Opaque Ventilated Façade (OVF) Thermal Performance Simulation for Office Buildings in Brazil

Abstract

1. Introduction

2. Opaque Ventilated Façades (OVFs) with Natural Ventilation

3. Methodology

3.1. Climatic Conditions Analysed

3.2. The Building Model (Case Study/Building Simulation)

3.3. Thermal Comfort in Brazilian Office Buildings

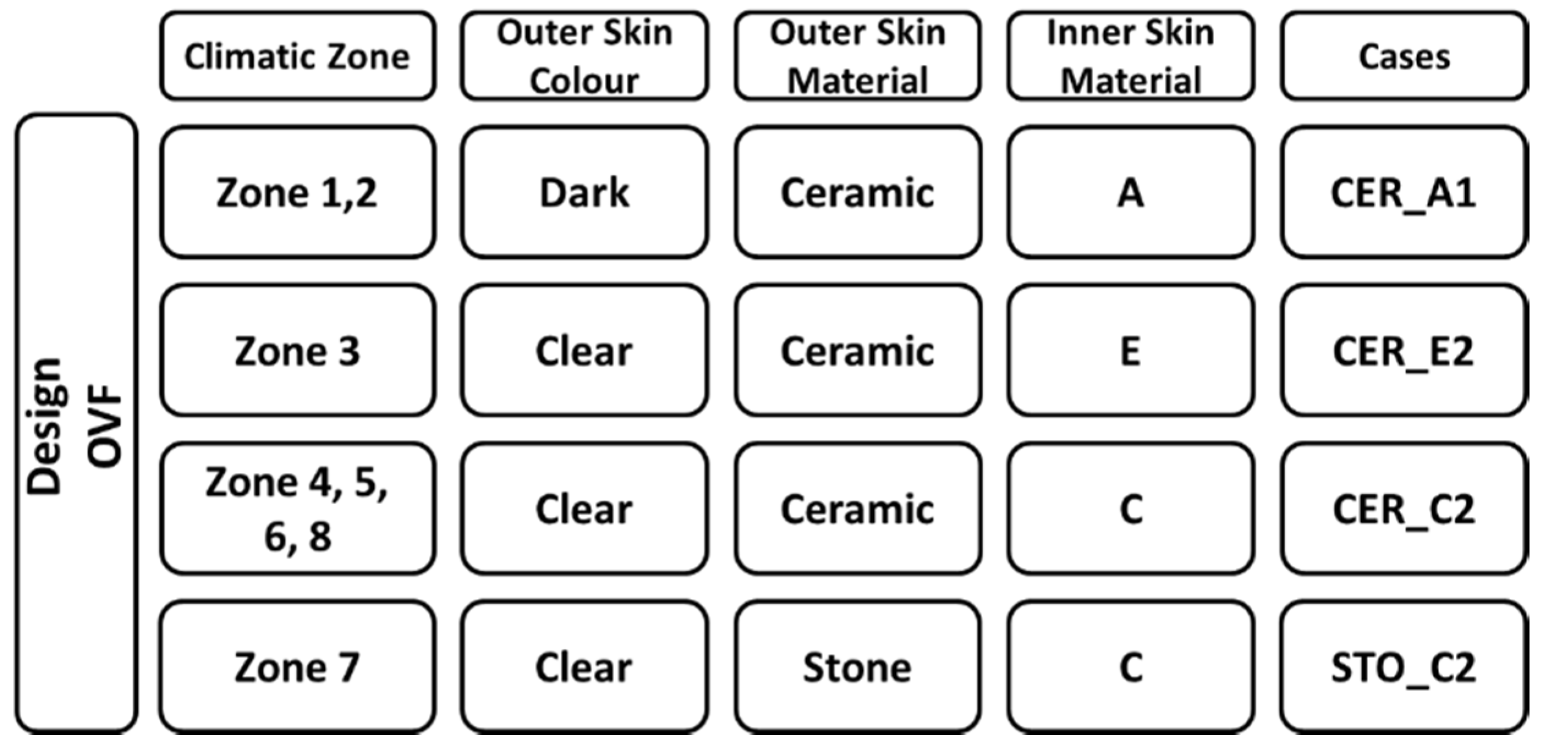

3.4. Parameters Considered

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| CASES | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Zone 5 | Zone 6 | Zone 7 | Zone 8 | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Heat | Cool | Total | Heat | Cool | Total | Heat | Cool | Total | Heat | Cool | Total | Heat | Cool | Total | Heat | Cool | Total | Heat | Cool | Total | Heat | Cool | Total | |

