Technology to Address Food Deserts: Low Energy Corner Store Groceries with Integrated Agriculture Greenhouse

Abstract

1. Introduction

1.1. Food Deserts

1.2. Healthy Corner Market Initiatives

1.3. Local Food Production

1.4. Barriers to Healthy Food in Corner Markets

2. Literature Review

2.1. Different Variants of Combined Heat Power (CHP)

2.2. Use of Waste Heat in Agriculture Greenhouse

2.3. Hybrid System for Greenhouse Application

2.4. Summary of Research and Development

- Demonstrate the feasibility of integrating a micro-CHP, thermal storage tank, and an agricultural greenhouse into a typical corner store in a heating-dominated climate.

- Optimize the cost of a combined CHP, storage tank, and greenhouse floor area.

- Develop an optimal solution of the combined system that leads to maximum crop yields continuously throughout the year.

3. Methodology and Model Descriptions

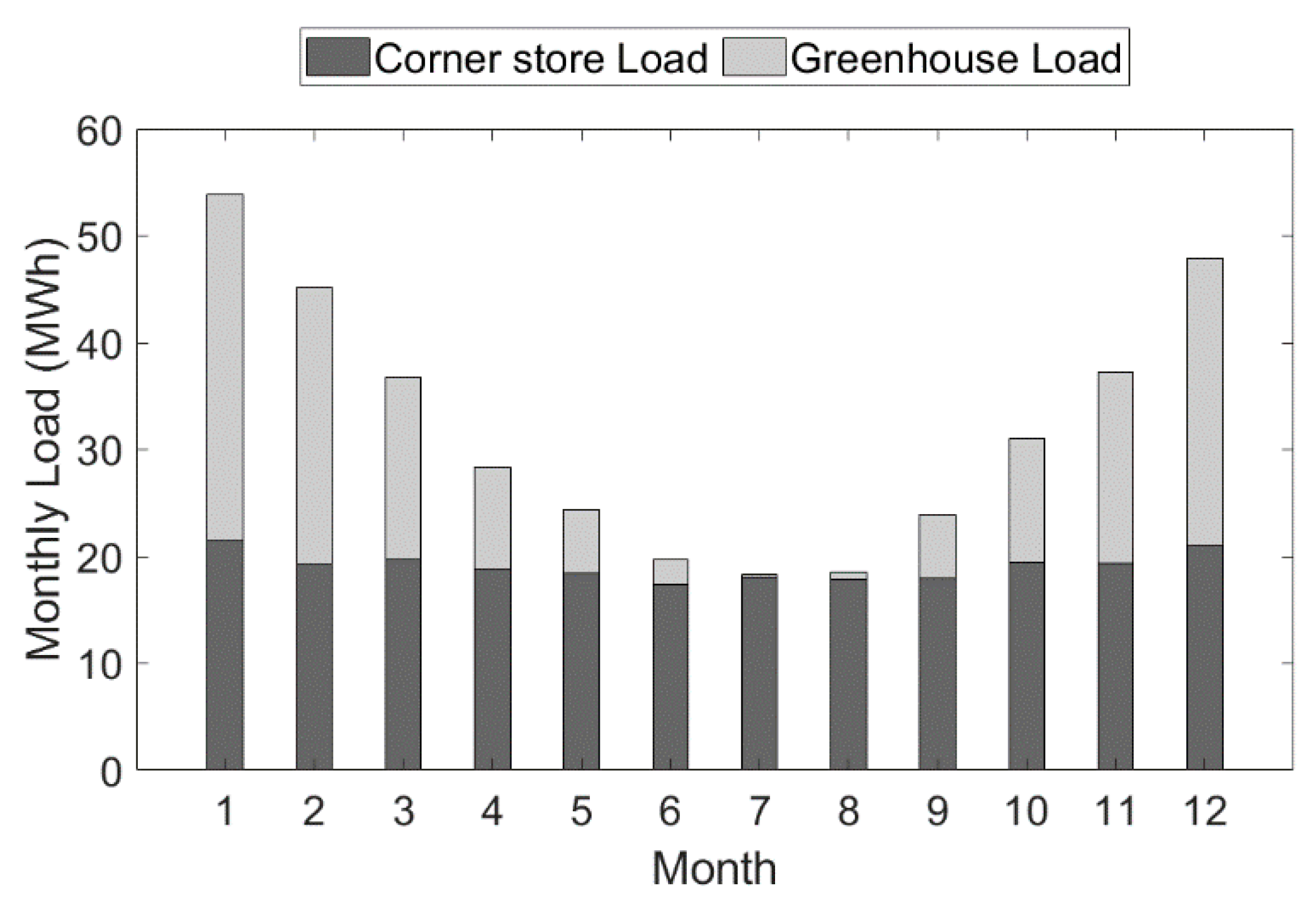

3.1. Corner Store Electric Load Profile

3.2. Greenhouse Load Profile

3.2.1. Physical Characteristics of the Greenhouse

3.2.2. Mathematical Model for the Greenhouse

- The greenhouse temperature is considered homogeneous and constant with time.

- Heat gain/lost to the ground is treated as quasi-steady, which means that the ground temperature is assumed nearly constant.

- The solar transmissivity for all greenhouse exterior panels is considered to be homogeneous.

- ,

- = ventilation heat losses from the greenhouse,

- = short wave radiation absorbed by the greenhouse,

- = transpiration heat losses due to the crops, [40]

- = heat conduction to the soil, [41]

- long wave radiation heat losses,

- = rate of energy required to maintain the greenhouse at desired internal temperature set point.

3.2.3. Greenhouse Model Validation

3.2.4. Greenhouse Heating Load Profile

3.3. CHP and Thermal Storage Loads

3.3.1. CHP and Thermal Storage Characteristics and Energy Flows

- Thermal losses of the storage tank to the ground are treated as quasi-steady, which means that the environmental temperature is assumed nearly constant.

- The operation of the CHP was controlled using an on/off controller.

- The CHP must run during peak time.

