Sustainability of Wine Production

Abstract

:1. Introduction

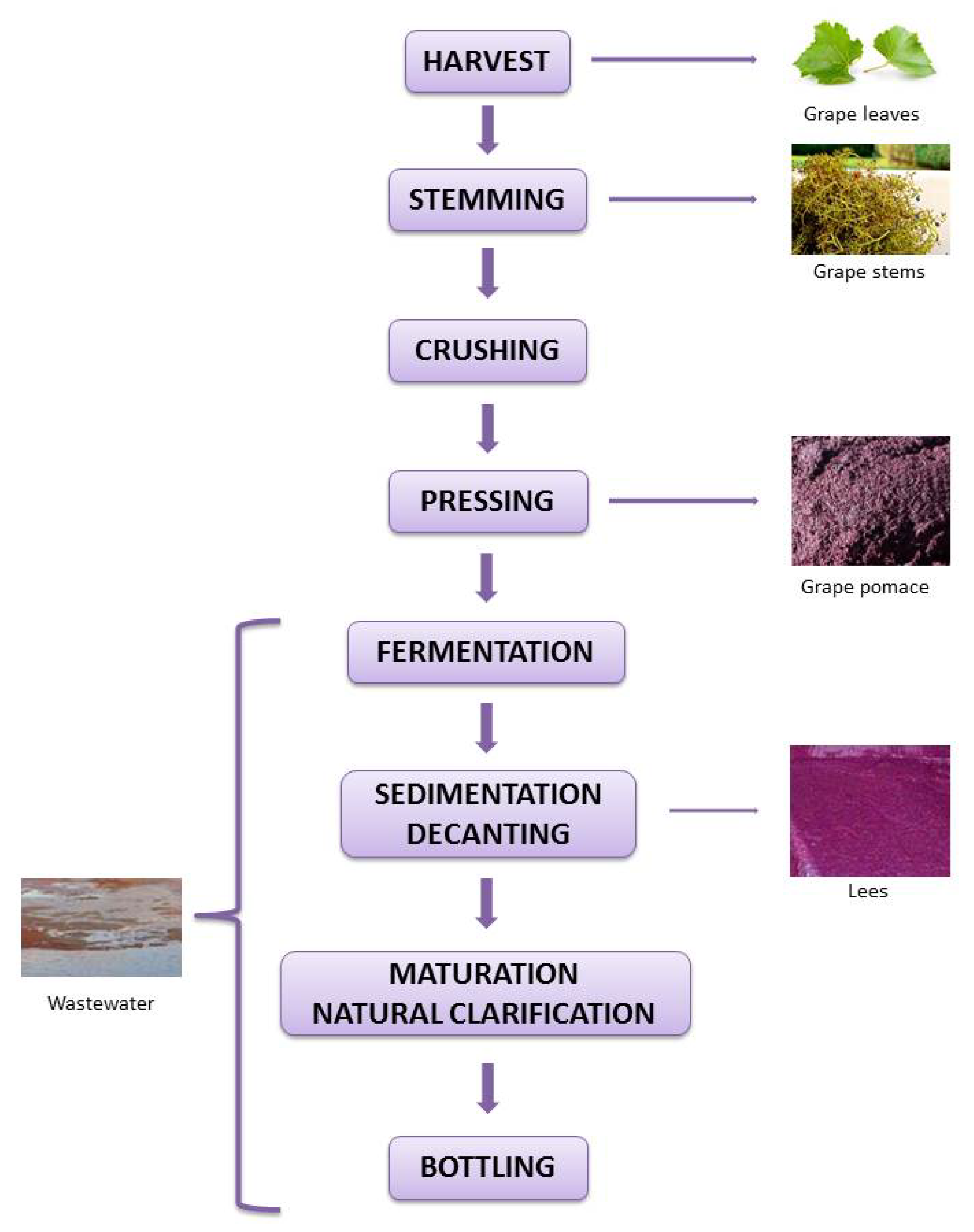

2. Characterization of Different Winery Residual Biomasses

2.1. Winery Industry

2.2. Grape Leaves

2.3. Grape Stems

2.4. Grape Pomace or Press Residues

2.5. Wine Lees

2.6. Winery Wastewater

3. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| WWW | winery wastewaters |

| GPS | grape pomace and stalks |

| GAE | gallic acid equivalent |

References

- Mateo, J.; Maicas, S. Valorization of winery and oil mill wastes by microbial technologies. Food Res. Int. 2015, 73, 13–25. [Google Scholar] [CrossRef]

