Abstract

The contract administration process is inevitably complex, and improper performance of the associated tasks and procedures may lead to disputes between the contracting parties whilst further driving against the sustainability bottom lines. Therefore, this paper proposes an assessment tool to improve the implementation of construction contract administration (CCA) through a multi-dimensional construction contract administration performance model (CAPM), construction contract administration performance index (CCAPI), and a mobile software to assess the CCA performance at the project level by integrating the crisp value of the fuzzy set theory within a second-order confirmatory factor analysis of the structural equation modeling technique. A hybrid mobile application (CAPM) is developed using the Ionic framework which can run either in full model mode or short model mode with 93 and 33 key construction administration factors, respectively. Assessment of sustainability practices in the area of contract administration is a part of the holistic model and CAPM defines 13 major key indicators relevant to social and environmental sustainability while economic sustainability is scattered over the rest of the CAPM indicators. The CAPM is practically implemented in 13 international construction projects and the results reveal that the proposed tool is reasonably captured in the different performance levels of CCA, and we conclude a low level of implementing in risk management. As part of the holistic model, assessment of sustainability practices in the area of contract administration is separately discussed and the study reveals the need to improve the environmental and social sustainability practices in contract administration.

1. Introduction

While the construction industry is as an enabler for achieving nationwide goals in modern society, the construction projects have a substantially high rate of business failure, bankruptcy, delays, losses and budget overruns, deviation from standards, quality issues and waste of resources [1]. Moreover, the construction projects are affected by economic, environmental, and social-political issues that result from the involvement of many stakeholders in the project. Not only this but, the construction industry is facing many challenges including low productivity, poor compliance, lack of adequate collaboration and information sharing, and poor payment practices [2]. Furthermore, the challenges of construction projects may be caused by improper management, lack of technical skills, lack of innovation and technology, financial resources, inadequate coordination, integration, communication, and control of project activities [1]. According to the World Bank, effective contract management is critical for ensuring that the contracting parties meet their contractual commitments to time, cost, quality, and other agreed matters; and any problems are managed and quickly dealt with [3]. It requires systematic and efficient planning, execution, monitoring, and evaluation to ensure that both parties fulfill their contractual obligations.

On the other side, poor contract administration performance is a significant cause of inefficient construction process, delays, reworks, unnecessary variations, poor communication among team players, conflicts and disputes for both employer and contractors [4]. As a result, investments in the construction industry face several risks when the contract administration practices do not adequately perform and poor contract administration works against the industry sustainability. Poor construction contract administration may refer to poor planning [5,6], poor communication and coordination [7], lack of systems [7] misunderstanding of processes [7], lack of skilled personnel [8], unclear roles [7], lack of training [7,8] and lack of performance measurement [7]. Yet the construction contract administration (CCA) team needs more training on better practices [7,8,9,10,11], to act responsively [12] with a sufficient level of competency [7,13] and to efficiently monitor the contract [7], and to make efficient decisions [13].

We provide a model and a software tool that address the effectiveness of contract administration and would help inform prime stakeholders to manage, track, and deal with such issues. The project employer is concerned about the execution of the project with the allocated budget, the planned time and the baseline quality set under control by the contract administration team. Therefore, CCA performance should be monitored by the employer, the CCA organization by the project contractor to ensure the success of the project. To foster successful projects, the proposed indicators and model focus on supporting proper coordination and integration among the contracting parties to achieve sustainable business [1].

From the sustainability perspective, the contract activities and decisions, such as compliance with the environmental requirement, selection of material, storage, and delivery of material have severe impacts on the project site and the surrounding areas [14]. The employer relies on the contact administration team to properly take the proper decision and control the construction activities to eliminate or minimize such impacts. With due diligence, the CCA team could enforce the contractor to implement approaches that would minimize the environmental construction impact [14]. Therefore, this paper details the common activities involved in contract administration while the broad concept of sustainability is integrated into a contract administration model. Contract administration ensures the main contractor and suppliers meet their sustainability commitments [15]. If CCA is practiced successfully, the CCA team will have great control and input on the environmental aspect such as: Review the contractor’s environmental plans; make several environmental audits; review and inspect the proposed material against the sustainability requirement. Moreover, the CCA team will have a contribution to the economic principle of sustainability by the timely response to queries; timely issuance of supplementary information; and timely management of operational issues. These sample key activities will reserve the additional costs generated from delay in decision making or unresponsive response. Furthermore, the CCA can prompt the social principle of sustainability by: Keeping workers safe through auditing of the contractor’s safety system; enforcing policies to maintain health of workers, instructing contractors to perform urgent works required to maintain safety, monitoring public interference arrangements and minimizing their impact by the project, and increasing capacity building of the CCA staff.

This study sheds light on the extent to which sustainability practices are integrated with the global view of the key operational activities of the CCA, and thus provides a mechanism to enable a planned and controlled-driven sustainable contract administration. Thus, social, economic, and environmental principles of sustainability become relevant to the contract administration framework. Based on integrating the crisp value of the fuzzy set theory (FST) into a second-order structural equation model, it formulates CCA performance indices for the major CCA process areas, and then weights each element to arrive at an overall CCA performance index. Furthermore, this is the first study in the literature to develop a mobile application for contract administration performance model (CAPM) to measure the different dimensions of contract administration performance to the best of the authors’ knowledge. The proposed study, therefore, would increase the operational efficiency and effectiveness through improved compliance, awareness, visibility, and control over contracts. The model and the mobile application can be used to track and measure the CCA performance during the different stages of the post-awarding phase. The CAPM is practically examined in 13 international construction projects and the results are presented in the study.

2. Literature Review

The literature review is divided into three main sections. The first section of the literature review begins with a brief background on performance management. The second section deals with the contract administration performance framework developed by the authors. The last section discusses mobile applications.

2.1. Performance Management in Construction

Performance measurement is a process of quantifying the effectiveness and efficiency of previous actions, using some parameters to measure performance. The literature reveals that the project performance measures that are linked to the project objectives are a good indicator of project success [16]. Many performance measurement frameworks/models such as balanced scorecard, quality-based performance excellence models, key performance indicators (KPI), benchmarking and activity-based management [17] do exist in the literature. KPI are accumulations of data used to evaluate the performance of construction operations or a task and are used to compare the actual and estimated values of performance. KPIs are referred to as measures of performance that are aligned to the key outcomes [3]. In the construction industry, executives and project managers need to recognize a set of KPIs for measuring performance at the project level while construction professionals need KPIs to control the performance at both the field and office levels. The useful KPIs would: (1) Include nonfinancial measures; (2) be measured frequently; (3) be acted on by senior management team; (4) clearly indicate what actions are required by staff; (5) be measures that tie responsibility down to a team; (6) have significant impact and; (7) encourage appropriate action [18]. According to Pollaphat and Zijin [19], the example of KPIs to measure the performance of construction management services are timeliness of deliverables; quality of services; effectiveness of project cost control; reliability in providing solutions; added value to the project in terms of problem-solving or improved coordination of team members; responsiveness to client’s needs; overall satisfaction with services; willingness to provide additional projects; and willingness to recommend services to other industry players.

2.2. Contract Administration Performance Framework

Perhaps because of the frequently nondeterminate nature of the contract administration process, there is very sparse literature on KPIs concerning the contract administration performance. CCA usually takes place as an integral part of the project management process, consisting of a set of coordinated and controlled activities, undertaken to achieve the project objectives within the obligations of each contracting party and including the constraints of time, cost, quality scope, safety, risk, and resources. CCA is generally concerned with aspects of daily operations and operational decisions to minimize the contract risks, therefore, this suggests applying project management KPIs to CCA.

Gunduz and Elsherbeny [20] established a systematic multi-dimensional CCA performance framework (CAPF) through comprehensive literature review and semi-structured interviews with four construction experts and two rounds of Delphi study. The authors collected a total of 93 key factors affecting the CCA performance in 11 project management process groups. This section briefly demonstrates the elements of leading practices that contribute to CCA performance and can be used as KPIs in a multi-dimensional performance model as follows:

Group 1: Project governance and startup [10,11,21,22,23,24,25]: It comprises activities related to F01.01—Establishment of project management plan, F01.02—Review contractor’s quality plan, F01.03—Review contractor’s health, safety, and security (HSS) plan, F01.04—Review contractor’s environmental plan, F01.05—Review the contractor’s program, F01.06—Review contractor’s key staff, F01.07—Review subcontractors’ qualifications, F01.08—Project kick-off meeting, F01.09—Review of contract securities, F01.10—Support handing project to a contractor, F01.11—Support nominated subcontractors appointment, F01.12—Remove violating persons from site, F01.13—Review contractor’s logistics plan., F01.14—Review contractor’s laboratory, and F01.15—Avoid bureaucracy and lengthy process.

Group 2: Contract administration team management [11,21,22,26,27,28]: It consists of activities related to F02.01—Assignment of a competent team, F02.02—Early assignment of a team, F02.03—Clear roles and responsibilities, F02.04—Training programs, F02.05—Regular performance assessment, and F02.06—Set of performance dialogue for the team.

Group 3: Communication and relationship management [22,23,25,26,28,29,30]: It contains of activities related to F03.01—Establish a communication system, F03.02—communication of project management plan (PMP), F03.03—Advising the employer, F03.04—Measuring the employer’s satisfaction, F03.05—Employer’s agreement for changes, F03.06—Regular meetings, F03.07—Effective coordination with third parties, F03.08—Timely response to queries, F03.09—Timely management of operational issues, F03.10—Manage interface between contractors, and F03.11—The clear language of communication.

Group 4: Quality and acceptance management [10,11,21,22,24,26,30,31]: It embraces activities related to F04.01—Auditing contractor’s quality management system (QMS), F04.02—Timely issuance of supplementary information, F04.03—Timely review of construction material, F04.04—Timely review of shop drawings, F04.05—Auditing contractor’s health, safety, and security system, F04.06—Auditing contractor’s environmental plans, F04.07—Timely inspection of work’s quality, F04.08—Control of noncompliance works, F04.09—Track corrective actions, and F04.10—Managing design development.

Group 5: Performance monitoring and reporting management [11,21,22,23,24,25,26,29,30,31,32]: It consists of activities related to F05.01—Establish a monitoring and reporting system (KPIs), F05.02—Report major issue, F05.03—Regular progress reports, F05.04—Review contractor’s reports, F05.05—Monitor contractor’s relationships, F05.06—Monitor contractor’s resources, F05.07—Monitor contractor care of works, F05.08—Notify the contractor for recovery schedule, F05.09—Monitor public interference arrangements, and F05 10—Notify contractor on obligation’s failure.

Group 6: Document and record management [11,21,25]: It contains activities related to F06.01—Establish documentation system, F06.02—Use information technology, F06.03—Maintain documentation with registers, and F06.04—Support stakeholders with statistics.

