1. Introduction

The constant extraction of raw materials used for producing low-quality products that are quickly turned into waste jeopardizes the ecological boundaries of the planet by exacerbating natural resource exploitation and environmental degradation [

1]. In light of these ecological crises, policymakers and industry organizations have promoted the Circular Economy (CE) as a path towards sustainable development [

2]. Geissdoerfer et al. [

3] define the CE as a regenerative system that minimizes resource inputs, waste, emissions and energy leakage by slowing, closing and narrowing material flows. This definition was chosen as a starting point for the study since it is brief, operational and emphasizes the benefits of a CE (i.e., minimizes resource inputs, waste, emissions and energy leakage), while at the same time pointing towards the mechanisms in which it can be achieved (i.e., slowing, closing and narrowing). More specifically, closing material flows involves transforming outputs into inputs (i.e., from waste into secondary raw materials) [

4]. Slowing material flows refers to reducing the time that it takes products, materials and components to exit the economic system and become waste, which can be achieved by maximizing and preserving their value [

5]. Lastly, narrowing material flows can be interpreted in two ways: from the production side, it refers to increasing material efficiency of products and services [

6]. From the consumer side, it involves an absolute reduction in consumption [

4].

A transition towards a CE requires systemic changes in the systems of production and consumption, including social practices such as regulations, norms and consumption patterns [

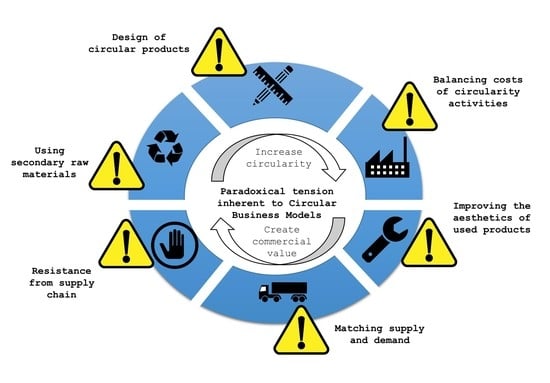

7]. Circular Business Models (CBMs) are considered a tool for planning, organizing and implementing circularity at the firm level [

5]. This makes them particularly appealing to the private sector due to their potential for reconciling circularity (i.e., narrowing, slowing and closing resource flows) and commercial value creation [

8]. This implies not only that economic sustainability is a necessary condition for CBMs, as Guldmann and Huulgaard [

9] emphasize, but that circularity and commercial value creation are intrinsically connected since it is through increasing circularity that commercial value is created.

Creating commercial value through increasing circularity can be achieved in a variety of ways, which leads to a multitude of potential CBMs [

10]. For example, firms that collect and transform waste into secondary raw materials align circularity (i.e., closing material flows) with commercial value creation (i.e., selling secondary raw materials in the market). However, these two elements are not always aligned (reconciled); instead, their relationship can be considered, at times, contradictory. Daddi et al. (2019) shed light to this tension by analyzing firms that utilize waste as a resource in the textile sector in Italy. In their study, they found that the strategy of relying on secondary raw materials (which is positive for circularity since it helps closing material flows) also brought a limitation for the commercial value creation of the company, since it restricts access to specific markets [

11]. This suggest that the relationship between circularity and commercial value is not always in synergy (win-win), but can be found in tension or contradiction (win-lose). Following the organizational theory of Smith and Lewis (2011), this tension should be considered as paradoxical, since circularity and commercial value are not only interconnected but also at times contradictory.

Paradoxical tensions represent a unique challenge for organizations. Compared to static barriers that can be eliminated with the right intervention, a paradoxical tension cannot be suppressed, since the elements that create the tension cannot be removed, instead, these must be continuously managed [

12]. The approach towards managing paradoxical tensions has proven to have a significant effect in regards to their effects on day-to-day operations as well as long-term survival of commercial firms [

13]. For example, in a recent study of sustainable business models, Bommel [

14] found that managers who exclusively understood the three pillars of sustainability (i.e., environmental, social and economic) as synergetic, experienced tensions as constraining and complex to manage. In turn, managers that acknowledged the interconnection and at times contradiction between theseelements of sustainability (i.e., paradoxical), experiencied tensions as sources of innovation that promoted the long-term survival of the business model. Translating these findings into the CBM context, it can be argued that acknowledging the paradoxical relationship between circularity and commercial value creation is a necessary step for transforming this tension into a source of innovation and promote the long-term sustainability of CBMs. It is in this context, the paradox perspective becomes a relevant approach for analyzing CBMs.