- Rockenbach, I.; Gonzaga, L.; Rizelio, V.; Gonçalves, A.; Genovese, M.; Fett, R. Phenolic compounds and antioxidant activity of seed and skin extracts of red grape (Vitis vinifera and Vitis labrusca) pomace from Brazilian winemaking. Food Res. Int. 2011, 44, 897–901. [Google Scholar] [CrossRef]

- Rondeau, P.; Gambier, F.; Jolibert, F.; Brosse, N. Compositions and chemical variability of grape pomaces from French vineyard. Ind. Crop. Prod. 2013, 43, 251–254. [Google Scholar] [CrossRef]

- Spigno, G.; Maggi, L.; Amendola, D.; Dragoni, M.; De Faveri, D. Influence of cultivar on the lignocellulosic fractionation of grape stalks. Ind. Crop. Prod. 2013, 46, 283–289. [Google Scholar] [CrossRef]

- Spigno, G.; Pizzorno, T.; De Faveri, D. Cellulose and hemicelluloses recovery from grape stalks. Bioresour. Technol. 2008, 99, 4329–4337. [Google Scholar] [CrossRef] [PubMed]

- Salgado, J.M.; Abrunhosa, L.; Venâncio, A.; Domínguez, J.M.; Belo, I. Integrated use of residues from olive mill and winery for lipase production by solid state fermentation with Aspergillus sp. Appl. Biochem. Biotechnol. 2014, 172, 1832–1845. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Musee, N.; Lorenzen, L.; Aldrich, C. Cellar waste minimization in the wine industry: A systems approach. J. Clean. Prod. 2007, 15, 417–431. [Google Scholar] [CrossRef]

- Hussain, M.; Cholette, S.; Castaldi, R. An analysis of globalization forces in the wine industry: Implications and recommendations for wineries. J. Glob. Mark. 2008, 21, 33–47. [Google Scholar] [CrossRef]

- Devesa-Rey, R.; Vecino, X.; Varela-Alende, J.; Barral, M.; Cruz, J.; Moldes, A. Valorization of winery waste vs. the costs of not recycling. Waste Manag. 2011, 31, 2327–2335. [Google Scholar] [CrossRef]

- Asselin, C.; Delteil, D. Vinificaciones: Principales operaciones unitarias comunes. In Enología: Fundamentos Científicos y Tecnológicos; Mundiprensa: Madrid, Spain, 2003; pp. 418–442. [Google Scholar]

- Navarro, P.; Sarasa, J.; Sierra, D.; Esteban, S.; Ovelleiro, J. Degradation of wine industry wastewaters by photocatalytic advanced oxidation. Water Sci. Technol. 2005, 51, 113–120. [Google Scholar] [CrossRef] [Green Version]

- Ioannou, L.A.; Puma, G.L.; Fatta-Kassinos, D. Treatment of winery wastewater by physicochemical, biological and advanced processes: A review. J. Hazard. Mater. 2015, 286, 343–368. [Google Scholar] [CrossRef] [PubMed]

- Chouchouli, V.; Kalogeropoulos, N.; Konteles, S.; Karvela, E.; Makris, D.; Karathanos, V. Fortification of yoghurts with grape (Vitis vinifera) seed extracts. LWT Food Sci. Technol. 2013, 53, 522–529. [Google Scholar] [CrossRef]

- Bustamante, M.; Moral, R.; Paredes, C.; Pérez-Espinosa, A.; Moreno-Caselles, J.; Pérez-Murcia, M. Agrochemical characterisation of the solid by-products and residues from the winery and distillery industry. Waste Manag. 2008, 28, 372–380. [Google Scholar] [CrossRef] [PubMed]

