1. Introduction

With the increasingly severe threat of climate change and resource depletion faced by human society, the demand for sustainable development is increasingly urgent [

1,

2]. Although the international definition of sustainable development is not uniform, it is currently focused on the following three aspects: sustainable development of the economy, environment and society. With the growth of urban population and the explosive growth of vehicle flow in urban logistics systems, climate change has become a huge burden on the urban healthy operation. The problems of congestion, emission, etc., are increasingly exposed [

1]. The development of urban logistics systems is facing difficulties in the economic, environmental and social aspects.

In early 2020, when the novel coronavirus epidemic broke out in China, to cut off the transmission route of the highly contagious disease, the Chinese government lost no time in taking measures of intersection control and virus detection, and subsequently adopted the prevention and control measures of classified quarantine in various districts and regions. As the intersection control began, all vehicles were required to go through the procedures of temperature measurement by queuing at each highway entrance/exit before they could pass, which resulted in a congestion-caused long queue and, what is more, a huge inconvenience to the passage of freight vehicles. The hindering in the transportation and circulation of goods, such as vegetables and flowers, was intensified by the shortage of couriers and drivers during the epidemic; the express delivery industry, in which the urban distribution logistics for supermarkets and Chinese urban residents are highly vested, was fairly slow; and, in particular, the e-commerce and express delivery and distribution of fresh food even failed to meet the needs of customers. The pandemic has strongly impacted China’s logistics industry, especially urban distribution logistics, which is excessively dependent on road transport, whose strong dependency on traffic smoothness and drivers leads to its failure in catering to people’s livelihood needs in the event of an emergency. In addition, road-reliant freight transport would bring another two important problems:

Congestion has become an urgent problem, that threatens the sound urban operation in the present and future. About two-thirds of the 667 cities in China are stuck with traffic jams during rush hours, and in seaports like Shanghai and Shenzhen, traffic congestion is exacerbated by a higher proportion of road transport by container trucks heading to the port, which occupies a large number of urban roads. According to the statistics in 2015, Beijing’s annual bill for traffic congestion amounted to 70 billion yuan ($11.3 billion).

What is more, the overuse of road transport also gives rise to air pollution. In particular, the contribution of road freight vehicles to urban air pollution is more significant, accounting for almost 50% of emissions [

3]. Statistical data show that the pollutant emission of a heavy-duty truck is equivalent to that of 100 cars compliant with “China V” emission standards. More than 96% of NOx emissions are caused by trucks on busy urban roads.

