Towards Forklift Safety in a Warehouse: An Approach Based on the Automatic Analysis of Resource Flows

Abstract

1. Introduction

2. Materials and Methods

- Make the company manager and staff aware of the internal flows of a system;

- Highlight how much the behavior of individuals moving within a control volume can impact the well-being of the entire company;

- Give information on the critical areas of a system and seek the causes of these issues and possible solutions.

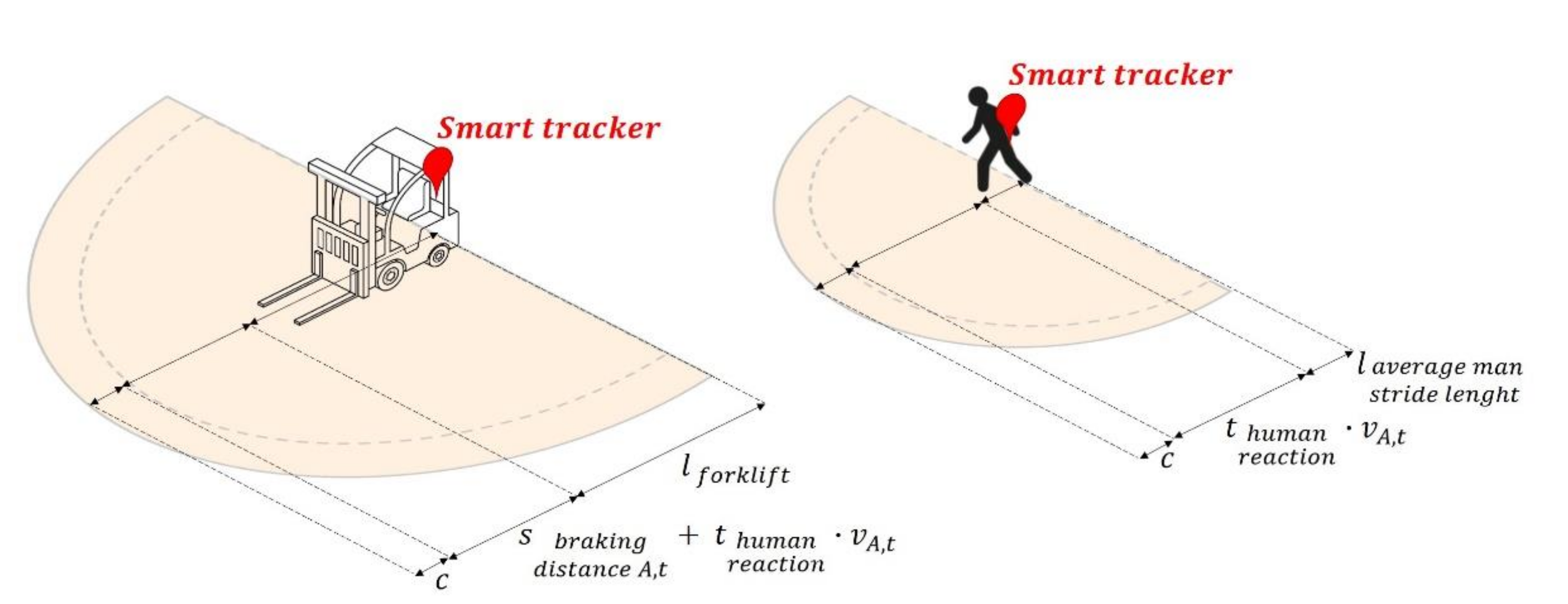

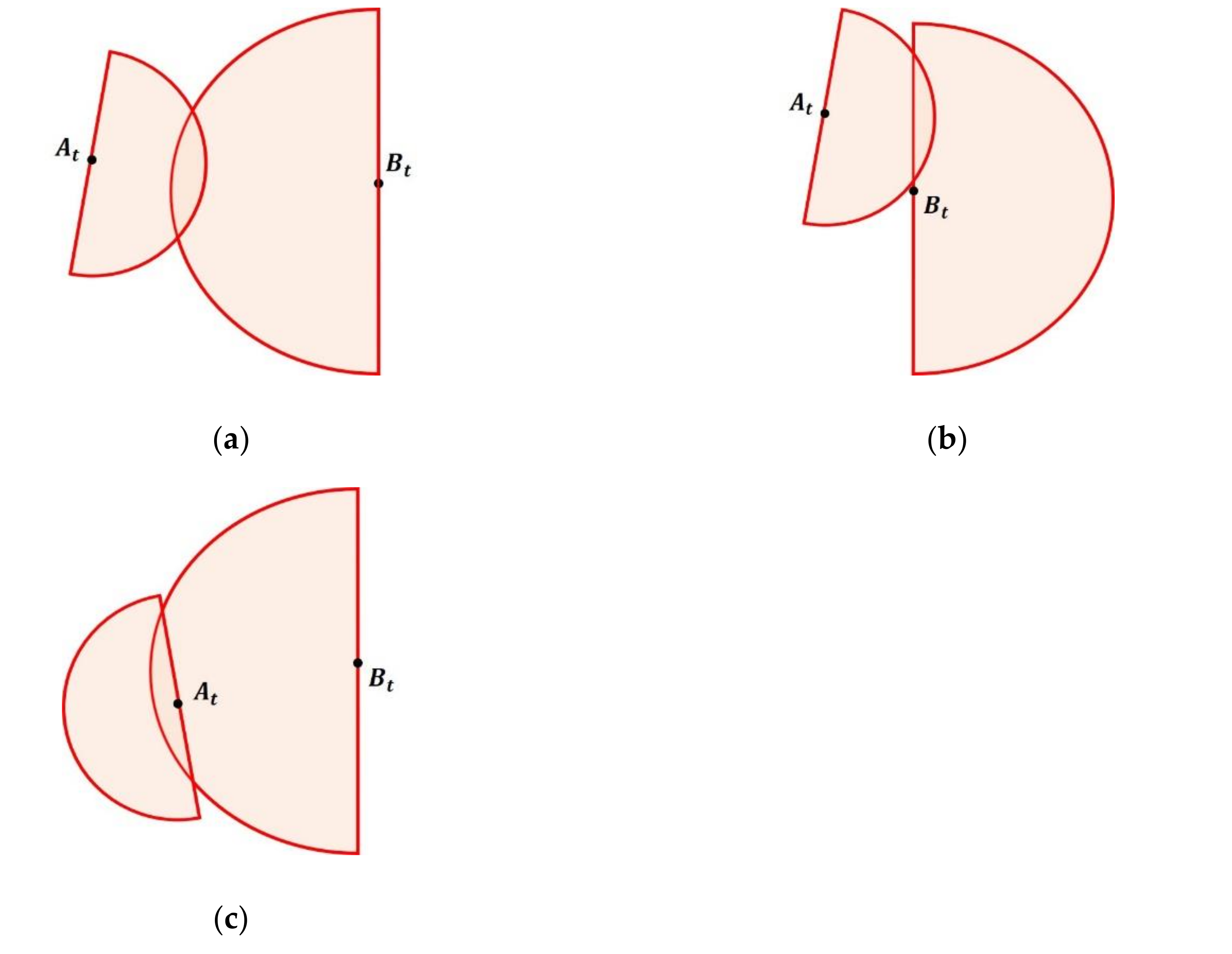

2.1. How to Evaluate Warehouse Safety Through Smart Spaghetti

- Automatically obtain a visual and objective, although qualitative, mapping of the safety situation of the structure;

- Identify critical areas and tasks;

- Plan possible improvements.

3. Results

Evaluation of Warehouse Safety Through the Proposed Approach

- a. Unloading of goods (finished products) to be delivered by airplanes to external customers. Due to the cost of air transport, only medicines that need to stay at a controlled temperature are shipped by air. In fact, they must be delivered quickly and immediately stored in the refrigerator.