Byl and Slawinski [

15] summarize the paradox perspective as an approach that embraces organizational tensions with the aim of understanding how firms can pursue A and B simultaneously, even when A and B appear contradictory. Several studies analyze (in different degrees) CBMs from a paradox perspective, including Daddi et al. [

11]; Franco [

16]; Vildåsen [

17]; Tong et al. [

18] and Prendeville et al. [

19]. Overall, the brief literature available confirms that CBMs are subject to multiple tensions emerging from the paradoxical relationship between circularity and commercial value creation. A critical reading of these studies shows that they do not provide an overview of paradoxical tensions, nor the management strategies that are suitable for dealing with them. These studies also focus on a single type of CBM (i.e., manufacturing companies using secondary raw materials), missing a wide variety of other CBM such as those focusing on extending the value of existing products. Moreover, they fail to incorporate knowledge from related research streams to CBMs that might be useful in providing insights in regard to paradoxical tensions such as Product-Service Systems [

20], business models for sustainability [

14] or sharing-economy platforms [

21].

Aim of the Study

Upon this background, this study aims to explore paradoxical tensions and management strategies in the context of CBMs. In order to drive this investigation, two main research questions (RQ) were formulated:

RQ1: What are the main paradoxical tensions and management strategies addressed in CBM literature and related fields?

RQ2: What paradoxical tensions and management strategies emerge in the practice of CBMs?

RQ1 is answered through an integrative literature review, which is presented in

Section 2. As Snyder [

22] explains, integrative literature reviews are recommended when addressing emerging topics scattered across disciplines, such as the case of CBMs. These types of reviews are not intended to provide an exhaustive and systematic overview of a well-defined topic, instead, they are used to create an initial and preliminary theoretical model upon which research can be built.

RQ2 is answered based on data collected through an empirical study of CBMs, specifically from eight commercial firms from North Europe operating in different industries (e.g., food-based industries, construction, furniture, etc.) and occupying different positions in the supply chain (e.g., manufacturer, service provider, remanufacturer, etc.). Details of the empirical study are described in

Section 3. The overall conceptual framework of the paper is depicted in

Figure 1 emphasizing the integration of knowledge derived from literature and practice in order to provide a comprehensive initial perspective of paradoxical tensions in CBMs.

The main contribution of this investigation is twofold. Firstly, it presents novel empirical evidence of paradoxical tensions inherent to CBMs. Secondly, it offers a literature-derived overview of the paradoxes and management strategies relevant in the context of CBMs. The literature review also helps consolidate a diffused stream of academic work and set a baseline for further studies. Overall, this study sheds light on the complex relationship between circularity and commercial value in the context of CBMs, the tensions that these two elements generate and the management strategies used to cope with this tension.

2. Literature Review

In order to locate and analyze studies that focus on paradoxical tensions in the context of CBMs, a systematic approach for reviewing the literature was required. The review protocol was designed following methodological recommendations from Tranfield, Denyer and Smart [

23]. Itstarts with the following guiding question

What are the main paradoxical tensions and management strategies discussed in the context of CBMs and related business models? With that question in mind, an appropriate literature review strategy—which is depicted in

Figure 2—was defined. The search was last revised in May 2020.

The keywords selected for the search include “paradoxical tension” OR “tension” since this is the main theoretical concept being sought. Moreover, “contradiction” OR “dilemma” were introduced as these are some of the colloquial synonyms of paradoxical tensions. These were incorporated in order to capture studies that may not be aligned specifically with paradox theory, yet they have analyzed “paradoxes” nevertheless. Using different terms is important since, as found by Luisa and Gold [

24], the concept of paradoxical tension is not always used consistently across studies.

These four keywords were matched with the AND function of the search query to determine the context of the study, that is, Circular Economy. Additionally, sustainable business models were incorporated since CBMs are often conceptualized as one type of sustainable business model [

10]. Moreover, the keyword “Product Service System” (PSS) was added since, as Rosa, Sassanelli and Terzi [

25] identified, PSSs are the most common manifestations of CBMs in practice. Based on the keywords selected, 189 potential studies were identified.

The titles and abstracts of each of these 189 studies were screened in order to determine if the study fulfilled one of the exclusion criteria. This process led to the final sample of the articles included in the review. These studies were analyzed by framework analysis, a technique that is focused on systematically extracting specific data from a text in order to answer the guiding question of the review [

26]. The main elements extracted were paradoxical tension and management strategies.

2.1. Paradoxical Tensions and Management Strategies in the Context of CBMs

After analyzing the final sample of studies located through the review protocol, the studies were arranged in three main groups: Sustainability, Servitization and Circular Economy.

Table 1 displays the composition of each group, including a brief description of the main paradox and the studies included. The main paradoxes and strategies included in each group are described below. Each section includes a summarizing table that aligns paradoxes, sub-tensions, strategies and references.

2.1.1. Corporate Sustainability

The corporate sustainability group is comprised of studies addressing a variety of tensions that emerge when traditional enterprises or sustainable business models aim to create environmental, social and commercial value simultaneously [

28]. Bommel (2018) identified that the main paradox is experienced as a conflict between expectations from shareholders (commercial objectives) and demands from stakeholders (social/environmental objectives). Examples of strategies for managing these tensions include creating governance structure, such as socio-commercial enterprises, in which multiple objectives are equally desirable [

27]. Similarly, Riel, Mcginnis and Phillips (2019) frame the main sustainability tension in the form of incompatible strategies related to exploitation vs. conservation of resources. Exploitation leading to maximizing shareholder value in the short term, while conservation leading to maximizing stakeholder value in the long term. Haffar and Searcy (2019) concluded that reflexivity, structured decision making and target settings were some of the main actions that could be used to successfully cope with the sustainability paradox.

