Wood-Logging Process Management in Eastern Amazonia (Brazil)

Abstract

1. Introduction

2. Material and Methods

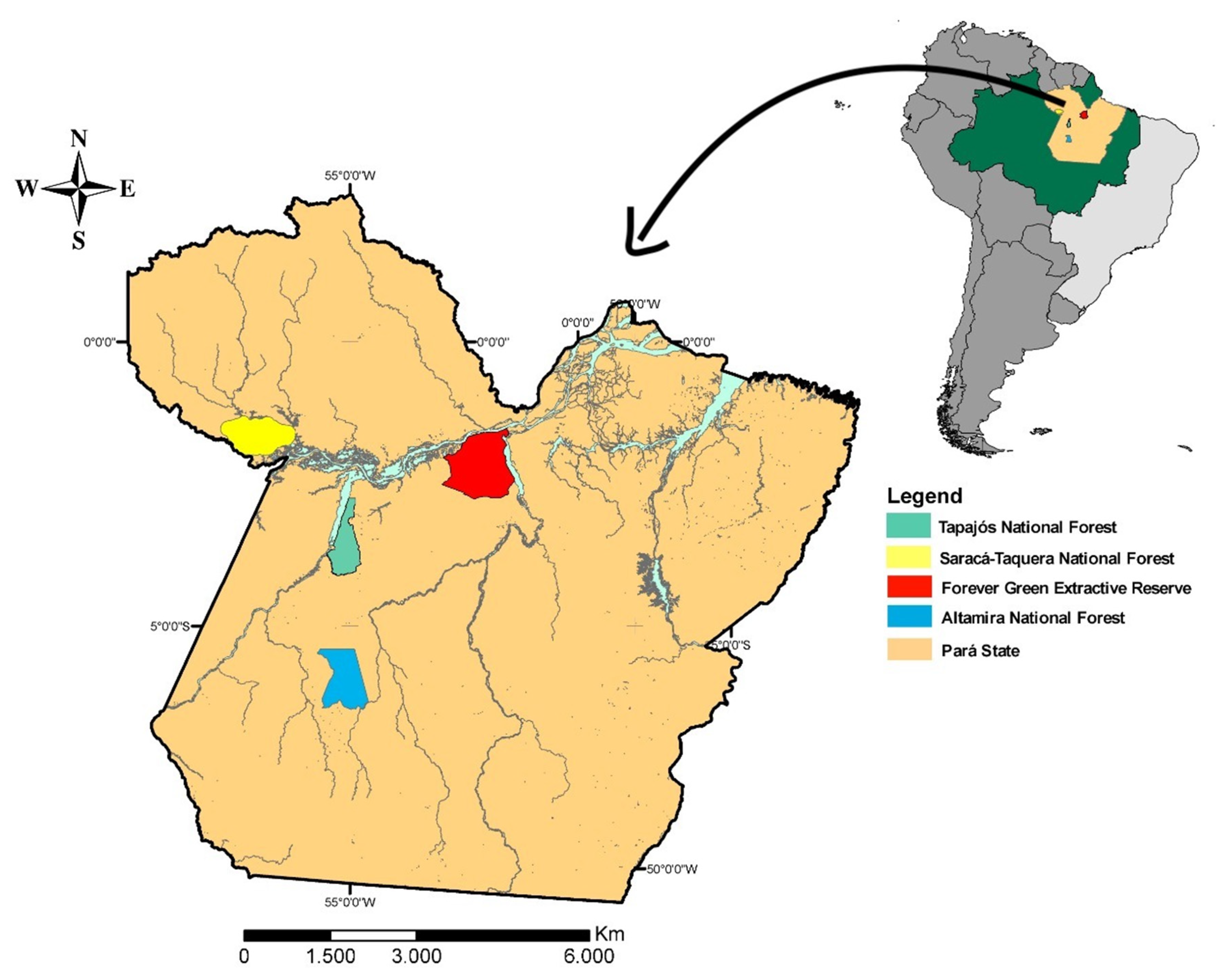

2.1. Study Area

2.2. Data Collection

2.3. Data Analysis

3. Results

3.1. General Organisation and Team Sizes

3.2. Activities in the Wood-Logging Process

3.3. The Technological Level of the Institutions

3.4. Environmental Certification and Work Conditions

4. Discussion

5. The Proposed Model

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- FAO and UNEP. The State of the World’s Forests 2020. Forests, Biodiversity and People; Food and Agriculture Organization: Rome, Italy, 2020. [Google Scholar] [CrossRef]

