Investigating the Theoretical Constructs of a Green Lean Six Sigma Approach towards Environmental Sustainability: A Systematic Literature Review and Future Directions

Abstract

:1. Introduction

- To investigate the theoretical constructs (drivers, enablers, CSFs, barriers, and outcomes) of a holistic GLSS approach.

- To develop an integrated framework combining the above GLSS constructs as a holistic approach.

- To highlight the possible gaps and future research directions of a holistic GLSS approach.

2. A Review of Green, Lean, and Six Sigma Approaches towards Environmental Sustainability

2.1. Green Approach

2.2. Lean Approach

2.3. Six Sigma Approach

2.4. Lean-Green Approach

2.5. Lean-Six Sigma Approach

2.6. Limitations of Lean, Green, and Six Sigma Approaches

2.7. Limitations of Lean-Green, Lean-Six Sigma, and Green-Six Sigma Approaches

2.8. Green Lean Six Sigma Approach

3. Research Methodology

4. Descriptive Analysis

4.1. Articles Classification by Year of Publication

4.2. Articles Classification by Journal

4.3. Articles Classification by Country

4.4. Articles Classification by Industry

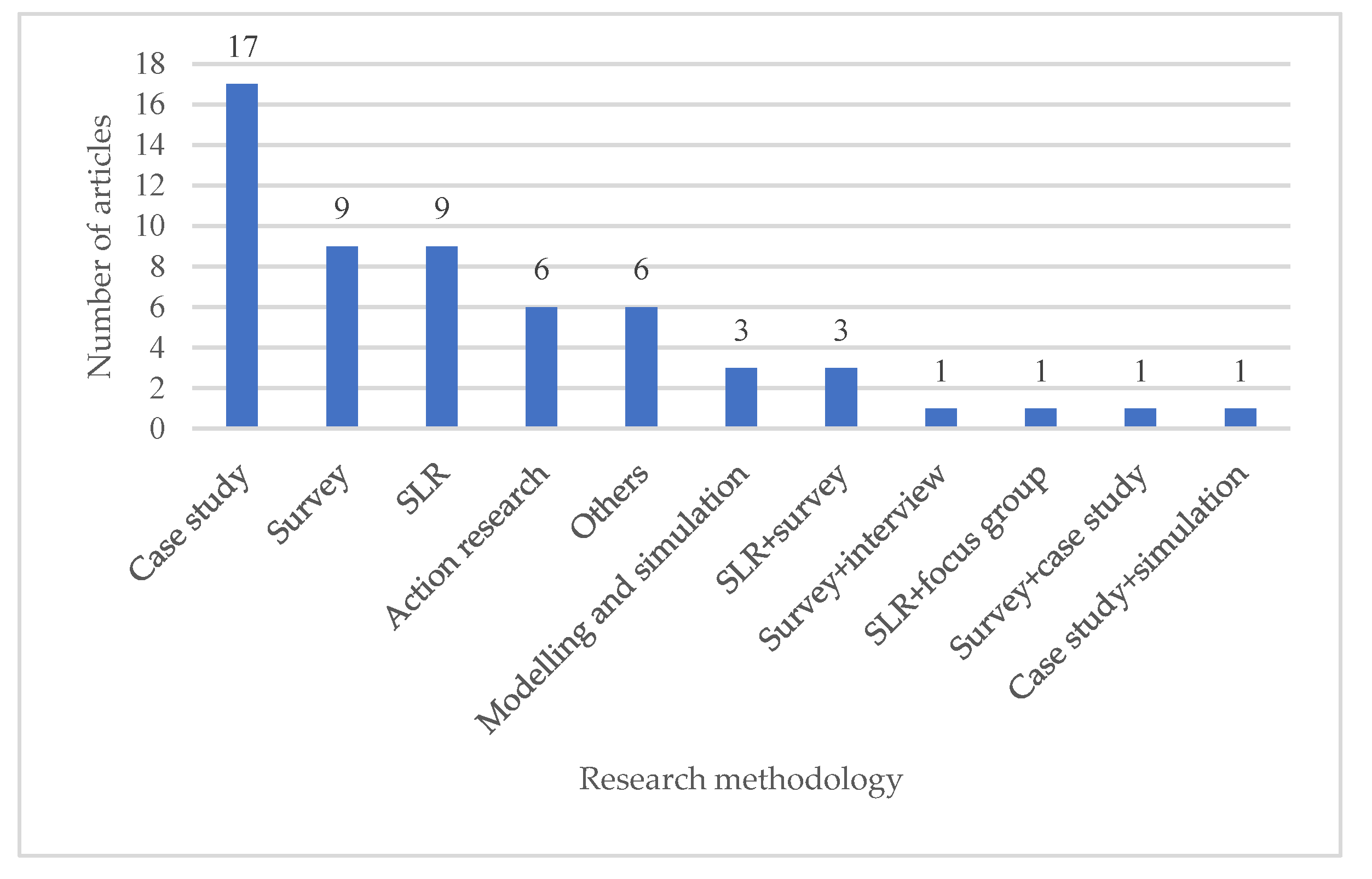

4.5. Articles Classification by Research Methodology

5. Analysis of the Research Findings

5.1. Drivers of Green Lean Six Sigma (GLSS) Approach

- Minimizing the barrier of market to enter international market.

- Sizing the environmental market prospects.

- Compliance with the regulatory requirements.

- Improving brand image.

- Meeting the customer requirements of environmental-friendly product.

- Social responsibility.

5.2. Enablers of GLSS Approach

5.3. Critical Success Factors of GLSS Approach

5.4. Barriers of GLSS Approach

- Fear among manufacturers and suppliers regarding expenses associated with green supply chain activities (as they might become costly) and customers may not be able to afford it.

- The implementation of GLSS can be affected if employees are reluctant to adopt environmental practices.

- Lack of customers’ trust on firm’s green activities.

- Lack of supervision for executing green supply practices as a result of inappropriate policies.

