1. Introduction

Making strategic decisions on where to source materials and manufacture products has become a difficult task, as products may have raw and intermediary materials from many different locations and be assembled in different places, near or far, from its customers and focal firms who govern product supply chains. As such, product supply chains can become complex and fragmented, leading to difficulty in sustainable supply chain management and visibility, two features necessary to ensure product quality and environmental/social compliance [

1]. These relate to business, environmental, and social/socio-economic dimensions of sustainability, known as the Triple Bottom Line (TBL) [

2]. Environmental and social issues often occur at manufacturing sites of sub-suppliers (including subcontractors and suppliers of suppliers) [

3]. These issues lead to more studies towards multi-tier sustainable supply chain management involving several aspects such as managing suppliers and sub-suppliers, sourcing from low-risk countries and locations, governance structure, environmental performance improvement, and physical and institutional distance between focal firms and suppliers [

3,

4,

5,

6,

7,

8]. Moreover, some of these studies, as well as other studies on sustainable manufacturing, have mentioned positive impacts of physical and institutional proximity on sustainable practices for enhancing TBL sustainability due to, for example, short distances allowing for easy inspection and governance visits to suppliers, as well as effective local environment- and social-related laws [

3,

7,

8,

9]. This demonstrates that supply location decisions are important for sustainable supply chain management and sustainable practice implementation for sustainability enhancement. However, none pay attention to how to choose supply locations, configure supply networks, or compare performance of different multi-tier supply chains in order to ensure all three dimensions of TBL sustainability, as well as reputational risk avoidance at any supply stage.

Supply chain sustainability can be constrained by some location- and distance-dependent factors such as energy sources of electricity and geographical distance, which cannot be changed or significantly improved on by focal firms or their suppliers after a supply chain has been established. Therefore, multi-tier supply location decisions require considerations of factors involved in activities along product supply chains to fully drive TBL sustainability and avoid switching costs from future changes of supply locations. In this paper, the phrase ‘supply location decisions’ refers to the decisions of focal firms on where to source raw and intermediary materials and where to manufacture or assemble final products, rather than who manufactures the materials and products.

Existing studies on supply location decisions and network design, especially those with the simulation and modelling approaches that have been the tools for many studies on complex and multi-tier supply chains [

5], pay little attention to third-tier suppliers and TBL sustainability. Most relevant existing studies consider only first-tier suppliers who produce final products, while recent studies have started to consider second-tier suppliers who supply materials to the first-tier suppliers, as shown in

Table 1. The nine articles in

Table 1 were selected by reading abstracts of all retrieved articles from the Scopus database with search terms relating to design or model and manufacturing or supplier locations.

Table 1 also shows that only two of the recently published studies on supply location decisions and network design consider environmental sustainability and none consider social sustainability. In addition to the studies in

Table 1, other related studies [

19,

20,

21,

22,

23,

24,

25] similarly show that few of them considered social sustainability. This is consistent with the results of the review article by Chen et al. [

26], which stated that few studies have explicitly used sustainability criteria in making facility location decisions, as well as the review article by Brandenburg et al. [

27], which stated that studies on quantitative models for sustainable supply chain management have neglected the social dimension. Although we found that the Dou and Sarkis [

28] study incorporated TBL factors into their offshoring outsourcing decisions model, their model is based on subjective opinions from managers for pairwise comparisons among factors rather than on objective measured performance for comparing different locations and suppliers. Objective measurement criteria are important in order to avoid possible mistakes from any one individual’s subjective opinions on interpretation, misperception, and inability to process and logically optimize a large amount of data [

29]. Moreover, quantifiable criteria allow data to be measured directly and input into the model, to understand users’ values, preferences, requirements, and/or objectives, and to objectively choose and evaluate systems/supply chains that match the user’s objectives, especially with trade-off criteria [

30]. Additionally, using objective and quantifiable measures helps avoid uncertainties from subjective judgements and imprecise data [

31].

For the supply location decisions, an empirical study by one of the authors [

9] shows that managers of focal firms usually compare and choose supply locations and suppliers by calculating landed costs of products based on supplier quotations, together with requirements of certificates, auditing reports, and/or supplier visits by the managers in order to ensure environmental and social compliance at the suppliers’ factories. However, few of them ensure that the quoted product prices by suppliers are not too low to allow the suppliers to produce high-quality products with proper environmental and social compliance. Furthermore, industrial practitioners mainly focus on waste reduction and sustainable design, including using sustainable materials for improving environmental sustainability; they overlook greenhouse gas emissions from energy sources used in manufacturing and transportation that are considered proximity manufacturing benefits on environmental and social dimensions of sustainability [

32]. It is also important to consider gas emissions from managers travelling from headquarters to visit factories for price and style discussion, operation control, product inspection, and environmental and social compliance assurance, as the managers usually travel by plane, a transportation mode that emits high carbon dioxide equivalents (CO

2e) [

9], where CO

2e is calculated from greenhouse gas emissions. Therefore, we aim to develop a supply location decision-making (SLDM) approach for finding multi-tier supply locations enhancing TBL sustainability in product supply chains with objective and quantitative measures on supply chain activities which are especially related to location- and distance-dependent factors. The SLDM approach will help answer two research questions:

Which supply chain configurations deliver low cost and/or CO2e for different markets?

Which supply chain factors, including potential risks, highly influence cost and CO2e of these configurations?

This paper has three main contributions:

Our SLDM approach extends the knowledge on supply chain cost and CO2e calculation by including sustainability assurance activities performed by both manufacturers and a focal firm, in addition to the manufacturing and logistics activities used in other studies.

This paper calls for attention to location- and distance-dependent factors from industrial practitioners and researchers for proper supply location decisions and network design and from governments and energy/logistics service providers for enhancing the factors towards TBL sustainability.