| ACM_A1 | 70.36 | 11.22 | 81.58 | 91.64 | 20.66 | 112.30 | 44.25 | 13.26 | 57.51 | 9.28 | 26.13 | 35.42 | 3.69 | 38.31 | 42.00 | 12.84 | 61.24 | 74.08 | 0.00 | 136.51 | 136.51 | 0.00 | 119.93 | 119.93 |

| CER_A1 | 70.6 | 10.94 | 81.54 | 91.81 | 20.39 | 112.20 | 44.35 | 13.00 | 57.35 | 9.26 | 25.64 | 34.90 | 3.71 | 37.66 | 41.38 | 12.86 | 60.48 | 73.33 | 0.00 | 135.46 | 135.46 | 0.00 | 118.86 | 118.86 |

| STO_A1 | 81.81 | 10.45 | 92.26 | 104.77 | 20.14 | 124.91 | 51.89 | 12.50 | 64.39 | 12.26 | 24.22 | 36.48 | 5.26 | 36.72 | 41.98 | 15.51 | 60.29 | 75.80 | 0.00 | 139.26 | 139.26 | 0.00 | 121.93 | 121.93 |

| ACM_A2 | 71.17 | 10.55 | 82.73 | 92.98 | 19.90 | 112.88 | 45.34 | 12.63 | 57.97 | 9.81 | 24.84 | 34.65 | 5.88 | 34.09 | 39.96 | 13.27 | 59.14 | 72.41 | 0.00 | 133.30 | 133.30 | 0.00 | 115.91 | 115.91 |

| CER_A2 | 84.96 | 9.45 | 94.41 | 101.36 | 19.42 | 120.78 | 50.96 | 12.24 | 63.20 | 12.74 | 24.02 | 36.76 | 6.12 | 33.53 | 39.65 | 15.45 | 58.41 | 73.86 | 0.00 | 133.60 | 133.60 | 0.00 | 115.32 | 115.32 |

| STO_A2 | 84.75 | 9.17 | 93.93 | 106.82 | 18.55 | 125.36 | 53.65 | 11.22 | 64.88 | 13.18 | 21.75 | 34.92 | 5.87 | 33.08 | 38.95 | 16.52 | 55.70 | 72.22 | 0.00 | 132.37 | 132.37 | 0.00 | 115.26 | 115.26 |

| ACM_B1 | 96.53 | 7.56 | 104.09 | 126.18 | 18.61 | 144.79 | 59.18 | 9.23 | 68.41 | 11.25 | 16.51 | 27.76 | 5.24 | 30.30 | 41.38 | 17.04 | 57.06 | 73.33 | 0.00 | 148.61 | 148.61 | 0.00 | 128.13 | 128.13 |

| CER_B1 | 96.74 | 6.77 | 103.50 | 125.97 | 17.47 | 143.44 | 60.05 | 8.42 | 68.47 | 11.02 | 14.98 | 25.99 | 5.28 | 27.82 | 33.10 | 16.99 | 53.48 | 70.47 | 0.00 | 142.63 | 142.63 | 0.00 | 122.10 | 122.10 |

| STO_B1 | 96.93 | 7.40 | 104.33 | 127.30 | 18.66 | 145.96 | 60.27 | 9.06 | 69.33 | 10.89 | 15.99 | 26.89 | 5.04 | 30.06 | 35.10 | 16.97 | 56.96 | 73.94 | 0.00 | 149.63 | 149.63 | 0.00 | 129.11 | 129.11 |

| ACM_B2 | 112.65 | 4.72 | 117.37 | 138.74 | 14.17 | 152.91 | 69.84 | 6.33 | 76.17 | 15.87 | 10.35 | 26.22 | 8.71 | 20.28 | 28.99 | 20.93 | 43.46 | 64.39 | 0.00 | 125.34 | 125.34 | 0.00 | 106.28 | 106.28 |

| CER_B2 | 108.2 | 4.69 | 112.89 | 134.33 | 14.16 | 148.49 | 66.87 | 6.31 | 73.18 | 14.33 | 10.46 | 24.79 | 7.84 | 20.4 | 28.24 | 19.78 | 43.24 | 63.02 | 0.00 | 124.71 | 124.71 | 0.00 | 105.4 | 105.4 |

| STO_B2 | 112.70 | 4.57 | 117.27 | 139.11 | 14 | 153.11 | 69.78 | 6.15 | 75.93 | 15.47 | 9.92 | 25.39 | 8.53 | 19.74 | 28.27 | 20.77 | 42.9 | 63.67 | 0.00 | 124.82 | 124.82 | 0.00 | 105.84 | 105.84 |

