 205–223. [Google Scholar] [CrossRef]

- Alkaraan, F.; Northcott, D. Strategic capital investment decision-making: A role for emergent analysis tools? A study of practice in large UK manufacturing companies. Br. Account. Rev. 2006, 38, 149–173. [Google Scholar] [CrossRef]

- Andor, G.; Nohanty, S.K.; Toth, T. Capital budgeting practices: A survey of Central and Eastern European firms. Emerg. Mark. Rev. 2015, 23, 148–172. [Google Scholar] [CrossRef]

- Bennouna, K.; Meredith, G.G.; Marchant, T. Improved capital budgeting decision making: Evidence from Canada. Manag. Decis. 2010, 48, 225–247. [Google Scholar] [CrossRef]

- Graham, J.R.; Harvey, C.R. The theory and practice of corporate finance: Evidence from the field. J. Financ. Econ. 2001, 60, 187–243. [Google Scholar] [CrossRef]

- Remer, D.S.; Stokdyk, S.B.; Van Driel, M. Survey of project evaluation techniques currently used in industry. Int. J. Prod. Econ. 1993, 32, 103–115. [Google Scholar] [CrossRef]

- Sandahl, G.; Sjögren, S. Capital budgeting methods among Sweden’s largest groups of companies. The state of the art and a comparison with earlier studies. Int. J. Prod. Econ. 2003, 84, 51–69. [Google Scholar] [CrossRef]

- Cooremans, C. Investments in energy efficiency: Do the characteristics of investments matter? Energy Effic. 2012, 5, 497–518. [Google Scholar] [CrossRef]

- Cooremans, C.; Schönenberger, C. Energy management: A key driver for energy-efficiency investment? J. Clean. Prod. 2019, 203, 264–275. [Google Scholar] [CrossRef]

- Clancy, D.K.; Collins, D. Capital budgeting research and practice: The state of the art. Adv. Manag. Account. 2014, 24, 117–161. [Google Scholar] [CrossRef]

- Glaser, M.; Lopez De Silanes, F.; Sautner, Z. Opening the black box: Internal capital markets and managerial power. J. Finance 2013, 68, 1577–1631. [Google Scholar] [CrossRef]

- Simons, R. Levers of Control: How Managers Use Innovative Control Systems to Drive Strategic Renewal; Harvard Business School Press: Brighton, MA, USA, 1995; ISBN 0-87584-559-2. [Google Scholar]

- Graham, J.R.; Harvey, C.R.; Puri, M. Capital allocation and delegation of decision-making authority within firms. J. Financ. Econ. 2015, 115, 449–470. [Google Scholar] [CrossRef]

- Journeault, M. The influence of the eco-control package on environmental and economic performance: A natural resource-based approach. J. Manag. Account. Res. 2016, 28, 149–178. [Google Scholar] [CrossRef]

- Pondeville, S.; Swaen, V.; De Ronge, Y. Environmental management control systems: The role of contextual and strategic factors. Manag. Account. Res. 2013, 24, 317–332. [Google Scholar] [CrossRef]

- Christensen, B.; Himme, A. Improving environmental management accounting: How to use statistics to better determine energy consumption. J. Manag. Control. 2017, 28, 227–243. [Google Scholar] [CrossRef]

- Epstein, M.J.; Roy, M.-J. Integrating environmental impacts into capital investment decisions. In The Green Bottom Line: Environmental Accounting for Management: Current Practice and Future Trends; Bennet, M., James, P., Eds.; Routledge: New York, NY, US, 1998; pp. 100–114. ISBN 9781874719243. [Google Scholar]

- Albelda, E. The role of management accounting practice as facilitators of the environmental management: Evidence from EMAS organisations. Sustain. Account. Manag. Policy J. 2011, 2, 76–100. [Google Scholar] [CrossRef]

- Jørgensen, B.; Messner, M. Accounting and strategising: A case study from new product development. Account. Organ. Soc. 2010, 35, 184–204. [Google Scholar] [CrossRef]

- Slagmulder, R. Using management control systems to achieve alignment between strategic investment decision and strategy. Manag. Account. Res. 1997, 8, 103–139. [Google Scholar] [CrossRef]

