Active Power Loss Reduction for Radial Distribution Systems by Placing Capacitors and PV Systems with Geography Location Constraints

Abstract

:1. Introduction

- (1)

- Select the appropriate control parameters of SFSOA for finding the best location and the most suitable values for capacitors to reduce total power losses;

- (2)

- Find the best location and capacity of PV systems for reducing total power loss

- (3)

- Demonstrate the fast search time of SFSOA for the considered problem;

- (4)

- Demonstrate the effectiveness of the placement solutions, only capacitors as well as a combination between capacitors and PV sources in reducing power loss and improving the voltage profile of systems.

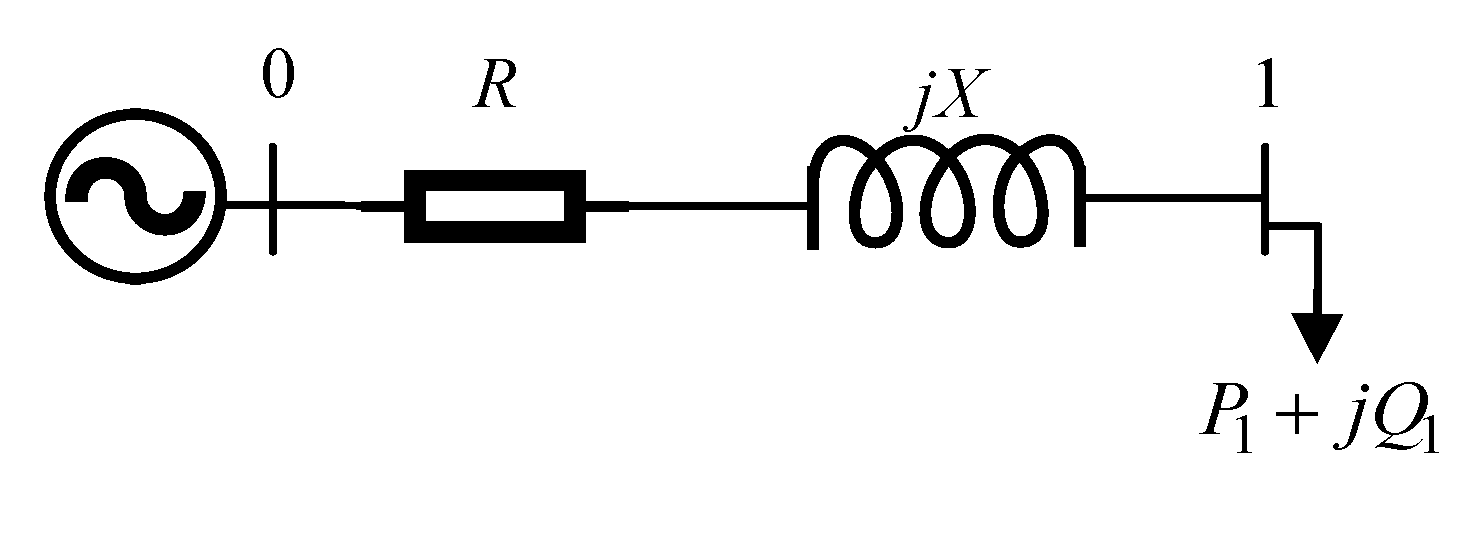

2. Problem Formulation

2.1. The Impact of Capacitors on Power Loss Reduction

- (1)

- Capacitor placement in a distribution power network can reduce power losses and voltage drop;

- (2)

- The power losses can be minimized if capacitors supply the full reactive power of loads;

- (3)

- The higher the capacitor’s capacity is, the better loss reduction is. However, the reactive power of capacitors should not be higher than the total reactive power of loads;

- (4)

- The capacitor’s capacity is directly proportional to the voltage drop reduction.

2.2. Objective Functions

2.3. Constraints

3. Stochastic Fractal Search Optimization Algorithm (SFSOA)

3.1. Diffusion Technique

3.2. The First Update Mechanism

3.3. The Second Update Mechanism

4. The Implementation of SFSOA for Placing Capacitors in Radial Distribution Networks

4.1. Determination of Control Variables

4.2. Determination of the Fitness Function

4.3. Termination Condition

4.4. The Search Process of SFSOA for Optimal Determining the Location and Size of Capacitors in Distribution Networks

5. Numerical Results

5.1. The Impact of Walk on the Performance of SFSOA

5.2. The Performance of SFSOA Compared to Other Similar Approaches for the 33-Node Distribution System

5.3. The Performance of SFSOA Compared to Other Similar Approaches for the 69-Node Distribution Network

5.4. The Impact of Capacitors and PV Systems on the Power Loss Reduction and Votlage Profile Improvement

- (1)

- Higher number of capacitors require higher total compensated capacity;

- (2)

- Power loss decreases once the total installed capacity increases;

- (3)

- Both capacitor and PV system placement can reach higher power loss reduction and better voltage profile; and

- (4)

- Voltage profile is improved significantly when installing one or two capacitors in the test distribution systems; however, the improvement is not in direct proportion to the compensated capacity.