| ACM_C1 | 106.77 | 7.05 | 113.82 | 140.26 | 18.18 | 158.44 | 66.83 | 8.56 | 75.39 | 12.64 | 14.98 | 27.62 | 5.81 | 28.83 | 34.64 | 18.86 | 56.39 | 75.25 | 0.00 | 152.55 | 152.55 | 0.00 | 130.92 | 130.92 |

| CER_C1 | 102.72 | 5.97 | 108.68 | 134.22 | 16.50 | 150.72 | 63.75 | 7.53 | 71.29 | 11.49 | 13.19 | 24.68 | 5.48 | 25.44 | 30.92 | 17.90 | 51.15 | 69.05 | 0.00 | 141.99 | 141.99 | 0.00 | 120.76 | 120.76 |

| STO_C1 | 100.94 | 6.16 | 107.10 | 134.95 | 17.54 | 152.49 | 62.41 | 7.71 | 70.13 | 9.81 | 13.05 | 22.86 | 4.48 | 26.68 | 31.16 | 17.00 | 54.27 | 71.27 | 0.00 | 150.76 | 150.76 | 0.00 | 129.42 | 129.42 |

| ACM_C2 | 120.82 | 3.62 | 124.44 | 149.19 | 12.7 | 161.89 | 74.52 | 5.06 | 79.58 | 15.94 | 7.67 | 23.61 | 9.02 | 16.55 | 25.57 | 21.98 | 39.46 | 61.44 | 0.00 | 122.38 | 122.38 | 0.00 | 102.62 | 102.62 |

| CER_C2 | 114.93 | 3.67 | 118.60 | 143.08 | 12.8 | 155.88 | 70.64 | 5.16 | 75.80 | 14.3 | 8.07 | 22.37 | 8 | 17.07 | 25.07 | 20.55 | 39.71 | 60.26 | 0.00 | 122.09 | 122.09 | 0.00 | 102.13 | 102.13 |

| STO_C2 | 121.33 | 3.52 | 124.85 | 149.96 | 12.57 | 162.53 | 74.76 | 4.94 | 79.70 | 15.74 | 7.39 | 23.13 | 8.93 | 16.17 | 25.10 | 21.94 | 39.08 | 61.02 | 0.00 | 122.02 | 122.02 | 0.00 | 102.3 | 102.3 |

| ACM_D1 | 82.84 | 8.58 | 91.42 | 108.15 | 18.69 | 126.84 | 51.79 | 10.35 | 62.14 | 10.28 | 19.86 | 30.13 | 4.30 | 32.56 | 36.85 | 14.79 | 56.99 | 71.78 | 0.00 | 139.22 | 139.22 | 0.00 | 121.35 | 121.35 |

| CER_D1 | 78.80 | 8.12 | 86.92 | 103.16 | 18.11 | 121.28 | 48.91 | 9.94 | 58.85 | 9.05 | 19.21 | 28.26 | 3.78 | 31.28 | 35.05 | 13.76 | 55.17 | 68.92 | 0.00 | 135.14 | 135.14 | 0.00 | 117.49 | 117.49 |

| STO_D1 | 83.10 | 8.20 | 91.31 | 108.89 | 18.48 | 127.37 | 51.83 | 10.02 | 61.85 | 9.93 | 19.01 | 28.95 | 4.19 | 31.76 | 35.95 | 14.68 | 56.31 | 70.99 | 0.00 | 139.20 | 139.20 | 0.00 | 121.37 | 121.37 |

| ACM_D2 | 77.64 | 7.46 | 85.10 | 100.68 | 17.21 | 117.89 | 47.92 | 9.32 | 57.24 | 8.8 | 17.85 | 26.65 | 3.79 | 29.01 | 32.80 | 13.5 | 52.32 | 65.82 | 0.00 | 129.27 | 129.27 | 0.00 | 112.68 | 112.68 |

| CER_D2 | 77.17 | 7.44 | 84.61 | 100.2 | 17.19 | 117.39 | 47.6 | 9.3 | 56.90 | 8.63 | 17.89 | 26.52 | 3.72 | 29.03 | 32.75 | 13.36 | 52.23 | 65.59 | 0.00 | 129.14 | 129.14 | 0.00 | 112.38 | 112.38 |

| STO_D2 | 77.54 | 7.41 | 84.95 | 100.66 | 17.17 | 117.83 | 47.84 | 9.27 | 57.11 | 8.69 | 17.74 | 26.43 | 3.74 | 28.89 | 32.63 | 13.44 | 52.22 | 65.66 | 0.00 | 129.17 | 129.17 | 0.00 | 112.61 | 112.61 |

| ACM_E1 | 81.67 | 7.85 | 89.52 | 107.94 | 18.00 | 125.94 | 50.78 | 9.60 | 60.38 | 9.34 | 18.74 | 28.08 | 3.71 | 31.23 | 34.94 | 14.05 | 55.75 | 69.80 | 0.00 | 138.42 | 138.42 | 0.00 | 120.59 | 120.59 |

