Advances in Struvite Precipitation Technologies for Nutrients Removal and Recovery from Aqueous Waste and Wastewater

Abstract

:1. Introduction

2. Chemical Bases on the Struvite Precipitation Process

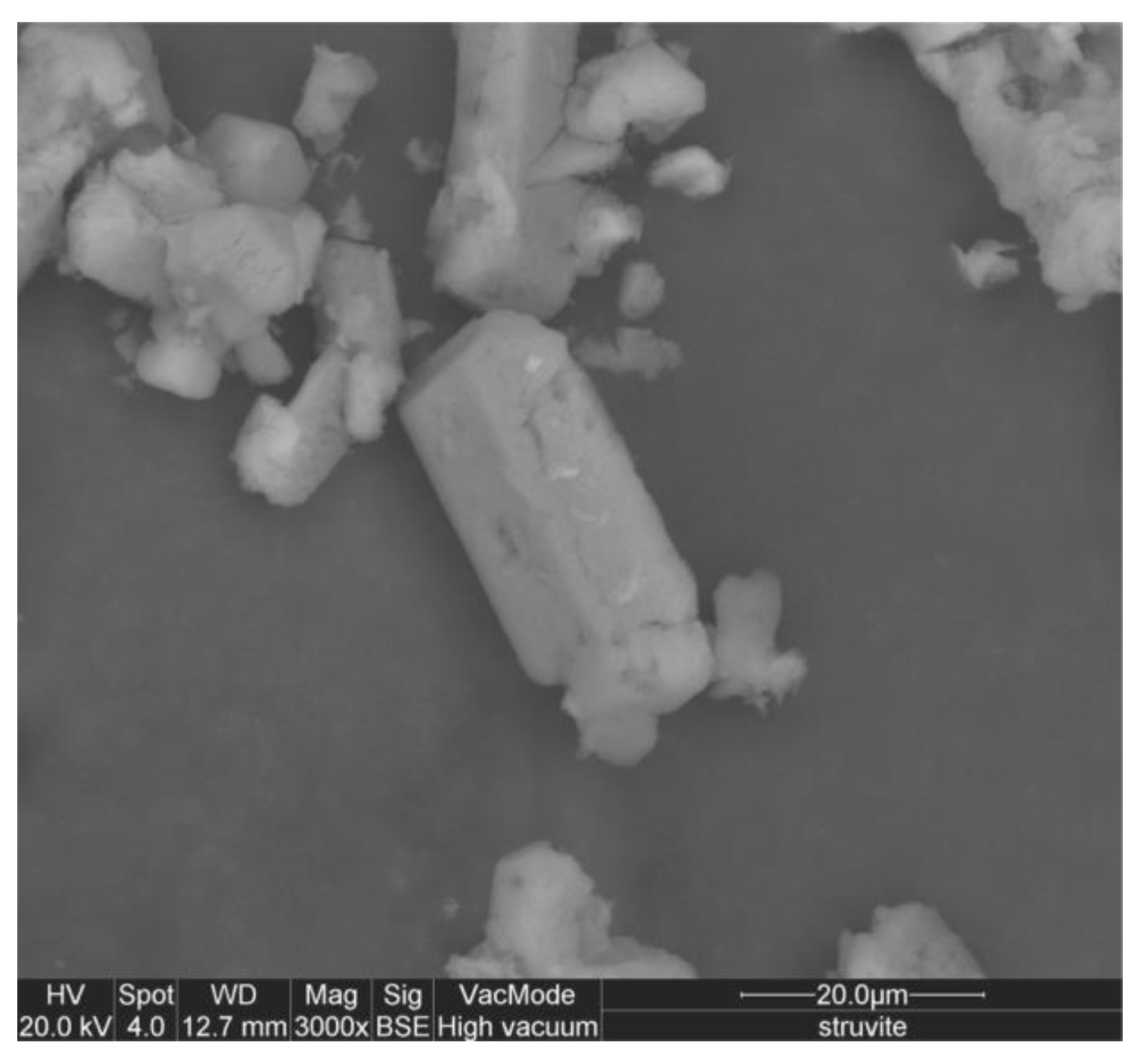

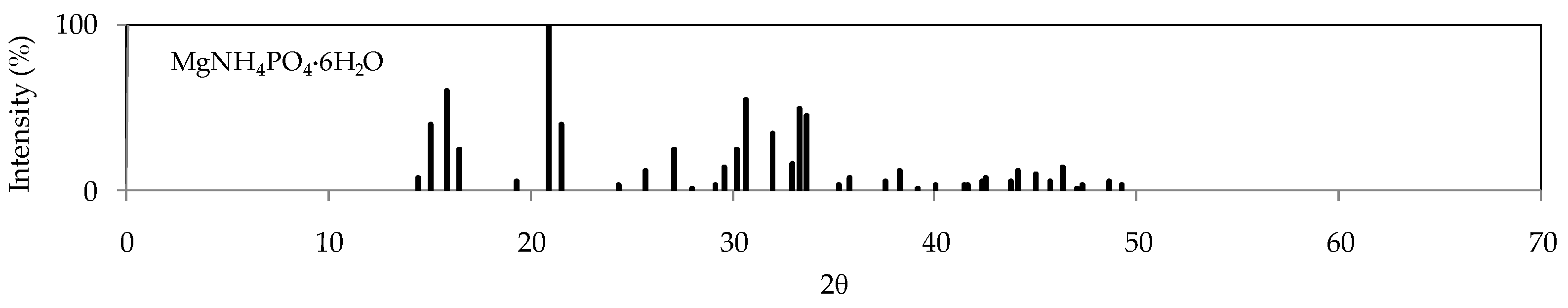

2.1. Generality on the Struvite Precipitation

2.2. Effects of pH on Struvite Formation

2.3. Effects of Molar Ratios on Struvite Formation

2.4. Temperature and Struvite Solubility

2.5. Presence of Competitive Ions

2.6. Reagents Used for Struvite Precipitation

2.6.1. Magnesium Sources

- -

- Magnesite (MgCO3) is a mineral rock particularly abundant in nature but its low solubility in aqueous solutions makes it necessary to apply adequate pretreatments. Gunay et al. [90] used magnesite (MgCO3) to evaluate ammonium removal from landfill leachate. In particular, the magnesite was pretreated with HCl to obtain a sufficient quantity of magnesium in solution. Ammonium removal yields in the form of struvite were 91%. The authors evaluated a reduction in the process costs of about 18.3% by using MgCO3 instead of MgCl2. However, a notable HCl addition was required to dissolve all the magnesium content of magnesite. In other studies, magnesite was calcined at high temperatures to produce a by-product (BMP), containing MgO, exploitable as a magnesium source in the MAP precipitation processes [54,80,105,115]. Quintana et al. [54,80] observed significantly lower performances in the struvite precipitation process using BMP produced from magnesite calcination compared to pure MgO. This can be justified by considering that BMP has an available Mg2+ amount lower than of pure MgO [54,80,105,115]. Moreover, BMP is generally characterized by greater particle sizes which slow down the reactivity [54,80,105].

- -

- Seawater has a magnesium content of about 146 kgMg/m3 and represents a low-cost source of magnesium exploitable for struvite precipitation [66]. Rubio-Rincón et al. [117] evaluated the use of seawater as a source of magnesium for phosphorus recovery through MAP formation from separate human urine. In particular, the seawater was mixed with non-hydrolyzed urine and hydrolyzed urine obtaining a 99% phosphorus removal after 10 min with a Mg:P molar ratio equal to 3.3:1 [117]. Struvite formation was favored with a urine/seawater ratio of 1:1.7 [117]. However, problems linked to the use of seawater were the formation of fine crystals [66] and the co-precipitation of calcite in addition to struvite [119].

- -

- Seawater bittern is a by-product obtained from sea salt manufacturing which contains mainly MgCl2 with small amounts of other inorganic compounds. Its Mg2+ content is notably higher than seawater and, therefore, it could represent a suitable low-cost source of magnesium [103]. The addition of bittern to a synthetic solution of swine wastewater was comparable to MgCl2 and seawater, as a magnesium ions source, in terms of phosphorus abatements [105].The effectiveness of seawater bittern was also proved for the phosphate recovery in real swine wastewater [105]. Moreover, Siciliano et al. [41,44,50] found that seawater bittern can be efficiently used as a source of magnesium in the removal of NH4+ through MAP precipitation from landfill leachates and digestate of calf manure.

- -

- Combustion ashes. Sakthivel et al. [118] investigated the possible application of wood combustion ashes as an alternative source of magnesium to favor struvite precipitation. By applying the wood ashes to the urine, 87% of the incoming phosphorus was removed after a 0.5 h treatment, but the production of hydroxyapatite was mainly observed [118]. Other studies detected mostly the presence of calcium insoluble compounds in the precipitate obtained using fly ashes and calcined paper mill sludge in the treatment of anaerobic digestion reject water [120]. Moreover, due to the high presence of metal compounds in combustion ashes [3], the recovered precipitate is generally incompatible with the legislation for fertilizers.