Hahn et al. (2015) elaborated further on the sustainability paradox and identified sub-tensions, for example, the requirement of fundamentally changing business practices (e.g., new business models) while at the same time retaining legitimacy (e.g., isomorphic pressures) with regard to other value chain members. In regard to this sub-tension, Schneider and Clauß (2019) found that firms managed this tension by accepting the limitations they have self-imposed by pursuing a socio-ecological goal and creating an identity that is consistent with their mission, which provides them with legitimacy amongst other like-minded external actors. Another sub-tension derived from this context refers exclusively to the goal of promoting sustainability in “controversial industries” whose main economic activity is considered detrimental in social or environmental terms, for example, fossil fuel or soft-drink industries. In this context, two studies analyzed defensive strategies aimed at avoiding or externalizing this tension, Iivonen (2018) focused on projection strategies whilst Ferns, Amaeshi and Lambert (2019) explored mythmaking. The different sub-tensions derived from the broader sustainability paradox are listed in

Table 2.

2.1.2. Servitization

Servitization can be understood as a business strategy in which a manufacturer expands its main value proposition from tangible products to intangible services [

38]. From this broad business strategy, a unique niche of studies has emerged focused specifically on understanding and devising strategies for dealing with the so-called

servitization paradox. The earliest study found was by Visnjic and Looy (2013), which explored the disconnection between expected and actual economic benefits for firms following a servitization strategy. More recently, the servitization paradox is described by Kohtam (2020) as the tension between effective customization of the value proposition vs. efficiency in the production process. Sjödin et al. (2020) explain that firms cannot focus only on increasing their value proposition (by adding services) they need to also lower their costs by simultaneously increasing their efficiency in production, which essentially requires them to follow two separate and often times contradictory) logics.

In order to overcome this paradox, literature offers several management strategies. Kuijken, Gemser, and Wijnberg (2017) suggest three characteristics for designing an effective PSS. Firstly, combine products and services that, at least in theory, have autonomous value on the market. Secondly, emphasize both the degree of the tangibility of the product element and the level of interaction in the service element. Thirdly, the value of the product and service should be synergetic (larger than each element separately). For their part, Li et al. (2018) emphasized that a modular portfolio of the service layer in the PSS allows manufacturers to achieve both objectives simultaneously; therefore, they propose a methodology for developing and evaluating modular services in PSSs. Lastly, Sjödin et al. (2020) elaborated upon a methodology for agile co-innovation as a potential pathway for developing effective PSS solutions.

Kohtam (2020) elaborated further on this topic and identified that the main servitization paradox (customization vs. efficiency) spurs more paradoxes (referred in this study as sub-tensions), namely: customer orientation vs. engineering mindset; integration vs. separation of products and services; exploratory innovation in solutions vs. exploitative innovation in product manufacturing. Kohtam (2020) also outlines unique management strategies for each of the sub-tensions. These are described in

Table 3.

2.1.3. Circular Economy

The last group of studies addresses several tensions that emerge in the context of value allocation between different actors involved in recycling systems, using waste raw material as the secondary raw material and designing products following eco-design. Related to product design in the context of CBMs, is the work of Prendeville et al. (2017) which studied four product-development processes in which eco-design practices were involved. Prendeville et al. (2017) identified several challenges that they categorized as tensions (i.e., two incompatible design strategies), hierarchies (i.e., preclusions and synergies between different eco-design strategies) contradictions (i.e., paradoxical outcomes of a design strategy) and oversights (i.e., emphasis on one eco-design strategy disavows other potential synergetic strategies). As mentioned before, Daddi et al. (2019) explored the tension of transforming waste into raw materials in the context of Italian textile companies. This tension was also explored by Vildåsen (2018) although this longitudinal study did not take place in the practice of CBMs, but rather in the process of developing one. Lastly, Tong et al. (2018) highlight the dilemma between excluding the informal sector vs. integrating informal collection channels in the process of developing recycling business models in China.

These studies not only identified tensions, but also management strategies, as outlined in

Table 4. Particularly, the companies analyzed by Daddi et al. (2019), relied on strategies used to reduce the economic impact of circularity by improving the quality of the secondary raw materials or enhancing their selection and sorting procedures. For their part, the main strategy suggested by Prendeville et al. (2017) for systematically managing the eco-design challenges was increasing the scope of focus from product characteristics to business models in order to contextualize the decision-making process and overcome the various dilemmas identified.

4. Results

The tensions experienced in the practice of CBMs are analyzed in this section.

Table 7 provides an overview of the main tensions experienced and the management strategies used to cope with these tensions. Each theme is presented in detail below.