| CER_E1 | 77.79 | 7.43 | 85.22 | 103.03 | 17.44 | 120.48 | 48.01 | 9.23 | 57.24 | 8.24 | 18.18 | 26.42 | 3.25 | 30.03 | 33.28 | 13.08 | 54.00 | 67.09 | 0.00 | 134.37 | 134.37 | 0.00 | 116.75 | 116.75 |

| STO_E1 | 82.04 | 7.54 | 89.58 | 108.74 | 17.83 | 126.57 | 50.90 | 9.33 | 60.23 | 9.09 | 18.04 | 27.13 | 3.64 | 30.61 | 34.25 | 13.99 | 55.23 | 69.21 | 0.00 | 138.54 | 138.54 | 0.00 | 120.73 | 120.73 |

| ACM_E2 | 77.04 | 6.77 | 83.81 | 100.88 | 16.5 | 117.38 | 47.26 | 8.61 | 55.87 | 8.1 | 16.79 | 24.89 | 3.32 | 27.64 | 30.96 | 12.91 | 51.04 | 63.95 | 0.00 | 128.31 | 128.31 | 0.00 | 111.77 | 111.77 |

| CER_E2 | 76.57 | 6.76 | 83.33 | 100.37 | 16.49 | 116.86 | 46.94 | 8.61 | 55.55 | 7.96 | 16.87 | 24.83 | 3.26 | 27.72 | 30.98 | 12.78 | 51 | 63.78 | 0.00 | 128.23 | 128.23 | 0.00 | 111.51 | 111.51 |

| STO_E2 | 77.01 | 6.74 | 83.75 | 100.9 | 16.48 | 117.38 | 47.23 | 8.58 | 55.81 | 8.04 | 16.74 | 24.78 | 3.29 | 27.6 | 30.89 | 12.88 | 51.03 | 63.91 | 0.00 | 128.28 | 128.28 | 0.00 | 111.77 | 111.77 |

| MAX | 121.33 | 9.45 | 124.85 | 149.96 | 20.66 | 162.53 | 74.76 | 13.26 | 79.70 | 15.94 | 26.13 | 36.76 | 9.02 | 38.31 | 42.00 | 21.98 | 61.24 | 75.80 | 0.00 | 152.55 | 152.55 | 0.00 | 130.92 | 130.92 |

| MIN | 71.17 | 3.52 | 81.54 | 91.64 | 12.57 | 112.20 | 44.25 | 4.94 | 55.55 | 7.96 | 7.39 | 22.37 | 3.25 | 16.17 | 25.07 | 12.78 | 39.08 | 60.26 | 0.00 | 122.02 | 122.02 | 0.00 | 102.13 | 102.13 |

References

- Wagner, K. Generation of a tropically adapted energy performance certificate for residential buildings. Sustainability 2014, 6, 8415–8431. [Google Scholar] [CrossRef]

- Kumar, G.; Raheja, G. Design Determinants of Building Envelope for Sustainable Built Environment: A Review. Int. J. Built Environ. Sustain. 2016, 3. [Google Scholar] [CrossRef]

- Ibañez-Puy, M.; Vidaurre-Arbizu, M.; Sacristán-Fernández, J.A.; Martín-Gómez, C. Opaque Ventilated Façades: Thermal and energy performance review. Renew. Sustain. Energy Rev. 2017, 79, 180–191. [Google Scholar] [CrossRef]

- Patania, F.; Gagliano, A.; Nocera, F.; Ferlito, A.; Galesi, A. Thermofluid-dynamic analysis of ventilated facades. Energy Build. 2010, 42, 1148–1155. [Google Scholar] [CrossRef]

- Sanjuan, C.; Suárez, M.-J.; Blanco, E.; Del Heras, M.R. Development and experimental validation of a simulation model for open joint ventilated façades. Energy Build. 2011, 43, 3456–3466. [Google Scholar] [CrossRef]

- Gagliano, A.; Nocera, F.; Aneli, S. Thermodynamic analysis of ventilated façades under different wind conditions in summer period. Energy Build. 2016, 122, 131–139. [Google Scholar] [CrossRef]

- Maciel, A.C.F.; Carvalho, M.T. Operational energy of opaque ventilated façades in Brazil. J. Build. Eng. 2019, 25. [Google Scholar] [CrossRef]

- Barth, F.; Grilo, A.C. IX Entorno Nacional de Tecnologia do Ambiente Construido. In Análise Higro-Térmica de Fachadas Ventiladas Nas Condições de Inverno; ENTAC, Ed.; ANTAC: Fowz do Iguacu-Parana, Brazil, 2002; pp. 203–212. [Google Scholar]

- BEN. Balanço Energético Nacional. 2019. Available online: http://www.epe.gov.br (accessed on 4 September 2020).