- b. Loading of goods (raw materials) from airplanes sent by suppliers (replenishment of the warehouse). These goods are picked up at the airport by a truck, which then transports them to the warehouse. They are distinguished from other goods because they are always placed in cold stores and arrive in the form of large metal containers, each containing five pallets.

- c. Unloading of goods to be delivered by ship to external customers. The capacity of the trucks is finite, so the number of trips needed to bring the materials from the warehouse to the port changes according to the number of pallets to unload (customer orders).

- d. Loading of goods from ships sent by suppliers. These goods (some of which are destined for cold storage) are recovered at the ports and transported to the warehouse by truck.

- e. Unloading of goods to be delivered by truck to external customers. The capacity of the trucks is finite, so the number of trips needed to bring the materials from the warehouse to the customer changes according to the number of pallets to unload.

- f. Loading of goods sent by suppliers by truck.

- g. Palletizing and labeling. Before each shipment, boxes of medicines are palletized and labeled with descriptive stickers. These tasks take time to be completed because pallet formats and product labeling standards vary depending on whether goods are shipped in or out of Europe.

- h. Unloading of goods to be delivered by truck to the internal customer (production plant). Based on the production orders, the raw materials and semi-finished products needed to feed the production lines are shipped from the warehouse to the factory. Since the production plant has a small warehouse that can hold raw materials for only 4 h of work, this activity is repeated several times a day.

- i. Preparation of pallets to be shipped to the internal customer. Pallets of this type, waiting to be shipped, are stored in a waiting bay, where they remain until the trucks arrive.

- j. Loading of goods in trucks from the internal customer. The finished products are stored in the warehouse waiting to be sold to external customers. Loads are made several times a day.

- 1.

- The area between the waiting bay and cold room 1 (left circles, Figure 6a–c). Here, the raw materials to be shipped to the internal customer accumulate, so they remain to occupy space and increase the probability of having a near miss. As stated by [5], the high volume of material on the ground is one of the causes of warehouse inefficiency and makes the processes unsafe and very time-consuming.

- 2.

- The area in front of the discharge doors C and D (right circles, Figure 6a–c). This is where palletizing and labeling operations and most truck transports are carried out. Even in this area, forklifts and personnel remain to occupy space, increasing the probability of collisions.

- To modify the warehouse layout by making more uniform use of the available surface, and gaining space in critical areas by relocating or eliminating some shelves (in this case, better stock management is necessary);

- To move the re-palletizing area to another area of the warehouse that is less frequented (not visible in Figure 5 for privacy reasons);

- To open a new bay for loading air cargo into another area of the warehouse and/or to relocate the bay for internal order preparation and replenishment;

- To establish one-way traffic directions (hypothesis to be evaluated by simulating the flows and obtaining automatic mapping of the warehouse also in the goods reception area, not only in the unloading area).

4. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Bartholdi, J.J.; Hackman, S.T. Warehouse & Distribution Science. Release 0.94; The Supply Chain and Logistics Institute School of Industrial and Systems Engineering, Georgia Institute of Technology: Atlanta, GA, USA, 2011. [Google Scholar]

- Rouwenhorst, B.; Reuter, B.; Stockrahm, V.; van Houtum, G.-J.; Mantel, R.J.; Zijm, W.H. Warehouse design and control: Framework and literature review. Eur. J. Oper. Res. 2000, 122, 515–533. [Google Scholar] [CrossRef]

- Bonilla-Ramirez, K.A.; Marcos-Palacios, P.; Quiroz-Flores, J.C.; Ramos-Palomino, E.D.; Alvarez-Merino, J.C. Implementation of Lean Warehousing to Reduce the Level of Returns in a Distribution Company. In Proceedings of the 2019 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Macao, China, 15–18 December 2019; pp. 886–890. [Google Scholar]

