Struvite Precipitation for Sustainable Recovery of Nitrogen and Phosphorus from Anaerobic Digestion Effluents of Swine Manure

Abstract

1. Introduction

2. Materials and Methods

2.1. Characteristics of Anaerobically Digested Swine Manure

2.2. Struvite Precipitation Experiments

2.3. Estimation of NH4-N and PO4-P Recovery as Struvite from AD Effluents

2.4. Analytical Procedures

3. Results and Discussion

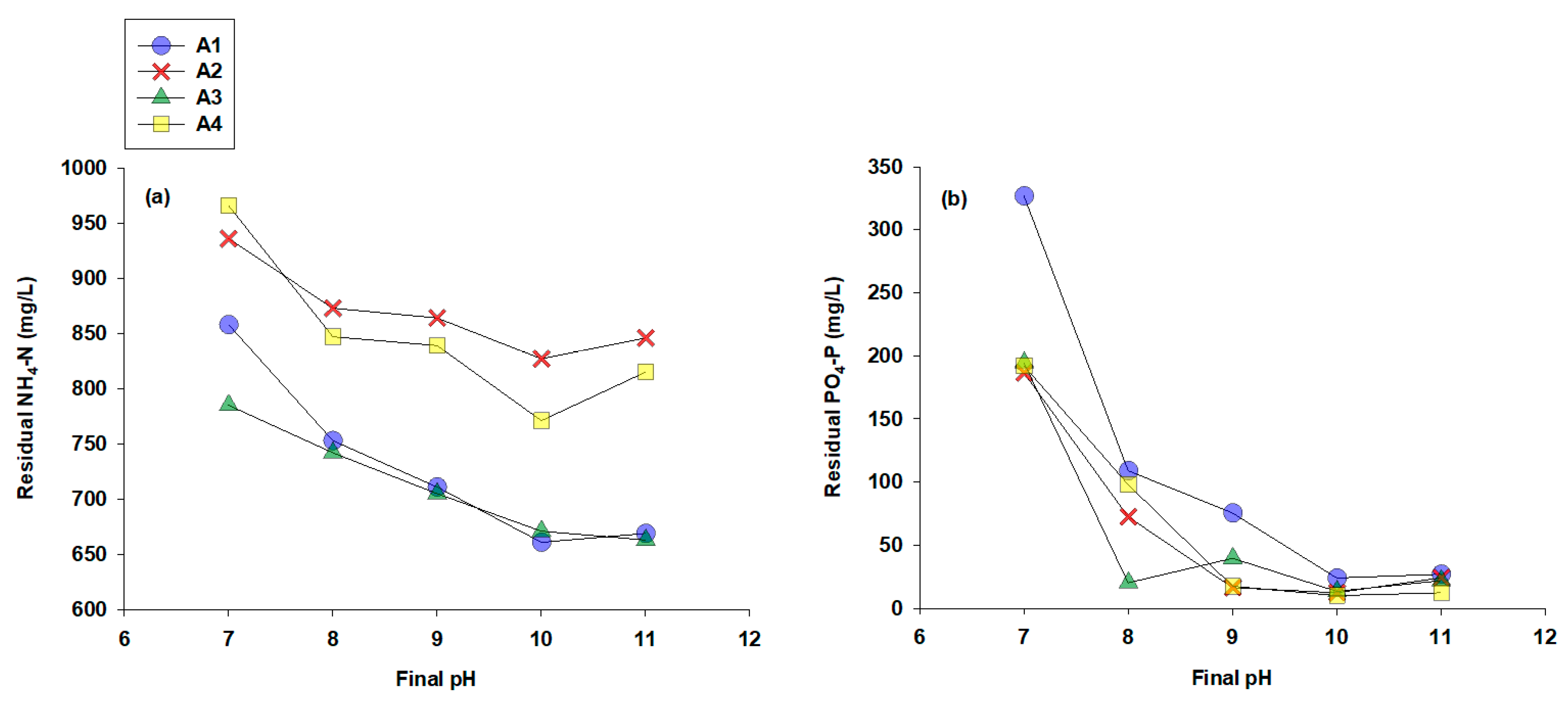

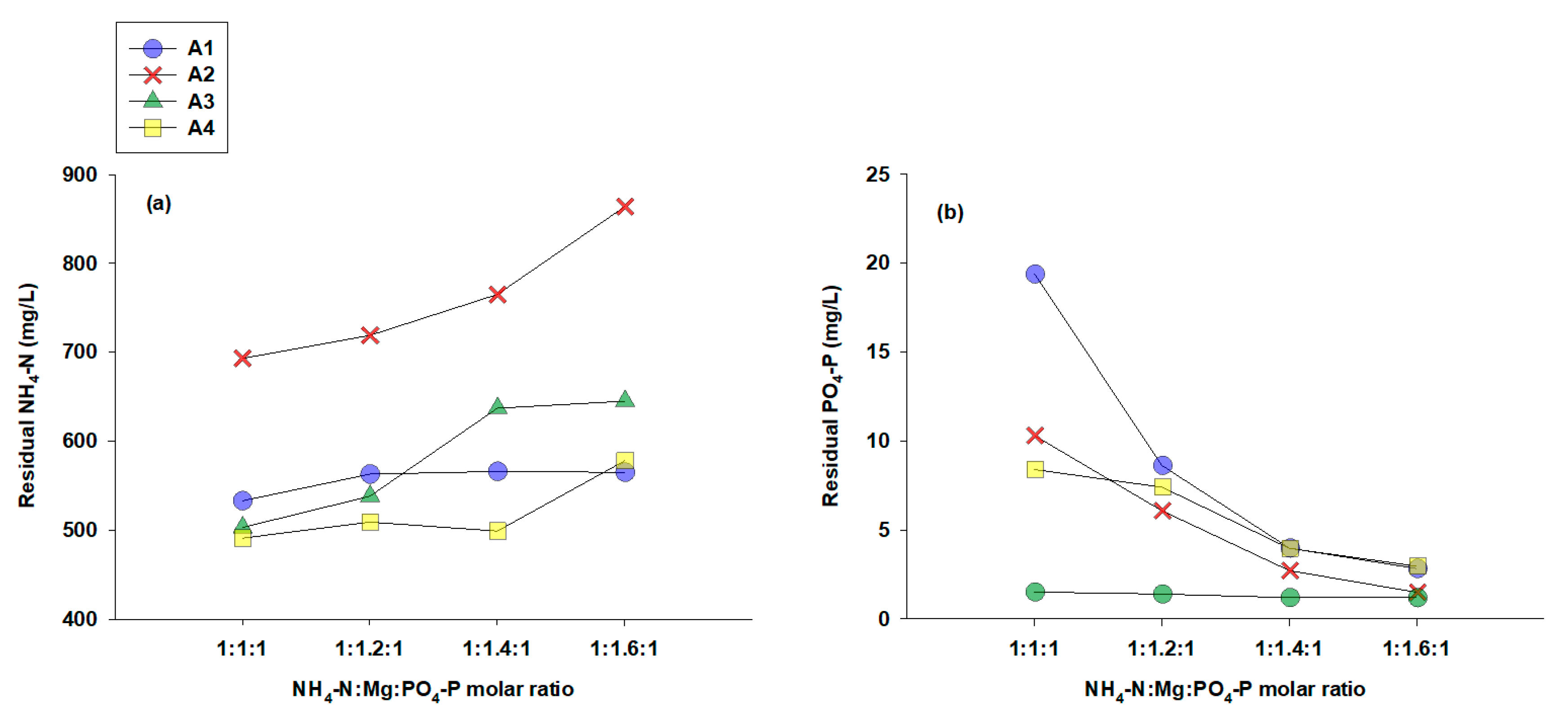

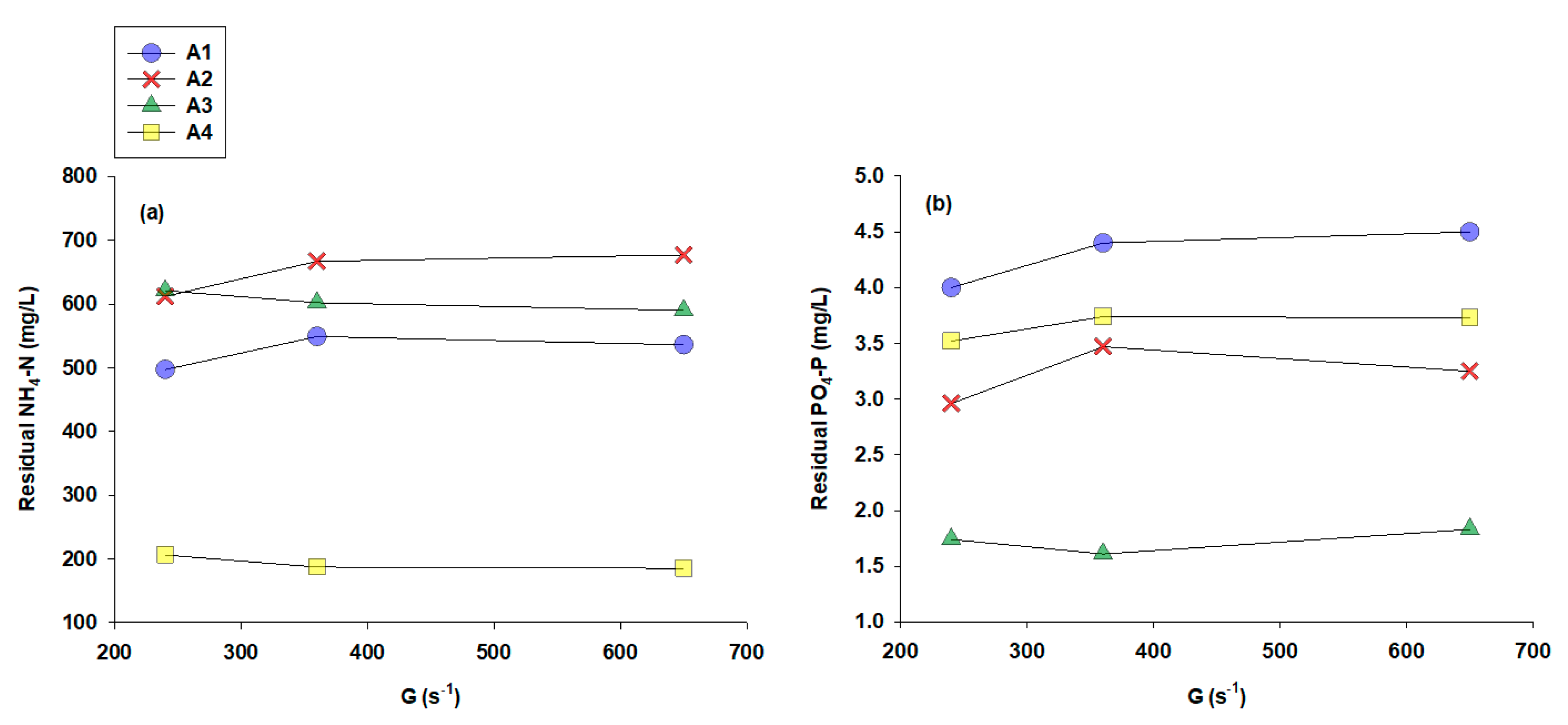

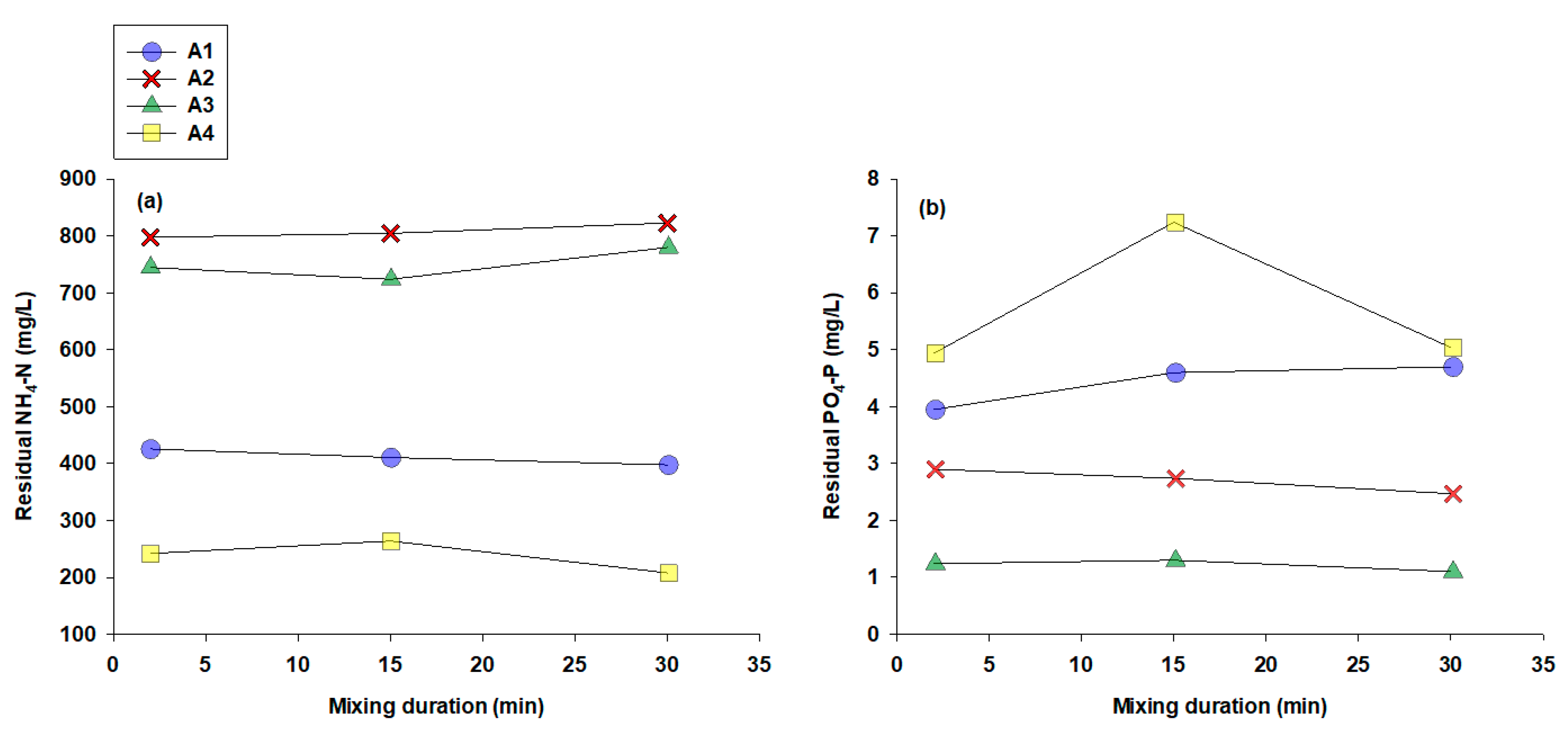

3.1. Optimal Conditions for Struvite Precipitation of AD Effluents from Swine Manure