5.5. Discussion on the Capacitor and PV System Placement

5.5.1. Discussion on the Objective Function of Loss Reduction

- -

- The installation of capacitors in distribution systems must be accomplished by power companies for the purpose of reducing loss and improving voltage profile.

- -

- The installation of PV systems must be accomplished by power companies due to the requirement of reducing power from thermal power plants for reducing polluted emissions to the air and for increasing renewable energies.

5.5.2. Discussion on the Geography Location Constraint for PV System Placement

- (1)

- For the 33-node distribution network, suitable nodes for the PV system placement are 5,6, 16, 17, 18, 20, 21, 22, 24, 25, 29, 30, 31 and 32.

- (2)

- For the 69-node distribution network, suitable nodes for the PV system placement are 20, 21, 22, 27, 34, 35, 43, 44, 45, 46, 48, 49, 50, 63, 64 and 65.

5.5.3. Discussion on the Change of Loads

5.5.4. Discussion on the Compensation Capacity

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| CIt | Current computation iteration. |

| HIt | The highest number of iterations |

| Npo | Population size |

| Ndf | The number of diffused solutions |

| Sbest | The best solution in the current set of solutions |

| Rdx | A random number of the xth solution produced in range of 0 and 1 |

| Srd1, Srd2 | Randomly chosen solutions from the population |

| ε | Random number within 0 and 1 |

| Nc | The number of installed capacitors in the distribution networks |

| IFx | The impact factor of the xth solution |

| Nn | The number of nodes in distribution systems |

| The possible maximum current of the lth distribution line | |

| Nl | Number of distribution lines in distribution systems |

| Fx | Fitness function of the xth solution |

| ω1 and ω2 | Penalty parameters |

| Il,x | Current magnitude in the lth branch corresponding to the xth solution |

| Um,x | Voltage magnitude of the mth node corresponding to the xth solution |

Appendix A

| Branch Number | Sending Node | Receiving Node | Resistance (Ω) | Reactance (Ω) | Nominal Load at Receiving Node | Maximum Line Capacity (kVA) | |

|---|---|---|---|---|---|---|---|

| P(kW) | Q(kVAr) | ||||||

| 1 | 1 | 2 | 0.0922 | 0.047 | 100 | 60 | 400 |

| 2 | 2 | 3 | 0.493 | 0.251 | 90 | 40 | 400 |

| 3 | 3 | 4 | 0.3661 | 0.1864 | 120 | 80 | 400 |

| 4 | 4 | 5 | 0.3811 | 0.1941 | 60 | 30 | 400 |

| 5 | 5 | 6 | 0.819 | 0.707 | 60 | 20 | 400 |

| 6 | 6 | 7 | 0.1872 | 0.6188 | 200 | 100 | 300 |

| 7 | 7 | 8 | 1.7117 | 1.2357 | 200 | 100 | 300 |

| 8 | 8 | 9 | 1.0299 | 0.74 | 60 | 20 | 200 |

| 9 | 9 | 10 | 1.044 | 0.74 | 60 | 20 | 200 |

| 10 | 10 | 11 | 0.1967 | 0.0651 | 45 | 30 | 200 |

| 11 | 11 | 12 | 0.3744 | 0.1237 | 60 | 35 | 200 |

| 12 | 12 | 13 | 1.468 | 1.1549 | 60 | 35 | 200 |

| 13 | 13 | 14 | 0.5416 | 0.7129 | 120 | 80 | 200 |

| 14 | 14 | 15 | 0.5909 | 0.526 | 60 | 10 | 200 |

| 15 | 15 | 16 | 0.7462 | 0.5449 | 60 | 20 | 200 |

| 16 | 16 | 17 | 1.2889 | 1.721 | 60 | 20 | 200 |

| 17 | 17 | 18 | 0.732 | 0.5739 | 90 | 40 | 200 |

| 18 | 2 | 19 | 0.164 | 0.1565 | 90 | 40 | 200 |

| 19 | 19 | 20 | 1.5042 | 1.3555 | 90 | 40 | 200 |

| 20 | 20 | 21 | 0.4095 | 0.4784 | 90 | 40 | 200 |

| 21 | 21 | 22 | 0.7089 | 0.9373 | 90 | 40 | 200 |

| 22 | 3 | 23 | 0.4512 | 0.3084 | 90 | 50 | 200 |

| 23 | 23 | 24 | 0.898 | 0.7091 | 420 | 200 | 200 |

| 24 | 24 | 25 | 0.8959 | 0.701 | 420 | 200 | 200 |

| 25 | 6 | 26 | 0.2031 | 0.1034 | 60 | 25 | 300 |

| 26 | 26 | 27 | 0.2842 | 0.1447 | 60 | 25 | 300 |

| 27 | 27 | 28 | 1.0589 | 0.9338 | 60 | 20 | 300 |

| 28 | 28 | 29 | 0.8043 | 0.7006 | 120 | 70 | 200 |

| 29 | 29 | 30 | 0.5074 | 0.2585 | 200 | 600 | 200 |

| 30 | 30 | 31 | 0.9745 | 0.9629 | 150 | 70 | 200 |

| 31 | 31 | 32 | 0.3105 | 0.3619 | 210 | 100 | 200 |

| 32 | 32 | 33 | 0.3411 | 0.5302 | 60 | 40 | 200 |

| Branch Number | Sending Node | Receiving Node | Resistance (Ω) | Reactance (Ω) | Nominal Load at Receiving Node | Maximum Line Capacity (kVA) | |

