Abstract

Between 2014 and 2019, an innovative small-pyrolysis system (the PPV300) using agrowaste as feedstock was transferred and adapted from Switzerland to Vietnam by a United Nations Industrial Development Organization (UNIDO) project. The coffee husk resulting from the processing of coffee beans is usually disposed of in Vietnam or burned inefficiently to dry coffee beans. Small-scale pyrolysis of coffee husk using the PPV300 avoids smoke emissions and local air pollution while providing an energy source for coffee drying and biochar as a by-product. This paper investigates the uncertainties in the “coffee husk to activated carbon” supply chain in Vietnam and discusses the pros and cons of different supply chain setups using a framework derived by Chopra and Meindl (2013). According to the analysis, a number of actors (an intermediary without previous direct involvement in the coffee supply chain, a coffee processor, or a hybrid between farm and processor), each with advantages and disadvantages, would be suitable from a supply chain perspective to attain an efficient strategy that would keep the price of the biochar low. However, in order to be attractive for one activated carbon producer, several PPV300 systems are needed to reach a significant economy of scale. Sufficient husk sourcing and storage capacity is also needed. If the purpose is simply to produce biochar for activated carbon, processors and intermediaries could consider a simpler and cheaper design than the PPV300. In conclusion, supply chain uncertainties and economic viability can be optimized when the PPV300 is used by coffee processors or intermediaries, who are able to make use of the co-products generated (biochar, heat, and wood vinegar). In addition to its financial viability, all of the other co-benefits of this technology should be taken into consideration (reduced smoke and environmental pollution, avoided health costs, greenhouse gas savings, etc.) for a proper assessment of its economic attractiveness.

1. Introduction

The present study builds upon the work carried out by the United Nations Industrial Development Organization (UNIDO) between 2014 and 2019 to transfer and adapt an innovative small-pyrolysis system (the PPV300) using agrowaste as feedstock in the Vietnamese context. The technology was originally developed by Oekozentrum, a Swiss research institute. The technology transfer was funded in the framework of the Global Resource Efficient and Cleaner Production (RECP) Programme through funding provided by the Swiss Government through the State Secretariat for Economic Affairs of Switzerland (SECO) and with support from the Swiss Renewable Energy, Energy and Resource Efficiency Promotion in Developing and Transition Countries (REPIC) initiative [1,2,3].

In 2017, the knowledge and capacity of a local manufacturer, Viet Hien Ltd., was strengthened and the new PPV300 was successfully piloted in Vietnam. Over the years, Viet Hien Ltd. commercially produced and sold a number of systems using coffee husk and rice husk as feedstock.

In 2019, at the completion of the UNIDO Global RECP Programme, the main recommendations by the project team revolved around the need to strengthen the business case of the PPV300 to increase its economic viability. One way of doing this is to add value to biochar, a by-product of pyrolysis of agricultural waste, by finding higher-return markets.

This paper investigates the uncertainties of the coffee husk to activated carbon chain in Vietnam and discusses the pros and cons of different supply chain setups using the framework derived by Chopra and Meindl [4]. In particular, Section 1 introduces the Vietnamese coffee supply chain, activated carbon, and the small-scale pyrolysis system under investigation. Section 2 presents the analytical framework along with the key research questions, information on the case studies used and on the data collection and treatment. Section 3 presents the results from the application of the analytical framework to assess the uncertainties along the coffee waste-to-activated carbon supply chain and how these could be mitigated. Section 4 discusses the pros and cons of having different supply chain actors as adopters of the pyrolysis technology, in view of reducing the supply chain uncertainties. Finally, Section 5 summarizes the overall conclusions.

1.1. Context

Vietnam is the world’s second-largest coffee producer with around USD 3 billion worth of exports each year according to the Vietnam Coffee-Cacao Association (2019) [5,6], while the coffee industry accounts for more than 2% of national GDP. The production covers over 650,000 hectares of land, with the absolute majority concentrated in the central parts of the country [5,6,7]. Of all coffee grown in Vietnam, 97% is of the Robusta sort, while the remaining 3% is Arabica, and a total of more than 10 million tonnes of coffee beans were produced in the country in 2018 (International Coffee Organization, 2019; Vietnam Coffee-Cacao Association, 2019).

Harvested Robusta coffee beans are dried to a water content of around 13% [8]. In Vietnam, after drying, the outer parts of the cherry that surrounds the bean, which is referred to as coffee husk, is usually disposed of or burned inefficiently to dry coffee beans (Dzung et al., 2013; Vietnam Coffee-Cacao Association, 2019) [6,9]. The coffee husk accounts for roughly 14% of the coffee production weight, meaning that every year, almost 1.4 million tonnes of waste needs to be disposed of (Montilla-Pérez et al. 2008) [10]. Occasionally, this waste is spread on the soils as a nutrient but with minimal effect. Burning the coffee husk can solve the direct disposal problem, but it also causes problems related to the smoke, such as the effect on the taste of the coffee beans as well as health problems for farmers (Luu Tien et al., 2018; Zellweger et al., 2017) [11].

Small-scale pyrolysis of coffee husk with the PPV300 avoids emissions of smoke and local air pollution while providing an energy source for coffee drying and biochar as a by-product, which is an efficient soil amendment that contributes to maintaining soil health and by extension coffee yields in the long term (UNIDO, 2019) [12]. However, it could also make economic sense to pyrolyze coffee husk with the primary purpose of producing biochar to be sold on the market, for example for activated carbon production.

The expansion of the biochar business will create new collaborations and supply chains, with the implication that new roles and responsibilities will arise. This paper is a first step toward exploring the potential supply chain uncertainties that may hinder an expansion of coffee husk-biochar production in Vietnam. The paper categorizes supply chain uncertainties into demand uncertainties and supply uncertainties. These will be investigated through a case study on the identified application area as raw material for activated carbon production. This will be achieved by examining the possibility of linking a coffee husk-biochar producer with activated carbon producers in Vietnam.

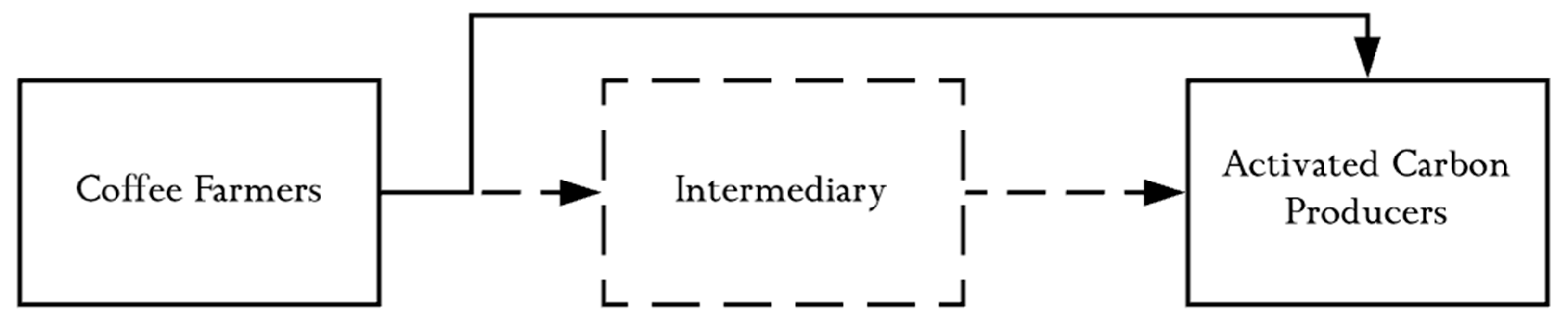

A coffee husk-biochar producer could be either coffee farmers, since they generate the coffee husk; an intermediary; or the activated carbon producers, who potentially buy the husk to produce biochar first and subsequently use the produced biochar as a raw material for their activated carbon. Depending on which actor takes on the role of biochar producer, the supply chain will have different configurations (Figure 1).

Figure 1.

A supply chain where coffee husk-biochar is used as raw material for activated carbon production.

As mentioned, these different supply chain configurations will be evaluated with the help of a framework developed by Chopra and Meindl [4], in order to test their ability to link the coffee husk-biochar with the activated carbon producers. The framework focuses on supply chain uncertainties and how these can be addressed through supply chain responsiveness. The matching of a correct level of responsiveness to the supply chain uncertainty is what Chopra and Meindl [4] call “achieving strategic fit”. Due to the range of potential factors that can affect supply chain responsiveness, the paper focuses on a limited number of factors identified by Chopra and Meindl [4]. These factors are facilities, transportation, and inventory, and they will be investigated for further understanding of the supply chain responsiveness needed to adjust to the uncertainties found. The findings from the evaluated case will support better understanding of the supply chain uncertainties that might hinder an expansion of coffee husk-biochar production as well as how the supply chain could be configured to address these.

1.2. The Coffee Supply Chain

In Vietnam, after harvest, coffee is sold to either buying agents, traders, or coffee processors (Nguyen and Bokelmann, 2019; Hoang, 2017) [13,14]. Nine out of ten farmers sell the coffee to buying agents, while the rest sell to traders or coffee processors in descending order (Nguyen and Bokelmann, 2019) [14].

Buying agents: These actors act as intermediaries between the farmers and companies that further process the beans. They arrange transport and help farmers ensure that coffee reaches the market through their wider network of actors further downstream in the supply chain (Nguyen and Bokelmann, 2019; Hoang, 2017) [13,14]. Important factors affecting the major involvement of buying agents include trust and strong relationships between buying agents and coffee farmers. In addition, a credit-bound relationship with farmers, where buying agents assist farmers with credits at other times during the year, is an important factor (Nguyen and Bokelmann, 2019) [14].

Traders: The traders buy coffee from several buying agents or directly from farmers and sell them to processors or other companies that, in turn, sell the product to international markets (Hoang, 2017) [13].

Coffee processors: These companies conduct different activities ranging from the dehusking of coffee cherries to quality testing and sorting of the beans before they are exported or sold to the local market (Nguyen and Bokelmann, 2019) [14]. The coffee will arrive at the processors either as fresh cherries, dried cherries, or as coffee beans. Farmers have dehusked the cherries if they arrive as beans, and the processor will dehusk them if they arrive as cherries. Nguyen and Sarker (2018) [15] mention that around half of the 137 farmers they surveyed in Dak Lak owned their own dehusking machine.

A small-scale processor could handle between 350 and 1000 tonnes of beans each year, corresponding to around 2000 to 5500 tonnes of fresh cherries (Vinh Le Viet, Viet Hien Ltd. 2020. E-mail correspondence of 30 March 2020). The coffee processor market is large, with hundreds of companies throughout the country, although most are located in the Central Highlands (International Coffee Organization, 2019) [6]. When the processors complete their work, the beans will either be sold to the international market or to domestic companies that make the final preparations for the bean for the domestic market.