- Degradation effect of the CHP is neglected. The impact of this assumptions is expected to be small. Degradation of the CHP, were it to be included, could lower the electric energy produced by the CHP over its lifespan, thus causing an increase in thermal energy produced. Taccani et at. studied the performance analysis of a micro CHP system subject to degradation. They concluded that if heat is recuperated, the overall efficiency impact can be mitigated [43].

3.3.2. CHP and Thermal Storage Characteristics and Energy Flows

3.3.3. Optimization of CHP and Thermal Storage System

4. Results

4.1. Cost Optimization

- CHP capacity is 40 kW

- Storage tank capacity is 80 kWh

- Greenhouse area is 312 m2

4.2. Sensitivity Analysis

5. Discussion and Conclusions

6. Future Work

- Investigate experimentally the performance of the proposed system.

- System configuration plays a major role in determining the overall performance. Future research may explore the use of other renewable energy sources such as geothermal.

- The dispatching algorithm for the CHP system has significant impact on the overall annual operation cost. Future studies may consider different power management strategies and extend or modify the objective functions used in this study.

- The degradation impact of the presented technologies is neglected. Future studies need to consider the degradation effect of the CHP and quantify its impact on the overall energy savings.

- The CHP with integrated agricultural greenhouse system considered in this study was focused on a heating-dominant climate (e.g., a cold climate with heating degree day (HDD) >> cooling degree day (CDD). In this case, the rejected heat from CHP was used to cover the greenhouse thermal loads. However, in cooling-dominant climates, future studies might consider the feasibility of using the rejected heat from the CHP to drive the absorption cycle in an absorption chiller. Thus, the cooling loads in the corner store and an agriculture greenhouse might both be supported by a CHP system.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| Estimated overall thermal conductivity of the greenhouse | W/(K) | |