- Poschen, P. Forestry, a safe and healthy profession? Unasylva 1993, 44, 1. Available online: http://www.fao.org/docrep/u8520e/u8520e00.htm (accessed on 20 July 2020).

- Azevedo-Ramos, C. Sustainable development and challenging deforestation in the Brazilian Amazon: The good, the bad and the ugly. Unasylva 2008, 59, 12–16. Available online: http://www.fao.org/3/i0440e03.htm (accessed on 11 September 2020).

- Araujo, M.; Kant, S.; Couto, L. Why Brazilian companies are certifying their forests? For. Policy Econ. 2009, 11, 579–585. [Google Scholar] [CrossRef]

- Siry, J.P.; Cubbage, F.W.; Ahmed, M.R. Sustainable forest management: Global trends and opportunities. For. Policy Econ. 2005, 7, 551–561. [Google Scholar] [CrossRef]

- Verissimo, A.; Barreto, P.; Mattos, M.; Tarifa, R.; Uhl, C. Logging impacts and prospects for sustainable forest management in an old Amazonian frontier: The case of Paragominas. For. Ecol. Manag. 1992, 55, 169–199. [Google Scholar] [CrossRef]

- Espada, A.; Pires, I.; Lentini, M.; Bittencourt, P. Manejo Florestal e Exploração de Impacto Reduzido em Florestas Naturais de Produção da Amazônia. IFP—Instituto Floresta Tropical, 2015. Available online: http://ift.org.br/wp-content/uploads/2014/11/Informativo-T%C3%A9cnico-1.pfd (accessed on 20 July 2020).

- Dykstra, P.; Heinrich, R. FAO Model Code of Forest Harvesting Practice; Food and Agriculture Organization: Rome, Italy, 1996; Available online: http://www.fao.org/3/v6530e/v6530e00.htm (accessed on 20 July 2020).

- Putz, E.; Sist, P.; Fredericksen, T.; Dykstra, D. Reduced-impact logging: Challenges and opportunities. For. Ecol. Manag. 2008, 256, 1427–1433. [Google Scholar] [CrossRef]

- Barreto, P.; Amaral, P.; Vidal, E.; Uhl, C. Costs and benefits of forest management for timber production in eastern Amazonia. For. Ecol. Manag. 1998, 108, 9–26. [Google Scholar] [CrossRef]

- West, T.A.P.; Vidal, E.; Putz, F.E. Forest biomass recovery after conventional and reduced-impact logging in Amazonian Brazil. For. Ecol. Manag. 2014, 314, 59–63. [Google Scholar] [CrossRef]

- Holmes, T.P.; Blate, G.; Zweede, J.; Pereira, R.; Barreto, P.; Boltz, F.; Bauch, R. Financial and ecological indicators of reduced impact logging performance in the eastern Amazon. For. Ecol. Manag. 2002, 163, 93–110. [Google Scholar] [CrossRef]

- Sabogal, C.; Lentini, M.; Pokorny, B.; Silva, J.; Zweede, J.; Veríssimo, A.; Boscolo, M. Manejo Florestal Empresarial na Amazônia Brasileira: Restrições e Oportunidades–Relatório Síntese. CIFOR—Center for International Foresty Research, 2006. Available online: http://www.ift.org.br/wp-content/uploads/2015/05/Sabogal_etal_2006a.pdf (accessed on 20 July 2020).

