A Sensorless Wind Speed and Rotor Position Control of PMSG in Wind Power Generation Systems

Abstract

:1. Introduction

- (1)

- Magnetic flux detection technique by integration of voltage;

- (2)

- Techniques using state estimators;

- (3)

- Control method using Kalman filter.

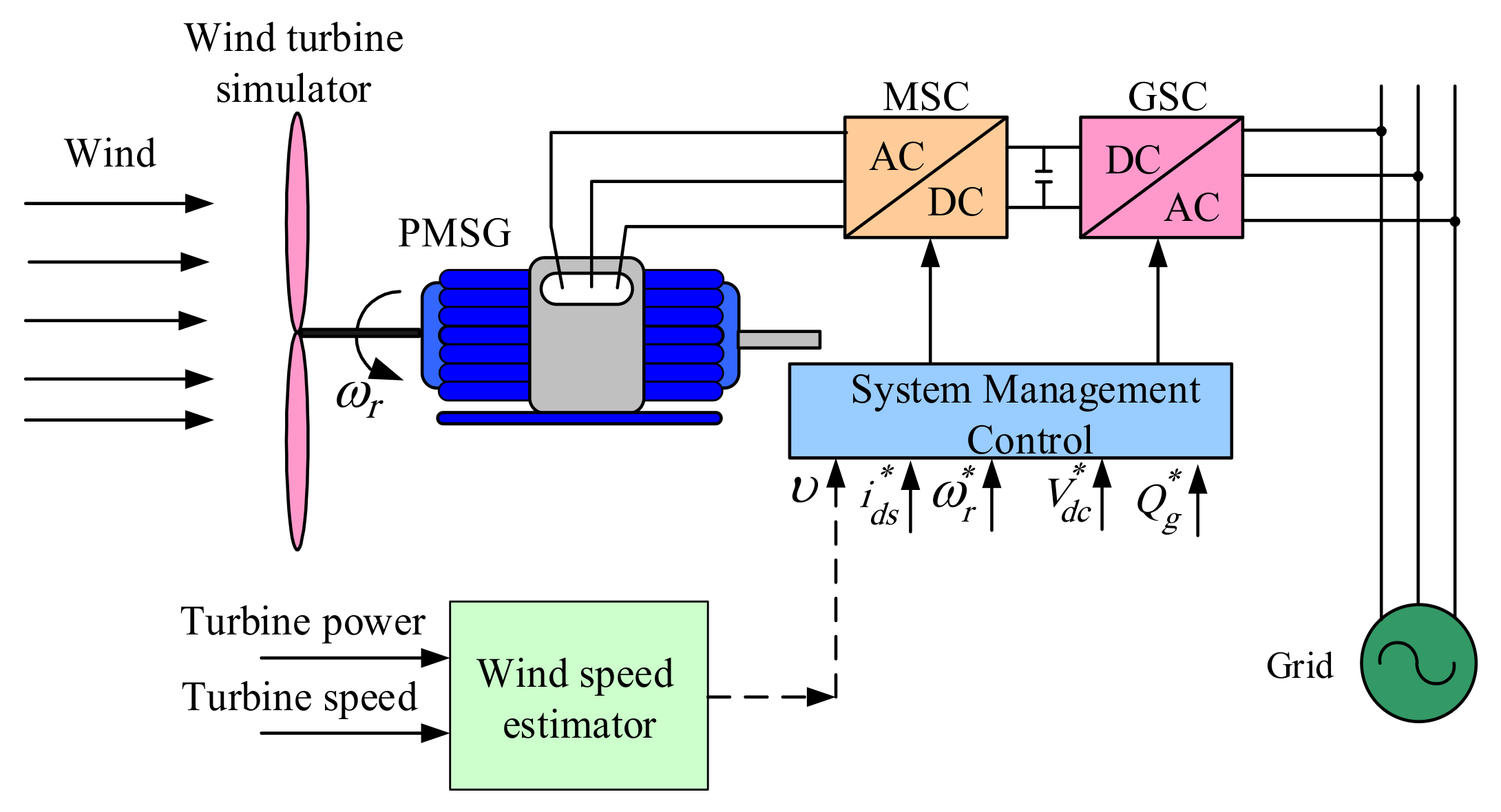

2. System Description

2.1. Wind Turbine Modeling

2.2. PMSG Modeling and Control

2.3. Grid-Side Control

3. Wind Speed Estimation

3.1. Support Vector Regression

3.2. The O-Particle Swarm Optimization

4. Experimental Results

5. Discussions and Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Parameters | Value |

|---|---|

| Stator resistance | 0.93 Ω |

| Rotor resistance | 0.533 Ω |

| Iron loss resistance | 190 Ω |

| Stator leakage inductance | 0.003 H |

| Rotor leakage inductance | 0.003 H |

| Mutual inductance | 0.076 H |

| Parameters | Value |

|---|---|

| Rated power | 2.7 kW |

| Rated speed | 1200 rpm |

| Number of poles | 6 |

| Rated current | 9.5 A |

| Stator resistance | 0.5 Ω |

| Stator inductance | 5.5 mH |

References

- Salah, M.M.; Abo-Khalil, A.G.; Praveen, R. Wind speed characteristics and energy potential for selected sites in Saudi Arabia. J. King Saud. Univ. Eng. Sci. 2019. [Google Scholar] [CrossRef]

- Morimoto, S.; Nakayama, H.; Sanada, M.; Takeda, Y. Sensorless output maximization control for variable-speed wind generation system using IPMSG. IEEE Trans. Ind. Appl. 2005, 41, 60–67. [Google Scholar] [CrossRef]

- Gonzalez, L.G.; Figueres, E.; Garcera, G.; Carranza, O.; Gonzalez-Espin, F. Synchronization techniques comparison for sensorless control applied to pmsg. In Proceedings of the International Conference on Renewable Energies and Power Quality (ICREPQ 09), Barcelona, Spain, 8–10 September 2009; pp. 978–980. [Google Scholar]

- Jiang, D.; Zhao, Z.; Wang, F. A sliding mode observer for pmsm speed and rotor position considering saliency. In Proceedings of the Power Electronics Specialists Conference, PESC 2008, Rhodes, Greece, 15–19 June 2008; pp. 809–814. [Google Scholar]

- Xiang, X.; He, Y. Sensorless vector control operation of a pmsm by rotating high-frequency voltage injection approach. In Proceedings of the International Conference on Electrical Machines and Systems (ICEMS), Seoul, South Korea, 8–11 October 2007; pp. 752–756. [Google Scholar]

