Prediction and Maintenance of Water Resources Carrying Capacity in Mining Area—A Case Study in the Yu-Shen Mining Area

Abstract

1. Introduction

2. Overview of the Study Area

2.1. Location and Climate of Yu-Shen Mining Area

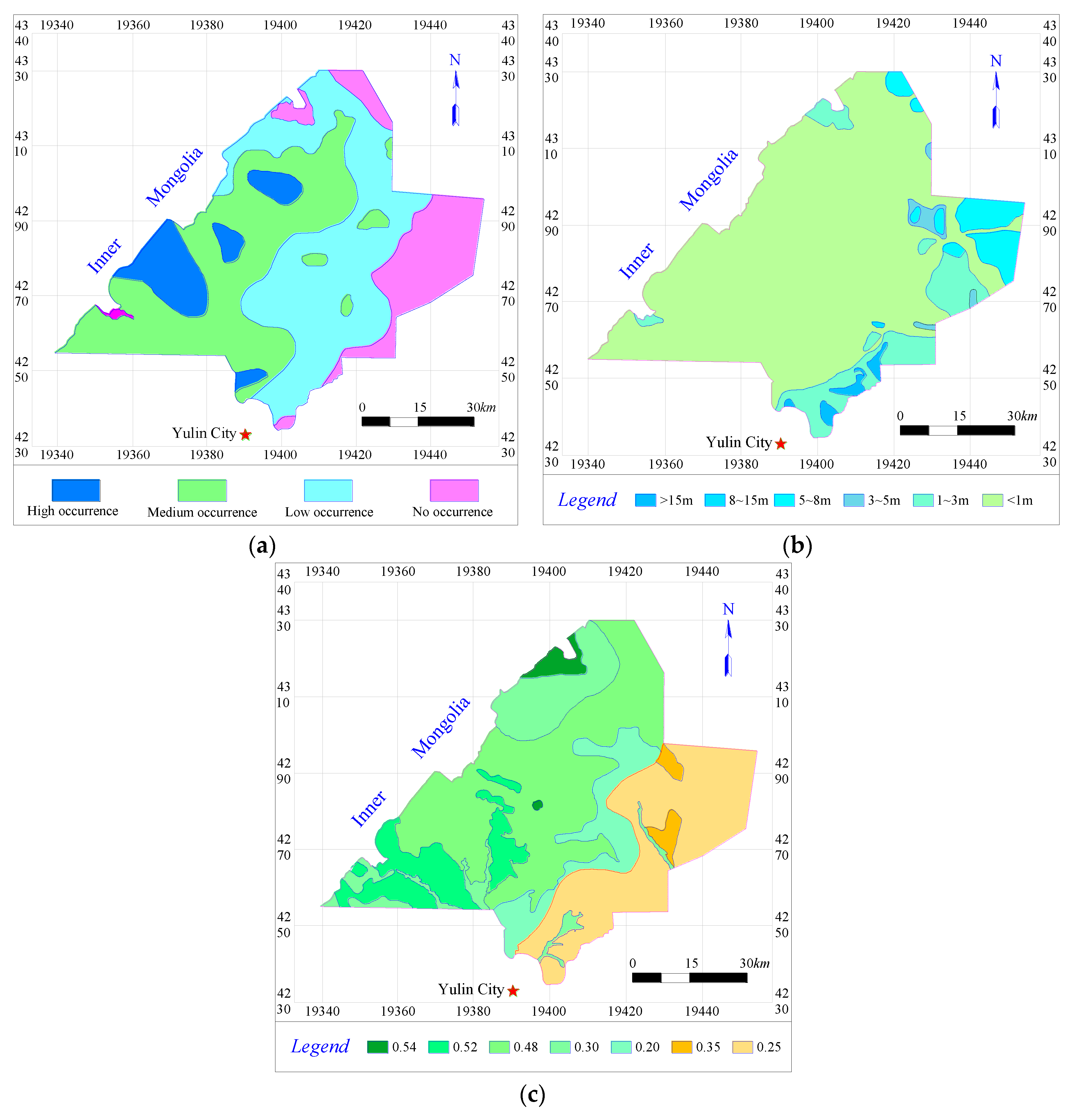

2.2. Geological and Underground Aquifer Characteristics

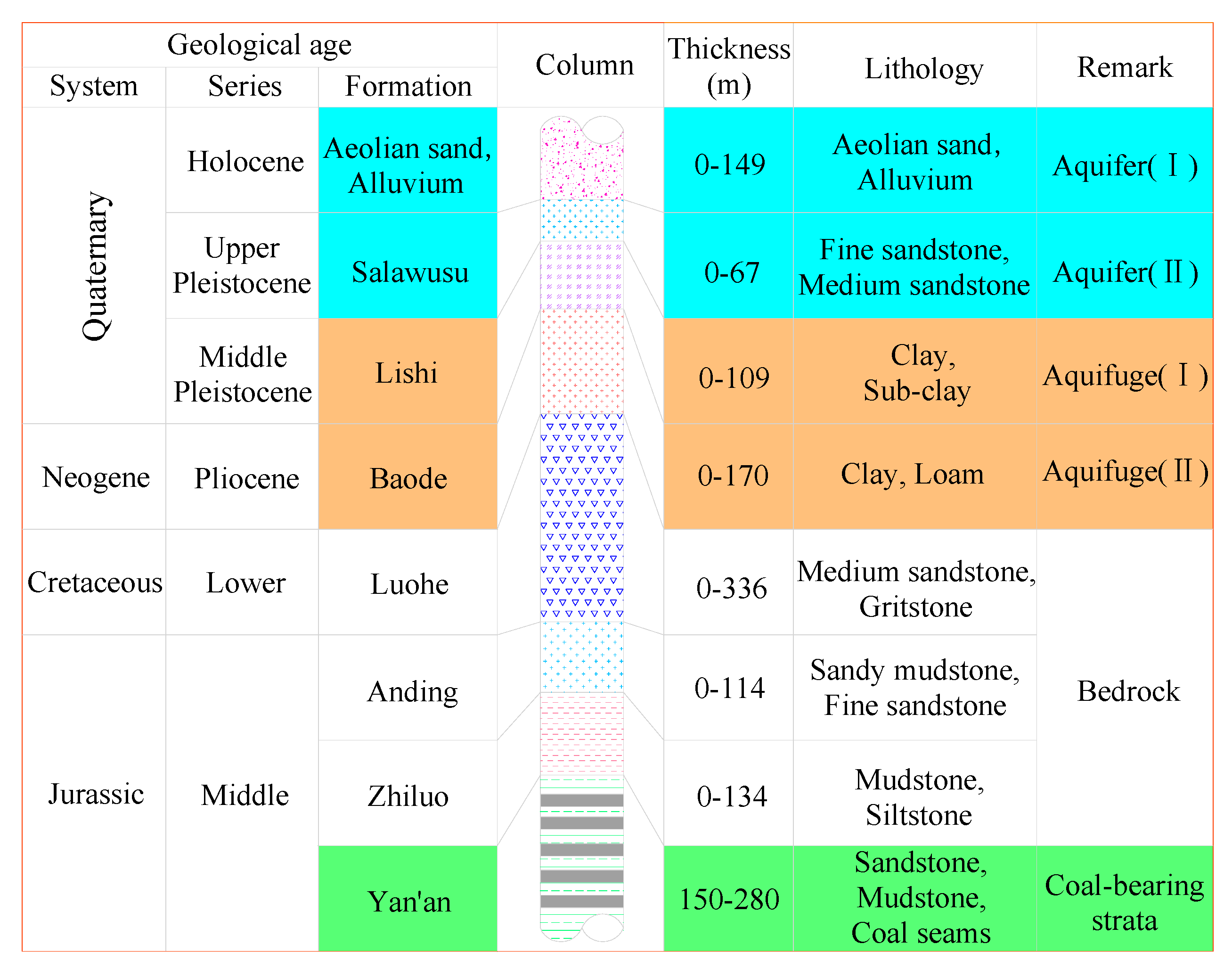

2.2.1. Geological Characteristics

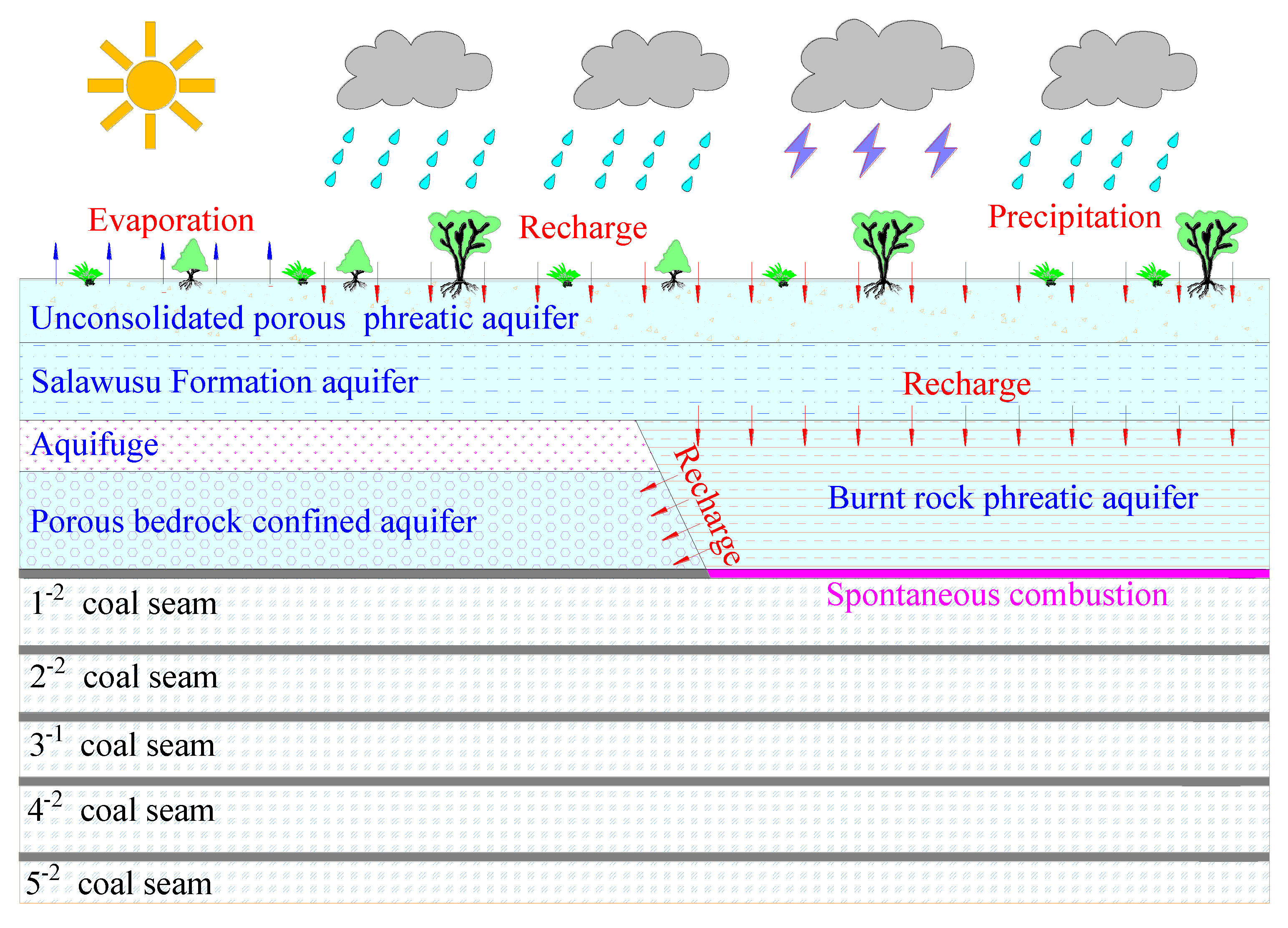

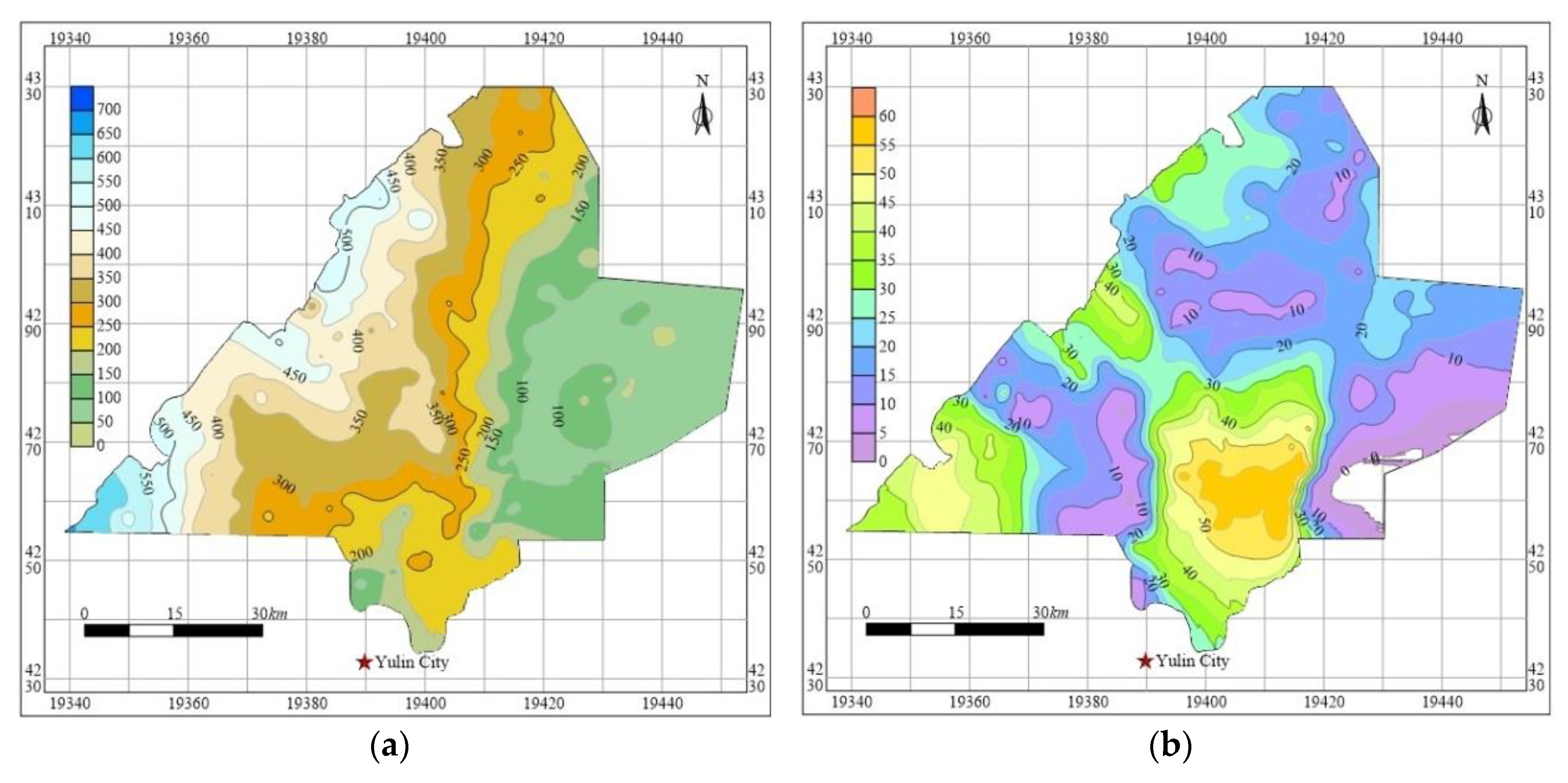

2.2.2. Underground Aquifer Characteristics

3. Identification of Influencing Factors of WRCCMA

3.1. Overburden Strata System

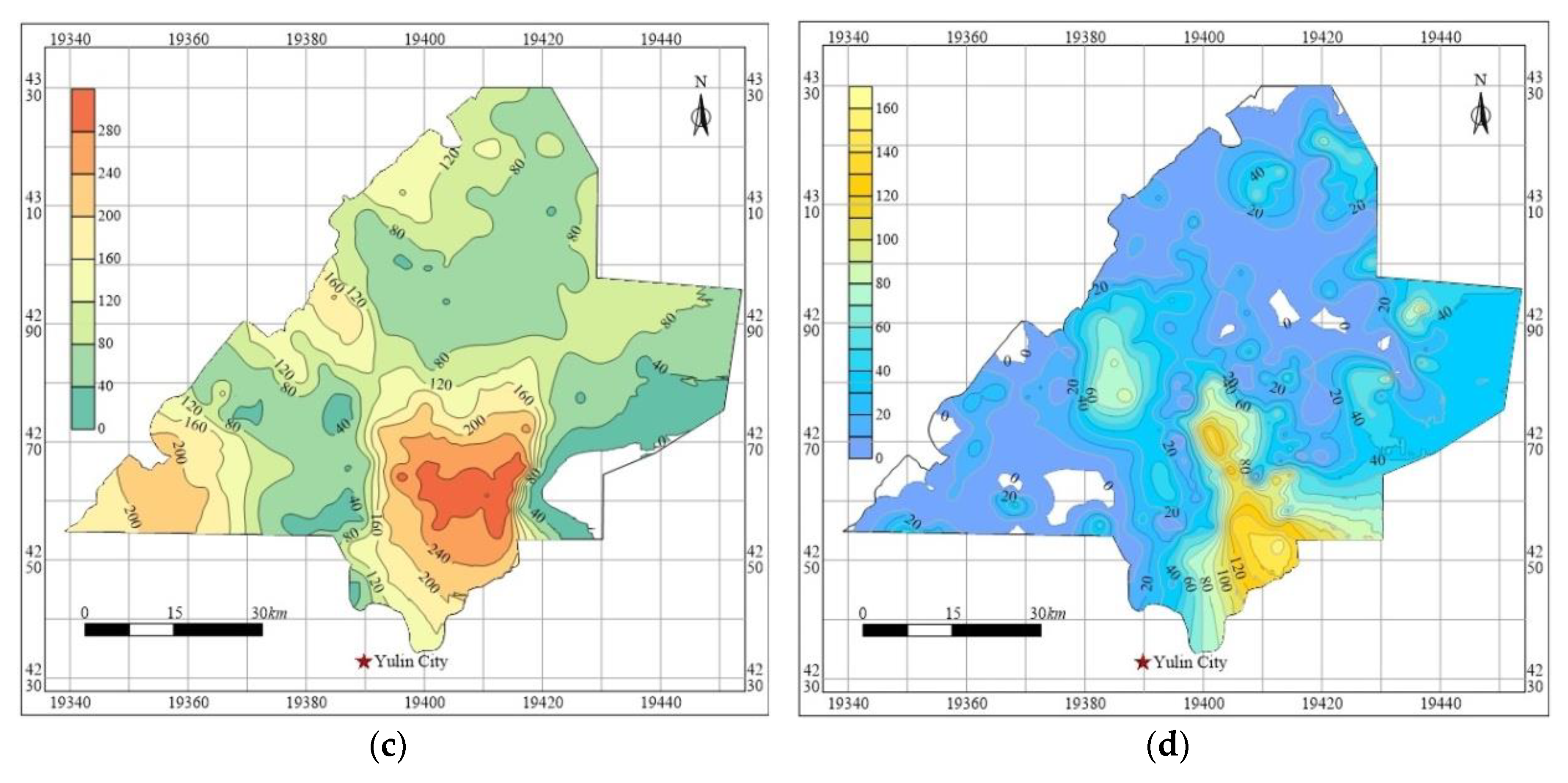

3.2. Geological Structure System

3.3. Groundwater System

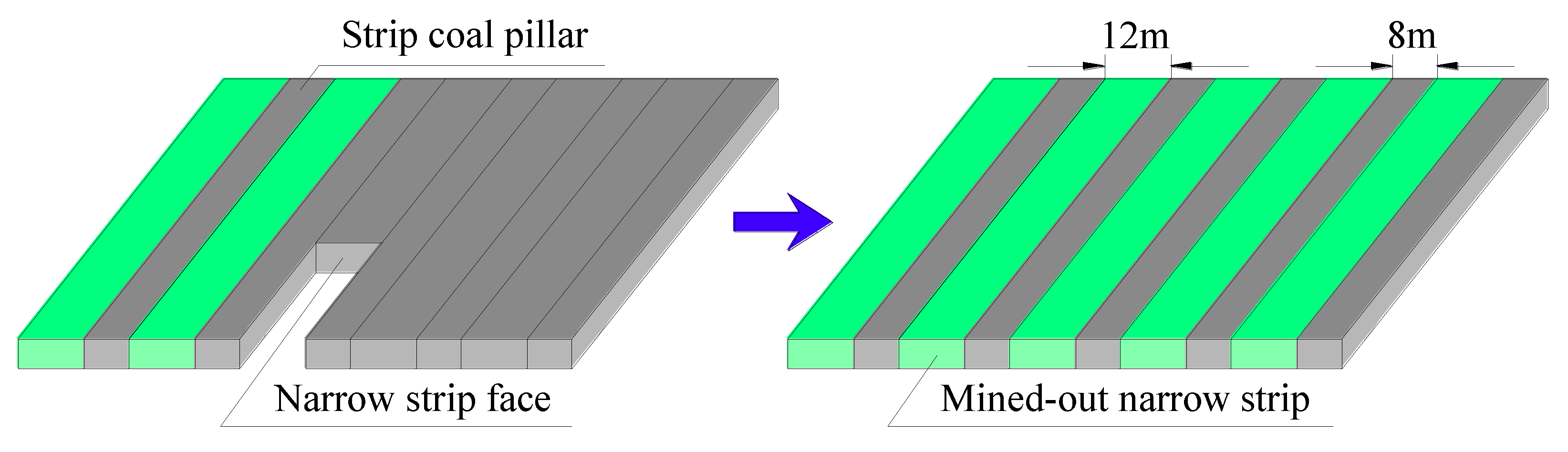

3.4. Coal Mining System

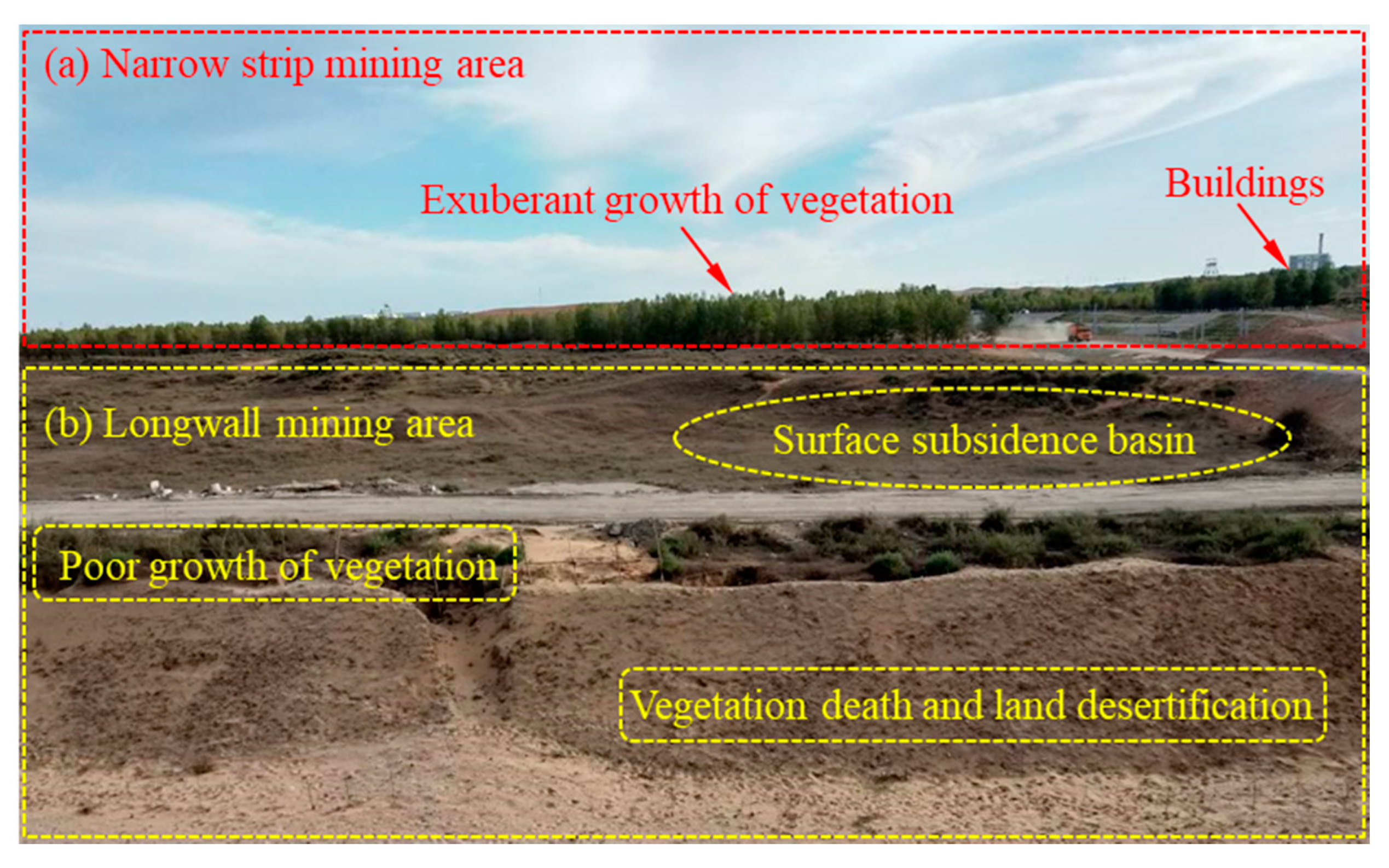

3.5. Ecological System

3.6. Social System

4. Mathematical Model of WRCCMA

4.1. Mathematical Modeling

4.2. Weight Determination

5. Model Verification and WRCCMA Prediction