- Van Cauwenbergh, A.; Durinck, E.; Martens, R.; Laveren, E.; Bogaert, I. On the role and function of formal analysis in strategic investment processes: Results from an empirical study in Belgium. Manag. Account. Res. 1996, 7, 169–184. [Google Scholar] [CrossRef]

- Hirst, M.K.; Baxter, J.A. A capital budgeting case study: An analysis of a choice process and roles of information. Behav. Res. Account. 1993, 5, 187–209. [Google Scholar]

- Cheng, M.M.; Mahama, H. The impact of capital proposal guidelines and perceived preparer biases on reviewers’ investment evaluation decisions. Aust. J. Manag. 2011, 36, 349–370. [Google Scholar] [CrossRef]

- Lumijärvi, O.P. Selling of capital investments to top management. Manag. Account. Res. 1991, 2, 171–188. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; De Donatis, A. A framework to characterize energy efficiency measures. Appl. Energy 2014, 118, 207–220. [Google Scholar] [CrossRef]

- Hosoda, M.; Suzuki, K. Using management control systems to implement CSR activities: An empirical analysis of 12 Japanese companies. Bus. Strateg. Environ. 2015, 24, 628–642. [Google Scholar] [CrossRef]

- Flyvbjerg, B. Five misunderstandings about case studies. Qual. Inq. 2006, 12, 219–245. [Google Scholar] [CrossRef]

- Patton, E.; Appelbaum, S.H. The case for case studies in management research. Manag. Res. News 2003, 9, 27–40. [Google Scholar] [CrossRef]

- Eisenhardt, K.M.; Graebner, M.E. Theory building from cases: Opportunities and challenges. Acad. Manag. J. 2007, 50, 25–32. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research: Design and Methods, 4th ed.; SAGE Publications, Inc.: Thousand Oakes, CA, USA, 2009; ISBN 978-1-4129-6099-1. [Google Scholar]

- Swedish Energy Agency. Energy in Sweden 2017; SEA: Eskilstuna, Sweden, 2018. [Google Scholar]

- SFIF, Swedish Forest Industries Federation. Roadmap for Fossil Free Competitiveness—Forest Sector; SFIF: Stockholm, Sweden, 2018. [Google Scholar]

- Fleiter, T.; Fehrenbach, D.; Worrell, E.; Eichhammer, W. Energy efficiency in the German pulp and paper industry—A model-based assessment of saving potentials. Energy 2012, 40, 84–99. [Google Scholar] [CrossRef]

- Möllersten, K.; Yan, J.; Westermark, M. Potential and cost-effectiveness of CO2 reductions through energy measures in Swedish pulp and paper mills. Energy 2003, 28, 691–710. [Google Scholar] [CrossRef]

- Kramer, K.J.; Masanet, E.; Worrell, E. Energy efficiency opportunities in the US pulp and paper industry. Energy Eng. 2010, 107, 21–50. [Google Scholar] [CrossRef]

- Eisenhardt, K.M. Building theories from case study research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Saldaña, J. The Coding Manual for Qualitative Researchers; SAGE Publications: London, UK, 2009; ISBN 978-1-84787-548-8. [Google Scholar]

- Ayres, L.; Kavanaugh, K.; Knafl, K.A. Within-case and across-case approaches to qualitative data analysis. Qual. Health Res. 2003, 13, 871–883. [Google Scholar] [CrossRef] [PubMed]

- European Commission. 2016. Available online: http://ec.europa.eu/environment/archives/air/stationary/ippc/summary.htm (accessed on 2 July 2019).

- European Commission. 2016. Available online: http://ec.europa.eu/environment/archives/air/stationary/ippc/ippc_revision.htm (accessed on 2 July 2019).

- Baldenius, T.; Dutta, S.; Reichelstein, S. Cost allocation for capital budgeting decisions. Account. Rev. 2007, 82, 837–867. [Google Scholar] [CrossRef]

- Carroll, A.B.; Shabana, K.M. The business case for corporate social responsibility: A review of concepts, research and practice. Int. J. Manag. Rev. 2010, 12, 85–105. [Google Scholar] [CrossRef]

- Guenther, E.; Endrikat, J.; Guenther, T.W. Environmental management control systems: A conceptualization and a review of the empirical evidence. J. Clean. Prod. 2016, 136, 147–171. [Google Scholar] [CrossRef]

- IEA (International Energy Agency). Energy and Climate Change, World Energy Outlook Special Report; OECD/IEA: Paris, France, 2015.