- Lack of cooperation between public and private sector and lack of collaboration from international organizations (e.g., world trade organization (WTO), the European union (EU)) for a successful implementation.

- Lack of clarity on environmental sustainability which may lead to poor understanding of this approach.

- Difficulty of relating measures to customer satisfaction and lack of environmental knowledge in suppliers.

5.5. Outcomes of GLSS Approach

5.6. GLSS Models and Frameworks

5.7. An integrated GLSS Framework towards Environmental Sustainability

6. Future Directions

6.1. Theoretical Constructs of GLSS

6.2. Discrete vs. Process Industry

6.3. Current Trends under GLSS

7. Conclusions and Limitations

Author Contributions

Funding

Conflicts of Interest

References

- Shokri, A.; Li, G. Green implementation of Lean Six Sigma projects in the manufacturing sector. Int. J. Lean Six Sigma 2020. [Google Scholar] [CrossRef]

- Garza-Reyes, J.A.; Yu, M.; Kumar, V.; Upadhyay, A. Total quality environmental management: Adoption status in the Chinese manufacturing sector. TQM J. 2018, 30, 2–19. [Google Scholar] [CrossRef] [Green Version]

- Parmar, P.S.; Desai, T.N. A systematic literature review on Sustainable Lean Six Sigma. Int. J. Lean Six Sigma 2019. [Google Scholar] [CrossRef]

- Galli, A.; Wiedmann, T.; Ercin, E.; Knoblauch, D.; Ewing, B.; Giljum, S. Integrating Ecological, Carbon and Water footprint into a “Footprint Family” of indicators: Definition and role in tracking human pressure on the planet. Ecol. Indic. 2012, 16, 100–112. [Google Scholar] [CrossRef]

- Bai, X.; Ren, X.; Khanna, N.Z.; Zhou, N.; Hu, M. Comprehensive water footprint assessment of the dairy industry chain based on ISO 14046: A case study in China. Resour. Conserv. Recycl. 2018, 132, 369–375. [Google Scholar] [CrossRef]

- Sreedharan, R.; Sandhya, G.; Raju, R. Development of a Green Lean Six Sigma model for public sectors. Int. J. Lean Six Sigma 2018, 9, 238–255. [Google Scholar] [CrossRef]

- Tseng, M.L.; Islam, M.S.; Karia, N.; Fauzi, F.A.; Afrin, S. A literature review on green supply chain management: Trends and future challenges. Resour. Conserv. Recycl. 2019, 141, 145–162. [Google Scholar] [CrossRef]

- Mangla, S.K.; Luthra, S.; Mishra, N.; Singh, A.; Rana, N.P.; Dora, M.; Dwivedi, Y. Barriers to effective circular supply chain management in a developing country context. Prod. Plan. Control 2018, 29, 551–569. [Google Scholar] [CrossRef] [Green Version]

- Garza-Reyes, J.A. Green lean and the need for Six Sigma. Int. J. Lean Six Sigma 2015, 6, 226–248. [Google Scholar] [CrossRef]

- Cherrafi, A.; Elfezazi, S.; Chiarini, A.; Mokhlis, A.; Benhida, K. The integration of lean manufacturing, Six Sigma and sustainability: A literature review and future research directions for developing a specific model. J. Clean. Prod. 2016, 139, 828–846. [Google Scholar] [CrossRef]

- Banawi, A.; Bilec, M.M. A framework to improve construction processes: Integrating Lean, Green and Six Sigma. Int. J. Constr. Manag. 2014, 14, 45–55. [Google Scholar] [CrossRef]

- De Freitas, J.G.; Costa, H.G.; Ferraz, F.T. Impacts of Lean Six Sigma over organizational sustainability: A survey study. J. Clean. Prod. 2017, 156, 262–275. [Google Scholar] [CrossRef]

- Farias, L.M.S.; Santos, L.C.; Gohr, C.F.; de Oliveira, L.C.; da Silva Amorim, M.H. Criteria and practices for lean and green performance assessment: Systematic review and conceptual framework. J. Clean. Prod. 2019, 218, 746–762. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Green Lean Six Sigma implementation framework: A case of reducing graphite and dust pollution. Int. J. Sustain. Eng. 2019. [Google Scholar] [CrossRef]

- Cagno, E.; Trucco, P. Integrated green and quality function deployment. Int. J. Prod. Lifecycle Manag. 2007, 2. [Google Scholar] [CrossRef]

- Shih, C.W.; Wang, C.H. Integrating wireless sensor networks with statistical quality control to develop a cold chain system in food industries. Comput. Stand. Interfaces 2016, 45, 62–78. [Google Scholar] [CrossRef]

- Garza-Reyes, J.A.; Kumar, V.; Chaikittisilp, S.; Tan, K.H. The effect of lean methods and tools on the environmental performance of manufacturing organisations. Int. J. Prod. Econ. 2018, 200, 170–180. [Google Scholar] [CrossRef]

- Al-Sheyadi, A.; Muyldermans, L.; Kauppi, K. The complementarity of green supply chain management practices and the impact on environmental performance. J. Environ. Manag. 2019, 242, 186–198. [Google Scholar] [CrossRef]

- Gaikwad, L.; Sunnapwar, V. An integrated Lean, Green and Six Sigma strategies. TQM J. 2020, 32, 201–225. [Google Scholar] [CrossRef]

- Kumar, S.; Luthra, S.; Govindan, K.; Kumar, N.; Haleem, A. Barriers in green lean six sigma product development process: An ISM approach. Prod. Plan. Control 2016. [Google Scholar] [CrossRef]

- Cherrafi, A.; Elfezazi, S.; Govindan, K.; Garza-Reyes, J.A.; Benhida, K.; Mokhlis, A. A framework for the integration of Green and Lean Six Sigma for superior sustainability performance. Int. J. Prod. Res. 2016, 55, 4481–4515. [Google Scholar] [CrossRef]

- Kaswan, M.S.; Rathi, R. Green Lean Six Sigma for sustainable development: Integration and framework. Environ. Impact Assess. Rev. 2020, 83. [Google Scholar] [CrossRef]

