Surface Dust and Aerosol Effects on the Performance of Grid-Connected Photovoltaic Systems

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental and Testing Layout

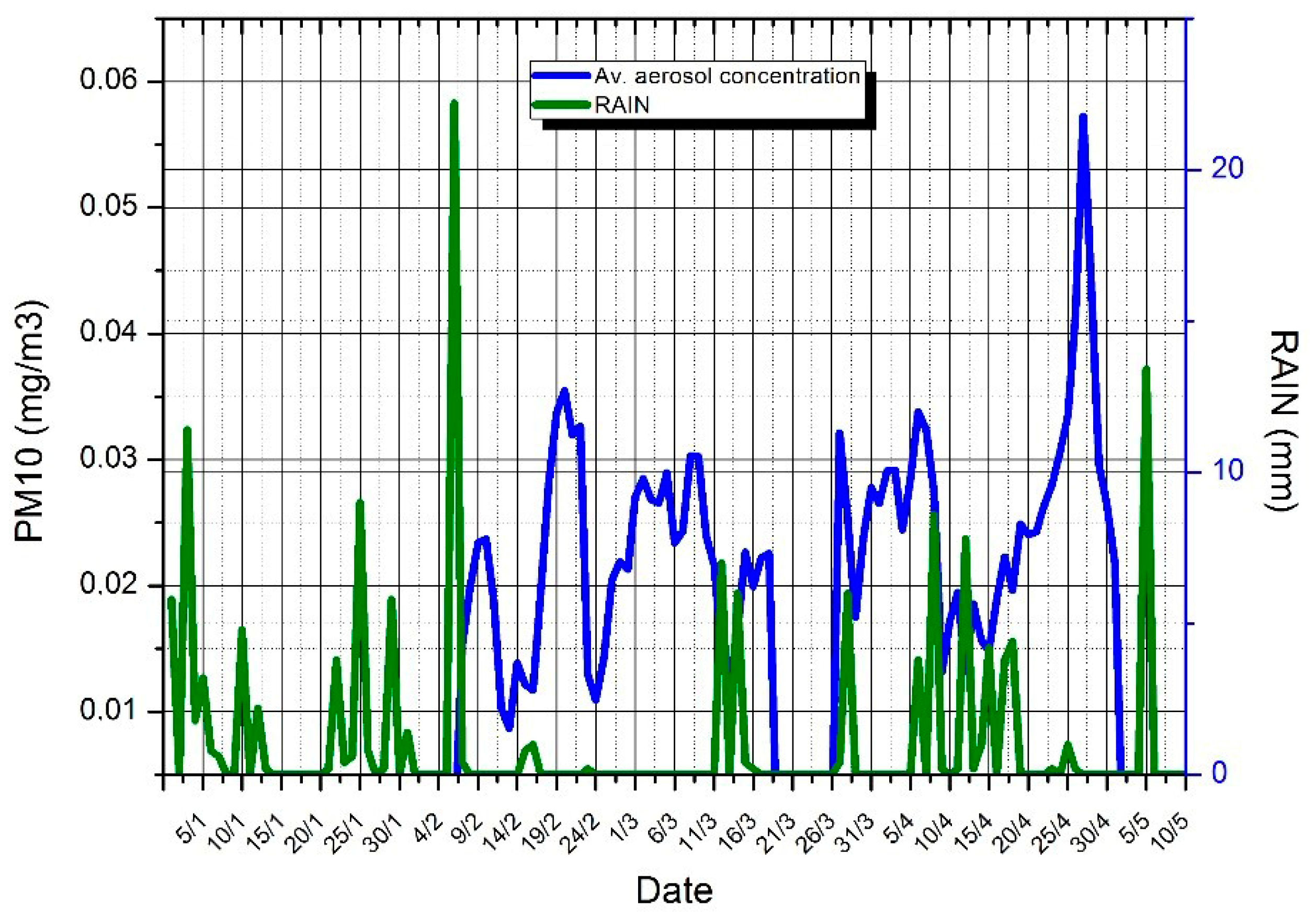

2.2. Ambient PM10 Concentration Measurement Setup

2.3. Method of Analysis