- Fan, S. A new sensorless control strategy used in direct-drive pmsg wind power system. In Proceedings of the IEEE International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Hefei, China, 16–18 June 2010; pp. 611–615. [Google Scholar]

- Yang, S.; Zhang, X.; Zhang, C.; Xie, Z.; Li, F. Sensorless control for pmsg in direct-drive wind turbines. In Proceedings of the IEEE International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Hefei, China, 16–18 June 2010; pp. 81–84. [Google Scholar]

- Eltamaly, A.M.; Alolah, A.I.; Abdel-Rahman, M.H. Improved simulation strategy for DFIG in wind energy applications. Int. Rev. Model. Simul. 2011, 4, 525–532. [Google Scholar]

- Abo-Khalil, A.G.; Lee, D.C. Optimal Efficiency Control of Wind Generation System Using Fuzzy Logic Control. In Proceedings of the KIEE Conference; The Korean Institute of Electrical Engineers: Seoul, Korea, 2005. [Google Scholar]

- Senjyu, T.; Tamaki, S.; Urasaki, N.; Uezato, K.; Higa, H.; Funabashi, T.; Fujita, H.; Sekine, H. Wind velocity and rotor position sensorless maximum power point tracking control for wind generation system. Renew. Energy 2006, 31, 1764–1775. [Google Scholar] [CrossRef]

- Zhi, D.; Xu, L.; Williams, B.W. Model-based predictive direct power control of doubly-fed induction generators. Ieee Trans. Power Electron. 2009, 25, 341–351. [Google Scholar]

- Chien-Hung, L.; Yuan-Yih, H. Effect of rotor excitation voltage on steady-state stability and maximum output power of a doubly-fed induction generator. IEEE Trans. Ind. Electron. 2010, 58, 1096–1109. [Google Scholar]

- Rahimi, M.; Parniani, M. Transient Performance Improvement of Wind Turbines With Doubly Fed Induction Generators Using Nonlinear Control Strategy. IEEE Trans. Energy Convers. 2009, 25, 514–525. [Google Scholar] [CrossRef]

- Ali, M.E. Modeling of wind turbine driving permanent magnet generator with maximum power point tracking system. J. King Saud Univ.-Eng. Sci. 2007, 19, 223–236. [Google Scholar]

- El-Sousy, F.F.M.; Orabi, M.; Godah, H. Maximum power point tracking control scheme for grid connected variable speed wind driven self-excited induction generator. KIPE J. Power Electron. 2006, 6, 45–51. [Google Scholar]

- Abokhalil, A.G. Grid Connection Control of DFIG for Variable Speed Wind Turbines under Turbulent Conditions. Int. J. Renew. Energy Res. 2019, 9, 1260–1271. [Google Scholar]