- Van Der Aalst, W.M. Process mining: Discovering and improving Spaghetti and Lasagna processes. In Proceedings of the 2011 IEEE Symposium on Computational Intelligence and Data Mining (CIDM), Paris, France, 11–15 April 2011; pp. 1–7. [Google Scholar]

- Ferreira, J.V.; Ramos, A.L.; Esteves, A.F. Continuous Improvement to Create Value: Warehouse Management in a Telecommunications Company. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Bangkok, Thailand, 5–7 March 2019; pp. 1803–1810. [Google Scholar]

- Nahavandi, S. Industry 5.0—A human-centric solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

- Uddin, M.; Gupta, A.; Maly, K.; Nadeem, T.; Godambe, S.; Zaritsky, A. SmartSpaghetti: Use of smart devices to solve health care problems. In Proceedings of the 2013 IEEE International Conference on Bioinformatics and Biomedicine, Shanghai, China, 18–21 December 2013; pp. 40–45. [Google Scholar] [CrossRef]

- Uddin, M.; Gupta, A.; Maly, K.; Nadeem, T.; Godambe, S.; Zaritsky, A. SmartSpaghetti: Accurate and robust tracking of Human’s location. In Proceedings of the IEEE-EMBS International Conference on Biomedical and Health Informatics (BHI), Valencia, Spain, 28 July 2014; pp. 129–132. [Google Scholar] [CrossRef]

- Costa, E.; Bragança, S.; Sousa, R.; Alves, A. Benefits from a SMED Application in a Punching Machine. World Acad. Sci. Eng. Technol. 2013, 7, 379–385. [Google Scholar]

- Falcone, D.; Silvestri, A.; Duraccio, V.; Bona, V.D. Material Flow Map and Layout Optimization: Action plan and software validation. In Proceedings of the XV Summer School “Francesco Turco” Impianti Industriali Meccanici, Porto Giardino, Monopoli, Italy, 14–18 September 2014. [Google Scholar]

- Chiarini, A. Waste savings in patient transportation inside large hospitals using lean thinking tools and logistic solutions. Leadersh. Health Serv. 2013, 26, 356–367. [Google Scholar] [CrossRef]

- Toussaint, J.S.; Berry, L.L. The promise of Lean in health care. In Mayo Clinic Proceedings; Elsevier: Amsterdam, The Netherlands, 2013; Volume 88, pp. 74–82. [Google Scholar] [CrossRef]

- Yorukoglu, K.; Özer, E.; Alptekin, B.; Öcal, C. Improving histopathology laboratory productivity: Process consultancy and A3 problem solving. Turk. Patoloji. Derg. Turk. J. Pathol. 2017, 33, 47–57. [Google Scholar] [CrossRef] [PubMed]

- Rauch, E.; Damian, A.; Holzner, P.; Matt, D.T. Lean Hospitality-Application of Lean Management methods in the hotel sector. Procedia CIRP 2016, 41, 614–619. [Google Scholar] [CrossRef]

- Abideen, A.Z.; Mohamad, F.B. Supply chain lead time reduction in a pharmaceutical production warehouse—A case study. Int. J. Pharm. Healthc. Mark. 2019, 14, 61–88. [Google Scholar] [CrossRef]

- Vivaldini, K.C.; Galdames, J.P.; Bueno, T.S.; Araújo, R.C.; Sobral, R.M.; Becker, M.; Caurin, G.A. Robotic forklifts for intelligent warehouses: Routing, path planning, and auto-localization. In Proceedings of the 2010 IEEE International Conference on Industrial Technology, Vina del Mar, Chile, 14–17 March 2010; pp. 1463–1468. [Google Scholar] [CrossRef]

- Michalos, G.; Karvouniari, A.; Dimitropoulos, N.; Togias, T.; Makris, S. Workplace analysis and design using virtual reality techniques. CIRP Ann. 2018, 67, 141–144. [Google Scholar] [CrossRef]