- Arroyo, P.; Gonzalez, V. Rethinking waste definition to account for environmental and social impacts. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 18–24 July 2016; pp. 20–22. [Google Scholar]

- Hussain, K.; He, Z.; Ahmad, N.; Iqbal, M.; Taskheer Mumtaz, S.M. Green, lean, Six Sigma barriers at a glance: A case from the construction sector of Pakistan. Build. Environ. 2019, 161. [Google Scholar] [CrossRef]

- Mishra. Identify critical success factors to implement integrated green and Lean Six Sigma. Int. J. Lean Six Sigma 2018. [Google Scholar] [CrossRef]

- Guo, C.; Xu, J.; Yang, L.; Guo, X.; Liao, J.; Zheng, X.; Zhang, Z.; Chen, X.; Yang, K.; Wang, M. Life cycle evaluation of greenhouse gas emissions of a highway tunnel: A case study in China. J. Clean. Prod. 2019, 211, 972–980. [Google Scholar] [CrossRef]

- Canellada, F.; Laca, A.; Laca, A.; Diaz, M. Environmental impact of cheese production: A case study of a small-scale factory in southern Europe and global overview of carbon footprint. Sci. Total Environ. 2018, 635, 167–177. [Google Scholar] [CrossRef]

- Nguyen, Q.A.; Hens, L. Environmental performance of the cement industry in Vietnam: The influence of ISO 14001 certification. J. Clean. Prod. 2015, 96, 362–378. [Google Scholar] [CrossRef]

- De Sousa Jabbour, A.B.L.; Verdério Júnior, S.A.; Jabbour, C.J.C.; Leal Filho, W.; Campos, L.S.; De Castro, R. Toward greener supply chains: Is there a role for the new ISO 50001 approach to energy and carbon management? Energy Effic. 2016, 10, 777–785. [Google Scholar] [CrossRef] [Green Version]

- Prasad, S.; Khanduja, D.; Sharma, S.K. An empirical study on applicability of lean and green practices in the foundry industry. J. Manuf. Technol. Manag. 2016, 27, 408–426. [Google Scholar] [CrossRef]

- Hines, P. Lean and green. In Source Magazine the Home of Lean Thinking, 3rd ed.; SA Partners: Caerphilly, UK, 2009. [Google Scholar]

- Kazancoglu, Y.; Kazancoglu, I.; Sagnak, M. A new holistic conceptual framework for green supply chain management performance assessment based on circular economy. J. Clean. Prod. 2018, 195, 1282–1299. [Google Scholar] [CrossRef]

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine That Changed the World: The Story of Lean Production—Toyota’s Secret Weapon in the Global Car Wars That is Now Revolutionizing World Industry; Simon and Schuster: New York, NY, USA, 2007. [Google Scholar]

- Panwar, A.; Jain, R.; Rathore, A.P.S.; Nepal, B.; Lyons, A.C. The impact of lean practices on operational performance—An empirical investigation of Indian process industries. Prod. Plan. Control 2017, 29, 158–169. [Google Scholar] [CrossRef]

- Alhuraish, I.; Robledo, C.; Kobi, A. A comparative exploration of lean manufacturing and six sigma in terms of their critical success factors. J. Clean. Prod. 2017, 164, 325–337. [Google Scholar] [CrossRef]

- Chugani, N.; Kumar, V.; Garza-Reyes, J.A.; Rocha-Lona, L.; Upadhyay, A. Investigating the green impact of Lean, Six Sigma and Lean Six Sigma. Int. J. Lean Six Sigma 2017, 8, 7–32. [Google Scholar] [CrossRef] [Green Version]

- Dieste, M.; Panizzolo, R.; Garza-Reyes, J.A.; Anosike, A. The relationship between lean and environmental performance: Practices and measures. J. Clean. Prod. 2019, 224, 120–131. [Google Scholar] [CrossRef]

- Ramos, A.R.; Ferreira, J.C.E.; Kumar, V.; Garza-Reyes, J.A.; Cherrafi, A. A lean and cleaner production benchmarking method for sustainability assessment: A study of manufacturing companies in Brazil. J. Clean. Prod. 2018, 177, 218–231. [Google Scholar] [CrossRef]

- Hilton, R.J.; Antony, J.; Sohal, A. A conceptual model for the successful deployment of Lean Six Sigma. Int. J. Qual. Reliab. Manag. 2012, 29, 54–70. [Google Scholar] [CrossRef]

- Singh, M.; Rathi, R. A structured review of Lean Six Sigma in various industrial sectors. Int. J. Lean Six Sigma 2018. [Google Scholar] [CrossRef]

- Pacheco, D.; Pergher, I.; Vaccaro, G.L.R.; Jung, C.F.; ten Caten, C. 18 comparative aspects between lean and Six Sigma: Complementarity and implications. Int. J. Lean Six Sigma 2015, 6, 161–175. [Google Scholar] [CrossRef]

- Andersson, R.; Mi Dahlgaard-Park, S.; Eriksson, H.; Torstensson, H. Similarities and differences between TQM, six sigma and lean. TQM Mag. 2006, 18, 282–296. [Google Scholar] [CrossRef] [Green Version]

- Sagnak, M.; Kazancoglu, Y. Integration of green lean approach with six sigma: An application for flue gas emissions. J. Clean. Prod. 2016, 127, 112–118. [Google Scholar] [CrossRef]

- Powell, D.; Lundeby, S.; Chabada, L.; Dreyer, H. Lean Six Sigma and environmental sustainability: The case of a Norwegian dairy producer. Int. J. Lean Six Sigma 2017, 8, 53–64. [Google Scholar] [CrossRef] [Green Version]

- Ben Ruben, R.; Vinodh, S.; Asokan, P. Implementation of Lean Six Sigma framework with environmental considerations in an Indian automotive component manufacturing firm: A case study. Prod. Plan. Control 2017, 28, 1193–1211. [Google Scholar] [CrossRef]