Group 7: Financial and payment management [11,21,22,23,24,28,31,32]: It includes activities related to F07.01—Establish financial management system, F07.02—Instructions to spend the provisional sum, F07.03—certify due payments, F07.04—Notify the employer about due payments, F07.05—Timely assess for payments compensation, F07.06—The advice in contingency planning, and F07.07—Collect quotations for price estimates.

Group 8: Changes and changes control management [10,11,21,22,25,30,31,32]: It includes activities related to F08.01—Establish a change control system, F08.02—Timely evaluate contractor’s proposals, F08.03—Suggestions for workable solutions, F08.04—Notify the contractor about urgent works, and F08.05—Timely process of change orders.

Group 9: Claims and disputes resolution management [10,11,21,22,24,29,31,32]: It includes activities related to F09.01—Establish claims and disputes resolution system, F09.02—Timely notify contractor about employer’s claim, F09.03—Timely assess extension of time claims, F09.04—Timely assess additional payment claims, F09.05—Effectively negotiate claims with the contractor, F09.06—Support parties in alternative dispute resolution, F09.07—Represent the employer in dispute resolution, and F09.08—Legal support employer during court cases.

Group 10: Contract risk management [11,21,22,25,26,27,28]: It includes activities related to F10.01—Periodically assess contractual risks, F10.02—Assign contractual risk responsibility, F10.03—Support employer for design risks, and F10.04—Monitor the contractor’s financial status and bankruptcy potential.

Group 11: Contract close-out management [11,21,22,24,25,29,31,32]: It includes activities related to F11.01—Establish a closeout system, F11.02—Communicate closeout activities, F11.03—Verify physical works completion, F11.04—Timely Review closeout documentation, F11.05—Timely issue taking over the certificate, F11.06—Timely release retentions, F11.07—Approve the return of contractor’s deployment, F11.08—work inspections during defects notification, F11.09—Timely issue performance certificate, F11.10—Document lessons learned and best practices, F11.11—Timely processing final account, F11.12—Management of suspension of work, and F11.13—Management of termination of the contract.

2.2.1. Integrated Sustainability Issues into CAPM

This CAPM is not limited to the traditional thought of CCA practices such as payment process, claim management, change management, and dispute management but also involving several indicators to serve the sustainable bottom lines. The CAPF promotes environmental sustainable practices by including: Review and audit contractor’s environmental plan (F01.04 and F04.06), review construction material for compliance with sustainability requirement of the contract (F04.03), control noncompliance works to minimize waste (F04.08), early design review to reduce waste of money and rework (F10.03), use of information technology to minimize papers consumption (F06.02), monitoring the contractor care of the works including employer’s provided properties. To conserve resources (F05.07) and reviewing the contractor’s logistics plan to minimize transportation impact (F06.02).

Moreover, the CAPF promotes the economic principle of sustainability by including timely response to queries (F03.08), timely issuance of supplementary information (F04.02), and timely management of operational issues (F03.09). These sample key activities will reserve the additional costs generated from delay in decision making or unresponsive response.

Furthermore, the CAPF promotes the social principle of sustainability by: Keeping workers safe through auditing of contractor’s HSS (F01.03 and F04.05), notifying the contractor about urgent works required to maintain safety (F08.04), and monitoring public interference arrangements (F05.09).

Additionally, it promotes the development of people and capacity building through training (F02.04). Finally, the model helps align employer-contract administrator-contractor interests and therefore will help build sustainable relations [15]. This sustainable relationship may be traced through monitoring contractor’s relationships (F05.05), and supporting parties in alternative dispute resolution (F09.06).

2.3. Mobile Applications

2.3.1. Mobile Solutions

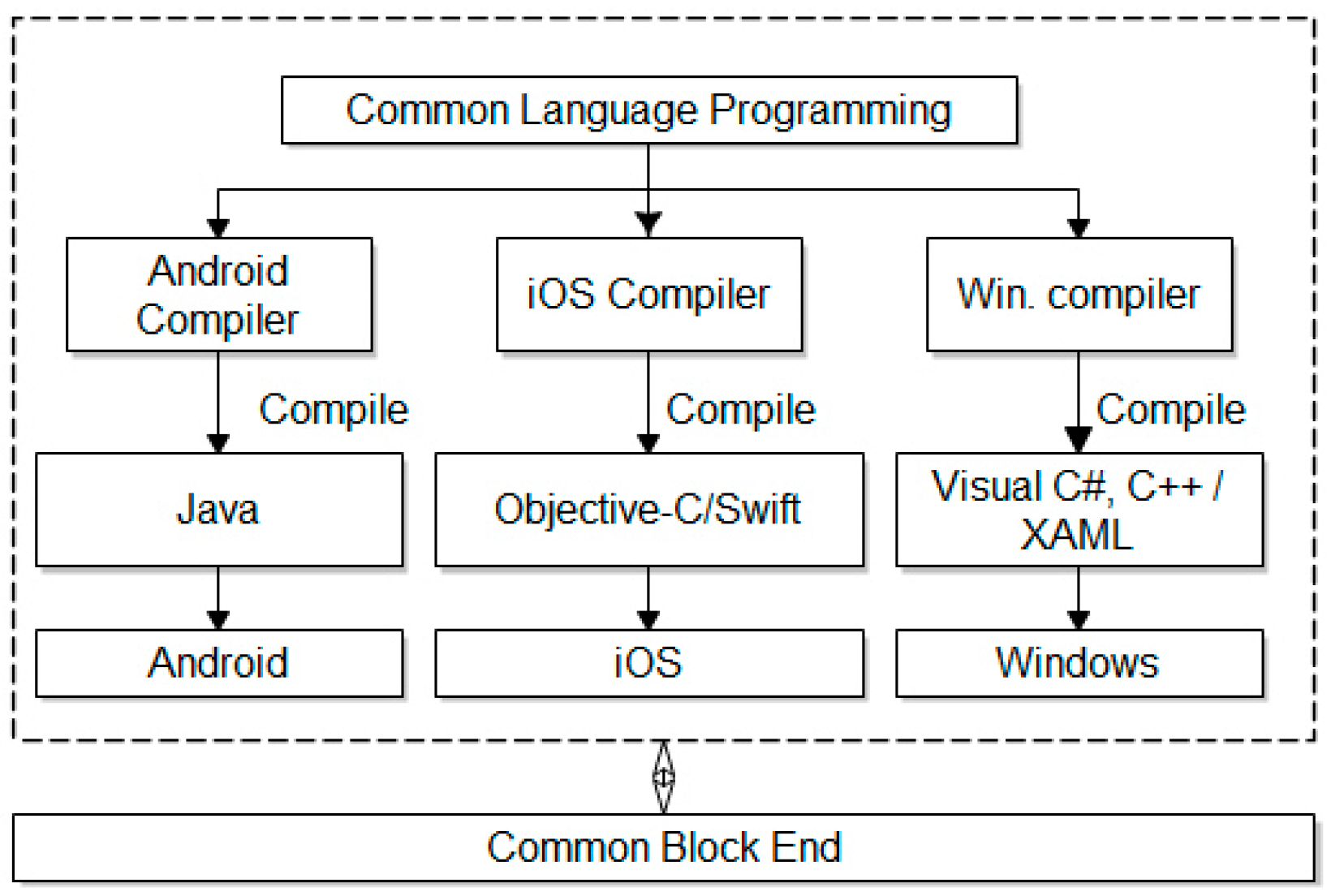

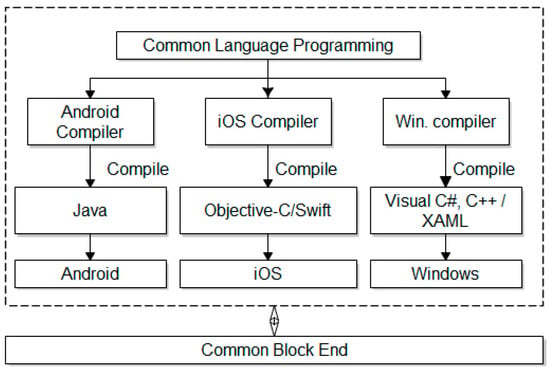

Mobile applications are generally classified as either native mobile, mobile-web, or hybrid mobile solutions [33,34]. The native solution consists of the development of a separate application for each platform (i.e., java for android, objective-C or swift for iOS and visual C#, C++, or XAML for Windows [33,35]). The mobile-web solution is a server-side application by using web browsers with hypertext markup language (HTML), cascading style sheets (CSS) and JavaScript codes. The application is implemented as an optimized website for mobile considering different screen sizes and their usage philosophy. These approaches do not require update of application but cannot reach the native functions of the device (i.e., notifications system, cameras, GPS) and require URL access [33,35]. The hybrid solution combines the web technologies and native functionalities in one application in which the application is executed through the browser engine. In other words, the hybrid solution uses a chromeless web browser to run the web application [33]. The developers of hybrid applications use application stores to distribute their applications and the native features are available through an abstract layer. Compared to native apps, the performance of the hybrid application is slower [35].

2.3.2. Cross-Platform Software Development Kits

At present, the use of smartphone technologies is growing at an accelerated rate and companies recognize the need to develop business applications by using smartphone access [35]. Cross-platform is a single software development kit (SDK) tool that allows developers to advance applications that can run under different mobile platforms with the same performance of native applications [35]. Through the cross-platform, development time and associated costs are reduced since the code is written within one environment to deploy the applications in many operating systems and to target multiple devices. Cross compilers transform these codes into a native code compatible with the device platform (Figure 1).

Figure 1.

Cross-compiled approach.

Therefore, the deployment of a cross-platform environment makes the development of mobile applications easier in coding and more efficient in development. The most popular five frameworks for mobile application development are: (a) Ionic, (b) React Native, (c) Xamarin, (d) PhoneGap, (e), and (f) Flutter. Ionic is a client-side framework that supports building hybrid solutions with a combination of HTML, CSS3, and JavaScript at cost-free. It functions better with the Angular, PhoneGap, and Cordova plugins. React Native is another popular open source framework by Facebook for creating native apps for iOS and Android platforms. Xamarin is introduced for developing apps for Android, iOS, and Windows using C# C# or Ruby coding. PhoneGap is an open source platform by Adobe that allows designing apps for iPhone, Android, Windows, and BlackBerry. PhoneGap performs best for mobile application that does not depend on the native features of the device and does not require graphics-intensive apps. Flutter is an open source mobile user interface by Google to help developers test easily and build quickly hybrid applications for mobile, web, and desktop from a single codebase under iOS and Android apps.