2.6.2. Phosphorus Sources

2.6.3. Reactants for pH Correction

2.6.4. Struvite Reuse as a Reactant

3. Reactors Configurations

3.1. Stirred Tank Reactors—STR

3.2. Fluidized Bed Reactors—FBR

3.3. Bioelectrochemical Systems—BES

3.3.1. Microbial Fuel Cells—MFC

3.3.2. Microbial Electrolysis Cells—MEC

3.4. Ion Exchange Technologies

3.5. Membrane Technologies for Nutrients Recovery

4. Full-Scale Struvite Recovery Technologies

- -

- OSTARA (Pearl®). Ostara technology uses a FBR for struvite crystals recovery consisting of three zones with an increasing diameter from the bottom to the top. In the lower area, there is reagents feeding and recovery of struvite crystals; in the central one the nucleation and growth of the crystals take place; while in the upper part, the discharge of the treated wastewater occurs. The effluent is recirculated with a flow rate of about 20 times the inlet flow [180]. MgCl2 is added to guarantee the molar ratio Mg:N:P equal to 1:1:1, while NaOH is added as an alkaline reagent [19]. This technology has been developed since 2005 by the University of British Columbia. Currently, 22 plants that use this technology are installed all over the world, most of which are located in the USA and Canada. Ostara technology allows up to 22% of total phosphorus to be recovered in an urban sidestream wastewater treatment plant, and up to 95% of phosphorus and 15% of ammonia nitrogen in the treatment of digestion supernatants [181]. Furthermore, the process allows daily productions of about 500 kg/d of struvite particles with sizes between 1.5 and 4.5 mm [20].

- -

- SEABORNE. The Seaborne process was developed in 2006 in Germany and it involves nutrients recovery from digested sludge pretreated with sulfuric acid [181]. The technology consists of a first acidification phase with H2SO4 to extract nutrients and metals. The remaining solid phase is incinerated while the liquid phase undergoes a process for the recovery of the heavy metals by gas-liquid precipitation using H2S-rich biogas [181]. Subsequently, nutrients recovery as struvite takes place in a completely mixed reactor after the addition of Mg(OH)2, as a magnesium source, and NaOH to reach the pH 9. Finally, the residual dissolved ammonium is recovered through a scrubber in the form of ammonium sulfate [19,20].

- -

- PHOSPAQTM. This process, developed in Holland, aims at the removal both of phosphorus and ammonium present in the wastewater. The process takes place in a completely mixed aerated reactor to obtain the simultaneous degradation of COD and nutrients recovery in the form of struvite. Aeration permits the biological COD oxidation and, at the same time, the CO2 stripping which favors the establishment of pH values around to 8.2, suitable for the struvite precipitation [19]. MgO is dosed as a source of Mg2+ to reach the stoichiometric N:Mg:P molar ratios. With this technology it is possible to produce MAP particles with dimensions of about 0.7mm [19,20]. Phosphorus removals between 75% and 81% were obtained in an industrial-scale application conducted on potato processing wastewater.

- -

- ANPHOS®. This technology for phosphorus recovery was developed in the Netherlands and operates in batch conditions. In particular, in a first aerated reactor the waste alkalinization takes place by CO2 stripping, while in a second reactor, Mg(OH)2 is introduced as a source of Mg2+ to promote the MAP formation. This process can recover 80–90% of the phosphorus contained in the influent. Once dried, the produced struvite can be directly used as a fertilizer [20]. With this treatment, a reduction in the influent COD also occurs, which leads to a lower oxygen consumption in the subsequent treatments [20].

- -

- PHOSNIX. The process involves the phosphorus recovery as struvite from supernatants of digested sludge in a fluidized bed reactor [67]. This process was developed by the Japanese company Unitika Ltd. Environmental and Engineering Division. Mg(OH)2 is dosed as a source of magnesium, until the molar ratio of Mg:P of 1:1 is reached to allow struvite crystals nucleation and growth. pH values between 8.2 and 8.8 are guaranteed by an aeration system and the addition of NaOH, which also promote the ammonium stripping. The process allows recovering struvite crystals directly usable as fertilizers between 0.5–1 mm in size [67].

- -

- NuReSYS. The NuReSYS (Nutrients Recovery System) process was developed in Belgium for struvite recovery from digested sludges and dewatering effluents. This process allows the continuous recovery of the phosphorus using a completely mixed reactor [67]. The pH suitable for struvite crystallization is guaranteed by an aeration system which induces the CO2 stripping. The process can operate in two different modes. Specifically, it can be applied to favor the spontaneous precipitation of struvite, without adding magnesium, to avoid the scale formation on the sludge management equipment. The other configuration, instead, exploits the introduction of Mg(Cl)2, as a source of magnesium, to allow better efficiency in phosphorus removal. Phosphorus abatement about 96% and a production of struvite particles of variable sizes between 2 and 6 mm, were obtained with NuReSYS process [126].

- -

- AirPrex®. AirPrex technology was developed in Germany to solve the struvite incrustation problems downstream of the anaerobic digestion processes [182]. This technology uses two reactors for struvite precipitation and recovery from digestates before dehydration treatment. In the first reactor, the nucleation and growth of struvite crystals take place. This unit is aerated to promote the pH increase around 8 and to keep the struvite crystals in agitation. Two vertical partitions further promote an effective circulation. The second conical bottom reactor allows the sedimentation of struvite crystals and the discharge of the purified effluent [20].

- -

- MULTIFORMTM. Multiform technology was developed in the United States for nutrients recovery from agro-industrial wastewater. The plant unit consists of a cone-shaped fluidized bed reactor that allows to remove about 80% of the phosphorus from wastewater with a struvite crystals retention time equal to three days [74]. Crystallization is favored by adding Mg(Cl)2, as a source of magnesium, and NaOH as an alkaline reagent. Although the struvite crystals are produced quickly, the crystals obtained have a low degree of purity [74].

5. Use of Struvite as a Fertilizer

6. Economic Considerations

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Di Iaconi, C.; Pagano, M.; Ramadori, R.; Lopez, A. Nitrogen recovery from a stabilized municipal landfill leachate. Bioresur. Technol. 2010, 101, 1732–1736. [Google Scholar] [CrossRef] [PubMed]

- Kabdaşli, I.; Parsons, S.A.; Tünay, O. Effect of major ions on induction time of struvite precipitation. Croatica Chemica Acta 2006, 79, 243–251. [Google Scholar]

- Kabdaşlı, I.; Tünay, O. Nutrient recovery by struvite precipitation, ion exchange and adsorption from source-separated human urine—A review. Environ. Technol. Rev. 2018, 7, 106–138. [Google Scholar] [CrossRef]

- Siciliano, A.; Stillitano, M.A.; Limonti, C.; Marchio, F. Ammonium Removal from Landfill Leachate by Means of Multiple Recycling of Struvite Residues Obtained through Acid Decomposition. Appl. Sci. 2016, 6, 375. [Google Scholar] [CrossRef] [Green Version]

- Siciliano, A.; De Rosa, S. Experimental formulation of a kinetic model describing the nitrification process in biological aerated filters filled with plastic elements. Environ. Technol. 2015, 36, 293–301. [Google Scholar] [CrossRef]

- Zhang, W.; Dixon, M.B.; Saint, C.; Teng, K.S.; Furumai, H. Electrochemical biosensing of algal toxins in water: The current-state-of-the-art. ACS Sens. 2018, 3, 1233–1245. [Google Scholar] [CrossRef]

- Siciliano, A.; Curcio, G.M.; Limonti, C. Experimental analysis and modeling of nitrate removal through zero-valent magnesium particles. Water 2019, 11, 1276. [Google Scholar] [CrossRef] [Green Version]

- Siciliano, A.; Limonti, C.; Mehariya, S.; Molino, A.; Calabrò, V. Biofuel Production and Phosphorus Recovery through an Integrated Treatment of Agro-Industrial Waste. Sustainability 2019, 11, 52. [Google Scholar] [CrossRef] [Green Version]

- Huang, H.; Zhang, D.; Wang, W.; Li, B.; Zhao, N.; Li, J.; Dai, J. Alleviating Na+ effect on phosphate and potassium recovery from synthetic urine by K-struvite crystallization using different magnesium sources. Sci. Total Environ. 2019, 655, 211–219. [Google Scholar] [CrossRef]

- Huygens, D.; Saveyn, H.G.M.; Tonini, D.; Eder, P.; Delgado Sancho, L. Technical Proposals for Selected New Fertilising Materials under the Fertilising Products Regulation (Regulation (EU) 2019/1009)—Process and Quality Criteria, and Assessment of Environmental and Market Impacts for Precipitated Phosphate Salts & Derivates, Thermal Oxidation Materials & Derivates and Pyrolysis & Gasification Materials, EUR 29841 EN; Publications Office of the European Union: Luxembourg, 2019; ISBN 978-92-76-09888-1. [Google Scholar]

- Siciliano, A.; Curcio, G.M.; Limonti, C. Chemical denitrification with Mg0 particles in column systems. Sustainability 2020, 12, 2984. [Google Scholar] [CrossRef] [Green Version]

- Le Corre, K.S.; Valsami-Jones, E.; Hobbs, P.; Parsons, A. Phosphorus recovery from wastewater by struvite crystallization: A review. Crit. Rev. Environ. Sci. Technol. 2009, 39, 433–477. [Google Scholar] [CrossRef] [Green Version]