This paper makes practical contributions by proposing the SLDM approach with pragmatic validity applicable to a wide variety of users with different organizational contexts and preferences.

The structure of this paper is as follows:

Section 2 shows how the SLDM approach is formulated, as well as diagrams of the ten-step SLDM approach, suggested factors and computational scopes, and pathways and interconnection of factors, cost, CO

2e, and TBL sustainability;

Section 3 explains the ten steps of the SLDM approach in detail;

Section 4 demonstrates the application of the SLDM approach in viscose t-shirt supply chains; and

Section 5 draws conclusion, research contributions, limitations, and implications, as well as practical and social implications.

2. Formulation of the Supply Location Decision-Making Approach

The development of the SLDM approach is based on industrial problems and practices from an empirical study and working experience of one of the authors, and accumulated knowledge from existing studies on location decisions, supply chain network design, and cost and environmental modelling, as shown in

Table 2.

The empirical study gave the authors insights of supply chain decisions and operations from interviewing 16 supply chain, purchasing, and sustainability control managers on why and how they choose local, nearshoring, and offshoring supply locations, calculate landed costs, ensure high product quality and sustainability compliances, and operate businesses with their suppliers and customers. The empirical study helps develop differentiating features of the SLDM approach from other existing studies, shown in

Table 2. Some results of the empirical study are published in Sirilertsuwan, Hjelmgren and Ekwall [

9]. Moreover, the insights on studied subject help enhance this research’s validity by aiding the authors in understanding what caused the research findings during interpretation and analysis [

37].

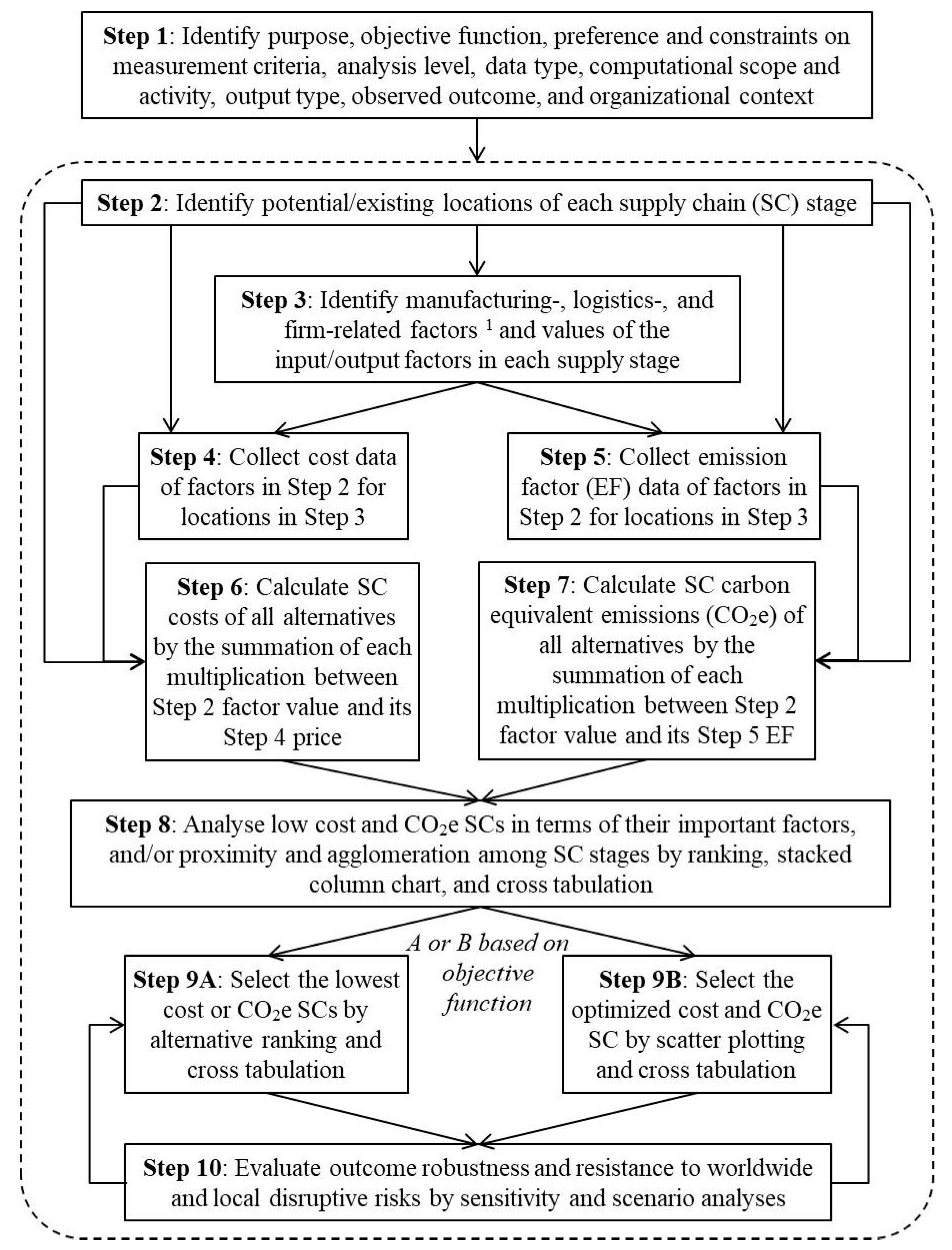

The SLDM approach consists of ten steps shown in

Figure 1, described in detail in

Section 3. The approach adopts two widely used objective measures from existing studies for comparing all possible supply chain configurations: cost and CO

2e from normalized greenhouse gas emissions. The approach adopts multivariate graphical and non-graphical exploratory data analysis [

33], such as cross tabulation, stacked column charts, and scatter plots, to reveal important factors, agglomeration and proximity between supply chain stages, and the lowest or optimized cost and CO