4.1. Using Waste as a Resource

Using waste as a resource represents a positive element in terms of increasing circularity; however, it can generate tensions for commercial value creation due to difficulty achieving industrial standards related to product characteristics. This is the case of AG, which is focused on creating bio-based textiles as an alternative for high-end leather in the fashion industry. The main tension experienced in this case is due to product requirements from the fashion industry, particularly an expectation that the material does not have a “plastic feeling”:

(…) it’s hard to be at the market, especially when you want to work on these constraints—which is using food waste to make a valuable product (…) coming from this angle, everything that we are doing is circular but we give ourselves several constraints in production where we won’t use any fossil fuel derived ingredients, and we won’t produce outside of Europe.

In order to manage this tension, two strategies were followed; on one hand, they continue improving the functional characteristics of their product to meet industry standards, and on the other hand, they also remain open for finding more suitable markets for their product. These management strategies of AG involve displays a both/and approach, aiming to continuously develop the technical characteristics of their product and the non-technical elements of their business model.

Moreover, secondary raw materials can also generate unstable supply chains that make it difficult to achieve high efficiency levels in production and logistics, which increases the overall costs of manufacturing. Such tension was experienced in case SK, which is focused on making meals based on recovered or donated food. As such, their sourcing is not homogenous; which has two major implications in relation to operational efficiency. Firstly, it is not possible to have standardized menus and preparation practices, instead new meals are continuously designed to match their incoming raw materials. Secondly, recovered food requires increased pre-treatment before preparation. These two conditions imply that any cost advantage obtained due to savings in materials is countered by the requirement of additional employees, compared to traditional restaurants/catering service providers, where raw materials are bought directly from wholesalers which have already passed a pre-sorting process and have homogenous characteristics (variety, quality, size, etc.).

4.2. Designing Circular Products

Even if waste is not the main raw material, designing products for CBMs can create tensions, particularly, whenever a product requires to be designed to meet specific aesthetic considerations while at the same time remaining standardized so it can be circulated after its initial use. This tension emerged from the case of AC, which is focused on producing signage that can be reused and upgraded. Designers from AC require to simultaneously design for standardization and customization, two apparent contradictory strategies. In order to manage this tension, they followed a modularity strategy, in which some parts of their products where standardized whilst others allowed for customization. This allowed them to apply their aesthetic design competences while at the same time manufacture products with the potential for further circulation after their first use. As explained by the owner from AC:

That’s also very important thing for us. The components that we are updating, those components we want to make in the same size. Very low grade of variables. But the signs that would be a part of the building (…) those could be more unique if we need to. And that’s important for us, not to lose our design competence and making signs that are attractive because we don’t want all signs to look alike. We also want harmony with architecture.

Designing products for a circular economy is an ongoing challenge, as designers must find ways to continuously develop new products that are suitable for circulating. In order to deal with this tension, designers require unique skills that can be acquired through formal education; however, based on case SA, which is a firm focused on facilitating the refurbishment of furniture, a different strategy focused on learning by doing was identified.

This strategy consisted of overlapping the roles between designer and refurbisher, as elaborated in the following quote:

(…) when they are taking old furniture and making them look like new, they are also learning how to construct new furniture proofed for recycling. So the same crafts, the same people who are making new furniture, they are also making this recycling.

SA acts as a type of supply chain coordinator, connecting potential refurbishment customers with companies capable of performing this service, they are not always exclusively remanufacturers, but they also produce and manufacture new furniture. This facilitates the overlap of roles between designer and refurbisher, however, based on the experiences of SA, there is no evidence that suggests that this strategy of role overlap cannot be translated into the context of a single firm and represent a useful management strategy for developing useful skills in the design of circular furniture.

Overall, product design presents different tensions including traditional design challenges (modular design for standardization and uniqueness) or due to specific constraints imposed by the firm due to the nature of the business model, for example, relying on waste as a raw material. Coping with these tensions requires skilled designers that are able to apply their aesthetic capabilities while still developing products suitable for circulation.

4.3. Improving the Aesthetics of Used Products

Multiple firms emphasized that extending the value of products, involved not only restoring or increasing their functional capacity, but also upgrading their aesthetics since product obsolescence, or a perceived loss of value from products, is not only related to functional, but also to aesthetic elements. This was identified across product groups, including furniture, lighting fixtures and signage. As the manager from SA explains:

(…) is very conceptual. I think that is why we are throwing all that furniture away, is conceptual and it becomes garbage because of how they look.

For traditional manufacturing companies, aesthetic improvement can be resolved through specialized design methodologies applicable in the early stages of the product design; however, not all CBMs are involved in design and manufacturing, instead some are constrained to working with existing (obsolete) products. In such cases, where the company that is operating the CBM is not directly involved in the design and manufacture of new products, a unique tension emerges in the quest to simultaneously upgrade functionality and aesthetics without relying on traditional product design methodologies.

As the interviewee from FL, which are focused on upgrading lighting fixtures with energy-efficient technology, expresses:

We mostly do technology upgrade but what we also want to be able to do is upgrade the design (…) lot of customers, we found out, they want something new to look at also, they don’t want to look at the same fixtures that they’ve looked at the last 20 years, they want to see something happening with the lighting as well, that is why we want to be able to upgrade the design also but still reuse as much of the materials as we can.