- Xia, E.Q.; Deng, G.F.; Guo, Y.J.; Li, H.B. Biological activities of polyphenols from grapes. Int. J. Mol. Sci. 2010, 11, 622–646. [Google Scholar] [CrossRef]

- Fernandes, F.; Ramalhosa, E.; Pires, P.; Verdial, J.; Valentão, P.; Andrade, P.; Bento, A.; Pereira, J. Vitis vinifera leaves towards bioactivity. Ind. Crop. Prod. 2013, 43, 434–440. [Google Scholar] [CrossRef]

- Llobera, A.; Cañellas, J. Dietary fibre content and antioxidant activity of Manto Negro red grape (Vitis vinifera): Pomace and stem. Food Chem. 2007, 101, 659–666. [Google Scholar] [CrossRef]

- Souquet, J.M.; Labarbe, B.; Le Guernevé, C.; Cheynier, V.; Moutounet, M. Phenolic composition of grape stems. J. Agric. Food Chem. 2000, 48, 1076–1080. [Google Scholar] [CrossRef]

- Corrales, M.; Toepfl, S.; Butz, P.; Knorr, D.; Tauscher, B. Extraction of anthocyanins from grape by-products assisted by ultrasonics, high hydrostatic pressure or pulsed electric fields: A comparison. Innov. Food Sci. Emerg. Technol. 2008, 9, 85–91. [Google Scholar] [CrossRef]

- Gonzalez-Centeno, M.; Rossello, C.; Simal, S.; Garau, M.; Lopez, F.; Femenia, A. Physico-chemical properties of cell wall materials obtained from ten grape varieties and their byproducts: Grape pomaces and stems. LWT Food Sci. Technol. 2010, 43, 1580–1586. [Google Scholar] [CrossRef]

- Karvela, E.; Makris, D.; Kalogeropoulos, N.; Karathanos, V. Deployment of response surface methodology to optimise recovery of grape (Vitis vinifera) stem polyphenols. Talanta 2009, 79, 1311–1321. [Google Scholar] [CrossRef]

- Kataliníc, V.; Možina, S.; Skroza, D.; Generalić, I.; Abramović, H.; Miloš, M.; Ljubenkov, I.; Piskernik, S.; Pezo, I.; Terpinc, P.; et al. Polyphenolic profile, antioxidant properties and antimicrobial activity of grape skin extracts of 14 Vitis vinifera varieties grown in Dalmatia (Croatia). Food Chem. 2010, 119, 715–723. [Google Scholar] [CrossRef]

- Boussetta, N.; Lanoisellé, J.L.; Bedel-Cloutour, C.; Vorobiev, E. Extraction of soluble matter from grape pomace by high voltage electrical discharges for polyphenol recovery: Effect of sulphur dioxide and thermal treatments. J. Food Eng. 2009, 95, 192–198. [Google Scholar] [CrossRef]

- Rockenbach, I.; Rodrigues, E.; Gonzaga, L.; Caliari, V.; Genovese, M.; Gonalves, A.; Fett, R. Phenolic compounds content and antioxidant activity in pomace from selected red grapes (Vitis vinifera L. and Vitis labrusca L.) widely produced in Brazil. Food Chem. 2011, 127, 174–179. [Google Scholar] [CrossRef]

- Ghafoor, K.; Choi, Y.; Jeon, J.; Jo, I. Optimization of ultrasound-assisted extraction of phenolic compounds, antioxidants, and anthocyanins from grape (Vitis vinifera) seeds. J. Agric. Food Chem. 2009, 57, 4988–4994. [Google Scholar] [CrossRef]

- Nawaz, H.; Shi, J.; Mittal, G.S.; Kakuda, Y. Extraction of polyphenols from grape seeds and concentration by ultrafiltration. Sep. Purif. Technol. 2006, 48, 176–181. [Google Scholar] [CrossRef]

- de Campos, L.; Leimann, F.; Pedrosa, R.; Ferreira, S. Free radical scavenging of grape pomace extracts from Cabernet sauvingnon (Vitis vinifera). Bioresour. Technol. 2008, 99, 8413–8420. [Google Scholar] [CrossRef]