2.3.3. Ionic

In 2013, Max Lynch, Ben Sperry, and Adam Bradley developed Ionic as an open source and front end HTML5 cellular application development framework. It is assembled on top of AngularJS and Cordova for building hybrid mobile applications [33]. Moreover, it is considered as “Bootstrap for Native”, with the ability to support a wide ranging of standard native mobile components, smooth animations, and attractive design [36]. The Ionic key features are: (1) Ionic is using the model view controller architecture of AngularJS for constructing rich applications, (2) Ionic is using CSS styling components to offer most of the elements needed by mobile apps, (3) Ionic is using the JavaScript components to extend HTML and CSS elements with JavaScript functionalities, (4) Apache Cordova plugins offer application programming interface (API) that is required for native functions of the device, (5) Ionic uses command language interpreter (CLI), NodeJS utility-driven for imitating, constructing, running, and emulating its applications, and (6) the view platform of Ionic is used for uploading, sharing, and testing the app on native devices [36].

The main advantages of Ionic are related to: (1) Use for hybrid applications development which can package the mobile application for Android, IOS, Windows Phone, and Firefox OS by a single source code, (2) presence of pregenerated application setup layouts for easy start, (3) build applications in a very clean and modular way, and (4) regular updates by Ionic and Google Developers [36]. On the other side, the critical limitations of the Ionic framework are: (1) Tricky testing under web browser, (2) hard to combine different native functionalities, and (3) slower hybrid applications compared with the native ones. In our case, the CAPM does not need either different native features or high-speed computation algorithms, therefore, limitations of Ionic are not an issue [36].

The typical architecture of Ionic’s applications includes five primary elements, namely: (1) Modules that outline a use into organized blocks of functionality by packaging components, directives, and services, (2) components are the basic building block to construct elements and logic on the user interface page, (3) templates are used to define a component view, (4) services (classes) that provide values, functions, or features needed to access remote (backend API’s) data, and (5) external resources which will empower the application to externally interact with other resources.

In this study, the CAPM mobile app is developed by using an Ionic side menu project and is available to run under Android devices.

3. Research Gap and Contributions to the Existing Knowledge

Limited studies have studied the influencing factors on construction contract administration performance. Additionally, no single study has come up with an overall performance index to assess the overall performance of CCA using a structural equation modeling approach. This study contributes to the construction management body of knowledge by formulating a construction contract administration performance index (CCAPI), developing a software tool (CAPM) to assess CCA performance and assess social and environmental sustainability in CCA. This is the first study in the literature to develop a CAPM mobile application to measure contract administration efficiency to the best of the authors’ knowledge. The current study proposes a novel application of the fuzzy structural equation modeling (FSEM) to assess the influential factors of construction contract administration and provides an analytical tool to determine the CCA performance in 11 project management process groups. To present a clear image of the proposed tool application, the model and the software application are tested in 13 international construction projects.

4. Research Methodology

The current research uses the survey research strategy to study the importance of the identified factors on the performance of CCA through the random sample from construction professionals. Following data analysis and the establishment of mobile software applications, the CAPM is practically implemented in 13 projects to examine the data within a specific context carefully. The research processes of this study consist of six main steps as follows: (1) Establishment and validation of the contract administration performance model, (2) determination of the weight importance of each key factor on the CCA performance, (3) establishment of CCA performance index formula, (4) development of a CCA performance assessment mobile application, (5) practical implementation in international construction projects, and (6) discussion about the results of the full and short models, environmental and social practices, and providing recommendations for improvement of the overall CCA performance.

5. Contract Administration Performance Model (CAPM)

Based on Gunduz and Elsherbeny’s [20] CCA performance framework, the authors circulate a self-administered questionnaire survey to determine the relative importance of the identified 93 variables and the 11 latent factors on CCA performance in the construction project. In the questionnaire, data were collected as linguistic terms in a five-point Likert scale as “Not at all important” to “Extremely important”. Three hundred and sixty six respondents successfully filled the survey and then the linguistic terms were defuzzified into tangible numbers following the method proposed by [34,37].

Cronbach’s alpha (α) reliability test is conducted to evaluate the reliability of a questionnaire for each indicator using the SPSS package (αmin = 0.839 > 0.7) [38].

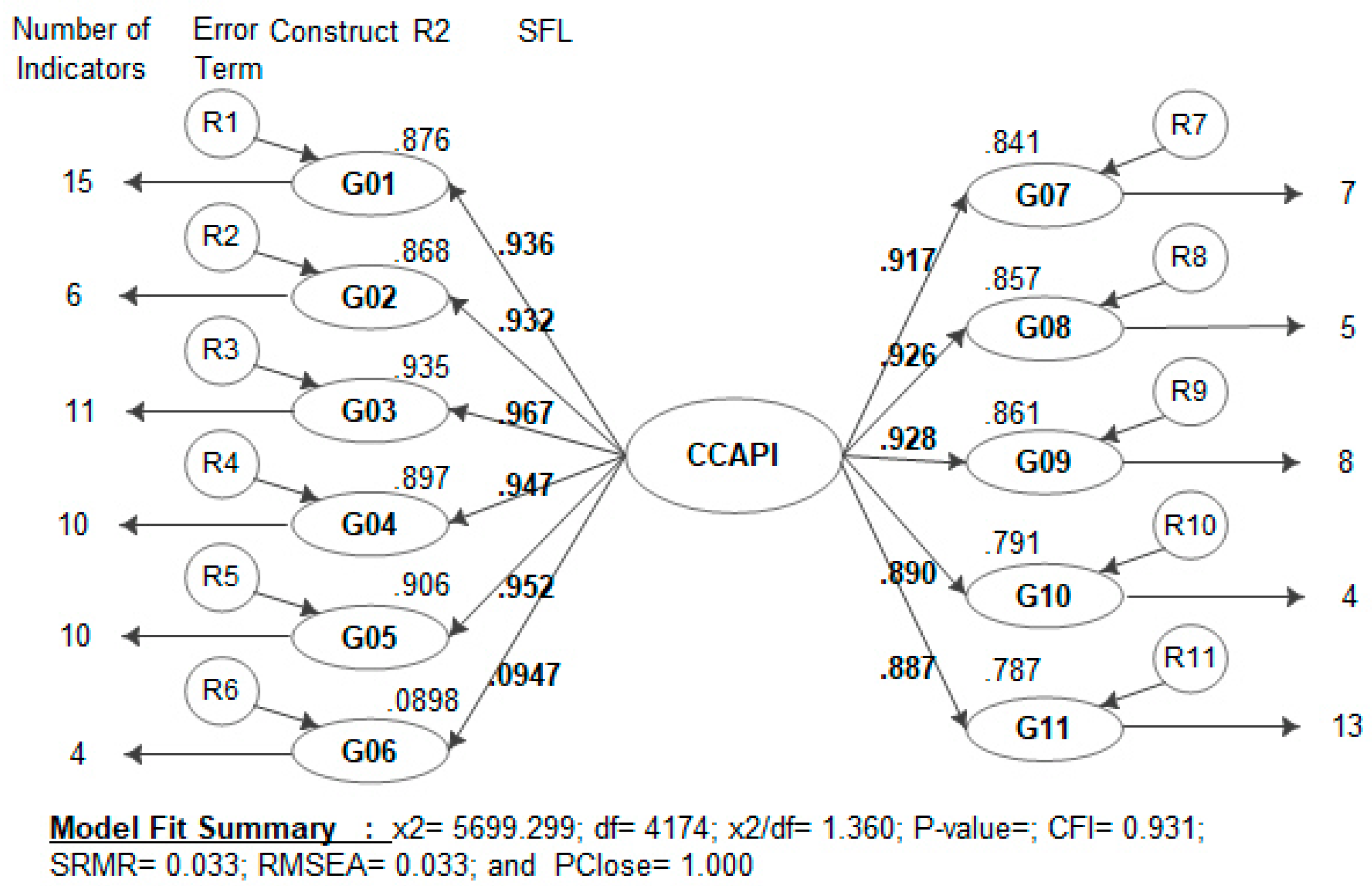

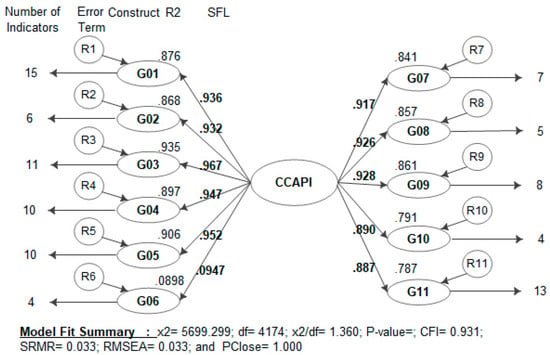

The confirmatory factor analysis (CFA) was used as a measurement model and then a second-order reflective structural model was established as shown in Figure 2. The measurement model consists of 93 key activities of the CAPF model (observed variables) in the process groups (latent factors). The structural model assumes that the construction contract administration performance index (CCAPI) as a second-order factor is reflected by the performance of 11 latent factors as first-order factors. The CAPM model suggests a positive relationship between the 11 first-order latent factors and the CCAPI. Following this assumption, the study establishes two main hypotheses and the first hypothesis is further subdivided into 11 sub-hypotheses. The study main hypotheses are:

Figure 2.

Structural model contract administration performance (CAPM) and model fit summary (R2 = squared multiple correlations, G = process group, SFL = standardized factor load).

Hypothesis 1 (H1).

Each latent factor (process group) has a positive influence on CCAPI.

Hypothesis 2 (H2).

The 11 first-order latent factors aggregate their effects on CCA performance.

The results of the measurement model indicate that the chi-squared statistics (χ2/df = 1.360 < 3.0), comparative fit index (CFI = 0.931 > 0.90), standardized root mean square residual (SRMR = 0.033 < 0.08) and root mean square error of approximation (RMSEA = 0.033 < 0.08). Having considered the measurement model output, the model achieved the requirement of the goodness-of-fit [38]. The content validity is priory achieved by selecting the key factors from several kinds of literature and using construction expert opinions. The convergent validity of the proposed model is supported by the high values of standardized factor loadings (SFLmin = 0.557 > 0.5), composite reliability (CRmin = 0.841 > 0.7), and average variance extracted (AVEmin = 0.515 > 0.50) [38]. The discriminant validity is supported by the correlations among constructs that differ significantly from unity [39]. Thus, the proposed measurement model of CAPM is well fit for goodness-of-fit, validity, and reliability tests. Therefore, observed variables represent and measure their respective latent factors.

For the structure model, the variance explained by the R-squared (R2) value is the most important output that reflects the strong relationship among first-order latent factors and related observed variables and between the second-order latent factor and the first-order latent factors of the model. Referring to the model output, Table 1, and Figure 2, the SFL values are higher than 0.5 [40], the significance of regression weights are less than 0.05 [41], and the minimum value of R2 is 0.787 which correlates the CCAPI to G11.