- MME Empresa de Pesquisa Energética. Plano Nacional de Energia 2030; EPE: Rio de Janeiro, Brazil, 2007; p. 408. [Google Scholar]

- Stazi, F.; Tomassoni, F.; Vegliò, A.; Di Perna, C. Experimental evaluation of ventilated walls with an external clay cladding. Renew. Energy 2011, 36, 3373–3385. [Google Scholar] [CrossRef]

- Marinosci, C.; Semprini, G.; Morini, G.L. Experimental analysis of the summer thermal performances of a naturally ventilated rainscreen façade building. Energy Build. 2014, 72, 280–287. [Google Scholar] [CrossRef]

- Ciampi, M.; Leccese, F.; Tuoni, G. Ventilated facades energy performance in summer cooling of buildings. Sol. Energy 2003, 75, 491–502. [Google Scholar] [CrossRef]

- Balocco, C. A simple model to study ventilated facades energy performance. Energy Build. 2002, 34, 469–475. [Google Scholar] [CrossRef]

- Suárez, M.J.; Sanjuan, C.; Gutiérrez, A.J.; Pistono, J.; Blanco, E. Energy evaluation of an horizontal open joint ventilated faade. Appl. Therm. Eng. 2012, 37, 302–313. [Google Scholar] [CrossRef]

- Giancola, E.; Sanjuan, C.; Blanco, E.; Heras, M.R. Experimental assessment and modelling of the performance of an open joint ventilated façade during actual operating conditions in Mediterranean climate. Energy Build. 2012, 54, 363–375. [Google Scholar] [CrossRef]

- Astorqui, J.S.C.; Porras-Amores, C. Ventilated Façade with double chamber and flow control device. Energy Build. 2017, 149, 471–482. [Google Scholar] [CrossRef]

- Guillén, I.; Gómez-Lozano, V.; Fran, J.M.; López-Jiménez, P.A. Thermal behavior analysis of different multilayer façade: Numerical model versus experimental prototype. Energy Build. 2014, 79, 184–190. [Google Scholar] [CrossRef]

- EnEdi (Grupo de Energética en la Edificación/Área Térmica Laboratorio de Calidad en la Edificación del Gobierno Vasco). Comportamiento Energético de una Fachada Ventilada en la Zona Climatica del Pais Vasco. Available online: https://www.euskadi.eus/contenidos/informacion/estudioareatermica/es_areaterm/adjuntos/fachadaventilada.pdf (accessed on 29 January 2020).

- Fantucci, S.; Marinosci, C.; Serra, V.; Carbonaro, C. Thermal Performance Assessment of an Opaque Ventilated Façade in the Summer Period: Calibration of a Simulation Model through in-field Measurements. Energy Procedia 2017, 111, 619–628. [Google Scholar] [CrossRef]

- Stazi, F.; Ulpiani, G.; Pergolini, M.; Di Perna, C.; D’Orazio, M. The role of wall layers properties on the thermal performance of ventilated facades: Experimental investigation on narrow-cavity design. Energy Build. 2020, 209, 109622. [Google Scholar] [CrossRef]

- Prada, A.; Baratieri, M.; Gasparella, A. Analysis of the impact of ventilated cavities on the performance of opaque components. In Proceedings of the Building Simulation Applications BSA 2013-1st IBPSA Italy Conference, Bozen-Bolzano, Italy, 30 January–1 February 2013; pp. 353–361. [Google Scholar]

- Aparicio-Fernández, C.; Vivancos, J.L.; Ferrer-Gisbert, P.; Royo-Pastor, R. Energy performance of a ventilated façade by simulation with experimental validation. Appl. Therm. Eng. 2014, 66, 563–570. [Google Scholar] [CrossRef]

- Pérez-Fargallo, A.; Rubio-Bellido, C.; Gallego-Maya, I. Influence of adaptive comfort models in execution cost improvements for housing thermal environment in Concepción, Chile. Sustainability 2018, 10, 2368. [Google Scholar] [CrossRef]

- ABNT. NBR 15222 ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS (ABNT). In NBR 15220: Desempenho Térmico de Edificações; ABNT: Rio de Janeiro, Brazil, 2005. [Google Scholar]

- Briones-Llorente, R.; Calderón, V.; Gutiérrez-González, S.; Montero, E.; Rodríguez, Á. Testing of the integrated energy behavior of sustainable improved mortar panels with recycled additives by means of energy simulation. Sustainability 2019, 11, 3117. [Google Scholar] [CrossRef]

- Alvares, C.A.; Stape, J.L.; Sentelhas, P.C.; De Moraes Gonçalves, J.L.; Sparovek, G. Köppen’s climate classification map for Brazil. Meteorol. Z. 2013, 22, 711–728. [Google Scholar] [CrossRef]

- Meteotest Meteonorm Handbook, Parts I, II and III; Meteotest: Bern, Switzerland, 2003.