- González-Manzano, S.; Rivas-Gonzalo, J.; Santos-Buelga, C. Extraction of flavan-3-ols from grape seed and skin into wine using simulated maceration. Anal. Chim. Acta 2004, 513, 283–289. [Google Scholar] [CrossRef]

- Bucić-Kojić, A.; Sovová, H.; Planinića, M.; Tomas, S. Temperature-dependent kinetics of grape seed phenolic compounds extraction: Experiment and model. Food Chem. 2013, 136, 1136–1140. [Google Scholar] [CrossRef]

- Furiga, A.; Lonvaud-Funel, A.; Badet, C. In vitro study of antioxidant capacity and antibacterial activity on oral anaerobes of a grape seed extract. Food Chem. 2009, 113, 1037–1040. [Google Scholar] [CrossRef]

- Pinelo, M.; Arnous, A.; Meyer, A.S. Upgrading of grape skins: Significance of plant cell-wall structural components and extraction techniques for phenol release. Trends Food Sci. Technol. 2006, 17, 579–590. [Google Scholar] [CrossRef]

- Chikwanha, O.C.; Raffrenato, E.; Opara, U.L.; Fawole, O.A.; Setati, M.E.; Muchenje, V.; Mapiye, C. Impact of dehydration on retention of bioactive profile and biological activities of different grape (Vitis vinifera L.) pomace varieties. Anim. Feed Sci. Technol. 2018, 244, 116–127. [Google Scholar] [CrossRef]

- Teixeira, A.; Baenas, N.; Dominguez-Perles, R.; Barros, A.; Rosa, E.; Moreno, D.; Garcia-Viguera, C. Natural bioactive compounds from winery by-products as health promoters: A review. Int. J. Mol. Sci. 2014, 15, 15638–15678. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pérez-Serradilla, J.; Luque de Castro, M. Microwave-assisted extraction of phenolic compounds from wine lees and spray-drying of the extract. Food Chem. 2011, 124, 1652–1659. [Google Scholar] [CrossRef]

- Mazauric, J.P.; Salmon, J.M. Interactions between yeast lees and wine polyphenols during simulation of wine aging: II. Analysis of desorbed polyphenol compounds from yeast lees. J. Agric. Food Chem. 2006, 54, 3876–3881. [Google Scholar] [CrossRef]

- Vattem, D.; Shetty, K. Ellagic acid production and phenolic antioxidant activity in cranberry pomace (Vaccinium macrocarpon) mediated by Lentinus edodes using a solid-state system. Process Biochem. 2003, 39, 367–379. [Google Scholar] [CrossRef]

- Arboleda Meija, J.; Parpinello, G.; Versari, A.; Conidi, C.; Cassano, A. Microwave-assisted extraction and membrane-based separation of biophenols from red wine lees. Food Bioprod. Process. 2019, 117, 74–83. [Google Scholar] [CrossRef]

- Arienzo, M.; Christen, E.; Quayle, W.; Kumar, A. A review of the fate of potassium in the soil-plant system after land application of wastewaters. J. Hazard. Mater. 2009, 164, 415–422. [Google Scholar] [CrossRef]

- Ruggieri, L.; Cadena, E.; Martínez-Blanco, J.; Gasol, C.; Rieradevall, J.; Gabarrell, X.; Gea, T.; Sort, X.; Sánchez, A. Recovery of organic wastes in the Spanish wine industry. Technical, economic and environmental analyses of the composting process. J. Clean. Prod. 2009, 17, 830–838. [Google Scholar] [CrossRef] [Green Version]

- Sheridan, C.; Glasser, D.; Hildebrandt, D.; Petersen, J.; Rohwer, J. An annual and seasonal characterisation of winery effuent in South Africa. S. Afr. J. Enol. Vitic. 2011, 32, 1–8. [Google Scholar]

- Toze, S. Reuse of effluent water—Benefits and risks. Agric. Water Manag. 2006, 80, 147–159. [Google Scholar] [CrossRef] [Green Version]