- Ohno, T. Toyota Production System: Beyond Large-Scale Production; Productivity Press: Portland, OR, USA, 1988; Volume 1. [Google Scholar]

- Womack, J.P.; Jones, D.T. Lean Thinking: Banish Waste and Create Wealth in Your Corporation; Free Press: New York, NY, USA, 2003. [Google Scholar]

- Goyal, G.; Verma, D.S. Optimization of plant layout in manufacturing industry. Int. J. Recent Technol. Eng. 2019, 8, 3115–3118. [Google Scholar] [CrossRef]

- Nahmens, I.; Mullens, M. The impact of product choice on lean homebuilding. Constr. Innov. 2009, 9, 84–100. [Google Scholar] [CrossRef]

- Pellegrini, S.; Shetty, D.; Manzione, L. Study and implementation of single minute exchange of die (SMED) methodology in a setup reduction kaizen. In Proceedings of the 2012 International Conference on Industrial Engineering and Operations Management, Istanbul, Turkey, 3–6 July 2012; pp. 1–11. [Google Scholar]

- Collins, J.W.; Smith, G.S.; Baker, S.P.; Landsittel, D.P.; Warner, M. A case-control study of forklift and other powered industrial vehicle incidents. Am. J. Ind. Med. 1999, 36, 522–531. [Google Scholar] [CrossRef]

- Tan, K.-S.; Ahmed, M.D.; Sundaram, D. Sustainable warehouse management. In Proceedings of the International Workshop on Enterprises & Organizational Modeling and Simulation, Amsterdam, The Netherlands, 8–9 June 2009; pp. 1–15. [Google Scholar] [CrossRef]

- Senderska, K.; Mareš, A.; Václav, Š. Spaghetti Diagram Application for Workers’movement Analysis. UPB Sci. Bull. Ser. D 2017, 79, 139–150. [Google Scholar]

- Hys, K.; Domagała, A. Application of spaghetti chart for production process streamlining. Case study. Int. Sci. J. 2018, 89, 64–71. [Google Scholar] [CrossRef]

- Dotoli, M.; Epicoco, N.; Falagario, M.; Costantino, N.; Turchiano, B. An integrated approach for warehouse analysis and optimization: A case study. Comput. Ind. 2015, 70, 56–69. [Google Scholar] [CrossRef]

- Ohu, I.P.; Cho, S.; Kim, D.H.; Lee, G.H. Ergonomic analysis of mobile cart–assisted stocking activities using electromyography. Hum. Factors Ergon. Manuf. Serv. Ind. 2016, 26, 40–51. [Google Scholar] [CrossRef]

- Stylianou, G. Relative indoor spatial tracking and navigation. Int. J. Wirel. Mob. Comput. 2015, 9, 8–26. [Google Scholar] [CrossRef]

- Savage, J. Ethnography and health care. BMJ 2000, 321, 1400–1402. [Google Scholar] [CrossRef]

- Pitapurapu, R.; Gupta, A.; Maly, K.; Nadeem, T.; Govindarajulu, R.; Godambe, S.; Zaritsky, A. Dead Reckoning with Smartphone Sensors for Emergency Rooms. In Proceedings of the International Conference on Smart Homes and Health Telematics, Geneva, Switzerland, 10–12 June 2015; pp. 206–217. [Google Scholar] [CrossRef]

- Hurtuk, J.; Červeňák, J.; Štancel, M.; Hulič, M.; Fecil’ak, P. Indoor navigation using IndoorAtlas library. In Proceedings of the 2019 IEEE 17th International Symposium on Intelligent Systems and Informatics (SISY), Subotica, Serbia, 12–14 September 2019; pp. 139–142. [Google Scholar] [CrossRef]

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine that Changed the World: The Story of Lean Production–Toyota’s Secret Weapon in the Global Car Wars that is Now Revolutionizing World Industry; Harper Perennial: New York, NY, USA, 1990; Volume 1. [Google Scholar]