- Daily Performance ratio calculation according to EN 61724

- Use of bilinear model as reference value

- Calculation of normalized to STC efficiency

3. Results and Discussion

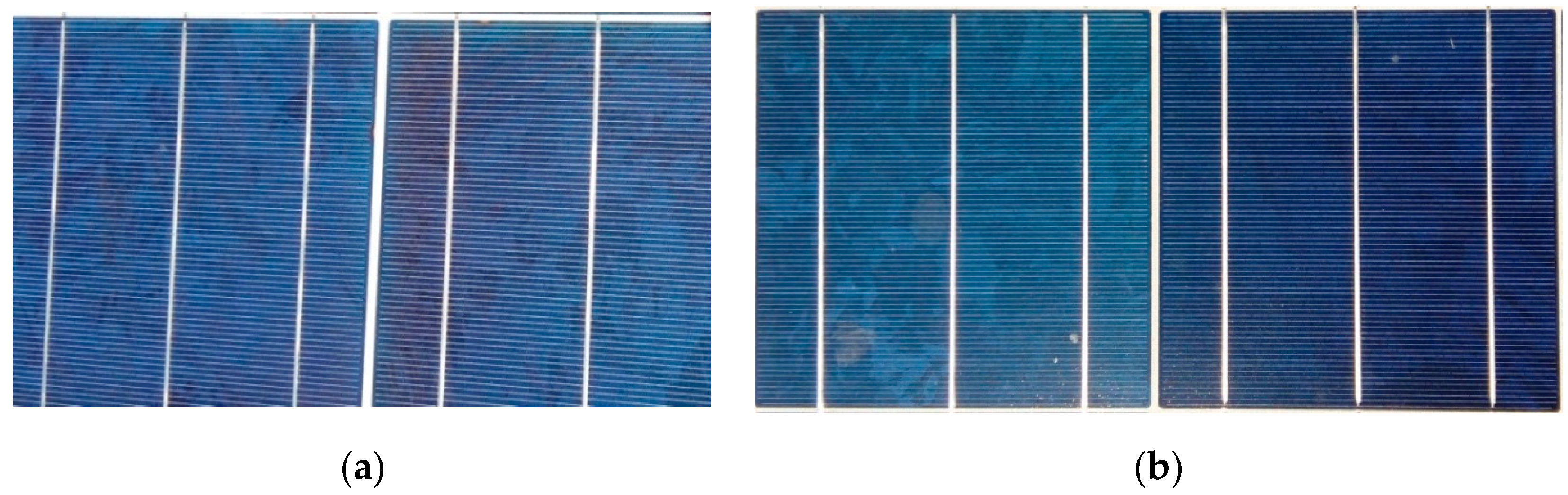

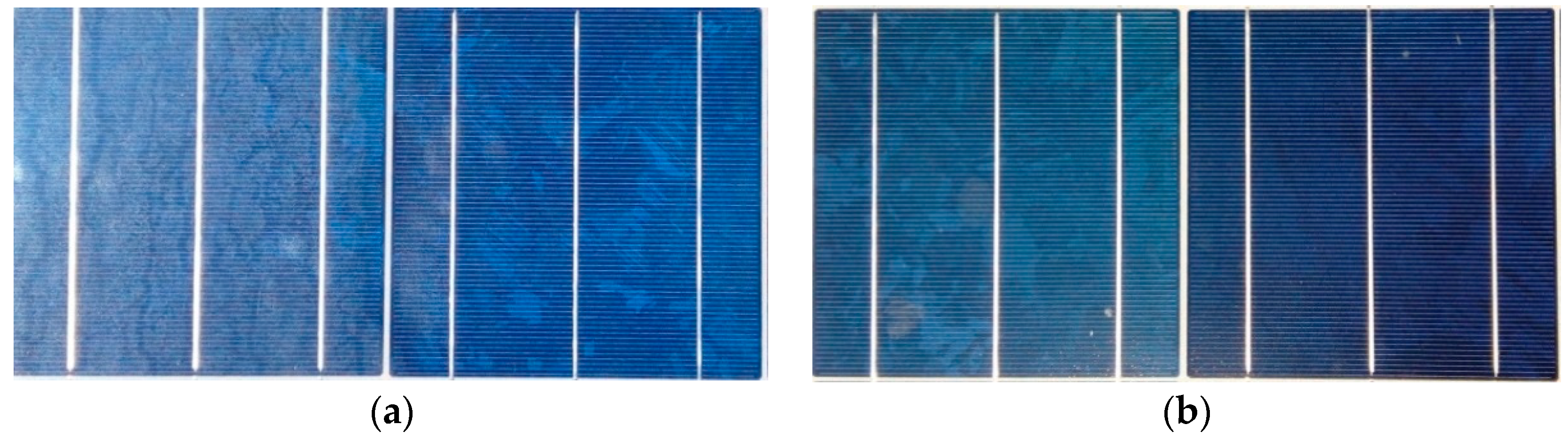

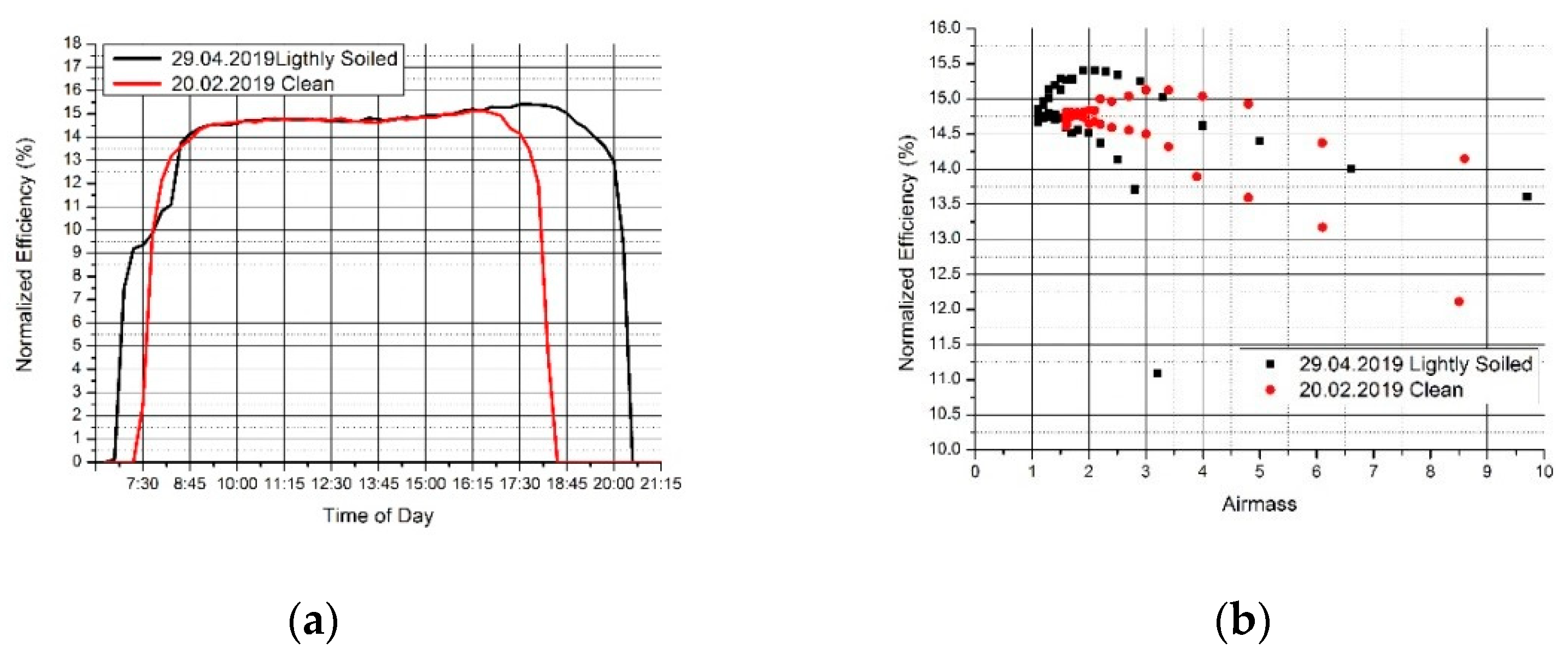