|---|---|---|---|---|---|---|---|

| P(kW) | Q(kVAr) | ||||||

| 1 | 1 | 2 | 0.0005 | 0.0012 | 0 | 0 | 10,761 |

| 2 | 2 | 3 | 0.0005 | 0.0012 | 0 | 0 | 10,761 |

| 3 | 3 | 4 | 0.0015 | 0.0036 | 0 | 0 | 10,761 |

| 4 | 4 | 5 | 0.0251 | 0.0294 | 0 | 0 | 5823 |

| 5 | 5 | 6 | 0.366 | 0.1864 | 2.6 | 2.2 | 1899 |

| 6 | 6 | 7 | 0.3811 | 0.1941 | 40.4 | 30 | 1899 |

| 7 | 7 | 8 | 0.0922 | 0.047 | 75 | 54 | 1899 |

| 8 | 8 | 9 | 0.0493 | 0.0251 | 30 | 22 | 1899 |

| 9 | 9 | 10 | 0.819 | 0.2707 | 28 | 19 | 1455 |

| 10 | 10 | 11 | 0.1872 | 0.0691 | 145 | 104 | 1455 |

| 11 | 11 | 12 | 0.7114 | 0.2351 | 145 | 104 | 1455 |

| 12 | 12 | 13 | 1.03 | 0.34 | 8 | 5.5 | 1455 |

| 13 | 13 | 14 | 1.044 | 0.345 | 8 | 5.5 | 1455 |

| 14 | 14 | 15 | 1.058 | 0.3496 | 0 | 0 | 1455 |

| 15 | 15 | 16 | 0.1966 | 0.065 | 45.5 | 30 | 1455 |

| 16 | 16 | 17 | 0.3744 | 0.1238 | 60 | 35 | 1455 |

| 17 | 17 | 18 | 0.0047 | 0.0016 | 60 | 35 | 2200 |

| 18 | 18 | 19 | 0.3276 | 0.1083 | 0 | 0 | 1455 |

| 19 | 19 | 20 | 0.2106 | 0.069 | 1 | 0.6 | 1455 |

| 20 | 20 | 21 | 0.3416 | 0.1129 | 114 | 81 | 1455 |

| 21 | 21 | 22 | 0.014 | 0.0046 | 5.3 | 3.5 | 1455 |

| 22 | 22 | 23 | 0.1591 | 0.0526 | 0 | 0 | 1455 |

| 23 | 23 | 24 | 0.3463 | 0.1145 | 28 | 20 | 1455 |

| 24 | 24 | 25 | 0.7488 | 0.2745 | 0 | 0 | 1455 |

| 25 | 25 | 26 | 0.3089 | 0.1021 | 14 | 10 | 1455 |

| 26 | 26 | 27 | 0.1732 | 0.0572 | 14 | 10 | 1455 |

| 27 | 3 | 28 | 0.0044 | 0.0108 | 26 | 18.6 | 10,761 |

| 28 | 28 | 29 | 0.064 | 0.1565 | 26 | 18.6 | 10,761 |

| 29 | 29 | 30 | 0.3978 | 0.1315 | 0 | 0 | 1455 |

| 30 | 30 | 31 | 0.0702 | 0.0232 | 0 | 0 | 1455 |

| 31 | 31 | 32 | 0.351 | 0.116 | 0 | 0 | 1455 |

| 32 | 32 | 33 | 0.839 | 0.2816 | 14 | 10 | 2200 |

| 33 | 33 | 34 | 1.708 | 0.5646 | 19.5 | 14 | 1455 |

| 34 | 34 | 35 | 1.474 | 0.4673 | 6 | 4 | 1455 |

| 35 | 3 | 36 | 0.0044 | 0.0108 | 26 | 18.55 | 10,761 |

| 36 | 36 | 37 | 0.064 | 0.1565 | 26 | 18.55 | 10,761 |

| 37 | 37 | 38 | 0.1053 | 0.123 | 0 | 0 | 5823 |

| 38 | 38 | 39 | 0.0304 | 0.0355 | 24 | 17 | 5823 |

| 39 | 39 | 40 | 0.0018 | 0.0021 | 24 | 17 | 5823 |

| 40 | 40 | 41 | 0.7283 | 0.8509 | 1.2 | 1 | 5823 |

| 41 | 41 | 42 | 0.31 | 0.3623 | 0 | 0 | 5823 |

| 42 | 42 | 43 | 0.041 | 0.0478 | 6 | 4.3 | 5823 |

| 43 | 43 | 44 | 0.0092 | 0.0116 | 0 | 0 | 5823 |

| 44 | 44 | 45 | 0.1089 | 0.1373 | 39.22 | 26.3 | 5823 |

| 45 | 45 | 46 | 0.0009 | 0.0012 | 39.22 | 26.3 | 6709 |

| 46 | 4 | 47 | 0.0034 | 0.0084 | 0 | 0 | 10,761 |

| 47 | 47 | 48 | 0.0851 | 0.2083 | 79 | 56.4 | 10,761 |

| 48 | 48 | 49 | 0.2898 | 0.7091 | 384.7 | 274.5 | 10,761 |

| 49 | 49 | 50 | 0.0822 | 0.2011 | 384 | 274.5 | 10,761 |

| 50 | 8 | 51 | 0.0928 | 0.0473 | 40.5 | 28.3 | 1899 |

| 51 | 51 | 52 | 0.3319 | 0.1114 | 3.6 | 2.7 | 2200 |

| 52 | 9 | 53 | 0.174 | 0.0886 | 4.35 | 3.5 | 1899 |

| 53 | 53 | 54 | 0.203 | 0.1034 | 26.4 | 19 | 1899 |

| 54 | 54 | 55 | 0.2842 | 0.1447 | 24 | 17.2 | 1899 |