Table 1.

The SEM standardized factor loading of the second-order SEM model, and relative weights of observed variable and latent factor.

Thus, the CCA performance was strongly associated with the 11 latent factors, and the contributions of CCAPI on its eleven sub-constructs were significant. In other words, a theory that 11 first-order latent factors aggregate their effects on CCA performance (H2) and each latent factor has a positive influence on CCAPI (H1) is well supported.

5.1. CAPM Weighting and Aggregation

Based on the second-order structural model, the standardized factor loadings are employed to calculate the relative weights of the 11 different latent factors. In other words, these standardized factor loadings become the weights of each observed variable and latent factor to compute the CCA performance index. For example, the relative weight of a group is the standardized factor loadings of that group divided by the sum of all standardized factor loadings [34,42]. Table 1 shows the application of the relative weight formula on the 11 latent factors.

5.2. The Construction of the Construction Contract Administration Performance Index (CCAPI)

This study implements a methodology based on second-order confirmatory factor analyses with different latent factors. As stated earlier, the relative weight of a group is the standardized factor loadings of that group divided by the sum of all standardized factor loadings. The formulas to calculate the CCA performance index (CCAPI) are:

where: SFLi = Standardized factor loading of the observed variable i (i = 15,6,11,10,10,4,7,5,8,4,13) for groups j = 1 to 11); RFW1i = Relative factor weight (within group) of the observed variable; RFW2i = Applicable relative factor weight (within group) of the observed variable (i.e., RFW2i = 0 for not applicable observed variable i); RFW3i = Updated relative factor weight (within group) of the observed variable i; Ci = conformity of observed variable based on actual implementation (i.e., Ci = 0 to 100 or NaN); SFLj = Standardized factor loading of group j (j = 1 to 11); RGW1j = Relative weight of group j; RGW2j = Applicable weight of group j (i.e., RGW2j = 0 if all observed variables within group j are not applicable); RGW3j = Updated weight of group j; FW2i = Overall final factor weight based on group availability and observed variable availability; Pj = Group performance; and % Pj = Group performance index; and CCAPI = CCA performance index.

The CCAPI represents the sum of the 11 process groups’ performance indices. Table 2 explains sample calculations for the different formulas adopted to calculate CCAPI for process groups numbers G01, G09, and G11 of Project #1. Those three groups are selected to represent calculations of the first group (G01), a random intermediate group with some “not applicable” factors (i.e., G09) and the last group (G11). The other groups are typically calculated in a similar way to these three groups and therefore are not presented in Table 2. Descriptions of the columns in Table 2 are explained as follows:

Table 2.

Sample calculation of groups 1, 9, and 11 of Project #1 by the full model.

- Column variable: In this table, observed variables were listed in the ascending order according to the variable coding (column variable).

- Column Ci: Represents the % of implementation (conformity of each variable on scale 0–100 (0 for major nonconformance, 100 for full conformance, and “NaN” for not applicable).

- Column SFLj: Standardized factor loadings of the observed variables I based on SEM output.

- Column RFW1i: Relative weight of the observed variable i (example: RFW1F09.01 = 0.643/(0.643 + 0.764 + 0.790 + 0.794 + 0.712 + 0.719 + 0.700 + 0.672) = 0.1110, Equation (1)).

- Column RFW2i: Applicable relative weight of the observed variable i (example: RFW2F09.01 = 0.1110 and RFW2F09.08 = NaN, Equation (2)).

- Column RFW3i: Updated relative weight of the observed variable (example: RFW3F09.01 = 0.1110 × 1.0/(0.1110 + 0.1319 + 0.1363 + 0.1370 + 0.1229) = 0.1736, Equation (3)). This updated take into consideration non applicability of the last three variables within group 9.

- Column SFLj: Standardized factor load of group j (latent factor) based on the SEM model.

- Column RGW1j: Demonstrated relative weight of group j (example: RGW1G09 = 0.9280/(0.936 + 0.932 + 0.967 + 0.947 + 0.952 + 0.947 + 0.917 + 0.926 + 0.928 + 0.890 + 0.887) = 0.0907, Equation (4)).

- Column RGW2j: Applicable relative weight of group j (example: RGW1G09 = 0.0907 because all groups are implemented, if the group is not applicable, then RGW2j = NaN, Equation (5)).

- Column RGW3j: Updated relative weight of group j (example: RGW3G09 = 0.0907, Equation (6)).

- Column FW2i: Final factor weight based on group availability and observed variable availability (example: FW2F09.01 = 90 × 0.1736 × 0.0907 = 1.4178 as per Equation (7)). If the variable is not applicable, then FW2i = NaN.

- Column Pj: Group performance (example: PG09 = 1.4178 + 1.6846 + 1.7419 + 1.7507 + 1.5699 = 8.17, Equation (9)).

- Column Pj (%): Group performance index (example: %PG09 = 8.17/0.0907 = 90.0%, Equation (9)).

- Cell construction contract administration performance index (example CCAPI for project #1 = 7.94 + 7.48 + 8.73 + 8.80 + 8.62 + 8.56 + 8.16 + 8.33 + 8.17 + 4.78 + 7.5 = 87.0%, Equation (10)).

5.3. Alternative CAPM Short Model

To simplify the data entry, reduce the time consumed to collect data and speed up the evaluation of CCA performance in construction projects. This paper proposes a short model that includes the top three most significant observed variables in each process group considering their standardized factor loadings are calculated previously. Contrary to the full model, which includes 93 key factors affecting CCA performance, the short model includes only 33 key factors and the same 11 process groups of the full model. The calculation concept of the short model is not different from the full model. Both models share the corresponding factor loadings and site evaluations of the observed variables.

Furthermore, standardized factor loadings and relative factor weights of the latent factors are not changed between models. The results of the full and short model results are different due to the difference in values of the updated relative weights (i.e., RFW3i and RGW2j). Table 3 shows a sample calculation for the selected groups by the short model for Project #1.

Table 3.

Sample calculation of the groups 1, 9, and 11 and CCA performance index of Project #1 by the short model.