2e supply chains to be selected. In the scatter plots, cost and CO

2e trade-offs are visualized, and optimized cost and CO

2e supply chains are revealed on the Pareto frontier. This helps inform users (i.e., decision makers) how an improvement in cost may negatively affect CO

2e, and vice-versa, when making their decisions [

35] regarding a preferred supply chain matching user’s cost and CO

2e preferences and constraints for this research. Our approach focuses on finding a low-cost and CO

2e supply chain from visualization techniques of Pareto frontiers rather than mathematical methods; therefore, we do not show computational methods for multi-dimensional sets relating to Pareto optimization. However, readers can further learn about computational methods from the Lotov [

35] book and the Perez Loaiza, Olivares-Benitez, Miranda Gonzalez, Guerrero Campanur and Martinez Flores [

10] study. Scenario analysis, which is a tool for strategic analysis [

34], is adopted to help users better understand the causality of events and critical uncertainties as risk factors impacting target outcomes: the lowest or optimized cost and CO

2e supply chains. The approach also adopts sensitivity analysis [

36] to analyze robustness on how changes or imprecision of input factors potentially affect the outcomes. Both scenario and sensitivity analyses help decision making with long-term planning [

38]. Additionally, sensitivity analysis has also been used as a validation procedure in some models to evaluate supply chain performance [

31].

Figure 2 presents a summary of the ten steps, supply chain stages, supply chain activities and their factors relating to manufacturing and remanufacturing, logistics and reverse-logistics, and focal firms for supply chain cost and CO

2e calculation. The factors and activities are from studies in

Table 2 and from authors after applying logic models and an activity-based costing (ABC) method in product supply chains. Logic models [

39,

40] are used as tools for identifying inputs, activities, outputs, and outcomes, as well as their pathways and interconnections shown in

Figure 3, while ABC is used for allocating indirect costs and CO

2e to all manufactured units and is widely used in studies relating to supply chain decisions on organization performance, profitability, cost, productivity, and processes [

41]. Furthermore, iteratively formulating and applying older versions of the approach into viscose t-shirt supply chains, as well as feedback from experts, also helps improve the lists of factors and the steps of the approach shown in

Figure 2. We improved the approach by repeatedly comparing results with existing studies and theories to enhance validity. This process has been used in other studies to strengthen their findings [

7]. Moreover, we also reflected what works in practice to produce intended outcomes for enhancing pragmatic validity [

42].

In accordance with

Figure 3, users who use the SLDM approach will understand which factors, from which activities performed by whom, influence which outcomes, aiding strategic supply chain planning and management. We consider cost and CO

2e outputs to be intermediate outcomes, and TBL sustainability to be a long-term outcome. The highlights in

Figure 3 are how factors from sustainability assurance activities ultimately impact TBL sustainability, and how future socio-economic measurement criteria could be added.

Our SLDM approach is normative in terms of required sustainability assurance activities performed by manufactures to ensure proper environmental and social compliance because minimum requirements for social and environmental standards at manufacturing sites can help sustainable supply chain management [

43]. With our approach, focal firms can estimate prices of materials and products that are produced with sustainability assurance activities for TBL sustainability. If quoted prices by manufacturers are significantly lower than estimated prices, it is possible that the manufacturers cannot produce high product quality with good environmental and social compliance, as mentioned by managers from a prior empirical study performed by the author.

The SLDM approach has three cost and CO

2e computation scopes. The first is ‘the landed scope,’ which is similar to traditional landed cost and CO

2e calculation in terms of accumulating costs and CO

2e from suppliers to warehouse in a market. However, our landed scope includes sustainability assurance activities performed by manufacturers in the cost and CO

2e calculation, leading to differentiation from the traditional calculation. The activities relate to the bolded manufacturing and recycling factors in

Figure 2. In addition to manufacturers, focal firms also perform sustainability-assurance activities, including visiting factories and paying interest to gain capital and cash flow for business operations. Different manufacturing locations vary cost and CO

2e generated by these activities. Therefore, if focal firms perform these sustainability assurance activities, supply chain cost and CO

2e calculations have to include cost and CO

2e from these activities into the landed scope, hereafter referred to as ‘the firm scope.’ All sustainability assurance activities performed by both manufacturers and focal firms differentiate our SLDM approach from other studies and quantitative approaches for location decisions, as well as traditional cost and environmental computations. If products are recycled at one of the factories in any supply stage(s) after the consumer use phase, cost and CO

2e from sending used products back to the factory and from recycling processes will be included into the landed scope or the firm scope, to be referred to as ‘the recycling scope.’

3. The Ten-Step Supply Location Decision-Making Approach

All ten steps of the SLDM approach in

Figure 1 are explained below.

3.1. Step 1 to Step 3: Identification

Step 1 involves identifying all nine correlated aspects shown in

Figure 4. These aspects help users identify what they want from and can do with the SLDM approach.

Figure 4 shows flexibility and applicability of the approach to wide user groups. As shown in

Figure 1 with the dashed frame, Step 1 is crucial for conducting the other steps of the SLDM approach to help align all steps and all possible supply chains to be comparable, ensuring validity.

In order to generate all possible supply chains to be compared, Step 2 involves identifying potential or existing locations of each supplier in each supply stage depending on the application purpose. The sampled potential supply locations are based on a country’s reputation on certain products, availability of suppliers and industrial setup, possible production capacity, and the proximity to natural resources, warehouses, and prior and subsequent supply stages.