- Sabogal, C.; Porkorny, B.; Silva, M.; Carvalho, P.; Zweede, C.; Puerta, R. Diretrizes técnicas de manejo para produção madeireira mecanizada em florestas de terra firme na Amazônia brasileira. Embrapa Amazônia Oriental, 2009. Available online: https://www.embrapa.br/busca-de-publicacoes/-/publicacao/853000/diretrizes-tecnicas-de-manejo-para-producao-madeireira-mecanizada-em-florestas-de-terra-firme-na-amazonia-brasileira (accessed on 20 July 2020).

- Nasi, R.; Frost, P. Sustainable forest management in the tropics: Is everything in order but the patient still dying? Ecol. Soc. 2009, 14, 40. Available online: http://www.ecologyandsociety.org/vol14/iss2/art40/ (accessed on 20 July 2020).

- Johansson, J. Why do forest companies change their CSR strategies? Responses to market demands and public regulation through dual-certification. J. Environ. Plan. Manag. 2014, 5, 349–368. [Google Scholar] [CrossRef]

- Schulze, M.; Grogan, J.; Vidal, E. Forest certification in Amazonia: Standards matter. Oryx 2008, 42, 229–239. [Google Scholar] [CrossRef]

- Pescador, C.; Lisboa, G.; Stepka, T.; Kurchaidt, S. Safety work in the forest harvest: The first results. Ambiência 2013, 9, 397–410. [Google Scholar] [CrossRef]

- Reyer, C. Sustainable development of the Amazon forest: A fine line between conservation and exploitation? Sustain. Sci. Pract. Policy 2017, 5, 38–44. [Google Scholar] [CrossRef][Green Version]

- McDermott, C.; Irlandb, L.; Pacheco, P. Forest certification and legality initiatives in the Brazilian Amazon: Lessons for effective and equitable forest governance. For. Policy Econ. 2015, 50, 134–142. [Google Scholar] [CrossRef]

- Legislação Brasileira. Normativa Nº 5, de 11 de dezembro de 2006. Available online: http://www.lex.com.br/doc_1081404_INSTRUCAO_NORMATIVA_N_5_DE_11_DE_DEZEMBRO_DE_2006.aspx (accessed on 20 July 2020).

- Legislação Brasileira. Decreto nº 73.684, de 19 de fevereiro de 1974. Available online: https://www.icmbio.gov.br/portal/images/stories/imgs-unidades-coservacao/flona_tapajos.pdf (accessed on 20 July 2020).

- ICMBIO (Instituto Chico Mendes De Proteção Da Biodiversidade). Ministério Do Meio Ambiente. Unidades de Conservação—Amazônia: Flona do Tapajós, 2020. Available online: https://www.icmbio.gov.br/portal/unidadesdeconservacao/biomas-brasileiros/amazonia/unidades-de-conservacao-amazonia/1963-flona-do-tapajos (accessed on 20 July 2020).

- Legislação Brasileira. Decreto nº 98.704, de 27 de dezembro de 1989. Available online: http://www.planalto.gov.br/ccivil_03/decreto/1980-1989/D98704.htm (accessed on 20 July 2020).

- Legislação Brasileira. Decreto S/N de 8 de novembro de 2004. Available online: http://www.planalto.gov.br/ccivil_03/_Ato2004-2006/2004/Dnn/Dnn10350.htm (accessed on 20 July 2020).

- Legislação Brasileira. Decreto nº 2.483, de 2 de fevereiro de 1998. Available online: http://www.planalto.gov.br/ccivil_03/decreto/D2483.htm (accessed on 20 July 2020).