3.2. Removal of TOC, NH4-N, PO4-P, and Toxic Metals from AD Effluents of Swine Manure under Optimal Conditions

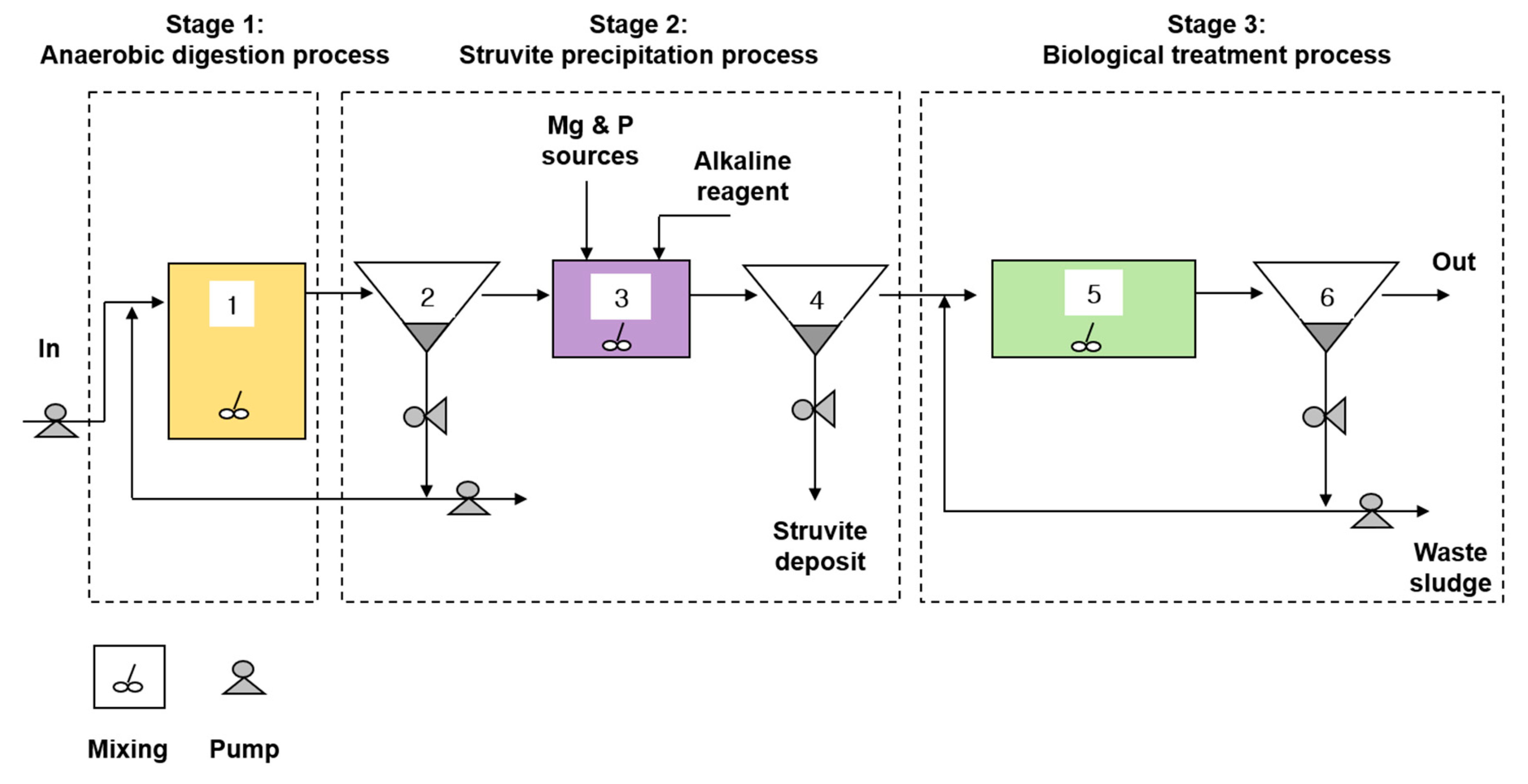

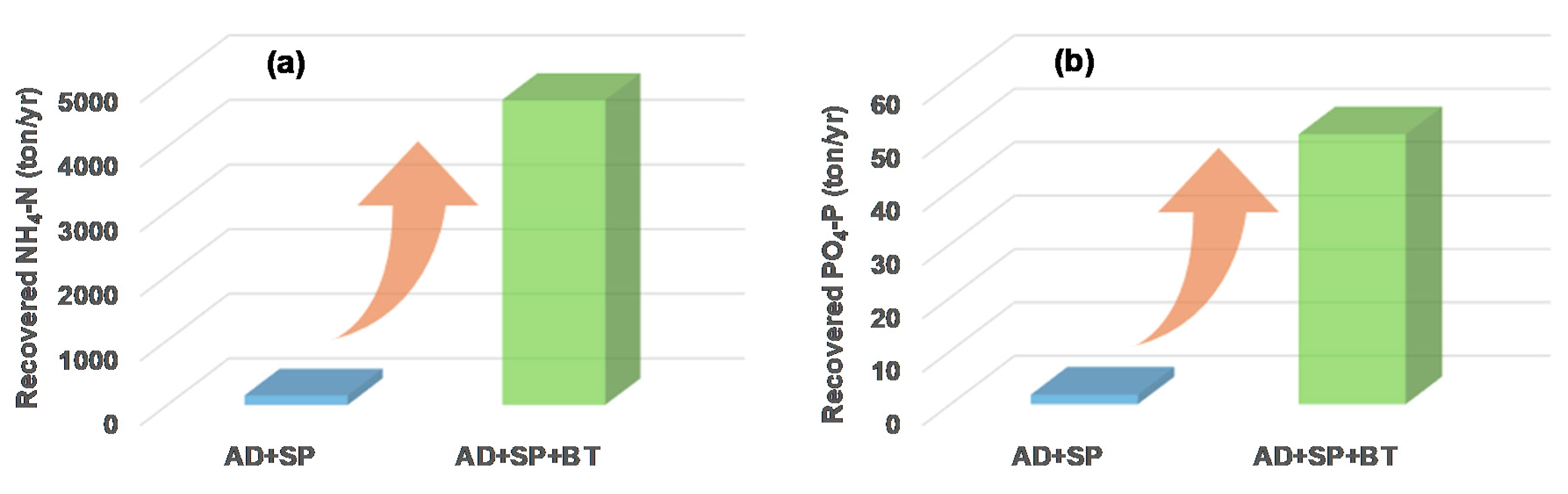

3.3. Application Model of Struvite Precipitation for the Recovery of N and P from Swine Manure

3.4. Economic Analysis of Struvite Recovery When Treating AD Effluents of Swine Manure

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ministry of Environment. The Annual Report to the Nation on the Status of Pollution Sources, 2017; National Institute of Environmental Research: Incheon, Korea, 2019.