- ISO. ISO 1991-1–4: 2018 Eurocode 1: Actions on structures. Part 1–4: General actions. Wind actions. International Standard Organization; International Organization for Standardization: Geneva, Switzerland, 2018; pp. 1–13. [Google Scholar]

- ISO. ISO 6946:2017 Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation Method 2017; International Organization for Standardization: Geneva, Switzerland, 2017; pp. 1–36. [Google Scholar]

- Lamberts, R.; Candido, C.; De Dear, R.; De Vecchi, R. Towards a Brazilian Standard on Thermal Comfort; Florianópolis LabEEE: Florianópolis, Brazil, 2013; p. 123. [Google Scholar]

- ISO. ISO 10456:1997 ISO Standard, Building Materials and Products—Hygrothermal Properties e Tabulated Design Values and Procedures for Determining Declared and Design Thermal Values; International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

- Westphal, F.S.; Yamakawa, M.A.; Tavares de Castro, L. Thermal insulation of building envelope toward zero energy design in hot-humid climate. In Proceedings of the International Building Performance Simulation Association, Sydney, Australia, 14–16 November 2011; pp. 2378–2384. [Google Scholar]

| Code | City | Latitude | Zone | AVERAGE Temp. | MAX Temp. | MIN Temp. | %HR ext | V_Speed (m/s) | V_Dir | Rad. Hours | Climate Type |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Z1 | Curitiba-PR | 25° 25′ 40″ S | Zone_1 | 17.42 | 31.75 | −0.95 | 84.73 | 3.43 | 114.04 | 4633.00 | Cfb |

| Z2 | Bagé-RS | 31° 19′ 53″ S | Zone_2 | 17.80 | 33.25 | 0.20 | 71.18 | 3.76 | 159.94 | 4324.00 | Cfa |

| Z3 | Sao Paulo-SP | 23° 32′ 51″ S | Zone_3 | 19.20 | 32.20 | 5.45 | 78.31 | 3.64 | 166.14 | 4344.00 | Cfa |

| Z4 | Brasilia-DF | 15° 46′ 47″ S | Zone_4 | 21.09 | 32.60 | 8.00 | 69.06 | 3.63 | 124.90 | 4350.00 | Aw |

| Z5 | Vitória da Conquista-BA | 14° 51′ 58″ S | Zone_5 | 20.2 | 34.35 | 10.90 | 78.12 | 2.56 | 105.85 | 4599.00 | BSh |

| Z6 | Campo Grande-MS | 20° 26′ 34″ S | Zone_6 | 22.52 | 35.50 | 3.40 | 74.07 | 3.03 | 146.17 | 4331.00 | Aw |

| Z7 | Petrolina-PE | 09° 23′ 55″ S | Zone_7 | 26.13 | 36.05 | 16.25 | 59.84 | 3.12 | 118.38 | 4382.00 | BSh |

| Z8 | Belém-PA | 01° 27′ 21″ S | Zone_8 | 25.90 | 33.95 | 19.65 | 84.26 | 3.48 | 127.11 | 4378.00 | Am |

| Internal Gains | |||

|---|---|---|---|

| People (W/m2) | Equipment (W/m2) | Lighting (W/m2) | |

| Occupancy * 08:00–12:00/14:00–18:00 (100%) | 18.65 | 17.41 | 17 |

| Occupancy 12:00–14:00 (20%) | 3.73 | 3.48 | 3.4 |

| Non-occupancy 18:00–08:00 (0%) | 0 | 0 | 0 |

| Infiltration | One renovation per hour | ||

| Lighting | Total heat gains 17 W/m2—convective part 50% | ||

| Equipment gains and appliances | 50 computers—140 W | ||

| Item | Description | Thickness [m] | Density [kg/m³] | Thermal Conductivity [W/mK] | Specific Heat (J/kg K) |