- Gil, C. Como Elaborar Projetos de Pesquisa, 4th ed.; Atlas: São Paulo, Brazil, 2009. [Google Scholar]

- Vergara, S. Métodos de Pesquisa em Administração; Atlas: São Paulo, Brazil, 2005. [Google Scholar]

- Cervo, A.; Bervian, P.; Silva, R. Metodologia Científica, 6th ed.; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2007. [Google Scholar]

- Lakatos, M.; Marconi, A. Fundamentos de Metodologia Científica, 5th ed.; Atlas: São Paulo, Brazil, 2003. [Google Scholar]

- Legislação Brasileira. Norma Regulamentadora 31—NR 31, Segurança e saúde no trabalho na agricultura, pecuária silvicultura, exploração florestal e aquicultura. 2013. Available online: http://www.guiatrabalhista.com.br/legislacao/nr/nr31.htm. (accessed on 4 August 2020).

- Lima, C. Manejo Florestal Comunitário na Amazônia Brasileira: Uma abordagem sobre manejo adaptativo e governança local dos recursos florestais em Reserva Extrativista. Universidade Federal do Pará: Belém, Brasil, 2018. Available online: http://repositorio.ufpa.br/jspui/handle/2011/10424 (accessed on 20 July 2020).

- Johns, J.; Barreto, P.; Uhl, C. Logging damage during planned and unplanned logging operations in the eastern Amazon. For. Ecol. Manag. 1996, 89, 59–77. [Google Scholar] [CrossRef]

- Uhl, C.; Barreto, P.; Veríssimo, A.; Vidal, E.; Amaral, P.; Barros, A.; Souza, C., Jr.; Johns, J.; Gerwing, J. Natural resource management in the Brazilian Amazon. Bioscience 1997, 47, 160–168. [Google Scholar] [CrossRef]

- Uhl, C.; Vieira, C. Ecological impacts of selective logging in the Brazilian Amazon: A case study from the Paragominas region of the state of Pará. Biotropica 1989, 21, 98–106. [Google Scholar] [CrossRef]

- Pearce, D.; Putz, F.; Vanclay, J. Sustainable forestry in the tropics: Panacea or folly? For. Ecol. Manag. 2003, 172, 229–247. [Google Scholar] [CrossRef]

- Leão, R. Avaliação e Otimização do Traçamento da Madeira Tropical: Estudo de Caso no Estado de Amazonas, Brasil. 2012. Available online: https://acervodigital.ufpr.br/handle/1884/27806 (accessed on 20 July 2020).

- Buchmann, M. Exploração Florestal e Seus Impactos em Áreas de Primeiro e Segundo Ciclo de Corte do Manejo Florestal na Amazônia Oriental, Brasil. Master’s Thesis, Universidade de Brasília, Brasília, Brazil, 2016. [Google Scholar] [CrossRef]

- Braz, M.; Mattos, P.; Figueiredo, O. Agricultura de precisão: Resultados de um novo olhar—Manejo de precisão em florestas naturais. Embrapa Florestas 2014, 488–491. Available online: http://ainfo.cnptia.embrapa.br/digital/bitstream/item/113993/1/Agricultura-de-precisao-2014.pdf (accessed on 20 July 2020).

- Nascimento, K.; Emmert, F.; Higuchi, N. Frequência cardíaca para estimativas da carga física de trabalho na exploração florestal. Biofix 2018, 3, 210–215. [Google Scholar] [CrossRef]

- Ackerknecht, C. Occupational accidents footprint: New concept linked to chain of custody in sustainable forest management. Cienc. Trab. 2014, 16, 131–136. [Google Scholar] [CrossRef]

- Basso, V.; Jacovine, L.; Alves, L.; Vieira, L. Influência da certificação florestal no cumprimento da legislação ambiental e trabalhista na região amazônica. Acta Amaz. 2011, 41, 69–76. [Google Scholar] [CrossRef]

- MacDicken, K.; Sola, P.; Hall, J.; Sabogal, C.; Tadoum, M.; Wasseige, C. Global progress toward sustainable forest management. For. Ecol. Manag. 2015, 352, 47–56. [Google Scholar] [CrossRef]

- Fernandes, A.; Guimarães, P.; Braz, E.; Hoelflich, V.; Arce, J. Alternativas de planejamento para a exploração florestal. Floresta 2013, 43, 339–350. [Google Scholar] [CrossRef]