1.3. External Influencers of the Coffee Supply Chain

The coffee industry is highly dependent upon the world market price for coffee, as 83.6% of the coffee goes to export (Tran, 2019) [16]. According to Tran (2019) [16], if the prices are deemed unfavorable by the farmers, they will stock up on coffee and await better prices. Given that the price of coffee fluctuates, with the biggest importers of Vietnamese coffee being Germany, the USA, and Italy, the stock levels of coffee will do so as well (Tran, 2019) [16]. When the farmers have deemed the price for the beans or cherries to be favorable, they will be sold for further processing, such as cleaning and quality checking (Nguyen Thanh Trung, VNCPC. E-mail correspondence 23 April 2020). This is not carried out by the small-scale farmers in Dak Lak but mainly by small-scale processors.

Another factor that affects the current supply chain among the small-scale farmers, according to Nguyen and Bokelmann (2019) [14], is poor infrastructure in the region. Transportation in Vietnam is expensive compared to neighboring countries. In addition, the Dak Lak region has a disadvantageous position in terms of logistics compared to the rest of the country (Nhân Dân, 2019) [17]. An illustration of this is that the improved margins that farmers would enjoy by bypassing the intermediaries are not high enough to cover the increased costs of transport (Nguyen and Bokelmann, 2019) [14]. Regardless of the transporter, transportation in the region takes place by road, either by farmers’ tractors or by larger trucks, depending on the transporter and size of the load (Thi Chau Trieu; Chairwoman of Binh Minh Cooperative. Interview 26 February 2020).

1.4. The PPV300

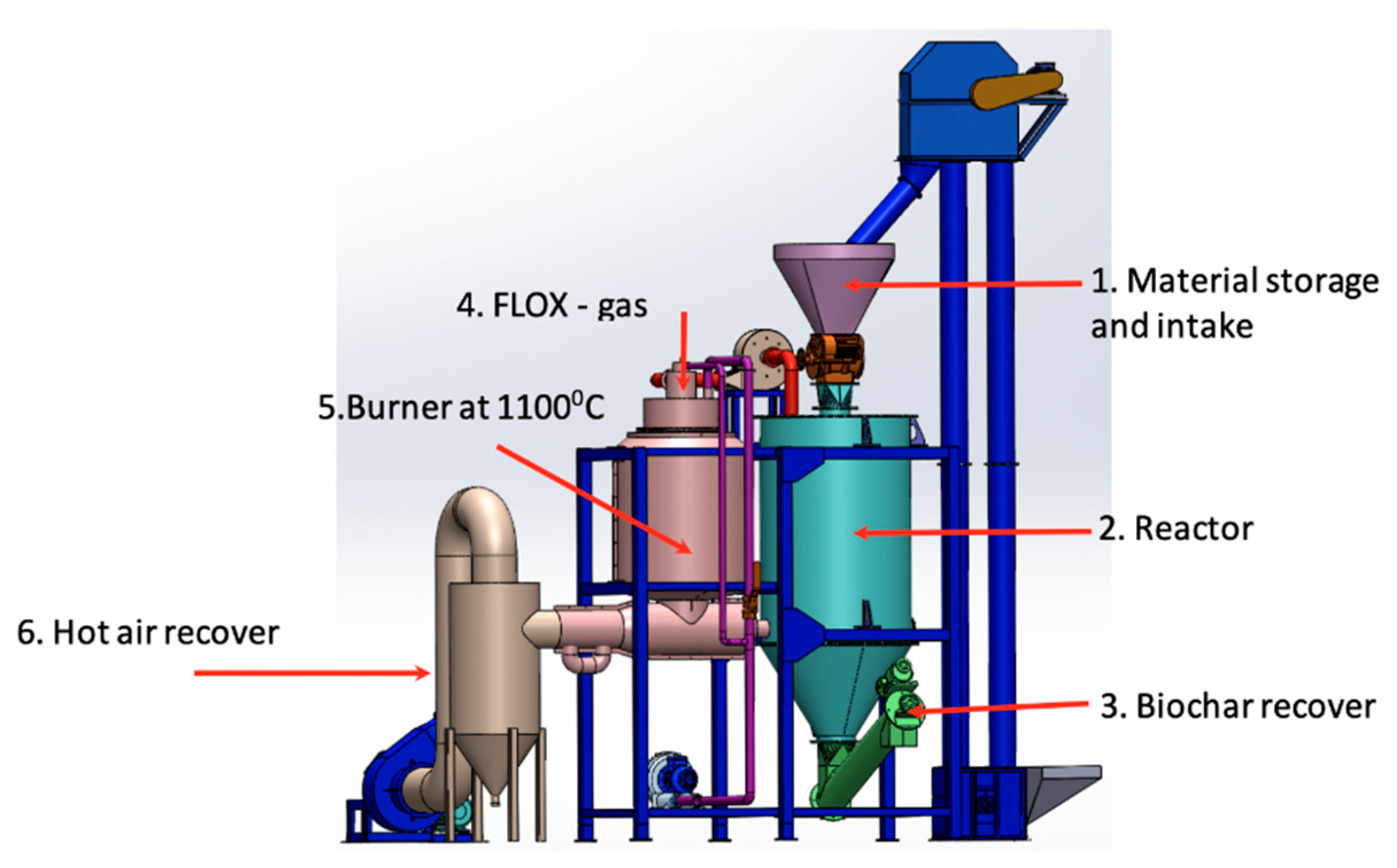

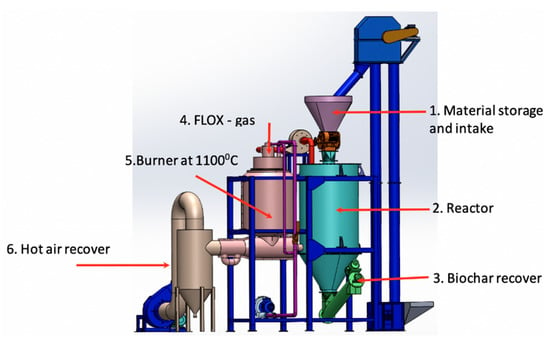

The pyrolysis unit that is the subject of scrutiny in this study is the PPV300, which is manufactured by the Dak Lak-based company Viet Hien Ltd. An illustration of the PPV300 is seen in Figure 2 below.

Figure 2.

The pyrolysis unit PPV300. Source: UNIDO (2019) [5].

The machine runs on external gas for the first two hours of operation to elevate the temperature, but it will then generate its own fuelling gas through reactions with the biomass in the reactor (UNIDO (2019) [12]. Around 50% of the heat generated from operating the machine will be excess heat that can be used for drying, for example, coffee cherries. Input biomass material with a moisture level up to 54% has been proven successful for operations with the PPV300, but it is recommended that the level does not exceed 40% (Draper, 2018) [18].

The biochar output per hour is around 30 kg when using the full capacity input of 100 kg coffee husk per hour (Zellweger et al., 2017) [19]. Depending on the input material for pyrolysis, the output biochar will have different carbon levels, porosity, and ash content, and it will demand different temperatures during the pyrolysis (Ronsse et al., 2012) [20]. When using coffee husk as input, the biochar output from the PPV300 has a carbon content of around 80% (UNIDO, 2019) [12]. According to UNIDO (2019) [12], the PPV300 could be running 24 h per day for six consecutive days when operating with coffee husk. After six days, it requires regular maintenance. This means that the yearly production, assuming a 90% utilization, will be approximately 200 tonnes of biochar at most. The cost for one tonne of biochar on the Vietnamese market, produced with the PPV300, is approximately USD 350 to 400 if the capital and operating expenses are entirely accounted to the biochar (Le Viet Hien, Viet Hien Ltd. Interview 26 February 2020).

1.5. Activated Carbon

Biochar has many application areas, most of them deriving from the biochar’s porous structure, which gives it capabilities such as water retention and filtration capabilities as an adsorbent (Kwiatkowski and Kalderis, 2019) [21].

Activated carbon, which is produced from either coal or carbonized biomass such as coffee husk, rice husk, or coconut shells (biochar), has an even higher porosity (Buysman et al., 2017). The higher porosity is achieved through either physical or chemical activation (Teshome, 2015) [22]. Physical activation achieves this by introducing the biochar to an activating agent such as air, steam, or carbon dioxide. Chemical activation is instead dependent on an impregnation of the biochar (Paraskeva et al., 2008) [23].

Activated carbon is mainly used in water treatment, air purification, the pharmaceutical/medical industry, the automotive industry, and in food and beverage processing. The demand for it is expected to rise steadily around the world, with a significant growth in the Asia-Pacific region for the coming years (Grand View Research, 2019) [24]. Depending on its area of use, the activated carbon will have different requirements such as size, shape, and porosity. To achieve this, larger pieces could be ground to the desirable size or different biomasses used, as the various biomasses will generate different activated carbon (Jacobi Carbons Ltd. Interview 11 March 2020).

2. Materials and Methods

This section presents an overview of the analytical framework used for the analysis and the key research questions that the study aims to answer. It also provides information on the concrete cases upon which the analysis is based, along with information on the key data and variables and how they were categorized and used in the analytical framework.

2.1. Research Questions and Case Studies

In order to fulfill the purpose of this research, the following two research questions are answered: RQ1: What are the supply chain uncertainties if activated carbon is made from coffee husk-biochar? RQ2: How could the supply chain be configured to address the uncertainties found and fit into the current context?

Actual data and information from real case studies assisted in finding what supply chain uncertainties exist, and how the supply chain could be configured to address them. In order to collect first-hand information from the case studies, field visits were undertaken in early 2020. The chosen cases are presented below.

Binh Minh Cooperative: A coffee farmer cooperative that currently makes use of the pyrolysis unit was chosen as a case unit, as it should have relevant insights. The coffee farmer cooperative is situated in the Dak Lak region in Vietnam and uses the pyrolysis unit to dry its coffee beans from the pyrolysis excess heat. Then, the biochar output is used as a soil conditioner for their own crops.

Viet Hien Ltd.: The pyrolysis unit PPV300 is manufactured by a company in the Dak Lak region, and this manufacturer was also chosen as a suitable case unit because of its direct involvement in the industry. Viet Hien itself also produces biochar from coffee husk for the biochar market, and therefore, it is identified as an example of an intermediary.

Husk Ventures: Another user of the PPV300 is an intermediary enterprise in Cambodia, which uses rice husk rather than coffee husk as an input for the machine. Therefore, it is not directly involved in the coffee biochar industry, but it has important knowledge about the pyrolysis unit and process as well as the biochar industry as a whole.