| 55 | 55 | 56 | 0.2813 | 0.1433 | 0 | 0 | 1899 |

| 56 | 56 | 57 | 1.59 | 0.5337 | 0 | 0 | 2200 |

| 57 | 57 | 58 | 0.7837 | 0.263 | 0 | 0 | 2200 |

| 58 | 58 | 59 | 0.3042 | 0.1006 | 100 | 72 | 1455 |

| 59 | 59 | 60 | 0.3861 | 0.1172 | 0 | 0 | 1455 |

| 60 | 60 | 61 | 0.5075 | 0.2585 | 1244 | 888 | 1899 |

| 61 | 61 | 62 | 0.0974 | 0.0496 | 32 | 23 | 1899 |

| 62 | 62 | 63 | 0.145 | 0.0738 | 0 | 0 | 1899 |

| 63 | 63 | 64 | 0.7105 | 0.3619 | 227 | 162 | 1899 |

| 64 | 64 | 65 | 1.041 | 0.5302 | 59 | 42 | 1899 |

| 65 | 11 | 66 | 0.2012 | 0.0611 | 18 | 13 | 1455 |

| 66 | 66 | 67 | 0.0047 | 0.0014 | 18 | 13 | 1455 |

| 67 | 12 | 68 | 0.7394 | 0.2444 | 28 | 20 | 1455 |

| 68 | 68 | 69 | 0.0047 | 0.0016 | 28 | 20 | 1455 |

References

- Jafari, A.; Ganjehlou, H.G.; Darbandi, F.B.; Mohammdi-Ivatloo, B.; Abapour, M. Dynamic and multi-objective reconfiguration of distribution network using a novel hybrid algorithm with parallel processing capability. Appl. Soft Comput. 2020, 90, 106146. [Google Scholar] [CrossRef]

- Jakus, D.; Čađenović, R.; Vasilj, J.; Sarajčev, P. Optimal reconfiguration of distribution networks using hybrid heuristic-genetic algorithm. Energies 2020, 13, 1544. [Google Scholar] [CrossRef] [Green Version]

- Guo, S.; Lin, J.; Zhao, Y.; Wang, L.; Wang, G.; Liu, G. A Reliability-based network reconfiguration model in distribution system with DGs and ESSs using mixed-integer programming. Energies 2020, 13, 1219. [Google Scholar] [CrossRef] [Green Version]

- Kadir, A.F.A.; Mohamed, A.; Shareef, H.; Wanik, M.Z.C. Optimal placement and sizing of distributed generations in distribution systems for minimizing losses and THD_v using evolutionary programming. Turk. J. Electr. Eng. Comput. Sci. 2013, 21, 2269–2282. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Nguyen, T.T. An improved cuckoo search algorithm for the problem of electric distribution network reconfiguration. Appl. Soft Comput. 2019, 84, 105720. [Google Scholar] [CrossRef]

- Kaveh, M.R.; Hooshmand, R.A.; Madani, S.M. Simultaneous optimization of re-phasing, reconfiguration and DG placement in distribution networks using BF-SD algorithm. Appl. Soft Comput. 2018, 62, 1044–1055. [Google Scholar] [CrossRef]

- Kishore, C.; Ghosh, S.; Karar, V. Symmetric fuzzy logic and IBFOA solutions for optimal position and rating of capacitors allocated to radial distribution networks. Energies 2018, 11, 766. [Google Scholar] [CrossRef] [Green Version]

- Sirjani, R. Optimal capacitor placement in wind farms by considering harmonics using discrete lightning search algorithm. Sustainability 2017, 9, 1669. [Google Scholar] [CrossRef] [Green Version]

- Al-Ammar, E.A.; Ghazi, G.A.; Ko, W. Impact of ambient temperature on shunt capacitor placement in a distorted radial distribution system. Energies 2018, 11, 1585. [Google Scholar] [CrossRef] [Green Version]