- Borsos, A.; Farah, H.; Laureshyn, A.; Hagenzieker, M. Are collision and crossing course surrogate safety indicators transferable? A probability based approach using extreme value theory. Accid. Anal. Prev. 2020, 143. [Google Scholar] [CrossRef]

- van der Schaaf, T.W.; Lucas, D.A.; Hale, A.R. Near Miss Reporting as a Safety Tool; Butterworth-Heinemann: Oxford, UK, 2013; Volume 1. [Google Scholar]

- Nagurnas, S.; Mitunevičius, V.; Unarski, J.; Wach, W. Evaluation of veracity of car braking parameters used for the analysis of road accidents. Transport 2007, 22, 307–311. [Google Scholar] [CrossRef]

- Falcone, D.; Silvestri, A.; Forcina, A.; Pacitto, A. Modeling and simulation of an assembly line: A new approach for assignment and optimization of activities of operators. In Proceedings of the MAS (The International Conference on Modeling and Applied Simulation), Rome, Italy, 12–14 September 2011; pp. 12–14. [Google Scholar]

- Di Bona, G.; Duraccio, V.; Silvestri, A.; Forcina, A. Productive line reengineering through simulation techniques. In Proceedings of the IASTED International Conference on Modelling, Identification and Control, Innsbruck, Austria, 17–19 February 2014; pp. 291–296. [Google Scholar]

- Muther, R. Systematic Layout Planning, 2nd ed.; Cahners Books: Boston, MA, USA, 1973; Volume 1. [Google Scholar]

- Hillier, F.S. Quantitative tools for plant layout analysis. J. Ind. Eng. 1963, 14, 33–40. [Google Scholar]

- Noy, P.C. Make the right plant layout-mathematically. Am. Mach. 1957, 101, 121–125. [Google Scholar]

- Lee, R.C.; Moore, J.M. CORELAP–Computerized Relationship Layout Planning. J. Ind. Eng. 1967, 18, 195–200. [Google Scholar]

- Agethen, P.; Gaisbauer, F.; Manns, M.; Link, M.; Rukzio, E. Towards realistic walk path simulation of single subjects: Presenting a probabilistic motion planning algorithm. In Proceedings of the 11th Annual International Conference on Motion, Interaction, and Games, Limassol, Cyprus, 8–10 November 2018; pp. 1–10. [Google Scholar]

- Gagliardi, J.P.; Renaud, J.; Ruiz, A. A simulation model to improve warehouse operations. In Proceedings of the 2007 Winter Simulation Conference, Washington, DC, USA, 9–12 December 2007; pp. 2012–2018. [Google Scholar] [CrossRef]

- Patriarca, R.; Gravio, G.D.; Mancini, M.; Costantino, F. Change management in the ATM system: Integrating information in the preliminary system safety assessment. Int. J. Appl. Decis. Sci. 2016, 9, 121–138. [Google Scholar] [CrossRef]

| Worker ID | Start Time | End Time | Task | N° of Repetitions | Type of Movement | Means of Transport | Near Miss | Comments |

|---|---|---|---|---|---|---|---|---|

| 9 | 10:50 | 11:10 | Pallet loading on the truck (door C) | 8 | O + R | F | The first three activities of this table are simultaneous but do not cause collision risks | |

| 1 | 10:56 | 11:03 | Thermal blankets are taken to cover medicines that need to be shipped while remaining at a controlled temperature | 4 | O + R | P | ||

| 1 | 10:57 | 11:04 | Withdrawal of raw materials for internal customer | 4 | O + R | F | ||

| 5 | 11:41 | 11:09 | Pallet preparation for internal customer | 3 | O + R | F | x | Workers 17 and 3 generated a near miss |

| 3 | 11:42 | 11:06 | Pallet preparation for internal customer | 2 | O + R | F | x |