- Robson, L.; Clark, J.; Cullen, K.; Bielecky, A.; Severin, C.; Bigelow, P.; Irvin, E.; Culyer, A.; Mahood, Q. The effectiveness of occupational health and safety management system interventions: A systematic review. Saf. Sci. 2007, 45, 329–353. [Google Scholar] [CrossRef]

- Veiga, J.; Trevisani, D.; Makishi, F.; Abreu, M.; Silva, M.; Zacareli, M. Health and safety standards in labor and extractivism: The case of rural communities in Brazilian Amazon. Saúde E Soc. 2017, 26, 774–785. [Google Scholar] [CrossRef][Green Version]

- Yovi, E.; Nurrochmat, D. An occupational ergonomics in the Indonesian state mandatory sustainable forest management instrument: A review. For. Policy Econ. 2018, 91, 27–35. [Google Scholar] [CrossRef]

| Institution A Workflow | Description of Activities | No. of Workers |

|---|---|---|

| (1) Infrastructure construction consists in removing the vegetation * with a crawler tractor, allowing machines and vehicles to move through the pathways towards the log storage yards. The obstacles are traced with a chainsaw while the trees that hinder the tractor traffic are ripped out. To avoid accidents with tires drilling in machines and vehicles, the cutting and cleaning of exposed roots are also included in this activity. | 01 Crawler tractor operator **; 01 Chainsaw operator; 01 Assistant; 01 Forestry technician. |

| (2) Consists of performing the planned cutting and felling, according to technical guidelines, before crosscutting the top trees ***. | 01 Chainsaw operator (Feller); 01 Helper. | |

| (3) Consists in laying out the area where the forestry tractor will drag the logs. Then all obstacles along the route that may hinder traffic are traced. | 01 Planner 01 Assistant (Planning); 02 Chainsaw operators (crosscutting). | |

| (4) Consists in crosscutting the remaining canopies and logs with a machete or hollow and slicing them to facilitate dragging. Then the logs are dragged with a tractor, which can also be performed by a steel cable with a hook or articulated grapple. At the same time, there is a chainsaw available to trace obstacles, if, by chance, they appear. | 02 Chainsaw operators (crosscutting); 01 Forestry tractor operator; 02 Assistants on the cable (Skidding) **** | |

| (5) Consists of measuring logs and confirming the species in accordance with the chain of custody presented on the harvest map, besides tracking and documenting each step on the packing list. Moreover, the process of sectioning with a sledgehammer and crosscutting the log according to commercial length is also carried out. Then the towers are stacked with a front loader. | 01 Annotator; 02 Chainsaw operators; 02 Measurers; 01 Sledgehammer user; 01 Loader operator. | |

| (6) Consists of loading logs onto trucks, aiming to transport them from the secondary log storage yards to the central yard, where they are unloading and sorted by species. Subsequently, the logs are transported from the central courtyard to industry, according to requirements prescribed by law. | 01 Truck driver 01 Loader operator (secondary yard); 01 Data annotator; 01 Truck driver; 01 Loader operator (central courtyard). |

| Institution B Workflow | Description of Activities | No. of Workers |

|---|---|---|

| (1) Consists in following the vegetation removal guidelines, with the assistance of a tablet and GPS, so that the tractor can remove the obstacles, allowing the traffic of machines and vehicles along the roads towards the log storage yard. The obstacles are traced with a chainsaw. In the end, the helper cuts the exposed roots to avoid accidents with the machines and vehicle tires. | 01 Crawler tractor operator; 01 Chainsaw operator; 01 Assistant. |

| (2) Consists of cutting and felling, according to technical guidelines. | 01 Chainsaw operator (Feller); 01 Helper. | |

| (3) Consists of arranging, in a detailed way, the roads where the logs will be dragged. Additionally, markings and notes are made on the map. | 01 Planner with 01 Assistant. | |

| (4) Consists of carrying out, singly, all the canopies cross-cutting operations. At this step, the logs with machete or hollow, the towers and the obstacles are traced to facilitate dragging through the pathway. | 01 Chainsaw operator; 01 Helper. | |