One strategy found from the furniture industry sector (in both the cases of SA and HB) is focused on simply exchanging some components of the product, this can be related to paint, textiles and even the size of the furniture, so it is no longer considered old, but classic yet with a contemporary aesthetic. However, not all product groups are suitable for this strategy, for example, if a product is not modular, it would be impossible to exchange some of its components.

In some cases where the potential for an aesthetic upgrade is limited, changing the context of use represents a useful alternative. This strategy consists of taking an old product from one context and placing it in a different context in order to provide new aesthetics with non-new products. For example, in the case of FL, they take lighting fixtures from demolishing buildings, retrofit them with energy-efficient technology and place them at another building, in order to provide the sense of new aesthetics (with old fixtures).

Changing one product into another context might solve the aesthetics tension. However, this spurs an additional tension of efficiently matching supply and demand, as expressed by the informant from case FL:

(…) demolishing companies (…) have actually already started to provide us with decent fixtures. The difficult part is to match the supply and demand to make sure that the fixtures that we get are actually the fixtures the customer wants to buy.

This reinforces the paradoxical nature of tensions in CBMs, which cannot be overcome or circumvented but continuously managed, not only because they are re-emergent in time, but also because the management strategies used to cope with one tension are the seeds for additional emergent tensions.

4.4. Matching Supply and Demand

Some CBMs are focused on matching the supply and demand for used products or secondary raw materials. This process requires to be carried out as fast as possible due to two main factors: (a) difficulty or impossibility of storage and transportation; or (b) residual value drainage.

The first factor was identified in cases related to furniture refurbishment (HB and SA), where the capacity for storing and transporting used furniture decreases significantly since the volume occupied by used furniture is much larger compared to new un-assembled furniture. In order to deal with this tension, these two cases both emphasized the importance of pre-sorting or accepting donations of furniture that they believe can have enough residual value. Each of the cases can help illustrate different approaches for this pre-sorting process, HB focused on “on-site” pre-sorting, which took place in the facility of their customers. In the case of SA, this pre-sorting was remote, since customers followed a specific process of furniture identification and uploaded pictures onto their website.

While this first tension was identified in the furniture industry, the construction sector epitomizes this tension where the volume of the waste construction materials makes it almost economically unfeasible to transport and store waste materials, even if their functionality or aesthetics remain intact. This creates a need for a virtually simultaneous match of supply and demand, as explained by the senior partner of SU, which is an architecture and design firm specializing in circular economy projects:

The good thing about building materials is that they are already relatively known to the market and if you don’t change that much to them, they can easily be re-adopted, but the problem is that they have a certain time-limit because the building has to be demolished within a certain time frame. So, it’s quite difficult to find the application within that time restriction.

In the case of SU, part of the value proposition (and value creation tool) is a digital platform where the material flows in a region are displayed. This tracking of regional flows through the use of digital technologies is aimed to reduce transaction costs and promote the close of loops between waste and raw materials.

The second factor that creates a tension in matching supply and demand is related to the fast decline in the potential value of certain products, such as used ICT equipment (e.g., computers, mobile phones, etc.) This tension was explored in the case of RF, which is focused on acquiring used ICT equipment, refurbishing it and selling it. In a few words, due to the market dynamics of new ICT equipment, characterized by low prices and exponential increases in computing capacity, even accepting a donation of a five-year-old computer (still with significant functional value) represents a cost for refurbishing companies, since it will not sell. Instead, it is only suitable for recycling. This tension sheds light on the importance of acquiring recent products for refurbishing companies, not just functional, and that product obsolescence is related to social perceptions and not just the physical properties of a product.

4.5. Balancing Costs in Circular Activities

CBMs focused on restoring the value of used products are characterized by constant tensions of keeping management costs below the level of the residual product value. This is particularly challenging in North European economies, where salary costs are relatively high since value extension activities such as refurbishment and use of secondary raw materials can be labor-intensive activities. The following quote from the case HB, which collects and refurbishes furniture, summarizes this tension:

The biggest balance is that we don’t spend too much labor cost on refurbishing or replacing, there is a tipping point of course when it won’t be feasible to put up a tabletop and sell it because we have spent too many hours on doing it (…) we have to very aware. That is also, why these single furniture pieces are very hard to manage because it does not take a lot to reach that tipping point.

The quote not only points towards the tension of keeping management costs down but also towards a management strategy—that is increasing the homogeneity of the products refurbished. This can be achieved, as in the case of SA, by focusing on specific sectors for sourcing such as hospitals, schools, public offices, etc., which are characterized by larger volumes of homogenous products that help with keeping product management costs down.