- Muthukumar, K.; Jayalalitha, S. Integrated approach of network reconfiguration with distributed generation and shunt capacitors placement for power loss minimization in radial distribution networks. Appl. Soft Comput. 2017, 52, 1262–1284. [Google Scholar]

- Haque, M.H. Capacitor placement in radial distribution systems for loss reduction. IEE Proc. Gener. Transm. Distrib. 1999, 146, 501–505. [Google Scholar] [CrossRef]

- Khodr, H.M.; Olsina, F.G.; de Oliveira-de Jesus, P.M.; Yusta, J.M. Maximum savings approach for location and sizing of capacitors in distribution systems. Electr. Power Syst. Res. 2008, 78, 1192–1203. [Google Scholar] [CrossRef] [Green Version]

- Abul’Wafa, A.R. Optimal capacitor allocation in radial distribution systems for loss reduction: A two stage method. Electr. Power Syst. Res. 2013, 95, 168–174. [Google Scholar] [CrossRef]

- Viral, R.; Khatod, D.K. An analytical approach for sizing and siting of DGs in balanced radial distribution networks for loss minimization. Int. J. Electr. Power Energy Syst. 2015, 67, 191–201. [Google Scholar] [CrossRef]

- Prakash, K.; Sydulu, M. Particle swarm optimization based capacitor placement on radial distribution systems. In Proceedings of the 2007 IEEE Power Engineering Society General Meeting, Tampa, FL, USA, 24–28 June 2007; pp. 1–5. [Google Scholar]

- Bapu, R.S.; Prakash, C.; Kannan, S.M. Optimal capacitor allocation in 69-bus radial distribution system to improve annual cost savings for dynamic load. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 834–840. [Google Scholar]

- Lee, C.S.; Ayala, H.V.H.; dos Santos Coelho, L. Capacitor placement of distribution systems using particle swarm optimization approaches. Int. J. Electr. Power Energy Syst. 2015, 64, 839–851. [Google Scholar] [CrossRef]

- Murthy, K.R.; Raju, M.R.; Rao, G.G. Comparison between conventional, GA and PSO with respect to optimal capacitor placement in agricultural distribution system. In Proceedings of the Annual IEEE India Conference (INDICON), Kolkata, India, 17–19 December 2010; pp. 1–4. [Google Scholar]

- Lohia, S.; Mahela, O.P.; Ola, S.R. Optimal capacitor placement in distribution system using genetic algorithm. In Proceedings of the IEEE 7th Power India International Conference (PIICON), Bikaner, India, 25–27 November 2016; pp. 1–6. [Google Scholar]

- Reddy, M.D. Optimal capacitor placement using fuzzy and real coded genetic algorithm for maximum savings. J. Theor. Appl. Inf. Technol. 2008, 4, 219–226. [Google Scholar]

- Nojavan, S.; Jalali, M.; Zare, K. Optimal allocation of capacitors in radial/mesh distribution systems using mixed integer nonlinear programming approach. Electr. Power Syst. Res. 2014, 107, 119–124. [Google Scholar] [CrossRef]

- Hung, D.Q.; Mithulananthan, N.; Bansal, R.C. A combined practical approach for distribution system loss reduction. Int. J. Ambient Energy 2015, 36, 123–131. [Google Scholar] [CrossRef]

- Sultana, S.; Roy, P.K. Optimal capacitor placement in radial distribution systems using teaching learning based optimization. Int. J. Electr. Power Energy Syst. 2014, 54, 387–398. [Google Scholar] [CrossRef]

- Kowsalya, M.; Mohamed, I.A. Optimal distributed generation and capacitor placement in power distribution networks for power loss minimization. In Proceedings of the International Conference on Advances in Electrical Engineering (ICAEE), Vellore, India, 9–11 January 2014; pp. 1–6. [Google Scholar]

- Shuaib, Y.M.; Kalavathi, M.S.; Rajan, C.C.A. Optimal capacitor placement in radial distribution system using gravitational search algorithm. Int. J. Electr. Power Energy Syst. 2015, 64, 384–397. [Google Scholar] [CrossRef]

- Abdelaziz, A.Y.; Ali, E.S.; Elazim, S.A. Flower pollination algorithm and loss sensitivity factors for optimal sizing and placement of capacitors in radial distribution systems. Int. J. Electr. Power Energy Syst. 2016, 78, 207–214. [Google Scholar] [CrossRef]

- Tamilselvan, V.; Jayabarathi, T.; Raghunathan, T.; Yang, X.S. Optimal capacitor placement in radial distribution systems using flower pollination algorithm. Alex. Eng. J. 2018, 57, 2775–2786. [Google Scholar] [CrossRef]

- Devabalaji, K.R.; Yuvaraj, T.; Ravi, K. An efficient method for solving the optimal sitting and sizing problem of capacitor banks based on cuckoo search algorithm. Ain Shams Eng. J. 2018, 9, 589–597. [Google Scholar] [CrossRef] [Green Version]

