Study on the Selection of Sections Applicable to Truck Platooning in the Expressway Network

Abstract

:1. Introduction

1.1. Research Background and Purpose

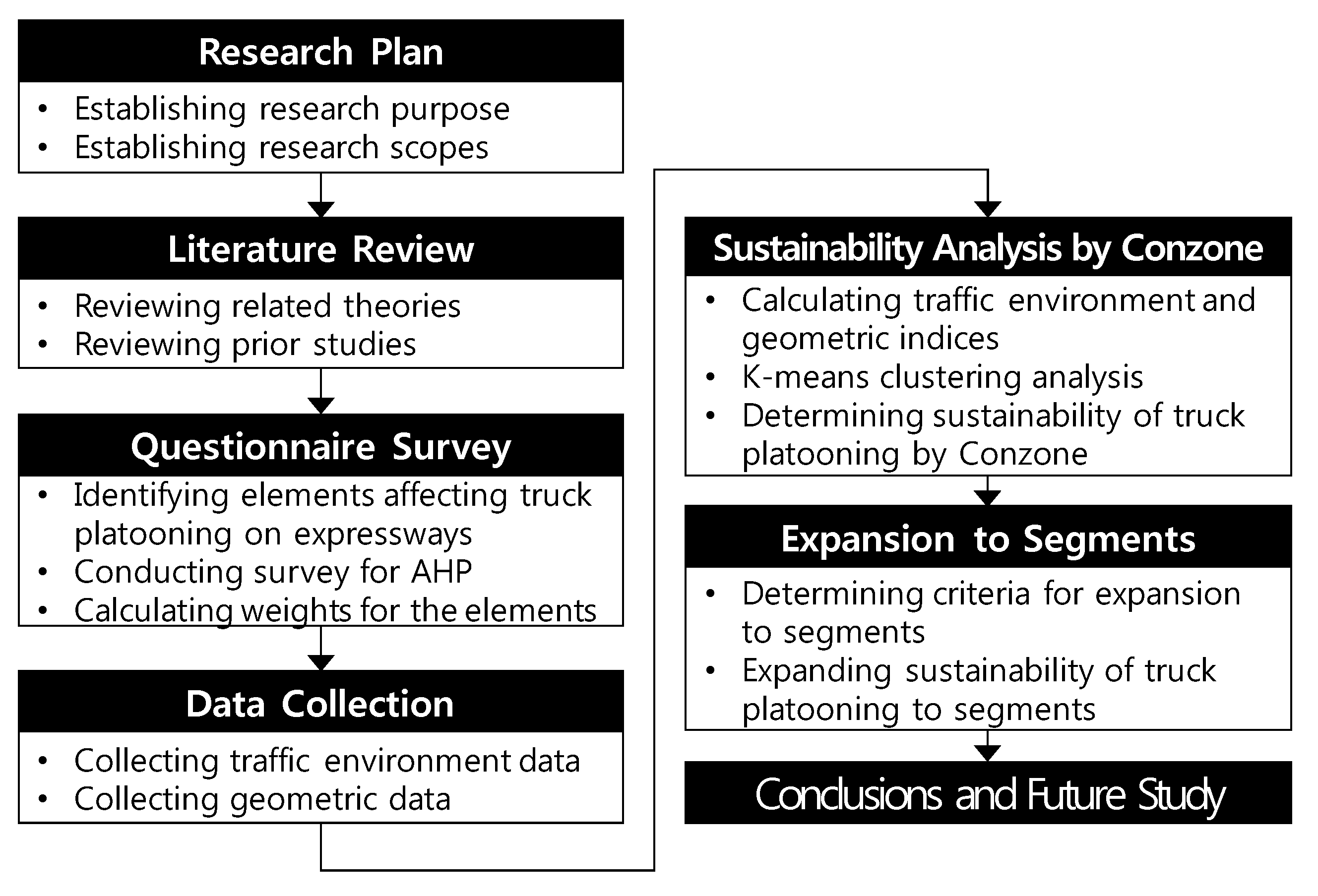

1.2. Research Scope and Process

2. Literature Review

2.1. Truck Platooning

2.2. Implications

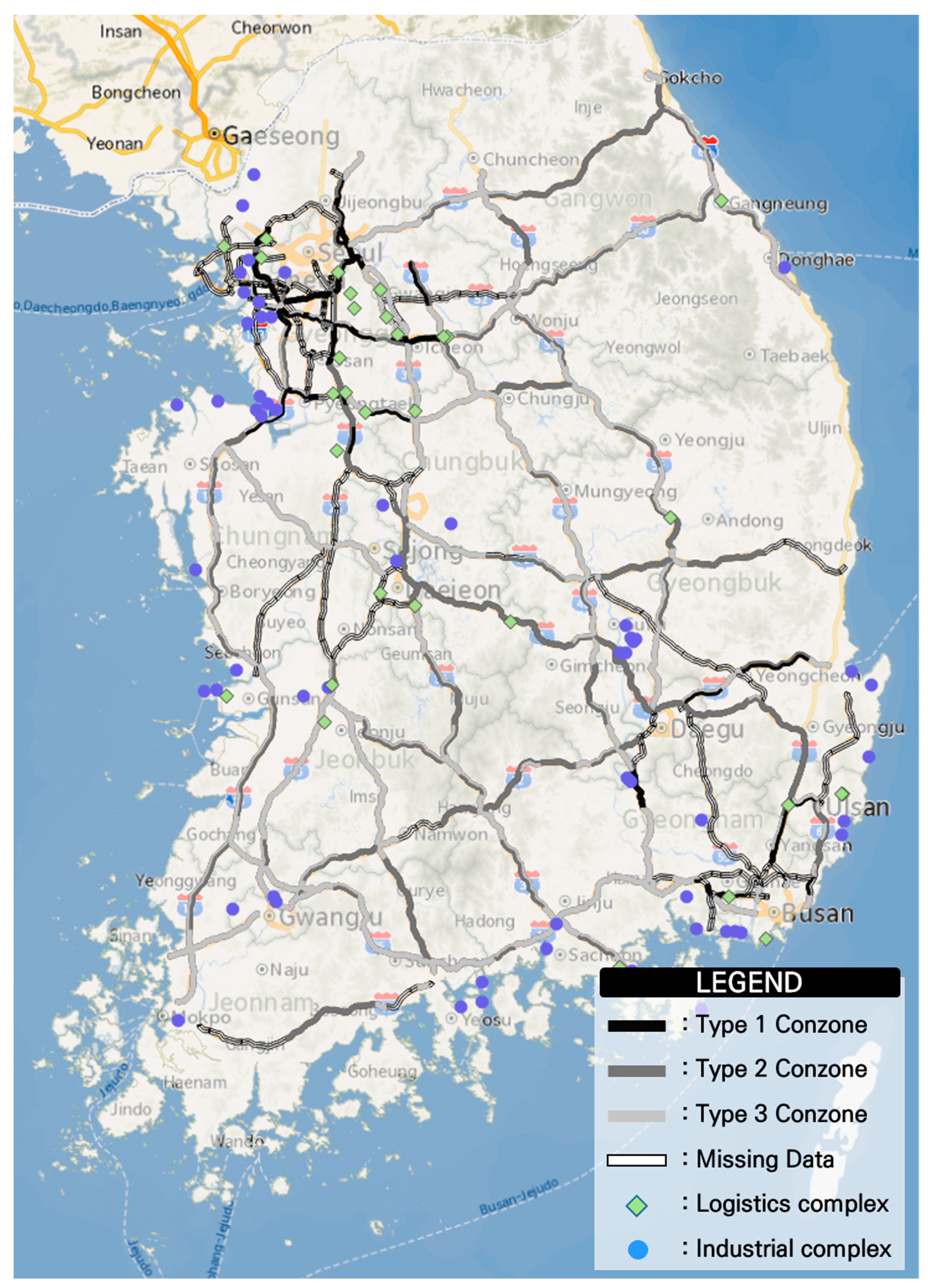