- Sony, M. Lean Six Sigma in the power sector: Frog into prince. Benchmarking Int. J. 2019, 26, 356–370. [Google Scholar] [CrossRef]

- Kaushik, P.; Khanduja, D.; Mittal, K.; Jaglan, P. A case study. TQM J. 2012, 24, 4–16. [Google Scholar] [CrossRef]

- Rimantho, D.; Hanantya, M.W. Enhancing the management of the noise level using six sigma method: A case study on the machining industry. IOP Conf. Ser. Mat. Sci. Eng. 2017, 277. [Google Scholar] [CrossRef]

- Duarte, S.; Cruz-Machado, V. Modelling lean and green: A review from business models. Int. J. Lean Six Sigma 2013, 4, 228–250. [Google Scholar] [CrossRef]

- EPA. The Lean and Environmental Toolkit; United States Environmental Protection Agency: Washington, DC, USA, 2007.

- Carvalho, H.; Duarte, S.; Machado, V.C. Lean, agile, resilient and green: Divergencies and synergies. Int. J. Lean Six Sigma 2011, 2, 151–179. [Google Scholar] [CrossRef]

- Maleyeff, J.; Arnheiter, E.A.; Venkateswaran, V. The continuing evolution of Lean Six Sigma. TQM J. 2012, 24, 542–555. [Google Scholar] [CrossRef]

- Klochkov, Y.; Gazizulina, A.; Muralidharan, K. Lean Six Sigma for Sustainable Business Practices: A Case Study and Standardisation. Int. J. Qual. Res. 2019, 13, 47–74. [Google Scholar] [CrossRef]

- Salah, S.; Rahim, A.; Carretero, J.A. The integration of Six Sigma and lean management. Int. J. Lean Six Sigma 2010, 1, 249–274. [Google Scholar] [CrossRef]

- Assarlind, M.; Gremyr, I.; Bäckman, K. Multi-faceted views on a Lean Six Sigma application. Int. J. Qual. Reliab. Manag. 2013, 30, 387–402. [Google Scholar] [CrossRef] [Green Version]

- Kaswan, M.S.; Rathi, R. Analysis and modeling the enablers of Green Lean Six Sigma implementation using Interpretive Structural Modeling. J. Clean. Prod. 2019, 231, 1182–1191. [Google Scholar] [CrossRef]

- Chan, C.C.; Yu, K.; Yung, K. Green manufacturing using integrated decision tools. In Proceedings of the 2010 IEEE International Conference on Industrial Engineering and Engineering Management, Macao, China, 7–10 December 2010; pp. 2287–2291. [Google Scholar]

- Nunes, B.; Bennett, D. Green operations initiatives in the automotive industry: An environmental reports analysis and benchmarking study. Benchmarking Int. J. 2010, 17, 396–420. [Google Scholar] [CrossRef]

- Zhang, Y. Green QFD-II: A life cycle approach for environmentally conscious manufacturing by integrating LCA and LCC into QFD matrices. Int. J. Prod. Res. 1999, 37, 1075–1091. [Google Scholar] [CrossRef]

- Han, S.H.; Chae, M.J.; Im, K.S.; Ryu, H.D. Six sigma-based approach to improve performance in construction operations. J. Manag. Eng. 2008, 24, 21–31. [Google Scholar] [CrossRef]

- Ndubisi, N.O.; Nair, S.R. Green entrepreneurship (GE) and green value added (GVA): A conceptual framework. Int. J. Entrep. 2009, 13, 21. [Google Scholar]

- Thanki, S.; Thakkar, J. Interdependence analysis of lean-green implementation challenges: A case of Indian SMEs. J. Manuf. Technol. Manag. 2018. [Google Scholar] [CrossRef]

- Goyal, A.; Agrawal, R.; Saha, C.R. Quality management for sustainable manufacturing: Moving from number to impact of defects. J. Clean. Prod. 2019, 241. [Google Scholar] [CrossRef]

- Snee, R.D. Lean Six Sigma—Getting better all the time. Int. J. Lean Six Sigma 2010, 1, 9–29. [Google Scholar] [CrossRef]

- Dües, C.M.; Tan, K.H.; Lim, M. Green as the new Lean: How to use Lean practices as a catalyst to greening your supply chain. J. Clean. Prod. 2013, 40, 93–100. [Google Scholar] [CrossRef] [Green Version]

- Green, K.W.; Inman, R.A.; Sower, V.E.; Zelbst, P.J. Impact of JIT, TQM and green supply chain practices on environmental sustainability. J. Manuf. Technol. Manag. 2019, 30, 26–47. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Kitchenham, B.; Pearl Brereton, O.; Budgen, D.; Turner, M.; Bailey, J.; Linkman, S. Systematic literature reviews in software engineering—A systematic literature review. Inf. Softw. Technol. 2009, 51, 7–15. [Google Scholar] [CrossRef]

- Sangwan, K.S.; Mittal, V.K. A bibliometric analysis of green manufacturing and similar frameworks. Manag. Environ. Qual. Int. J. 2015, 26, 566–587. [Google Scholar] [CrossRef]

- Verrier, B.; Rose, B.; Caillaud, E. Lean and Green strategy: The Lean and Green House and maturity deployment model. J. Clean. Prod. 2016, 116, 150–156. [Google Scholar] [CrossRef]

- Groening, C.; Sarkis, J.; Zhu, Q. Green marketing consumer-level theory review: A compendium of applied theories and further research directions. J. Clean. Prod. 2018, 172, 1848–1866. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. Int. J. Surg. 2010, 8, 336–341. [Google Scholar] [CrossRef] [Green Version]

- Berenson, M.L.; Levine, D.M. Basic Business Statistics: Concepts and Applications; Prentice-Hall: Englewood Cliffs, NJ, USA, 1989. [Google Scholar]

- Rauch, E.; Dallasega, P.; Matt, D.T. Sustainable production in emerging markets through Distributed Manufacturing Systems (DMS). J. Clean. Prod. 2016, 135, 127–138. [Google Scholar] [CrossRef]

