High-Performance Sustainable Asphalt Mixtures for High-Volume Traffic Roads in Severe Climates

Abstract

1. Introduction

2. Methodology

2.1. Materials

2.2. Testing Plan

3. Analysis of the Results

3.1. Laboratory Study

3.2. Reproducibility of Mixtures in a Real Plant

3.3. Trial Section

4. Conclusions

- The laboratory study of the crumb rubber-modified bitumen and the mixture manufactured with it at 30 °C lower than the hot conventional mixtures revealed a mechanical performance comparable to that recorded for traditional high-performance asphalt binders and hot mixtures in terms of elasticity, thermal susceptibility, workability, indirect tensile strength, water sensitivity, plastic deformations, and stiffness.

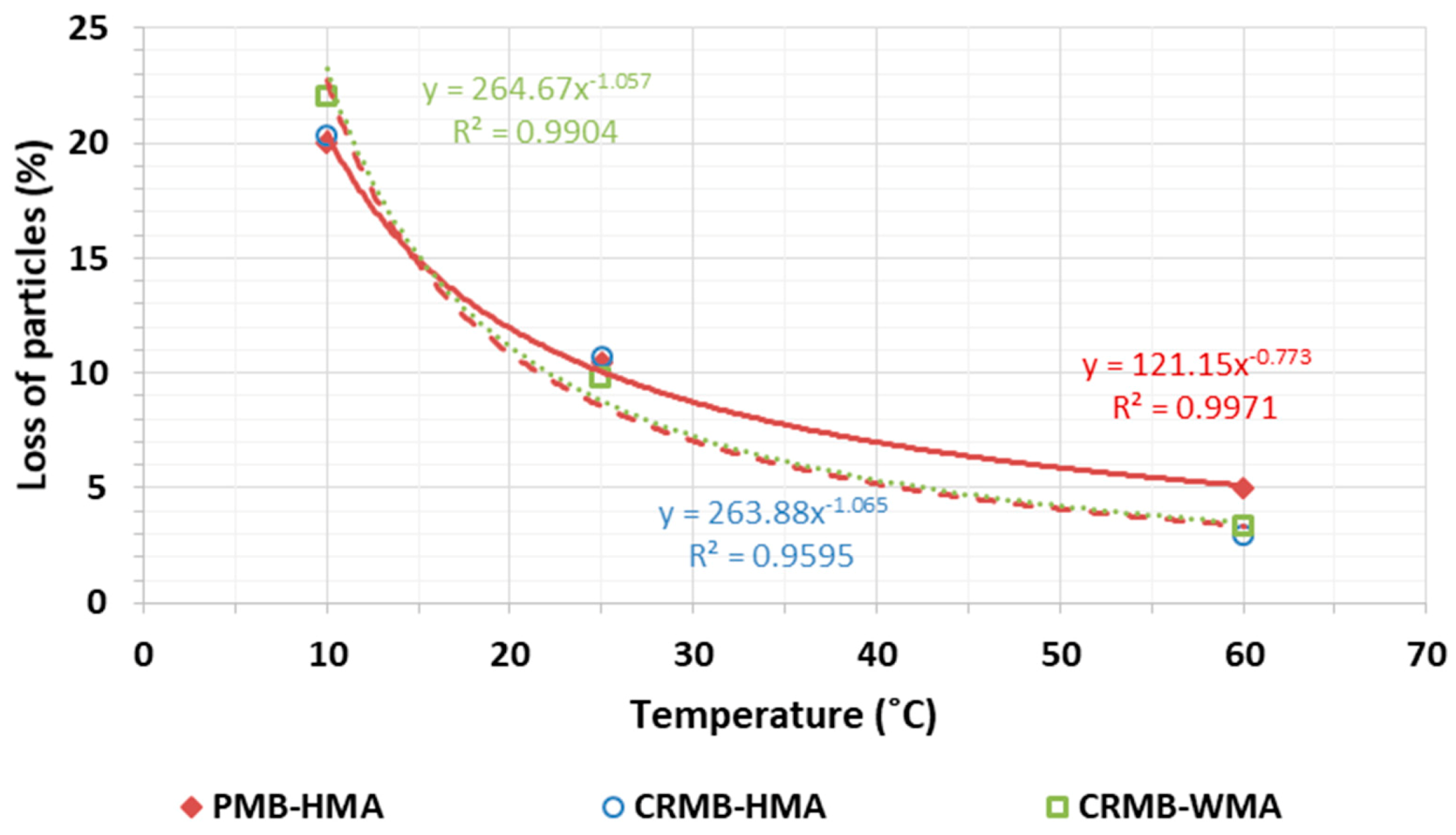

- High-performance sustainable mixtures manufactured with crumb rubber-modified asphalt binders at 30 °C lower than the hot conventional mixtures can be produced in conventional asphalt plants and spread and compacted with conventional equipment, achieving a material with a similar mechanical response to that of the reference hot mixtures (even higher in terms of resistance to fatigue and thermal cracking, particle loss, and permanent deformations) and a similar cost (the cost overrun associated with the use of additives can be partially compensated by the reduced energy consumption in-plant).

- High-performance sustainable mixtures manufactured with crumb rubber-modified asphalt binders at 30 °C lower than the hot conventional mixtures can be transported long distances (one hour transport) without having workability or compaction problems.

- Taken together, these findings suggest that sustainable high-performance mixtures presented in this paper could offer an interesting alternative to conventional hot mixtures for improving the durability of road pavements while reducing the environmental impacts associated with their construction/rehabilitation.

Author Contributions

Funding

Conflicts of Interest

References

- Abtahi, S.M.; Sheikhzadeh, M.; Hejazi, S.M. Fiber-reinforced asphalt-concrete—A review. Constr. Build. Mater. 2010, 24, 871–877. [Google Scholar] [CrossRef]