- Siciliano, A.; Stillitano, M.A.; De Rosa, S. Increase of the anaerobic biodegradability of olive mill wastewaters through a pre-treatment with hydrogen peroxide in alkaline conditions. Desal. Water. Treat. 2014, 55, 1735–1746. [Google Scholar] [CrossRef]

- Siciliano, A.; Stillitano, M.A.; Limonti, C. Energetic valorization of wet olive mill wastes through a suitable integrated treatment: H2O2 with lime and anaerobic digestion. Sustainability 2016, 8, 1150. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.; Lawlor, P.G.; Hu, Z.; Zhan, X. Nutrient removal from separated pig manure digestate liquid using hybrid biofilters. Environ. Technol. 2013, 34, 645–651. [Google Scholar] [CrossRef]

- Siciliano, A.; De Rosa, S. An experimental model of COD abatement in MBBR based on biofilm growth dynamic and on substrates’ removal kinetics. Environ. Technol. 2016, 37, 2058–2071. [Google Scholar] [CrossRef]

- He, S.; Zhang, Y.; Yang, M.; Du, W.; Harada, H. Repeated use of MAP decomposition residues for the removal of high ammonium concentration from landfill leachate. Chemosphere 2007, 66, 2233–2238. [Google Scholar] [CrossRef]

- Tchobanoglous, G.; Burton, F.L.; Stensel, H.D. Wastewater Engineering: Treatment and Reuse, 4th ed.; Metcalf & Eddy Inc. McGraw-Hill: New York, NY, USA, 2003. [Google Scholar]

- Ghosh, S.; Lobanov, S.; Lo, V.K. An overview of technologies to recover phosphorus as struvite from wastewater: Advantages and shortcomings. Environ. Sci. Pollut. R. 2019, 26, 19063–19077. [Google Scholar] [CrossRef]

- Desmidt, E.; Ghyselbrecht, K.; Zang, Y.; Pinoy, L.; van der Bruggen, B.; Verstraete, W.; Rabaey, K.; Meesshaert, B. Global Phosphorus Scarcity and Full-Scale P-recovery techniques: A review. Crit. Rev. Environ. Sci. Technol. 2015, 45, 336–384. [Google Scholar] [CrossRef]

- Korchef, A.; Saidou, H.; Amor, M.B. Phosphate recovery through struvite precipitation by CO2 removal: Effect of magnesium, phosphate and ammonium concentrations. J. Hazard Mater 2011, 186, 602–613. [Google Scholar] [CrossRef]

- Saidou, H.; Moussa, B.; Ben, A.M. Influence of airflow rate and substrate nature on heterogeneous struvite precipitation. Environ. Technol. 2009, 30, 75–83. [Google Scholar] [CrossRef] [Green Version]

- Fattah, K.P.; Sabrina, N.; Mavinic, D.S.; Koch, F.A. Reducing operating costs for struvite formation with a carbon dioxide stripper. Water Sci. Technol. 2008, 58, 957–962. [Google Scholar] [CrossRef] [PubMed]

- Fattah, K.P.; Mavinic, D.S.; Koch, F.A.; Jacob, C. Determining the feasibility of phosphorus recovery as struvite from filter press centrate in a secondary wastewater treatment plant. J. Environ. Sci. Health Part A 2008, 43, 756–764. [Google Scholar] [CrossRef] [PubMed]

- Shih, Y.J.; Abarca, R.R.M.; de Luna, M.D.G.; Huang, Y.H.; Lu, M.C. Recovery of phosphorus from synthetic wastewaters by struvite crystallization in a fluidized-bed reactor: Effects of pH, phosphate concentration and coexisting ions. Chemosphere 2017, 173, 466–473. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, K.; Tanaka, Y.; Kuroda, K.; Hanajima, D.; Fukumoto, Y.; Yasuda, T.; Waki, M. Removal and recovery of phosphorous from swine wastewater by demonstration crystallization reactor and struvite accumulation device. Bioresour. Technol. 2007, 98, 1573–1578. [Google Scholar] [CrossRef] [PubMed]

- Rahaman, M.S.; Mavinic, D.S.; Meikleham, A.; Ellis, N. Modelling phosphorus removal and recovery from anaerobic digester supernatant through struvite crystallization in a fluidized bed reactor. Water Res. 2014, 51, 1–10. [Google Scholar] [CrossRef]

- Pastor, L.; Mangin, D.; Barat, R.; Seco, A. A pilot- scale study of struvite precipitation in a stirred tank reactor: Conditions influencing the process. Bioresur. Technol. 2008, 99, 6285–6291. [Google Scholar] [CrossRef]

- Pastor, L.; Mangin, D.; Ferrer, J.; Seco, A. Struvite formation from the supernatants of an anaerobic digestion pilot plant. Biores. Technol. 2010, 101, 118–125. [Google Scholar] [CrossRef]

- Iqbal, M.; Bhuiyan, H.; Mavinic, D.S. Assessing struvite precipitation in a pilot-scale fluidized bed crystallizer. Environ. Technol. 2008, 29, 1157–1167. [Google Scholar] [CrossRef]

- Latifian, M.; Liu, J.; Mattiasson, B. Struvite-based fertilizer and its physical and chemical properties. Environ. Technol. 2012, 33, 2691–2697. [Google Scholar] [CrossRef]

- Uludag-Demirer, S.; Demirer, G.N.; Chen, S. Ammonia removal from anaerobically digested dairy manure by struvite precipitation. Process. Biochem. 2005, 40, 3667–3674. [Google Scholar] [CrossRef]

- Uysal, A.; Yilmazel, Y.D.; Demirer, G.N. The determination of fertilizer quality of the formed struvite from effluent of a sewage sludge anaerobic digester. J. Hazard. Mater. 2010, 181, 248–254. [Google Scholar] [CrossRef] [PubMed]

- Uysal, A.; Demir, S.; Sayilgan, E.; Eraslam, F.; Kucukyumuk, Z. Optimization of struvite fertilizer formation from baker’s yeast wastewater: Growth and nutrition of maize and tomato plants. Environ. Sci. Pollut. Res. 2014, 2, 3264–3274. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Zhou, S. Improving the prediction of ammonium nitrogen removal through struvite precipitation. Environ. Sci. Pollut. Res. 2012, 19, 347–360. [Google Scholar] [CrossRef]

- Perwitasari, D.S.; Muryanto, S.; Jamari, J.; Bayuseno, A.P. Kinetics and morphology analysis of struvite precipitated from aqueous solution under the influence of heavy metals: Cu2+, Pb2+, Zn2+. J. Environ. Chem. Eng. 2018, 6, 37–43. [Google Scholar] [CrossRef] [Green Version]

- Jones, A.G. Crystallization Process System; Butterworth/Heinemann: Oxford, UK, 2002; ISBN 9780750655200. [Google Scholar]

- Bouropoulos, N.C.; Koutsoukos, P.G. Spontaneous precipitation of struvite from aqueous solutions. J. Cryst. Growth. 2000, 213, 381–388. [Google Scholar] [CrossRef]

- Li, B.; Boiarkina, I.; Huang, H.M.; Munir, T.; Wang, G.Q.; Young, B.R. Phosphorus recovery through struvite crystallization: Challanges for future design. Sci. Total Environ. 2019, 648, 1244–1256. [Google Scholar] [CrossRef]

- Bing, L.; Boiarkina, I.; Yu, W.; Young, B. A new thermodynamic approach for struvite product quality prediction. Environ. Sci. Pollut. Res. 2019, 26, 3954–3964. [Google Scholar] [CrossRef]

- Siciliano, A. Assessment of fertilizer potential of the struvite produced from the treatment of methanogenic landfill leachate using low-cost reagents. Environ. Sci. Pollut. Res. 2016, 23, 5949–5959. [Google Scholar] [CrossRef]

- Ohlinger, K.N.; Young, T.M.; Schroeder, E.D. Predicting struvite formation in digestion. Water Res. 1998, 32, 3607–3614. [Google Scholar] [CrossRef]

- Buchanan, J.R.; Mote, C.R.; Robinson, R.B. Struvite control by chemical treatment. Trans. Am. Soc. Agric. Eng. 1994, 37, 1301–1308. [Google Scholar] [CrossRef]

- Siciliano, A.; De Rosa, S. Recovery of ammonia in digestates of calf manure through a struvite precipitation process using unconventional reagents. Environ. Technol. 2014, 35, 841–850. [Google Scholar] [CrossRef] [PubMed]

- Tünay, O.; Kabdaşli, I.; Orhon, D.; Kolçak, S. Ammonia removal by magnesium ammonium phosphate precipitation in industrial wastewaters. Water Sci. Technol. 1997, 36, 225–228. [Google Scholar] [CrossRef]

- Hao, X.; Wang, C.; Van Loosdrecht, M.C.M.; Hu, Y. Looking beyond struvite for Precovery. Environ. Sci. Technol. 2013, 47, 4965–4966. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.M.; Zhang, D.D.; Li, J.; Guo, G.J.; Tang, S.F. Phosphate recovery from swine wastewater using plant ash in chemical crystallization. J. Clean. Prod. 2017, 168, 338–345. [Google Scholar] [CrossRef]

- Tomei, M.C.; Stazi, V.; Daneshgar, S.; Capodaglio, A.G. Holistic approach to phosphorus recovery from urban 3 wastewater: Enhanced biological removal combined with precipitation. Sustainability 2020, 12, 575. [Google Scholar] [CrossRef] [Green Version]