- Christen, E.; Quayle, W.; Marcoux, M.; Arienzo, M.; Jayawardane, N. Winery wastewater treatment using the land filter technique. J. Environ. Manag. 2010, 91, 1665–1673. [Google Scholar] [CrossRef] [PubMed]

- Mosse, K.; Patti, A.; Smernik, R.; Christen, E.; Cavagnaro, T. Physicochemical and microbiological effects of long- and short-term winery wastewater application to soils. J. Hazard. Mater. 2012, 201–202, 219–228. [Google Scholar] [CrossRef] [PubMed]

- Rončević, Z.; Grahovac, J.; Dodić, S.; Vučurović, D.; Dodić, J. Utilisation of winery wastewater for xanthan production in stirred tank bioreactor: Bioprocess modelling and optimisation. Food Bioprod. Process. 2019, 117, 113–125. [Google Scholar] [CrossRef]

- Mirabella, N.; Castellani, V.; Sala, S. Current options for the valorization of food manufacturing waste: A review. J. Clean. Prod. 2014, 65, 28–41. [Google Scholar] [CrossRef] [Green Version]

- Maia, M.; Ferreira, A.; Laureano, G.; Marques, A.; Torres, V.; Silva, A.; Matos, A.; Cordeiro, C.; Figueiredo, A.; Silva, M. Vitis vinifera ’Pinot noir’ leaves as a source of bioactive nutraceutical compounds. Food Funct. 2019, 10, 3822–3827. [Google Scholar] [CrossRef] [Green Version]

| Country | Media 2013–2017 | 2017 | 2018 | Variation 2018/2017 in % |

|---|---|---|---|---|

| Italy | 48.3 | 42.5 | 54.8 | 28.9 |

| France | 43.5 | 36.4 | 49.1 | 34.8 |

| Spain | 38.9 | 32.5 | 44.4 | 36.7 |

| USA | 23.2 | 23.3 | 23.9 | 2.3 |

| Argentina | 13.0 | 11.8 | 14.5 | 22.8 |

| Chile | 11.0 | 9.5 | 12.9 | 35.9 |

| Australia | 12.6 | 13.7 | 12.9 | −6.1 |

| Germany | 8.6 | 7.5 | 9.8 | 30.7 |

| South Africa | 11.0 | 10.8 | 9.5 | −12.5 |

| China | 13.1 | 11.6 | 9.3 | −20.2 |

| Russian Federation | 5.4 | 6.3 | 6.5 | 3.0 |

| Portugal | 6.4 | 6.7 | 6.1 | −10.0 |

| Romania | 4.0 | 4.3 | 5.1 | 17.9 |

| Hungary | 2.8 | 3.2 | 3.6 | 14.6 |

| Brazil | 2.6 | 3.6 | 3.1 | −13.2 |

| New Zealand | 2.8 | 2.9 | 3.0 | 5.8 |

| Austria | 2.2 | 2.5 | 23.8 | 10.8 |

| Greece | 2.7 | 2.6 | 2.2 | −15.4 |

| Moldavia | 1.8 | 1.8 | 1.9 | 5.5 |

| Switzerland | 0.9 | 0.8 | 1.1 | 40.4 |

| Bulgaria | 1.3 | 1.1 | 1.0 | −3.6 |

| Other countries | 14.8 | 14.5 | 15.0 | 3.4 |

| Total | 270.9 | 249.8 | 292.3 | 17.0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maicas, S.; Mateo, J.J. Sustainability of Wine Production. Sustainability 2020, 12, 559. https://doi.org/10.3390/su12020559

Maicas S, Mateo JJ. Sustainability of Wine Production. Sustainability. 2020; 12(2):559. https://doi.org/10.3390/su12020559

Chicago/Turabian StyleMaicas, Sergi, and José Juan Mateo. 2020. "Sustainability of Wine Production" Sustainability 12, no. 2: 559. https://doi.org/10.3390/su12020559

APA StyleMaicas, S., & Mateo, J. J. (2020). Sustainability of Wine Production. Sustainability, 12(2), 559. https://doi.org/10.3390/su12020559