| (5) Consists in dragging the logs with a forestry tractor, which is carried out exclusively with an articulated grapple. A chainsaw is rarely needed to trace any obstacle on the route at this step. | 01 Forestry tractor operator. | |

| (6) Consists in measuring the logs and confirming the species in accordance with the chain of custody presented on the harvest map, as well as documenting each step on both packing list and section with mark canvas. Additionally, the log is traced according to commercial compliance. Then, the towers are stacked with a loader. | 01 Data annotator; 01 Chainsaw operator; 01 Measurer; 01 Painter; 01 Poster warning worker; 01 Loader operator. | |

| (7) Consists of loading the logs onto trucks, aiming to transport them from secondary log storage yards to the central yard, where they are unloaded and sorted by species. Due to the proximity of the industry, the loading from the central yard to the industry does not always occur, so that the transportation can be performed from the secondary yard to the industry, directly. | 01 Truck driver; 01 Loader operator; 01 Annotator. |

| Institution C Workflow | Description of Activities | No. of Workers |

|---|---|---|

| (1) Consists in following the vegetation removal planning guidelines, with the assistance of a manual map, so that the tractor can remove the obstacles, allowing the traffic of machines and vehicles along the roads towards the log storage yard. The obstacles are traced with a chainsaw. In the end, the helper cuts the exposed roots to avoid accidents with the machines and vehicle tires. | 01 Planner; 01 Assistant; 01 Chainsaw operator; 01 Crawler tractor operator; 01 Assistant * |

| (2) Consists of cutting and felling, according to technical guidelines. | 01 Chainsaw operator (Feller); 02 Helpers. | |

| (3) Consists in setting up the path where the tractor will drag the logs, and then all obstacles to tractor movement along the route are traced. | 01 Planner; 01 Assistant; and 01 Chainsaw operator. | |

| (4) Consists in carrying out a crosscutting operation on the crowns and logs bases with a machete or hollow and sectioning the logs, making the drag easier **. | 01 Chainsaw operator; 02 Helper. | |

| (5) Consists in dragging the logs with either forestry tractor or steel cable with hook/hydraulic claw ***. The chainsaw from the storage yard helps to trace obstacles along the route. | 01 Forestry tractor operator; 02 Cable helper; and 01 Claw helper. | |

| (6) Consists of measuring the logs and confirming the species in accordance with the chain of custody presented on the harvest map. Additionally, each step is documented on both the packing list and section with an aluminium plate inscription. Additionally, the log is traced according to commercial compliance. Then the towers are stacked with a loader. | 01 Annotator; 02 Chainsaw operators; 02 Measurers; 01 Poster worker; 01 Loader operator. | |

| (7) Consists of loading logs onto trucks, aiming to transport them from secondary log storage yards to the central yard, where they are unloaded and sorted by species. Subsequently, the logs in the central yard are loaded onto ferries, using only the front loader, which takes the cargo to the industry by water, as recommended by law. | 01 Truck driver and 01 Loader operator; 01 Data annotator; 01 Loader operator. |

| Institution D Workflow | Description of Activities | No. of Workers |

|---|---|---|

| (1) Consists in following the vegetation removal planning guidelines, with the assistance of GPS and an altimeter map, considering the level curves and location of rocks for the vegetation removal with a crawler tractor, allowing the traffic of machines and vehicles along the roads toward the log storage yard. Obstacles are traced with a chainsaw when necessary. | 01 Planner; 02 Assistant; 01 Chainsaw operator; 01 Crawler tractor operator * |

| (2) Consists of performing the cutting and felling planned, according to technical guidelines, before crosscutting the top trees **. | 01 Chainsaw operator; 01 Helper. | |

| (3) Consists in laying out the area where the tractor will drag the logs. Then, all obstacles along the route that may hinder traffic are traced. | 01 Planner with 01 Assistant; 01 Chainsaw operator. | |