Another management strategy for dealing with this tension was displayed in the case of HB. This strategy consisted of reducing salary costs and creating additional revenues by operating as a socio-economic enterprise that provided educational and training services to their employees through furniture refurbishment activities. However, as time passed and the structure of the firm change, and the socio-economic enterprise was transformed into a traditional commercial company, which resulted in anan increase in salary costs and loss of revenue from the educational services. This increased the pressure related to keeping operational costs at a minimum. However, since employees have acquired skills during their time in the training program, it allowed them to be more efficient in their tasks, particularly of pre-sorting and identifying which furniture should be destined for recycling, donation or refurbishment. These developed skills allowed HB to balance operational costs with increased efficiency.

The case of SK also displayed this tension as well as reported a different management strategy. In order to reduce time and costs, both for SK and their partners, they establish long-term collaborations with supermarkets which allowed SK to standardize logistics procedures and, at the same time, secure a steady intake of raw materials. Developing partnerships for business models that rely on periodic donations or sales of used products was also identified as a strategy in RF. The disposal cycles from food may be weekly, whilst ICT equipment may take 2–3 years. Nevertheless, ICT refurbishment companies also aim to establish long-term collaborations, which would help guarantee a steady (and homogenous) inflow of used equipment.

Some services offered by CBMs can create value for customers and increase circularity; however, they are unable to generate sufficient commercial value to be maintained. Such was the case of AC, which explored the implementation of a take-back service in order to collect signage from their customers to use in other locations. They quickly realized that the costs of the service overtook the potential value captured. As explained by the owner:

(…) We have looked into that [take-back system], and we were first looking for a model where we wanted to say that without any charge we would take the sign, dismount the sign. Unfortunately, there are too high costs in these actions, many times you have to go with a sky lift, permissions to the municipality and so on, so there is a gap between the value of the sign compared to the actions required.

The manager of AC considered that a take-back service of signage was not economically viable due to increased management costs. Therefore, the take-back service was suspended; instead, they changed target customers, from individual users to facility owners. Essentially, increasing their scope from selling single signs to selling signage systems for infrastructures. This way, AC could reduce the movement of the signs from one location to another, and instead provide upgrade services at a facility level and keep logistics costs down.

4.6. Managing Resistance from the Value Chain

One tension that was brought up in several cases was related to resistance from suppliers and customers to the novelty of the practices involved in CBMs. This resistance was attributed by the informants, not to the inferior quality or performance of the value proposition, but to the fact that CBMs represented unfamiliar practices to their customers and other actors across the value chain. For example, the value proposition of FL, refurbishment of lighting fixtures, clashed with dominant practices of engineers in charge of infrastructure lighting:

This is a totally new way of doing lighting and especially it’s engineers that are quite skeptical when we introduce our solutions (…) because they are just used to buying new fixtures all the time, so that is often a huge barrier for us (…) for them it is something new that they have to find out how to handle, of course, is also some extra work for them, and that is why often we struggle.

In terms of management strategies, evidence from case SK suggests two approaches for dealing with the initial resistance to innovative practices. On one hand, SK has found that organizations that share a similar ideology (e.g., stores focused on organic food) are somewhat “natural allies” and collaborations are easier to set up. Furthermore, they have focused on establishing formal collaborations mediated through legal contracts that transfer all liability from the supermarket to SK in case there would exist some health impact to one of the customers of the market.

5. Discussion

In this section, paradoxical tensions and management strategies are discussed. The discussion is structured as follows:

Section 4.1 addresses paradoxes and management strategies that overlapped, both in the literature review and in the empirical study.

Section 4.2 focuses on tensions and strategies found only in the empirical study, which can be considered as novel theoretical constructs in the field of CBMs. Lastly,

Section 4.3 focuses on tensions and management strategies found only in the literature review but empirical evidence was not available for their comparison.

5.1. Tensions and Strategies Found in the Literature and Empirical Study

Using waste as a resource was the main paradoxical tension explored by Daddi et al. (2019). This tension was confirmed in the empirical study, since product competitiveness was found to be in partial contradiction with using secondary raw materials, or in other words, in contradiction with circularity. However, this finding was not only confirmed but also expanded, since product characteristics were not the only element that created tension when using waste as a raw material. Based on the cases reviewed, it was found that secondary raw materials also put pressure on management and production processes, even if equal product characteristics can be achieved compared to “non-circular” products. Particularly, operational inefficiency can result from a non-homogenous source of raw material, which can create complex logistics or additional sorting and pre-treatment requirements.

By expanding the scope of the tension, contradictions between circularity and commercial value creation become salient in other elements of the business model, such as value creation mechanisms (i.e., production processes). This creates a bridge with the literature stream of product–service systems studies where Kohtam (2020) concluded that managers should avoid either/or mentalities when thinking about customization and efficiency of product operations, but instead should accept the tension between them and embrace both the need to increase customization as well as creating unique solutions. Translating this into the context of CBMs can be interpreted has exhorting managers to expect and embrace the tension that using waste as a raw material would inherently generate. This also opens the opportunity, for managers to find ways to achieve both objectives simultaneously, that is, continue using secondary raw materials yet, at the same time, find mechanisms for improving the efficiency in production, including end-product characteristics and efficient logistics.