As seen in

Figure 4, supply chain cost and CO

2e of all possible supply chains to be compared can be either relative or actual total values, which influences Step 3. The relative values can fulfil the aim of the SLDM approach by focusing on location- and distance-dependent factors from activities generating different cost and CO

2e among different supply locations. Users can calculate relative values of cost and CO

2e based on the factors in

Figure 2. On the other hand, the actual values can be calculated by including additional activities such as distribution, retailing, consumption, waste management, product design and development, and sales and marketing. Users can use logic models and ABC to reveal these factors. Amounts of manufacturing inputs and outputs, as well as distance and time for sample, product, and manager transportations, are gathered in Step 3. Data for these factors are stored in manufacturing-, logistics-, firm-, reverse logistics-, and recycling-data matrices, whose cells are multiplied with coefficient values from manufacturing-, logistics-, and firm-coefficient matrices. Every data matrix in Step 3 to Step 5 has its own coefficient matrix. The coefficients are beneficial to sensitivity and scenario analyses in Step 10 as they allow for easy changing of factor values and comparison, and are initially set to values of 1.

3.2. Step 4 and Step 5: Data Collection on Cost and Emission Factors

Cost and Emission factors (EFs) of the identified factors in Step 3 for each potential location in Step 2 are stored in cost and EF matrices whose cells are multiplied with coefficient values from their own cost- and EF-coefficient matrices. EFs of the main GHGs to be collected are CO

2, CH

4, and N

2O EFs, which can be found online, for example, on the websites of Greenhouse Gas Protocol [

44] and The Intergovernmental Panel on Climate Change (IPCC) [

45]. Users need to collect EFs for different locations from the same source for comparable results. The CO

2, CH

4, and N

2O EFs are normalized into the same unit, which is CO

2e, by multiplying the Global Warming Potential (GWP) by the CO

2, CH

4, and N

2O EFs, as shown in Equation (1).

where GWP

CO2, GWP

CH4, and GWP

N2O from the IPCC fifth assessment report are 1, 28, and 265, respectively.

3.3. Step 6 and Step 7: Supply Chain Cost and CO2e Computation

Each of the possible supply chains has its supply chain cost or CO

2e of producing one-batch products by summing all factor costs from all activities within the identified computational scope in Step 1. CO

2e computation involves the italicized factors shown in

Figure 2. Based on the identified scope, activities, and the number of supply stages and suppliers in each stage, supply chain cost and CO

2e of the three scopes can be calculated by Equation (2).

where

i represents each supply stage of

N, the total number of supply stages;

j represents each supplier in each supply stage, and

S is the maximum number of the total number of required suppliers in each

ith supply stage;

CM,

CL,

CF,

CRL, and

CR are accumulated costs or CO

2e of factors from activities relating to manufacturing (CM) at a factory, logistics (CL) from a factory, firms’ sustainability assurance (CF) involving a factory, reverse-logistics (CRL) to a factory, and recycling process (CR).

Each factor cost or CO2e from the activities is calculated by multiplying its factor value from Step 3 with its cost rate from Step 4, or its normalized CO2, CH4, and N2O EFs from Step 5. Indirect and fixed costs or CO2e are allocated into a production batch using ABC. Time-based costs are allocated by using factory operating time per day and per month, rather than 24 h and 30 days, respectively.

3.4. Step 8: Supply Chain Analysis on Important Factors and Proximity among Stages

This step adopts exploratory data analysis to reveal important factors influencing supply chain costs and CO2e, as well as which supply chain stages should be agglomerated or be in proximity to each other in order to achieve very low cost and CO2e supply chains, and ultimately what those locations are. Therefore, the SLDM approach helps users not only with supply location decisions, but also with supply chain planning on possible future disruptions and investing resources to find and establish relationships with proper suppliers from the locations that generate very low cost and CO2e. Agglomeration between supply stages in the approach refers to either two suppliers for subsequent supply stages located in the same area (resembling business clusters), or one supplier performing manufacturing of two supply stages (resembling vertical integration).

All possible supply chains are ranked by cost and CO2e from the lowest to the highest values. Users choose a set of supply chains to be analyzed based on their cost and CO2e preferences, as well as any constraints. After that, stacked column charts of the supply chains are plotted to reveal important factors influencing total costs and CO2e. Cross-tabulation of agglomeration or proximity between two supply chain stages and their common countries or continents shows which supply chain stages should be agglomerated or located in proximity in order to achieve supply chains with preferred cost and CO2e. Cross-tabulation can also be used to compare results of different markets and computational scopes in order to find their common supply chains. Comparing results of different computational scopes also aids users in seeing the feasibility of adopting a firm’s sustainability assurance and recycling activities.

3.5. Step 9: Supply Chain Selection Based on an Objective Function

As shown in

Figure 1, Step 9 has options A and B. Option A is for selecting a supply chain with the lowest cost or the lowest CO

2e that are known from supply chain cost and CO

2e rankings in Step 8, while Option B is for selecting an optimized low-cost and CO

2e supply chain by scatter plotting. The scatter plot between cost and CO

2e of all alternatives reveals a Pareto frontier containing optimized low cost and CO

2e supply chains, which represents cost and CO

2e trade-off solutions for conflicting multi-criteria [

35]. The optimized supply chains on the Pareto frontier can be found automatically by coding Pareto computational methods into a program. Alternatively, optimized supply chains can be found manually by identifying the supply chain with the lowest value of a selected criterion on either the x-axis or y-axis, and then identifying the next optimized supply chain with the next lowest value of the same criterion from supply chains located between the previously identified supply chain and zero in the scatter plot. Repeat this until reaching the supply chain with the lowest value of the other criterion. Users can choose a final supply chain based on their cost and CO

2e preferences and constraints. Users can also choose a set of optimized supply chains to look for suppliers and then use other criteria to choose a final supply chain, such as relatively superior knowledge and technology, optimal collaboration or existing relationships with suppliers, government support and trade policies, and political situations of manufacturing areas. As shown in

Figure 1, results of sensitivity and scenario analyses in Step 10 will serve as feedback to this step to help in choosing a supply chain which has high resistance to risk and changing environments. Additionally, different markets may have common and different optimized supply chains which can be revealed by cross-tabulation.

