Environmental Analysis of Sustainable and Traditional Cooling and Lubrication Strategies during Machining Processes

Abstract

1. Introduction

2. Materials and Methods

- (a)

- The first step includes the goal and scope definition of the assessment, as interpreted in ISO 14041 [30]. It includes the purpose of the LCA, the definition of the considered product, and the needed resources to conduct the LCA.

- (b)

- The second step represents the inventory analysis according to ISO 14041. It shows the product’s material flow. It also provides information during all four stages of the product’s life in regard to input quantities, consumed amounts of different types of energy and water, and consumed resources during transportation during each of the product’s four life stages.

- (c)

- The third step is the impact assessment according to ISO 14042 [31]. During this step, the environmental and health impacts of products are calculated. This step is considered to be the most important one, due to its crucial impact on the conducted LCA’s results.

- (d)

- The fourth and final step is used to represent the results interpolation according to ISO 14043 [32]. Results of conducted LCA are analyzed and conclusions are provided to the end-user.

2.1. The System Boundary of the Cooling Strategies

2.2. IMPACT 2002+

2.3. Functional Unit

3. Results and Discussion

3.1. Life Cycle Assessment (LCA) of Conventional Cutting Fluids

3.2. LCA of Vegetable Oils

3.3. LCA of Nano-Cutting Fluids

3.3.1. Nanoparticle Synthesis

Molybdenum Disulfide (MoS2) Nanoparticle Synthesis

Multi-Walled Carbon Nanotubes (MWCNTs) Nanoparticles Synthesis

Titanium Dioxide (TiO2) Nanoparticles Synthesis

Aluminum Oxide (Al2O3) Nanoparticles Synthesis

3.3.2. Preparation Process of Nano-Cutting Fluids

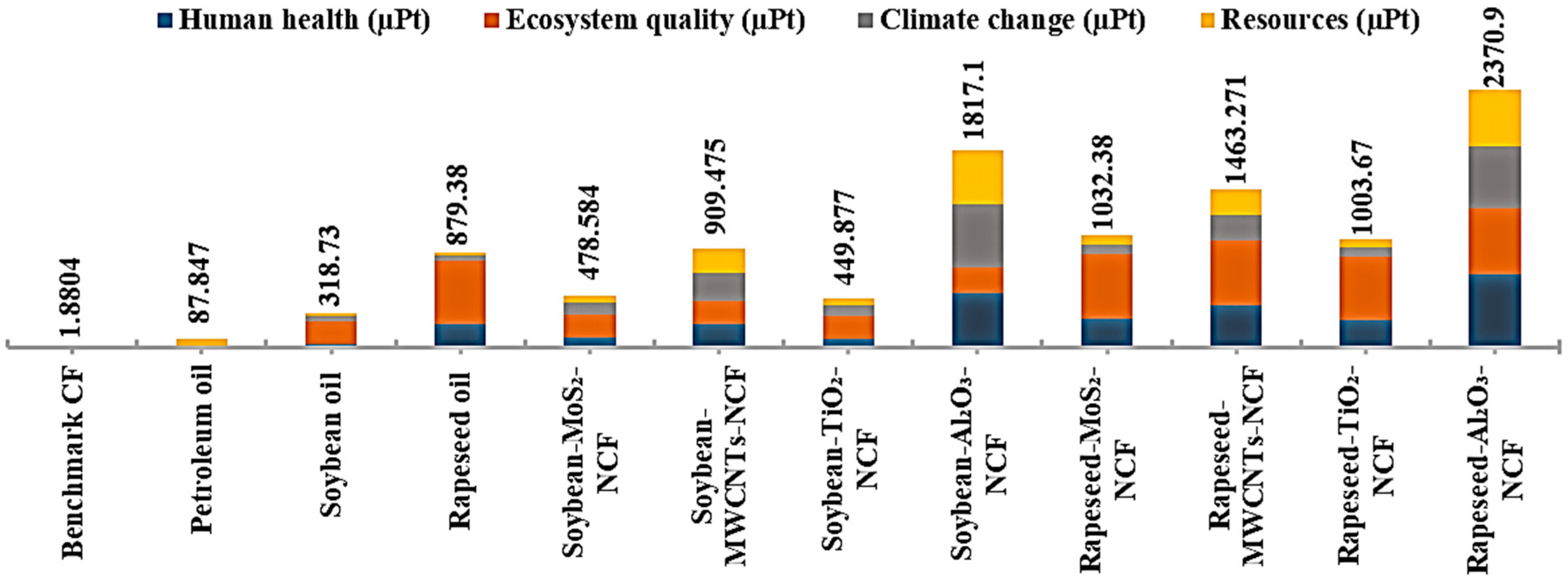

3.4. LCA Comparison of Cutting Fluids

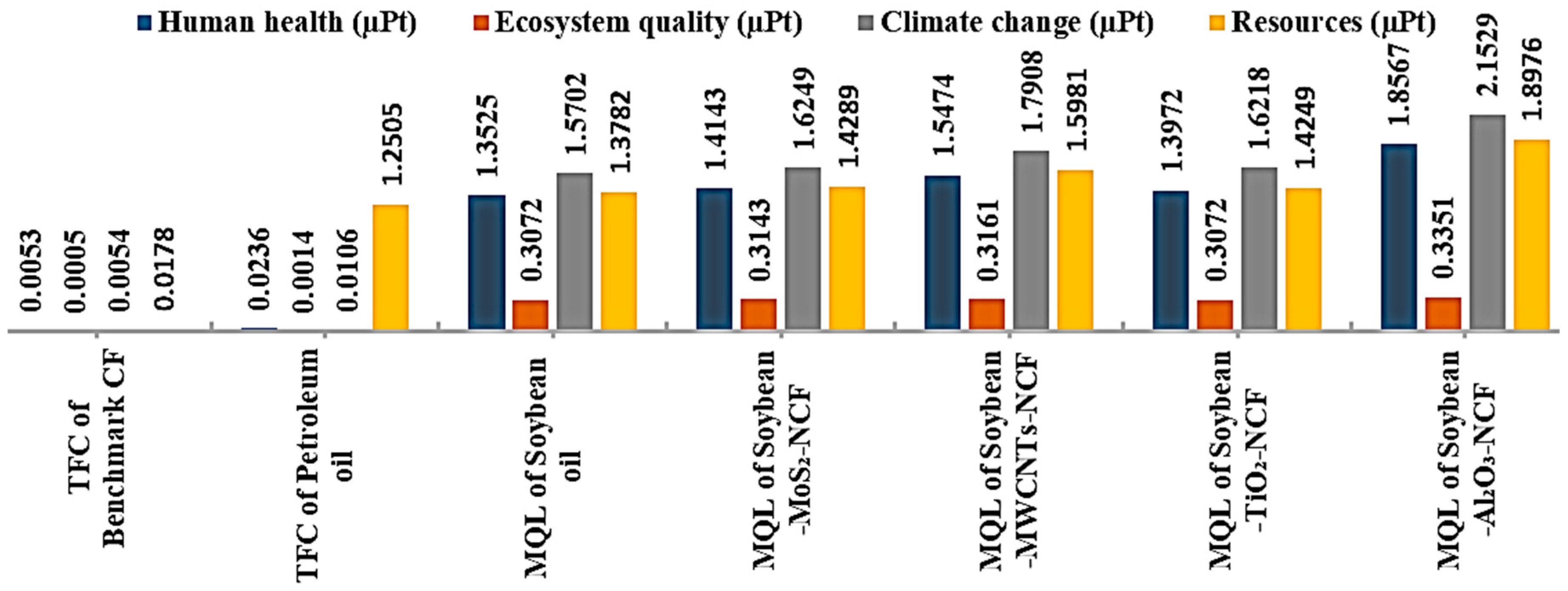

3.5. LCA of Cooling Strategies

4. Overall Evaluation of the Cooling Strategies

5. Conclusions and Future Work

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Çakīr, O.; Yardimeden, A.; Ozben, T.; Kilickap, E. Selection of cutting fluids in machining processes. J. Achiev. Mater. Manuf. Eng. 2007, 25, 99–102. [Google Scholar]