| (4) Consists in crosscutting the remaining canopies and logs with a machete or hollow and slicing them to facilitate the harrow. | 01 Chainsaw operator (Feller); 01 Helper | |

| (5) Consists of dragging logs with a tractor coupled to a steel cable with pyrite. The chainsaw from the storage yard helps to trace obstacles along the route when necessary. | 01 Forestry tractor operator; and 01 Helper. | |

| (6) Consists in measuring the logs and confirming the species in accordance with the chain of custody presented on the harvest map and recording on a tablet using the packing list software section with bar code printing. Additionally, the log is traced according to commercial compliance. Then the towers are stacked with a loader. | 01 Data annotator; 02 Chainsaw operator; 02 Measurer; 01 Poster warning worker; 01 Loader operator. | |

| (7) Consists of loading logs onto trucks, aiming to transport them from secondary log storage yards to the central yard, where they are unloaded and sorted by species. Subsequently, the logs in the central yard are loaded for industry, according to requirements prescribed by law ***. | 01 Truck driver; 01 Loader operator; 01 Controller; 01 Truck driver and 01 Loader operator. |

| Workflow | Description of Activities | No. of Workers |

|---|---|---|

| (1) Consists in removing vegetation and obstacles with a crawler tractor and a chainsaw, allowing machines and vehicles to move through the forest, and construction of roads to allow the flow of personnel, machines, and wood across the forest and yards. | 01 Planner; 01 Crawler Tractor Operator; 01 Chainsaw Operator; 01 Helper. |

| (2) Consists of cutting and felling the previously selected trees, taking into account the natural inclination of trees, the projection of their branches in the canopy, and the spatial distribution of the neighbouring trees. | 01 Chainsaw Operator; 01 Helper. | |

| (3) Consists of carefully planning the path through which the logs will be dragged by a forestry tractor and inserting orientation signs with the aid of coloured ribbons. This path should also be inserted on the planning map. | 01 Planner; 01 Helper. | |

| (4) Consists of carrying out complementary cutting operations, such as the separation of the canopy from the rest of the tree, the separation of the base of the logs, and the shortening of very long logs to facilitate the dragging and the cutting of roots or fallen trees that are obstacles in the paths previously defined for dragging the wood. | 01 Chainsaw Operator; 01 Helper. | |

| (5) Consists of dragging the logs along the planned paths, using a forestry tractor, preferably equipped with an articulated grapple. | 01 Forestry Tractor Operator. | |

| (6) Consists of measuring the diameters and lengths of segments of felled tree logs and dragging them to the storage yard where the wood volume will be estimated. Then, the logs will be accommodated in an organised manner in the storage yards. | 01 Annotator; 01 Chainsaw Operator; 02 Measures; 01 Sledgehammer user; 01 Loader operator. | |

| (7) Consists of the packaging of the tree logs in trucks using a front loader to transport the wood to the central yard and to the industry. | 01 Truck driver and 01 Loader operator; 01 Data annotator; |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lima, K.S.; Meira Castro, A.C.; Santos Baptista, J.; Silva, U. Wood-Logging Process Management in Eastern Amazonia (Brazil). Sustainability 2020, 12, 7571. https://doi.org/10.3390/su12187571

Lima KS, Meira Castro AC, Santos Baptista J, Silva U. Wood-Logging Process Management in Eastern Amazonia (Brazil). Sustainability. 2020; 12(18):7571. https://doi.org/10.3390/su12187571

Chicago/Turabian StyleLima, Killian S., Ana C. Meira Castro, J. Santos Baptista, and Ulisses Silva. 2020. "Wood-Logging Process Management in Eastern Amazonia (Brazil)" Sustainability 12, no. 18: 7571. https://doi.org/10.3390/su12187571

APA StyleLima, K. S., Meira Castro, A. C., Santos Baptista, J., & Silva, U. (2020). Wood-Logging Process Management in Eastern Amazonia (Brazil). Sustainability, 12(18), 7571. https://doi.org/10.3390/su12187571