- Khodabakhshian, A.; Andishgar, M.H. Simultaneous placement and sizing of DGs and shunt capacitors in distribution systems by using IMDE algorithm. Int. J. Electr. Power Energy Syst. 2016, 82, 599–607. [Google Scholar] [CrossRef]

- Mohamed, E.A.; Mitani, Y. MSA for optimal reconfiguration and capacitor allocation in radial/ring distribution networks. IJIMAI 2018, 5, 107–122. [Google Scholar] [CrossRef]

- Kamel, S.; Amin, A.; Selim, A.; Ahmed, M.H. Optimal placement of DG and capacitor in radial distribution systems considering load variation. In Proceedings of the International Conference on Computer, Control, Electrical, and Electronics Engineering (ICCCEEE), Khartoum, Sudan, 21–23 September 2019; pp. 1–6. [Google Scholar]

- Bayat, A.; Bagheri, A. Optimal active and reactive power allocation in distribution networks using a novel heuristic approach. Appl. Energy 2019, 233, 71–85. [Google Scholar] [CrossRef]

- Pérez Abril, I. Capacitor placement by variables’ inclusion and interchange improved algorithm. Int. Trans. Electr. Energy Syst. 2020, 30, e12377. [Google Scholar] [CrossRef]

- Salimi, H. Stochastic fractal search: A powerful metaheuristic algorithm. Knowl. Based Syst. 2015, 75, 1–18. [Google Scholar] [CrossRef]

- Lakervi, E.; Holmes, E.J. Electricity Distribution Network Design, 2nd ed.; IET: London, UK, 1995. [Google Scholar]

- Nguyen, T.T.; Pham, T.D.; Kien, L.C.; van Dai, L. Improved coyote optimization algorithm for optimally installing solar photovoltaic distribution generation units in radial distribution power systems. Complexity 2020, 2020, 1603802. [Google Scholar] [CrossRef]

- Rajendran, A.; Narayanan, K. Novel multi-objective hybrid WIPSO-GSA algorithm-based optimal DG and capacitor planning for techno-economic benefits in radial distribution system. Int. J. Energy Sector Manag. 2019, 13, 98–127. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Vo, D.N.; Dinh, B.H. An effectively adaptive selective cuckoo search algorithm for solving three complicated short-term hydrothermal scheduling problems. Energy 2018, 155, 930–956. [Google Scholar] [CrossRef]

| Family Method | Method, Published Year | Study Cases |

|---|---|---|

| Deterministic methods | Two-step method [11], 1999 Two-step method [12], 2008 Two-step method [13], 2013 Two-step method [14], 2015 MINPA [21], 2014 CPA [22], 2015 PLSF-AA [31], 2019 NFBHA [32], 2019 | 15 and 33-node systems 15 and 33-node systems 28 and 85-node systems 15 and 33-node systems 10, 34, and 85-node systems 33 and 687-node systems 33, 69-node systems 33, 69 and 119-node systems |

| PSO methods | CIF-PSO [15], 2007 MAs-PSO [16], 2013 DADs-PSO [17], 2015 | 10, 15, 34, 69 and 85 bus 69-node system 9-node system |

| GA methods | GA [18], 2010 GA [19], 2016 RCGA [20], 2008 | 22-node system 33-node system 15, 34 and 69-node systems |

| Other metaheuristic algorithms | TLA [23], 2014 BFOA [24], 2014 GSA [25], 2015 FPA [26], 2016 FPA [27], 2018 CSA [28], 2018 IMDE [29], 2016 MSA [30], 2018 IIA [33], 2020 | 22, 69, 85 and 141-node systems 33-node system 33, 69, 85-node systems 10, 33 and 69-node systems 33, 34, 69 and 85-node systems 34 and 69-node systems 33 and 69-node systems 33 and 69 and 85-nodes systems 33, 34, 69 and 85-nodes systems |

| Study Case | PPV = 20% PLoad | PPV < PLoad | ||||

|---|---|---|---|---|---|---|

| Nc = 1 | Nc = 2 | Nc = 3 | Nc = 1 | Nc = 2 | Nc = 3 | |

| Min. loss (kW) | 83.531 | 75.383 | 72.016 | 58.458 | 50.373 | 47.232 |

| Mean loss (kW) | 83.807 | 75.404 | 72.037 | 58.593 | 50.413 | 47.429 |

| Max. loss (kW) | 85.129 | 75.600 | 72.212 | 60.242 | 52.121 | 48.974 |

| Std. dev. | 0.335 | 0.047 | 0.044 | 0.442 | 0.248 | 0.532 |

| Study Case | Nc = 1 | Nc = 2 | Nc = 3 |

|---|---|---|---|

| Min. loss (kW) | 152.04 | 146.44 | 145.12 |

| Mean loss (kW) | 154.70 | 146.60 | 145.49 |

| Max. loss (kW) | 199.53 | 149.27 | 146.61 |

| Std. dev. | 9.49 | 0.576 | 0.477 |

| Study Case | PPV = 20% PLoad | PPV < PLoad | ||||

|---|---|---|---|---|---|---|

| Nc = 1 | Nc = 2 | Nc=3 | Nc = 1 | Nc = 2 | Nc = 3 | |

| Min. loss (kW) | 64.632 | 59.345 | 58.198 | 23.198 | 18.144 | 17.100 |

| Mean loss (kW) | 67.035 | 61.812 | 59.399 | 26.413 | 24.511 | 23.457 |

| Max. loss (kW) | 123.833 | 118.462 | 117.224 | 102.92 | 97.733 | 96.549 |

| Std. dev. | 11.712 | 11.683 | 8.345 | 15.777 | 21.811 | 21.773 |

| Study Case | Method | Npo | HIt | Bus (Size) (kVAr) | Total Capacity (kVAr) | Power Loss (KW) |