- Debnath, S.; Reddy, M.M.; Yi, Q.S. Environmental friendly cutting fluids and cooling techniques in machining: A review. J. Clean. Prod. 2014, 83, 33–47. [Google Scholar] [CrossRef]

- Adler, D.; Hii, W.-S.; Michalek, D.; Sutherland, J. Examining the role of cutting fluids in machining and efforts to address associated environmental/health concerns. Mach. Sci. Technol. 2006, 10, 23–58. [Google Scholar] [CrossRef]

- Sharma, V.S.; Singh, G.; Sørby, K. A review on minimum quantity lubrication for machining processes. Mater. Manuf. Process. 2015, 30, 935–953. [Google Scholar] [CrossRef]

- Najiha, M.; Rahman, M.; Yusoff, A. Environmental impacts and hazards associated with metal working fluids and recent advances in the sustainable systems: A review. Renew. Sustain. Energy Rev. 2016, 60, 1008–1031. [Google Scholar] [CrossRef]

- Abubakr, M.; Abbas, A.T.; Tomaz, I.; Soliman, M.S.; Luqman, M.; Hegab, H. Sustainable and Smart Manufacturing: An Integrated Approach. Sustainability 2020, 12, 2280. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Hegab, H.; Saad, E. Design for sustainable manufacturing: Approach, implementation, and assessment. Sustainability 2018, 10, 3604. [Google Scholar] [CrossRef]

- Lawal, S.; Choudhury, I.; Nukman, Y. Application of vegetable oil-based metalworking fluids in machining ferrous metals—A review. Int. J. Mach. Tools Manuf. 2012, 52, 1–12. [Google Scholar] [CrossRef]

- Singh, R.K.; Sharma, A.K.; Dixit, A.R.; Tiwari, A.K.; Pramanik, A.; Mandal, A. Performance evaluation of alumina-graphene hybrid nano-cutting fluid in hard turning. J. Clean. Prod. 2017, 162, 830–845. [Google Scholar] [CrossRef]

- Lee, K.; Hwang, Y.; Cheong, S.; Choi, Y.; Kwon, L.; Lee, J.; Kim, S.H. Understanding the role of nanoparticles in nano-oil lubrication. Tribol. Lett. 2009, 35, 127–131. [Google Scholar] [CrossRef]

- Khandekar, S.; Sankar, M.R.; Agnihotri, V.; Ramkumar, J. Nano-cutting fluid for enhancement of metal cutting performance. Mater. Manuf. Process. 2012, 27, 963–967. [Google Scholar] [CrossRef]

- Shahnazar, S.; Bagheri, S.; Hamid, S.B.A. Enhancing lubricant properties by nanoparticle additives. Int. J. Hydrogen Energy 2016, 41, 3153–3170. [Google Scholar] [CrossRef]

- Uysal, A.; Demiren, F.; Altan, E. Applying minimum quantity lubrication (MQL) method on milling of martensitic stainless steel by using nano MoS2 reinforced vegetable cutting fluid. Procedia Soc. Behav. Sci. 2015, 195, 2742–2747. [Google Scholar] [CrossRef]

- Amrita, M.; Srikant, R.; Sitaramaraju, A. Performance evaluation of nanographite-based cutting fluid in machining process. Mater. Manuf. Process. 2014, 29, 600–605. [Google Scholar] [CrossRef]

- Sen, B.; Mia, M.; Krolczyk, G.; Mandal, U.K.; Mondal, S.P. Eco-friendly cutting fluids in minimum quantity lubrication assisted machining: A review on the perception of sustainable manufacturing. Int. J. Precis. Eng. Manuf. Green Technol. 2019, 1–32. [Google Scholar] [CrossRef]