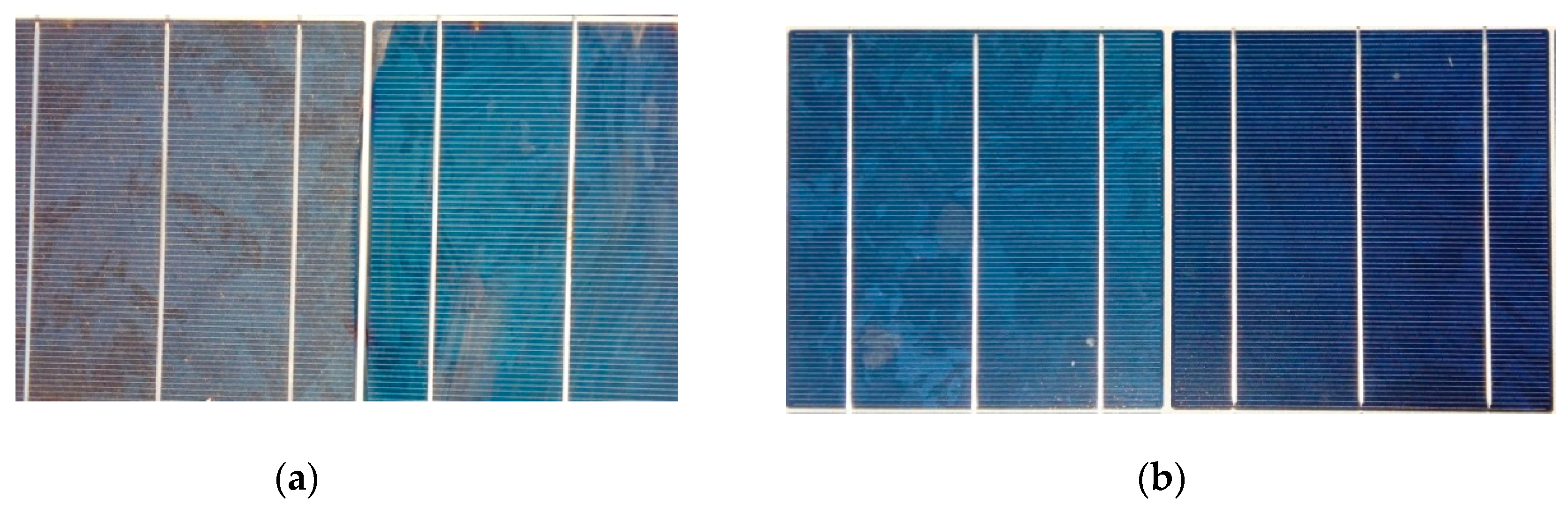

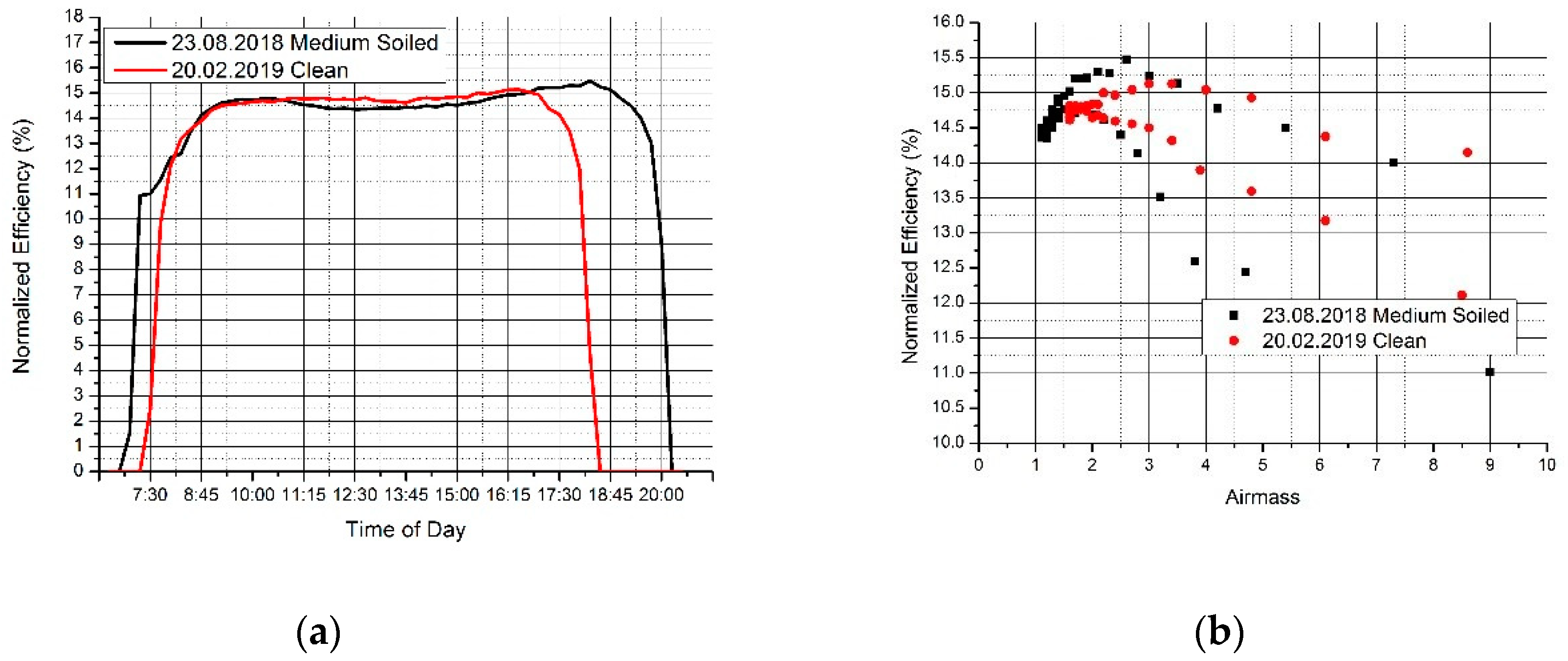

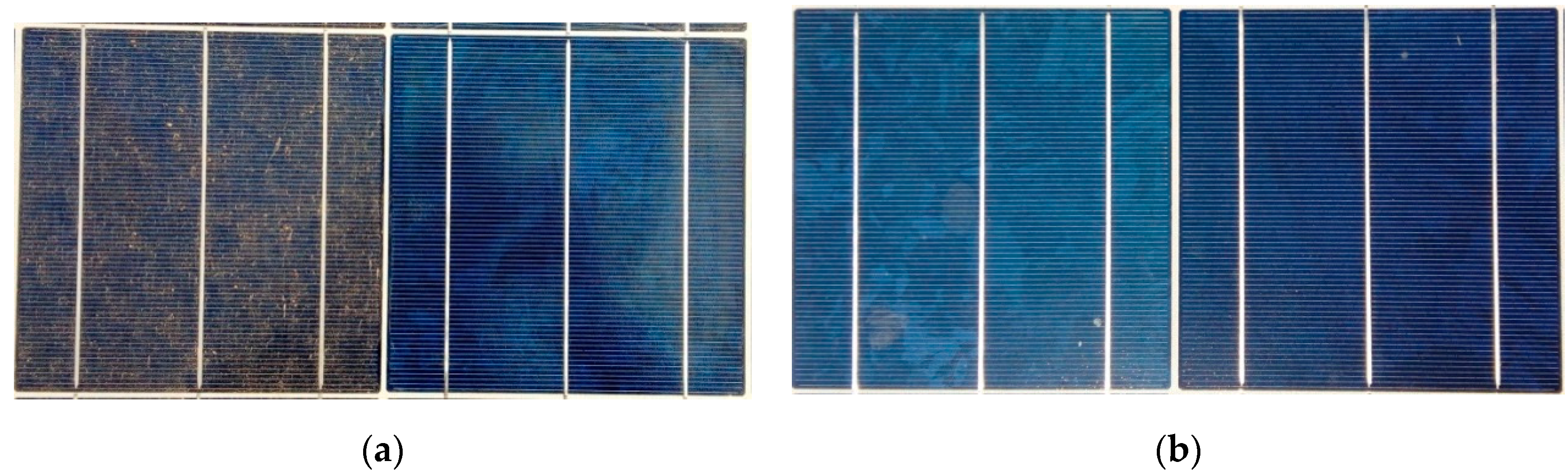

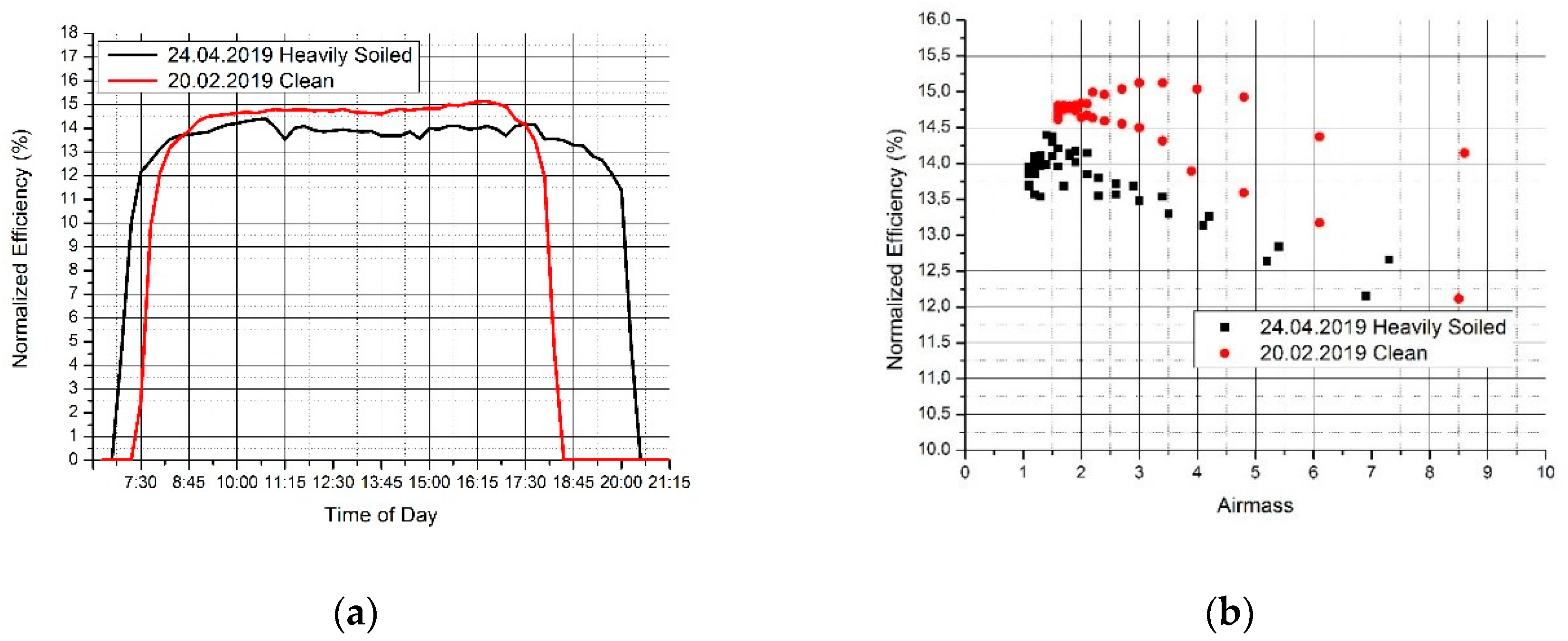

3.1. Effect of Dust Accumulation

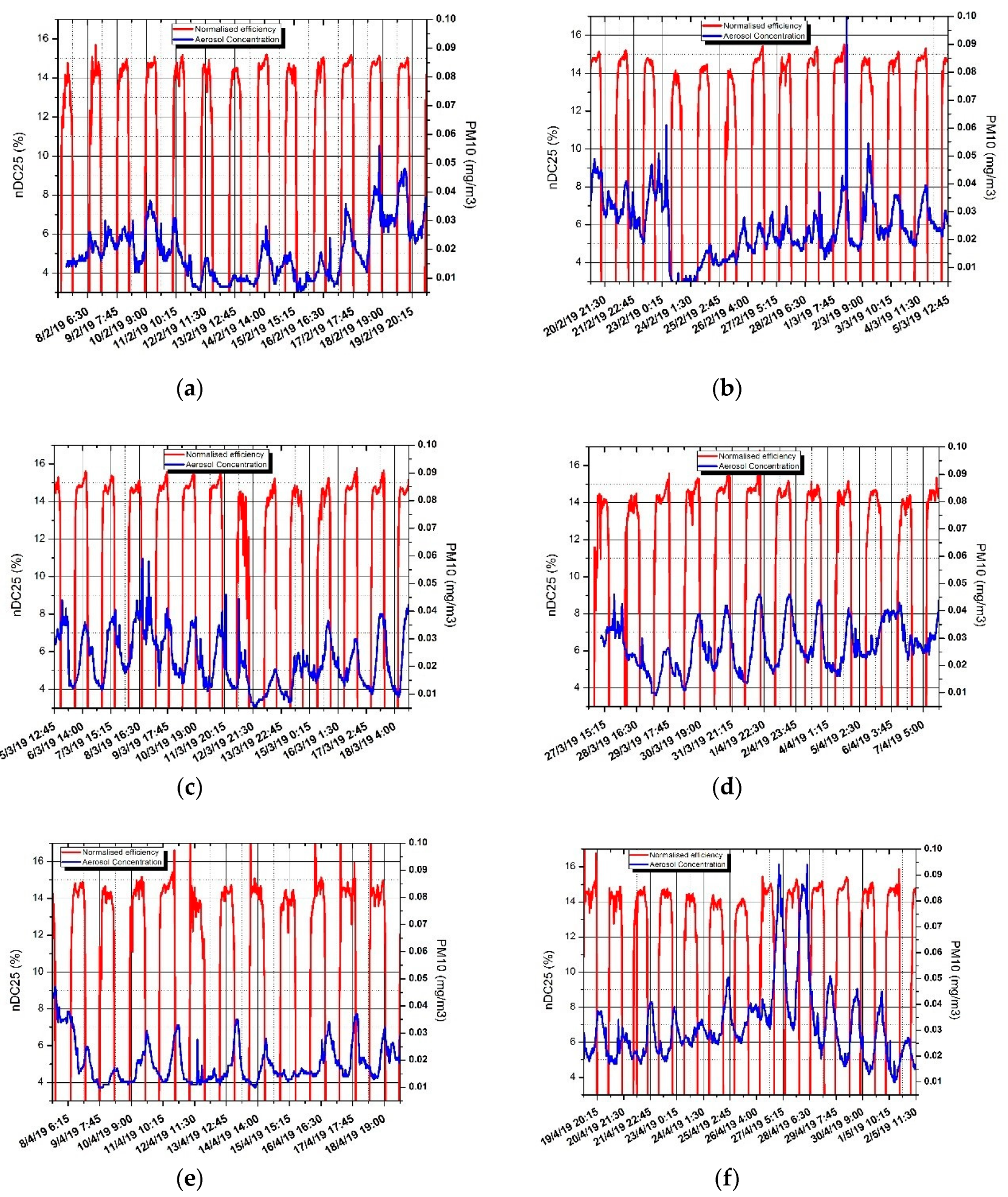

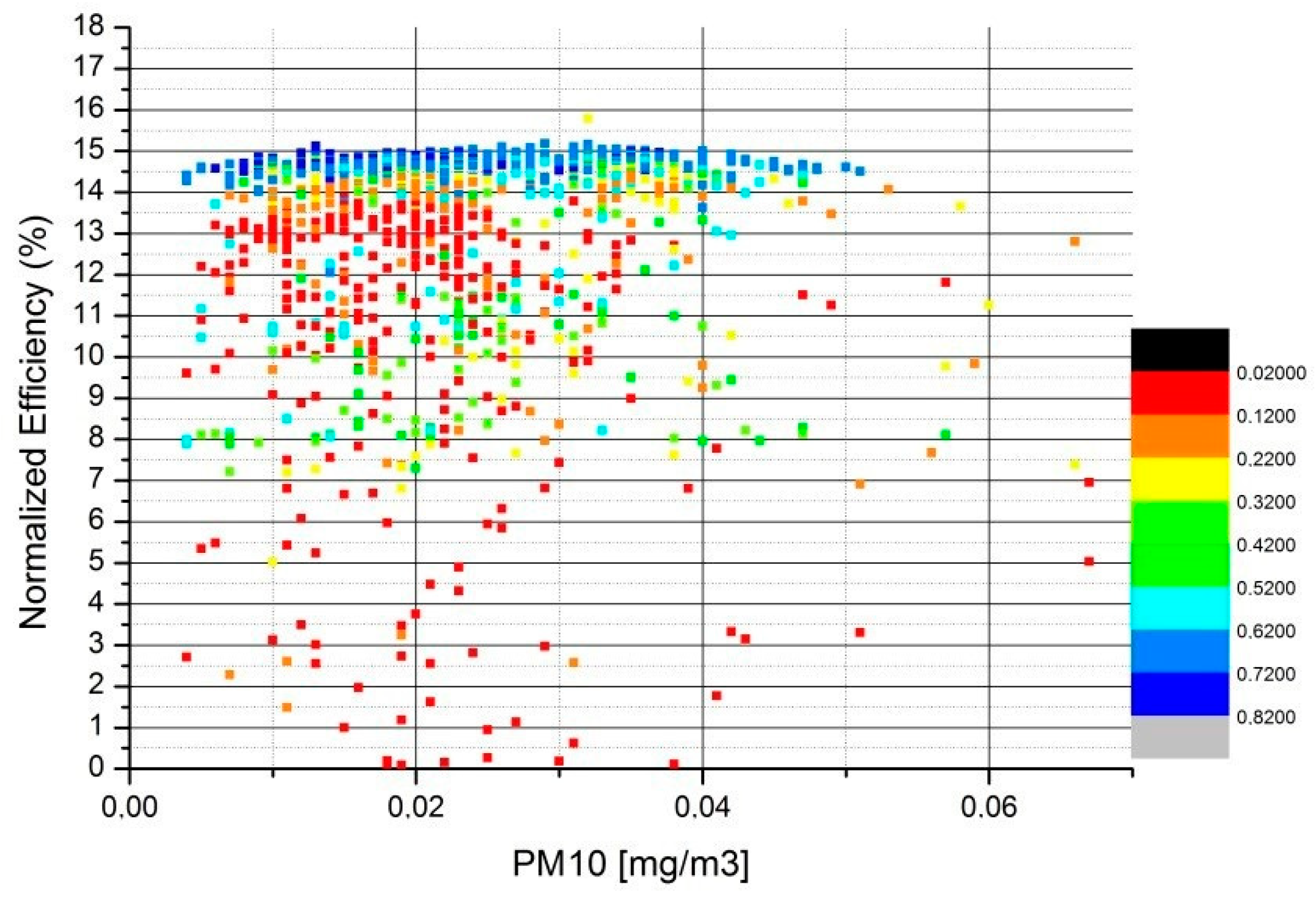

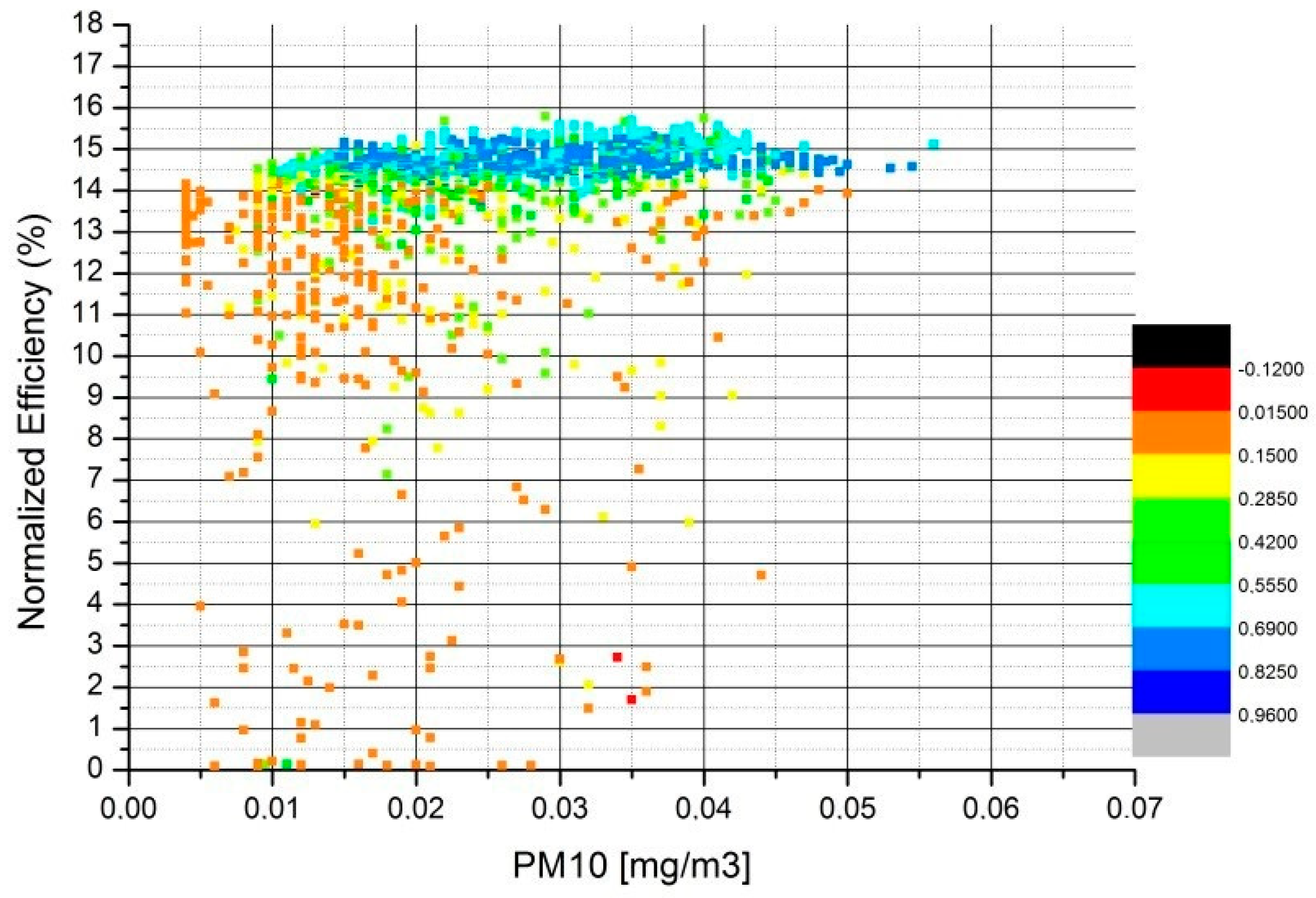