Jacobi Carbons: Jacobi Carbons Ltd. (Jacobi Group) is a national leader in the activated carbon market and produces many different kinds of activated carbon. Their activated carbon is mainly made from coconut-biochar.

2.2. Field Visits and Interviews

Five field visits took place between 31 January 2020 and 18 March 2020. The aim was to enhance case-contextual understanding and knowledge, identify uncertainties, and add new dimensions to the literature. The field visits were also essential for understanding the interviews in their context. The field visits covered at least one case unit in every identified position in the viable supply chains in order to understand all perspectives.

Interviewees were chosen with the help of the UNIDO office in Hanoi. The aim was that each actor should be both knowledgeable and able to fit into the supply chain. However, due to the limited number of actors, this was complemented with expert opinion from knowledgeable persons who could confirm statements and enhance the contextual understanding. Depending on the interviewee’s background, a different questionnaire was used, even if a number of questions were the same in order to enhance the understanding from several perspectives or as to validate previous statements. The interview guide is provided in Appendix B, and this targeted practitioners at each of the 4 case studies. All of the questions originated from theoretical findings in the frame of reference and applied to the position that the interview object had in the possible supply chain. Mail correspondence was also used as a source of information before and after the field visits to collect some basic information and to clarify specific doubts.

2.3. Data Analysis

The data are categorized into responsiveness and supply chain uncertainties, which were represented by demand uncertainties and supply uncertainties. Demand and supply uncertainties were investigated through field visits, interviews, and mail correspondence. The responsiveness of the supply chain in addressing these uncertainties was analyzed through a literature review, whereas findings that might affect such measures were gathered from field visits, interviews, and mail correspondence. Logistical responsiveness is mainly influenced by facilities, inventory, and transportation, while responsiveness was further categorized into these subcategories. Specific statements regarding demand uncertainties, supply uncertainties, and responsiveness were categorized into findings that were relevant to the research.

In order to find the right place on the uncertainty spectrum, three levels were created to evaluate the uncertainty on a set number of variables based on Lee’s (2002) [25] descriptions of uncertainties (Appendix A). Level 3 represents an uncertain variable. Level 2 means that the variable has some degree of uncertainty, and Level 1 means that the variable has few of the uncertainty characteristics. This enabled conclusions to be reached on the average uncertainty in the range from one to three, with configurations of either farmers or intermediaries as biochar producers having a separate overall uncertainty.

Unlike the original framework, which evaluates the actual responsiveness, the responsiveness section was structured to present the level of responsiveness needed in order to meet the uncertainties. From the identified level, an appropriate strategy that fulfills the responsiveness was analyzed.

2.4. Analytical Framework

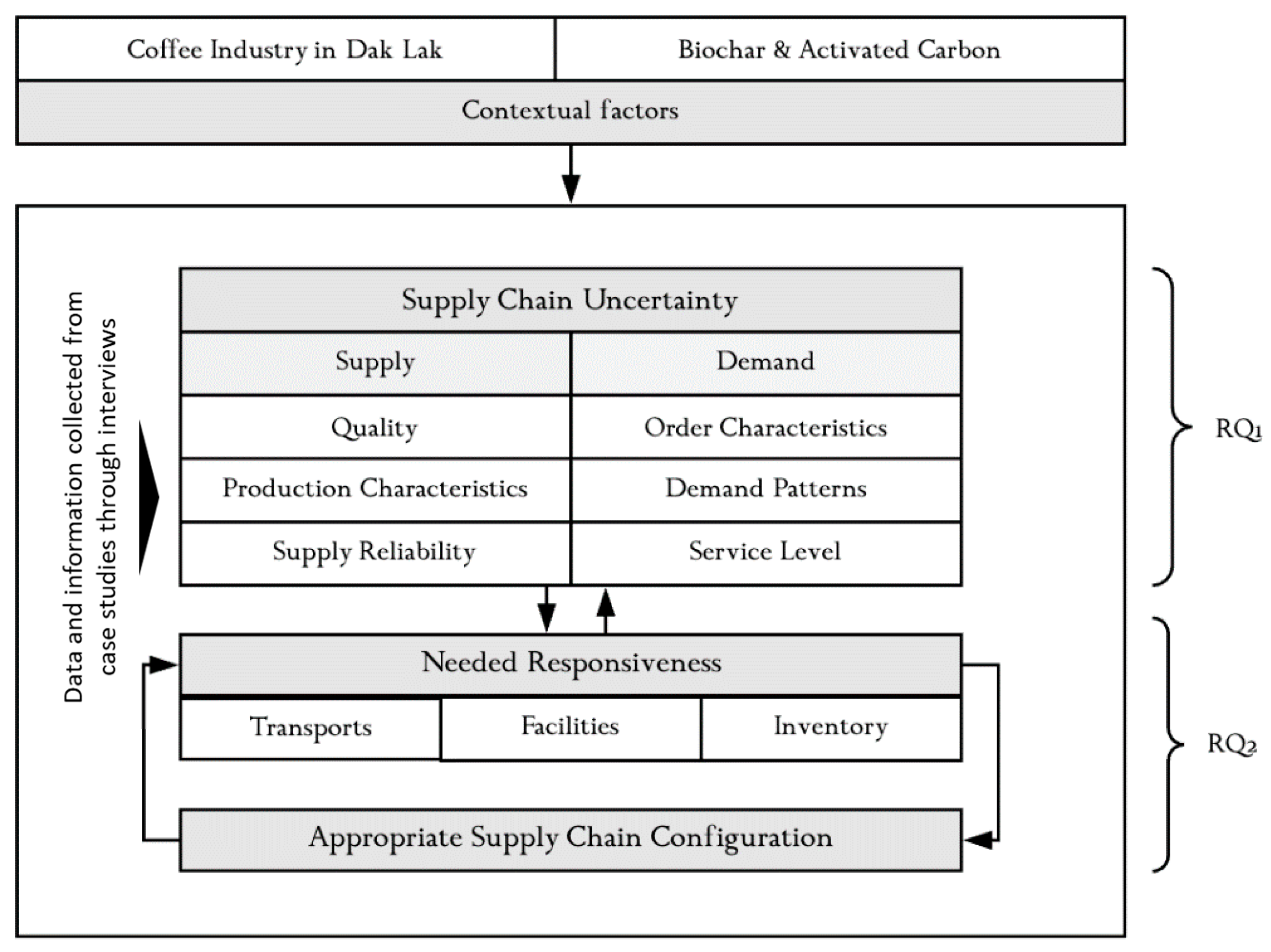

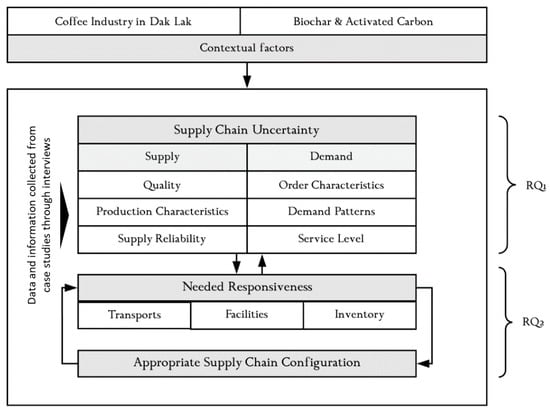

The analytical framework that was used throughout the report is displayed in Figure 3.

Figure 3.

Analytical framework used throughout the report.

Firstly, the contextual factors that affect supply chain uncertainty, the responsiveness needed, and appropriate supply chain configurations were investigated. By combining the contextual understanding with the theoretical supply chain understanding, the dimensions of uncertainty and responsiveness illustrated in Figure 3 were identified. These dimensions were subsequently used during the interviews with the stakeholders identified from the context research. At this stage, RQ1 was answered using the data and information collected from case studies through the interviews, and a deeper understanding of supply chain uncertainties was achieved.

The responsiveness needed to address the identified supply chain uncertainties was analyzed thereafter. Then, appropriate supply chain configurations were recommended according to findings regarding uncertainties and the viability among different actors in order to conduct the needed responsiveness measures. When this was concluded, RQ2 was answered, on the basis of how the supply chain could be configured to address the found supply chain uncertainties.

3. Results

This section presents details on the coffee waste to activated carbon value chain and the results from the application of the analytical framework to the supply chain under investigation, highlighting sources of uncertainties, their relevance for different actors, and how actors could cope with such uncertainties.

3.1. Introduction to Results

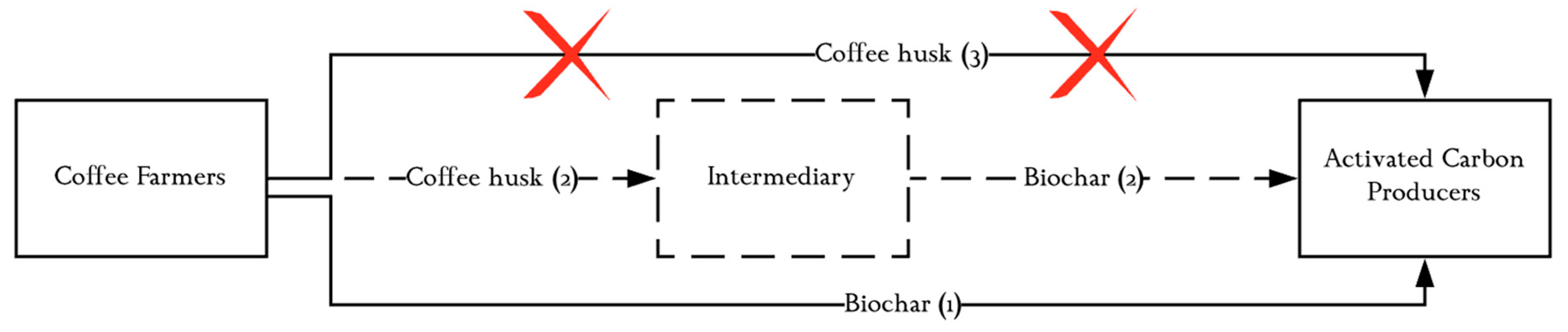

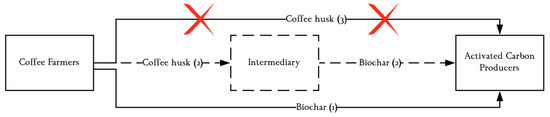

While uncertainty is a very broad term, we have chosen to narrow it down to a set of variables derived from Lee (2002) [25] to fit the case, as well as using these variables in the context of the strategic fit framework of Chopra and Meindl (2013) [4]. There are theoretically three viable supply chain configurations in the current case (Figure 4):

Figure 4.

Investigated configurations.