- Crutzen, N.; Zvezdov, D.; Schaltegger, S. Sustainability and management control. Exploring and theorizing control patterns in large European firms. J. Clean. Prod. 2017, 143, 1291–1301. [Google Scholar] [CrossRef]

- Rotzek, J.N.; Scope, C.; Günther, E. What energy management practice can learn from research on energy culture? Sustain. Account. Manag. Policy J. 2018, 9, 515–551. [Google Scholar] [CrossRef]

- Johnstone, L. Theorising and conceptualising the sustainability control system for effective sustainability management. J. Manag. Control. 2019, 30, 25–64. [Google Scholar] [CrossRef]

| Data Source | Description |

|---|---|

| Interviews | Ten in total, two at group level and eight at mill level. Eight interviews conducted face-to-face, two by phone. See Table 2 for interviewee descriptions. |

| Information meeting | Introductory meeting with the division manager. Presentation of the unit and its operations. Notes. |

| Mill tour | By Division Manager in connection with the information meeting. |

| Financial and sustainability reports | External documents, publicly available. |

| Press releases | For the case investment and other sustainability-related investments. External documents, publicly available. |

| Template for investment application | Three-page form stipulating the requirements for the investment application. Internal document. Received copy. |

| Template for environmental analysis | Two-page form stipulating required information on environmental impact. Internal document. Received copy. |

| Template for risk analysis | Internal program and document. Restricted to observe on site and take notes. |

| Presentation of case investment | Presentation of the results of the case investment, approximately one year after implementation. Internal document. Received copy. |

| Interviewee | Description | Organizational Level |

|---|---|---|

| Sustainability Director | Part of executive management. Responsible for sustainability issues at the group level. Was also at the time communications director at the group level (i.e., combined role). | Group |

| Investment Coordinator | Coordinator of major investment applications at the group level. Part of investment committee at the group level. | Group |

| Department Manager | Head of Pulp Department with operational responsibility for its processes. Part of management board and energy steering committee at the mill. | Mill |

| Environmental Manager | Department manager for process development and environmental issues. Overall responsibility for energy issues. Part of mill’s and its subdivisions’ energy committees. | Mill |

| Division Manager | Division manager for a subdivision of the sulphate pulp mill, including the case investment. Responsible for continuous improvements in energy and in general for the division. Was involved during the process for the case investment as project leader for the evaporation plant. | Mill |

| Investments Manager | Coordinating role at the mill for investment planning. Reviews investment applications requiring approval at group level. Was main project manager for the case investment. | Mill |

| Financial Manager | Head of Financial Department and part of the mill’s management board. Reviews investment applications before submission to management board. | Mill |

| Maintenance Manager | Head of Maintenance Department at the mill. Administers and is responsible for prioritizing between investments. Part of the mill’s management board. Manager of committee with all maintenance managers within the company group. | Mill |

| Technical Controller | Works with energy and environmental issues, including budgeting, reporting, and coordinating. Reviews investment applications before submission to the mill’s management board. Part of the energy steering committee at the mill and energy council on group level. | Mill |

| Manager Health, safety & environment (HSE) | Head of work environment and safety at the mill. Part of the group-level work environment committee. | Mill |

| Procedures | Level | Activity in Investment Process | |

|---|---|---|---|

| Investment classification A† | Maintain, strategic, enhance. | Group | Investment application |

| Investment classification B | Strategic, market, mandatory, capacity, quality, rationalization, building, environment, replacement. Multiple classifications possible. | Mill | Investment application |

| Financial evaluation A | Primarily Net Present Value (NPV), Internal Rate of Return (IRR), Modified IRR (MIRR), payback (PB), occasionally Life Cycle Cost (LCC). Firm-specific discount rate. | Group | Pilot studies, pre-project, investment application |

| Financial evaluation B | Often limited to PB. Occasionally LCC. | Mill | Pilot studies, pre-project, investment application |

| Investment committee review | Committee reviewing larger investment proposals before authorization by group management. Structure for revision of proposals before being sent for authorization. | Group | Evaluation and decision |

| Investment proposal review | Finance, technology, process, environment, management. Who and when stated in the manual. | Mill | Evaluation and decision |