| thermal conductivity of soil | W/(K) | |

| Stefan-Boltzmann constant | ||

| soil temperature | °C | |

| outdoor temperature | ||

| long wave transmission | - | |

| solar transmissivity | - | |

| leaf area index | - | |

| aerodynamic resistances of the leaves | s/m | |

| depth of underground soil | m | |

| ACH | number of air change per hour | 1/hr |

| CHP capacity | kW | |

| hot water tank thermal storage capacity | kWh | |

| hourly store electric demand | kWh | |

| hourly CHP electrical output | kWh | |

| hourly CHP thermal output | kWh | |

| electrical conversion efficiency for CHP | - | |

| thermal conversion efficiency for CHP | - | |

| hourly amount of thermal energy stored in thermal storage tank | kWh | |

| R | hourly hot water released from thermal storage tank | kWh |

| hourly thermal energy produced by CHP delivered to the greenhouse | kWh | |

| hourly electric energy produced by CHP delivered to the store | kWh | |

| hourly greenhouse thermal load | kWh | |

| Tank capitol cost per kwh | ||

| NG | Yearly cost of natural gas | $/year |

| Gr | Construction cost of the greenhouse | $/ |

| Lifetime of the system | Years | |

| I | Loan interest rate | - |

| Total annual system cost | $ |

References

- Dutko, P.; Ploeg, M.V.; Farrigan, T. Characteristics and Influential Factors of Food Deserts. Available online: https://www.ers.usda.gov/webdocs/publications/45014/30940_err140.pdf (accessed on 8 September 2020).

- Ploeg, M.V.; Breneman, V.; Farrigan, T.; Hamrick, K.; Hopkins, D.; Kaufman, P.; Lin, B.-H.; Nord, M.; Smith, T.; Williams, R.; et al. Access to Affordable and Nutritious Food: Measuring and Understanding Food Deserts and Their Consequences. Available online: https://www.ers.usda.gov/webdocs/publications/42711/12716_ap036_1_.pdf (accessed on 8 September 2020).

- USDA ERS Documentation. Available online: https://www.ers.usda.gov/data-products/food-access-research-atlas/documentation/ (accessed on 8 September 2020).

- Coolidge, A.C.S. Jesse Jackson Calls to Expand Kroger Boycott over Its Shuttering of Stores in Minority Neighborhoods. Available online: https://www.usatoday.com/story/money/nation-now/2018/04/10/jesse-jackson-kroger-protest/502688002/ (accessed on 8 September 2020).

- Walmart to Shutter 269 Stores, with Most Located in the US. Available online: http://www.theguardian.com/business/2016/jan/15/walmart-closing-store-employee-brazil (accessed on 8 September 2020).

- The Impact of Coronavirus on Food Insecurity Feeding America. Available online: https://www.feedingamerica.org/research/coronavirus-hunger-research (accessed on 8 September 2020).

- Food Empowerment Project. Available online: https://foodispower.org/shame-on-safeway-and-albertsons/ (accessed on 8 September 2020).

- Unshared Bounty: How Structural Racism Contributes to the Creation and Persistence of Food Deserts. Available online: https://digitalcommons.nyls.edu/cgi/viewcontent.cgi?article=1002&context=racial_justice_project (accessed on 8 September 2020).

- CDC Coronavirus Disease 2019 (COVID-19). Available online: https://www.cdc.gov/coronavirus/2019-ncov/covid-data/investigations-discovery/hospitalization-death-by-race-ethnicity.html (accessed on 8 September 2020).

- Living in a Food Desert: How Lack of Access to Healthy Foods Can Affect Public Health Notes From NAP. Available online: https://notes.nap.edu/2011/01/25/living-in-a-food-desert-how-lack-of-access-to-healthy-foods-can-affect-public-health/ (accessed on 8 September 2020).

- Benson, N.; Clark, J. Healthy Corner Stores; The Ohio State University: Columbus, OH, USA, 2011; p. 20. [Google Scholar]

- Healthy on the Block Healthy Corner Store Toolkit. Available online: https://bphc.org/whatwedo/healthy-eating-active-living/healthy-on-the-block/Documents/Healthy_On_The_Block_Toolkit.pdf (accessed on 8 September 2020).

- Healthy Corner Stores Network. Available online: http://thefoodtrust.org/administrative/healthy-corner-stores-network (accessed on 8 September 2020).

- Obama Administration Details Healthy Food Financing Initiative. Available online: https://www.treasury.gov/press-center/press-releases/Pages/tg555.aspx (accessed on 8 September 2020).

- Reps. Evans and Fudge Introduce Bill to Reauthorize the Healthy Food Financing Initiative. Available online: https://evans.house.gov/media-center/press-releases/reps-evans-and-fudge-introduce-bill-reauthorize-healthy-food-financing (accessed on 9 September 2020).

- Yanamandra, N. Food Deserts, Food Hubs, and Farmers Markets in Arizona an Analysis of Proximity and Potential for Increasing Food Access; Arizona State University: Tempe, AZ, USA, 2015. [Google Scholar]

- Anderson, E.; Cushing, B.; Davis, A. Watering the Food Desert: A Policy Analysis of Urban Food Access Disparities in the Lower Ninth Ward, New Orleans. Available online: https://d31kydh6n6r5j5.cloudfront.net/uploads/sites/75/2019/05/Anderson_Cushing_and_Davis.pdf (accessed on 9 September 2020).