- Velthof, G.L.; Hou, Y.; Oenema, O. Nitrogen excretion factors of livestock in the European Union. J. Sci. Food Agric. 2015, 95, 3004–3014. [Google Scholar] [CrossRef]

- Gooddy, D.C.; Lapworth, D.J.; Bennett, S.A.; Heaton, T.H.E.; Williams, P.J.; Surridge, B.W.J. A multi-stable isotope framework to understand eutrophication in aquatic ecosystems. Water Res. 2016, 88, 623–633. [Google Scholar] [CrossRef]

- Zhang, L.; Jahng, D. Enhanced anaerobic digestion of piggery wastewater by ammonia stripping: Effect of alkali types. J. Hazard. Mater. 2010, 182, 536–543. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Lee, Y.W.; Jahng, D. Anaerobic co-digestion of food waste and piggery wastewater: Focusing on the role of trace elements. Bioresour. Technol. 2011, 102, 5048–5059. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Lang, Q.; Wu, S.; Li, W.; Bah, H.; Dong, R. Anaerobic digestion characteristics of pig manures depending on various growth stages and initial substrate concentrations in a scaled pig farm in Southern China. Bioresour. Technol. 2014, 156, 63–69. [Google Scholar] [CrossRef] [PubMed]

- Molinuevo-Salces, B.; Mahdy, A.; Ballesteros, M.; González-Fernández, C. From piggery wastewater nutrients to biogas: Microalgae biomass revalorization through anaerobic digestion. Renew. Energy 2016, 96, 1103–1110. [Google Scholar] [CrossRef]

- Guo, H.G.; Chen, Q.L.; Hu, H.W.; He, J.Z. High-solid anaerobic co-digestion of pig manure with lignite promotes methane production. J. Clean. Prod. 2020, 258, 120695–120705. [Google Scholar] [CrossRef]

- Jin, H.; Chang, Z. Distribution of heavy metal contents and chemical fractions in anaerobically digested manure slurry. Appl. Biochem. Biotechnol. 2011, 164, 268–282. [Google Scholar] [CrossRef]

- Franchino, M.; Tigini, V.; Varese, G.C.; Sartor, R.M.; Bona, F. Microalgae treatment removes nutrients and reduces ecotoxicity of diluted piggery digestate. Sci. Total Environ. 2016, 569–570, 40–45. [Google Scholar] [CrossRef]

- Liu, R.; Chen, L.; Wang, G.; Ye, Z. On the pollution with antibiotics, heavy metals and conventional indicators in digested wastewater from large-scale pig farms in Jiaxing city, China. Environ. Eng. Manag. J. 2016, 15, 2253–2260. [Google Scholar]

- Petersen, S.O.; Sommer, S.G.; Béline, F.; Burton, C.; Dach, J.; Dourmad, J.Y.; Leip, A.; Misselbrook, T.; Nicholson, F.; Poulsen, H.D.; et al. Recycling of livestock manure in a whole-farm perspective. Livest. Sci. 2007, 112, 180–191. [Google Scholar] [CrossRef]

- Zhang, L.; Lee, Y.W.; Jahng, D. Ammonia stripping for enhanced biomethanization of piggery wastewater. J. Hazard. Mater. 2012, 199–200, 36–42. [Google Scholar] [CrossRef] [PubMed]

- OECD Data for Nutrient Balance. Available online: https://data.oecd.org/agrland/nutrient-balance.htm#indicator-chart (accessed on 7 April 2020).

- Tchobanoglous, G.; Burton, F.L. Wastewater Engineering, 4th ed.; McGraw-Hill: New York, NY, USA, 1991. [Google Scholar]

- Deng, L.W.; Zheng, P.; Chen, Z.A. Anaerobic digestion and post-treatment of swine wastewater using IC–SBR process with bypass of raw wastewater. Process Biochem. 2006, 41, 965–969. [Google Scholar] [CrossRef]

- Rajagopal, R.; Rousseau, P.; Bernet, N.; Beline, F. Combined anaerobic and activated sludge anoxic/oxic treatment for piggery wastewater. Bioresour. Technol. 2011, 102, 2185–2192. [Google Scholar] [CrossRef] [PubMed]

- Lotti, T.; Cordola, M.; Kleerebezem, R.; Caffaz, S.; Lubello, C.; van Loosdrecht, M.C. Inhibition effect of swine wastewater heavy metals and antibiotics on anammox activity. Water Sci. Technol. 2012, 66, 1519–1526. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.Z.; Zhang, Q.Q.; Xu, J.J.; Shi, Z.J.; Guo, Q.; Jiang, X.Y.; Wang, H.Z.; Chen, G.H.; Jin, R.C. Long-term effects of heavy metals and antibiotics on granule-based anammox process: Granule property and performance evolution. Appl. Microbiol. Biotechnol. 2016, 100, 2417–2427. [Google Scholar] [CrossRef]

- Buchanan, J.R.; Mote, C.R.; Robinson, R.B. Thermodynamics of struvite formation, Trans. ASAE 1994, 37, 617–621. [Google Scholar] [CrossRef]

- Wikipedia. Available online: https://en.wikipedia.org/wiki/Struvite (accessed on 7 April 2020).