5.1. Model Verification

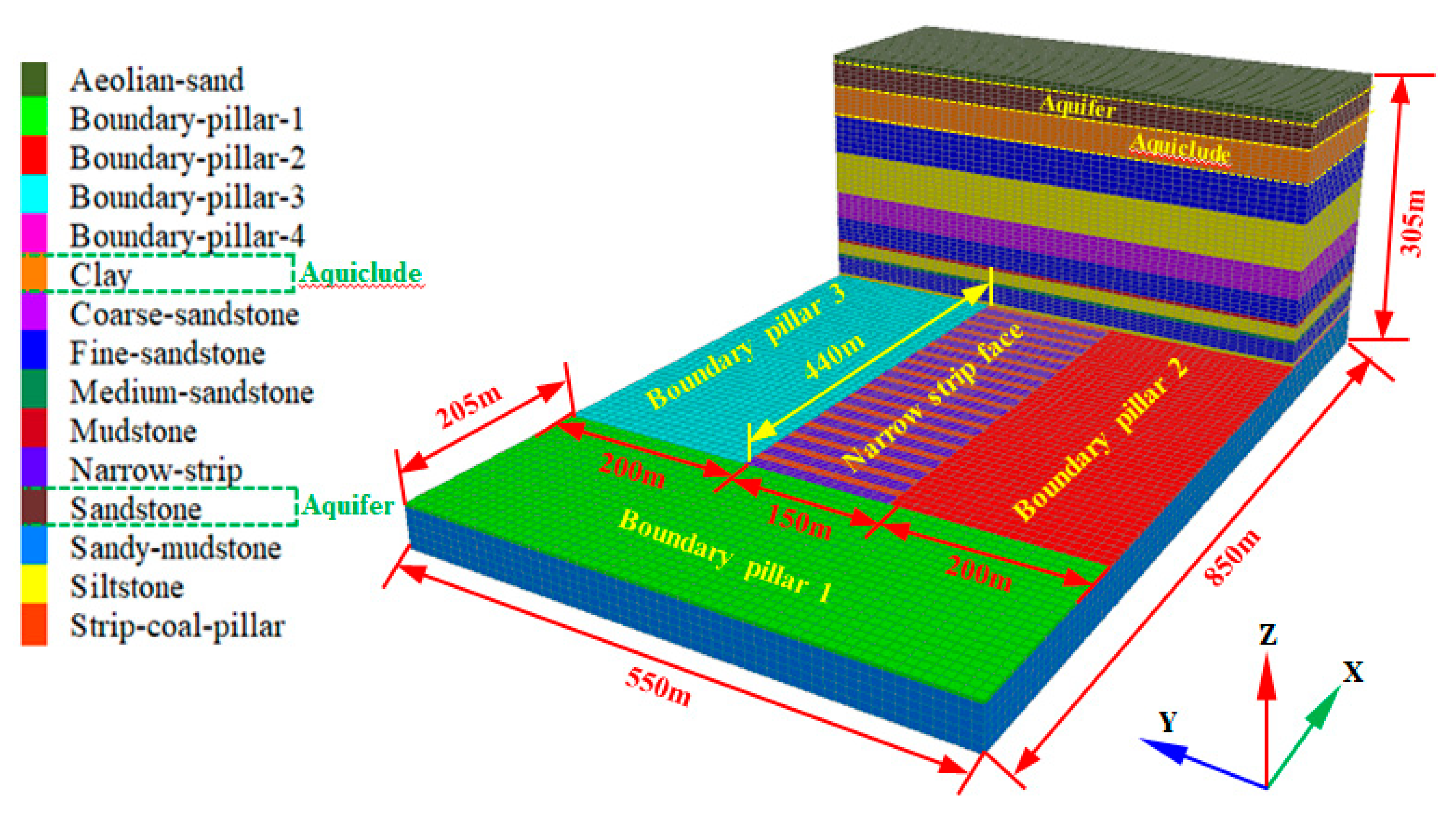

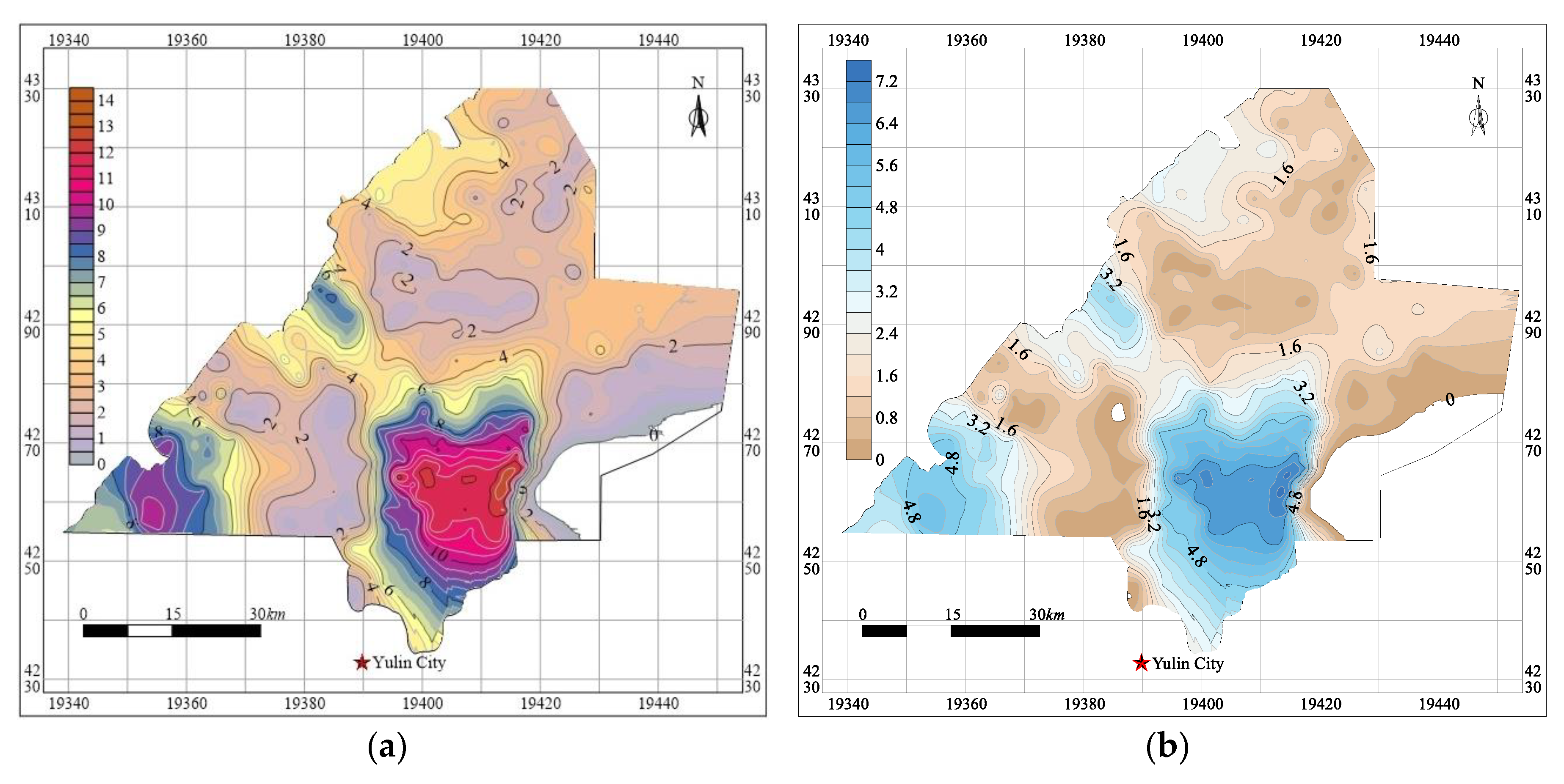

5.1.1. Numerical Simulation of Groundwater Level Decline

5.1.2. The Evaluation of the WRCCMA for Yubujie Colliery

5.1.3. The Changes in Vegetation Coverage and Surface Deformation after Mining

5.2. WRCCMA Prediction for Yu-Shen Mining Area

5.2.1. Membership Degree Determination

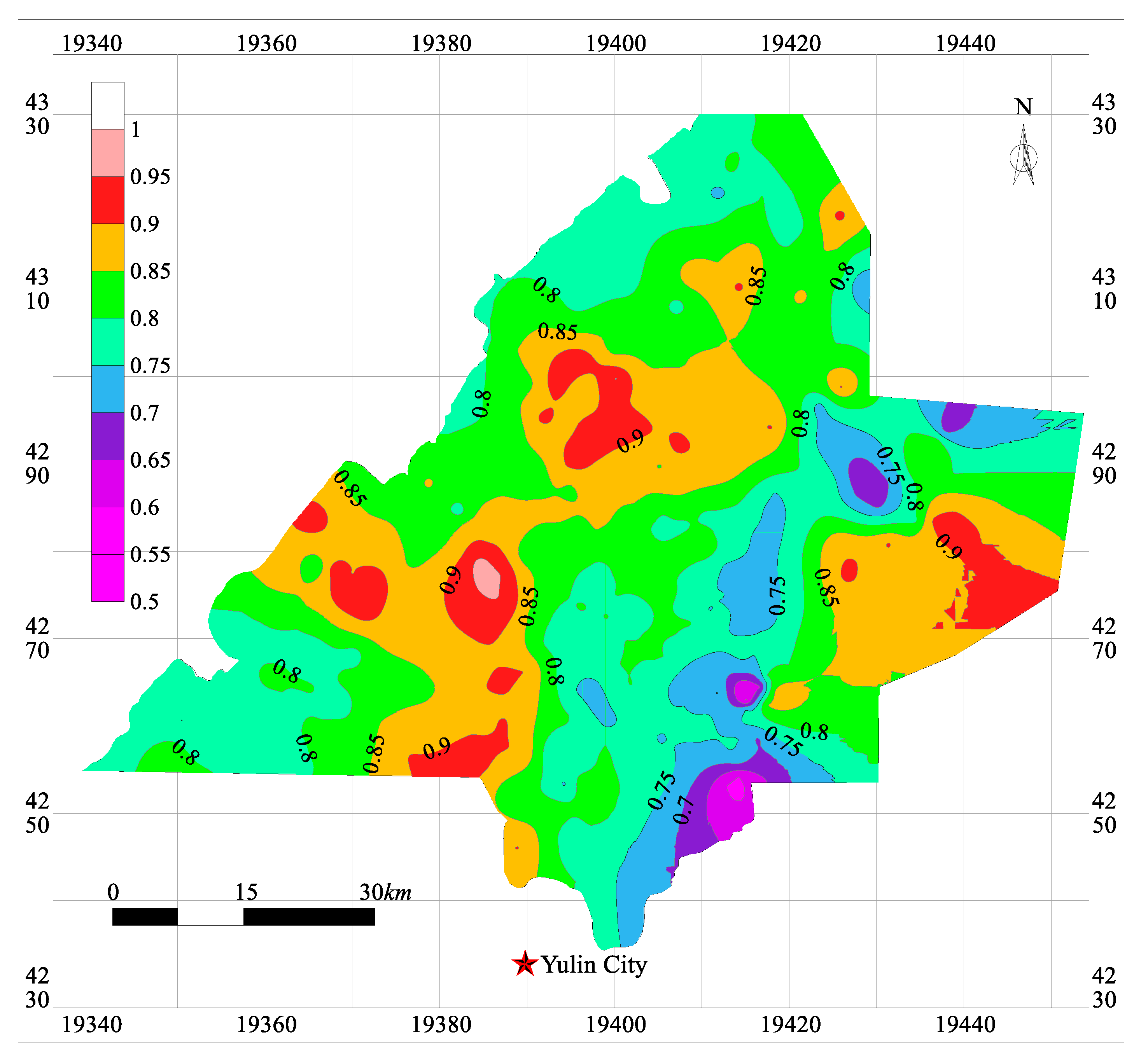

5.2.2. Results of WRCCMA Prediction

6. Discussion

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, D.; Fan, G.; Ma, L.; Wang, X. Aquifer protection during longwall mining of shallow coal seams: A case study in the Shendong Coalfield of China. Int. J. Coal Geol. 2011, 86, 190–196. [Google Scholar] [CrossRef]

- Liu, S.; Li, W. Zoning and management of phreatic water resource conservation impacted by underground coal mining: A case study in arid and semiarid areas. J. Clean. Prod. 2019, 224, 677–685. [Google Scholar] [CrossRef]