| Observed Scenarios | ||||||||

|---|---|---|---|---|---|---|---|---|

| Transport to External Customer | Transport to Internal Customer | |||||||

| Inspection Date | Start Time | End Time | a. Unloading of Air Cargo | c. Unloading of Ship’s Cargo | e. Unloading of Truck’s Cargo | g. Palletizing and Labeling | h. Unloading of Truck’s Cargo | i. Internal Order Preparation and Replenishment |

| Day 1 | 08:25 | 08:59 | ✓ | |||||

| Day 1 | 09:37 | 10:23 | ✓ | |||||

| Day 1 | 10:45 | 11:03 | ✓ | ✓ | ✓ | |||

| Day 1 | 11:37 | 11:54 | ✓ | |||||

| Day 2 | 13:51 | 14:02 | ✓ | ✓ | ||||

| Day 2 | 14:38 | 14:48 | ✓ | |||||

| Day 2 | 14:54 | 15:00 | ✓ | ✓ | ||||

| Day 2 | 15:02 | 15:53 | ✓ | ✓ | ✓ | |||

| Day 2 | 15:54 | 16:04 | ✓ | ✓ | ✓ | |||

| Day 2 | 16:12 | 15:19 | ✓ | ✓ | ||||

| Day 2 | 16:21 | 16:24 | ✓ | ✓ | ||||

| Day 2 | 16:24 | 16:34 | ✓ | |||||

| Day 2 | 16:36 | 16:49 | ✓ | ✓ | ||||

| Day 2 | 16:49 | 16:58 | ✓ | |||||

| Day 2 | 16:57 | 17:18 | ✓ | ✓ | ||||

| Day 3 | 08:14 | 08:25 | ✓ | ✓ | ||||

| Day 3 | 08:26 | 08:35 | ✓ | |||||

| Day 3 | 08:36 | 08:40 | ✓ | |||||

| Day 3 | 08:40 | 08:53 | ✓ | ✓ | ||||

| Day 3 | 08:55 | 09:02 | ✓ | |||||

| Day 3 | 09:07 | 09:17 | ✓ | |||||

| Day 3 | 09:19 | 10:08 | ✓ | |||||

| Day 3 | 10:12 | 10:20 | ✓ | |||||

| Day 3 | 11:23 | 11:26 | ✓ | ✓ | ||||

| Day 3 | 11:31 | 12:00 | ✓ | ✓ | ||||

| Resource A | Resource B | Measuring Unit | |

|---|---|---|---|

| xt | 44.1 | 42.9 | [m] |

| yt | 40.3 | 41.9 | [m] |

| xt-1 | 43.0 | 42.5 | [m] |

| yt-1 | 39.9 | 43.2 | [m] |

| vt | 1.17 | 1.36 | [m/s] |

| ϑt | 19.98 | −72.90 | [°] |

| Means of Transport | Forklift | Forklift | [-] |

| rt | 2.36 | 2.68 | [m] |

| Distance Between ABt | 2.00 | [m] | |

| Sum of Radiit | 5.03 | [m] | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cantini, A.; De Carlo, F.; Tucci, M. Towards Forklift Safety in a Warehouse: An Approach Based on the Automatic Analysis of Resource Flows. Sustainability 2020, 12, 8949. https://doi.org/10.3390/su12218949

Cantini A, De Carlo F, Tucci M. Towards Forklift Safety in a Warehouse: An Approach Based on the Automatic Analysis of Resource Flows. Sustainability. 2020; 12(21):8949. https://doi.org/10.3390/su12218949

Chicago/Turabian StyleCantini, Alessandra, Filippo De Carlo, and Mario Tucci. 2020. "Towards Forklift Safety in a Warehouse: An Approach Based on the Automatic Analysis of Resource Flows" Sustainability 12, no. 21: 8949. https://doi.org/10.3390/su12218949

APA StyleCantini, A., De Carlo, F., & Tucci, M. (2020). Towards Forklift Safety in a Warehouse: An Approach Based on the Automatic Analysis of Resource Flows. Sustainability, 12(21), 8949. https://doi.org/10.3390/su12218949