The empirical study also pointed out management strategies used for coping with the various tensions arising from using waste as a raw material. Some of them were already found in the literature reviewed, for example, investments on improved sourcing and homogeneity of raw material [

11]. Moreover, flexibility in terms of market segments and manufacturing processes proved crucial for managing this tension. These strategies were already suggested in the study of Birrell et al. (2018) which poses that resource fluidity, which is defined as the capacity for swift reconfiguration of business systems, is a key characteristic for coping with paradoxical tensions in organizations that require them to simultaneously pursue efficiency and customization.

As argued by Prendeville et al. (2017), some of the main tensions experienced in applying an eco-design methodology cannot be resolved unless the scope of analysis is expanded from single product characteristics to business models. This same approach was observed in the case of AC, where the company transitioned from selling single signs to individual consumers, to selling signage systems to building managers. This change was instrumental in balancing economic value creation with circularity and confirms the management strategy suggested by Prendeville et al. (2017), where a change in value proposition can become a tool for coping with a paradoxical tension. The change not only allowed the company to deliver circularity (i.e., upgradable signs) but it also reduced costs in the process of delivering the value proposition (i.e., avoiding the moving costs of signs from customer to customer).

As elaborated in

Section 2 of this study, supply chain resistance has been identified by Hahn et al. (2015) as one of the sub-tensions that emerge whenever a company aims to create environmental, social, and commercial value simultaneously, in other words, as part of the sustainability paradox. The cases analyzed in this study confirm that CBMs indeed face resistance from the value chain due to what appears to be the innovativeness of their practices, not a reduction in quality and functionality. By itself, this finding is far from surprising, however, by doing a cross-case analysis, it was possible to identify patterns behind this resistance. In particular, the evidence suggests that resistance displayed towards the different CBMs is derived from different factors, including formal, informal and underlying assumptions. For example, case SK reported that “the biggest challenge is the health regulations on the governmental level in Sweden, which are really high, too high”. The informant from case SU stated, “the problem with many materials is they have not been researched for the specific purpose that we want to apply them to (…) if a certain material does not have fireproof regulations it needs to be tested first”. In turn, case TU, which is a traditional convenience store offering everyday household products in bulk and free of packaging, expressed the following:

The main difficulty is to educate people and encourage them that this is not difficult. Also, of course, there are a lot of people who would never be satisfied with this kind of shop (…) they find that products in bulk are not hygienic. They need everything to be sealed, wrapped, closed in their own package. Only then do they feel safe.

This type of resistance appears to be derived not from authority guidelines, but from taken-for-granted assumptions and cognitive frames of reference. This differentiation between the sources of resistance has significant implications regarding how to manage and promote the acceptance of CBMs.

5.2. Tensions and Strategies Found Only in Empirical Study

Firms focused on extending the value of products through repair, refurbishment and resell face a constant tension between balancing the value that can be created based on used products and the potential costs involved in creating this value. Managing this tension requires firms to focus on multiple aspects simultaneously including (a) assessing how much residual value is left in products they acquire or accept as donations; (b) estimating the potential value that can be re-loaded into these products through repair and refurbishment activities; and (c) reducing product handling costs in order to avoid overtaking the potential value of the product.

In order to manage this tension, firms can apply management strategies specifically addressed to each element. For example, lowering product-handling costs by improving their used product valuation mechanisms. This can improve the accuracy of calculating the residual value of used products. These types of practices can already be seen in mature circular markets, such as the automobile industry and in ICT equipment, however, they need to be improved and expanded for other industries such as furniture. Furthermore, increasing the homogeneity of the incoming used products can also reduce management costs since it allows standardization in repair processes. This can be achieved by focusing on product groups that are homogenous and come in large volumes such as furniture or ICT equipment from large corporations or public sector organizations.

Moreover, alternative governance structures such as the socio-economic enterprise model were also identified as a potential strategy that can reduce costs, particularly for CBMs with labor-intensive activities such as furniture refurbishment. This strategy of alternative governance structures has already been mentioned by Hahn et al. (2015) as a potential strategy for dealing with performance tensions in the context of corporate sustainability; however, it has not yet been translated in the context of CBMs, nor has its potential been highlighted as a strategy for cost reduction and simultaneously creating social value.

Firms can also focus on developing medium and long-term partnerships. This strategy is similar to the findings of Schneider and Clauß (2019), which found that sustainable business models rely on a network of stakeholders that share their beliefs and facilitate the value creation process. The cases analyzed in this study suggest that partnerships provide stability to CBMs since they guarantee that eventually or periodically, they would have access to a certain amount of (valuable) products or secondary raw materials. These types of partnerships are common in periodic collaborations, for example, in the form of weakly donation of food waste from supermarkets or restaurants to CBMs focused on using waste food as raw material. However, this approach also shows the potential to be applied to waste streams whose expiration data can be calculated in the mid- to long-term future, such as server farms, windmill blades or materials from building demolitions. If the timeframe for the end-life of these waste streams can be calculated, then they can provide a significant opportunity to firms since it would guarantee a pre-defined income of valuable products around which a CBM can be modeled.