3.6. Step 10: Evaluation on Outcome Robustness and Resistance to Risks

This step evaluates the robustness and resistance to risk of outcomes and the selected supply chains by sensitivity and scenario analyses. Various what-if situations are generated by changing coefficients of each factor value possibly affecting supply chains. This helps users foresee risk impact on supply chain/location attractiveness and competitiveness [

38] in terms of cost and CO

2e.

Sensitivity analysis is performed by changing coefficients of each factor value in either all locations at once, or each location at a time, to imitate global and local disruptions, respectively. The results of the sensitivity analysis help users recognize important factors, including risk factors, which make the selected supply chains in Step 9 less competitive. Risk factors are those for which small changes in factor coefficients cause the selected supply chain to lose its cost and CO2e competitiveness or to violate the user’s cost or CO2e preferences and constraints.

Scenario analysis is performed by changing a coefficient of a factor at different levels to represent different scenarios of possible future problems which arise from current situations, such as trade wars, and from important factors revealed in Step 8 and in this step by the sensitivity analysis. Common results of different scenarios should be chosen because they have high resistance to changing environments that help avoid the switching costs of changing suppliers for new supply chains in the future and ensure smooth operations [

46].

4. Application for Selecting Supply Locations of Viscose T-Shirts

We choose to apply our proposed approach in the textile and clothing industry, as we have expertise and insights into the industry, benefiting the application. Viscose t-shirts were selected due to the possibility to generate several possible supply chains and scenarios. T-shirts are a basic product without specialized manufacturing-skill requirements, affording a high degree of flexibility in finding various potential manufacturing locations in proximity to or far from warehouse and materials supply locations. Together with worldwide viscose fiber production with controlled quality due to man-made materials, viscose t-shirts can have several comparable possible supply chain configurations. Regarding several possible scenarios, t-shirts allow both repetitive and non-repetitive production scenarios because t-shirts are basic products that usually have continuous demand, except for some styles and materials with low sales. Of note, details of calculation, data inputs, and results are shown in the

Appendix A–C.

4.1. Step1: Identification of Core Aspects

We identify core aspects shown in

Figure 4. The purpose of this application is to design a new supply chain for producing 1800 t-shirts to serve the main market in Europe with consideration of future markets in US and China. We assume that headquarters and a warehouse of the focal firm are at the same location in Germany because it is the main market for the European clothing industry [

47]. The objective is to optimize cost and CO

2e within the 10,000-euro budget and with the least possible CO

2e. Analysis levels for proximity and agglomeration between supply chain stages are at the country and continent levels. Due to a new supply chain, there are no specific and previous data from suppliers to be collected. Therefore, all collected data are generic and publicly available at the country or city level. The computational scope is the firm scope based on industrial practices of visiting factories regularly and rarely having in-house recycling programs. Additionally, headquarters have in-house garment design with nominated materials and suppliers, and as such, suppliers must send samples to headquarters and laboratories for quality assurance. The computational outputs are relative values of supply chain cost and CO

2e. Regarding organizational contexts, there are three supply stages with one major supplier in each stage. As mentioned before, as viscose t-shirts have the possibility of low sales, the cost and CO

2e computation will start with a one-batch scenario followed by six-, twelve-, and eighteen-batch scenarios for one-, two-, and three-year sales of the same product, respectively. We will observe important factors, potential locations of each supply stage, and proximity and agglomeration among supply chain stages.

4.2. Step 2: Location Identification

Starting with fiber production locations, we assumed six potential locations of fiber manufacturing based on manufacturing locations of the Lenzing Company, which uses environmentally friendly manufacturing technology. Fabric and garment manufacturing have the same potential locations as fiber manufacturing and warehouse and headquarters in Germany, as shown in

Figure 5. The other potential fabric and garment manufacturing locations are selected due to country reputation and availability of viscose fabric and t-shirt manufacturing from online searches. To observe the effects of local, nearshoring, and offshoring manufacturing to supply chain cost and CO

2e, we sampled the locations based on cost and distance to Germany. In total, there are 1536 potential supply chain configurations from 6 fiber manufacturing locations, 16 fabric manufacturing locations, and 16 garment manufacturing locations.

Hereafter, acronyms of locations in

Figure 5 will be used when mentioning three-tier supply locations of a supply chain. For example, AT-EG-LT refers to fiber manufacturing in Austria, fabric manufacturing in Egypt, and garment manufacturing in Lithuania.

4.3. Step 3: Factor and Their Value Identification

In accordance with the firm scope identified in Step 1, we considered factors shown in

Figure 2, from fiber, fabric, to garment manufacturing stages. Fabric manufacturing includes thread spinning, knitting, and dyeing. Garment manufacturing includes cutting and sewing. The inputs and outputs of each process are calculated based on inventory data in the Angelstam, et al. [

48] study by starting with 360 kg of 1800 t-shirts. This allows us to find the transported weights of fabrics and fibers, which are 442.64 and 540.02 kg, respectively. The fiber quantity is used for finding energy use in fiber manufacturing based on the Shen and Patel [

49] study. Fabric dyeing and cutting machine capacities are based on studies of Amin [

50] and Phakphonhamin and Chudokmai [

51]. Operation time is assumed to be 6.48 min per t-shirt [

52].

Based on Step 2, only Austrian fiber manufacturing uses the environmentally friendly manufacturing technology, which provides much lower amounts of non-renewable energy use (NREU) than the normal technology in the other locations. We also consider cost and CO

2e from electricity used in wastewater treatment that are calculated based on the study of Yin et al. [

53]. Distance and delivery time between locations for assigned transportation mode are obtained from Searates.com, a logistics provider’s website. Trucking is used for domestic transportation in China and between factories and ports for international transportation by ship, as well as international transportation between Germany, Italy, Poland, and Lithuania. International transportation between the other locations uses shipping. More manufacturing data are in

Table A1,

Table A2,

Table A3,

Table A4,

Table A5,

Table A6,

Table A7 and

Table A8 in

Appendix A.