- Benedicto, E.; Carou, D.; Rubio, E. Technical, economic and environmental review of the lubrication/cooling systems used in machining processes. Procedia Eng. 2017, 184, 99–116. [Google Scholar] [CrossRef]

- Wusiman, K.; Jeong, H.; Tulugan, K.; Afrianto, H.; Chung, H. Thermal performance of multi-walled carbon nanotubes (MWCNTs) in aqueous suspensions with surfactants SDBS and SDS. Int. J. Heat Mass Transf. 2013, 41, 28–33. [Google Scholar] [CrossRef]

- Hegab, H.; Umer, U.; Soliman, M.; Kishawy, H.A. Effects of nano-cutting fluids on tool performance and chip morphology during machining Inconel 718. Int. J. Adv. Manuf. Technol. 2018, 96, 3449–3458. [Google Scholar] [CrossRef]

- Das, A.; Patel, S.; Biswal, B.; Sahoo, N.; Pradhan, A. Performance evaluation of various cutting fluids using MQL technique in hard turning of AISI 4340 alloy steel. Measurement 2020, 150, 107079. [Google Scholar] [CrossRef]

- Rapeti, P.; Pasam, V.K.; Gurram, K.M.R.; Revuru, R.S. Performance evaluation of vegetable oil based nano cutting fluids in machining using grey relational analysis-A step towards sustainable manufacturing. J. Clean. Prod. 2018, 172, 2862–2875. [Google Scholar] [CrossRef]

- Gupta, M.K.; Jamil, M.; Wang, X.; Song, Q.; Liu, Z.; Mia, M.; Hegab, H.; Khan, A.M.; Collado, A.G.; Pruncu, C.I. Performance Evaluation of Vegetable Oil-Based Nano-Cutting Fluids in Environmentally Friendly Machining of Inconel-800 Alloy. Materials 2019, 12, 2792. [Google Scholar] [CrossRef]

- Sen, B.; Mia, M.; Gupta, M.K.; Rahman, M.A.; Mandal, U.K.; Mondal, S.P. Influence of Al2O3 and palm oil–mixed nano-fluid on machining performances of Inconel-690: IF-THEN rules–based FIS model in eco-benign milling. Int. J. Adv. Manuf. Technol. 2019, 103, 3389–3403. [Google Scholar] [CrossRef]

- Salem, A.; Hegab, H.; Kishawy, H.; Rahnamayan, S. Multi-objective Optimization During Sustainable Machining of Difficult-to-Cut Materials. In Proceedings of the Joint Canadian Society for Mechanical Engineering and CFD Society of Canada International Congress 2019, London, ON, Canada, 2–5 June 2019. [Google Scholar]

- Deorsola, F.; Russo, N.; Blengini, G.; Fino, D. Synthesis, characterization and environmental assessment of nanosized MoS2 particles for lubricants applications. Chem. Eng. J. 2012, 195, 1–6. [Google Scholar] [CrossRef]

- Krajnik, P.; Pusavec, F.; Rashid, A. Nanofluids: Properties, applications and sustainability aspects in materials processing technologies. In Advances in Sustainable Manufacturing; Springer: Heidelberg, Germany, 2011; pp. 107–113. [Google Scholar]

- Campitelli, A.; Cristóbal, J.; Fischer, J.; Becker, B.; Schebek, L. Resource efficiency analysis of lubricating strategies for machining processes using life cycle assessment methodology. J. Clean. Prod. 2019, 222, 464–475. [Google Scholar] [CrossRef]

- Mia, M.; Gupta, M.K.; Lozano, J.A.; Carou, D.; Pimenov, D.Y.; Królczyk, G.; Khan, A.M.; Dhar, N.R. Multi-objective optimization and life cycle assessment of eco-friendly cryogenic N2 assisted turning of Ti-6Al-4V. J. Clean. Prod. 2019, 210, 121–133. [Google Scholar] [CrossRef]