|---|---|---|---|---|---|---|

| Nc = 0 | - | - | - | - | 211 | |

| Nc = 1 | NFBHA [32] | - | - | 30 (1190) | 1190 | 151.55 |

| SFSOA | 10 | 30 | 30 (1258) | 1258 | 151.37 | |

| Nc = 2 | NFBHA [32] | - | - | 13 (405), 30 (1052) | 1457 | 141.9 |

| SFSOA | 10 | 30 | 12 (473), 30 (1059) | 1522 | 141.84 | |

| Nc = 3 | BFOA [24] | 50 | 50 | 18(349.6),30 (820.6), 33 (277.3) | 1447.5 | 144.04 |

| FPA [27] | NR | NR | 13 (450), 24 (450), 30 (900) | 1800 | 139.075 | |

| PLSF-AA [31] | - | - | 13 (359), 24 (520), 30 (1016) | 1895 | 138.37 | |

| NFBHA [32] | - | - | 13 (383), 25 (386), 30 1000) | 1769 | 138.65 | |

| SFSOA | 10 | 30 | 14 (335), 24 (539), 30 (1050) | 1924 | 138.41 |

| Study Case | Method | Npo | HIt | Bus (Size) (kVAr) | Total Capacity (KVAr) | Total Loss (KW) |

|---|---|---|---|---|---|---|

| Nc = 0 | - | - | - | - | - | 225 |

| Nc = 1 | SFSOA | 10 | 40 | 61 (1330) | 1330 | 152.04 |

| Nc = 2 | RCGA [20] | 30 | 1000 | 61 (1029), 64 (207) | 1236 | 152.0541 |

| SFSOA | 10 | 40 | 17 (361), 61 (1275) | 1636 | 146.44 | |

| Nc = 3 | Two-step [13] | - | - | 19 (225), 63 (900), 63 (225) | 1350 | 148.91 |

| CIF-PSO [15] | NR | NR | 46 (241), 47 (365), 50 (1015) | 1621 | 152.48 | |

| TLA [23] | 50 | 100 | 12 (600), 61 (1050), 64 (150) | 1800 | 146.35 | |

| FPA [27] | NR | NR | 11 (450), 22 (150), 61 (1350) | 1950 | 145.86 | |

| CSA [28] | 50 | NR | 18 (350), 61 (1150), 65 (65) | 1565 | 146.1 | |

| MSA [30] | 50 | 100 | 12 (450), 21 (150), 61 (1200) | 1800 | 145.41 | |

| PLSF-AA [31] | - | - | 11 (368), 21 (231), 61 (1196) | 1795 | 145.21 | |

| SFSOA | 10 | 40 | 11 (412), 21 (230), 61 (1232) | 1874 | 145.11 |

| Study Case | Number of Capacitors | 33-Node Network | 69-Node Network | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Total kVAr | TPL (KW) | PLR (kW) | PLR (%) | Total kVAr | TPL (KW) | PLR (kW) | PLR (%) | ||

| Without PV system | Nc = 0 | - | 211 | - | - | - | 225 | - | - |

| Nc = 1 | 1258 | 151.37 | 59.63 | 28.26 | 1330 | 152.04 | 72.96 | 32.43 | |

| Nc = 2 | 1447.5 | 144.04 | 66.96 | 31.73 | 1636 | 146.44 | 78.56 | 34.92 | |

| Nc = 3 | 1922 | 138.41 | 72.59 | 34.4 | 1874 | 145.11 | 79.89 | 35.51 | |

| With PV system (20% PLoad) | Nc = 1 | 1258 | 83.531 | 127.469 | 60.41 | 1330 | 64.632 | 160.368 | 71.27 |

| Nc = 2 | 1447.5 | 75.383 | 135.617 | 64.27 | 1636 | 59.345 | 165.655 | 73.62 | |

| Nc = 3 | 1922 | 72.016 | 138.984 | 65.87 | 1874 | 58.198 | 166.802 | 74.13 | |

| With PV system (<PLoad) | Nc = 1 | 1258 | 58.458 | 152.542 | 72.29 | 1330 | 23.198 | 201.802 | 89.69 |

| Nc = 2 | 1447.5 | 50.373 | 160.627 | 76.13 | 1636 | 18.144 | 206.856 | 91.94 | |