- Wang, S.; Ma, L. Characteristics and control of mining induced fractures above longwall mines using backfilling. Energies 2019, 12, 4604. [Google Scholar] [CrossRef]

- Xu, Y.; Ma, L.; Yu, Y. Water preservation and conservation above coal mines using an innovative approach: A case study. Energies 2020, 13, 2818. [Google Scholar] [CrossRef]

- Yu, Y.; Ma, L.; Zhang, D. Characteristics of roof ground subsidence while applying a continuous excavation continuous backfill method in longwall mining. Energies 2020, 13, 95. [Google Scholar] [CrossRef]

- Newman, C.; Agioutantis, Z.; Leon, G.B.J. Assessment of potential impacts to surface and subsurface water bodies due to longwall mining. Int. J. Min. Sci. Technol. 2017, 27, 57–64. [Google Scholar] [CrossRef]

- Qiao, W.; Li, W.; Li, T.; Chang, J.; Wang, Q. Effects of coal mining on shallow water resources in semiarid regions: A case study in the Shennan mining area, Shaanxi, China. Mine Water Environ. 2017, 36, 104–113. [Google Scholar] [CrossRef]

- Ma, L.; Jin, Z.; Liu, W.; Zhang, D.; Zhang, Y. Wongawilli roadway backfilling coal mining method—A case study in Wangtaipu coal mine. Int. J. Oil Gas Coal T. 2019, 20, 342–359. [Google Scholar] [CrossRef]

- Ma, L.; Jin, Z.; Liang, J.; Sun, H.; Zhang, N.; Li, P. Simulation of water resource loss in short-distance coal seams disturbed by repeated mining. Environ. Earth Sci. 2015, 74, 5653–5662. [Google Scholar] [CrossRef]

- Wang, A.; Ma, L.; Wang, Z.; Zhang, D.; Li, K.; Zhang, Y.; Yi, X. Soil and water conservation in mining area based on ground surface subsidence control: Development of a high-water swelling material and its application in backfilling mining. Environ. Earth Sci. 2016, 75, 779. [Google Scholar] [CrossRef]

- Chi, M.; Zhang, D.; Fan, G.; Zhang, W.; Liu, H. Prediction of water resource carrying capacity by the analytic hierarchy process-fuzzy discrimination method in a mining area. Ecol. Indic. 2019, 96, 647–655. [Google Scholar] [CrossRef]