- Gupta, M.K.; Song, Q.; Liu, Z.; Pruncu, C.I.; Mia, M.; Singh, G.; Lozano, J.A.; Carou, D.; Khan, A.M.; Jamil, M. Machining characteristics based life cycle assessment in eco-benign turning of pure titanium alloy. J. Clean. Prod. 2020, 251, 119598. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Inaba, A.; Tan, R.; Christiansen, K.; Klüppel, H.-J. The new international standards for life cycle assessment: ISO 14040 and ISO 14044. Int. J. Life Cycle Assess. 2006, 11, 80–85. [Google Scholar] [CrossRef]

- Ekvall, T.; Finnveden, G. Allocation in ISO 14041—A critical review. J. Clean. Prod. 2001, 9, 197–208. [Google Scholar] [CrossRef]

- Ryding, S.-O. ISO 14042 Environmental management* Life cycle assessment* life cycle impact assessment. Int. J. Life Cycle Assess. 1999, 4, 307. [Google Scholar] [CrossRef]

- Lecouls, H. ISO 14043: Environmental management· life cycle assessment· life cycle interpretation. Int. J. Life Cycle Assess. 1999, 4, 245. [Google Scholar] [CrossRef]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in life cycle assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Menoufi, K.A.I. Life Cycle Analysis and Life Cyle Impact Assessment Methodologies: A State of the Art. 2011. Available online: http://hdl.handle.net/10459.1/45831 (accessed on 13 October 2020).

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. IMPACT 2002+: A new life cycle impact assessment methodology. Int. J. Life Cycle Assess. 2003, 8, 324. [Google Scholar] [CrossRef]

- Padmini, R.; Krishna, P.V.; Rao, G.K.M. Effectiveness of vegetable oil based nanofluids as potential cutting fluids in turning AISI 1040 steel. Tribol. Int. 2016, 94, 490–501. [Google Scholar] [CrossRef]

- Hegab, H. Towards Sustainable Machining of Difficult-to-Cut Materials Using Nano-Cutting Fluids. Ph.D. Thesis, University of Ontario Institute of Technology, Oshawa, ON, Canada, 2018. [Google Scholar]

- Zhu, D.; Li, X.; Wang, N.; Wang, X.; Gao, J.; Li, H. Dispersion behavior and thermal conductivity characteristics of Al2O3–H2O nanofluids. Curr. Appl. Phys. 2009, 9, 131–139. [Google Scholar] [CrossRef]

- Ginting, Y.; Boswell, B.; Biswas, W.; Islam, M.N. Advancing environmentally conscious machining. Procedia Cirp 2015, 26, 391–396. [Google Scholar] [CrossRef]

- Clarens, A.F.; Zimmerman, J.B.; Keoleian, G.A.; Hayes, K.F.; Skerlos, S.J. Comparison of life cycle emissions and energy consumption for environmentally adapted metalworking fluid systems. Environ. Sci. Technol. 2008, 42, 8534–8540. [Google Scholar] [CrossRef] [PubMed]

- Sahasrabudhe, S.N.; Rodriguez-Martinez, V.; O’Meara, M.; Farkas, B.E. Density, viscosity, and surface tension of five vegetable oils at elevated temperatures: Measurement and modeling. Int. J. Food Prop. 2017, 20, 1965–1981. [Google Scholar] [CrossRef]

- Griffiths, O.G.; O’Byrne, J.P.; Torrente-Murciano, L.; Jones, M.D.; Mattia, D.; McManus, M.C. Identifying the largest environmental life cycle impacts during carbon nanotube synthesis via chemical vapour deposition. J. Clean. Prod. 2013, 42, 180–189. [Google Scholar] [CrossRef]

- Grubb, G.F.; Bakshi, B.R. Life cycle of titanium dioxide nanoparticle production: Impact of emissions and use of resources. J. Ind. Ecol. 2011, 15, 81–95. [Google Scholar] [CrossRef]

- Ojeda, K.A.; Herrera, A.P.; Sierra, M.J.; Tamayo, K. Environmental impact study by life cycle assessment of the use of alumina nanoparticles as an additive in biodiesel/diesel blends. Ing. Compet. 2015, 17, 133–142. [Google Scholar]