- Luken, R.; Van Rompaey, F. Drivers for and barriers to environmentally sound technology adoption by manufacturing plants in nine developing countries. J. Clean. Prod. 2008, 16, S67–S77. [Google Scholar] [CrossRef]

- Creswell, J.W.; Hanson, W.E.; Clark Plano, V.L.; Morales, A. Qualitative Research Designs. Couns. Psychol. 2016, 35, 236–264. [Google Scholar] [CrossRef]

- Yin, R.K. Applications of Case Study Research; Sage: Los Angeles, CA, USA, 2011. [Google Scholar]

- Turner III, D.W. Qualitative interview design: A practical guide for novice investigators. Qual. Rep. 2010, 15, 754–760. [Google Scholar]

- Caiado, R.; Quelhas, O.L.G.; Nascimento, D.; Anholon, R.; Leal Filho, W. Towards sustainability by aligning operational programmes and sustainable performance measures. Prod. Plan. Control 2019, 30, 413–425. [Google Scholar] [CrossRef]

- Zhu, Q.; Johnson, S.; Sarkis, J. Lean six sigma and environmental sustainability: A hospital perspective. Supply Chain Forum Int. J. 2018, 19, 25–41. [Google Scholar] [CrossRef]

- Ruben, B.; Vinodh, S.; Asokan, P. Lean Six Sigma with environmental focus: Review and framework. Int. J. Adv. Manuf. Technol. 2017, 94, 4023–4037. [Google Scholar] [CrossRef]

- Niñerola, A.; Ferrer-Rullan, R.; Vidal-Suñé, A. Climate Change Mitigation: Application of Management Production Philosophies for Energy Saving in Industrial Processes. Sustainability 2020, 12, 717. [Google Scholar] [CrossRef] [Green Version]

- Chaplin, L.; Rourke, S.T.J. Could lean and green be the driver to integrate business improvement throughout the organisation? Int. J. Product. Perform. Manag. 2018, 67, 207–219. [Google Scholar] [CrossRef]

- Sarkis, J.; Pati, N.; Bai, C.; Jabbour, A.B.L.d.S.; Jabbour, C.J.C.; Sobreiro, V.A. Connecting the pieces of the puzzle toward sustainable organizations. Benchmarking Int. J. 2016, 23, 1605–1623. [Google Scholar] [CrossRef] [Green Version]

- Yadav, R.; Varghese, V.; Pareek, S. Six Sigma in the context of Environmental Management System-A mechanism design approach. Int. J. Pure Appl. Manag. Sci. 2016, 1, 26–38. [Google Scholar]

- Fai Pun, K. Determinants of environmentally responsible operations: A review. Int. J. Qual. Reliab. Manag. 2006, 23, 279–297. [Google Scholar] [CrossRef]

- Furukawa Pde, O.; Cunha, I.C.; Pedreira Mda, L. Evaluation of environmentally sustainable actions in the medication process. Rev. Bras. Enferm. 2016, 69, 16–22. [Google Scholar] [CrossRef] [Green Version]

- Tasdemir, C.; Gazo, R. Validation of Sustainability Benchmarking Tool in the Context of Value-Added Wood Products Manufacturing Activities. Sustainability 2019, 11, 2361. [Google Scholar] [CrossRef] [Green Version]

- Marrucci, L.; Marchi, M.; Daddi, T. Improving the carbon footprint of food and packaging waste management in a supermarket of the Italian retail sector. Waste Manag. 2020, 105, 594–603. [Google Scholar] [CrossRef] [PubMed]

- Kaswan, M.S.; Rathi, R. Investigating the enablers associated with implementation of Green Lean Six Sigma in manufacturing sector using Best Worst Method. Clean Technol. Environ. Policy 2020. [Google Scholar] [CrossRef]

- Ruben, B.; Vinodh, S.; Asokan, P. ISM and Fuzzy MICMAC application for analysis of Lean Six Sigma barriers with environmental considerations. Int. J. Lean Six Sigma 2018, 9, 64–90. [Google Scholar] [CrossRef]

- Caiado, R.; Nascimento, D.; Quelhas, O.; Tortorella, G.; Rangel, L. Towards Sustainability through Green, Lean and Six Sigma Integration at Service Industry: Review and Framework. Technol. Econ. Dev. Econ. 2018, 24, 1659–1678. [Google Scholar] [CrossRef] [Green Version]

- De Oliveira Furukawa, P.; Cunha, I.; Pedreira, M.; Marck, P.B. Characteristics of nursing professionals and the practice of ecologically sustainable actions in the medication processes. Rev. Lat. Am. Enferm. 2017, 25, e2909. [Google Scholar] [CrossRef] [Green Version]

- Pal Pandi, A.; Rajendra Sethupathi, P.V.; Jeyathilagar, D. The IEQMS model for augmenting quality in engineering institutions—An interpretive structural modelling approach. Total Qual. Manag. Bus. Excell. 2014, 27, 292–308. [Google Scholar] [CrossRef]

- Erdil, N.O.; Aktas, C.B.; Arani, O.M. Embedding sustainability in lean six sigma efforts. J. Clean. Prod. 2018, 198, 520–529. [Google Scholar] [CrossRef]

- Portela, P.P.; Mussi, F.C.; Gama, G.G.G.; Santos, C.A.D.S.T. Fatores associados ao descontrole da pressão arterial em homens. Acta Paul. Enferm. 2016, 29, 307–315. [Google Scholar] [CrossRef] [Green Version]

- Mishra, K.A.; Sharma, A.; Sachdeo, M.; Kandasamy, J. Development of sustainable value stream mapping (SVSM) for unit part manufacturing. Int. J. Lean Six Sigma 2019, 11, 493–514. [Google Scholar] [CrossRef]

- Belhadi, A.; Kamble, S.S.; Zkik, K.; Cherrafi, A.; Touriki, F.E. The integrated effect of Big Data Analytics, Lean Six Sigma and Green Manufacturing on the environmental performance of manufacturing companies: The case of North Africa. J. Clean. Prod. 2020, 252. [Google Scholar] [CrossRef]