|---|---|---|---|---|---|

| 1 | Natural gypsum plasterboard | 0.016 | 900 | 0.25 | 1000 |

| 2 | Mineral wool | 0.08 | 50 | 0.036 | 1000 |

| 3 | Mortar Panel | 0.01 | 1200 | 0.23 | 1500 |

| 4 | Rigid polyurethane foam (PUR/PIR) | 0.04 | 12 | 0.031 | 1500 |

| 5 | Hollow ceramic | 0.10 | 1200 | 0.49 | 900 |

| 6 | Solid ceramic | 0.10 | 1800 | 0.87 | 1400 |

| 7 | Lime cement plaster | 0.025 | 1600 | 1.4 | 1100 |

| 8 | Rigid polyurethane foam (PUR/PIR) | 0.05 | 12 | 0.031 | 1500 |

| 9 | Stone tile (STO) | 0.03 | 2600 | 2.8 | 1000 |

| 10 | Ceramic tile (CER) | 0.015 | 1600 | 0.76 | 1000 |

| 11 | Aluminium composite material (ACM) | 0.004 | 980 | 5.65 | 1500 |

| Item | Materials from Table 2 from the Wall’s Inner Layer to the Outer Layer | Thickness [m] | U-Value [W/m2 K] | Energy MJ/m2 |

|---|---|---|---|---|

| A | 1 + 2 + 3 + 4 | 0.146 | 0.245 | 357.50 |

| B | 7 + 5 + 7 | 0.153 | 2.285 | 211.75 |

| C | 7 + 6 + 7 | 0.15 | 2.92 | 298.43 |

| D | 7 + 5 + 8 | 0.178 | 0.603 | 345.83 |

| E | 7 + 6 + 8 | 0.175 | 0.64 | 432.51 |

| Skin Type | Description | Skin Type | Description | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Inner Skin | Thermal Insolation | Outer Skin | External Colour | Inner Skin | Thermal Insolation | Outer Skin | External Colour | ||

| ACM_A1 | A | Yes | ACM | 0.6 | ACM_C2 | C | No | ACM | 0.2 |

| CER_A1 | A | Yes | CER | 0.6 | CER_C2 | C | No | CER | 0.2 |

| STO_A1 | A | Yes | STO | 0.6 | STO_C2 | C | No | STO | 0.2 |

| ACM_A2 | A | Yes | ACM | 0.2 | ACM_D1 | D | Yes | ACM | 0.6 |

| CER_A2 | A | Yes | CER | 0.2 | CER_D1 | D | Yes | CER | 0.6 |

| STO_A2 | A | Yes | STO | 0.2 | STO_D1 | D | Yes | STO | 0.6 |

| ACM_B1 | B | No | ACM | 0.6 | ACM_D2 | D | Yes | ACM | 0.2 |

| CER_B1 | B | No | CER | 0.6 | CER_D2 | D | Yes | CER | 0.2 |

| STO_B1 | B | No | STO | 0.6 | STO_D2 | D | Yes | STO | 0.2 |

| ACM_B2 | B | No | ACM | 0.2 | ACM_E1 | E | Yes | ACM | 0.6 |

| CER_B2 | B | No | CER | 0.2 | CER_E1 | E | Yes | CER | 0.6 |

| STO_B2 | B | No | STO | 0.2 | STO_E1 | E | Yes | STO | 0.6 |

| ACM_C1 | C | No | ACM | 0.6 | ACM_E2 | E | Yes | ACM | 0.2 |

| CER_C1 | C | No | CER | 0.6 | CER_E2 | E | Yes | CER | 0.2 |

| STO_C1 | C | No | STO | 0.6 | STO_E2 | E | Yes | STO | 0.2 |

| CASES | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Zone 5 | Zone 6 | Zone 7 | Zone 8 |