- Yetilmezsoy, K.; Ilhan, F.; Kocak, E.; Akbin, H.M. Feasibility of struvite recovery process for fertilizer industry: A study of financial and economic analysis. J. Clean. Prod. 2017, 152, 88–102. [Google Scholar] [CrossRef]

- Luo, Z.; Wang, D.; Yang, J.; Huang, H.; Su, G. Nitrogen removal from digested piggery wastewater using fermented superphosphate within the pretreatment stage and an MAP fertilizer pot test. J. Clean. Prod. 2019, 152, 88–102. [Google Scholar] [CrossRef]

- Muhmood, A.; Lu, J.; Dong, R.; Wu, S. Formation of struvite from agricultural wastewaters and its reuse on farmlands: Status and hindrances to closing the nutrient loop. J. Environ. Manag. 2019, 230, 1–13. [Google Scholar] [CrossRef]

- Ryu, H.D.; Lee, S.I. Application of struvite precipitation as a pretreatment in treating swine wastewater. Process Biochem. 2010, 45, 563–572. [Google Scholar] [CrossRef]

- Ryu, H.D.; Choo, Y.D.; Kang, M.G.; Lee, S.I. Integrated application of struvite precipitation and biological treatment in treating autothermal thermophilic aerobic digestion supernatant liquid. Environ. Eng. Sci. 2014, 31, 167–175. [Google Scholar] [CrossRef]

- Lee, E.Y.; Oh, M.H.; Yang, S.H.; Yoon, T.H. Struvite crystallization of anaerobic digestive fluid of swine manure containing highly concentrated nitrogen. Asian-Australas. J. Anim. Sci. 2015, 28, 1053–1060. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.; Min, K.J.; Lee, K.; Yu, M.S.; Park, K.Y. Effects of pH, molar ratios and pre-treatment on phosphorus recovery through struvite crystallization from effluent of anaerobically digested swine wastewater. Environ. Eng. Res. 2017, 22, 12–18. [Google Scholar] [CrossRef]

- Kwon, G.; Kang, J.; Nam, J.H.; Kim, Y.O.; Jahng, D. Recovery of ammonia through struvite production using anaerobic digestate of piggery wastewater and leachate of sewage sludge ash. Environ. Technol. 2018, 39, 831–842. [Google Scholar] [CrossRef]

- Uludag-Demirer, S.; Demirer, G.N.; Chen, S. Ammonia removal from anaerobically digested dairy manure by struvite precipitation. Process Biochem. 2005, 40, 3667–3674. [Google Scholar] [CrossRef]

- Perera, P.W.A.; Han, Z.Y.; Chen, Y.X.; Wu, W.X. Recovery of nitrogen and phosphorus as struvite from swine waste biogas digester effluent. Biomed. Environ. Sci. 2007, 20, 343–350. [Google Scholar]

- Perera, P.W.A.; Wu, W.X.; Chen, Y.X.; Han, Z.Y. Struvite recovery from swine waste biogas digester effluent through a stainless steel device under constant pH conditions. Biomed. Environ. Sci. 2009, 22, 201–209. [Google Scholar] [CrossRef]

- Yilmazel, Y.D.; Demirer, G.N. Removal and recovery of nutrients as struvite from anaerobic digestion residues of poultry manure. Environ. Technol. 2011, 32, 783–794. [Google Scholar] [CrossRef]

- Siciliano, A.; De Rosa, S. Recovery of ammonia in digestates of calf manure through a struvite precipitation process using unconventional reagents. Environ. Technol. 2014, 35, 841–850. [Google Scholar] [CrossRef]

- Vidlarova, P.; Heviankova, S.; Kyncl, M. Contribution to the study of ammonia removal from digestate by struvite precipitation. IOP Conf. Ser. Earth Environ. Sci. 2017, 92, 012072–012076. [Google Scholar] [CrossRef]

- Gong, W.; Li, Y.; Luo, L.; Luo, X.; Cheng, X.; Liang, H. Application of struvite-MAP crystallization reactor for treating cattle manure anaerobic digested slurry: Nitrogen and phosphorus recovery and crystal fertilizer efficiency in plant trials. Int. J. Environ. Res. Public Health 2018, 15, 1397. [Google Scholar] [CrossRef] [PubMed]

- Wrigley, T.J.; Webb, K.M.; Venkitachalm, H. A laboratory study of struvite precipitation after anaerobic digestion of piggery wastes. Bioresour. Technol. 1992, 41, 117–121. [Google Scholar] [CrossRef]

- Szymanska, M.; Szara, E.; Sosulski, T.; Was, A.; van Pruissen, G.W.P.; Cornelissen, R.L.; Borowik, M.; Konkol, M. A bio-refinery concept for N and P recovery—A chance for biogas plant development. Energies 2019, 12, 155. [Google Scholar] [CrossRef]

- Nelson, N.O.; Mikkelsen, R.L.; Hesterberg, D.L. Struvite precipitation in anaerobic swine lagoon liquid: Effect of pH and Mg:P ratio and determination of rate constant. Bioresour. Technol. 2003, 89, 229–236. [Google Scholar] [CrossRef]

- Iqbal, M.; Bhuiyan, H.; Mavinic, D.S. Assessing struvite precipitation in a pilot-scale fluidized bed crystallizer. Environ. Technol. 2008, 29, 1157–1167. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Xiao, Q.; Zhong, H.; Zheng, X.; Wei, Y. Effect of organic matter on phosphorus recovery from sewage sludge subjected to microwave hybrid pretreatment. J. Environ. Sci. 2016, 39, 29–36. [Google Scholar] [CrossRef]

- Huang, H.; Liu, J.; Wang, S.; Jiang, Y.; Xiao, D.; Ding, L.; Gao, F. Nutrients removal from swine wastewater by struvite precipitation recycling technology with the use of Mg3(PO4)2 as active component. Ecol. Eng. 2016, 92, 111–118. [Google Scholar] [CrossRef]

- Kim, D.; Ryu, H.D.; Kim, M.S.; Kim, J.; Lee, S.I. Enhancing struvite precipitation potential for ammonia nitrogen removal in municipal landfill leachate. J. Hazard. Mater. 2007, 146, 81–85. [Google Scholar] [CrossRef]

- Cornwell, D.A.; Bishop, M.M. Determining velocity gradients in laboratory and full-scale systems. J. Am. Water Works Assoc. 1983, 75, 470–475. [Google Scholar] [CrossRef]

- Ministry of Environment. Korea Standard Methods for the Examination of Water and Wastewater; National Institute of Environmental Research: Incheon, Korea, 2017.