- Fatemi, S.; Franchetti, M.J. An application of sustainable lean and green strategy with a Six Sigma approach on a manufacturing system. Int. J. Six Sigma Compet. Advant. 2016, 10, 62. [Google Scholar] [CrossRef]

- Kendrick, B.A.; Dhokia, V.; Newman, S.T. Strategies to realize decentralized manufacture through hybrid manufacturing platforms. Robot. Comput. Integr. Manuf. 2017, 43, 68–78. [Google Scholar] [CrossRef]

- Ratnayake, R.M.C.; Chaudry, O. Maintaining sustainable performance in operating petroleum assets via a lean-six-sigma approach. Int. J. Lean Six Sigma 2017, 8, 33–52. [Google Scholar] [CrossRef]

- Martin, D.M.; Yanez, N.D.; Treggiari, M.M. An Initiative to Optimize Waste Streams in the Operating Room: RECycling in the Operating Room (RECOR) Project. Am. Assoc. Nurse Anesth. 2017, 85, 108–112. [Google Scholar]

- Belamkar, N. development of green high performance liquid chromatographymethod for determination for ranitidine hydrochloride in solid dosage form by applying lean sigma principles. Res. J. Pharm. Biol. Chem. Sci. 2016, 7, 1949–1961. [Google Scholar]

- Aldairi, J.; Khan, M.K.; Munive-Hernandez, J.E. Knowledge-based Lean Six Sigma maintenance system for sustainable buildings. Int. J. Lean Six Sigma 2017, 8, 109–130. [Google Scholar] [CrossRef]

- Galeazzo, A.; Furlan, A.; Vinelli, A. Lean and green in action: Interdependencies and performance of pollution prevention projects. J. Clean. Prod. 2014, 85, 191–200. [Google Scholar] [CrossRef]

- Chiarini, A. Sustainable manufacturing-greening processes using specific Lean Production tools: An empirical observation from European motorcycle component manufacturers. J. Clean. Prod. 2014, 85, 226–233. [Google Scholar] [CrossRef]

- Duflou, J.R.; Sutherland, J.W.; Dornfeld, D.; Herrmann, C.; Jeswiet, J.; Kara, S.; Hauschild, M.; Kellens, K. Towards energy and resource efficient manufacturing: A processes and systems approach. CIRP Ann. 2012, 61, 587–609. [Google Scholar] [CrossRef] [Green Version]

- Orji, I.J. Examining barriers to organizational change for sustainability and drivers of sustainable performance in the metal manufacturing industry. Resour. Conserv. Recycl. 2019, 140, 102–114. [Google Scholar] [CrossRef]

- Jasiulewicz-Kaczmarek, M.; Legutko, S.; Kluk, P. Maintenance 4.0 technologies–new opportunities for sustainability driven maintenance. Manag. Prod. Eng. Rev. 2020, 11, 74–87. [Google Scholar]

- Muhuri, P.K.; Shukla, A.K.; Abraham, A. Industry 4.0: A bibliometric analysis and detailed overview. Eng. Appl. Artif. Intell. 2019, 78, 218–235. [Google Scholar] [CrossRef]

- Yin, Y.; Stecke, K.E.; Li, D. The evolution of production systems from Industry 2.0 through Industry 4.0. Int. J. Prod. Res. 2017, 56, 848–861. [Google Scholar] [CrossRef] [Green Version]

- Buer, S.V.; Strandhagen, J.O.; Chan, F.T.S. The link between Industry 4.0 and lean manufacturing: Mapping current research and establishing a research agenda. Int. J. Prod. Res. 2018, 56, 2924–2940. [Google Scholar] [CrossRef] [Green Version]

- Jasiulewicz-Kaczmarek, M.; Gola, A. Maintenance 4.0 Technologies for Sustainable Manufacturing—An Overview. IFAC-PapersOnLine 2019, 52, 91–96. [Google Scholar] [CrossRef]

- De Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Foropon, C.; Godinho Filho, M. When titans meet—Can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? The role of critical success factors. Technol. Forecast. Soc. Chang. 2018, 132, 18–25. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Papadopoulos, T.; Luo, Z.; Wamba, S.F.; Roubaud, D. Can big data and predictive analytics improve social and environmental sustainability? Technol. Forecast. Soc. Chang. 2019, 144, 534–545. [Google Scholar] [CrossRef]

- Gaustad, G.; Krystofik, M.; Bustamante, M.; Badami, K. Circular economy strategies for mitigating critical material supply issues. Resour. Conserv. Recycl. 2018, 135, 24–33. [Google Scholar] [CrossRef]

- Nadeem, S.P.; Garza-Reyes, J.A.; Anosike, A.I.; Kumar, V. Coalescing the lean and circular economy. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Bangkok, Thailand, 5–7 March 2019. [Google Scholar]

- Nagalingam, S.V.; Kuik, S.S.; Amer, Y. Performance measurement of product returns with recovery for sustainable manufacturing. Robot. Comput. Integr. Manuf. 2013, 29, 473–483. [Google Scholar] [CrossRef]