- Doyle, J.D.; Parsons, S.A. Struvite formation, control and recovery. Water Res. 2002, 36, 3925–3940. [Google Scholar] [CrossRef]

- Siciliano, A.; Ruggiero, C.; De Rosa, S. A new integrated treatment for the reduction of organic and nitrogen loads in methanogenic landfill leachates. Process. Saf. Environ. Prot. 2013, 91, 311–320. [Google Scholar] [CrossRef]

- Li, X.Z.; Zhao, Q.L. Recovery of ammonium-nitrogen from landfill leachate as a multi-nutrient fertilizer. Ecol. Eng. 2003, 20, 171–181. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.; Ryu, H.D.; Kim, M.S.; Kim, J.; Lee, S.I. Enhancing struvite precipitation potential for ammonia nitrogen removal in municipal landfill leachate. J. Hazard. Mater. 2007, 146, 81–85. [Google Scholar] [CrossRef]

- Kim, D.; Min, K.J.; Lee, K.; Yu, M.S.; Park, K.Y. Effect of pH, molar ratios and pre-treatment on phosphorus recovery through struvite crystallization from effluent of anaerobically degisted swine wastewater. Environ. Eng. Res. 2017, 22, 12–18. [Google Scholar] [CrossRef]

- Quintana, M.; Colmenarejo, M.F.; Barrera, J.; García, G.; García, E.; Bustos, A. Use of bioproduct of Magnesium oxide production to precipitate phosphorus and nitrogen as struvite from wastewater treatment liquors. J. Agric. Food Chem. 2004, 52, 294–299. [Google Scholar] [CrossRef] [PubMed]

- Xavier, L.D.; Cammarota, M.C.; Yokoyama, L.; Volschan, I.J. Study of the recovery of phosphorus from struvite precipitation in supernatant line from anaerobic digesters of sludge. Water Sci. Technol. 2014, 14, 751–757. [Google Scholar] [CrossRef]

- Aguado, D.; Barat, R.; Bouzas, A.; Seco, A.; Ferrer, J. P-recovery in a pilot-scale struvite crystallisation reactor for source separated urine system using seawater and magnesium chloride as magnesium sources. Sci. Total Environ. 2019, 672, 88–96. [Google Scholar] [CrossRef] [PubMed]

- Stratful, I.; Scrimshaw, M.D.; Lester, J.N. Removal of struvite to prevent problems associated with its accumulation in wastewater treatment works. Water Environ. Res. 2004, 76, 437–443. [Google Scholar] [CrossRef] [PubMed]

- Taddeo, R.; Lepistö, R. Struvite precipitation in raw and co-digested swine slurries for nutrients recovery in batch reactors. Water Sci. Technol. 2015, 71, 892–897. [Google Scholar] [CrossRef]

- Brown, K.; Harrison, J.; Bowers, K. Struvite precipitation from anaerobically digested diary manure. Water Air Soil Pollut. 2018, 229, 217. [Google Scholar] [CrossRef]

- Zhang, T.; Fang, C.; Li, P.; Jiang, R. Application of struvite process for nutrient recovery fom anaerobic digesters of livestock wastewater. Environ. Prot. Eng. 2014, 40, 29–42. [Google Scholar] [CrossRef]

- Ramaswami, S.; Behrendt, J.; Wang, G.; Eggers, S.; Otterpohl, R. Combining magnesium ammonium phosphate precipitation with membrane processes for ammonia removal from methanogenic leachate. Water Environ. J. 2016, 30, 218–226. [Google Scholar] [CrossRef]

- Xu, S.; Luo, L.; He, H.; Liu, H.; Cui, L. Nitrogen and Phosphate Recovery from Source-Separated Urine by Dosing with Magnesite and Zeolite. Pol. J. Environ. Stud. 2015, 24, 2269–2275. [Google Scholar] [CrossRef]

- El-Diwani, G.; El Rafie, S.; El Ibiari, N.N.; El-Aila, H.I. Recovery of ammonia nitrogen from industrial wastewater treatment as struvite slow releasing fertilizer. Desalination 2006, 214, 200–2014. [Google Scholar] [CrossRef]

- Huang, H.; Mavinic, D.S.; Lo, K.V.; Koch, F.A. Production and Basic Morphology of Struvite Crystals from a Pilot-Scale Crystallization Process. Environ. Technol. 2006, 27, 233–245. [Google Scholar] [CrossRef] [PubMed]

- Adnan, A.; Koch, F.A.; Mavinic, D.S. Pilot-scale study of phosphorus recovery through struvite crystallization-II. Applying in-reactor supersatuartion ratio as a process control parameter. J. Environ. Eng. Sci. 2003, 2, 473–483. [Google Scholar] [CrossRef]

- Liu, X.; Hu, Z.; Mu, J.; Zang, H.; Liu, L. Phosphorus recovery from urine with different magnesium resourse in an air-agitated reactor. Envirn. Technol. 2014, 35, 2781–2787. [Google Scholar] [CrossRef] [PubMed]

- Ueno, Y.; Fujii, M. Three years of operating and selling recovered struvite from full-scale plant. Environ. Technol. 2001, 22, 1373–1381. [Google Scholar] [CrossRef]

- Bhuiyan, M.I.H.; Mavinic, D.S.; Koch, F.A. Phosphorus recovery from wastewater through struvite formation in fluidized bed reactors: A sustainable approach. Water Sci. Technol. 2008, 57, 175–181. [Google Scholar] [CrossRef] [Green Version]

- Battistoni, P.; Boccadoro, R.; Fatone, F.; Pavan, P. Auto-Nucleation and Crystal Growth of Struvite in a Demonstrative Fluidized Bed Reactor (FBR). Environ. Technol. 2005, 26, 975–982. [Google Scholar] [CrossRef]

- Guadie, A.; Xia, S.; Jiang, W.; Zhou, L.; Zhang, Z.; Hermanowicz, S.W.; Xu, X.; Shen, S. Enhanced struvite recovery from wastewater using a novel cone-inserted fluized bed reactor. J. Environ. Sci. 2014, 26, 765–774. [Google Scholar] [CrossRef]

- Rahaman, M.S.; Ellis, N.; Mavinic, D.S. Effects of various process parameters on struvite precipitation kinetics and subsequent determination of rate constants. Water Sci. Technol. 2008, 57, 647–654. [Google Scholar] [CrossRef] [Green Version]

- Jordaan, E.M.; Rezania, B.; Ҫiҫek, N. Investigation of chemical-free nutrient removal and recovery from CO2-rich wastewater. Water Sci. Technol. 2013, 67, 2195–2201. [Google Scholar] [CrossRef]

- Shimamura, K.; Tanaka, T.; Miura, Y.; Ishikawa, H. Development of a high-efficiency phosphorus recovery method using a fluidized-bed crystallized phosphorus removal system. Water Sci. Technol. 2003, 48, 163–170. [Google Scholar] [CrossRef]

- Bowers, K.E.; Westerman, P.W. Performance of cone-shaped fluidized bed struvite crystallizer in removing phosphorus from wastewater. Trans. ASAE 2005, 48, 1227–1234. [Google Scholar] [CrossRef]

- Shin, H.S.; Lee, S.M. Removal of nutrients in wastewater by using magnesium salts. Environ. Technol. 1997, 19, 283–290. [Google Scholar] [CrossRef]

- Ryu, H.D.; Choo, Y.D.; Kang, M.K.; Lee, S.I. Integrated application of struvite precipitation and biological treatment in treating autothermal thermophilic aerobic digestion supernatant liquid. Environ. Eng. Sci. 2014, 31, 167–175. [Google Scholar] [CrossRef]

- Tao, W.; Fattah, K.P.; Huchzermeier, M.P. Struvite recovery from anaerobically digested dairy manure: A review of application potenzial and hindrances. J. Envirin. Manag. 2016, 169, 46–57. [Google Scholar] [CrossRef]

- Cao, X.; Harris, W. Carbonate and magnesium interactive effect on calcium phosphate precipitation. Environ. Sci. Technol. 2008, 42, 436–442. [Google Scholar] [CrossRef] [PubMed]

- Babić-Ivančić, V.; Kontrec, J.; Kralj, D.; Brečević, L. Precipitation diagrams of struvite and dissolution kinetics of different struvite morphologies. Croatica Chemica Acta 2002, 75, 89–106. [Google Scholar]

- Quintana, M.; Sánchez, E.; Colmenarejo, M.F.; Barrera, J.; García, G.; Borja, R. Kinetics of phosphorus removal and struvite formation by the utilization of by-product of magnesium oxide production. Chem. Eng. J. 2005, 111, 45–52. [Google Scholar] [CrossRef]

- Nelson, N.O.; Mikkelsen, R.L.; Hesterberg, D.L. Struvite precipitation in anaerobic swine lagoon liquid: Effect of pH and Mg:P ratio and determination of rate constant. Bioresour. Technol. 2003, 89, 229–236. [Google Scholar] [CrossRef]

- Martí, N.; Pastor, L.; Bouzas, A.; Ferrer, J.; Seco, A. Phosphorus recovery by struvite crystallization in WWTPs: Influence of the sludge treatment line operation. Water Res. 2010, 44, 2371–2379. [Google Scholar] [CrossRef] [Green Version]