- Dai, D.; Sun, M.; Xu, X.; Lei, K. Assessment of the water resource carrying capacity based on the ecological footprint: A case study in Zhangjiakou City, North China. Environ. Sci. Pollut. Res. 2019, 26, 11000–11011. [Google Scholar] [CrossRef] [PubMed]

- Bao, C.; He, D. Scenario modeling of urbanization development and water scarcity based on system dynamics: A case study of Beijing-Tianjin-Hebei urban agglomeration, China. Int. J. Environ. Res. Public Health 2019, 16, 3834. [Google Scholar] [CrossRef] [PubMed]

- Xiufeng, X.; Zhenghe, X.; Limin, P.; Yunhai, Z.; Min, D.; Penggang, L. Water resources carrying capacity forecast of Jining based on non-linear dynamics model. Energy Procedia 2011, 5, 1742–1747. [Google Scholar] [CrossRef][Green Version]

- Wang, S.; Xu, L.; Yang, F.; Wang, H. Assessment of water ecological carrying capacity under the two policies in Tieling City on the basis of the integrated system dynamics model. Sci. Total. Environ. 2014, 472, 1070–1081. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Xu, S. Dynamic successive assessment method of water environment carrying capacity and its application. Ecol. Indic. 2015, 52, 134–146. [Google Scholar] [CrossRef]

- Min, D.; Zhenghe, X.; Limin, P.; Yunhai, Z.; Xiufeng, X. Comprehensive evaluation of water resources carrying capacity of Jining City. Energy Procedia 2011, 5, 1654–1659. [Google Scholar] [CrossRef][Green Version]

- Ren, C.; Guo, P.; Li, M.; Li, R. An innovative method for water resources carrying capacity research—Metabolic theory of regional water resources. J. Environ. Manag. 2016, 167, 139–146. [Google Scholar] [CrossRef]

- Pires, A.; Morato, J.; Peixoto, H.; Botero, V.; Zuluaga, L.; Figueroa, A. Sustainability Assessment of indicators for integrated water resources management. Sci. Total. Environ. 2017, 578, 139–147. [Google Scholar] [CrossRef] [PubMed]

- Milano, M.; Ruelland, D.; Dezetter, A.; Fabre, J.; Ardoin-Bardin, S.; Servat, E. Modeling the current and future capacity of water resources to meet water demands in the Ebro basin. J. Hydrol. 2013, 500, 114–126. [Google Scholar] [CrossRef]