- The farmers themselves produce biochar and sell to activated carbon producers. Farmers are defined as actors that grow and harvest the coffee, as well as performing non value-adding activities with the cherries. The farmers may dry and dehusk the cherries, but further quality checking, sorting, roasting, or exporting of the beans are activities performed further down the value chain. The average single coffee farmer in Vietnam has a monthly income of USD 250 to 500 and an area of three hectares.

- The farmers supply coffee husk to an intermediary who produces biochar and sells to activated carbon producers. The intermediary is defined as an actor that is not growing or cultivating coffee. This means that the intermediary could be an already established actor in the coffee supply chain, such as a processor who is performing value-adding activities to coffee but not growing it themself, or they could be a new actor without previous involvement in the coffee supply chain, such as a completely new company.

- The farmers supply coffee husk directly to the activated carbon producer, who handles the whole production. This means that the activated carbon producer would firstly need to carbonize the coffee husk bought from the coffee farmers before further processing the carbonized husk—the biochar—into activated carbon.

The third alternative was not investigated due to the limited data from the single activated carbon producer interviewed. This would lead to analysis considered too speculative. In fact, the activated carbon producers currently buy only already carbonized biomass, while buying coffee husk to carbonize themself would imply a transformed business strategy.

It shall also be stated that during the interview with the activated carbon producer, it became clear that the activated carbon market in Vietnam is dominated by two actors, one of whom was interviewed for this study. This has implications on the analysis. The framework originally states that it is the implied demand uncertainty that should be investigated; however, since there is an oligopoly market, there are in practice no segments to target, with the implied demand uncertainty instead equivalent to the overall demand uncertainty.

The greatest uncertainty in the investigated case is whether or not coffee husk-biochar is viable as input material for activated carbon in the context of current market demand, the current price of the biochar, and current production equipment at the activated carbon producer. However, since this uncertainty cannot be mitigated by any responsiveness, the analysis and findings will assume that the activated carbon producers can and want to use coffee husk-biochar.

This allows for a structured analysis in which the current case will portray one demand uncertainty scenario, which will in turn be complemented by other scenarios to analyze how the supply chain should best be configured to support coffee husk-biochar production expansion. The case of the activated carbon is, as stated, not primarily used to evaluate the precise requirements for establishing a business, but rather as a tool to evaluate further expansion of the biochar production from a supply chain perspective. Therefore, it is deemed necessary to make these assumptions.

Lastly, the analysis will be based on the use of the PPV300 for the coffee husk-biochar production, even though carbonization can be performed with much simpler and cheaper equipment, although this equipment does not possess the other important benefits of the PPV300, namely addressing health issues from smoke in production as well as producing excess heat that can be used for other purposes.

To understand the results and how these are evaluated, it is also important to first present the findings regarding the context in which the uncertainties will take place. These are not uncertainties, but they have a great effect on how the operation will need to be organized, which in turn could affect uncertainties and supply chain configurations.

3.1.1. The Utilization of the PPV300 Must Be as High as Possible

A large share of the operating cost for the PPV300 is the natural gas required in the start-up phase to obtain a high enough temperature to start the pyrolysis (Federico Tempestilli, Husk Ventures. Interview 17 February 2020). The relatively high start cost meant that if the machine could not produce almost at full capacity for a long time, it would be more (economically) worthwhile not to produce. At the same time, the cost of the machine must be depreciated over as many tonnes of biochar as possible in order to keep the biochar price down. The current price of coffee husk-biochar appears to be higher than coconut-biochar sourced by the investigated activated carbon producer. The current price from Viet Hien is around USD 400 per tonne, whereas the highest known biochar price to date according to a Vietnamese biochar expert was approximately USD 300 per tonne (Vu Duc Thao. E-mail correspondence 26 March 2020). In addition, the activated carbon producer mentioned that at least 100 tonnes a month of a specific type of biochar would be needed for them to sustain a business around it, as they have a continuous production throughout the year and thus need continuous supply.

The cost structures for the production, in combination with a demand from the activated carbon producer that widely exceeds the production capacity of one machine, leads to the finding that at least an equivalent of six machines should be running on full capacity all year round if targeting the specific investigated activated carbon producer. However, even if the demand is not great enough to sustain several machines, the cost structures still conclude that at least one machine should be running on full capacity all year round. This is in order to reduce the overhead cost, such as depreciation and facilities, per tonne of produced biochar to improve the chances of reaching the market. The alternative to a continuous production is instead to invest in more machines that can produce the same amount over a shorter period of time. Since this will impose a higher depreciation cost per tonne due to the machines being idle most of the year, this is not deemed a viable option.

3.1.2. A Great Amount of Husk Needs to Be Stored over Longer Periods of Time

Most of the husk will also arise during a short period of time once per year during the harvest season, with only a smaller portion of the cherries being stored and dehusked later in the year (Chung Duc Tran, UNIDO. E-mail correspondence 13 May 2020). Nguyen an Bokelmann (2019) [14] supports this, mentioning that the coffee cherries could be stored for a couple of weeks or be dehusked immediately after harvest to avoid the decomposition of the cherries. This leads to the finding that significant amounts of coffee husk must be stored to sustain this production for a full year, if following our suggestion rather than having more machines that could produce as much biochar in a shorter period of time. Producing over a shorter time would also imply that higher inventory levels of biochar would be needed if demanded during the whole year, which would mean more capital tied up in inventory, as the finished product is more valuable than the raw material.

3.1.3. The Coffee Supply Chain Is Highly Complex

While on paper the coffee supply chain resembles a straightforward supply chain in which coffee cherries are harvested by farmers and then further stepwise processed downstream in the supply chain by designated actors, the reality is more complex.

Firstly, the apparently simple question of where the husk arises has been highly difficult to assess. While the current coffee supply chain literature either takes it for granted that the husk arises on the farmers’ side when using the dry method or not addressing the issue at all, it was reported that around 50% of the farmers dry at the farm themselves, with the other 50% selling their coffee cherries to small processors to dry it. Nguyen and Sarker (2018) [15] supported this, as only 76 of the 137 (55.5%) farmers that they surveyed in Dak Lak owned their own machine for dehusking or roasting. At the same time, another knowledgeable source stated that “small-scale processors prefer buying bean already dehusked” and that “after drying, the dried cherries will be dehusked by the farmers so the beans can be sold to the processing companies”. A third source claimed that only 20% of the coffee cherries are dehusked by the farmers (Hoang, 2017) [13], meaning that there is no conclusive answer to the questions.

Beyond not being able to fully state where the husk arises, the incentive structures are also difficult to assess regarding the husk. A source stated that the price for the cherries that are not dehusked is higher than the dehusked ones (beans), due to the fact that the low-value husk then arises at the processors (Hoang Thi Dieu Linh, UNIDO. E-mail correspondence 5 May 2020), as there is a market for the husk. Another source said that farmers do not want the husk4, indicating that the incentive structure should be for farmers to always sell the cherries that are not dehusked. This would also reduce their workload. However, a third source as well as the literature stated that farmers currently use the husk for drying coffee cherries or spreading it on the fields as fertilizers (Dzung et al., 2013; Vietnam Coffee-Cacao Association, 2019) [6,9], while further literature claimed that 26% of the husk is separately collected at the farmers by private companies without further stating for what purpose (Nguyen and Sarker, 2018) [15]. This makes it difficult not only to assess the incentives but also to assess the amount of husk that would be available in terms of actual supply, as the husk could be a crucial component of the business model of some actors.

Secondly, the available literature makes little or no distinction between coffee processors and coffee exporters (Nguyen and Bokelmann, 2019; Nguyen and Sarker, 2018; Vietnam Supply Chain, 2015; Hoang, 2017) [7,13,14,15], and findings from interviews, mail conversations, and the literature define the coffee processor’s role differently. Additionally, there is no common definition of the different supply chain actors, and the literature and experts seem to use a different definition of the different actors (Hoang, 2017) [13]. This makes it difficult to understand the core business and incentives of the actors as well as determine the scale of their operation. The processors, who are defined by many as sometimes conducting the dehusking of the coffee cherries and sometimes not, have been difficult to fully assess (Hoang, 2017) [13]. However, from the literature as well as the interviews, we conclude that there are several processors in the region with an average size of 350 to 1000 tonnes of capacity of beans per year, although these claims were stated regarding beans (already dehusked cherries), and it is unclear if this capacity corresponds to the equivalent of fresh cherries that are needed for the mentioned quantity of beans.

In addition, some actors possess capabilities that would see them defined as both an intermediary and farmers. They could be either a large-scale farm that conducts further processing of the coffee cherries or, as we observed during the field visits, they could act more as a processor but with dedicated farmers connected to the company (Nguyen, 2015) [26]. Vietnam’s largest coffee company, Trung Nguyen Coffee, has a supply chain consisting of both contracted farmers as well as their own farms, all of which share the processing facilities controlled by Trung Nguyen Coffee (Nguyen, 2015) [26]. As the literature suggests that the majority of farmers are small-scale farmers, it is assumed that the number of larger-scale farmers with processing capability is limited, although it was not possible to confirm the exact number.

Lastly, it could be stated that the supply chain is highly dependent upon long-term relationships and structures, which are often related to different financing structures toward the farmers (Dzung et al., 2013) [9]. For example, both processors and buying agents tend to lend money to farmers for larger parts of the year, which is later repaid during the harvest period (Nguyen and Bokelmann, 2019) [14]. These financial obligations appear to make the supply chain rather static and difficult to change. In addition, depending on the capabilities of both farmers and processors, the coffee cherries or beans might undergo different amounts of processing at each stage, which are difficult to assess. For instance, there may be situations in which the processors only perform some simpler cleaning and sorting, with further processing needed by yet another actor downstream, while some farmers can process the coffee to the extent that the processors are not needed. The conclusion from this is that even if a general supply chain has been illustrated in Section 1, there are many exceptions that have not been possible to assess due to the cultural complexity.

3.2. Understanding the Supply Chain Uncertainty

Supply chain uncertainty is made up of demand and supply uncertainty. Demand uncertainty can arise from order characteristics, demand patterns, and service level, whereas supply uncertainty can arise from quality, production characteristics, and supply reliability.

3.2.1. Demand Uncertainty

Order Characteristics

The overall uncertainty from order characteristics is deemed as Level 2. This level considers the negative impact from power imbalance between activated carbon producers and their suppliers, as well as the positive impact from low product variety in orders from activated carbon producers.

Indeed, activated carbon producers were found to use a large supplier base, partly because of the farmer structure in Vietnam, with many small-scale farmers and few larger ones, but also as a means of reducing supplier risk.