- Lin, X.; Han, Z.; Yu, H.; Ye, Z.; Zhu, S.; Zhu, J. Struvite precipitation from biogas digestion slurry using a two chamber electrolysis cell with a magnesium anode. J. Clean. Prod. 2018, 174, 1598–1607. [Google Scholar] [CrossRef]

- Taddeo, R.; Honkanen, M.; Kolppo, K.; Lepistö, R. Nutrient management via struvite precipitation and recovery from various agroindustrial wastewaters: Process feasibility and struvite quality. J. Environ. Manag. 2018, 212, 433–439. [Google Scholar] [CrossRef] [PubMed]

- Joko, I. Phosphorus removal from wastewater by the crystallization method. Water Sci. Technol. 1984, 17, 121–132. [Google Scholar] [CrossRef]

- Van Dijk, J.C.; Braakensiek, H. Phosphate removal by crystallization in a fluidized bed. Water Sci. Technol. 1985, 17, 133–142. [Google Scholar] [CrossRef]

- Lee, S.I.; Weon, S.Y.; Lee, C.W.; Koopman, B. Removal of nitrogen and phosphate from wastewater by addition of bittern. Chemosphere 2003, 51, 265–271. [Google Scholar] [CrossRef]

- Stratful, I.; Scrimshaw, M.D.; Lester, J.N. Conditions influencing the precipitation of magnesium ammonium phosphate. Water Res. 2001, 35, 4191–4199. [Google Scholar] [CrossRef]

- Uysal, A.; Yilmazel, Y.D.; Demirer, G.N. The determination of fertilizer quality of the formed struvite from effluent of a sewage sludge anaerobic digester. J. Hazard. Mater. 2010, 181, 248–254. [Google Scholar] [CrossRef] [PubMed]

- Ma, N.; Rouff, A.A. Influence of pH and oxidation state on the interaction of arsenic with struvite during mineral formation. Environ. Sci. Technol. 2012, 46, 8791–8798. [Google Scholar] [CrossRef]

- Rouff, A.A.; Ma, N.; Kustka, A.B. Adsorption of arsenic with struvite and hydroxylapatite in phosphate-bearing solutions. Chemosphere 2016, 146, 574–581. [Google Scholar] [CrossRef]

- Huang, H.; Li, B.; Li, J.; Zhang, P.; Yu, W.; Zhao, N.; Guo, G.; Young, B. Influence of process parameters on the heavy metal (Zn2+, Cu2+ and Cr3+) content of struvite obtained from synthetic swine wastewater. Environ. Pollut. 2019, 245, 658–665. [Google Scholar] [CrossRef]

- Córdoba, V.; Fernández, M.; Santalla, E. The effect of different inoculums on anaerobic digestion of swine wastewater. J. Environ. Chem. Eng. 2016, 4, 115–122. [Google Scholar] [CrossRef]

- Korea Price Research Center, Corp. Available online: https://www.kprc.or.kr (accessed on 14 August 2020).

| Livestock Manure | Initial Concentration (mg/L) | Sources of Mg & P | pH | Molar Ratio of Ions | Mixing Intensity (rpm) | Reaction Time (min) | Removal (%) | Reactor Types | Reference | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| NH4-N | PO4-P | NH4-N | PO4-P | ||||||||

| Swine manure | 589–607 | 21–22 | MgSO4 Fermented super-phosphate | 9.51 | n.a. 2 | 200 | 30 | 55 | 64 | Batch | [23] |

| Swine manure | 2974–3907 | 1120–1468 | MgCl2·6H2O | 8.8 | Mg:PO43− = 1.5:1.0 | 100 | 60 | 40 | 89 | Batch | [27] |

| Swine manure | 1725–1825 | 226–216 | MgCl2·6H2O KH2PO4 | 9.0 | Mg:NH4+:PO43− = 1.2:1.0:1.0 | n.a. | 10 | 95 | 97 | CSTR 3 | [28] |

| Swine manure | 2511–3771 | 54–68 | MgCl2·6H2O Sewage sludge ash | 10.0 | Mg:NH4-N:PO4-P = 1.2:1.0:1.0 | 400 | 60 | 92 | 100 | Batch | [29] |

| Dairy manure | 255–519 | n.a. | MgCl2·6H2O Na2HPO4 | n.a. | Mg:NH4+:PO43− = 2.2:1.0:4.8 | n.a. | n.a. | 95 | n.a. | Batch | [30] |

| Swine manure | 234 | 42 | MgCl2·6H2O KH2PO4 | 9.0 | Mg:NH4+:PO43− = 1.0:1.0:1.0 | 500 | 60 | 71 | 97 | Batch | [31] |

| Swine manure | 296 | 64 | MgCl2·6H2O KH2PO4 | 9.0 | Mg:NH4+:PO43− = 1.2:1.0:1.2 | 500 | 900 | 71 | 97 | Batch | [32] |

| Poultry manure | 4495–4729 | 163 | MgCl2·6H2O 75% H3PO4 | 8.5 | Mg:NH4-N:PO4-P = 1.5:1.0:1.0 | 250 | 30 | 97 | 32 | Batch | [33] |

| Cattle manure & food waste | 1060 | 450 | Bittern Bone meal | 9.0 | Mg:NH4-N:PO4-P = 1.3:1.0:1.3 | 300 | 15 | 91 | 99 | Batch | [34] |