- Chomicz-Kowalska, A.; Gardziejczyk, W.; Iwa’nski, M. Moisture resistance and compactibility of asphalt concrete produced in half-warm mix asphalt technology with foamed bitumen. Constr. Build. Mater. 2016, 126, 108–118. [Google Scholar] [CrossRef]

- Sol-Sánchez, M.; Moreno-Navarro, F.; García-Travé, G.; Rubio-Gámez, M.C. Analysing industrial manufacturing in-plant and in-service performance of asphalt mixtures cleaner technologies. J. Clean. Prod. 2016, 121, 56–63. [Google Scholar] [CrossRef]

- Pouranian, M.R.; Shishehbor, M. Sustainability Assessment of Green Asphalt Mixtures: A Review. Environments 2019, 6, 73. [Google Scholar] [CrossRef]

- Xu, O.; Xiao, F.; Han, S.; Amirkhanian, S.N.; Wang, Z. High temperature rheological properties of crumb rubber modified asphalt binders with various modifiers. Constr. Build. Mater. 2016, 112, 49–58. [Google Scholar] [CrossRef]

- Moreno-Navarro, F.; Rubio-Gámez, M.C.; Jiménez del Barco, A. Tire crumb rubber effect on hot bituminous mixtures fatigue cracking behaviour. J. Civ. Eng. Manag. 2015, 22, 65–72. [Google Scholar] [CrossRef][Green Version]

- Moreno-Navarro, F.; Sol-Sánchez, M.; Jiménez del Barco, A.; Rubio-Gámez, M.C. Analysis of the influence of binder properties on the mechanical response of bituminous mixtures. Int. J. Pavement Eng. 2017, 18, 73–82. [Google Scholar] [CrossRef]

- Kök, B.V.; Çolak, H. Laboratory comparison of the crumb-rubber and SBS modified bitumen and hot mix asphalt. Constr. Build. Mater. 2011, 25, 3204–3212. [Google Scholar] [CrossRef]

- Nejad, F.M.; Aghajani, P.; Modarres, A.; Firoozifar, H. Investigating the properties of crumb rubber modified bitumen using classic and SHRP testing methods. Constr. Build. Mater. 2012, 26, 481–489. [Google Scholar] [CrossRef]

- Huang, M.; Liu, J.; Zhang, X.; Li, D. Laboratory assessment of workability of asphalt rubber hot mixes using warm mix technology. Appl. Mech. Mater. 2012, 193–194, 452–457. [Google Scholar] [CrossRef]

- D’Angelo, J.; Harm, E.; Bartoszek, J.; Baumgardner, G.; Corrigan, M.; Cowsert, J.; Harman, T.; Jamshidi, M.; Jones, W.; Newcomb, D.; et al. Warm-Mix Asphalt: European Practice; Report No. FHWA-PL-08-007; Federal Highway Administration, U.S. Department of Transportation: Alexandria, VA, USA, 2008.