- Qiyong, Y.; Zhang, F.; Jiang, Z.; Yuan, D.; Jiang, Y. Assessment of water resource carrying capacity in karst area of Southwest China. Environ. Earth Sci. 2015, 75, 1–8. [Google Scholar] [CrossRef]

- Mhlongo, S.; Mativenga, P.T.; Marnewick, A. Water quality in a mining and water-stressed region. J. Clean. Prod. 2018, 171, 446–456. [Google Scholar] [CrossRef]

- Zhang, Z.; Lu, W.; Zhao, Y.; Song, W. Development tendency analysis and evaluation of the water ecological carrying capacity in the Siping area of Jilin Province in China based on system dynamics and analytic hierarchy process. Ecol. Model. 2014, 275, 9–21. [Google Scholar] [CrossRef]

- Fan, L. Scientific connotation of water-preserved mining. J. Chin. Coal Soc. 2017, 42, 27–35. [Google Scholar]

- Qian, M.; Xu, J.; Miao, X. Green technique in coal mining. J. Chin. Univ. Min. Technol. 2003, 32, 343–347. [Google Scholar]

- Palchik, V. Formation of fractured zones in overburden due to longwall mining. Environ. Earth Sci. 2003, 44, 28–38. [Google Scholar] [CrossRef]

- Liu, S.; Li, W.; Wang, Q. Height of the water-flowing fractured zone of the jurassic coal seam in Northwestern China. Mine Water Environ. 2018, 37, 312–321. [Google Scholar] [CrossRef]

- Guo, W.; Zou, Y.; Hou, Q. Fractured zone height of longwall mining and its effects on the overburden aquifers. Int. J. Min. Sci. Technol. 2012, 22, 603–606. [Google Scholar] [CrossRef]

- Ma, L.; Guo, J.; Liu, W.; Zhang, D.; Yu, Y. Water conservation when mining multiple, thick, closely-spaced coal seams: A case study of mining under Weishan Lake. Mine Water Environ. 2019, 38, 643–657. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, H.; Deng, X.; Ju, F. Prediction of the height of the water-conducting zone above the mined panel in solid backfill mining. Mine Water Environ. 2014, 33, 317–326. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, D.; Jin, Z.; Wang, S.; Yu, Y. Theories and methods of efficiency water conservation mining in short-distance coal seams. J. Chin. Coal Soc. 2019, 44, 727–738. [Google Scholar]

- Huang, Q. Simulation of clay aquiclude stability of water conservation mining in shallow-buried coal seam. Chin. J. Rock Mech. Eng. 2009, 28, 987–992. [Google Scholar]

- Wu, Q.; Wang, M.; Wu, X. Investigations of groundwater bursting into coal mine seam floors from fault zones. Int. J. Rock Mech. Min. Sci. 2004, 41, 557–571. [Google Scholar] [CrossRef]

- Wu, Q.; Shen, J.; Wang, Y. Mining techniques and engineering application for “Coal-Water” dual-resources mine. J. Chin. Coal Soc. 2017, 42, 8–16. [Google Scholar]

- Wu, Q.; Fan, Z.; Liu, S.; Zhang, Y.; Sun, W. Water-richness evaluation method of water-filled aquifer based on the principle of information fusion with GIS: Water-richness index method. J. Chin. Coal Soc. 2011, 36, 1124–1128. [Google Scholar]

- Zhang, H.; Zhou, R.; Guo, D.; Du, P. Investigation on Predicting roof water gush in coal mines based on multi-factor analysis. J. Chin. Univ. Min. Technol. 2005, 34, 115–119. [Google Scholar]

- Booth, C.J.; Spande, E.D.; Pattee, C.T.; Miller, J.D.; Bertsch, L.P. Positive and negative impacts of longwall mine subsidence on a sandstone aquifer. Environ. Earth Sci. 1998, 34, 223–233. [Google Scholar] [CrossRef]

- Booth, C. Groundwater as an environmental constraint of longwall coal mining. Environ. Earth Sci. 2006, 49, 796–803. [Google Scholar] [CrossRef]

- Hill, J.G.; Price, D.R. The impact of deep mining on an overlying aquifer in western Pennsylvania. Ground Water Monit. Remediat. 1983, 3, 138–143. [Google Scholar] [CrossRef]

- Stoner, J.D. Probable hydrologic effects of subsurface mining. Ground Water Monit. Remediat. 1983, 3, 128–137. [Google Scholar] [CrossRef]

- Gülçin, Ö.; Karaman, A.; Akhiev, S.S.; Carpenter, P.J. A new method of analysis of water-level response to a moving boundary of a longwall mine. Water Resour. Res. 1999, 35, 1001–1010. [Google Scholar] [CrossRef]

- Robertson, J. Challenges in sustainably managing groundwater in the Australian Great Artesian Basin: Lessons from current and historic legislative regimes. Hydrogeol. J. 2019, 28, 343–360. [Google Scholar] [CrossRef]

- Howladar, M.F. Coal mining impacts on water environs around the Barapukuria coal mining area, Dinajpur, Bangladesh. Environ. Earth Sci. 2012, 70, 215–226. [Google Scholar] [CrossRef]

- Gandhe, A.; Venkateswarlu, V.; Gupta, R.N. Extraction of coal under a surface water body—A strata control investigation. Rock Mech. Rock Eng. 2005, 38, 399–410. [Google Scholar] [CrossRef]

- Li, W.; Liu, S.; Pei, Y.; He, J.; Wang, Q. Zoning for eco-geological environment before mining in Yu-Shenfu mining area, northern Shaanxi, China. Environ. Monit. Assess. 2018, 190, 619. [Google Scholar] [CrossRef]

- Wang, S.; Huang, Q.; Fan, L.; Yang, Z.; Shen, T. Study on overburden aquclude and water protection mining regionazation in the ecological fragile mining area. J. Chin. Coal Soc. 2010, 35, 7–14. [Google Scholar]

- Ma, X.; Fan, L.; Zhang, X.; Li, W.; Zhang, H. Water-preserved mining based on relationship between vegetation and groundwater. J. Chin. Coal Soc. 2017, 42, 1277–1283. [Google Scholar]

- Yang, Z.; Li, W.; Li, X.; He, J. Quantitative analysis of the relationship between vegetation and groundwater buried depth: A case study of a coal mine district in Western China. Ecol. Indic. 2019, 102, 770–782. [Google Scholar] [CrossRef]

- Fan, L.; Ma, L.; Yu, Y.; Wang, S.; Xu, Y. Water-conserving mining influencing factors identification and weight determination in northwest China. Int. J. Coal Sci. Technol. 2019, 6, 95–101. [Google Scholar] [CrossRef]

- Yu, Y.; Ma, L. Application of roadway backfill mining in water-conservation coal mining: A case study in Northern Shaanxi, China. Sustainability 2019, 11, 3719. [Google Scholar] [CrossRef]

- Yu, X.; Mao, X.; Guo, W. Coordinated waterproof mining mode under thick loose sand stratum in Barapukuria coal mine. J. Chin. Coal Soc. 2019, 44, 739–746. [Google Scholar]

- Gao, W.; Ge, M. Stability of a coal pillar for strip mining based on an elastic-plastic analysis. Int. J. Rock Mech. Min. Sci. 2016, 87, 23–28. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, D.; Wang, S.; Xie, Y.; Yu, Y. Water-preserved mining with the method named “backfilling while mining”. J. Chin. Coal Soc. 2018, 43, 62–69. [Google Scholar]