- EC. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: On the Implementation of the Circular Economy Action Plan; Publications Office of the European Union: Brussels, Belgium, 2019. [Google Scholar]

| Unit of analysis | Journal articles in green lean six sigma |

| Type of analysis | Qualitative |

| Time period | 1990–2020 |

| Search fields | Title, abstract, keywords |

| Databases | Emerald, Science Direct, Scopus, and Web of Science |

| Total number of articles used in this study | 58 |

| Keywords | Notations |

|---|---|

| Lean | L |

| Lean manufacturing | LM |

| Lean six sigma | LSS |

| Six sigma | SS |

| Green | G |

| Environmental | E |

| Environmentally | EY |

| Eco-efficiency | EC |

| Eco-sustainability | ES |

| Top Critical Success Factors (CSFs) | References | Other CSFs | References |

|---|---|---|---|

| Management commitment | Cherrafi et al. [21], Chugani et al. [36], Kaswan and Rathi [56], Mishra [25], Powell et al. [44] | Compliance to regulatory requirements and ethics relation | Caiado et al. [92] |

| Training and education | Caiado et al. [92], Ruben et al. [81], Furukawa et al. [93] | Corporate social responsibility | Pandi et al. [94] |

| Employee involvement | Marrucci et al. [89], Caiado et al. [79] | System approach to management | Pandi et al. [94] |

| Organizational culture | Erdil, et al. [95], Niñerola, Ferrer-Rullan and Vidal-Suñé [82] | Effective jidoka automation | Caiado et al. [92] |

| Effective measurement system | Ruben et al. [81], Kaswan and Rathi [90] | Understanding the process | Ruben et al. [45] |

| Teamwork | Kaswan and Rathi [56], Ruben et al. [81] | Provision of suitable solutions | Ruben et al. [45] |

| Financial support | Kaswan and Rathi [90], Ruben et al. [91] | Mindset of implementing eco-friendly practices | Chugani et al. [36] |

| Motivation | Zhu et al. [80], Ruben et al. [91] | Utilization of top talent | Ruben et al. [81] |

| Knowledge management | Caiado et al. [92], Ruben et al. [81] | Organizational learning through human resource development | Kaswan and Rathi [56] |

| Linking GLSS with business strategy | Kaswan and Rathi [56] | Integration of GLSS | Kaswan and Rathi [56] |

| Readiness of organization to implement GLSS | Kaswan and Rathi [56], Mishra [25] | Integrated KPIs | Caiado et al. [92] |

| Resource availability | Mishra [25] | Data assimilation | Kaswan and Rathi [56] |

| Awareness among employees | Furukawa et al. [93] | ||

| GLSS infrastructure | Ruben et al. [81] | ||

| Customer satisfaction | Caiado et al. [92], Pandi et al. [94] | ||

| Change in attitude and behavior | Portela, et al. [96], Caiado et al. [92] | ||

| Communication | Caiado et al. [92], Powell et al. [44] | ||

| Rewards | Ruben et al. [81], Ruben et al. [91] | ||

| Appropriate project selection | Mishra [25], Ruben et al. [81] | ||

| Employee empowerment | Caiado et al. [92], Caiado et al. [79] | ||

| Analytical decision making | Shokri and Li [1], Mishra et al. [97] | ||

| Use of technology | Caiado et al. [79] | ||

| Green lean six sigma metrics | Kaswan and Rathi [56] |

| Environmental Outcomes | References | Environmental Outcomes | References |

|---|---|---|---|

| Energy reduction | Tasdemir and Gazo [88], Cherrafi et al. [21], Fatemi and Franchetti [99], Kendrick et al. [100], Mishra et al. [97], Sagnak and Kazancoglu [43], Zhu et al. [80] | Reduction in GHG emission (carbon monoxide, nitrous oxide) | Sagnak and Kazancoglu [43], Marrucci et al. [89] |

| Waste reduction | Cherrafi et al. [21], Powell et al. [44], Ratnayake and Chaudry [101], Tasdemir and Gazo [88] | Increase in reusable/recyclable material | Sagnak and Kazancoglu [43] |

| Material and resource conservation | Cherrafi et al. [21], Kendrick et al. [100], Sagnak and Kazancoglu [43], Zhu et al. [80] | Pollution/air acidification | Sagnak and Kazancoglu [43], Mishra et al. [97] |

| Carbon footprint | Mishra et al. [97] | Reduction in disposal cost | Deanna Martin [102] |

| Increase in recycling | Marrucci et al. [89], Portela et al. [96] | Use of environmental-friendly material | Kendrick et al. [100] |

| Emission reduction | Zhu et al. [80], Kendrick et al. [100], Sony and Naik [14], Tasdemir and Gazo [88], Fatemi and Franchetti [99] | Landfill reduction | Chaplin and Rourke [83] |

| Reduction in the use of hazardous chemical | Belamkar [103] | Incineration | Marrucci et al. [89] |

| Reduction in water consumption | Sagnak and Kazancoglu [43], Cherrafi et al. [21] | Additional income from recycling | Chaplin and Rourke [83] |

| Water eutrophication | Mishra et al. [97] | Environmental risk assessment | Cherrafi et al. [21] |

| Water footprint | Tasdemir and Gazo [88] | Reducing airborne particulates | Chaplin and Rourke [83] |

| Wastewater reduction | Powell et al. [44] | Environmental cost reduction | Sony and Naik [14] |

| Waste disposal | Furukawa et al. [87] | Increase environmental revenues | Sony and Naik [14] |

| Defect reduction | Powell et al. [44] | Environmental compliance | Tasdemir and Gazo [88] |

| Decrease in transportation | Tasdemir and Gazo [88] | Company image | Garza-Reyes et al. [2] |

| Reduction in hazardous waste | Portela et al. [96] | Stakeholder satisfaction | Garza-Reyes et al. [2] |

| Sr No. | Author | Description | Limitation |

|---|---|---|---|

| 1 | Banawi and Bilec [11] | Developed a framework for the construction industry by integrating green, lean, and six sigma practices for improving the process and reducing environmental waste. | The framework requires additional verification as it is originally developed for the construction industry and entails considerable implementation time. |

| 2 | Garza-Reyes [9] | The author highlighted the need of integrating six sigma with lean and green to overcome their limitations. | Validation of the proposed concept is required in the industrial sector through empirical studies and simulation and there is a need to develop an integrated model of green lean six sigma as a single approach. Further, the framework lacks the implementation of assessment tools in different phases. |

| 3 | Cherrafi et al. [21] | A framework has been developed by integrating green, lean, and six sigma strategies based on a five stage and 16 step process and validated through a research project in four companies. | The proposed framework may not be suitable for improving processes such as painting, chemical treatment, and metal finishing due to their complex and sensitive nature. |