6. The CAPM Application for Mobile Devices

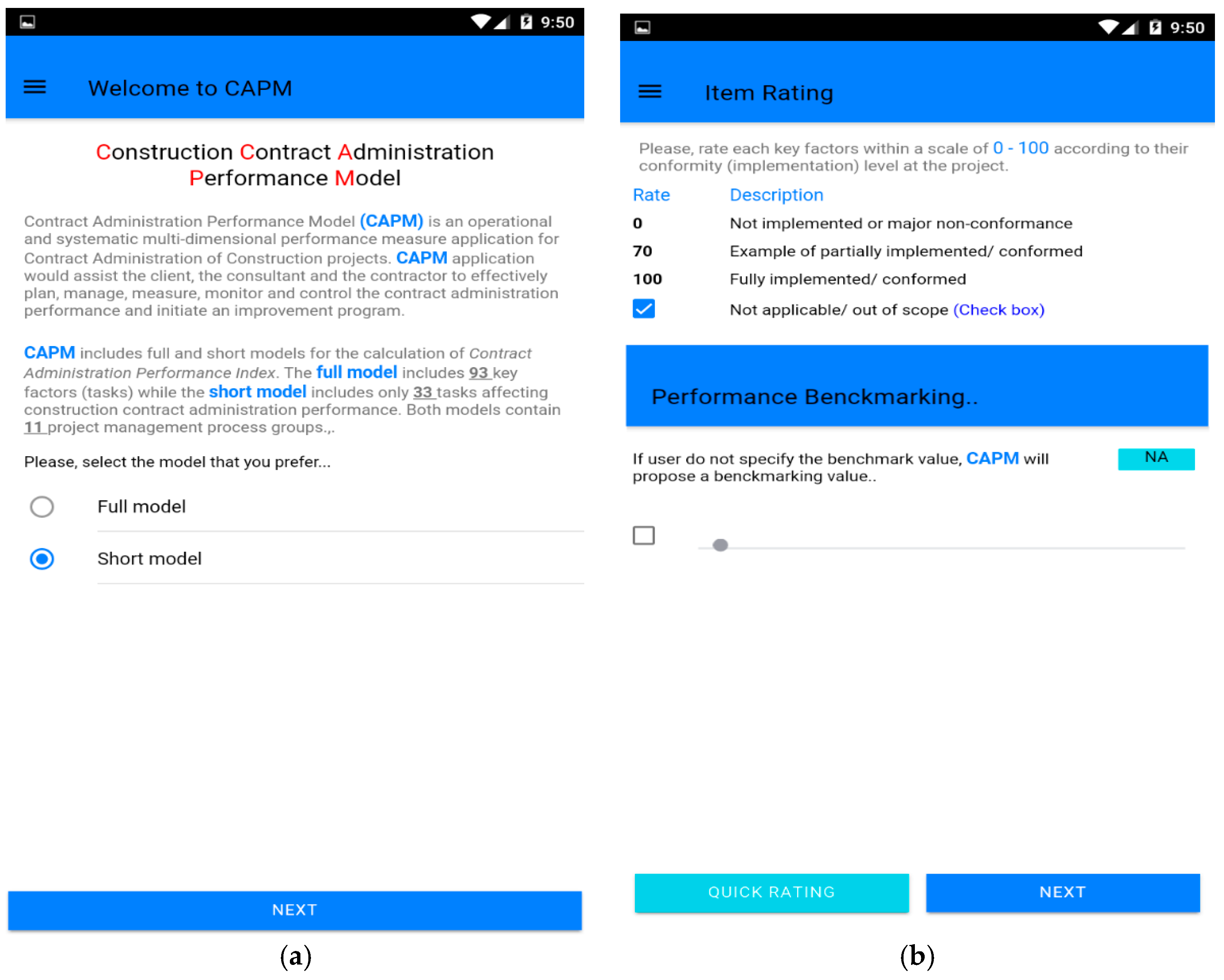

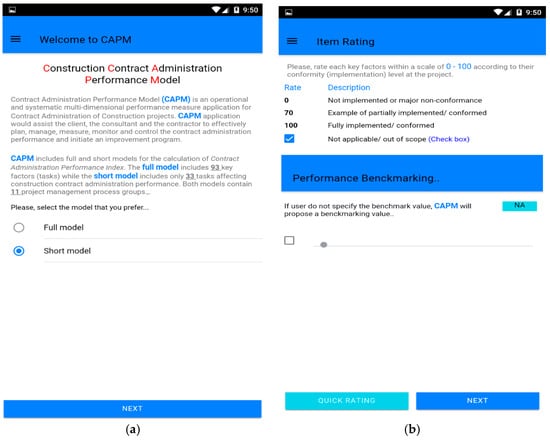

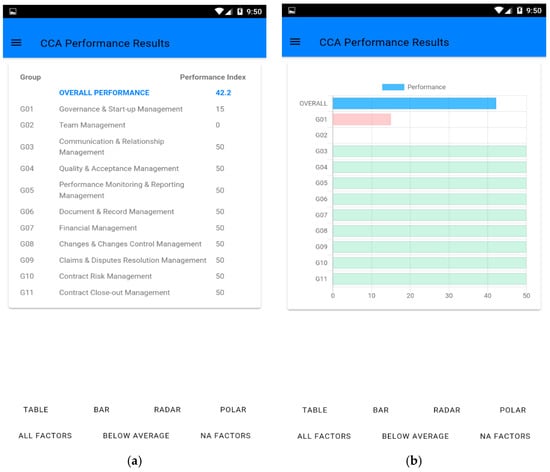

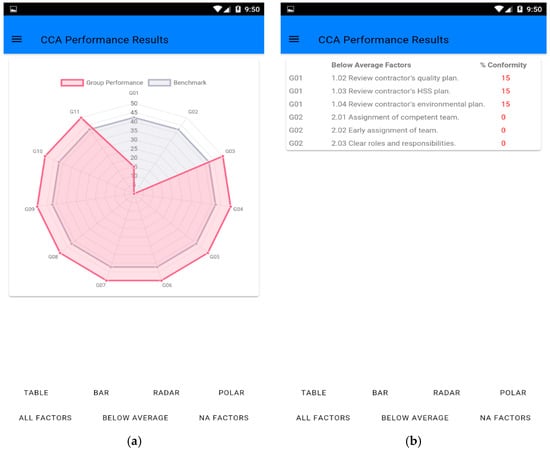

The CAPM application for mobile devices is briefly explained as follows. As shown in Figure 3, Figure 4 and Figure 5, the CAPM mobile application general flow contains three main parts, namely: (1) Introduction and instruction, (2) input screens, and (3) output screens.

Figure 3.

User interface contract administration performance model (CAPM) application: (a) Introduction and model type screen, (b) item rating instructions screen.

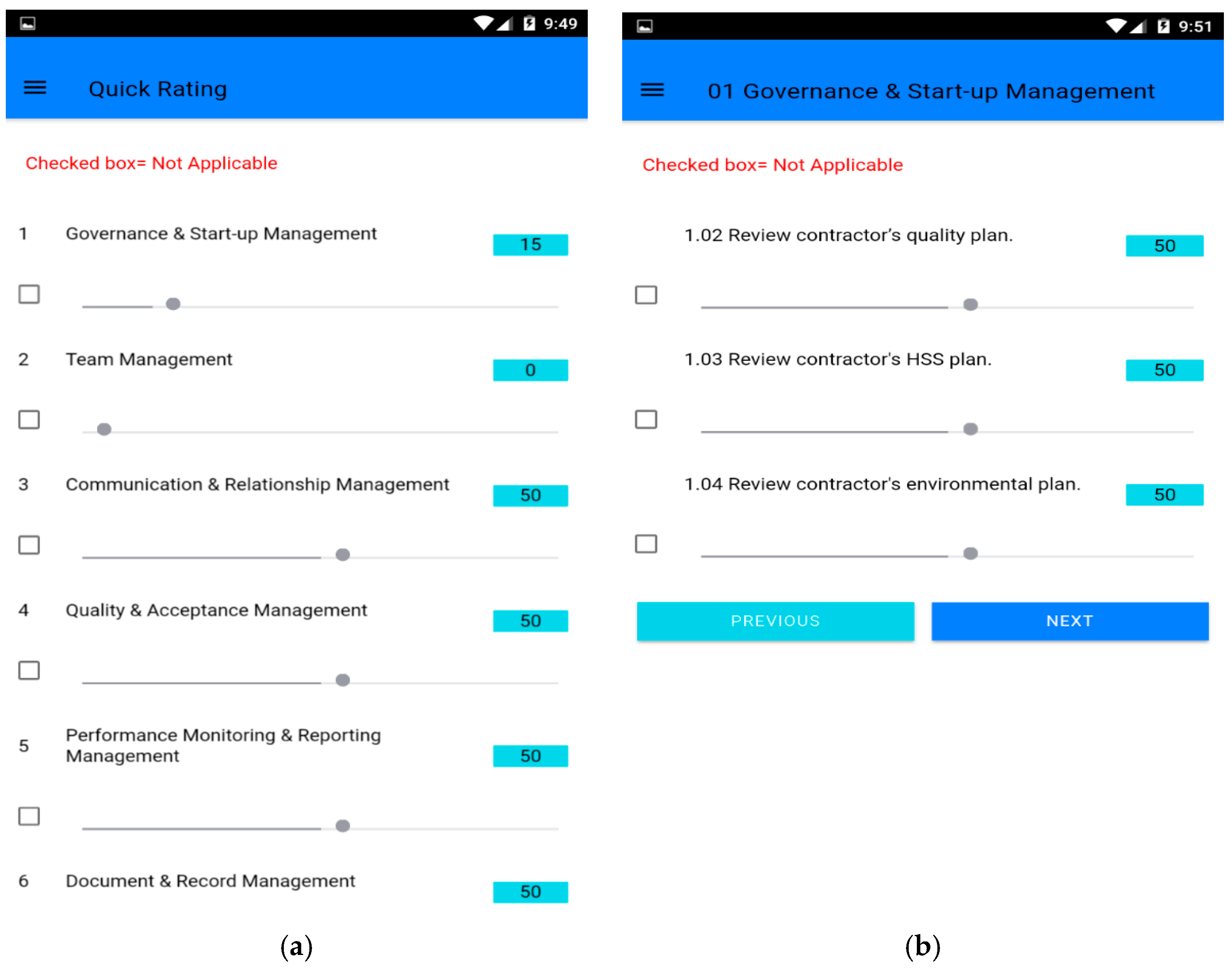

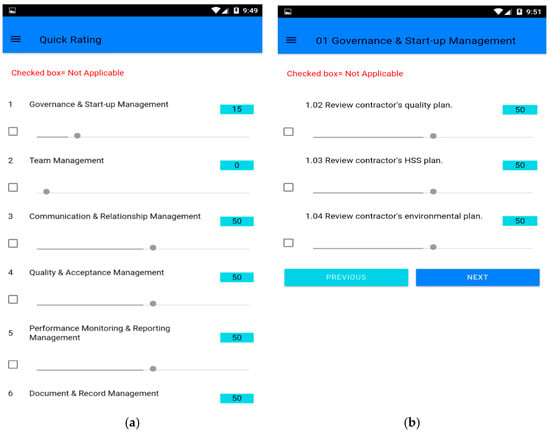

Figure 4.

User interface CAPM application: (a) Quick rating screen input screens, and (b) sample process group input screen for short mode.

Figure 5.

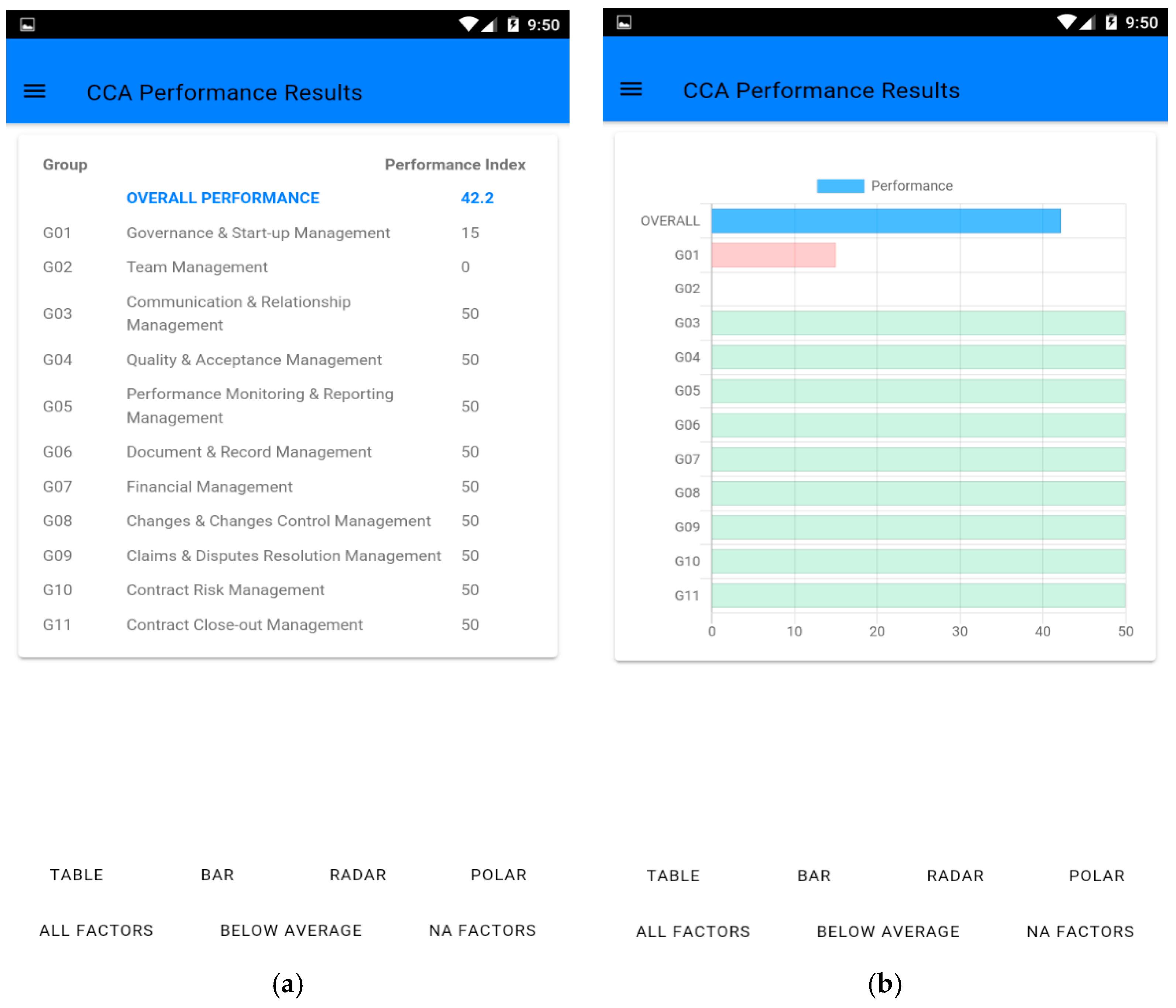

User interface CAPM application: (a) construction contract administration performance index (CCAPI) table, and (b) bar chart.