3. Selection of Sections Applicable to Truck Platooning in the Expressway Network

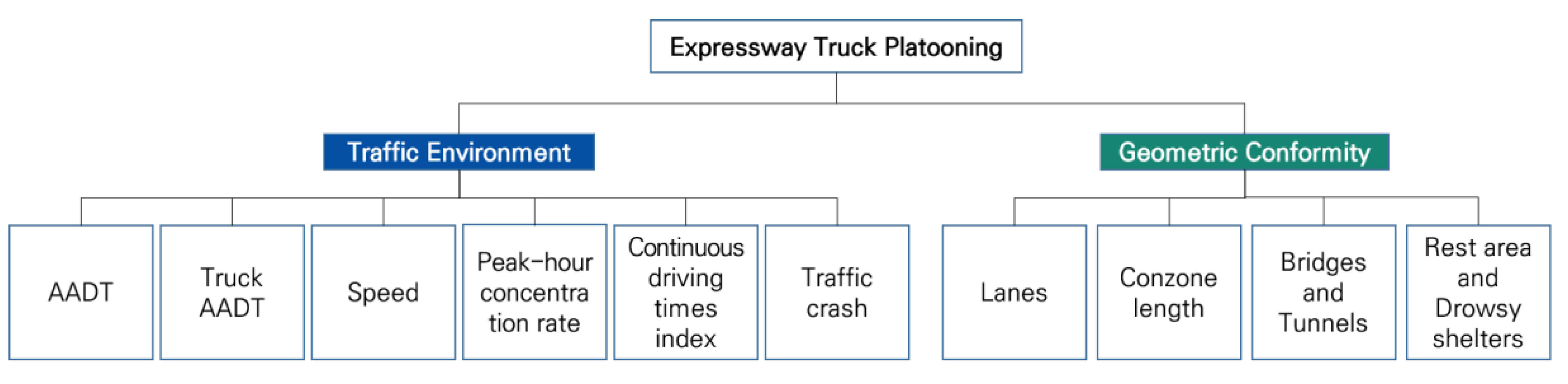

3.1. Elements Affecting Truck Platooning on Expressway

3.2. Calculation of Element Weights

3.3. Conzone Date Collection

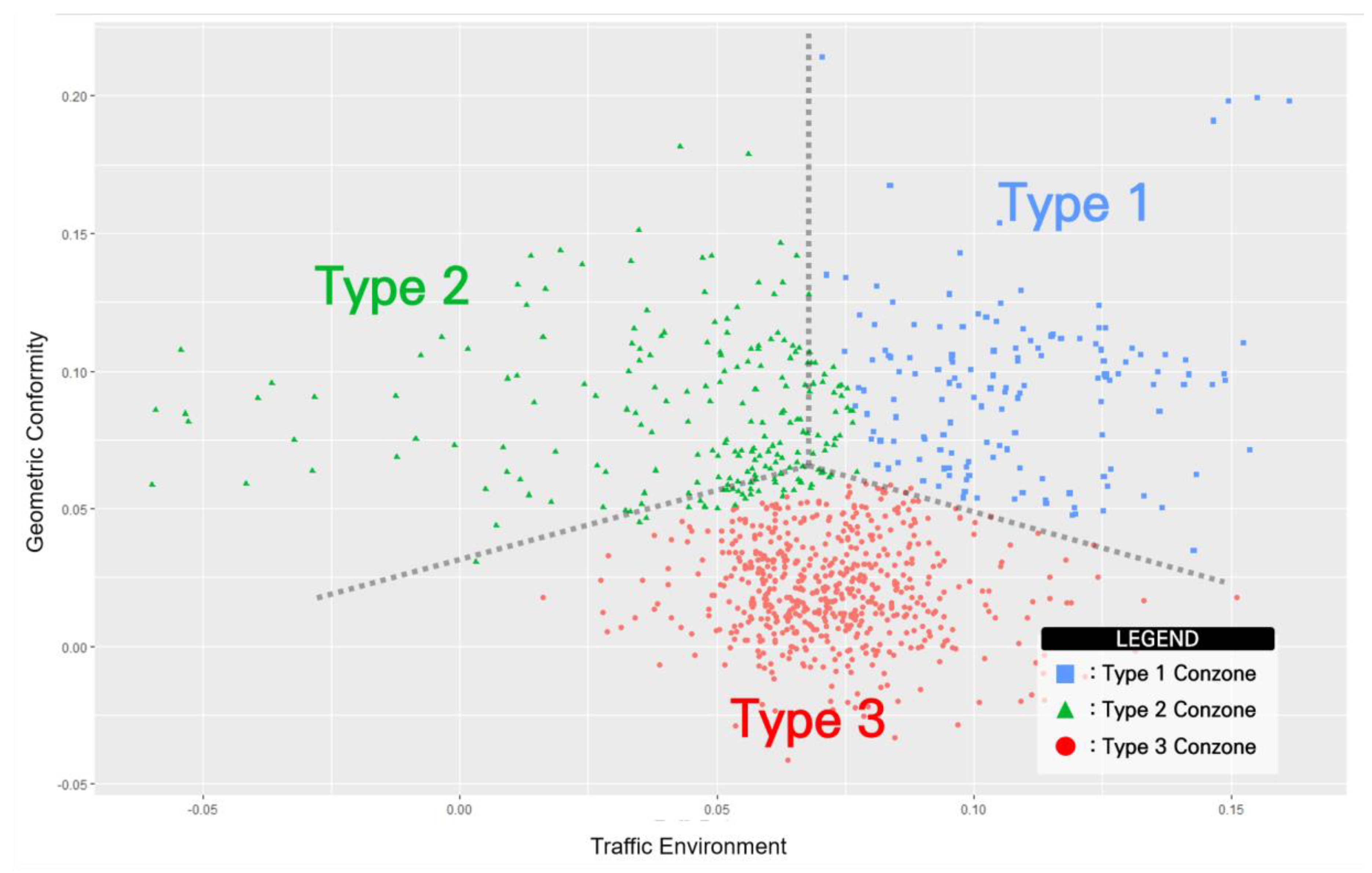

3.4. Conzone Unit Suitability Analysis

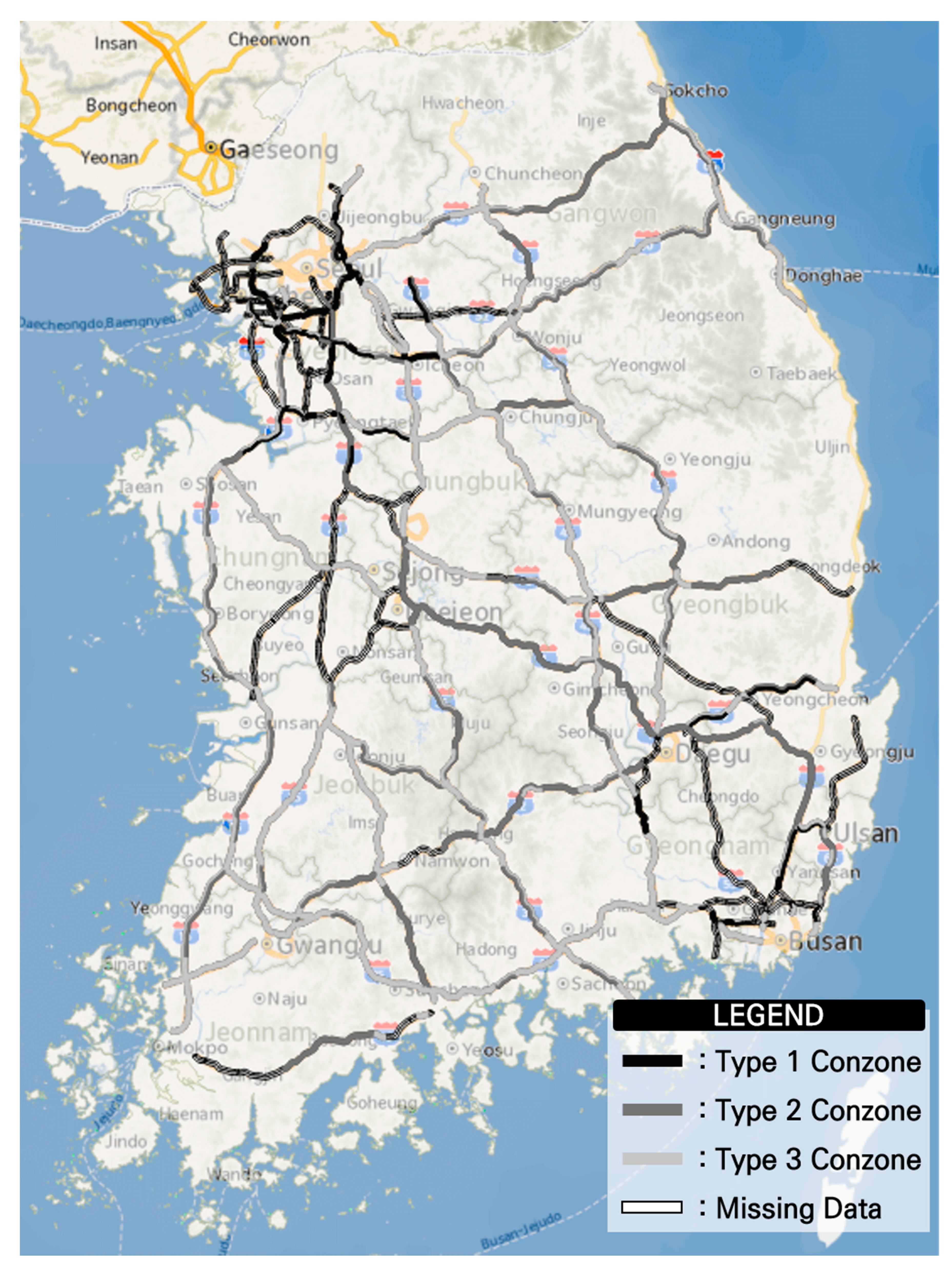

3.5. Sectional Expansion

4. Conclusions and Future Research

4.1. Conclusions

4.2. Future Research

Author Contributions

Funding

Conflicts of Interest

Data Availability

References

- Tsugawa, S.; Kato, S.; Aoki, K. An Automated Truck Platoon for Energy Saving. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems 2011, San Francisco, CA, USA, 25–30 September 2011. [Google Scholar] [CrossRef]

- Bergenhem, C.; Shladover, S.; Coelingh, E.; Englund, C.; Tsugawa, S. Overview of Platooning Systems. In Proceedings of the 19th World Congress on Intelligent Transport Systems, Vienna, Austria, 22–26 October 2012. [Google Scholar]

- Nguyen, T.; Xie, M.; Liu, X.; Arunachalam, N.; Rau, A.; Lechner, B.; Busch, F.; Wong, Y.D. Platooning of Autonomous Public Transport Vehicles: The InfluencE of Ride Comfort on Travel Delay. Sustainability 2019, 11, 5237. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.L.; Chen, F.; Ma, X.X.; Pan, X.D. Fuel Economy in Truck Platooning: A Literature Overview and Directions for Future Research. J. Adv. Transp. 2020, 2020, 1–10. [Google Scholar] [CrossRef]