4.4. Step 4 and Step 5: Data Collection of Cost and Emission Factors

We searched for the costs of factors related to

Figure 2 online in 2019. Costs of employees to train themselves and write reports for the certificate and auditing, as well as costs of managers to visit factories, are calculated based on employees’ time spent on the activities; the costs are allocated into one-batch production using ABC, based on the number of years that the certificate is valid, factory working time for one-batch production, and the number of manufacturing batches before a new factory visit by a manager from headquarters. Cost data in details are in

Table A9,

Table A10,

Table A11,

Table A12,

Table A13,

Table A14,

Table A15,

Table A16,

Table A17,

Table A18,

Table A19,

Table A20,

Table A21 and

Table A22 in

Appendix A.

Electricity EFs of each country are obtained from emissions per kWh of electricity consumed shown in the Brander et al. [

54] technical paper. EFs of NREU, renewable energy use (REU), landfill gas, good transportation by truck and ship, and passenger car for domestic travelling of managers to visit factories are from an excel sheet provided by Greenhouse Gas Protocol [

44]. Without using EFs for CO

2e calculation, kgCO

2e of sample delivery and flights for a manager to visit factories are from the DHL carbon calculator on its website, as well as from the flight search function of the FlyGreen website [

55].

4.5. Step 6 and Step 7: Supply Chain Cost and CO2e Computation

We multiplied factor values from Step 3 by cost rates and EFs from Steps 4 and 5, respectively, to get costs and CO

2e from manufacturing, logistics, and firm activities involved in each supply stage. Detailed calculation of these costs and CO

2e is shown in

Appendix B. After that, the costs and CO

2e are input into Equation (2) to compute supply chain costs and CO

2e of all 1536 possible supply chains for the European market. As we stated in Step 1 regarding the future markets in China and US, we also calculated another two sets of costs and CO

2e of 1536 possible supply chains for the Chinese and US markets. Selected results of the three markets are shown in the next steps.

4.6. Step 8: Supply Chain Analysis

In this step, we focus on only the current market in Europe; therefore, we ranked all 1536 possible supply chains of the European market from the lowest to the highest values of cost and CO

2e. After that, we select the 1% lowest-value supply chains, as shown in

Table A23 in

Appendix C, to analyze important factors as well as potential locations and proximity among supply chain stages.

Stacked column charts are used to break down costs and CO

2e from all activities along each supply chain to reveal which factors significantly influence the supply chain costs and CO

2e, as shown in

Figure A1 and

Figure A2 in

Appendix C. Cost of visiting factories (in terms of a manager’s compensation) is the greatest influence of the supply chain cost, followed by fiber price, fiber transport, transportation cost of visiting factories, and fabric overhead of administrative employees, including manager and their social security contribution. The high costs of manager compensation and transportation to visit factories can be reduced by repetitive manufacturing before a new factory visit. The effects of repetitive manufacturing on costs and CO

2e will be shown in Step 10 during the scenario analysis on different numbers of manufacturing batches. Of note, the 1% lowest-cost supply chains have agglomerated fabric and t-shirt manufacturing locations in Egypt, Tunisia, Turkey, and Poland, which are relatively lower cost countries located in proximity to warehouse and headquarters in Germany. The results highlight that paying relatively high transportation cost of materials to have components and product manufacturing in a relatively low cost country located in proximity to the market helps achieve very low cost supply chains. This contributes to the Weber [

25] theory by adding international location aspects with different manufacturing costs and three supply stages.

The stacked column chart of the 1% lowest-CO

2e supply chains shows that fiber REU significantly influences the firm-scope CO

2e of the 16 lowest CO

2e supply chains, followed by fiber NREU. The results highlight the importance of environmentally friendly technology in fiber manufacturing to achieve very low CO

2e. All 16 lowest CO

2e supply chains have fiber manufacturing in Austria, the only location with environmentally friendly technology. Electricity EFs and proximity to Germany, implying lower transportation emissions, are important factors to fabric and garment manufacturing locations of very low CO

2e supply chains. This is evidenced by the fact that half of the 16 lowest CO

2e supply chains have fabric and garment manufacturing in Germany rather than America, Thailand, and Bangladesh, whose electricity EFs are smaller than Germany’s. The CO

2e stacked column chart also demonstrates that transportation CO

2e rates are much lower than manufacturing CO

2e rates. This calls for attention to proper interpretations on the reduction of GHG emissions in some countries, such as high reduction of European industrial GHG emissions [

56]. The reduction can be from migrating European industries and industrial emissions to other relatively lower cost countries rather than effective policies, infrastructure, and technology to reduce world CO

2e. Therefore, consumption-based accounting is a good alternative for calculation carbon dioxide emissions [

57]. Moreover, manufacturing products for European consumers in other countries possibly increases total GHG emissions due to longer transportation and unclean sources of energy.

Agglomeration and proximity analyses on the 16 lowest cost and CO

2e supply chains are shown in

Table 3. Fabric and garment manufacturing locations in the same countries, especially in Tunisia and Egypt, show high possibilities to achieve very low cost supply chains, while proximity among all supply chain stages in Europe helps achieve very low CO

2e supply chains.