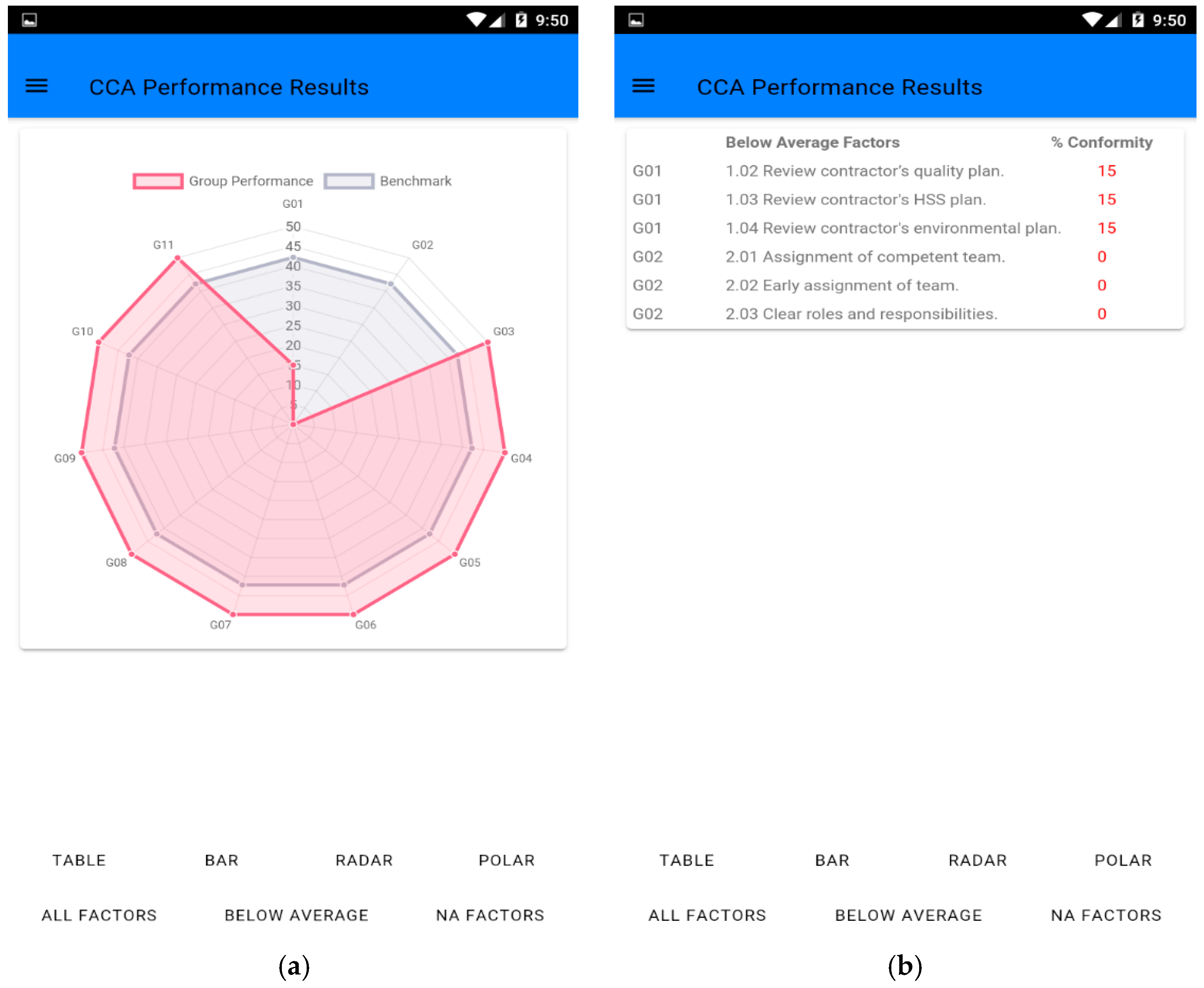

The CAPM starts with an introductory page which contains the program name and background. After clicking the next button, the CAPM item rating instructions page opens. This page contains descriptions of the model and a selection between short and full models as shown in Figure 3a. The next screen contains instructions on how to rate each individual key observed variable and the benchmarking value for which the CCA performance can be referred to as Figure 3b. If the user entered no value for the benchmarking, the application considers the overall performance (CCAPI) as the benchmarked value for each process group. At the bottom of this screen, the user has two options, either to go to the quick rating page and enter the average performance for each process group (these average performance values are set for all factors within the same group) or to rate the 93 factors for the full model/the 33 factors for the short model from scratch as shown in Figure 4. When all data are entered and the user presses the calculation button, the results tab will be displayed on the screen as a summary table for the process group performance and CCAPI as shown in Figure 5a, bar chart as shown in Figure 5b, radar chart with benchmarked values as shown in Figure 6a, pie chart, full list of observed variables and their rating, below average list as compared with the benchmarking value (Figure 6b) and not implemented factors. When the previous button is clicked, the program returns to the previous screen and maintains the saved values of data. There is no expiration period for the CAPM application, and it always starts by default values of 50% for each observable variable.

Figure 6.

User interface CAPM application: (a) radar chart, and (b) not applicable factors.

7. Practical Implementation of CAPM in International Construction Projects

The CAPM is employed to assess the CCA performance in 13 international construction projects. The assessment forms are completed by the CCA experts (minimum 15 years of experience in contract administration) according to a scale between 0 to 100. Where the variable is not implemented, the assessment is recorded as “NaN”. CAPM is used to calculate the process group performance and the overall CCAPI for the 13 projects for both short and full models. Table 4 shows the profile of the 13 projects.

Table 4.

The profile of the 13 case studies projects.

Six projects are public projects and seven projects are private projects. Ten projects represent building type construction (i.e., mega administration building, educational and health facilities, malls and central markets, tower, villa compounds, and apartment buildings). The remaining three projects represent two infrastructures (drainage network) projects and one industrial facility (warehouses). The construction contract values are ranged between 1000 to 4 million USD. Three projects are completely completed, three projects are passing testing on completion, and the remaining seven projects are under construction at the time of assessment.

8. Benchmarking CCA Performance for the 13 Case Studies

8.1. Full Model

Table 5 shows the complete performance indices for the 11 process groups for 13 projects and average performance indices as well.

Table 5.

Calculated CCA performance indices for each process group for Projects #1 to 13.

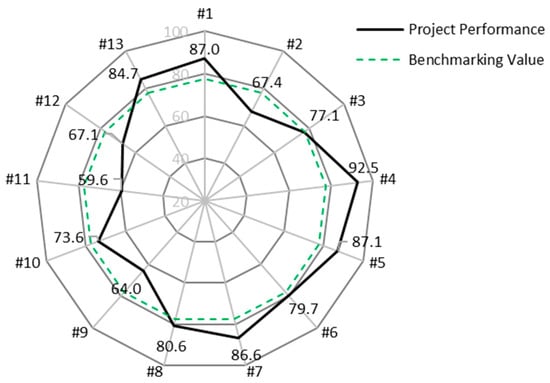

It worth not noting that four process groups namely: Project governance and start-up (G01), communication and relationship (G03), document and record (G06), and financial management (G07) demonstrate a performance index slightly above the average values. Changes and changes control (G08) represent the highest process group performance (average value 87.8%) and is followed by claims and disputes resolution (G09) with an average value of 85.5%. On the negative side, four process groups (contract administration team management (G02), quality and acceptance (G04), performance monitoring and reporting (G05), and contract close-out management (G11) slightly fall below the average values but within 5% difference. Contract risk management (G10) represents the lowest process group performance (average value 50.5%) among the other process groups and therefore, the authors recommend that there is an urgent need to re-structure this process and initiate an urgent continual improvement program for risk management.

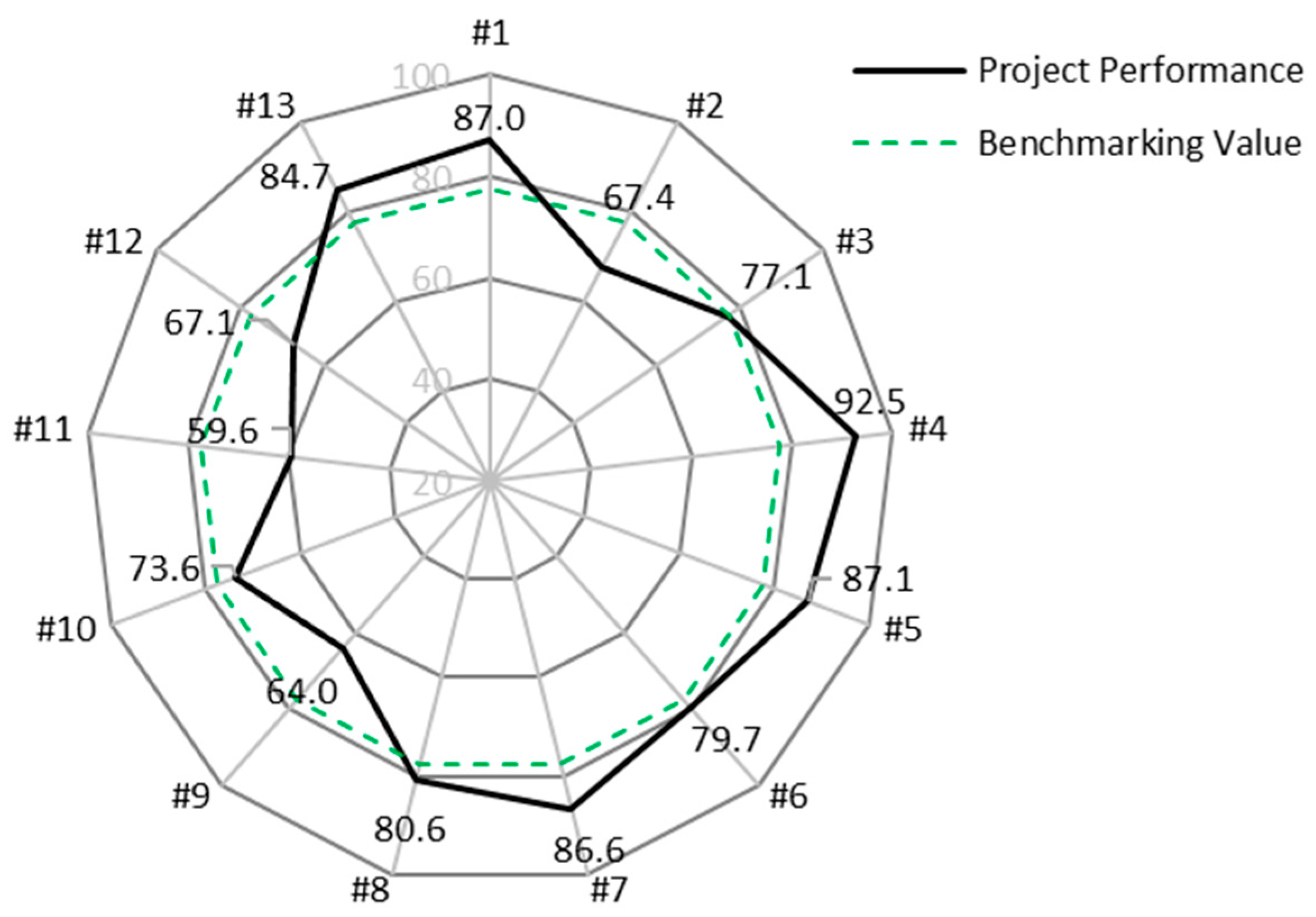

The overall CCAPI of the 13 projects are demonstrated in Figure 7. The result shows the highest calculated CCA performance index as 92.5% for Project #4, while the lowest calculated CCA performance index is calculated as 59.6% for Project #11. The overall CCAPIs for Projects #1, 4, 8, and 13 exceed the benchmarking value, the CCAPI of Projects #3 and 10 slightly fall below the benchmarking value while CCAPI of Projects #2, 9, 11, and 12 significantly falls below average.