- Gu, D. Theory framework and technological system of coal mine underground reservoir. J. Chin. Coal Soc. 2015, 40, 239–246. [Google Scholar]

- Gu, D.; Zhang, J. Modern coal mining affected to underground water deposit environment in West China mining area. Coal Sci. Technol. 2012, 40, 114–117. [Google Scholar]

- Li, W.; Wang, Q.; Li, X. Reconstruction of aquifuge: The engineering geological study of N2 laterite located in key aquifuge concerning coal mining with water protection in northwest China. J. Chin. Coal Soc. 2017, 42, 88–97. [Google Scholar]

- Xu, Y. Study on “Five Maps, Three zones and Two Zoning Plans” Water Conservation Mining Method in Yu-Shen Mining Area. Master’s Thesis, China University of Mining Science & Technology, Xuzhou, China, 2019. [Google Scholar]

- Gu, D. Groundwater Protection and Utilization and Ecological Restoration of Large Coal Base in the Contiguous Area of Shanxi Province, Shaanxi Province and Inner Mongolia Autonomous Region, 1st ed.; Science Press: Beijing, China, 2015. [Google Scholar]

- Zhao, C.; Hu, W.; Jin, D. Research on Disturbing Mechanism of Groundwater Environment System and its Evaluation Technique in Shaanxi-Inner Mongolia Coal Mining Region, 1st ed.; China University of Mining and Technology Press: Xuzhou, China, 2018. [Google Scholar]

- Wang, S.; Huang, Q.; Fan, L.; Wang, W. Coal Mining and Ecological Water Level Protection in Ecologically Fragile Areas, 1st ed.; Science Press: Beijing, China, 2010. [Google Scholar]

- Liang, B.; Cao, D. Fuzzy Mathematics and its Application, 1st ed.; Science Press: Beijing, China, 2007; pp. 41–47. [Google Scholar]

- Shaanxi Forestry Department. Available online: http://lyj.shaanxi.gov.cn/ (accessed on 8 July 2020).

- Shaanxi Provincial Water Resources Department. Available online: http://slt.shaanxi.gov.cn/ (accessed on 8 July 2020).

- National Bureau of Statistics. Available online: http://www.stats.gov.cn/ (accessed on 11 July 2020).

- Citroni, R.; Di Paolo, F.; Livreri, P. A novel energy harvester for powering small UAVs: Performance analysis, model validation and flight results. Sensors 2019, 19, 1771. [Google Scholar] [CrossRef]

| Grade | Classification | Φ Value | Remark |

|---|---|---|---|

| I | Carrying surplus | Φ > 0.9 | Mining activity almost has no influence on the WRCCMA, and water resources can contribute to ecology and social development in a good way. |

| II | Capable of carrying | 0.9 ≥ Φ > 0.8 | WRCCMA is slightly affected by mining, while both of them show coordinated development. |

| III | Moderate carrying | 0.8 ≥ Φ > 0.7 | Mining has influenced the WRCCMA to some extent, and some damage has been caused to the surface ecology, but it can be controlled by taking countermeasures. |

| IV | Slightly over-carrying | 0.7 ≥ Φ > 0.6 | Coal mining’s impacts on the WRCCMA have already threatened ecological and human development, and the WRCCMA has reached the critical state. |

| V | Severely over-carrying | Φ ≤ 0.6 | In order to keep the WRCCMA and preserve the eco-environment from continuous deteriorating, mining must be stopped, since its impacts on the WRCCMA have already exceeded the critical state. |

| Weights of Layer B | Weights of Layer C |

|---|---|

| Overburden strata system B1 0.0818 | The distance from coal seam to aquifer C1 0.0273 |

| The thickness of aquifuge C2 0.0545 | |

| Geological structures system B2 0.0434 | Fault strength C3 0.0434 |

| Groundwater system B3 0.3795 | Buried depth of groundwater table C4 0.1550 |

| Recharge of groundwater C5 0.0371 | |

| Groundwater mineralization C6 0.0324 | |

| Water yield property of aquifer C7 0.0775 | |

| Groundwater quality C8 0.0775 | |

| Coal mining system B4 0.3319 | Mining methods C9 0.1791 |

| Mining parameters C10 0.0542 | |

| Surface deformation C11 0.0986 | |

| Ecological system B5 0.0817 | Vegetation coverage C12 0.0272 |

| Total water resources C13 0.0545 | |

| Social system B6 0.0817 | Water utilization rate C14 0.0163 |

| Water resources per capita C15 0.0654 | |

| Total of weights of layer B 1.0000 | Total of weights of layer C 1.0000 |

| Number | Strata | Density (kg/m3) | Bulk Modulus (GPa) | Shear Modulus (GPa) | Cohesion (MPa) | Friction Angle (°) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|---|

| 1 | Fine sandstone | 2600 | 30.8 | 20.3 | 5.6 | 35 | 4.0 |

| 2 | Sandstone | 2500 | 2.5 | 2.3 | 2.2 | 36 | 1.3 |

| 3 | Clay | 1900 | 0.28 | 0.093 | 0.85 | 25 | 0.35 |

| 4 | Siltstone | 2460 | 16.1 | 11.6 | 2.0 | 21 | 1.2 |

| 5 | Gritstone | 2500 | 20.8 | 11.9 | 3.0 | 23 | 1.4 |

| 6 | Mudstone | 2200 | 8.3 | 4.3 | 2.1 | 25 | 1.0 |

| 7 | Medium sandstone | 2560 | 23.1 | 14.5 | 4.4 | 2.8 | 2.0 |

| 8 | Coal seam | 1400 | 2.0 | 1.4 | 1.7 | 28 | 1.5 |

| Name of Fault | F1 | F2 | F3 | F4 | F5 | F6 | F7 |

|---|---|---|---|---|---|---|---|

| Fault strength | 1.23 | 1.38 | 2.77 | 2.87 | 2.87 | 2.34 | 2.58 |

| Year | 2014 | 2015 | 2016 | 2017 | 2018 |

|---|---|---|---|---|---|

| Water utilization rate (%) | 34.28 | 40.12 | 29.63 | 31.19 | 34.99 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Y.; Ma, L.; Khan, N.M. Prediction and Maintenance of Water Resources Carrying Capacity in Mining Area—A Case Study in the Yu-Shen Mining Area. Sustainability 2020, 12, 7782. https://doi.org/10.3390/su12187782

Xu Y, Ma L, Khan NM. Prediction and Maintenance of Water Resources Carrying Capacity in Mining Area—A Case Study in the Yu-Shen Mining Area. Sustainability. 2020; 12(18):7782. https://doi.org/10.3390/su12187782

Chicago/Turabian StyleXu, Yujun, Liqiang Ma, and Naseer Muhammad Khan. 2020. "Prediction and Maintenance of Water Resources Carrying Capacity in Mining Area—A Case Study in the Yu-Shen Mining Area" Sustainability 12, no. 18: 7782. https://doi.org/10.3390/su12187782

APA StyleXu, Y., Ma, L., & Khan, N. M. (2020). Prediction and Maintenance of Water Resources Carrying Capacity in Mining Area—A Case Study in the Yu-Shen Mining Area. Sustainability, 12(18), 7782. https://doi.org/10.3390/su12187782