Another uncertainty for suppliers to the activated carbon producer is that contracts with the suppliers are negotiated over two to four weeks of supply. This allows for quick changes in orders and suppliers, if not satisfied. Given that the coffee market is similar to the coconut market, with a large number of small-scale farmers with limited resources, the same power structures and risks would be applicable, and thus, it contains the same risk with altering order quantities and uneven power balance.

The findings that the activated carbon producer has a large supplier base and uses short-term contracts increase demand uncertainty, as the activated carbon producer can bargain or alternate ordered quantities unless they are fully satisfied.

However, it was also stated that there is a competition for the biochar from other markets, meaning that even if there is an uneven power balance, the activated carbon producer does not possess full power over the market. Neither did they misuse their assumed power concerning lead times, which makes it unlikely that they will cause any uncertainty issues.

The activated carbon producer prefers to purchase larger pieces of biochar, which they later refine to smaller ones, as this allows for a broader product offering, given that the size of the activated carbon piece gives it certain capabilities. The producers have worked with their suppliers over a longer period to make sure that they can meet the required quality and size specifications. Their suppliers also mainly use very simple equipment, such as carbonization of the biomass in a barrel, indicating that their equipment will not be able to offer great varieties of product output. This means that the variety of raw material bought by the activated carbon producer will be low.

Demand Patterns

The uncertainty originating from demand patterns is deemed as Level 1. This level considers that there is no seasonality in demand, which is positive, as this will ensure lower fluctuations, and therefore, the supplier can have a more stable capacity.

The activated carbon producers have their production running 24 h per day, all year long. Although the biomass currently used by the activated carbon producer—coconut—is seasonal, the farmers know that they want continuous supply throughout the year and can adjust accordingly. In this way, there is a low risk of uncertain demand patterns and, combined with the increased demand for activated carbon in the Asia-Pacific region, the stable demand pattern is deemed to be long-lasting.

Service Level

The total uncertainty originating from demanded service level is deemed low (Level 1). This level considers the positive impact from the high flexibility toward suppliers of the activated carbon producer, as well as the fact that emergency orders are unusual.

Suppliers to the activated carbon producer will not be forced to adapt to specific standards regarding delivery and packaging, as the priority is to make it easier for them as long as it is cost-efficient and fulfills basic requirements, such as the biochar moisture content. In addition, there is no strict requirement on precise time deliveries, as the activated carbon producer seemed to accept that orders could sometimes be delayed. They understand the limits of small-scale farmers in performing according to big company standards, as well as potential hindrances during rainy seasons. The risk that the activated carbon producer may suddenly change procedures to which suppliers must adapt is limited.

It is not expected that suppliers will adapt to a certain stock policy and keep buffer stocks to ensure the constant availability of raw material for the activated carbon producer. Suppliers will only need to keep as much stock as it takes to deliver the agreed contractual volumes. Instead, the activated carbon producer will hold the necessary safety stock for potential abruptions in the supply chain, absorbing much of the uncertainty in the supply chain. Their own production and demand from customers is stable, and emergency orders are therefore unnecessary.

Concluded Demand Uncertainty

The concluded demand uncertainty from activated carbon producers from the three different uncertainty sources is considered low, as it scores only 1.3 on average.

3.2.2. Supply Uncertainty

The investigated sources of supply uncertainty are, as mentioned, quality, production characteristics, and supply reliability.

Quality

It is assumed that with clear instructions regarding the storing of the husk, the overall uncertainty regarding quality is low (Level 1) for both farmers and intermediaries. The clear instructions should concern keeping stored goods dry, as the quality of biochar and coffee husk is stable if kept dry.

Wet coffee husk can begin to decompose and lose its carbon content, while also posing safety issues, and this risk increases if there is no proper storage facility or if the storing method is inappropriate. In addition, dry and wet biomass will require a different setup by the PPV300, meaning that it could affect the final quality if both dry and wet input material are mixed. The PPV300 should preferably not have raw material with a moisture level above 40%, which is a level that could be hard to calculate, thereby increasing uncertainty. However, by connecting the PPV300 to a drum dryer, as performed at the farmer cooperative visited, the excess heat from the pyrolysis could be utilized to dry the biomass.

The biochar is not affected in the sense that it can be spoiled by poor rainfalls or poor handling. However, it is not recommended that it be exposed to rain, as there might be a desire to control the moisture of the biochar to a certain level. Husk Ventures, for instance, indicate that their customers prefer a moisture level of 20%. As biochar acts as a sponge and attracts water, it could also become expensive to transport on account of higher weight. Overall, the quality of the biochar was not an issue experienced by either the intermediaries visited or the farmer cooperative.

Production Characteristics

Production characteristics are a source of supply uncertainty that deserves attention. The uncertainties from production characteristics are medium high, and therefore, they are at Level 2 for the farmers. The intermediaries interviewed showed signs of having the ability to quickly solve problems, such as more experienced personnel working with the machine all year long. However, given that most of the uncertainties arise from the machine and procedures, the uncertainty is still deemed to be medium-high and therefore at Level 2. The main findings that influenced the levels are that there might be potential disruptions due to machine characteristics, there might be potential disruptions from safety procedures, and production with the PPV300 can be inflexible.

The PPV300 has been and is continuously subject to redesign. This could mean that customers who have already purchased the machine can experience issues with, for instance, rust or overheating, as these are aspects that Viet Hien has addressed with design changes. This uncertainty is not expected to disappear until the design changes concern finer details of the machine operations, and therefore, users of the machine must be prepared for disruptions due to an evolving design of the machine. In addition, disassembling the machine can be dangerous and time consuming. Intermediaries could have better opportunities than farmers to fix issues, as they have no other core business obligations.

Safety procedures in the production could be improved, especially as there is no formalized training programme for the machine operators.

In addition, due to the high start-up cost for the PPV300, combined with the need to reduce costs, the machine will ideally need to be up and running for six consecutive days once production begins. The machine also has different requirements depending on the feedstock used, such as the time between maintenance and the time it takes to transform it into biochar. This means that materials cannot be mixed if the quality of the biochar should be guaranteed, meaning in turn that it is preferable to use just one feedstock for the whole production cycle. If the producer is using the same feedstock, the inflexibility is not of great importance.

Supply Reliability

The findings conclude that the supply of coffee husk for biochar production has dependence on external risks that can hinder a reliable supply. The supply uncertainties from the intermediaries take some supply uncertainties from the farmers into consideration, since farmers supply the husk that the intermediary uses as raw material. In conclusion, both the intermediaries and farmers face the same type of external risks. However, since intermediaries have a greater ability to both hedge themselves and source from a large network of suppliers makes their uncertainty regarding supply reliability low, and therefore at Level 1. Farmers are deemed to be more vulnerable, and their uncertainty for supply is deemed to be medium high and thus at Level 2. Apart from the dependence on external risks, the supply reliability was affected by the finding that habits might limit supply as well as the positive finding that it is possible to achieve long-term storing of coffee husk and biochar.

Coffee growing is vulnerable to changing weather patterns, which have been more unpredictable the last couple of years (Vietnam Coffee-Cacao Association, 2019) [6]. Unattractive prices for coffee may also cause farmers to hold onto their beans and husk for a couple of weeks until the price is right. The external risk is deemed more prominent for single farmers, cooperatives, or larger-scale farms, since the farmlands are located closely together. This means that they are more vulnerable to the same risks. Intermediaries could perhaps adapt to these external risks more easily, as they could hedge themselves and buy coffee husk from different farmers and regions. In combination with Dak Lak being home to a very large number of farmers, the uncertainty for running out of suppliers is low for intermediaries.

In addition to external risks, until now, there has been no widespread culture to store the husk and, according to UNIDO (2019) [12], farmers may be reluctant to get involved in a new business area. When the coffee cherry is dried correctly—to 12-13% moisture—the husk can be stored for long periods of time if later stored correctly, which does not increase the supply uncertainty. According to Dumfort et al. (2018) [27], below 20% moisture, the biomass will not start degrading. The intermediaries have better opportunity for correct handling of the husk, as farmers have been observed to have limited opportunities for dedicated storing, but they are still in the hands of the farmers who provide the raw material. However, they can refuse to buy damaged husk and use a larger supply network, meaning that the risk of not being able to store the husk is somewhat mitigated. The refined product of coffee husk, biochar, was proven to not be a sensitive storing unit, and therefore, it could easily be stored in the long term.

Concluded Supply Uncertainty

When considering the findings, the concluded supply uncertainty from coffee farmers is 1.7 on the scale from 1 to 3, whereas the concluded supply uncertainty from intermediaries is 1.3 on the scale.

3.2.3. Concluded Supply Chain Uncertainty

The supply chain uncertainty that occurs from having coffee farmers as producers of coffee husk-biochar is the average of the demand uncertainty and the supply uncertainty that occurs from having this supply chain configuration.

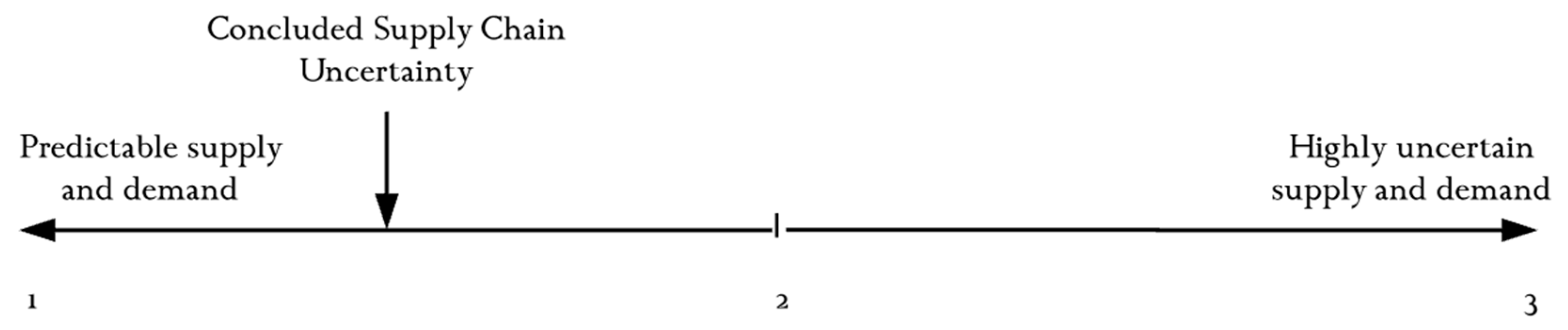

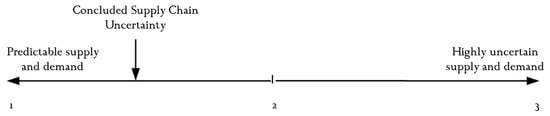

The concluded supply chain uncertainty of 1.5 is illustrated on the uncertainty spectrum in Figure 5 below.