- Jaffer, Y.; Clark, T.A.; Pearce, P.; Parson, S.A. Potential phosphorus recovery by struvite formation. Water Res. 2002, 36, 1834–1842. [Google Scholar] [CrossRef]

- Crutchik, D.; Garrido, J.M. Kinetics of the reversible reaction of struvite crystallization. Chemosphere 2016, 154, 567–572. [Google Scholar] [CrossRef] [PubMed]

- Capdevielle, A.; Korov, E.B.; Line, F.; Daumer, M.L. Kinetics of struvite precipitation in synthetic biologically treated swine wastewaters. Environ. Technol. 2014, 35, 1250–1262. [Google Scholar] [CrossRef] [PubMed]

- Moussa, S.B.; Tlili, M.M.; Batis, N.; Amor, M.B. Influence of temperature on Struvite precipitation by CO2-degassing method. Cryst. Res. Technol. 2011, 46, 255–260. [Google Scholar] [CrossRef]

- Boistelle, R.; Abbona, F.; Lundager Madsen, H.E. On the transformation of struvite into newberyite in aqueous systems. Phys. Chem. Miner. 1983, 9, 216–222. [Google Scholar] [CrossRef]

- Aage, H.K.; Andersen, B.L.; Blom, A.; Jensen, I. The solubility of struvite. J. Radio Anal. Nucl. Chem. 1997, 223, 213–215. [Google Scholar] [CrossRef]

- Loewenthal, R.E.; Kornmuller, U.R.C.; Van Heerden, E.P. Modelling struvite precipitation in anaerobic treatment systems. Water Sci. Technol. 1994, 30, 107–116. [Google Scholar] [CrossRef]

- Gunay, A.; Karadag, D.; Tosun, I.; Ozturk, M. Use of magnesite as a magnesium source for ammonium removal from leachate. J. Hazard. Mater. 2008, 156, 619–623. [Google Scholar] [CrossRef]

- Koutsoukos, P.G.; Kofina, A.N.; Klepetsanis, P.G. Exploration of Alternatives for Phosphorus Recovery from Wastewater by Crystallization; Wasic Workshop: Istanbul, Turkey, 2003. [Google Scholar]

- Le Corre, K.S.; Valsami-Jones, E.; Hobbs, P.; Parsons, S. Impact of calcium on struvite crystal size, shape and purity. J. Crystal. Growth 2005, 283, 514–522. [Google Scholar] [CrossRef] [Green Version]

- Kofina, A.N.; Koutsoukos, P. Spontaneous precipitation of struvite from synthetic wastewater. Cryst. Growth Des. 2005, 5, 489–496. [Google Scholar] [CrossRef]

- Bhuiyan, M.I.H.; Mivinic, D.S.; Beckie, R.D. A solubility and thermodynamic study of struvite. Environ. Technol. 2007, 28, 1015–1026. [Google Scholar] [CrossRef]

- Hanhoun, M.; Montastruct, L.; Azzaro-Pantel, C.; Biscans, B.; Fréche, M.; Pibouleau, L. Temperature impact assessment on struvite solubility product: A thermodynamic modeling approach. Chem. Eng. J. 2011, 167, 50–58. [Google Scholar] [CrossRef] [Green Version]

- Harris, W.G.; Wilkie, A.C.; Cao, X.; Sirengo, R. Bench-scale recovery of phosphorus from flushed dairy manure wastewater. Bioresour. Technol. 2008, 99, 3036–3043. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Bowers, K.E.; Harrison, J.H.; Chen, S. Releasing phosphorus from calcium for struvite fertilizer production from anaerobically digested dairy manure. Water Environ. Res. 2010, 82, 34–42. [Google Scholar] [CrossRef] [Green Version]

- Huchzermeier, M.; Tao, W. Overcoming challenges to struvite recovery from anaerobically digested dairy manure. Water Environ. Res. 2012, 84, 34–41. [Google Scholar] [CrossRef] [Green Version]

- Fattah, K.P.; Zhang, Y.; Mavinic, D.S.; Koch, F.A. Use of carbon dioxide stripping for struvite crystallization to save caustic dosage: Performance at pilot-scale operation. Can. J. Civ. Eng. 2010, 37, 1271–1275. [Google Scholar] [CrossRef]

- Zhao, Q.-B.; Ma, J.; Zeb, I.; Yu, L.; Chen, S.; Zheng, Y.-M.; Frear, C. Ammonia recovery from anaerobic digester effluent through direct aeration. Chem. Eng. J. 2015, 279, 31–37. [Google Scholar] [CrossRef]

- Kabdaşli, I.; Tünay, O.; Özcan, P. Application of struvite precipitation coupled with biological treatment to slaughterhouse wastewaters. Environ. Technol. 2009, 30, 1095–1101. [Google Scholar] [CrossRef]

- Chimenos, J.M.; Fernández, A.I.; Villalba, G.; Segarra, M.; Urruticoechea, A.; Artazab, B.; Espiella, F. Removal of ammonium and phosphates from wastewater resulting from the process of cochineal extraction using MgO-containing by-product. Water Res. 2003, 37, 1601–1607. [Google Scholar] [CrossRef]

- Lee, S.I.; Weon, S.Y.; Lee, C.W.; Koopman, B. Removal of nitrogen and phosphate from wastewater by addition of bittern. Chemosphere 2003, 51, 265–271. [Google Scholar] [CrossRef]

- Huang, H.; Xu, C.; Zhang, W. Removal of nutrients from piggery wastewater using struvite precipitation and pyrogenation technology. Bioresour. Technol. 2011, 102, 2523–2528. [Google Scholar] [CrossRef]

- Huang, H.; Jiang, Y.; Ding, L. Recovery and removal of ammonia–nitrogen and phosphate from swine wastewater by internal recycling of struvite chlorination product. Bioresour. Technol. 2014, 172, 253–259. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Liu, J.; Jiang, Y. Crystallization and precipitation of phosphate from swine wastewater by magnesium metal corrosion. Sci. Rep. 2015, 5, 16601. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, F.; Wei, J.; Zou, X.; Fu, R.; Li, J.; Wu, D.; Lv, H.; Zhu, G.; Wu, X.; Chem, H. Enhanced electrochemical phosphate recovery from livestock wastewater by adjusting pH with plant ash. J. Environ. Manag. 2019, 250, 109473. [Google Scholar] [CrossRef] [PubMed]

- Le Corre, K.S.; Valsami-Jones, E.; Hobbs, P.; Parsons, S.A. Impact of Reactor Operation on Success of Struvite Precipitation from Synthetic Liquors. Environ. Technol. 2007, 28, 1245–1256. [Google Scholar] [CrossRef] [Green Version]

- Kataki, S.; West, H.; Clarke, M.; Baruah, D.C. Phosphorus recovery as struvite: Recent concerns for use of seed, alternative Mg source, nitrogen conservation and fertilizer potential. Resur. Conserv. Recy. 2016, 107, 142–156. [Google Scholar] [CrossRef]

- Yetilmezsoy, K.; Zengin, Z.S. Recovery of ammonium nitrogen from the effluent of UASB treating poultry manure wastewater by MAP precipitation as a slow release fertilizer. J. Hazard. Mater. 2009, 166, 260–269. [Google Scholar] [CrossRef]

- Munch, E.V.; Barr, K. Controlled struvite crystallization for removing phosphorus from anaerobic digester sidestreams. Water Res. 2001, 35, 151–159. [Google Scholar] [CrossRef]

- Kruk, D.J.; Elektorowicz, M.; Oleszkiewicz, J.A. Struvite precipitation and phosphorus removal using magnesium sacrificial anode. Chemosphere 2014, 101, 28–33. [Google Scholar] [CrossRef]

- Hug, A.; Udert, K.M. Struvite precipitation from urine with electrochemical magnesium dosage. Water Res. 2013, 47, 289–299. [Google Scholar] [CrossRef]

- Song, G.; Atrens, A.; John, D.; Wu, X. The anodic dissolution of magnesium in chloride and sulphate solutions. Corros. Sci. 1997, 39, 1981–2004. [Google Scholar] [CrossRef]

- Krähenbühl, M.; Etter, B.; Udert, K.M. Pretreated magnesite as a source of low cost magnesium for producing struvite from urine in Nepal. Sci. Total Environ. 2016, 542, 1155–1161. [Google Scholar] [CrossRef] [PubMed]

- Etter, B.; Tilley, E.; Khadka, R.; Udert, K.M. Low-cost struvite production using source-separated urine in nepal. Water Res. 2011, 45, 825–862. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rubio-Rincón, F.J.; Lopez-Vasquez, C.M.; Ronteltap, M.; Brdjanovic, D. Seawater for phosphorus recovery from urine. Desalination 2014, 348, 49–56. [Google Scholar] [CrossRef]

- Sakthivel, S.R.; Tilley, E.; Udert, K.M. Wood ashas a magnesium source for phosphorus recovery from source-seprated urine. Sci. Total Environ. 2012, 419, 68–75. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Giannis, A.; Zhang, J.; Chang, V.; Wang, J.Y. Characterization of induced struvite formation from source-separated urine using seawater and brine as magnesium sources. Chemosphere 2013, 93, 2738–2747. [Google Scholar] [CrossRef]