5.3. Tensions and Strategies Found Only in the Literature

Based on the literature review it was possible to identify two main groups of research that addressed paradoxical tensions and management strategies relevant to CBMs. Firstly, corporate sustainability literature represents the largest academic field related to CBMs that has embraced the notion of paradoxical tensions. It analyzes both sustainability initiatives from firms, as well as full business models focused on the triple bottom line (environmental, social and commercial value creation) [

14]. It is relevant for CBMs since these are aimed to create commercial value and promote circularity, which in some conditions, can be equated to creating environmental value. Moreover, if the social element of sustainability is incorporated into CBMs, then additional tensions related to the social effects of CBMs would gain importance, such as governance structures of CBMs (e.g., cooperatives, social enterprises, etc.), worker–employee relationships and distribution of benefits.

For its part, servitization literature provides relevant insights regarding tensions experienced in the process of adding intangible services to tangible product offerings. While the discussion of these tensions is limited to the economic aspect of the business model, it remains relevant in the context of CBMs since commercial value creation is intrinsically connected to circularity. As the empirical data suggest, CBMs struggle to balance increasing costs with circularity, which resembles the servitization paradox. CBM research could take inspiration from this literature and focus on an in-depth exploration of a paradox which, in turn, would allow to break it down into sub-tensions, just as Kohtam (2020) did in their study. Moreover, CBM research would also benefit from a combination of research methods (i.e., qualitative and quantitative) similar to how the servitization literature has done. Particularly qualitative methods, such as in the case of Sjödin et al. (2020), help in the conceptualization and building of models for understanding the paradox, whilst quantitative methods, such as in the cases of Kuijken, Gemser and Wijnberg (2017) or Li et al. (2018), offer a suitable approach for the evaluation of management strategies.

6. Conclusions

The point of departure of this study was that CBMs experienced paradoxical tensions, either in the process of designing circular products [

19] or when manufacturing products using secondary raw materials [

11]. By incorporating literature and practice insights, it was possible to not only explore and further detail these paradoxes but also identify additional paradoxical tensions (and management strategies) relevant in the context of CBMs.

From the literature review, it was possible to identify two academic fields that can help understand paradoxical tensions in the context of CBMs. Firstly, the corporate sustainability literature explores the sustainability paradox, which emerges when firms aim to generate social, economic and environmental value simultaneously. Secondly, a niche in the literature of product–service systems explores the servitization paradox that focuses on the disconnect between expected and actual revenues of firms transitioning from product-based to service-based value propositions. This well-defined niche in the literature is past the stage of conceptualizing and, instead, is focused on the evaluation of potential management strategies.

Through the empirical study of nine firms operating a wide variety of CBMs, it was possible to identify novel paradoxical tensions relevant to CBMs, namely, improving the aesthetics of used products, matching supply and demand and balancing costs of circularity activities. These three tensions were mostly relevant in the context of CBMs that extend the value of used products (i.e., slowing resource flows), which in the past have been overlooked compared to recycling business models. The cases analyzed suggest that, depending on the circularity approach followed by the CBM, different tensions will be experienced, and a variety of management strategies will gain importance. Some of these strategies are technology-focused (i.e., using digital technologies to reduce transaction costs), others, related to innovation in “softer” elements of the business models such as changing target customers or expanding the scope of the value proposition from product to service offerings. However, none of the management strategies identified in this study eliminate the tensions, but instead help managers cope with the continuous effects these create. This initial exploration of tensions and strategies offers but a superficial glimpse into the journey of each individual CBM.

One of the main limitations of the study is that empirical data collection relied purposely on an interview-based study whose main goal was not specifically designed to analyze and explore paradoxical tensions and management strategies, but rather to understand the advantages and disadvantages of CBMs in comparison to linear models. Considering this limitation, future research could rely on in-depth longitudinal studies to analyze the identification, management and re-emergence of specific tensions in a single case. This would allow deeper engagement with the causes and variety of management strategies related to a specific paradox.

Another limitation is related to the sampling approach in which product-groups and types of CBMs were pre-defined. This means that the paradoxes and management strategies identified are not applicable to all types of CBMs, nor all industries or product groups. However, since the objective of the study was to conduct an initial exploration, this sampling bias is considered acceptable. Future research could follow different sampling approaches, such as cluster sampling, in order to analyze in depth one type of paradox relevant to unique value chains or industries. This could obtain different perspectives from the same phenomenon and provide a more comprehensive analysis of a single tension or strategy.

Overall, by analyzing CBMs from a paradox perspective, it was possible to shed light on the challenge (and the ways firms cope with this challenge) of reconciling two interconnected, yet at times contradictory, objectives in a single business model: increasing circularity and creating commercial value. This study advances the theoretical understanding of CBMs by offering a nuanced understanding of the relationship between circularity and commercial value creation, a perspective that is necessary for the successful management of CBMs.