Figure 5.

The concluded supply chain uncertainty, on the uncertainty spectrum, when coffee farmers produce biochar.

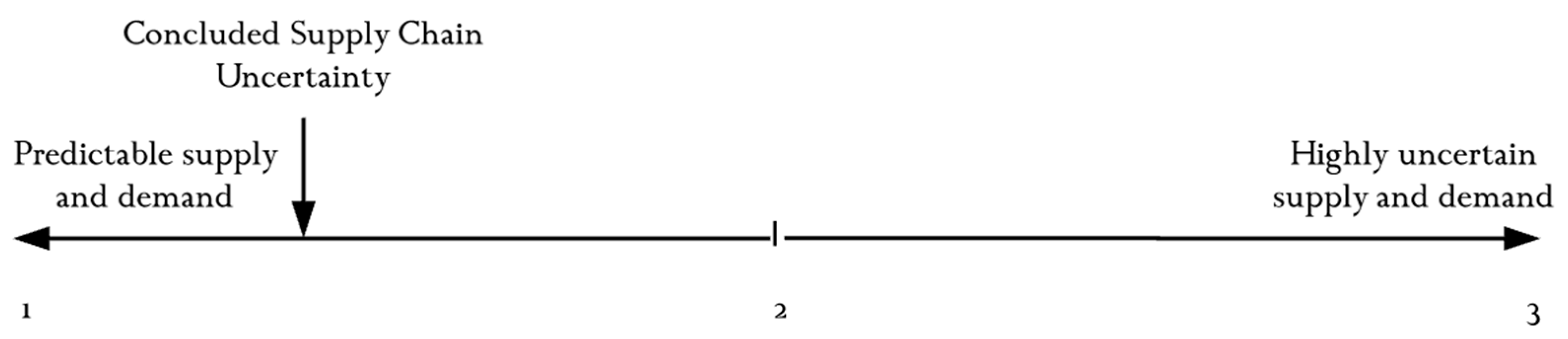

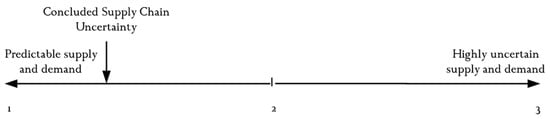

The supply chain uncertainty that occurs from having intermediaries as producers of coffee husk-biochar is the average of the demand uncertainty and the supply uncertainty. The concluded supply chain uncertainty of 1.3 is illustrated on the uncertainty spectrum in Figure 6 below.

Figure 6.

The concluded supply chain uncertainty, on the uncertainty spectrum, when an intermediary produces biochar.

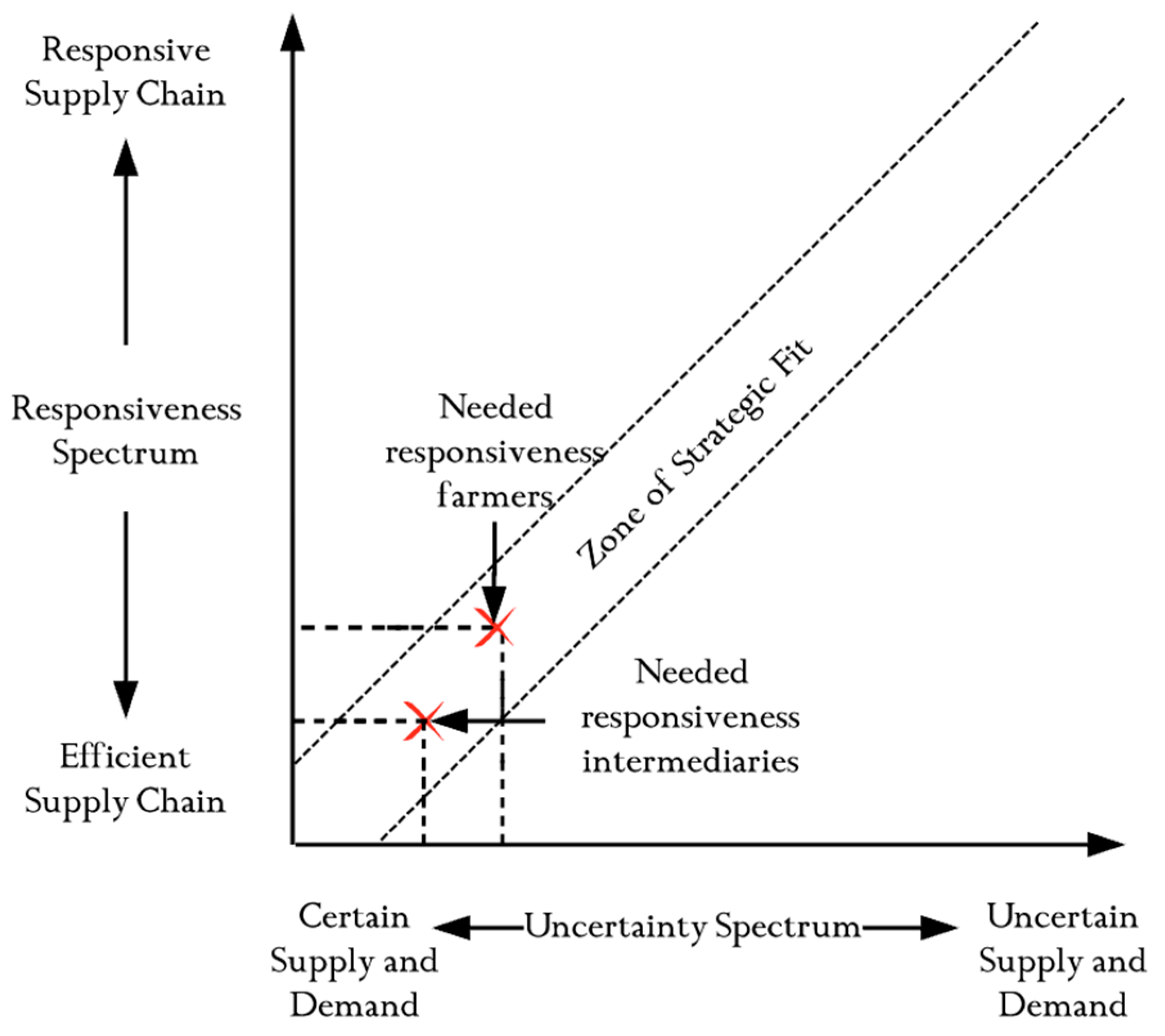

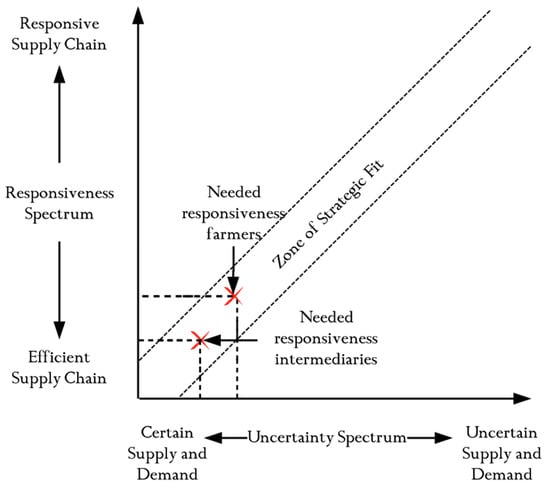

3.3. Supply Chain Responsiveness

Responsiveness is defined as “the ability to react purposefully and within an appropriate time-scale to customer demand or changes in the marketplace”, and this section presents how actors can cope with the found uncertainties with an appropriate level of responsiveness (Figure 7). If there is a strategy within the zone of strategic fit, the responsiveness is chosen accordingly to the given uncertainty. A high uncertainty requires high responsiveness, and a low uncertainty should be met with low responsiveness (Chopra and Meindl, 2013) [4]. Figure 7 shows that both farmers and intermediaries require rather low responsiveness, although intermediaries require even lower levels than farmers.

Figure 7.

Desired level of responsiveness according to the found uncertainty (Chopra and Meindl, 2013) [4].