| Authorization by group management | Group management accepts or dismisses investment proposals, based on investment committee review. | Group | Evaluation and decision |

| Ranking/investment prioritization A | Prioritization of larger investments administered by mill manager. | Mill | Evaluation and decision |

| Ranking/investment prioritization B | Investments within the mill’s investment budget, administered by maintenance manager. Based on ranking from division managers. | Mill | Evaluation and decision |

| Authorization limits | Division/mill/investment committee and group management/executive board. | Group, mill | Evaluation and decision |

| Investment manual | Application (motive, time frame and plan, financial details), authorization route. | Group, mill | Pre-project, evaluation and decision |

| Environmental analysis | Mandatory supplement to the investment manual, concerning external environment. Limits on emissions, noise, etc. | Mill | Pre-project, evaluation and decision |

| Risk assessment | Mandatory supplement to the investment manual. | Mill | Pre-project, evaluation and decision |

| Work environment analysis | Supplement to investment manual. Not mandatory, but representatives from work environment and safety should be consulted for all projects. Work environmental aspects should be addressed in the appendix or proposal. | Mill | Pre-project, evaluation and decision |

| Energy | Energy should be acknowledged for all investments and upgrades. | Mill | Pre-project, investment application |

| Supplier involvement | Tenders required at the pre-project stage. | Mill | Pre-project |

| Documentation routines A | According to the manual and additional pre-project report, presentation to the investment committee, and occasionally executive board. | Group, mill | Pre-project, evaluation and decision |

| Documentation routines B | According to the manual and additional pre-project report. | Mill | Pre-project, evaluation and decision |

| Front cover | Summary, main purpose, key financial figures, authorization signatures. |

| Background | Commercial, strategic, technical. |

| Motive | Business impact, secondary motives. |

| Project description | Goal, scope, boundaries, organization, time plan, risk analysis, alternative solutions. |

| Project costs | Investment amount, cash out plan, direct costs, production losses. |

| Financial justification | Assumptions, profitability calculation, sensitivity analysis. |

| Appendices | Pre-project report, presentation, environmental analysis, risk assessment. |

| Impact | Cost (C)/ Revenue (R) | Comment |

|---|---|---|

| Reduced dust emissions | R | Main objective of the investment. |

| Increased energy efficiency | C | - |

| Increased productivity | R | - |

| Increased production | R | - |

| Increased capacity | R | - |

| Increased production reliability | C | One less production stop per year. |

| Prolonged lifetime of equipment | C | - |

| Reduced material costs | C | - |

| Reduced use of raw materials | C/R | C: Reduced costs for bark and oil, R: Possibility to sell bark. |

| Reduced need for maintenance | C | - |

| Reduced water consumption | C | Not included in the application. |

| Need for cooling | C | Negative impact, resulted in increased costs. |

| Improved work environment | n/a | Not included in the application. |

| Reduced need for engineering control | n/a | - |

| Reduced wastewater | C | - |

| Reduced internal and external noise | n/a | Not included in the application. |

| Improved temperature control | n/a | Not included in the application. |

| Improved air quality | n/a | Not included in the application. |

| Improved lighting | n/a | Not included in the application. |

| Waste fuel | C | - |

| Worker morale | n/a | Not included in the application. |

| Other emissions (CO2, SOx, NOx) | n/a | No change in CO2 or SOx. Difficulties retaining NOx levels (negative). |

| Improved public image | R | Not included in the application. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rasmussen, J. The Role of Structural Context in Making Business Sense of Investments for Sustainability–A Case Study. Sustainability 2020, 12, 7006. https://doi.org/10.3390/su12177006

Rasmussen J. The Role of Structural Context in Making Business Sense of Investments for Sustainability–A Case Study. Sustainability. 2020; 12(17):7006. https://doi.org/10.3390/su12177006

Chicago/Turabian StyleRasmussen, Josefine. 2020. "The Role of Structural Context in Making Business Sense of Investments for Sustainability–A Case Study" Sustainability 12, no. 17: 7006. https://doi.org/10.3390/su12177006

APA StyleRasmussen, J. (2020). The Role of Structural Context in Making Business Sense of Investments for Sustainability–A Case Study. Sustainability, 12(17), 7006. https://doi.org/10.3390/su12177006