| N c= 3 | 1922 | 47.232 | 163.768 | 77.62 | 1874 | 17.1 | 207.9 | 92.4 | |

| Study Case | PPV = 20% PLoad | PPV = 20% PLoad & Constrained PV Location | ||||

|---|---|---|---|---|---|---|

| Nc = 1 | Nc = 2 | Nc = 3 | Nc = 1 | Nc = 2 | Nc = 3 | |

| Min. loss (kW) | 83.531 | 75.383 | 72.016 | 85.43 | 77.18 | 73.806 |

| Mean loss (kW) | 83.807 | 75.404 | 72.037 | 85.72 | 77.18 | 73.929 |

| Max. loss (kW) | 85.129 | 75.600 | 72.212 | 91.18 | 77.24 | 79.059 |

| Std. dev. | 0.335 | 0.047 | 0.044 | 1.15 | 0.01 | 0.742 |

| PV location | 14 | 14 | 14 | 16 | 16 | 16 |

| Size of PV (kW) | 742.97 | 743 | 143 | 143 | 743 | 743 |

| Study Case | PPV < PLoad | PPV < PLoad & Constrained PV Location | ||||

|---|---|---|---|---|---|---|

| Nc = 1 | Nc = 2 | Nc = 3 | Nc = 1 | Nc = 2 | Nc = 3 | |

| Min. loss (kW) | 58.458 | 50.373 | 47.232 | 58.458 | 50.373 | 47.232 |

| Mean loss (kW) | 58.593 | 50.413 | 47.429 | 61.050 | 51.292 | 48.916 |

| Max. loss (kW) | 60.242 | 52.121 | 48.974 | 81.413 | 72.844 | 69.664 |

| Std. dev. | 0.442 | 0.248 | 0.532 | 7.052 | 4.446 | 5.571 |

| PV location | 6 | 6 | 6 | 6 | 6 | 6 |

| Size of PV (kW) | 2531 | 2519.32 | 2517.17 | 2532 | 2519.32 | 2517.17 |

| Study Case | PPV = 20% PLoad | PPV = 20% PLoad & Constrained PV Location | ||||

|---|---|---|---|---|---|---|

| Nc = 1 | Nc = 2 | Nc = 3 | Nc = 1 | Nc = 2 | Nc = 3 | |

| Min. loss (kW) | 64.632 | 59.345 | 58.198 | 64.845 | 59.557 | 58.410 |

| Mean loss (kW) | 67.035 | 61.812 | 59.399 | 73.462 | 69.397 | 65.824 |

| Max. loss (kW) | 123.833 | 118.462 | 117.224 | 126.052 | 120.670 | 119.449 |

| Std. dev. | 11.712 | 11.683 | 8.345 | 21.435 | 22.605 | 20.013 |

| PV location | 61 | 61 | 61 | 63 | 63 | 63 |

| Size of PV (kW) | 760 | 760 | 760 | 760 | 760 | 760 |

| Study Case | PPV < PLoad | PPV < PLoad & Constrained PV Location | ||||

|---|---|---|---|---|---|---|

| Nc = 1 | Nc = 2 | Nc = 3 | Nc = 1 | Nc = 2 | Nc = 3 | |

| Min. loss (kW) | 23.198 | 18.144 | 17.100 | 26.455 | 21.389 | 20.342 |

| Mean loss (kW) | 26.413 | 24.511 | 23.457 | 52.686 | 41.435 | 38.369 |

| Max. loss (kW) | 102.92 | 97.733 | 96.549 | 126.052 | 120.670 | 119.449 |

| Std. dev. | 15.777 | 21.811 | 21.773 | 43.96 | 40.037 | 38.391 |

| PV location | 61 | 61 | 61 | 63 | 63 | 63 |

| Size of PV (kW) | 1830.25 | 1826.99 | 1826.515 | 1769.32 | 1767.45 | 1766.94 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, T.T.; Dinh, B.H.; Pham, T.D.; Nguyen, T.T. Active Power Loss Reduction for Radial Distribution Systems by Placing Capacitors and PV Systems with Geography Location Constraints. Sustainability 2020, 12, 7806. https://doi.org/10.3390/su12187806

Nguyen TT, Dinh BH, Pham TD, Nguyen TT. Active Power Loss Reduction for Radial Distribution Systems by Placing Capacitors and PV Systems with Geography Location Constraints. Sustainability. 2020; 12(18):7806. https://doi.org/10.3390/su12187806

Chicago/Turabian StyleNguyen, Thuan Thanh, Bach Hoang Dinh, Thai Dinh Pham, and Thang Trung Nguyen. 2020. "Active Power Loss Reduction for Radial Distribution Systems by Placing Capacitors and PV Systems with Geography Location Constraints" Sustainability 12, no. 18: 7806. https://doi.org/10.3390/su12187806

APA StyleNguyen, T. T., Dinh, B. H., Pham, T. D., & Nguyen, T. T. (2020). Active Power Loss Reduction for Radial Distribution Systems by Placing Capacitors and PV Systems with Geography Location Constraints. Sustainability, 12(18), 7806. https://doi.org/10.3390/su12187806