- Ali, N.; Teixeira, J.A.; Addali, A. A review on nanofluids: Fabrication, stability, and thermophysical properties. J. Nanomater. 2018, 2018, 6978130. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

| Midpoint Impact Category | Unit | Damage Category | Unit | Normalization Factor |

|---|---|---|---|---|

| Carcinogens | kg C2H3Cl eq | Human health | DALY | 141 |

| Non-carcinogens | kg C2H3Cl eq | |||

| Respiratory inorganics | kg PM2.5 eq | |||

| Ionizing radiation | Bq C-14 eq | |||

| Ozone layer depletion | kg CFC-11 eq | |||

| Photochemical oxidation | kg C2H4 eq | |||

| Ecosystem | PDF * m2 * yr | 0.000073 | ||

| Aquatic ecotoxicity | kg TEG water | |||

| Terrestrial ecotoxicity | kg TEG soil | |||

| Terrestrial nutrification | kg SO2 eq | |||

| Land occupation | m2 org.arable | |||

| Aquatic acidification | kg SO2 eq | |||

| Aquatic eutrophication | kg PO4 eq | |||

| Global warming | kg CO2 eq | Climate change | kg CO2 eq | 0.000101 |

| Non-renewable energy | MJ primary | Resources | MJ primary | 0.00000658 |

| Mineral extraction | MJ surplus |

| Inputs | Quantity |

|---|---|

| Ammonium molybdate | 1.2 g |

| Citric acid | 2.52 g |

| Ammonium sulfide | 3.51 g |

| Electricity use | 0.15 MJ |

| Output | Quantity |

| Ammonium citrate | 0.27 g |

| Inputs | Quantity |

|---|---|

| Ferrocene | 0.2 g |

| Toluene | 10 mL |

| Argon (stage 2, stage 3, and stage 4 for 7 h) | 450 sccm for 4 h, 50 sccm for 3 h |

| Hydrogen (stage 3 for 1 h) | 0.287 g |

| HCl (37% volume solution) | 20 mL |

| Energy consumption | 1.32192 kWh |

| Outputs | Quantity |

| Toluene | 3014 mg |

| Benzene | 496 mg |

| Methane | 0.4 mg |

| Inputs | Quantity |

|---|---|

| Ilmenite | 2.165 kg |

| Iron powder | 0.103 kg |

| Hydrochloric acid | 0.065 kg |

| Methane | 0.866 kg |

| Steam | 14.948 kg |

| Energy consumption | 52.895 MJ |

| Inputs | Quantity |

|---|---|

| Aluminum nitrate | 7.98 g |

| Citric acid | 4.47 g |

| Water vapor | 253.819 g |

| Electricity use | 11.695 kWh |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salem, A.; Hopkins, C.; Imad, M.; Hegab, H.; Darras, B.; Kishawy, H.A. Environmental Analysis of Sustainable and Traditional Cooling and Lubrication Strategies during Machining Processes. Sustainability 2020, 12, 8462. https://doi.org/10.3390/su12208462

Salem A, Hopkins C, Imad M, Hegab H, Darras B, Kishawy HA. Environmental Analysis of Sustainable and Traditional Cooling and Lubrication Strategies during Machining Processes. Sustainability. 2020; 12(20):8462. https://doi.org/10.3390/su12208462

Chicago/Turabian StyleSalem, Amr, Connor Hopkins, Mohamd Imad, Hussien Hegab, Basil Darras, and Hossam A. Kishawy. 2020. "Environmental Analysis of Sustainable and Traditional Cooling and Lubrication Strategies during Machining Processes" Sustainability 12, no. 20: 8462. https://doi.org/10.3390/su12208462

APA StyleSalem, A., Hopkins, C., Imad, M., Hegab, H., Darras, B., & Kishawy, H. A. (2020). Environmental Analysis of Sustainable and Traditional Cooling and Lubrication Strategies during Machining Processes. Sustainability, 12(20), 8462. https://doi.org/10.3390/su12208462