Figure 7.

Calculated construction contract administration performance index (CCAPI) for Projects #1 to 13.

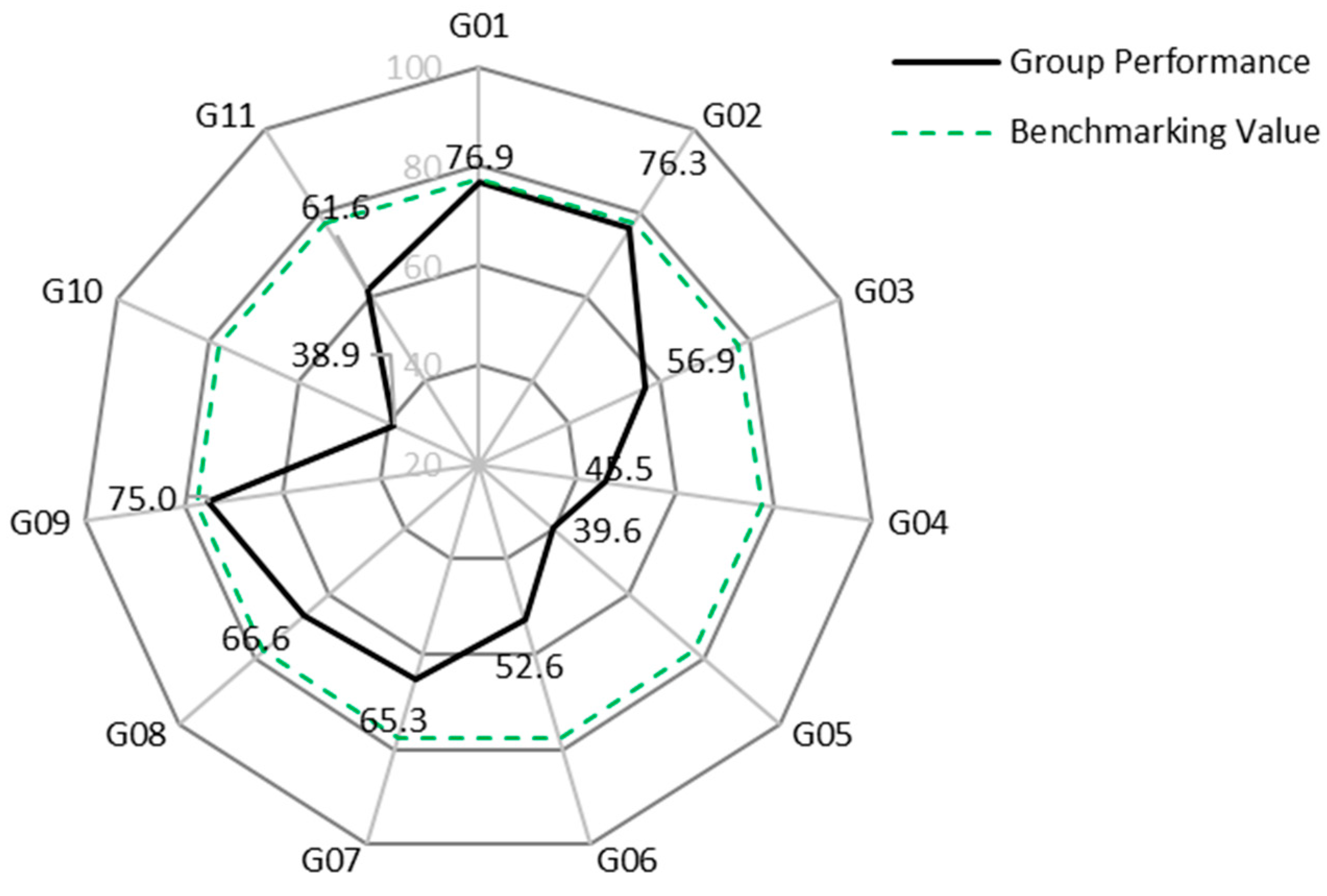

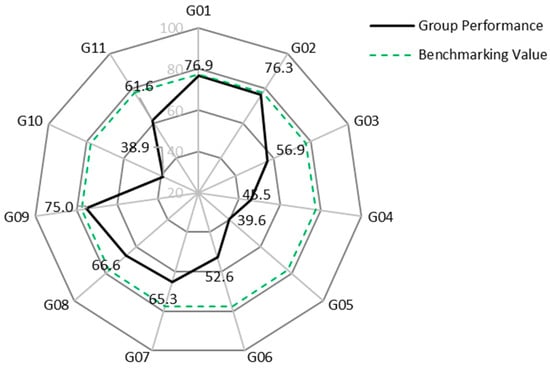

The significant differences between the CCA performance indices highlight the necessity to identify the performance of the project team across the different project and management groups. As mentioned above, the performance index of Project #11 (59.6%) represents the lowest calculated CCAPI among the other projects and thus suggests a further analysis of key factors and the associated process groups of this project. Figure 8 shows the different performance levels of the process groups of Project #11.

Figure 8.

Calculated performance indices for Project #11.

The overall low performance of Project #11 is explained by the very low-performance levels of groups: Contract risk management (G10), performance monitoring and reporting (G05), quality and acceptance (G04), document and record (G06), and communication and relationship (G03). The authors recommend that there should be a structured improvement effort for these process groups in the first instance and then to the other groups.

8.2. The Short Model

The results of CCAPI for the full and the short models are shortly presented in Table 6.

Table 6.

Comparison between the short model and the full model for Projects #1 to 13.

In order to compare the short model to full model results, the percentage of error (deviation) of the results is calculated as the difference between CCAPI of the short and full model, respectively divided by the full model CCAPI [34]. For example, % CCAPI Error for Project #1 by short model = (87.7−87.0%)/87.0%) = 0.8%. The average error value is calculated as 1.8% while the maximum error value is 3.90% for Project #9. This indicates that within the studied projects, the short model is able to capture the overall CCA performance with reasonable accuracy. The authors would recommend using the short model to accurately capture the overall CCA performance where the performances observed variables within each process group are almost consistent across the group. In case of great differences between the observed variables within the same group, the full model will be better capturing the CCAPI.

8.3. The CCA Sustainability Practices

As we have demonstrated under Section 2.2.1, the CAPM model contains sustainability indicators in contract administration practices. The economic indicators are distributed over the model components and CCAPI reflects their performance. Within this study, 13 indicators are selected to assess the environmental and social sustainability practices in CCA in comparison to the overall benchmarked value. Table 7 illustrates the performances of those sustainability practices.

Table 7.

Assessment of environmental and social sustainability indicators within Project #1 to 13.

The timely reviewing of the construction material (F04.03) and controlling noncompliant works (F04.08) are exceeding the benchmarked value while using information communication technology (ICT) in administering the contract (F06.02) is very close to this value. On the contrary, reviewing the logistics plan (F01.13), auditing compliance with environmental requirements (F04.06), early issues of design review findings (F10.03), and reviewing environmental management plan (F01.04) are not reaching the benchmarked value. The performances of social sustainability in terms of reviewing the contractor’s health, safety, and security plan (HSS) plan (F01.03), notifying the contractor about urgent works (F08.04), monitoring care of the works and properties (F05.07) are exceeding the benchmarked value while auditing compliance with HSS (F04.05) is very close to the benchmarked value. On the contrary, monitoring public interference arrangements (F05.09), and establishing training and development programs (F02.04) are areas that need improvement.

9. Conclusions

This paper proposes a construction contract administration performance index (CCAPI) based on a multi-dimensional systematic construction contract administration performance framework (CAPF) and a fuzzy structural equation model (CAPM). A hybrid mobile application that implements the proposed model is developed with a similar name using the cross-platform “Ionic”. CAPM contains three introduction and instruction screens, twelve input screens, and seven output screens. Optionally, the application may run in a prime full model mode with 93 key input factors sorted in 11 process groups affecting the contract administration performance. Moreover, CAPM may run in an alternative short model mode with only 33 key input factors to save the data gathering and entry time. The data is simply entered through sliding bars and the outputs are represented by performance indices table, bar chart, radar chart, and pie chart. A brief demo for using the CAPM mobile app is demonstrated. The CAPM application is able to evaluate the construction contract administration performance of any type of construction project at any stage of the post-award phase. The end-user may decide to enter a certain benchmark value or the application will use CCAPI as a benchmarked value. The CAPM mobile application is practically implemented in 13 construction projects and the ability of CAPM to capture the performance levels of different projects is demonstrated.

The results of the 13 case studies reveal that the maximum absolute deviation of the short model from full model results is 3.9% while the average absolute deviation is only 1.8%. This indicates the ability of the short model to capture the overall CCA performance with reasonable accuracy. Moreover, the results present the highest calculation of CCAPI as 92.5% for Project #4 while the lowest CCAPI is 59.6% for Project #11. Project #11 had very low performance and the management of this project should draw more attention to the contract administration process and competency of the staff carrying out the relevant activities. Furthermore, the contract risk management is poorly managed in several projects and we would recommend restoring this process to improve its performance.

Assessment of sustainability practices in the area of contract administration is a part of the holistic model and CAPM defines 13 major key indicators relevant to social and environmental sustainability while economic sustainability is scattered over the rest of the CAPM indicators. Using the identified environmental and social sustainability indicators, recommendations made for suggesting contract administration team should: (1) Ideally plan, review, and audit the contractor’s environmental management system and logistic plans which should include a detailed environmental policy and demonstration of how it is actively enforced; (2) gain opportunity from sustainability specialists to improve sustainable practices within CCA; (3) early review of design to minimize risk of rework and waste resources; and (4) structure proper procedures to monitor and control interference. Moreover, CCA organizations should structure a capacity building program for their team. The limitation of this study is related to model implementation in the post-awarding phase of the construction projects.