4.7. Step 9: Supply Chain Selection

Based on the objective, we plot all 1536 supply chains in a scatter plot between cost and CO

2e to find optimized cost and CO

2e supply chains which are located on its Pareto frontier line, as shown in

Figure A3 in

Appendix C. The results show ten optimized supply chains, six of which have costs within the budget. Ultimately, we selected Poland and Austria for t-shirt/fabric production and fiber sourcing, respectively (AT-PL-PL), because this supply chain has the lowest CO

2e. Of note, five of the ten optimized supply chains have fiber, fabric, and garment manufacturing in Europe, while the other five supply chains have fabric and garment manufacturing in Africa with Austrian, US, and Indonesian fibers. This shows that the supply locations of the optimized supply chains are similar to the locations of very low cost and CO

2e supply chains in terms of the proximity between fabric and garment manufacturing, and that their locations are in proximity to Germany.

To ensure the selected supply chain can serve the future markets in China and America, we use cross-tabulation among Pareto-optimized supply chains of all three markets, as shown in

Table 4.

Table 4 shows that the selected AT-PL-PL supply chain exceeds the 10,000-euro budget when producing 1800 t-shirts to be delivered to the Chinese and US markets. Therefore, we select a new supply chain that uses Austrian fibers to produce fabrics and t-shirts in Egypt (AT-EG-EG) because this represents the lowest CO

2e optimized supply chain within budget.

4.8. Step 10: Supply Chain Evaluation by Sensitivity and Scenario Analyses

We perform sensitivity analysis as a validation procedure [

31]. The application outcomes in terms of the lowest cost and CO

2e supply chains are robust when increasing or decreasing coefficient values of the following manufacturing factors by 25 percent: productivity, solid waste amounts, percentages of profits and factory overheads, and interest rates.

When changing coefficients of each cost factor in all locations or one location at a time by 25 percent, the lowest cost supply chain (US-EG-EG) is affected by changing values of fiber prices and transportation costs. The results show that fabric and garment manufacturing in Egypt will still be the best alternative location for achieving the lowest cost supply chain, but fibers would have to be sourced from Indonesia instead of America. Other fiber manufacturing locations aside from Great Britain will be fiber locations of the new lowest cost supply chain if their prices decrease. Furthermore, Tunisia will become the fabric and garment manufacturing location instead of Egypt after decreasing Tunisian operator wages, ship freight to Tunisia, or manager and transportation costs to visit factories in Tunisia, or after increasing ship freight to Egypt or manager and transportation costs to visit Egypt. Changes of the following factors do not change the lowest cost supply chain: truck fees, duty fees of fibers, fabrics, and garments from and to every location, indirect labor wages, wood prices for onsite energy, electricity fees, rent, solid waste management fees, certificate fees and implementation, sample delivery, lab test fees, and hotel costs during factory visits.

When changing coefficients of each CO2e factor at all locations or one location at a time, only increasing CO2e of factory-visiting flights to Austria or all locations at once changes the lowest CO2e supply chain to have fabric and garment manufacturing in Germany instead of Austria. The lowest CO2e supply chain remains the same after changing values of the following factors by 25 percent: CO2, CH4, and N2O EFs of NRUE, REU, solid waste landfill, truck vehicle, and ship vessels, and CO2e of sample delivery.

To see whether the selected optimized supply chain (AT-EG-EG) has high resistance to changing environments, we changed the coefficients of each manufacturing and cost factor relating to Austrian and Egyptian manufacturing, logistics, and sustainability assurance activities until the firm-scope cost of the supply chain exceeded the 10,000-euro budget. The results are in

Table 5 and show that the selected supply chain has high resistance to all of the factor changes.

As mentioned in Step 8, different scenarios will be created by varying the number of manufacturing batches to see their effects on supply chain costs and CO

2e. Scatter plotting in Step 9B is used to find optimized supply chains of 6-, 12-, and 18-manufacturing batches that are compared by cross-tabulation as shown in

Table 6. High numbers of manufacturing batches allow costs of sustainability assurance activities to be allocated into several product units across the number of manufacturing batches leading to lower costs per batch.

Table 6 shows that after increasing the number of batches to a certain level, per-batch cost and CO

2e do not decrease significantly. Cost and CO

2e of one-batch manufacturing are much higher than those of 6-, 12-, and 18-batch manufacturing. This demonstrates the importance of calculating cost and CO

2e from sustainability assurance activities for products with low numbers of manufacturing units and batches per factory visit.

Table 6 also shows that the more manufacturing batches, the more Pareto-optimized supply chains exist. There are six common optimized supply chains among 1-, 6-, 12-, and 18-manufacturing batches, and three of them have costs within budget. Out of the three, AT-EG-EG is the only one applicable to all three markets. This step confirms that the selected supply chain (AT-EG-EG) has high resistance to different markets and number of manufacturing batches.

5. Conclusions, Contributions, Limitations, and Implications

This paper proposes a strategic supply location decision-making (SLDM) approach for systematically analyzing and selecting multi-tier supply locations of a product supply chain, taking into consideration triple bottom line (TBL) sustainability and resistance to risk and changing environments. Its development is based on industrial practices and problems as well as literature relating to supply location decisions and network design, and cost and carbon dioxide equivalents (CO2e) modelling. Adopting key aspects from existing studies and expert opinions, as well as iteratively developing and applying the previous version of the approach in product supply chains, helps improve the SLDM approach and increase its validity and reliability. Following the ten steps of the approach for application in the viscose t-shirt supply chain allows us to find, within specified cost constraints, the lowest and optimized cost and CO2e supply chains for two different scenarios: first, with one supply chain that supplies all markets; and second, with separate supply chains for each market. Sensitivity and scenario analyses demonstrate the approach’s capability in delivering robust and high-resistance outcomes to changing factor values and environments.