- Clark, M. Bringing Hope to Food-Insecure Communities. Available online: https://socialenterprise.us/2018/08/31/urban-farming-bringing-hope-to-food-insecure-communities/ (accessed on 8 September 2020).

- Rankin, B. Another Angle in the Fight to Fix South Dallas’ Food Desert: Low-Cost Gardening. Available online: https://www.dallasobserver.com/restaurants/the-seedling-farm-wants-to-fix-a-south-dallas-food-desert-through-low-cost-gardening-10068193 (accessed on 8 September 2020).

- What 5 Cities Are Doing to Change the Way America Eats. Available online: https://nextcity.org/daily/entry/five-cities-food-justice-american-food-deserts-solutions (accessed on 8 September 2020).

- Wang, H.; Qiu, F.; Swallow, B. Can community gardens and farmers’ markets relieve food desert problems? A study of Edmonton, Canada. Appl. Geogr. 2014, 55, 127–137. [Google Scholar] [CrossRef]

- Behjat, A. Exploring the Geography of Food Deserts and Potential Association with Obesity in Rural British Columbia. Ph.D. Thesis, University of Victoria, Greater Victoria, BC, Canada, 2016. [Google Scholar]

- Mukhopadhyay, J. An Analysis of Energy Consumption in Grocery Stores in a Hot and Humid Climate. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2013. [Google Scholar]

- Maidment, G.; Tozer, R. Combined cooling, heat and power (CCHP) in Supermarkets. Heat Powered Cycles. 2001, 1, 653–665. [Google Scholar] [CrossRef]

- Navarro-Esbrí, J.; Molés, F.; Peris, B.; Mota-Babiloni, A.; Pascual Martí, J.; Collado, R.; González, M. Combined cold, heat and power system, based on an organic Rankine cycle, using biomass as renewable heat source for energy saving and emissions reduction in a supermarket. Energy Procedia 2017, 129, 652–659. [Google Scholar] [CrossRef]

- Sugiartha, N.; Chaer, I.; Tassou, S.A.; Marriot, D.; Marriot, D. Assessment of a Micro-Gas Turbine based Tri-generation System in a Supermarket. In Proceedings of the International Conference on Fluid and Thermal Energy Conversion, Jakarta, Indonesia, 10–14 December 2006; pp. 1–12. [Google Scholar]

- Chinese, D.; Meneghetti, A.; Nardin, G. Waste-to-energy based greenhouse heating: Exploring viability conditions through optimisation models. Renew. Energy 2005, 30, 1573–1586. [Google Scholar] [CrossRef]

- Parker, T.; Kiessling, A. Low-grade heat recycling for system synergies between waste heat and food production, a case study at the European Spallation Source. Energy Sci. Eng. 2016, 4, 153–165. [Google Scholar] [CrossRef]

- Vourdoubas, J. Possibilities of Using Industrial Waste Heat for Heating Greenhouses in Northern Greece. J. Agric. Sci. 2018, 10, 116. [Google Scholar] [CrossRef]

- Kiyan, M.; Bingöl, E.; Melikoǧlu, M.; Albostan, A. Modelling and simulation of a hybrid solar heating system for greenhouse applications using Matlab/Simulink. Energy Convers. Manag. 2013, 72, 147–155. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, P.; Mao, J.; Tang, X.; Li, Z.; Shi, J. A low cost seasonal solar soil heat storage system for greenhouse heating: Design and pilot study. Appl. Energy 2015, 156, 213–222. [Google Scholar] [CrossRef]

- El-Maghlany, W.M.; Teamah, M.A.; Tanaka, H. Optimum design and orientation of the greenhouses for maximum capture of solar energy in North Tropical Region. Energy Convers. Manag. 2015, 105, 1096–1104. [Google Scholar] [CrossRef]

- Almehmadi, F.A.; Hallinan, K.P. Performance Analysis of an Integrated Solar Dehumidification System with HVAC in A Typical Corner Store in the USA. Sustainability 2020, 12, 4068. [Google Scholar] [CrossRef]

- Ferreira, A.; Pinheiro, M.D.; de Brito, J.; Mateus, R. Combined carbon and energy intensity benchmarks for sustainable retail stores. Energy 2018, 165, 877–889. [Google Scholar] [CrossRef]

- Ambach, G.; Dickenson, R.; Dvorak, B.; Kelly, N.; Samuelson, C.; Jogwuia, V. Improving Energy Efficiency in Convenience Stores. Available online: http://www.michaelsenergy.com/PDFs/36538-Michaels-2013-Conv-Store.pdf (accessed on 8 September 2020).