| Swine manure | 1660 | 209 | MgSO4 Na2HPO4·12H2O | 9.0 | Mg:NH4+:PO43− = 1.3:1.0:0.8 | 250 | n.a. | 78 | 6 | Batch | [35] |

| Cattle manure | 100–700 | 10–60 | MgCl2 Na2HPO4 | 10.0 | Mg:NH4-N:PO4-P = 1.6:1.2:1.0 | n.a. | n.a. | 90 | 100 | CSTR | [36] |

| Swine manure | 800 | 10–30 | MgSO4 | 9.0 | n.a. | n.a. | 1440 | n.a. | 75 | Batch | [37] |

| Cattle manure | 3000 | 183 | MgCl2 | 9.0 | n.a. | n.a. | n.a. | n.a. | 44 | CSTR | [38] |

| Facility | Influent Source | Mixing Ratio of Swine Manure to Food Waste | Influent Flow Rate (m3/d) | Post-Treatment of AD Effluent |

|---|---|---|---|---|

| A1 | Swine manure and food waste | 8:2 | 140 | None |

| A2 | Swine manure and food waste | 6:4 | 60 | Biological treatment |

| A3 | Swine manure and food waste | 5:5 | 130 | Biological treatment |

| A4 | Swine manure and food waste | 8:2 | 100 | Biological treatment |

| Parameter | Facility | Mean Value | |||

|---|---|---|---|---|---|

| A1 | A2 | A3 | A4 | ||

| pH | 9.65 | 8.24 | 8.20 | 9.65 | 8.94 ± 0.83 1 |

| TOC 2 (mg/L) | 1961 | 709 | 1085 | 1256 | 1253 ± 524 |

| NH4-N (mg/L) | 1742 | 2110 | 2010 | 1990 | 1963 ± 156 |

| T-N (mg/L) | 2505 | 2697 | 2314 | 2306 | 2455 ± 186 |

| PO4-P (mg/L) | 36.0 | 20.9 | 1.9 | 15.8 | 18.7 ± 14.1 |

| T-P (mg/L) | 402.5 | 74.0 | 14.8 | 62 | 138.3 ± 178.0 |

| As (mg/L) | 0.162 | 0.171 | 0.132 | 0.236 | 0.175 ± 0.044 |

| Cd (mg/L) | 0.021 | 0.020 | n.d. | n.d. | 0.021 ± 0.001 |

| Pb (mg/L) | n.d. | 0.132 | 0.072 | 0.078 | 0.094 ± 0.033 |

| Cu (mg/L) | 9.714 | 1.389 | 0.146 | 0.815 | 3.016 ± 4.494 |

| Zn (mg/L) | 43.858 | 4.772 | 0.416 | 1.679 | 12.681 ± 20.865 |

| Cr (mg/L) | 0.251 | 0.082 | 0.024 | 0.300 | 0.164 ± 0.132 |

| Ni (mg/L) | 0.429 | 0.078 | 0.135 | 0.403 | 0.261 ± 0.181 |

| Parameter | Sample Numbers (n) | Removal (%) | |

|---|---|---|---|

| Value Range | Mean Value | ||

| TOC 1 (mg/L) | 9 | 32.1–89.7 | 57.6 ± 22.0 2 |

| NH4-N | 9 | 62.2–89.6 | 73.7 ± 9.6 |

| PO4-P | 9 | 68.7–89.0 | 83.0 ± 7.4 |

| As | 4 | 23.7–49.0 | 34.8 ± 12.4 |

| Cd | 4 | 0–89.6 | 22.4 ± 44.8 |

| Pb | 4 | 0–75.9 | 28.9 ± 36.0 |

| Cu | 4 | 44.1–97.2 | 74.3 ± 22.1 |

| Zn | 4 | 58.1–97.4 | 79.2 ± 16.9 |

| Cr | 4 | 13.3–100 | 65.7 ± 42.0 |

| Ni | 4 | 12.1–48.7 | 32.1 ± 17.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ryu, H.-D.; Lim, D.Y.; Kim, S.-J.; Baek, U.-I.; Chung, E.G.; Kim, K.; Lee, J.K. Struvite Precipitation for Sustainable Recovery of Nitrogen and Phosphorus from Anaerobic Digestion Effluents of Swine Manure. Sustainability 2020, 12, 8574. https://doi.org/10.3390/su12208574

Ryu H-D, Lim DY, Kim S-J, Baek U-I, Chung EG, Kim K, Lee JK. Struvite Precipitation for Sustainable Recovery of Nitrogen and Phosphorus from Anaerobic Digestion Effluents of Swine Manure. Sustainability. 2020; 12(20):8574. https://doi.org/10.3390/su12208574

Chicago/Turabian StyleRyu, Hong-Duck, Do Young Lim, Sun-Jung Kim, Un-Il Baek, Eu Gene Chung, Kyunghyun Kim, and Jae Kwan Lee. 2020. "Struvite Precipitation for Sustainable Recovery of Nitrogen and Phosphorus from Anaerobic Digestion Effluents of Swine Manure" Sustainability 12, no. 20: 8574. https://doi.org/10.3390/su12208574

APA StyleRyu, H.-D., Lim, D. Y., Kim, S.-J., Baek, U.-I., Chung, E. G., Kim, K., & Lee, J. K. (2020). Struvite Precipitation for Sustainable Recovery of Nitrogen and Phosphorus from Anaerobic Digestion Effluents of Swine Manure. Sustainability, 12(20), 8574. https://doi.org/10.3390/su12208574