The application reveals that agglomerated fabric and garment manufacturing located in a relatively low-cost country in Africa in proximity to a German warehouse and headquarter helps achieve very low cost supply chains, while proximity among fiber, fabric, and garment manufacturing located in European countries, whose emission factors of consumed energy and electricity are low, helps achieve very low CO2e supply chains. Fiber manufacturing technology highly influences supply chain CO2e while sustainability-assurance activities performed by focal firms highly influence supply chain costs especially of products with a low ratio of production units per factory visit by the focal firm. The application shows the potential and pragmatic validity of the approach for aiding users to choose a supply chain configuration which enhances positive impact and attempts to reduce negative impact on each TBL dimension of sustainability, based on users’ cost and CO2e constraints and preferences, as well as organizational contexts.

5.1. Research Contributions

The application results show that the approach can deliver answers to both research questions on finding the lowest or optimized low cost and CO2e supply chains for different markets and their important cost and CO2e factors, including potential risks. By considering cost and CO2e from sustainability assurance activities that are overlooked by existing studies which calculated cost and CO2e in supply chains, our approach differentiates itself from the other cost and CO2e computation methods in the existing studies. Moreover, its application reveals that supply locations of the lowest cost and CO2e supply chains are not the lowest wage location and the market for zero transportation CO2e. This is because reduced costs of transportation, duty, and factory visits from geographical proximity between fabric and garment manufacturing locations and headquarters outweigh reduced labor costs at factories. Furthermore, sources of energy and electricity for manufacturing activities have more influence on supply chain CO2e than transportation activities. As such, this research contributes to the following:

Supply location and manufacturing decision literature and quantitative decision-making approaches, by proposing a comprehensive supply location decision-making approach with manageable numbers of objective measurement criteria that integrate cost and CO

2e from all business, environmental, and socio-economic factors of sustainability, as there is a need to integrate environmental and social aspects into criteria of sustainable supplier selection with solvable problems [

27].

Computations of cost and CO2e in supply chains for the purpose of comparing supply chains, locations, and products, by considering cost and CO2e from sustainability assurance activities performed by focal firms. These activities have significant influence on supply chain cost and CO2e, especially for products requiring high degrees of control by the focal firms.

Sustainable supply chain management literature, by helping identify which cost and CO2e factors most significantly influence supply chain cost and CO2e. Moreover, readers can identify which of the factors are location- or distance-dependent and thus cannot be improved by manufacturers and focal firms, implying limits to supply chain performance improvements. Manufactures and focal firms will have to rely on other stakeholders, such as governments and logistics providers, to improve the cost and CO2e factors by means such as implementing clean sources of electricity and transportation technology to reduce transportation CO2e.

5.2. Research Limitations, Future Research Directions, and Practical Implications

The limitation of the SLDM approach is that users have to know their manufacturing activities and related factors, as well as how to quantify cost and CO2e from them. They can learn these from the suggested factors and the pathways of each factor influencing costs and CO2e and each TBL dimension shown in this paper. Moreover, as the approach usually gives a set of low-cost and CO2e supply chains, users will need to know their cost and CO2e constraints and preferences to effectively choose a final supply chain. This implies that the chosen supply chain is not necessarily the most sustainable. However, most important is that the approach shows focal firms how much the cost of a product should be when it is manufactured with environmental and social compliance, and that they should be skeptical of low product prices quoted by suppliers if the price is much lower than the calculated cost from this approach, as the suppliers may squeeze their costs via environmental and social non-compliance.

Another limitation of this paper is that the application does not include socio-economic measurement criteria. As mentioned in the model formulation section and in the pathway figure, future research can measure human health impact from CO2e and contribution to gross domestic production at each supply stage. These measures will help link business, environmental, and socio-economic dimensions of sustainability. Furthermore, if users evaluate and compare existing supply chains, different supply chains and suppliers may have, for example, different manufacturing technologies, productivity, and difficulty in collaboration; therefore, due to the flexibility of the approach, users can adjust coefficients of manufacturing consumption among different locations and add extra relevant costs which are not suggested in this paper. Moreover, users may use our approach to find a set of low cost and CO2e supply chains and select a final supply chain from them with qualitative criteria and approach.

Another limitation is the difficulty of data collection, though this can be lowered by choosing only one or two main suppliers per each supply stage with a limited number of potential locations. Governments can help overcome the difficulty by having a database providing all cost and emission factor data, such as electricity emission factors, import taxes, and prices of industrial water, electricity, waste collection and treatment, in order to support research and practices on sustainable supply network design, potentially resulting in industrial and sustainability improvement.

The purpose of showing the model application is to demonstrate how to use the model with real data in practice, as well as the model’s potential to reveal the lowest or optimized cost and CO2e supply chains, their most important factors, and possible local and global risks that impact the lowest cost and CO2e supply chains. Readers should bear in mind that the results of the model application, such as the locations of the lowest cost and CO2e supply chains and the landed cost and CO2e, cannot be generalized because they are specific to the settings of the application in terms of product type and material, sampled locations, manufacturing consumption, and focal firm organizational contexts which influence which activities and their factors to include into supply chain cost and CO2e calculation. Additionally, future research may test the SLDM approach in other industries, production batch sizes, and locations in order to improve the approach and possibly find patterns of common results among different industries and locations.

The SLDM approach is useful to various groups of practitioners. It allows industrial practitioners to plan and design their supply chain locations with long-term perspectives on risk factors, expansion markets, and future products with different governance levels, manufacturing batches, manufacturing technology, and recycling programs. The approach helps users understand interconnections among supply chain stages, as well as factors, activities, and outcomes leading to supply chain visibility to improve operations of different activities towards TBL sustainability in supply chains. As the sensitivity and scenario analyses during the application demonstrate that some locations cannot compete with others even if their factor values are dramatically changed, policymakers can use the SLDM approach to strategically invest resources in the factors that potentially improve their location competitiveness in terms of cost and CO2e. The approach can help policy makers to realize which location- and distance-dependent factors should be improved to support TBL sustainability.