- Abo-Khalil, A.G.; Ab-Zied, H. Sensorless Control for DFIG Wind Turbines Based on Support Vector Regression. In Proceedings of the Industrial Electronics Conference IECON, Montreal, QC, Canada, 25–28 October 2012. [Google Scholar]

- Abo-Khalil, A.G.; Lee, D.C.; Seok, J.K. Variable Speed Wind Power Generation System Based on Fuzzy Logic Control for Maximum Output Power Tracking. In Proceedings of the 2004 IEEE 35th Annual Power Electronics Specialists Conference (IEEE Cat. No.04CH37551), Aachen, Germany, 20–25 June 2004; pp. 2039–2043. [Google Scholar]

- Ab-Khalil, A.G. Control system of DFIG for Wind Power Generation Systems; LAP LAMBERT Academic Publishing: Raja, Latvia, 2015; ISBN-10: 3659649813, ISBN-13: 978-3659649813. [Google Scholar]

- Abo-Khalil, A.G.; Kim, H.G.; Lee, D.C.; Seok, J.K. Maximum Output Power Control of Wind Generation System Considering Loss Minimization of Machines. In Proceedings of the 30th Annual Conference of IEEE Industrial Electronics Society, 2004 (IECON 2004), Busan, South Korea, 2–6 November 2004; pp. 1676–1681. [Google Scholar]

- Ma, Z.; Zhang, X. FPGA Implementation of Sensorless Sliding Mode Observer with a Novel Rotation Direction Detection for PMSM Drives. IEEE Access 2018, 6, 55528–55536. [Google Scholar] [CrossRef]

- Flieh, H.; Slininger, T.; Lorenz, R.D.; Totoki, E. Self-Sensing via Flux Injection with Servo Dynamics including a Smooth Transition to Back-EMF Tracking. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018; pp. 1762–1769. [Google Scholar]

- Park, J.; Sandberg, I.W. Universal Approximation Using Radial-Basis-Function Networks. Neural Comput. 1991, 3, 246–257. [Google Scholar] [CrossRef] [PubMed]

- Xu, D.; Wang, B.; Zhang, G.; Wang, G.; Yu, Y. A review of sensorless control methods for AC motor drives. China Electrotech. Soc. Trans. Electr. Mach. Syst. 2018, 2, 104–115. [Google Scholar] [CrossRef]

- Abokhalil, A.G.; Alyami, S.; Sayed, K.; Alhejji, A. Dynamic Modeling of Wind Turbines Based on Estimated Wind Speed under Turbulent Conditions. Energies 2019, 12, 1907. [Google Scholar] [CrossRef] [Green Version]

- Abo-Khalil, A.G.; Alghamdi, A.; Tlili, I.; Eltamaly, A. A Current Controller Design for DFIG-based Wind Turbines Using State Feedback Control. IET Renew. Power Gener. 2019, 13, 1938–1949. [Google Scholar] [CrossRef]

- Strachan, B.P.W.; Jovcic, D. Dynamic Modelling, Simulation and Analysis of an Offshore Variable-Speed Directly-Driven Permanent-Magnet Wind Energy Conversion and Storage System (WECSS). In Proceedings of the OCEANS 2007—Europe, Aberdeen, UK, 18–21 June 2007. [Google Scholar]

- Hansen, A.D.; Michalke, G. Multi-pole permanent magnet synchronous generator wind tubines’ grid support capability in uninterrupted operation during grid faults. IET Renew. Power Gener. 2008, 3, 333–348. [Google Scholar] [CrossRef]

- Dai, J.; Xu, D.D.; Wu, B. A Novel Control Scheme for Current-Source-Converter-Based PMSG Wind Energy Conversion Systems. IEEE Trans. Power Electron. 2009, 24, 963–972. [Google Scholar]

- Jul-Ki Seok, Jong-Kun Lee and Dong-Choon Lee, Sensorless speed control of nonsalient permanent-magnet synchronous motor using rotor-position-tracking PI controller. IEEE Trans. Ind. Electron. 2006, 53, 399–405. [CrossRef]

- Nuller, K.R.; Smola, A.; Ratrch, G.; Scholkopf, B.; Kohlmargen, J.; Vapnik, V. Predicting time series with support vector machine. In Proceedings of the 1997 International Conference on Artificial Neural Networks, Lausanne, Switzerland, 8–10 October 1997; pp. 999–1004. [Google Scholar]

- Schölkopf, B.; Burges, C.J.C.; Smola, A.J. Using support vector support machines for time series prediction. In Advances in Kernel Methods; MIT Press: Cambridge, MA, USA, 1999; pp. 242–253. [Google Scholar]