- Lammert, M.P.; Duran, A.; Diez, J.; Burton, K.; Nicholson, A. Effect of Platooning on Fuel Consumption of Class 8 Vehicles Over a Range of Speeds Following Distances and Mass. SAE Int. J. Commer. Veh. 2014, 7, 626–639. [Google Scholar] [CrossRef] [Green Version]

- Agriesti, S.; Gandini, P.; Marchionni, G.; Paglino, V.; Ponti, M.; Studer, L. Evaluation Approach for a Combined Implementation of Day 1 C-ITS and Truck Platooning. In Proceedings of the 2018 IEEE 87th Vehicular Technology Conference (VTC Spring), Porto, Portugal, 3–6 June 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Bibeka, A.; Songchitruksa, P.; Zhang, Y. Assessing environmental impacts of ad-hoc truck platooning on multilane freeways. J. Intell. Transp. Syst. 2019. [Google Scholar] [CrossRef]

- Jo, Y.; Kim, J.; Oh, C.; Kim, I.; Lee, G. Benefits of travel time savings by truck platooning in Korean freeway networks. Transp. Policy 2019, 83, 37–45. [Google Scholar] [CrossRef]

- Ploeg, J.; Serrarens, A.; Heijenk, G. Connect & Drive: Design and Evaluation of Cooperative Adaptive Cruise Control for Congestion Reduction. J. Mod. Transp. 2011, 19, 207–213. [Google Scholar] [CrossRef] [Green Version]

- Bergenhem, C.; Hedin, E.; Skarin, D. Vehicle-to-Vehicle Communication for a Platooning System, Transport Research Aren–Europe. Procedia-Soc. Behav. Sci. 2012, 48, 1222–1233. [Google Scholar] [CrossRef] [Green Version]

- European Road Transport Research Advisory Council. Automated Driving Roadmap. 2015. Available online: https://www.ertrac.org/uploads/documentsearch/id38/ERTRAC_Automated-Driving-2015.pdf (accessed on 29 September 2020).

- Janssen, R.; Zwijnenberg, H.; Blankers, I.; de Kruijff, J. Truck Platooning–Driving the Future of Transportation; TNO: The Hague, The Netherlands, 2015. [Google Scholar]

- Amoozadeh, M.; Deng, H.; Chuah, C.N.; Zhang, H.M.; Ghosal, D. Platoon Management with Cooperative Adaptive Cruise Control Enabled by VANET. Veh. Commun. 2015, 2, 110–123. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.G.; Lee, C.; Park, B.J. Use of Digital Tachograph Data to Provide Traffic Safety Education and Evaluate Effects on Bus Driver Behavior. Transp. Res. Rec. 2016, 2585, 77–84. [Google Scholar] [CrossRef]

- Wang, L.; Pei, Y. The impact of continuous driving time and rest time on commercial drivers’ driving performance and recovery. J. Saf. Res. 2014, 50, 11–15. [Google Scholar] [CrossRef] [PubMed]

- Saaty, T.L. How to make a decision: The Analytic Hierarchy Process. Eur. J. Oper. Res. 1990, 48, 9–26. [Google Scholar] [CrossRef]

- Yuan, C.; Yang, H. Research on K-Value Selection Method of K-Means Clustering Algorithm. Multidiscip. Sci. J. 2019, 2, 226–235. [Google Scholar] [CrossRef] [Green Version]

| Platooning Levels | Features | Remarks |

|---|---|---|

| 1: CACC truck platooning | Automation of longitudinal control | Drivers have to ride in each vehicle |

| 2: Automated truck platooning | Automation of longitudinal and lateral control | Drivers have to ride in each vehicle |

| 3: Highway pilot platooning | Automation of longitudinal and lateral control Lane change, overtaking | Unmanned following vehicle in specific road |