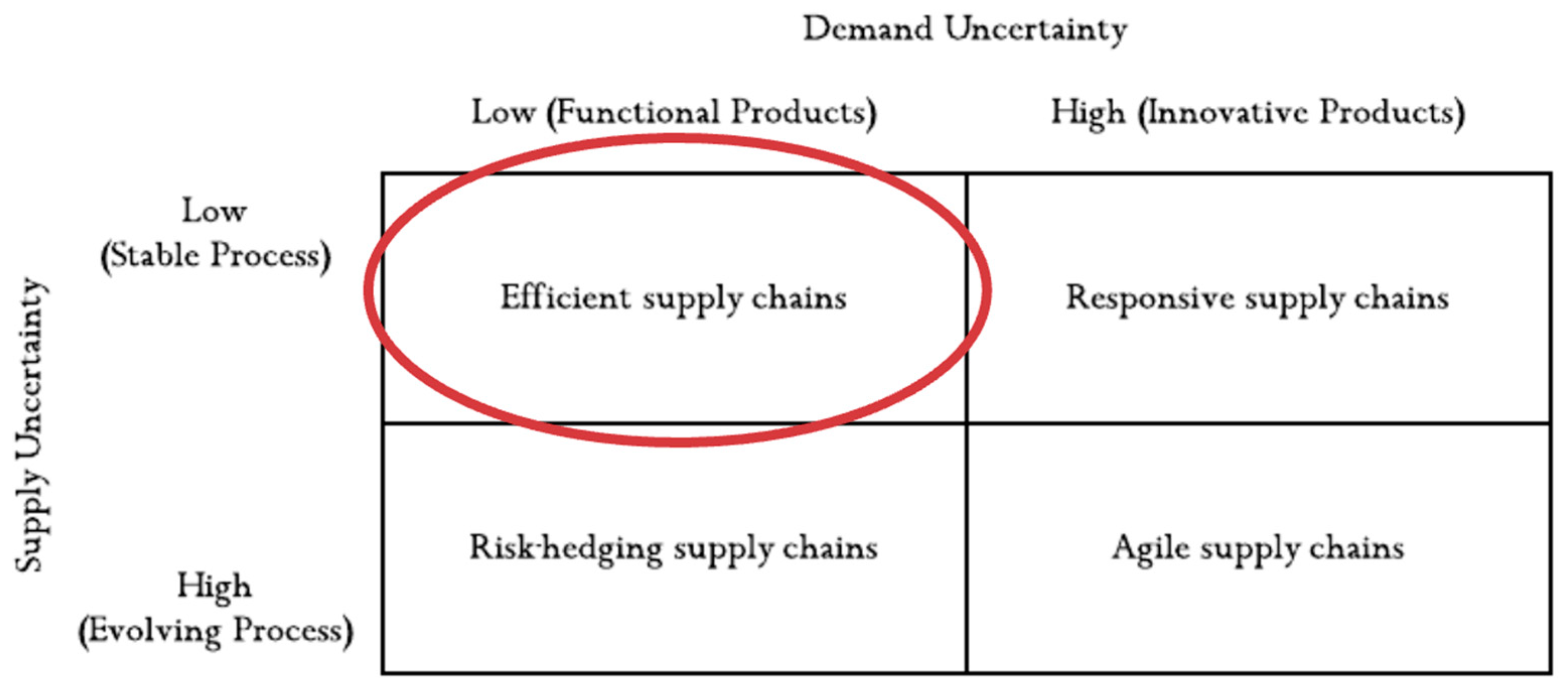

3.3.1. Choosing an Appropriate Strategy

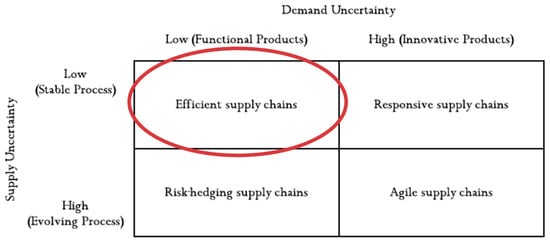

As can be concluded from Figure 7, the required responsiveness to meet the found uncertainty is fairly low both in the case of farmers and intermediaries. Adjusting to the correct level of responsiveness is not a straightforward task, as it also needs to take into consideration where the uncertainties originates, as the framework concludes the aggregated uncertainty. In order to find where the responsiveness should be focused (toward suppliers or customers), the strategy framework from Lee (2002) [25] will be used. Lee (2002) [25] suggests that, under the current circumstances with both low demand and supply uncertainty, the focus should be on an efficient supply chain, as illustrated below in Figure 8.

Figure 8.

Chosen strategy from Lee (2002) [25].

An efficient supply chain is one in which the company should be focused on cutting costs through the efficient use of resources and competing on price. This strategy resonates well with the finding that in order for the coffee husk-biochar to be considered by the activated carbon producer, it would quite drastically need to reduce its price. As decisions regarding facilities, inventory, and transports are the biggest influencers of supply chain responsiveness, suggested measures in these areas, as well as an analysis of potential contextual hindrances to these measures, will follow.

Facilities

Schmitt et al. (2015) [28] and Snyder and Shen (2006) [29] have concluded that facilities could benefit from being decentralized when there is either uncertain supply or both uncertain supply and demand. As concluded, there would be rather low supply uncertainty for both farmers and intermediaries and, as demand uncertainty in this case is low, decentralization should not be sought from this point of view. Decentralization could cause asymmetric information, misaligned incentives, as well as incongruent objectives, all of which result in discontent and inefficiencies in the supply chain. Centralization seems viable in this context, as an evolving and immature industry such as the biochar industry could naturally cause asymmetric information between the supply chain partners involved, as roles and responsibilities may be undefined.

The chosen efficient strategy also suggests that facilities should be centralized, and all findings indicate that neither farmers nor intermediaries would be hindered from adopting the suggested efficient strategy. These findings are as follows:

(a) Many farmers are needed. In general, a farm in Dak Lak has a monthly income of around USD 250 to 500, while, according to Viet Hien, the PPV300 costs around USD 40,000. This implies that around ten yearly incomes for one farmer would be needed to invest in one machine. In a survey by Nguyen and Sarker (2018) [15], 96.4% of 137 farmers in Dak Lak confirmed that they would be willing to invest more than 10 million Vietnamese Dong (around USD 430) if it would improve their farming or lead to higher sustainability. Assuming that the farmer would be willing to invest as much as USD 500, this would still require an investment in the PPV300 by a total of 80 farmers. Another financial consideration affecting the viability of centralizing is the capacity utilization of the PPV300. Using up to 90% of the capacity should be desired to reduce the cost of the produced biochar and thereby follow an efficient strategy, as a large portion of the cost for the produced biochar will otherwise be represented by machine depreciation costs. A calculation of the number of average farms needed to utilize 90% of the machine capacity is as follows: one coffee farmer (in Vietnam) averages 3 hectares of land. Each hectare yields 12.8 tonnes of fresh coffee cherries per year, meaning that 38.4 tonnes per year per farmer are produced. Of every fresh kilo of fresh coffee cherries, 14% of the weight will become dry husk. The PPV300 requires 100 kg of coffee husk per hour and can run 24 h per day, 6 days a week. The calculations will assume a 90% utilization rate, as it is unreasonable to plan for full capacity. This would mean that the PPV300 requires 0.9 (utilization) * 52 (weeks) * 6 (days) * 24 (hours) * 100 (kg) = 673.2 tonnes biomass each year. A total of 673.2 tonnes of biomass would mean 4808.6 tonnes of fresh coffee, which would mean 4808.6/38.4 = an equivalent of 125 average farmers would be needed to use capacity of up to 90%.

(b) Machine operations benefit from centralization. Another consideration regarding the use of centralized versus decentralized production facilities is the increased need for flexible personnel and education on the PPV300 if decentralizing. In addition, the machine’s characteristics can affect whether it would be beneficial to focus production in one or several places. Around 200 square meters could be needed for the use of the machine. If the business can support more than one machine, it could be beneficial to centralize, with many machines in one place rather than being spread out.

Inventory

The efficient strategy suggests that inventory levels should be kept as low as possible in order to reduce costs, both for raw material as well as for finished products. The stable supply and demand indicates that there will be a limited need for safety stock. Our previous finding that a great amount of husk needs to be stored over longer periods of time makes it difficult to follow the efficient strategy regarding inventory management, and the finding that it is possible to achieve long-term storing of coffee husk enables this excess stock. Regardless of the actor, the need for a large raw material inventory creates the need for both larger facilities and more capital tied up than required by the suggested strategy. Therefore, it can be investigated whether the raw material inventory could be distributed among the actors in the supply chain to share this additional cost. However, long-term storage might prove difficult for farmers, as Hoang (2017) [13] mentions that more than 90% of the 139 farms she studied in the central highlands lacked an appropriate storage area.

Meanwhile, the finished goods inventory made up of biochar in contrast to the raw material could be limited. Given that demand is predictable and stable, only low levels of inventory would be needed to meet the needs of the activated carbon customer. The predictable production would also allow for regular shipments that would keep the finished goods inventory at a low level. This is true regardless of the biochar producer.

Transports

The efficient strategy suggests that if possible, the lead times of transports should be kept short but not at the expense of increased costs. As supply and demand uncertainties were found to be low, long-term planning where only full truck loads are being shipped at favorable rates should be possible.

It could be costly for farmers to transport goods in Vietnam, as transportation costs could hinder farmers from the desired strategy. However, the analysis did not find any major hindrances of following an efficient strategy for an intermediary to arrange cheap transports and thereby follow an efficient strategy. Another finding that may affect transports in the region is that the reliability of transports is varying.

Roads may be unpaved or have weight limitations along with low standards on vehicles and equipment. This needs consideration, as low reliability can cause varieties that must be mitigated through costly responsiveness measures.

4. Discussion

This section presents, on the basis of the results, the type of actor that could reasonably act as a biochar producer, considering the context and the low demand uncertainty, such as in the case of supplying to activated carbon producers. This is part of our suggestion of how the coffee husk-biochar supply chain can be adjusted to address its uncertainties and reduce them at their source. A full description of the underlying assumptions and calculations will be made available in an open access Lund University Masters thesis report (immediately after the publication of the present article). The section also discusses the importance of co-benefits deriving from the PPV300 for the different actors and how this could significantly influence the technology choice.

4.1. Appropriate Producer of Coffee Husk-Biochar

4.1.1. Farmers

If farmers were the producers of biochar, we conclude that they would either need to be of considerably bigger size than the average farm or be part of very large cooperatives to enable production. These options make up a very small fraction of the farms in Dak Lak, but the average farm is not an option due to two main factors. Firstly, the economics of the PPV300 are difficult to match with the finances of average farms, as the price of the machine corresponds to almost ten years of earnings for the average farmer. Realistically, many average farmers would need to come together to finance the machine entering a new business that is not in their area of expertise, which is unlikely.

Secondly, from the findings regarding the price of the PPV300 as well as the price of the coffee husk biochar, it should be desirable to use as much of the capacity as possible to decrease the cost per tonne of produced biochar. It would take the husk from about 125 farmers to achieve high utilization of the machine, unless it is accepted that the machine is unused for the major part of the year, i.e., outside of the coffee harvest season, which is a suboptimal option. However, it might be difficult to bring 125 average farmers together to produce biochar, as farmers in the region have limited cooperation between each other, along with the fact that they are geographically scattered. Coordinating a large number of farmers requires that a farmer take on a serious leadership role. It is uncertain whether any farmer has the interest or ability to do this, and it would also interfere with daily farming operations. In addition, since the transport costs are already a constraining factor on the farmers’ operations, there could be difficulties in arranging the full truck loads to keep down the cost per tonne.

The analysis shows that it is highly unlikely that average farmers would be willing to become involved in the biochar business due to economic and organizational constraints. One option would be farmer cooperatives, such as the one visited, which already produces biochar. Having a cooperative of around 30 members would drastically reduce the investment per farmer, while a larger supply of husk would be available from the start. However, there would still be a large shortfall of husk, meaning that the cooperative would need to organize the supply of almost 100 more average farmers to sustain a yearly production to reduce the biochar price. The analysis also found higher levels of uncertainty related to the farmer cooperatives than the intermediaries visited.

This analysis does not address the other benefits that the PPV300 brings, such as reducing the smoke and the possibility of using its excess heat for drying. The cooperative would be able to dry their beans as it produces the biochar, which is an operation that otherwise costs between VND 400 and 800 per kg of coffee (Hoang, 2017) [13]. By allocating the savings from the drying, the price of the biochar could be reduced. Despite this, the intermediaries visited to date are not using this feature. This in an important advantage of the PPV300 in comparison with cheaper alternatives, and it could significantly change the economics of biochar production. This would reduce the cost allocated to biochar production, but it does not compensate for the increased depreciation per tonne unless the cooperative sources husk outside their own supply to sustain a yearly production.