- Pouranian, M.R.; Notani, M.A.; Tabesh, M.T.; Nazeri, B.; Shishehbor, M. Rheological and environmental characteristics of crumb rubber asphalt binders containing non-foaming warm mix asphalt additives. Constr. Build. Mater. 2020, 238, 117707. [Google Scholar] [CrossRef]

- Rubio, M.C.; Martínez, G.; Baena, L.; Moreno, F. Warm mix asphalt: An over-view. J. Clean. Prod. 2012, 24, 76–84. [Google Scholar] [CrossRef]

- UNE-EN 13108-2. Bituminous Mixtures—Material Specifications—Part 2: Asphalt Concrete for very Thin Layers; AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2007. [Google Scholar]

- PG-3. Pliego de Prescripciones Técnicas Generales para Obras de Carreteras y Puentes. Orden FOM/2523/2014; Ministerio de Fomento: Madrid, Spain, 2014. [Google Scholar]

- EN 1426. Bitumen and Bituminous Binders—Determination of Needly Penetration; AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2015. [Google Scholar]

- EN 1427. Bitumen and Bituminous Binders—Determination of the Softening Point—Ring and Ball Method; AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2015. [Google Scholar]

- EN 13398. Bitumen and bituminous binders, Determination of the elastic recovery of modified bitumen; AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2010. [Google Scholar]

- EN 12697-12. Bituminous mixtures. In Test Methods for Hot Mix Asphalt—Part 12: Determination of the Water Sensitivity of Bituminous Specimens; AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2009. [Google Scholar]

- EN 12697-22. Bituminous mixtures. In Test Methods for Hot Mix Asphalt—Part 22: Wheel Tracking; AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2008. [Google Scholar]

- EN 12697-6. Bituminous mixtures. In Test Methods for Hot Mix Asphalt—Part 6: Determination of Bulk Density of Bituminous Specimens; AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2012. [Google Scholar]

- EN 12697-8. Bituminous mixtures. In Test Methods for Hot Mix Asphalt—Part 8: Determination of Void Characteristics of Bituminous Specimens; AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2003. [Google Scholar]

- EN 12697-26. Bituminous mixtures. In Test Methods for Hot Mix Asphalt—Part 26: Stiffness; AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2012. [Google Scholar]

- EN 12697-17. Bituminous mixtures. In Test Methods for Hot Mix Asphalt—Part 17: Particle Loss of Porous Asphalt Specimen; AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2007. [Google Scholar]

- EN 12697-46. Bituminous mixtures. In Test Methods for Hot Mix Asphalt—Part 46: Low Temperatura Cracking and Properties by Uniaxial Tests; AENOR, Asociación Española de Normalización y Certificación: Madrid, Spain, 2013. [Google Scholar]

- Moreno-Navarro, F.; Rubio-Gámez, M.C. A review of fatigue damage in bituminous mixtures: Understanding the phenomenon from a new perspective. Constr. Build. Mater. 2016, 113, 927–938. [Google Scholar] [CrossRef]

- Moreno-Navarro, F.; Sol-Sánchez, M.; Rubio-Gámez, M.C. (c) Exploring the recovery of fatigue damage in bituminous mixtures: The role of healing. Road Mater. Pavement Des. 2015, 16 (Suppl. 1), 75–89. [Google Scholar] [CrossRef]