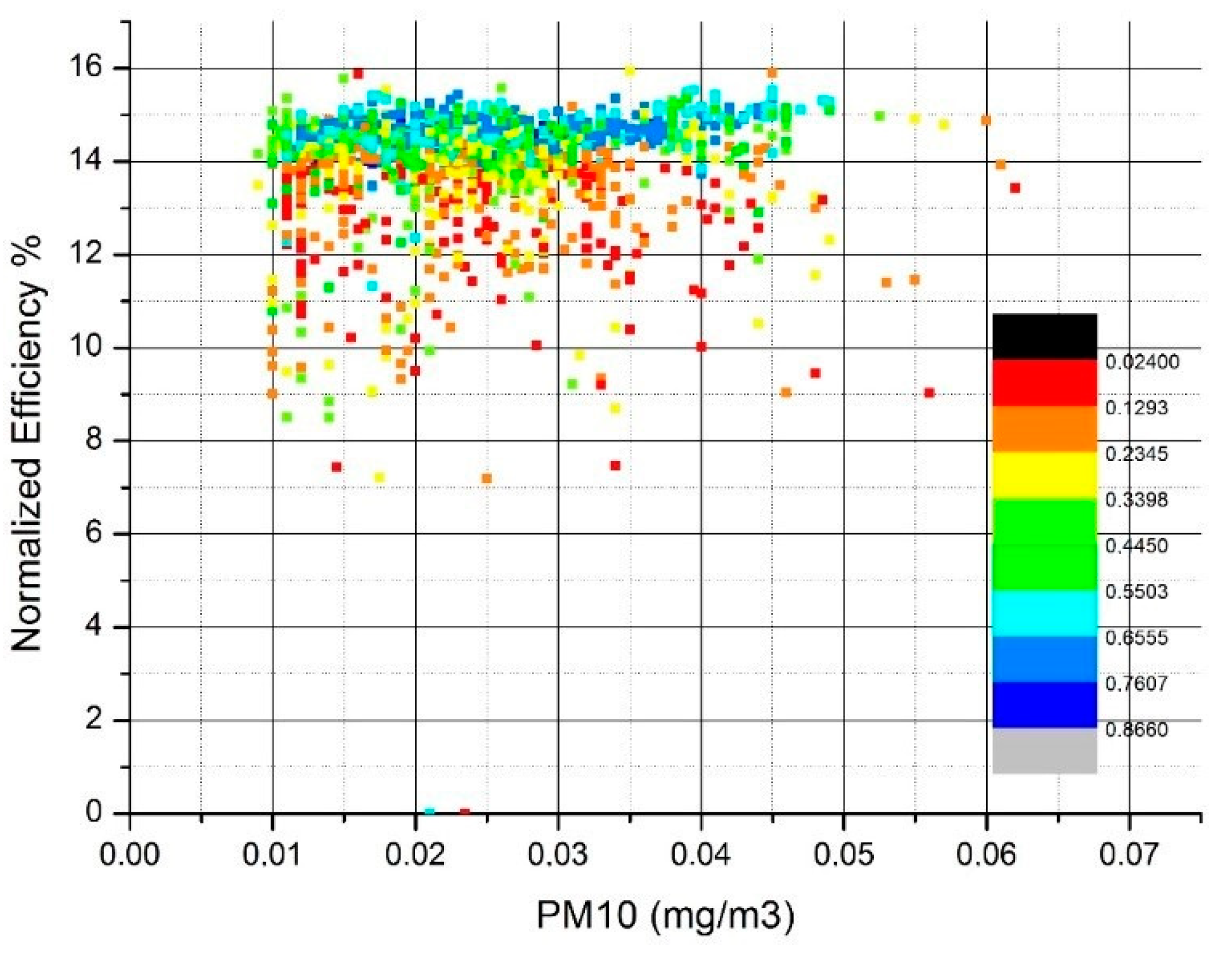

3.2. Effect of Aerosols

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Yingli 60 Cell YGE SERIES | |||

|---|---|---|---|

| Module Type | YL240P-29b | ||

| STC | NOCT | ||

| Power Output | W | 240 | 174.3 |

| Module efficiency | % | 14.7 | 13.3 |

| Voltage at Pmax | W | 29.5 | 26.6 |

| Current at Pmax | A | 8.14 | 6.56 |

| Open-circuit voltage | V | 37.5 | 34.2 |

| Short-circuit current | A | 8.65 | 7.01 |

| Normal operating cell temperature (NOCT) | °C | 46+/−2 | |

| Temperature coefficient of Pmax | %/°C | −0.45 | |

| Temperature coefficient of Voc | %/°C | −0.33 | |

| Temperature coefficient of Isc | %/°C | 0.06 | |

| Temperature coefficient of Vmpp | %/°C | −0.45 | |

| Dimensions(L/W/H) | Mm | 1650/990/40 | |

| STC: 1000 W/m2 irradiance, 25 °C cell temperature, AM1.5 G spectrum according to EN 60904-3 | |||