|---|---|---|---|---|---|---|---|---|

| Total | Total | Total | Total | Total | Total | Total | Total | |

| ACM_A1 | 81.58 | 112.30 | 57.51 | 35.42 | 42.00 | 74.08 | 136.51 | 119.93 |

| CER_A1 | 81.54 | 112.20 | 57.35 | 34.90 | 41.38 | 73.33 | 135.46 | 118.86 |

| STO_A1 | 92.26 | 124.91 | 64.39 | 36.48 | 41.98 | 75.80 | 139.26 | 121.93 |

| ACM_A2 | 82.73 | 112.88 | 57.97 | 34.65 | 39.96 | 72.41 | 133.30 | 115.91 |

| CER_A2 | 94.41 | 120.78 | 63.20 | 36.76 | 39.65 | 73.86 | 133.60 | 115.32 |

| STO_A2 | 93.93 | 125.36 | 64.88 | 34.92 | 38.95 | 72.22 | 132.37 | 115.26 |

| ACM_B1 | 104.09 | 144.79 | 68.41 | 27.76 | 41.38 | 73.33 | 148.61 | 128.13 |

| CER_B1 | 103.50 | 143.44 | 68.47 | 25.99 | 33.10 | 70.47 | 142.63 | 122.10 |

| STO_B1 | 104.33 | 145.96 | 69.33 | 26.89 | 35.10 | 73.94 | 149.63 | 129.11 |

| ACM_B2 | 117.37 | 152.91 | 76.17 | 26.22 | 28.99 | 64.39 | 125.34 | 106.28 |

| CER_B2 | 112.89 | 148.49 | 73.18 | 24.79 | 28.24 | 63.02 | 124.71 | 105.4 |

| STO_B2 | 117.27 | 153.11 | 75.93 | 25.39 | 28.27 | 63.67 | 124.82 | 105.84 |

| ACM_C1 | 113.82 | 158.44 | 75.39 | 27.62 | 34.64 | 75.25 | 152.55 | 130.92 |

| CER_C1 | 108.68 | 150.72 | 71.29 | 24.68 | 30.92 | 69.05 | 141.99 | 120.76 |

| STO_C1 | 107.10 | 152.49 | 70.13 | 22.86 | 31.16 | 71.27 | 150.76 | 129.42 |

| ACM_C2 | 124.44 | 161.89 | 79.58 | 23.61 | 25.57 | 61.44 | 122.38 | 102.62 |

| CER_C2 | 118.60 | 155.88 | 75.80 | 22.37 | 25.07 | 60.26 | 122.09 | 102.13 |

| STO_C2 | 124.85 | 162.53 | 79.70 | 23.13 | 25.10 | 61.02 | 122.02 | 102.3 |

| ACM_D1 | 91.42 | 126.84 | 62.14 | 30.13 | 36.85 | 71.78 | 139.22 | 121.35 |

| CER_D1 | 86.92 | 121.28 | 58.85 | 28.26 | 35.05 | 68.92 | 135.14 | 117.49 |

| STO_D1 | 91.31 | 127.37 | 61.85 | 28.95 | 35.95 | 70.99 | 139.20 | 121.37 |

| ACM_D2 | 85.10 | 117.89 | 57.24 | 26.65 | 32.80 | 65.82 | 129.27 | 112.68 |

| CER_D2 | 84.61 | 117.39 | 56.90 | 26.52 | 32.75 | 65.59 | 129.14 | 112.38 |

| STO_D2 | 84.95 | 117.83 | 57.11 | 26.43 | 32.63 | 65.66 | 129.17 | 112.61 |

| ACM_E1 | 89.52 | 125.94 | 60.38 | 28.08 | 34.94 | 69.80 | 138.42 | 120.59 |

| CER_E1 | 85.22 | 120.48 | 57.24 | 26.42 | 33.28 | 67.09 | 134.37 | 116.75 |

| STO_E1 | 89.58 | 126.57 | 60.23 | 27.13 | 34.25 | 69.21 | 138.54 | 120.73 |

| ACM_E2 | 83.81 | 117.38 | 55.87 | 24.89 | 30.96 | 63.95 | 128.31 | 111.77 |

| CER_E2 | 83.33 | 116.86 | 55.55 | 24.83 | 30.98 | 63.78 | 128.23 | 111.51 |

| STO_E2 | 83.75 | 117.38 | 55.81 | 24.78 | 30.89 | 63.91 | 128.28 | 111.77 |

| MAX | 124.85 | 162.53 | 79.70 | 36.76 | 42.00 | 75.80 | 152.55 | 130.92 |

| MIN | 81.54 | 112.20 | 55.55 | 22.37 | 25.07 | 60.26 | 122.02 | 102.13 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gregório-Atem, C.; Aparicio-Fernández, C.; Coch, H.; Vivancos, J.-L. Opaque Ventilated Façade (OVF) Thermal Performance Simulation for Office Buildings in Brazil. Sustainability 2020, 12, 7635. https://doi.org/10.3390/su12187635

Gregório-Atem C, Aparicio-Fernández C, Coch H, Vivancos J-L. Opaque Ventilated Façade (OVF) Thermal Performance Simulation for Office Buildings in Brazil. Sustainability. 2020; 12(18):7635. https://doi.org/10.3390/su12187635

Chicago/Turabian StyleGregório-Atem, Camila, Carolina Aparicio-Fernández, Helena Coch, and José-Luis Vivancos. 2020. "Opaque Ventilated Façade (OVF) Thermal Performance Simulation for Office Buildings in Brazil" Sustainability 12, no. 18: 7635. https://doi.org/10.3390/su12187635

APA StyleGregório-Atem, C., Aparicio-Fernández, C., Coch, H., & Vivancos, J.-L. (2020). Opaque Ventilated Façade (OVF) Thermal Performance Simulation for Office Buildings in Brazil. Sustainability, 12(18), 7635. https://doi.org/10.3390/su12187635