- Moreno-Navarro, F.; Rubio-Gámez, M.C. Mean damage parameter for the characterization of fatigue cracking behavior in bituminous mixes. Mater. Des. 2014, 54, 748–754. [Google Scholar] [CrossRef]

| Coarse Aggregate (4/12 mm) | Fine Aggregate (0/6 mm) | ||

|---|---|---|---|

| Ophite | Limestone | ||

| Particle granulometry, (UNE-EN 933-1) | Sieve | % of material passing | % of material passing |

| 11.2 | 96.5 | 100 | |

| 8 | 47.5 | 100 | |

| 4 | 7.5 | 82.2 | |

| 2 | 0.4 | 73.9 | |

| 0.5 | 0.3 | 31.9 | |

| 0.063 | 0.3 | 2.5 | |

| Sand equivalent, (UNE-EN 933-8) | - | 81 | |

| Percent of fractured face (UNE-EN 933-5) | 100% | - | |

| Flakiness index, (UNE-EN 933-3) | 20 | - | |

| Resistance to fragmentation (UNE-EN1097-2) | 14 | - | |

| Resistance to polishing (UNE 146130 annex D) | 0.51 | - | |

| Cleaning of coarse aggregate (UNE 146130 annex C) | 0.02% | - | |

| Relative density and absorption (EN 1097-6) | Apparent relative density | 2.85 g/cm3 | 2.80 g/cm3 |

| Absorption coefficient | 1.57 % | 0.77 % | |

| Characteristics | CRMB | PMB |

|---|---|---|

| Penetration at 25 °C (dmm), EN 1426 [16] | 45–80 | 45–80 |

| Softening point (°C), EN 1427 [17] | >60 | >60 |

| Elastic Recovery at 25 °C (%), EN 13398 [18] | >70 | >70 |

| Characteristics | PMB-HMA | CRMB-HMA | CRMB-WMA |

|---|---|---|---|

| Bulk density (Mg/m3), EN 12697-6 | 2.146 | 2.134 | 2.137 |

| Air voids (%), EN 12697-8 | 16.5 | 18.0 | 17.9 |

| Indirect tensile strength at 15 °C (kPa), EN 12697-23 | 1287 | 1161 | 1182 |

| ITSR (%), EN 12697-12 | 91.9 | 90.7 | 94.0 |

| WTS at 60 °C (mm/103 ciclos), EN 12697-22 | 0.056 | 0.054 | 0.068 |

| Characteristics | CRMB-HMA | CRMB-WMA |

|---|---|---|

| Aggregates temperature (°C) | 172–178 | 146–148 |

| Flame of the drum dryer (%) | 72–81 | 37–59 |

| Fuel consumption (kg/tn) | 6.8–7.2 | 5.4–5.9 |

| Characteristics | PMB-HMA | RMB-HMA | RMB-WMA |

| Indirect tensile strength at 15 °C (kPa), EN 12697-23 | 1111 | 1040 | 1108 |

| ITSR (%), EN 12697-12 | 90.5 | 90.9 | 90.1 |

| WTS at 60 °C (mm/103 ciclos), EN 12697-22 | 0.048 | 0.066 | 0.056 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moreno-Navarro, F.; Sierra, F.J.; Sol-Sánchez, M.; Rubio-Gámez, M.C.; Castillo, M.; Estévez, E. High-Performance Sustainable Asphalt Mixtures for High-Volume Traffic Roads in Severe Climates. Sustainability 2020, 12, 8765. https://doi.org/10.3390/su12218765

Moreno-Navarro F, Sierra FJ, Sol-Sánchez M, Rubio-Gámez MC, Castillo M, Estévez E. High-Performance Sustainable Asphalt Mixtures for High-Volume Traffic Roads in Severe Climates. Sustainability. 2020; 12(21):8765. https://doi.org/10.3390/su12218765

Chicago/Turabian StyleMoreno-Navarro, Fernando, Francisco Javier Sierra, Miguel Sol-Sánchez, M. Carmen Rubio-Gámez, Manuel Castillo, and Eugenio Estévez. 2020. "High-Performance Sustainable Asphalt Mixtures for High-Volume Traffic Roads in Severe Climates" Sustainability 12, no. 21: 8765. https://doi.org/10.3390/su12218765

APA StyleMoreno-Navarro, F., Sierra, F. J., Sol-Sánchez, M., Rubio-Gámez, M. C., Castillo, M., & Estévez, E. (2020). High-Performance Sustainable Asphalt Mixtures for High-Volume Traffic Roads in Severe Climates. Sustainability, 12(21), 8765. https://doi.org/10.3390/su12218765