| Classification | Elements | Weights |

|---|---|---|

| Traffic environment | AADT for all vehicle types | 0.057 |

| AADT for truck | 0.160 | |

| Average daily speed for all vehicle types | 0.039 | |

| Peak-hour concentration rate | 0.072 | |

| Continuous driving times index | 0.078 | |

| Number of traffic crashes | 0.104 | |

| Geometry | Number of lanes | 0.186 |

| Length of Conzone | 0.172 | |

| Number of bridges and tunnels | 0.051 | |

| Number of rest areas and Drowsy shelters | 0.081 |

| Elements | Means | Standard Deviations | Min | Max |

|---|---|---|---|---|

| AADT for all vehicle types in vehicles per day | 31,152.63 | 26,186.56 | 786.00 | 141,472.00 |

| AADT for truck in vehicles per day | 8400.00 | 6522.59 | 70.00 | 34,406.00 |

| Average daily speed for all vehicle types in kph | 94.56 | 12.66 | 14.72 | 112.11 |

| Peak-hour concentration rate in percentage | 0.21 | 0.04 | 0.08 | 0.42 |

| Continuous driving times index | 2.96 | 3.16 | 0.00 | 39.40 |

| Number of traffic crashes | 1.26 | 2.72 | 0.00 | 15.00 |

| Number of lanes | 2.47 | 0.79 | 2.00 | 6.00 |

| Length of Conzone in kilometer | 7666.15 | 5269.41 | 110.00 | 30,790.00 |

| Number of bridges and tunnels | 3.89 | 4.99 | 0.00 | 30.00 |

| Number of rest areas and Drowsy shelters | 0.19 | 0.43 | 0.00 | 2.00 |

| Cluster Types | Type 1 | Type 2 | Type 3 |

|---|---|---|---|

| Number of Conzones in Cluster | 147 | 212 | 583 |

| Expressway Lines | Line Lengths (km) | Sections | Direction | Lengths (km) |

|---|---|---|---|---|

| Gyoengbu | 431.50 | Nopo IC–W.Ulsan IC | Seoul | 33.40 |

| 431.50 | Cheonan IC–Singal JC | Seoul | 54.82 | |

| South Cost | 171.99 | E.Changwon–Gimhae JC | Suncheon | 22.40 |

| West Cost | 340.60 | Dangjin IC–Ansan JC | Seoul | 61.62 |

| Guri-Pochoen | 89.20 | S.Guri–Soheul JC | Pocheon | 30.52 |

| Jungbu | 117.19 | E.Seoul TG–Hanam JC | Hanam | 7.62 |

| Pyeongtaek-Jecheon | 126.91 | W.Pyeongtaek JC–Ansung IC | Jechoen | 23.70 |

| 126.91 | Ansung IC–W.Pyeongtaek JC | Pyeongtaek | 23.70 | |

| Yeongdong | 243.7 | Ansan JC–Yangji IC | Gangneung | 43.37 |

| 243.7 | W.Ansan IC–Seochang JC | Incheon | 11.98 | |

| Yeoju JC–DeokPyeong IC | Incheon | 20.72 | ||

| Seoul Outer Ring | 128.00 | Pangyo JC–Cheonggye TG | Outer | 90.94 |

| Cheonggye TG–Pangyo JC | Inner | 90.94 | ||

| The 2nd Gyeongin | 49.55 | Munhak IC–Anhyeon JC | Seongnam | 9.09 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, H.; Park, S.; Park, S.; Cho, H.; Yun, I. Study on the Selection of Sections Applicable to Truck Platooning in the Expressway Network. Sustainability 2020, 12, 8058. https://doi.org/10.3390/su12198058

Jeong H, Park S, Park S, Cho H, Yun I. Study on the Selection of Sections Applicable to Truck Platooning in the Expressway Network. Sustainability. 2020; 12(19):8058. https://doi.org/10.3390/su12198058

Chicago/Turabian StyleJeong, Harim, Sangmin Park, Sungho Park, Hyonbae Cho, and Ilsoo Yun. 2020. "Study on the Selection of Sections Applicable to Truck Platooning in the Expressway Network" Sustainability 12, no. 19: 8058. https://doi.org/10.3390/su12198058