| Average relative efficiency reduction of 5% at 200 W/m2 according to EN 60904-3 | |||

| NOCT: Open-circuit module operation temperature at 800 W/m2 irradiance, 20 °C ambient temperature, 1 m/s wind speed | |||

| Fronius IG Plus 150V-3 | ||

|---|---|---|

| PDC,MAX | W | 12,770 |

| IDC,MAX | A | 55.5 |

| UDC,MIN | V | 230 |

| UDC,START | V | 260 |

| UDC,R | V | 370 |

| UDC,MAX | V | 600 |

| PAC,R | W | 12,000 |

| IAC,MAX | A | 17.4 |

| UAC,R | V | 3-NPE 400/230 |

| Maximum efficiency ninv | % | 95.9 |

| ninv at 5% PAC,R (230V/370V/500V) | % | 91.8/92.5/91.1 |

| ninv at 10% PAC,R (230V/370V/500V) | % | 91.0/94.3/93.2 |

| ninv at 20% PAC,R (230V/370V/500V) | % | 94.7/95.1/94.6 |

| ninv at 25% PAC,R (230V/370V/500V) | % | 95.1/95.3/94.7 |

| ninv at 30% PAC,R (230V/370V/500V) | % | 95.1/95.3/94.9 |

| ninv at 50% PAC,R (230V/370V/500V) | % | 95.3/95.9/95.3 |

| ninv at 75% PAC,R (230V/370V/500V) | % | 94.7/95.6/95.4 |

| ninv at 100% PAC,R (230V/370V/500V) | % | 94.0/95.2/95.1 |

| PDC,MAX | W | 12,770 |

| IDC,MAX | A | 55.5 |

| UDC,MIN | V | 230 |

| UDC,START | V | 260 |

| Sensor | Mono-Crystalline Si-Sensor |

|---|---|

| Sensor voltage | 75 mV at 1000 W/m2 (exact calibration voltage written on sensor) |

| Accuracy | ±5% (average of a year) |

| Ambient temperature | −40 °C to +85 °C |

| Design | Sensor mounted on z-shaped aluminum profile |

| Dimensions | L × W × H = 55 × 55 × 10 mm |

| Fronius Product Nr. | 4,300,011,189 |

| Sensor | PT 100 |

|---|---|

| Measuring Range | −40 °C to +188 °C |

| Accuracy | ±0.8 °C (in the range −40 °C to +100 °C) |

| Design | Sensor on an adhesive film for measurements on surfaces |

| Dimensions | 32 × 32 mm |

| Fronius Art.Nr. | 4,300,011,190 |

| Sensor Type | 90° Light Scattering |

|---|---|

| Range | 8530 Desktop 0.001 to 400 mg/m3 |

| Resolution | ±0.8 °C (in the range −40 °C to +100 °C) ±0.1% of reading of 0.001 mg/m3, whichever is greater |

| Zero Stability | ±0.002 mg/m3 24 h at 10 s time constant |

| Particle Size Range | Approximately 0.1 to 10 μm |

| Flow Rate | 3.0 L/min set at factory 1.4 to 3.0 L/min adjustable |

| Flow Accuracy | ±5% factory setpoint Internal flow controlled |

| Temperature Coefficient | +0.001 mg/m3 per °C |

| Operational Temp | 0 to 50 °C |

| Storage Temp | −20 to 60 °C |

| Operational Humidity | 0–95% RH, non-condensing |

| Time Constant | Adjustable 1 to 60 s |

| Data Logging | 45 days at 1 min samples |

| Log Interval | 1 s to 1 h |

| Physical Size | (HWD) 5.3 × 8.5 × 8.8 in. |

References

- Kumar, N.M.; Malvoni, M. A preliminary study of the degradation of large-scale c-Si photovoltaic system under four years of operation in semi-arid climates. Results Phys. 2019, 12, 1395–1397. [Google Scholar] [CrossRef]

- Balaska, A.; Tahri, A.; Tahri, F.; Stambouli, A.B. Performance assessment of five different photovoltaic module technologies under outdoor conditions in Algeria. Renew. Energy 2017, 107, 53–60. [Google Scholar] [CrossRef]

- Kaldellis, J.; Kokala, A. Quantifying the decrease of the photovoltaic panels’ energy yield due to phenomena of natural air pollution disposal. Energy 2010, 35, 4862–4869. [Google Scholar] [CrossRef]

- Darwish, Z.A.; Kazem, H.A.; Sopian, K.; Al-Goul, M.; Alawadhi, H. Effect of dust pollutant type on photovoltaic performance. Renew. Sustain. Energy Rev. 2015, 41, 735–744. [Google Scholar] [CrossRef]

- Ullah, A.; Imran, H.; Maqsood, Z.; Butt, N.Z. Investigation of optimal tilt angles and effects of soiling on PV energy production in Pakistan. Renew. Energy 2019, 139, 830–843. [Google Scholar] [CrossRef]

- Saidan, M.; Albaali, A.G.; Alasis, E.; Kaldellis, J.K. Experimental study on the effect of dust deposition on solar photovoltaic panels in desert environment. Renew. Energy 2016, 92, 499–505. [Google Scholar] [CrossRef]

- Ramli, M.A.; Prasetyono, E.; Wicaksana, R.W.; Windarko, N.A.; Sedraoui, K.; Al-Turki, Y.A. On the investigation of photovoltaic output power reduction due to dust accumulation and weather conditions. Renew. Energy 2016, 99, 836–844. [Google Scholar] [CrossRef]

- Pavan, A.M.; Mellit, A.; De Pieri, D. The effect of soiling on energy production for large-scale photovoltaic plants. Sol. Energy 2011, 85, 1128–1136. [Google Scholar] [CrossRef]

- Beattie, N.S.; Moir, R.S.; Chacko, C.; Buffoni, G.; Roberts, S.H.; Pearsall, N.M. Understanding the effects of sand and dust accumulation on photovoltaic modules. Renew. Energy 2012, 48, 448–452. [Google Scholar] [CrossRef] [Green Version]

- Javed, W.; Guo, B.; Figgis, B. Modeling of photovoltaic soiling loss asa function of environmental variables. Sol. Energy 2017, 157, 397–407. [Google Scholar] [CrossRef]

- Hegazy, A.A. Effect of dust accumulation on solar transmittance through glass covers of plate-type collectors. Renew. Energy 2001, 22, 525–540. [Google Scholar] [CrossRef]

- Hottel, H.; Woertz, B. Performance of flat-plate solar-heat collectors. Trans. ASME 1942, 64, 91. [Google Scholar]