- Myllymäki, P.; Pesonen, J.; Nurmesniemi, E.T.; Romar, H.; Tynjälä, P.; Hu, T.; Lassi, U. The Use of Industrial Waste Materials for the Simultaneous Removal of Ammonium Nitrogen and Phosphate from the Anaerobic Digestion Reject Water. Waste Biomass Valor. 2020, 11, 4013–4024. [Google Scholar] [CrossRef] [Green Version]

- Huang, H.; Xiao, D.; Zhang, Q.; Ding, L. Removal of ammonia from landfill leachate by struvite precipitation with the use of low-cost phosphate and magnesium sources. J. Environ. Manag. 2014, 145, 191–198. [Google Scholar] [CrossRef]

- Darwish, M.; Aris, A.; Puteh, M.H.; Jusoh, M.N.H.; Kadir, A.A. Waste bones ash as an alternative source of P for struvite precipitation. J. Environ. Manag. 2017, 203, 861–866. [Google Scholar] [CrossRef]

- Ylivainio, K.; Uusitaloand, R.; Turtola, E. Meat bone meal and fox manure as P sources for ryegrass (loliummultiflorum) grown on a limited soil. Nutr. Cycl. Agroecosyst 2008, 81, 267–278. [Google Scholar] [CrossRef]

- Coutand, M.; Cyr, M.; Deydier, E.; Guilet, R.; Clastres, P. Characteristics of industrial and laboratory meat and bone meal ashes and their potential applications. J. Hazard. Mater. 2008, 150, 522–532. [Google Scholar] [CrossRef]

- Deydier, E.; Guilet, R.; Sarda, S.; Sharrock, P. Physical and chemical characterisation of crude meat and bone meal combustion residue: “waste or raw material?”. J. Hazard. Mater. 2005, 121, 141–148. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moerman, W.; Carballa, M.; Vandekerckhove, A.; Derycke, D.; Verstraete, W. Phosphate removal in agro-industry: Pilot- and full-scale operational considerations of struvite crystallization. Water Res. 2009, 43, 1887–1892. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fattah, K.; Mavinic, D.; Koch, F. Influence of process parameters on the characteristics of struvite pellets. J. Environ. Eng. 2015, 138, 1200–1209. [Google Scholar] [CrossRef]

- Huang, H.; Xiao, D.; Liu, J.; Hou, L.; Ding, L. Recovery and removal of nutrients from swine wastewater by using a novel integrated reactor for struvite decomposition and recycling. Sci. Rep. 2015, 5, 10183. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Yao, C.; Feng, X.; Yang, M. Repeated use of MgNH4PO4⋅6H2O residues for ammonium removal by acid dipping. Desalination 2004, 170, 27–32. [Google Scholar] [CrossRef]

- Liu, Y.H.; Rahman, M.M.; Kwag, J.H.; Kim, J.H.; Ra, C.S. Eco-friendly production of maize using struvite recovered from swine wastewater as a sustainable fertilizer source. Asian-Aust. J. Anim. Sci. 2011, 24, 1699–1705. [Google Scholar] [CrossRef]

- Zhang, T.; Ding, L.; Ren, H.; Xiong, X. Ammonium nitrogen removal from coking wastewater by chemical precipitation recycle technology. Water Res. 2009, 43, 5209–5215. [Google Scholar] [CrossRef]

- Zhang, T.; Wu, X.; Li, H.; Tsang, D.C.W.; Li, G.; Ren, H. Struvite pyrolysate cycling technology assisted by thermal hydrolysis pretreatment to recover ammonium nitrogen from composting leachate. J. Clean. Prod. 2020, 242, 118442. [Google Scholar] [CrossRef]

- Yu, R.; Geng, J.; Ren, H.; Wang, Y.; Xu, K. Struvite pyrolysate recycling combined with dry pyrolysis for ammonium removal from wastewater. Bioresour. Technol. 2013, 132, 154–159. [Google Scholar] [CrossRef]

- Türker, M.; Celen, I. Removal of ammonia as struvite from anaerobic digester effluents and recycling of magnesium and phosphate. Bioresour. Technol. 2007, 98, 1529–1534. [Google Scholar] [CrossRef]

- Liu, Y.H.; Kumar, S.; Kwag, J.H.; Kim, J.H.; Kim, J.D.; Ra, C.S. Recycle of electrolytically dissolved struvite as an alternative to enhance phosphate and nitrogen recovery from swine wastewater. J. Hazard. Mater. 2011, 195, 175–181. [Google Scholar] [CrossRef] [PubMed]

- Momballiu, A.; Desmidt, E.; Ghyselbrecht, K.; Meesschaert, B. Phoshate recovery as hydroxyapatite from nitrified UASB effluent at neutral pH in a CSTR. J. Environ. Chem. Eng. 2018, 6, 4413–4422. [Google Scholar] [CrossRef]

- Gao, Y.; Ling, B.; Chen, H.; Yin, P. An experimental study on the recovery of potassium (K) and phosphorous (P) from synthetic urine by crystallization of magnesium potassium phosphate. Chem. Eng. J. 2018, 337, 19–29. [Google Scholar] [CrossRef]

- Ohlinger, K.N.; Young, T.M.; Schroeder, E.D. Kinetics effects on preferential struvite accumulation in wastewater. J. Environ. Eng. 1999, 125, 730–737. [Google Scholar] [CrossRef]

- Mangin, D.; Klein, J.P. Fluid dynamic concepts for a phosphate precipitation reactor design. In Phosphorus in Environmental Technologies: Principles and Applications; IWA Publishing: London, UK, 2004; pp. 358–401. [Google Scholar]

- Ohlinger, K.N.; Membre, P.E.; Young, T.M.; Schroeder, E.D. Post digestion struvite precipitation using a fluidized bed reactor. J. Environ. Eng. 2000, 126, 361–368. [Google Scholar] [CrossRef]

- Suzuki, K.; Tanaka, Y.; Juroda, K.; Hanajima, D.; Fukumoto, Y. Recovery of phosphorous from swine wastewater through crystallization. Bioresur. Technol. 2005, 96, 1544–1550. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Zhao, Q.; Lee, D.J.; Yang, N. Enhancing phosphorus recovery by a new internal recycle seeding MAP reactor. Bioresour. Technol. 2008, 99, 6488–6493. [Google Scholar] [CrossRef]

- Liu, Y.H.; Kwnag, J.H.; Kim, J.H.; Ra, C.S. Recovery of nitrogen and phosphorus by struvite crystallization from swine wastewater. Desalination 2011, 277, 364–369. [Google Scholar] [CrossRef]

- Modin, O.; Gustavsson, D.J.I. Opportunities for microbial electrochemistry in municipal wastewater treatment—An overview. Water Sci. Technol. 2014, 69, 1359–1372. [Google Scholar] [CrossRef]

- Pant, D.; Singh, A.; Van Bogaert, G.; Irving Olsen, S.; Singh Nigam, P.; Diels, L.; Vanbroekhoven, K. Bioelectrochemical systems (BES) for sustainable energy production and product recovery from organic wastes and industrial wastewaters. RSC Adv. 2012, 2, 1248–1263. [Google Scholar] [CrossRef]

- Cusick, R.D.; Logan, B.E. Phosphate recovery as struvite within a single chamber microbial electrolysis cell. Bioresur. Technol. 2012, 107, 110–115. [Google Scholar] [CrossRef] [PubMed]

- Cusick, R.D.; Ullery, M.L.; Dempsey, B.A.; Logan, B.E. Electrochemical struvite precipitation from digestate with a fluidized bed cathode microbial electrolysis cell. Water Res. 2014, 54, 297–306. [Google Scholar] [CrossRef] [PubMed]

- You, J.; Greenman, J.; Melhuish, C.; Ieropoulos, I. Electricity generation and struvite recovery from human urine using microbial fuel cells. J. Chem. Technol. Biot. 2016, 91, 647–654. [Google Scholar] [CrossRef]

- Kelly, T.P.; He, Z. Nutrients removal and recovery in bioelectrochemical systems: A review. Bioresour. Technol. 2014, 153, 351–360. [Google Scholar] [CrossRef] [PubMed]

- Hirooka, K.; Ichihashi, O. Phosphorus recovery from artificial wastewater by microbial fuel cell and its effect on power generation. Bioresur. Technol. 2013, 137, 368–375. [Google Scholar] [CrossRef]

- Chen, T.; Barton, S.C.; Binyamin, G.; Gao, Z.; Zhang, Y.; Kim, H.H.; Heller, A. A miniature biofuel cell. J. Am. Chem. Soc. 2001, 123, 8630–8631. [Google Scholar] [CrossRef]

- Liu, H.; Cheng, S.; Logan, B.E. Production of electricity from acetate or butyrate using a single-chamber microbial fuel cell. Environ. Sci. Technol. 2005, 32, 658–662. [Google Scholar] [CrossRef]

- Rabaey, K.; Verstraete, W. Microbial fuel cells: Novel biotechnology for energy generations. Trends Biotechnol. 2005, 23, 291–298. [Google Scholar] [CrossRef]

- Kim, B.H.; Kim, H.J.; Hyun, M.S.; Park, D.H. Direct electrode reaction of Fe (III) reducing bacterium, Shewanellaputrefacience. J. Microbiol. Biotechnol. 1999, 9, 127–131. [Google Scholar] [CrossRef]