| 4 | Kumar et al. [20] | A hierarchical model comprising 21 barriers has been developed by utilizing interpretive structural modelling (ISM) technique in the green lean six sigma product development process for the automotive industry of India. | The model has been based on experts’ opinions, therefore, requires additional validation in industrial sectors. |

| 5 | Sagnak and Kazancoglu [43] | The authors have proposed to integrate six sigma with green lean to overcome their limitation of lack of controlling process variation by utilizing measurement system analysis and gage control methodology. The model has been tested in a case study of a natural gas-powered boiler. | The execution of the framework has not been presented, and the study was confined to the pollution reduction project. |

| 6 | Aldairi et al. [104] | The authors have proposed a framework on knowledge based lean six sigma maintenance system for eco-sustainable buildings. | The model requires empirical validation in industrial sectors. |

| 7 | Ruben et al. [45] | The authors implemented the proposed framework in an automotive plant with the aim of improving operational and environmental performance and sigma levels by using various lean six sigma tools. | The proposed framework has been validated in a single automotive component manufacturing company and requires additional validation in other manufacturing industries. |

| 8 | Powell et al. [44] | The authors have implemented VSM-DMAIC lean six sigma model in a dairy industry and achieved economic and environmental benefits. | Only one organization in the dairy sector has been considered and requires further investigation in other food and process industries. |

| 9 | Ruben et al. [81] | The authors have conducted a literature review and proposed a GLSS framework based on DMAIC methodology | The framework requires validation through empirical studies and simulation in industrial organizations. |

| 10 | Ruben et al. [91] | The authors have identified 20 barriers regarding LSS implementation with environmental considerations and developed an ISM based model. | The ISM model has been developed based on experts’ opinions. Additional validation through industrial application and case studies is needed. |

| 11 | Caiado et al. [92] | The authors have developed an integrated GLSS framework for service organizations based on SLR. | The framework was developed for service industry and requires practical application and statistical validation. |

| 12 | Mishra [25] | The authors have proposed a GLSS implementation framework based on the critical success factors. | The GLSS implementation framework has not been validated through industrial application. Further, the relationship between CSFs need to be explored using other modelling techniques. |

| 13 | Sreedharan et al. [6] | The authors have developed a GLSS model of the green supply chain for public sector. The framework comprises three stages with a set of 17 activities. | The proposed framework has not been tested in industrial sector and was developed only for public sector organizations. Moreover, the framework has not addressed the lean green wastes. |

| 14 | Zhu et al. [80] | The authors have developed a framework of integrating green and lean for hospital supply chain based on the traditional IDEF meta model comprising input, control, mechanism, and output. Additionally, the model has been validated through three case studies in different hospitals. | The framework has been validated in healthcare sector but requires validation in other industrial sectors. Additionally, the propositions made in this study need to be validated by conducting further studies and specific factors need to be identified that support the propositions. |

| 15 | Kaswan and Rathi [56] | The authors have developed a GLSS enablers model through interpretive structure modelling. | The model has been developed based upon experts’ opinions, therefore, requires additional validation in industrial sectors. |

| 16 | Hussain et al. [24] | The authors have developed an ISM based model of GLSS barriers according to the construction industry of Pakistan. | The developed model and identified barriers may not be appropriate for other industries as these were investigated specific to Pakistan’s construction sector considering its industrial and cultural characteristics. |

| 17 | Sony and Naik [14] | A GLSS implementation framework has been developed in which DMAIC methodology is applied on five principles of lean thinking cycle. The framework was designed to achieve the five objectives of environmental performance and has been implemented in an open cast mine industry. | A single case study has been conducted to validate the framework and consumed considerable amount of time. More studies are required in different industrial sectors to generalize the results. |

| 18 | Mishra et al. [97] | The authors have developed a sustainable value stream mapping framework through simulation modelling by ARENA to evaluate the bonnet manufacturing process from lean and green perspectives. They have compared the current VSM and future VSM of the process which resulted in dramatic operational and environmental improvements. | A limitation of the study was that a single case study has been conducted to validate the model and mainly lean tools are addressed in the study. |

| 19 | Gaikwad and Sunnapwar [19] | The authors have conducted a SLR and presented a framework for Indian manufacturing industries. | The framework requires empirical validation in industrial sectors. |

| 20 | Shokri and Li [1] | The authors have proposed a hybrid approach of green LSS projects and developed a mathematical model to facilitate decision making under LSS projects by which the final outputs can also be environmentally friendly. The volume of production and final price of products for consumers are characterized as "mediating factors" to balance the LSS projects’ operational outputs and environmental performance. | Empirical data and case studies are needed for validation by utilizing the analytical model. Moreover, the factors such as price, volume, and energy should also be considered as indicators in the "sustain" stage of the DMAIC cycle. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farrukh, A.; Mathrani, S.; Taskin, N. Investigating the Theoretical Constructs of a Green Lean Six Sigma Approach towards Environmental Sustainability: A Systematic Literature Review and Future Directions. Sustainability 2020, 12, 8247. https://doi.org/10.3390/su12198247

Farrukh A, Mathrani S, Taskin N. Investigating the Theoretical Constructs of a Green Lean Six Sigma Approach towards Environmental Sustainability: A Systematic Literature Review and Future Directions. Sustainability. 2020; 12(19):8247. https://doi.org/10.3390/su12198247

Chicago/Turabian StyleFarrukh, Amna, Sanjay Mathrani, and Nazim Taskin. 2020. "Investigating the Theoretical Constructs of a Green Lean Six Sigma Approach towards Environmental Sustainability: A Systematic Literature Review and Future Directions" Sustainability 12, no. 19: 8247. https://doi.org/10.3390/su12198247

APA StyleFarrukh, A., Mathrani, S., & Taskin, N. (2020). Investigating the Theoretical Constructs of a Green Lean Six Sigma Approach towards Environmental Sustainability: A Systematic Literature Review and Future Directions. Sustainability, 12(19), 8247. https://doi.org/10.3390/su12198247