4.1.2. Intermediaries

An intermediary is deemed to have better opportunities to both finance and utilize the machine than a farmer. The intermediary is also deemed to have better prerequisites for establishing such a large supply network due to the fact that biochar would be their main operation. An intermediary could also optimize its location in contrast to the farmers who are bound to their farmlands, and the intermediary would not need to focus on generating its own raw material through farming operations. On the other hand, the intermediary as a newly founded company, such as the one visited in Cambodia, would presumably not have the same opportunities to fully utilize the PPV300 and allocate savings from its excess heat unless expanding their business to include different drying services. As concluded, they would also need to store great amounts of husk, meaning that large facilities are needed, thus absorbing a large portion of the costs. As found, the option of sharing the stock among upstream farmers is not deemed to be viable.

The potential storage problem could be solved by using the advantage that the intermediaries could locate their business more freely. This means that they should consider cooperating with coffee processors. Our findings indicated that between 20 and 50% of the coffee cherries are not dehusked at the farmers but rather at external processors, meaning that an alternative is to buy husk from the latter instead of the farmers. As well as solving the storage problem, this would provide an opportunity to centralize close to one or two larger processors, who could provide the raw material from a focal point instead of dealing with hundreds of farmers. For example, this would use the already established business relationships between the processor and farmers as well as the established logistics between them, meaning that many of the uncertainties that come with dealing with a large number of actors can be mitigated. As the findings show that the farmers have an ambiguous attitude toward the husks and new types of business, the advantage of piggybacking on an existent supply chain should not be underestimated, as it could be difficult to set this up for a new company.

This setup would further increase efficiency, but it requires the cooperation of one or more coffee processors. If being placed in the same facilities, it is beneficial if the intermediary is also allowed to source from other processors to avoid the supply risk generated from the dependence upon a single supplier. If it is not possible to rent part of a facility owned by a processor that is located as close to the processor as possible, it is recommended that transportation be limited. There is also the possibility for the intermediary to utilize the PPV300′s excess heat by engaging in the processor’s drying activities. This would create synergies between the actors but still allow the intermediary to be flexible in terms of supply and choice of location.

However, this supply chain configuration would imply that one more type of actor is needed in the supply chain, thereby potentially increasing costs.

A threat with the additional actor, and the relatively high dependence upon it, is the potentially conflicting interests that might arise. It is important to remember that when adding another actor into the supply chain, there is a higher risk that the new actor is more powerful than the intermediary. Thus, the new actor could take the supply chain leader role, which might limit the intermediary to acting according to the most efficient biochar production strategy.

In the end, the setup of having an intermediary close to coffee processors as producers is preferred over having farmer cooperatives as producers. The reasons for this are as follows. (1) Less overall transport is needed in the system, as the coffee processor already makes the long journeys for coffee cherries. (2) The correct, and presumably efficient, flows of material already exist, and it is likely that fewer parties would need convincing of this solution than if new cooperatives were created or if many farmers needed to act as suppliers. (3) The producer could have the biochar production as their core business and avoid coffee production as a distraction, therefore focusing on making processes more efficient and aligning more easily with the overall business strategy.

4.1.3. Coffee Processors

The main uncertainties that surround the intermediary are the potentially amplified uncertainty and the potential conflict of interests between the supply chain actors. Both of these could be mitigated by the processors themselves being the intermediary that produces biochar, thus also avoiding conflicting interests with the biochar producer. The coffee processor would also utilize many of the advantages mentioned for the intermediary, such as using the existing supply chain and enjoying established relationships with the important buying agents, or in some cases, directly with farmers. Therefore, they would not need to establish new sales channels to the same extent as an external intermediary, for example, as they could also start by selling biochar through the same channels through which they have sourced their coffee cherries. According to Sofies’ experience in other countries such as Peru, processors can better capitalize on labor costs, which is the main cost driver for a biochar output in the order of 30 kg/h, which supports the case of coffee processors. Processors usually have logistics experience and available storage room. They could also use the excess heat for drying coffee cherries as part of their original business. A reduced need for energy for drying beans gives the opportunity to allocate less costs to the produced biochar, as it creates value that decreases costs in other areas. Therefore, this is aligned with the objective of reducing costs for the biochar, assuming that the processor can make full use of the excess heat. Well-established processors are also assumed to have more solid finances than both farmers and potentially newly founded companies.

While the processors might conduct some additional businesses, such as trading with coffee between other actors or engaging in the tourism industry, the actual processing does only takes place during a few months of the year. This means that facilities, machines, and similar overhead costs must be allocated to this short period of processing. The processors can either engage in the biochar business themselves or rent out their facilities to an intermediary, which should be a desirable option as long as it generates a profit. As well as the potential synergy of using the excess heat, theoretically, it should be desirable from an economical perspective to diversify their sources of income.

However, the processor would also have several of the disadvantages experienced by the farmers, such as adding another large business area to their core business, as well as potentially not having the same opportunities to source as freely as an independent intermediary. Since they have already invested in fixed assets, they will not have the same opportunities as the intermediary has to adjust their business to an efficient strategy.

Thus, it is difficult to state if a processor, in the end, would be a better alternative as the biochar producer than an intermediary. However, it can be concluded that their involvement in the supply chain configuration would be a favorable option, as they already have important relationships and distribution channels in place.

4.1.4. Large-Scale Farmers

As discussed in the contextual findings, it has become clear that there are also actors who cannot be classified as either processors or farmers, since they are either farmers who also process their coffee, or processors with such close connections to specific farmers that they cannot be distinguished from each other. This type of actor would possess the benefits of being able to use the excess heat from the PPV300, would have a proper supply chain and necessary relations for the husk, and is assumed to have the resources to make the necessary investments. As the visited farms and literature stated, the common procedure for farmers is to grow additional crops in the coffee fields, such as pepper; then, the actor could continue to utilize the PPV300 for drying other crops besides the coffee.

This hybrid actor would presumably still need to source additional husk to sustain production for a full year and would not be as flexible as an intermediary in designing their strategy toward efficiency due to fixed assets. It would also interfere with their core business during harvest and current use of the husk. Even so, they would have greater ability and a larger workforce to handle the new business area than the small-scale farmers. They would also, as with the processors, add another source of income during the remaining parts of the year by producing biochar. Lastly, since they also are closely connected to the farms, they would be able to use the biochar themselves if the demand was fluctuating, meaning that they could reduce the need for fertilizers while limiting their water usage.

While this type of actor possesses both advantages and disadvantages from the previously discussed alternatives, there are both advantages and disadvantages that could have been foreseen. However, since the absolute majority of farmers are small scale, there are a limited number of these actors.

In conclusion, according to the analysis, there are several actors who would be able to take on the role of biochar producer: an intermediary without previous direct involvement in the coffee supply chain, a coffee processor, or a hybrid between farm and processor, each with advantages and disadvantages. However, how to evaluate their abilities would require a much deeper study of each actor and their respective preferences. They would all be suitable from a supply chain perspective to attain an efficient strategy that would keep the price of the biochar low.

4.2. Relationships in the Coffee Husk-Biochar Supply Chain

A question highly related to the cultural aspects that will affect the supply chain is the role of the supply chain leader and what effect this might have on the choice of configuration. In the case of an operation that requires a complex supply chain that to a large extent is built on trust, relationships, and financial obligations, the supply chain leader’s role might be more important than strictly coordinating the strategy and action across the chain. In this case, the leader may be the enabler of the whole business. Without an actor who both understands the complexity and has the trust of the farmers, it is highly unlikely that an efficient flow of goods will be possible. In other words, the processor, with their contacts and trust from both buying agents and farmers, might be the enabler of the business and thus the only natural supply chain leader. Therefore, a configuration in which they participate is deemed necessary.

However, it is uncertain whether the processors actually want to engage in biochar production. The processors who handle coffee husk in many cases already have a stable market for their husk, which is either sold as fertilizers or as material to burn, or they use it themselves for the same purpose. This already brings them economic benefits, however small. When engaging in biochar, they will need to make rather large investments in machinery and possibly storage space, as well as changing much of their current method of working to adapt to the requirements of the new business. Presumably, they would only consider this rather large risk if they believed in the possibility of a higher income than that generated by their current use of the husk. Unless the processors have a very long investment horizon, which we deem unlikely, the increased income must also be rather high, in order to compensate for the risk and investment within a few years.

However, since the findings have indicated that the coffee husk-biochar has problems competing with biochar from other biomasses, and that lowering the price is crucial for the product to succeed, the margins will most likely be very small. In order to make the product viable, there need to be economies of scale. This implies that the first movers will need to pay a higher price. For the product to be viable, actors need to invest in it, but they will only do so if there is a high chance of significantly increasing their income, which currently there is not.

4.3. The PPV300 vs. Cheaper Alternatives for Biochar Production

Throughout this paper, the PPV300 has been the assumed machine unit for the production of coffee husk-biochar. However, consideration must be given to whether the PPV300 is the best alternative for the production of biochar, if considering our findings that the exclusive production of biochar (i.e., without use of the heat generated) is too costly compared to other types of biochar on the market. The main issue that needs consideration is whether a system that generates excess heat and re-supplies its own fuel is needed for this purpose in the specific context, as this causes higher financial costs for the technology. However, these functionalities could be utilized by a coffee processor producing biochar, for example, as they could also dry coffee cherries with the heat or use the excess heat to generate electricity needed for other purposes. A reduced need for energy for drying coffee cherries, or for electricity, gives the opportunity to allocate less costs to the produced biochar, as it creates value that decreases costs in other areas. This is aligned with the objective of reducing costs for the biochar, assuming that the biochar producer can make use of the excess heat.

To allocate the costs correctly between the biochar and other co-products (e.g., heat or black liquor, which could be used as bio-pesticide) is not straightforward. The cost of biochar production with the PPV300 should always be calculated in light of the co-products and the co-benefits that the system provides. If all capital costs are allocated to biochar, or the system is used only for biochar production, this would lead to low margins for the investor. Therefore, it is of high importance that the actor who engages in this is not only willing to take a risk but also able to allocate the costs correctly to reach the full potential of this technology.

Another important benefit of the PPV300 is the smoke-free production process. This means that production with the PPV300 reduces health costs related to the emission of smoke and air pollutants. The reduced costs related to this are primarily social costs (rather than costs for the enterprise or the investor), and the benefit to society should be somehow internalized in the “real” cost of biochar—for example, through public incentives for clean technology. It is difficult to argue for these cost reductions unless society, rather than the enterprises, realizes the benefits and compensates the cost difference between a smoke-free and a conventional polluting biochar-producing technology. The co-benefits of a clean energy technology such as the PPV300 usually significantly outweigh the financial benefits [30,31]. Another alternative, from the society perspective, is of course to use regulations as incentives favoring “green” technologies to reduce the externalities, which rather force the enterprise to strive for such cost reductions (Flammini et al., 2018) [30]. Although such incentives would not mitigate the original hindrances, they would further support the expansion of coffee husk-biochar production in Vietnam.