- Cuong, A.P.; Jung, S.J.; Phung, N.T.; Lee, J.; Chang, I.S.; Kim, B.H.; Yi, H.; Chun, J. A novel electrochemically active and Fe (III)-reducing bacterium phylogenetically related to Aeromonas hydrophila, isolated from a microbial fuel cell. FEMS Microbiol. Lett. 2003, 223, 129–134. [Google Scholar] [CrossRef] [Green Version]

- Fischer, F.; Bastian, C.; Happe, M.; Mabillard, E.; Schmidt, N. Microbial fuel cell enables phosphate recovery from digested sewage sludge as struvite. Bioresur. Technol. 2011, 102, 5824–5830. [Google Scholar] [CrossRef] [PubMed]

- Ichihashi, O.; Hirooka, K. Removal and recovery of phosphorus as struvite from swine wastewater using microbial fuel cell. Bioresour. Technol. 2012, 114, 303–307. [Google Scholar] [CrossRef] [PubMed]

- Fornero, J.J.; Rosenbaum, M.; Cotta, M.A.; Angenent, L.T. Carbon dioxide addition to microbial fuel cell cathodes maintains sustainable catholyte pH and improves anolyte pH, alkalinity, and conductivity. Environ. Sci. Technol. 2010, 44, 2728–2734. [Google Scholar] [CrossRef] [PubMed]

- Santoro, C.; Ieropoulos, I.; Greenman, J.; Cristiani, P.; Vadas, T.; Mackay, A.; Li, B. Power generation and contaminant removal in single chamber microbial fuel cells (SCMFCs) treating human urine. Int. J. Hydrogen Energy 2013, 38, 11543–11551. [Google Scholar] [CrossRef]

- Tao, Q.; Zhou, S.; Luo, J.; Yuan, J. Nutrient removal and elctricity production from wastewater using microbial fuel cell technique. Desalinization 2015, 365, 92–98. [Google Scholar] [CrossRef]

- Almatouq, A.; Babatunde, A.O. Concurrent hydrogen production and phosphorus recovery in dual chamber microbial electrolysis cell. Bioresur. Technol. 2017, 237, 193–203. [Google Scholar] [CrossRef]

- Tang, X.; Li, H.; Du, Z.; Ng, H.Y. A phosphorus-free anolyte to enhance coulombic efficiency of microbial fuel cells. J. Power Sources 2014, 268, 14–18. [Google Scholar] [CrossRef]

- Petruzzelli, D.; Dell’Erba, A.; Liberti, L.; Notarnicola, M.; Sengupta, A.K. A phosphate-selective sorbent for the REM NUT® process: Field experience at Massafra Wastewater Treatment Plant. React. Funct. Polym. 2003, 60, 195–2020. [Google Scholar] [CrossRef]

- Nur, T.; Loganathan, P.; Kandasamy, J.; Vigneswaran, S. Phosphate Adsorbtion from Membrane bioreactor effluent using Dowex 21K XLT and recovery as struvite and idroxyapatite. Int. J. Environ. Res. Public Health 2016, 13, 277. [Google Scholar] [CrossRef] [Green Version]

- Mijangos, F.; Kamel, M.; Lesmes, G.; Muraviev, D.N. Synthesis of struvite by ion exchange isothermal supersaturation technique. React. Funct. Polym. 2004, 60, 151–161. [Google Scholar] [CrossRef]

- Mijangos, F.; Celaya, A.; Ortueta, M.; Muraviev, D. Analysis of ion exchange isothermal supersaturation process for struvite production. Ind. Eng. Chem. Res. 2013, 52, 10276–10283. [Google Scholar] [CrossRef]

- Ortueta, M.; Celaya, A.; Mijangos, F.; Muraviev, D. Ion Exchange synthesis of struvite accompanied by isothermal supersaturation: Influence of polymer matrix and functional groups Type. Solvent Extr. Ion Exch. 2015, 33, 65–74. [Google Scholar] [CrossRef]

- Gonder, Z.B.; Kaya, Y.; Vergili, I.; Barlas, H. Capacity loss in an organically fouled anion exchanger. Desalination 2006, 189, 303–307. [Google Scholar] [CrossRef]

- van Reis, R.; Zydney, A. Bioprocess membrane technology. J. Membrane Sci. 2007, 297, 16–50. [Google Scholar] [CrossRef]

- Sengupta, S.; Nawaz, T.; Beaudry, J. Nitrogen and phosphorus recovery from wastewater. Curr. Pollut. Rep. 2015, 1, 155–166. [Google Scholar] [CrossRef] [Green Version]

- Pramanik, B.K.; Hai, F.I.; Ansari, A.J.; Roddick, F.A. Mining phosphorus from anaerobically treated dairy manure by forward osmosis membrane. J. Ind. Eng. Chem. 2019, 78, 425–432. [Google Scholar] [CrossRef]

- Bu, F.; Du, S.; Xie, L.; Cao, R.; Zhou, Q. Swine manure treatment by anaerobic membrane bioreactor with carbon, nitrogen and phospforusrecovery. Water Sci. Technol. 2017, 76, 1939–1949. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Pal, P. Membrane-integrated hybrid system for the effective treatment of ammoniacal wastewater of coke-making plant: A volume reduction approach. Environ. Technol. 2014, 35, 2018–2027. [Google Scholar] [CrossRef]

- Monfet, E.; Aubry, G.; Ramirez, A.A. Nutrient removal and recovery from digestate: A review of the technology. Biofuels 2018, 9, 247–262. [Google Scholar] [CrossRef]

- Volpin, F.; Heo, H.; Johir, M.A.H.; Cho, J.; Phuntsho, S.; Shon, H.K. Techno-economic feasibility of recovering phosphorus, nitrogen and water from dilute human urine via forward osmosis. Water Res. 2019, 150, 47–55. [Google Scholar] [CrossRef]

- Hakimi, M.H.; Jegatheesan, V.; Navaratna, D. The potential of adopting struvite precipitation as a strategy for the removal of nutrients from pre-AnMBR treated abattoir wastewater. J. Environ. Manag. 2020, 259, 109783. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; She, Q.; Chang, V.W.; Tang, C.Y.; Webster, R.D. Mining nutrients (N, K, P) from urban source-separated urine by forward osmosis dewatering. Environ. Sci. Technol. 2014, 48, 3386–3394. [Google Scholar] [CrossRef] [PubMed]

- Xue, W.; Tobino, T.; Nakajima, F.; Yamamoto, K. Seawater-driven forward osmosis for enrichingnitrogen and phosphorous in treated municipal waste water: Effect of membrane properties and feed solution chemistry. Water Res. 2015, 69, 120–130. [Google Scholar] [CrossRef] [PubMed]

- Xie, M.; Nghiem, L.D.; Price, W.E.; Elimelech, M. Toward Resource Recovery from Wastewater: Extraction of Phosphorus from Digested Sludge Using a Hybrid Forward Osmosis–Membrane Distillation Process. Environ. Sci. Technol. Lett. 2014, 1, 191. [Google Scholar] [CrossRef]

- Benisch, M.; Baur, R.; Britton, A.; Neethling, J.B.; Oleszkiewicz, J.A. Startup of the first commercial phosphorus recycling facility in the US at Durham AWWTP. Proc. Water Environ. Fed. 2009, 2009, 102–119. [Google Scholar] [CrossRef]

- Cornel, P.; Schaum, C. Phosphorus recovery from wastewater: Needs, technologies and costs. Water Sci. Technol. 2009, 59, 1069–1076. [Google Scholar] [CrossRef]

- Heinzmann, B.; Engel, G. Induced magnesium ammonium phosphate precipitation to prevent incrustations and measures for phosphorus recovery. Water Pract. Technol. 2006, 1. [Google Scholar] [CrossRef]

- Zhang, T.; Jiang, R.; Deng, Y. Phosphous recovery by struvite crystallization from livestock wastewater and reuse as fertilizer: A review. Physico-Chem. Wastewater Treat. Resour. Recover. 2017, 135–152. [Google Scholar] [CrossRef]

- Peng, L.; Dai, H.; Wu, Y.; Peng, Y.; Lu, X. A comprensive review of phosphorus recovery from wastewater by cristallization processes. Chemosphere 2018, 197, 768–781. [Google Scholar] [CrossRef]

- The European Parliament and the Council of the European Union. Regulation (EU) 2019/1009 of the European Parliament and the Council of 5 June 2019 Laying Down Rules on the Making Available on the Market of EU Fertilising Products and Amending Regulations (EC) No 1069/2009 and (EC) No 1107/2009 and Repealing Regulation (EC) No 2003/2003; Official Journal of the European Union: Brussels, Belgium, 2019; p. L 170/1–114. [Google Scholar]

- Ryu, H.D.; Lim, C.S.; Kang, M.K.; Lee, S.I. Evaluation of struvite obtained from semiconductor wastewater as a fertilizer in coultivating Chinese cabbage. J. Hazard. Mate. 2012, 221–222, 248–255. [Google Scholar] [CrossRef]

- Cao, L.; Wang, J.; Xiang, S.; Huang, Z.; Ruan, R.; Liu, Y. Nutrient removal from digested swine wastewater by combining ammonia stripping with struvite precipitation. Environ. Sci. Pollut. Res. 2019, 26, 6725–6734. [Google Scholar] [CrossRef] [PubMed]