10. Recommendations for Future Study

The item rating depends mainly on the evaluator experience under the understanding of the implementation of the CCA factors. The authors recommend that future studies shall develop detailed performance matrices and KPIs to measure the performance of CCA activities on a scale between 0 and 100 or a 5-point Likert scale (very poor, poor, average, good, and excellent). This will ensure consistency amongst the raters and improve the results’ quality among different projects. A web version can be further developed to establish a database for measuring the CCA performance, benchmark the CCA performance among different organizations, and develop running charts for CCA performance. Moreover, more sustainability indicators may be integrated or categized into a CCA model.

11. Data Availability

Data and models generated or used during the study are available from the corresponding author by request.

Author Contributions

Conceptualization, M.G. and H.A.E.; Methodology, H.A.E.; Software, H.A.E.; Validation, M.G. and H.A.E.; Formal analysis, M.G. and H.A.E.; Investigation, H.A.E.; Resources, H.A.E.; Data curation, H.A.E.; Writing—original draft preparation, H.A.E.; Writing—review and editing, M.G. and H.A.E.; Visualization, H.A.E.; Supervision, M.G.; Project administration, M.G. All authors have read and agreed to the published version of the manuscript.

Funding

The publication of this article was funded by the Qatar National Library.

Acknowledgments

The authors would like to thank the general engineering consultants in the state of Qatar, and CEG International for facilitating data collection from several construction sites. Moreover, the authors particularly thank the editors and anonymous reviewers for their supportive comments.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hijazi, I.; Isikdag, U.; Abunemeh, M.; Li, X.; Hashash, M.; El Meouche, R.; Cansiz, S. Mapping the processes of donor-funded construction projects. Sustainability 2018, 10, 2355. [Google Scholar] [CrossRef]

- Li, J.; Greenwood, D.; Kassem, M. Blockchain in the built environment and construction industry: A systematic review, conceptual models and practical use cases. Automat. Constr. 2019, 102, 288–307. [Google Scholar] [CrossRef]

- Bank, W. Procurement Guidance: Contract Management General Principles, 1st ed.; The World Bank Office of the Publisher: Washington, DC, USA, 2017; pp. 1–24. [Google Scholar]

- El-adaway, I.H.; Abotaleb, I.S.; Eid, M.S.; May, S.; Netherton, L.; Vest, J. Contract administration guidelines for public infrastructure projects in the United States and Saudi Arabia: Comparative analysis approach. J. Constr. Eng. Manag. 2018, 144, 04018031. [Google Scholar] [CrossRef]

- Alzara, M.; Kashiwagi, J.; Kashiwagi, D.; Al-Tassan, A. Important causes of delayed projects in Saudi Arabia vs. PIPS: A university campus case study. Procedia Eng. 2016, 145, 932–939. [Google Scholar] [CrossRef]

- Memon, A.H.; Rahman, I.A. Analysis of cost overrun factors for small scale construction projects in Malaysia using PLS-SEM method. Mod. Appl. Sci. 2013, 7, 78–88. [Google Scholar] [CrossRef]

- Surajbali, R.R. Determining Contract Management Challenges Relating to Supply Chain Management in the Eastern Cape Department of Education. Master’s Thesis, North-West University Potchefstroom, Potchefstroom, South Africa, October 2016. [Google Scholar]

- Ahmed, J.U. Determinants and Constraints to Effective Procurement Management in Government Projects: A practitioner’s Perspective. Master’s Thesis, BRAC University, Dhaka, Bangladesh, October 2015. [Google Scholar]

- Niraula, R.; Goso, T.; Kusayanagi, S. Establishing construction contract administration education/training program for developing countries. Int. J. Constr. Manag. 2008, 15, 415–427. [Google Scholar] [CrossRef][Green Version]

- Kayastha, G.P. Importance of contract administration for timely construction of hydropower projects without disputes. Hydro Nepal J. Water Energy Environ. 2014, 14, 49–51. [Google Scholar] [CrossRef]

- Bartsiotas, G.A. Contract Management and Administration in the United Nations System; United Nations, Joint Inspection Unit: Geneva, Switzerland, 2014; pp. 1–71. [Google Scholar]

- Ssegawa, J.K. Adequacy of Project-Based Financial Management Systems of Small and Medium Construction Enterprises in Botswana. Ph.D. Thesis, University of South Africa, Pretoria, South Africa, October 2008. [Google Scholar]

- Puil, J.; Weele, A. International Contracting: Contract Management in Complex Construction Projects; Imperial College Press: London, UK, 2014; pp. 1–490. [Google Scholar]

- Hostetler, M. Beyond design: The importance of construction and post-construction phases in green developments. Sustainability 2010, 2, 1128–1137. [Google Scholar] [CrossRef]

- Dubey, V.K.; Chavas, J.-P.; Veeramani, D. Analytical framework for sustainable supply-chain contract management. Int. J. Prod. Econ. 2018, 200, 240–261. [Google Scholar] [CrossRef]

- Ying, F.; Tookey, J.; Seadon, J. Measuring the invisible: A key performance indicator for managing construction logistics performance. Benchmark Int. J. 2018, 25, 1921–1934. [Google Scholar] [CrossRef]

- Bassioni, H.A.; Price, A.D.F.; Hassan, T.M. Performance measurement in construction. J. Manage. Eng. 2004, 20, 42–50. [Google Scholar] [CrossRef]

- Pollaphat, N.; Zijin, T. Determinants for effective performance of external project management consultants in Malaysia. Eng. Constr. Archit. Manag. 2007, 14, 463–478. [Google Scholar] [CrossRef]

- Parmenter, D. Key Performance Indicators: Developing, Implementing, and Using Winning KPIs, 3rd ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2015; pp. 1–28. [Google Scholar] [CrossRef]

- Gunduz, M.; Elsherbeny, H.A. Operational framework for managing construction-contract administration practitioners’ perspective through modified Delphi method. J. Constr. Eng. Manag. 2020, 146, 04019110. [Google Scholar] [CrossRef]

- Appiah, K.S. An assessment of Post-Contract Award Management Practices at the Ahafo Ano North District Assembly. Master’s Thesis, Kwame Nkrumah University of Science and Technology, Kumasi, Ghana, November 2015. [Google Scholar]

- Crampton, C. Project Management Manual: SM 011, 1st ed.; NZ Transport Agency: Wellington, New Zealand, 2010; p. 405. [Google Scholar]

- Miller, F.D.; Newton, J.M.; D’Amato, S.A. Defining and Measuring the Success of Service Contracts. Master’s Thesis, Naval Postgraduate School, Monterey, CA, USA, June 2012. [Google Scholar] [CrossRef]

- Mwanaumo, E.; Muya, M.; Matakala, L.; Mwiya, B.; Kaliba, C.; Sanga, S. Module 003: Introduction to Contract Management and Administration; National Council for Construction: Lusaka, Zambia, 2017; pp. 1–35. [Google Scholar]

- Solis, M.M. Contract Management for Dutch Wastewater Industry. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, December 2016. [Google Scholar]

- Doloi, H. Cost overruns and failure in project management: Understanding the roles of key stakeholders in construction projects. J. Constr. Eng. Manag. 2013, 139, 267–279. [Google Scholar] [CrossRef]

- Okere, G.O. An Investigative Study of Contract Administration Practices of General Contractors on Federal and State DOT Projects. Ph.D. Thesis, Indiana State University, Terre Haute, IN, USA, December 2012. [Google Scholar]

- Oluka, P.N.; Basheka, B.C. Determinants and constraints to effective procurement contract management in Uganda: A practitioner’s perspective. Int. J. Logist. Syst. Manag. 2014, 17, 104–124. [Google Scholar] [CrossRef]

- Joyce, C.R. Contract Management Practice and Operational Performance of State Corporations in Kenya. Master’s Thesis, University of Nairobi, Nairobi, Kenya, October 2014. [Google Scholar]

- Moore, K.M. Contract Administration Organization: A Case Study of the US Marine Corps Advanced Amphibious Assault Vehicle Program. Master’s Thesis, Naval Postgraduate School, Monterey, CA, USA, December 1996. [Google Scholar]

- Taccad, C.C. A model of contract administration for the Armed Forces of the Philippines (AFP) modernization program. Master’s Thesis, Naval Postgraduate School, Monterey CA, USA, December 1999. [Google Scholar]

- Park, S.H.; Kim, Y.S. An assessment of contract management capabilities for overseas construction projects. KSCE J. Civ. Eng. 2018, 55, 2147–2158. [Google Scholar] [CrossRef]

- Griffith, C. Mobile App Development with Ionic, Cross-Platform Apps with Ionic, Angular, and Cordova; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2017; pp. 1–269. [Google Scholar]

- Gunduz, M.; Birgonul, M.T.; Ozdemir, M. Development of a safety performance index assessment tool by using a fuzzy structural equation model for construction sites. Automat. Constr. 2018, 85, 124–134. [Google Scholar] [CrossRef]

- Latif, M.; Lakhrissi, Y.; Nfaoui, E.H.; Es-Sbai, N. Cross platform approach for mobile application development: A survey. In Proceedings of the International Conference on Information Technology for Organizations Development (IT4OD), Fez, Morocco, 30 March–1 April 2016; pp. 1–5. [Google Scholar] [CrossRef]

- TutorialsPoint. Ionic—Overview. Available online: https://www.tutorialspoint.com/ionic/ionic_overview.htm (accessed on 8 May 2019).

- Shyi, M.C. A new method for tool steel materials selection under fuzzy environment. Fuzzy Set Syst. 1997, 92, 265–274. [Google Scholar] [CrossRef]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis, 7th ed.; Pearson: Hoboken, NJ, USA, 2014; pp. 1–734. [Google Scholar]

- Steenkamp, J.-B.E.M.; van Trijp, H.C.M. The use of LISREL in validating marketing constructs. Int. J. Res. Mark. 1991, 8, 283–299. [Google Scholar] [CrossRef]

- Xiong, B.; Skitmore, M.; Xia, B. A critical review of structural equation modeling applications in construction research. Automat. Constr. 2015, 49, 59–70. [Google Scholar] [CrossRef]

- Zahoor, H.; Chan, A.P.C.; Utama, W.P.; Gao, R.; Memon, S.A. Determinants of safety climate for building projects: SEM-based cross-validation study. J. Constr. Eng. Manage. 2017, 143, 05017005. [Google Scholar] [CrossRef]

- Yoo, B.; Donthu, N. Developing and validating a multidimensional consumer-based brand equity scale. J. Bus. Res. 2001, 52, 1–14. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).