- Sanford, S. Reducing greenhouse energy consumption—An overview. Energy 2011, 3907, 1–16. [Google Scholar]

- Fabrizio, E. Energy reduction measures in agricultural greenhouses heating: Envelope, systems and solar energy collection. Energy Build. 2012, 53, 57–63. [Google Scholar] [CrossRef]

- Ahamed, M.S.; Guo, H.; Tanino, K. A quasi-steady state model for predicting the heating requirements of conventional greenhouses in cold regions. Inf. Process. Agric. 2018, 5, 33–46. [Google Scholar] [CrossRef]

- Effat, M.B.; Shafey, H.M.; Nassib, A.M. Solar greenhouses can be promising candidate for CO2 capture and utilization: Mathematical modeling. Int. J. Energy Environ. Eng. 2015, 6, 295–308. [Google Scholar] [CrossRef]

- Shen, Y.; Wei, R.; Xu, L. Energy consumption prediction of a greenhouse and optimization of daily average temperature. Energies 2018, 11, 65. [Google Scholar] [CrossRef]

- Tunc, M.; Venart, J.E.S.; Sollows, K. Bivalent (hybrid) heat pump-oil heating systems for greenhouses. J. Heat Recovery Syst. 1985, 5, 483–491. [Google Scholar] [CrossRef]

- Alqaed, S.; Hallinan, K.P. Developing a Cost-Optimal Retrofit Chp System for Multi-Family Buildings Using Historical Demand. Int. J. Adv. Res. 2017, 5, 1786–1800. [Google Scholar] [CrossRef]

- Taccani, R.; Chinese, T.; Zuliani, N. Performance analysis of a micro CHP system based on high temperature PEM fuel cells subjected to degradation. Energy Procedia 2017, 126, 421–428. [Google Scholar] [CrossRef]

- Combined Heat and Power (CHP) | WBDG—Whole Building Design Guide. Available online: https://www.wbdg.org/resources/combined-heat-and-power-chp (accessed on 9 September 2020).

- Learn how much It Costs to Build a Greenhouse. Available online: https://www.homeadvisor.com/cost/outdoor-living/build-a-greenhouse/ (accessed on 9 September 2020).

- Yu, D.; Meng, Y.; Yan, G.; Mu, G.; Li, D.; Le Blond, S. Sizing combined heat and power units and domestic building energy cost optimisation. Energies 2017, 10, 771. [Google Scholar] [CrossRef]

- Kayo, G.; Ooka, R. Building energy system optimizations with utilization of waste heat from cogenerations by means of genetic algorithm. Energy Build. 2010, 42, 985–991. [Google Scholar] [CrossRef]

- Greenhouse Vegetables (Cucumber, Tomato, Lettuce) Crop Guide | Small Acreage Horticultural Crops. Available online: https://aggie-horticulture.tamu.edu/smallacreage/crops-guides/greenhouse-nursery/greenhouse-vegetables/ (accessed on 9 September 2020).

- US EPA. CHP Benefits. Available online: https://www.epa.gov/chp/chp-benefits (accessed on 9 September 2020).

- US EPA. What Is CHP? Available online: https://www.epa.gov/chp/what-chp (accessed on 9 September 2020).

- Natural Gas and the Environment NaturalGas.org. Available online: http://naturalgas.org/environment/naturalgas/#:~:text=Natural%20gas%2C%20as%20the%20cleanest,of%20pollutants%20into%20the%20atmosphere.&text=Natural%20gas%2C%20emitting%20fewer%20harmful,some%20of%20these%20environmental%20issues (accessed on 30 August 2020).