- Abo-Khalil, A.G.; Lee, D.C. SVR-based wind speed estimation for power control of wind energy generation system. In Proceedings of the Power Conversion Conference, Nagoya, Japan, 2–5 April 2007; pp. 1431–1436. [Google Scholar]

- Cherkassky, V.; Miller, F. Learning from Data Concepts, Theory and Methods; John Wiley & Sons: New York, NY, USA, 1998. [Google Scholar]

- Rastgoufard, S.; Charalampidis, D. Parameter selection of multi-class SVM with evolutionary optimization methods for static security evaluation in power systems. In Proceedings of the IEEE Electrical Power and Energy Conference (EPEC), Ottawa, ON, Canada, 12–14 October 2016. [Google Scholar]

- Abo-Khalil, A.G.; Lee, D.C. Maximum Power Point Tracking Based on Sensorless Wind Speed Using Support vector Regression. IEEE Trans. Ind. Electron. 2008, 55, 678–682. [Google Scholar]

- Abo-Khalil, A.G. Maximum Power Point Tracking Based on Sensorless Wind Speed Using Support Vector Regression. In Proceedings of the Middle East Power Conference MEPCON, Cairo, Egypt, 19–21 December 2010. [Google Scholar]

- Abokhalil, A.G.; Murtaza, G.; Eltamaly, A.M.; Al-Saud, M.S.; RP, P.; Sayed, K.; Bindu, G.R.; Tlili, I. Design of State Feedback Current Controller for Fast Synchronization of DFIG in Wind Power Generation Systems. Energies 2019, 12, 2427. [Google Scholar] [CrossRef] [Green Version]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the International Conference on Neural Networks (ICNN’95), Perth, Australia, 27 November–1 December 1995; pp. 1942–1948. [Google Scholar]

- Eltamaly, A.M.; Al-Saud, M.S.; Abokhalil, A.G.; Farh, H.M. Photovoltaic maximum power point tracking under dynamic partial shading changes by novel adaptive particle swarm optimization strategy. Trans. Inst. Meas. Control. 2019, 42, 104–115. [Google Scholar] [CrossRef]

- Eltamaly, A.M.; Farah, H.; Abo-Khalil, A.G. A novel PSO strategy for improving dynamic change partial shading photovoltaic maximum power point tracker. J. Energy Sources Part A Recovery Util. Environ. Eff. 2020. [Google Scholar] [CrossRef]

- Eltamaly, A.M.; Al-Saud, M.S.; Abokhalil, A.G. A Novel Bat Algorithm Strategy for Maximum Power Point Tracker of Photovoltaic Energy Systems under Dynamic Partial Shading. IEEE Access 2020, 8, 10048–10060. [Google Scholar] [CrossRef]

- Eltamaly, A.M.; Al-Saud, M.S.; Sayed, K.; Abokhalil, A.G. Sensorless Active and Reactive Control for DFIG Wind Turbines Using Opposition-Based Learning Technique. Sustainability 2020, 12, 3583. [Google Scholar] [CrossRef]

- Abokhalil, A.G.; Al-Qawasmi, A.-R.; Eltamaly, A.M.; Yu, B.G. Condition Monitoring of DC-Link Electrolytic Capacitors in PWM Power Converters Using OBL Method. Sustainability 2020, 12, 3719. [Google Scholar] [CrossRef]

- Jabeen, H.; Baig, A.R. Opposition based particle swarm optimization (O-PSO). In Proceedings of the Genetic and Evolutionary Computation Conference (GECCO ‘09), Montreal, QC, Canada, 8–12 July 2009. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abo-Khalil, A.G.; Eltamaly, A.M.; R.P., P.; Alghamdi, A.S.; Tlili, I. A Sensorless Wind Speed and Rotor Position Control of PMSG in Wind Power Generation Systems. Sustainability 2020, 12, 8481. https://doi.org/10.3390/su12208481

Abo-Khalil AG, Eltamaly AM, R.P. P, Alghamdi AS, Tlili I. A Sensorless Wind Speed and Rotor Position Control of PMSG in Wind Power Generation Systems. Sustainability. 2020; 12(20):8481. https://doi.org/10.3390/su12208481

Chicago/Turabian StyleAbo-Khalil, Ahmed G., Ali M. Eltamaly, Praveen R.P., Ali S. Alghamdi, and Iskander Tlili. 2020. "A Sensorless Wind Speed and Rotor Position Control of PMSG in Wind Power Generation Systems" Sustainability 12, no. 20: 8481. https://doi.org/10.3390/su12208481