- Dockhorn, T. About the Economy of Phosphorus Recovery. In International Conference on Nutrient Recovery from Wastewater Streams, Vancouver, Canada; IWA Publishing: London, UK, 2009; pp. 145–158. ISBN 9781843392323. [Google Scholar]

| Reference | Wastewater Influent | Reactor Typology | Reactor Volume | Hydraulic Retention Time (HRT) | Reaction Time | Mixing | pH Control | pH | Mg Source | P Source | N:Mg:P | P-Removal | N-Removal |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | min | min | rpm | % | % | ||||||||

| [1] | Landfill leachate | Batch | 1 | 30 | NaOH | 9 | MgO | H3PO4 | 1:2:1 | ≈100 | 95 | ||

| [28] | Synthetic wastewater | Batch | 21 | 630 | NaOH | 8.7 | MgCL2∙6H2O | NH4H2PO4 | 2.4:09:1 | 81.40 | |||

| [33] | Sewage sludge | Batch | 0.25 | 30 | 250 | NaOH | 9 | MgCL2∙6H2O | H3PO4 | 1.5:1:1 | 95 | 89.35 | |

| [41] | Landfill leachate | Batch | 4.8 | 15 | 300 | NaOH | 9 | Seawater bittern | Bone meal | 1:1.1:1.1 | 99 | 95 | |

| [44] | Anaerobic digestate | Batch | 0.25 | 15 | 300 | NaOH | 9 | Seawater bittern | Bone meal | 1:1.3:1.3 | 99 | 91 | |

| [50] | Pretreated landfill leachate | Batch | 0.4 | 1 | 300 | NaOH | 9 | Seawater bittern | Bone meal | 1:1.3:1.3 | 99 | 90 | |

| [51] | Landfill leachate | Batch | 0.5 | 30 | NaOH | 9 | MgCL2∙6H2O | Na2HPO4 | 1:1:1 | 92 | |||

| [52] | Landfill leachate | Batch | 1 | 3 | 200 | NaOH | 9 | MgCL2∙6H2O | KH2PO4 | 1:1.2:1.2 | ≈86 | ≈99 | |

| [53] | Synthetic swine wastewater | Continuous | 5 | 10 | 180 | NaOH | 9 | MgCL2∙6H2O | KH2PO4 | 1:1.2:1.1 | ≈98.9 | ≈85 | |

| [54] | Wastewater treatment liquors | Batch | 1 | 240 | 120 | Aeration | 8.5 | MgO | -:2.5:1 | ≈90 | |||

| [55] | Anaerobic digestion supernatant | Batch | 1 | 60 | 300 | NaOH | 10 | MgCl2∙6H2O | Na2HPO4 | 7.7:1:1 | >90 | 29 | |

| [56] | Synthetic urine | Continuous | 20.55 | 261 | 400 | NaOH | 8.8 | MgCl2∙6H2O | KH2PO4 | 4.3:1:1 | 90 | ||

| [57] | Synthetic wastewater | Continuous | 2.4 | 125 | 83 | 500 | NaOH | 8.5 | MgSO4 | Na2HPO4 | 9.4:1:1 | 88 | |

| [58] | Raw swine slurry | Batch | 0.35 | 240 | NaOH | 10 | MgO | H3PO4 | 1:1:1 | 80 | 77 | ||

| [59] | Anaerobically digested manure | Batch | 1 | 60 | NaOH | 8.7 | MgCL2∙6H2O | -:1.5:1 | 80 | ||||

| [60] | Anaerobically digested centrate | Batch | 1 | 30 | 9 | MgO | 30.7:1.1:1 | >90 | |||||

| [61] | Landfill leachate | Batch | 1 | 125 | NaOH | 8.5 | MgCL2∙6H2O | H3PO4 | 1:1:1 | 72 | |||

| [62] | Synthetic urine | Batch | 0.4 | 30 | 200 | NaOH | 9 | MgO | 1:1.4:1 | 96.70 | |||

| [63] | Synthetic solution | Batch | 1 | 20 | 150 | Aeration | 9–10 | Seawater bittern | KH2PO4 | 1:1:1 | >96 | >88 |

| Reference | Wastewater Influent | Seed Material | Reactor Volume | Flowrate | HRT | pH Control | Mg:P | Mg Source | pH | Airflow Rate | P Removal | Recovered Struvite | Grain Size | Grain Retention Time | Upflow Velocity |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | L/h | h | m3/h | % | kg/m3 | mm | d | cm/min | |||||||

| [25] | Synthetic wastewater | Struvite | 1.35 | 0.72 | 1.4 | NaOH | 1.3:1 | MgCl2·6H2O | 9.5 | 95.8 | |||||

| [30] | Anaerobic digester centrate | Struvite | 90 | 180 | 0.075 | 1.3:1 | MgCl2·6H2O | 8.2 | 80% | 0.5–3.5 | |||||

| [64] | Anaerobic digester supernatant | Struvite | 24.5/28.3 | 18–36 | 0.75–1.5 | 3.3:1 | MgCl2·6H2O | 7.6–8.4 | >85% | 0.5–4.75 | 10 | ||||

| [65] | Synthetic wastewater | 24.5/28.3 | NaOH | 1.6:1 | 7.9 | >90% | 2.5–4 | ||||||||

| [66] | Urine | 2.6 | 2 | Aeration | 1.3:1 | Seawater | 0.06 | >98.7% | 0.036–0136 | 4–5 | |||||

| [67] | Wastewater | Struvite | Mg(OH)2 | 1:1 | Mg(OH)2 | 8.2–8.8 | >90% | 0.087 | 0.5–1 | 10 | |||||

| [68] | Anaerobic digester centrate | Struvite | 24.5/28.3 | 0.074 | NaOH | 1.3:1 | MgCl2·6H2O | 8.2 | 85% | 0.5–3.5 | 410 | ||||

| [69] | Anaerobic liquor | Quartz sand | 18000 | Aeration | MgCl2·6H2O | 8.2 | 21 | 83.30% | 0.43 | 0.7 | |||||

| [70] | Synthetic wastewater | 9.5 | 1.8 | 10 | NaOH | 1.75:1 | MgCl2·6H2O | 9.5 | >90% | ||||||

| [71] | Synthetic wastewater | Struvite | 2 | 4 | 4.1 | NaOH | 1.6:1 | MgCl2·6H2O | 8.5 | 83% | |||||

| [72] | Synthetic wastewater | Struvite | 12 | 6 | 2 | Aeration | 1:1 | MgCl2·6H2O | 8 | 0.042 | >91% | 0.025 | 0.4–2 | ||

| [73] | Raw water | struvite | 279.17 | Aeration/NaOH | 1.9:1 | MgCl2·6H2O | 8.4 | 92% | 0.55–1.18 | 3–4 | |||||

| [74] | Swine lagoon liquid | Struvite | 30.15 | 568 | 0.05 | MgOH2 | MgO | 8 | 70 | 0.25–1.19 |

| Reference | Temperature (°C) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 15 | 20 | 25 | 30 | 35 | 37 | 40 | 45 | 50 | 55 | 60 | 65 | |

| KSP | |||||||||||||

| [79] | 4.31 × 10−14 | 5.14 × 10−14 | |||||||||||

| [84] | 5.51 × 10−14 | 7.12 × 10−14 | 7.90 × 10−14 | ||||||||||

| [88] | 5.42 × 10−14 | 6.90 × 10−14 | 1.17 × 10−13 | 1.58 × 10−13 | 3.02 × 10−13 | 3.73 × 10−13 | 2.50 × 10−13 | ||||||

| [94] | 4.36 × 10−15 | 9.16 × 10−15 | 2.05 × 10−14 | 4.33 × 10−14 | 6.84 × 10−14 | 5.92 × 10−14 | 4.00 × 10−14 | 2.53 × 10−14 | 2.11 × 10−14 | 1.46 × 10−14 | 9.73 × 10−15 | ||

| [95] | 5.13 × 10−14 | 6.03 × 10−14 | 6.76 × 10−14 | 1.00 × 10−13 | 8.32 × 10−14 | ||||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siciliano, A.; Limonti, C.; Curcio, G.M.; Molinari, R. Advances in Struvite Precipitation Technologies for Nutrients Removal and Recovery from Aqueous Waste and Wastewater. Sustainability 2020, 12, 7538. https://doi.org/10.3390/su12187538

Siciliano A, Limonti C, Curcio GM, Molinari R. Advances in Struvite Precipitation Technologies for Nutrients Removal and Recovery from Aqueous Waste and Wastewater. Sustainability. 2020; 12(18):7538. https://doi.org/10.3390/su12187538

Chicago/Turabian StyleSiciliano, Alessio, Carlo Limonti, Giulia Maria Curcio, and Raffaele Molinari. 2020. "Advances in Struvite Precipitation Technologies for Nutrients Removal and Recovery from Aqueous Waste and Wastewater" Sustainability 12, no. 18: 7538. https://doi.org/10.3390/su12187538

APA StyleSiciliano, A., Limonti, C., Curcio, G. M., & Molinari, R. (2020). Advances in Struvite Precipitation Technologies for Nutrients Removal and Recovery from Aqueous Waste and Wastewater. Sustainability, 12(18), 7538. https://doi.org/10.3390/su12187538