- Frequently Asked Questions (FAQs)—U.S. Energy Information Administration (EIA). Available online: https://www.eia.gov/tools/faqs/faq.php?id=74&t=11 (accessed on 9 September 2020).

| Characteristics | Base Case (Parameters) |

|---|---|

| Plan shape | Rectangular |

| Number of floors | 1 |

| Floor height | 6.10 m |

| Floor area | 330 |

| Floor dimensions | 24 m × 14 m |

| Window area | 7% of the total gross wall area |

| Overall heat transfer coefficient for windows ( | 2.84 |

| Solar heat gain coefficient (SHGC) | 0.4 |

| Lighting power density | 15 W/ |

| Ventilation | 0.20 |

| Weather file | Dayton TMY3 |

| Thermostat | ON/Off |

| Solar absorbance for exterior surfaces | 0.55 |

| Overall heat transfer coefficient for exterior walls () | 0.78 |

| Overall heat transfer coefficient for roof () | 0.287 |

| Thermostat setting | T = 24 °C and RH = 55% |

| HVAC unit size | 32 of floor area per ton |

| Operating hours | 6 AM to 10 PM |

| Peak electric plug load | 5.4 W/ |

| Occupancy | 150 W/person |

| Air conditioning system coefficient of performance (COP) | 3.33 |

| Moisture generation rate inside store | 0.70 kg of water/kg of air per hour |

| Parameters | Definitions | Value | Source |

|---|---|---|---|

| Estimated overall thermal conductivity of the greenhouse | 1.5 W/(K) | [37] | |

| Thermal conductivity of soil | 1.4 W/(K) | [38] | |

| Stefan-Boltzmann constant | |||

| Soil temperature | 15 °C | [39] | |

| Outdoor temperature | Varies hourly for typ. weather year | - | |

| Long wave transmission | 0.5 | - | |

| Solar transmissivity | 0.78 | [38] | |

| Leaf area index | 2 | [40] | |

| Aerodynamic resistances of the leaves | 275 s/m | [40] | |

| Depth of underground soil | 3 m | - | |

| ACH | Number of air change per hour | 0.5 1/h | - |

| Variable Name | Units | Definition |

|---|---|---|

| kW | CHP capacity | |

| hot water tank thermal storage capacity | ||

| hourly store electric demand | ||

| hourly CHP electrical output | ||

| Hourly CHP thermal output | ||

| - | electrical conversion efficiency for CHP | |

| - | thermal conversion efficiency for CHP | |

| hourly amount of thermal energy stored in thermal storage tank | ||

| hourly hot water released from thermal storage tank | ||

| hourly thermal energy produced by CHP delivered to the greenhouse | ||

| hourly electric energy produced by CHP delivered to store | ||

| hourly greenhouse thermal load, (equal to |

| Condition | Description | Equations |

|---|---|---|

| Identifying store electric demand during peak hours. CHP must run during these hours. | ||

| CHP output is more than the store demand. Sell the extra energy to the grid. | ||

| Greenhouse load is more than the CHP thermal output. Use the available thermal energy from the CHP and supply the rest by the furnace. | ||

| Greenhouse load is less than the thermal energy from the CHP. Satisfy the greenhouse load and pass the remaining to the storage tank. | ||

| Storage tank is enough to cover the greenhouse thermal load. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Awjah Almehmadi, F.; Hallinan, K.P.; Mulford, R.B.; Alqaed, S.A. Technology to Address Food Deserts: Low Energy Corner Store Groceries with Integrated Agriculture Greenhouse. Sustainability 2020, 12, 7565. https://doi.org/10.3390/su12187565

Awjah Almehmadi F, Hallinan KP, Mulford RB, Alqaed SA. Technology to Address Food Deserts: Low Energy Corner Store Groceries with Integrated Agriculture Greenhouse. Sustainability. 2020; 12(18):7565. https://doi.org/10.3390/su12187565

Chicago/Turabian StyleAwjah Almehmadi, Fahad, Kevin P. Hallinan, Rydge B. Mulford, and Saeed A. Alqaed. 2020. "Technology to Address Food Deserts: Low Energy Corner Store Groceries with Integrated Agriculture Greenhouse" Sustainability 12, no. 18: 7565. https://doi.org/10.3390/su12187565

APA StyleAwjah Almehmadi, F., Hallinan, K. P., Mulford, R. B., & Alqaed, S. A. (2020). Technology to Address Food Deserts: Low Energy Corner Store Groceries with Integrated Agriculture Greenhouse. Sustainability, 12(18), 7565. https://doi.org/10.3390/su12187565