- Abderrezek, M.; Fathi, M. Experimental study of the dust effect on photovoltaic panels’ energy yield. Sol. Energy 2017, 142, 308–320. [Google Scholar] [CrossRef]

- Adıgüzel, E.; Özer, E.; Akgündoğdu, A.; Yılmaz, A.E. Prediction of dust particle size effect on efficiency of photovoltaic modules with ANFIS: An experimental study in Aegean region, Turkey. Sol. Energy 2019, 177, 690–702. [Google Scholar] [CrossRef]

- Mussard, M.; Amara, M. Performance of solar photovoltaic modules under arid climatic conditions: A review. Sol. Energy 2018, 174, 409–421. [Google Scholar] [CrossRef]

- Gutiérrez, C.; Somot, S.; Nabat, P.; Mallet, M.; Gaertner, M.Á.; Perpiñán, O. Impact of aerosols on the spatiotemporal variability of photovoltaic energy production in the Euro-Mediterranean area. Sol. Energy 2018, 174, 1142–1152. [Google Scholar] [CrossRef]

- Neher, I.; Buchmann, T.; Crewell, S.; Evers-Dietze, B.; Pfeilsticker, K.; Pospichal, B.; Schirrmeister, C.; Meilinger, S. Impact of atmospheric aerosols on photovoltaic energy production Scenario for the Sahel zone. Energy Procedia 2017, 125, 170–179. [Google Scholar] [CrossRef]

- TSI. Model 8530/8531/8532 DUSTTRAK II Aerosol Monitor, Operation and Service Manual. Available online: https://www.manualslib.com/manual/1378066/Tsi-Instruments-Dusttrak-Ii-8530.html (accessed on 2 January 2020).

- Zogou, O.; Stamatelos, A. Analysis of Data from Ambient PM10 Concentration Monitoring in Volos in the Period 2005–2010. Am. J. Environ. Eng. 2012, 2, 97–108. [Google Scholar]

- Heal, M.R.; Beverland, I.J.; McCabe, M.; Hepburn, W.; Agius, R.M. Intercomparison of five PM10 monitoring devices and the implications for exposure measurement in epidemiological research. J. Environ. Monit. 2000, 2, 455–461. [Google Scholar] [CrossRef] [Green Version]

- Chow, J.C.; Watson, J.G.; Lowenthal, D.H.; Richards, L.W. Comparability between PM2.5 and particle light scattering measurements. Environ. Monit. Assess. 2002, 79, 29–45. [Google Scholar] [CrossRef]

- Kokhanovsky, A. Aerosol Optics: Light Absorption and Scattering by Particles in the Atmosphere; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Roumpakias, E.; Stamatelos, A. Comparative performance analysis of grid-connected photovoltaic system by use of existing performance models. Energy Convers. Manag. 2017, 150, 14–25. [Google Scholar] [CrossRef]

- Roumpakias, E.; Stamatelos, A. Performance analysis of a grid-connected photovoltaic park after 6 years of operation. Renew. Energy 2019, 141, 368–378. [Google Scholar] [CrossRef]

- Marion, B.; Adelstein, J.; Boyle, K.; Hayden, H.; Hammond, B.; Fletcher, T.; Canada, B.; Narang, D.; Kimber, A.; Mitchell, L.; et al. Performance parameters for grid-connected PV systems. In Proceedings of the Conference Record of the Thirty-First IEEE Photovoltaic Specialists Conference, Lake Buena Vista, FL, USA, 3–7 January 2005; pp. 1601–1606. [Google Scholar]

- Marion, B. Comparison of predictive models for photovoltaic module performance. In Proceedings of the 2008 33rd IEEE Photovolatic Specialists Conference, San Diego, CA, USA, 11–16 May 2008; pp. 1–6. [Google Scholar]

- Necaibia, A.; Bouraiou, A.; Ziane, A.; Sahouane, N.; Hassani, S.; Mostefaoui, M.; Dabou, R.; Mouhadjer, S. Analytical assessment of the outdoor performance and efficiency of grid-tied photovoltaic system under hot dry climate in the south of Algeria. Energy Convers. Manag. 2018, 171, 778–786. [Google Scholar] [CrossRef]

- Piliougine, M.; Elizondo, D.; Mora-López, L.; Sidrach-de-Cardona, M. Modelling photovoltaic modules with neural networks using angle of incidence and clearness index. Prog. Photovolt. Res. Appl. 2015, 23, 513–523. [Google Scholar] [CrossRef]

- Wang, H.; Muñoz-García, M.; Moreda, G.; Alonso-García, M. Seasonal performance comparison of three grid connected photovoltaic systems based on different technologies operating under the same conditions. Sol. Energy 2017, 144, 798–807. [Google Scholar] [CrossRef]

- Al Shehri, A.; Parrott, B.; Carrasco, P.; Al Saiari, H.; Taie, I. Impact of dust deposition and brush-based dry cleaning on glass transmittance for PV modules applications. Sol. Energy 2016, 135, 317–324. [Google Scholar] [CrossRef]

- Herrmann, J.; Lorenz, T.; Slamova, K.; Klimm, E.; Koehl, M.; Weiss, K.A. Desert applications of PV modules. In Proceedings of the 2014 IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014. [Google Scholar]

| PV Panel Surface | PR | Averaged Deviation from Reference Value 1 < AM < 3 (%) | Mean of Normalized Efficiency for the Range 1 < AM < 3 (%) |

|---|---|---|---|

| Clean, 20-02-2019 | 0.892 | −2.26 | 14.76 |

| Clean, 18-03-2019 | 0.869 | −1.45 | 14.65 |

| Lightly Soiled, 29-04-2019 | 0.866 | −3.2 | 14.83 |

| Medium Soiled, 23-08-2018 | 0.853 | −2.32 | 14.69 |

| Heavily soiled, 24-04-2019 | 0.856 | 2.25 | 13.92 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roumpakias, E.; Stamatelos, T. Surface Dust and Aerosol Effects on the Performance of Grid-Connected Photovoltaic Systems. Sustainability 2020, 12, 569. https://doi.org/10.3390/su12020569

Roumpakias E, Stamatelos T. Surface Dust and Aerosol Effects on the Performance of Grid-Connected Photovoltaic Systems. Sustainability. 2020; 12(2):569. https://doi.org/10.3390/su12020569

Chicago/Turabian StyleRoumpakias, Elias, and Tassos Stamatelos. 2020. "Surface Dust and Aerosol Effects on the Performance of Grid-Connected Photovoltaic Systems" Sustainability 12, no. 2: 569. https://doi.org/10.3390/su12020569

APA StyleRoumpakias, E., & Stamatelos, T. (2020). Surface Dust and Aerosol Effects on the Performance of Grid-Connected Photovoltaic Systems. Sustainability, 12(2), 569. https://doi.org/10.3390/su12020569