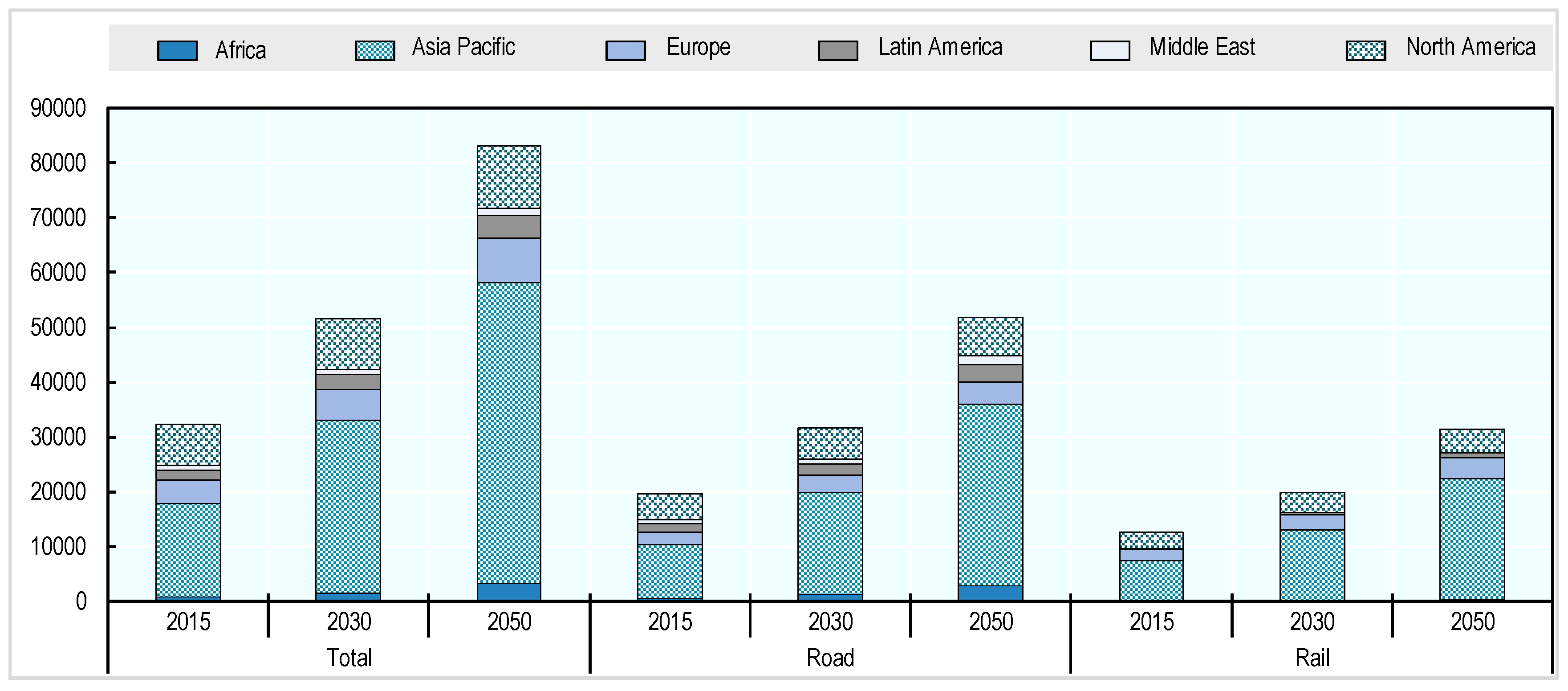

It can be seen that the high proportion of road freight transport not only causes serious environmental problems, including urban congestion and pollution, but also counts against the assurance of urban logistics in the case of road control caused by accidents like the COVID-19 pandemic. However, the demand for road freight is still growing at a high speed, which will further aggravate its damage to the urban environment [

4]. OECD (Organization for Economic Cooperation and Development) has carried out a project to forecast the global freight demand, whose results demonstrated that the global ground freight ton-kilometers (road and rail freight) will double from 2015 to 2030, especially in Asia, where they will increase 3.2 times, accounting for more than two-thirds of the global value [

5,

6]. China will have the largest and fastest-growing ground freight demand in Asia, as shown in

Figure 1. In addition, China’s e-commerce is in the stage of expansive development. By 2019, the number of urban express delivery in China has reached 63 billion and is still growing at a high speed of more than 20%. The subsequent pressure on urban distribution is also increasing. To sum up, it is urgent to better plan future urban freight transport.

With such a background, more and more attention and research have been devoted to the sustainable development of supply chains and logistics, which are becoming hot and complex research fields [

7]. The research and innovation of key core issues in practice, especially the integrated issues of economic, environmental and social performance, are getting more attention [

2,

8]. In the field of logistics, people began to try to explore new modes of transport to coordinate economic, environmental and social issues such as cost, time, emissions and congestion, in which the underground logistics system is the result. The ULS (underground logistics system) [

3,

9], also known as UFT (Underground Freight Transportation) or pipeline transportation system [

5] (freight transport by underground pipeline, tube freight transportation, capsule freight pipelines) refers to the intracity and intercity logistics system which uses dual-model trucks and guided vehicles to transport goods through large-diameter underground pipelines or tunnels. As shown in

Figure 2, JD.com, a well-known Chinese e-commerce and logistics company, proposes a concept of an underground urban distribution logistics system. As shown in

Figure 2, underground intelligent hub stations are set up in different areas to connect capillary-like underground passages and cover nodes of underground logistics networks in certain areas. Furthermore, the stereoscopic lifting system is adopted to connect those nodes with the demand node of ground logistics, and the transport capsule is used to circulate goods in the underground pipeline. However, this concept is currently lacking a specific layout and planning, as well as the next step action.

The 20-plus-year study on the feasibility and socio-economic benefits of the underground logistics system since the beginning of the 1990s has proved that the underground logistics system can work as an alternative to modern modes of transport such as roadway, railway and waterway, since it can independently separate freight transportation and passenger transportation and is immune to the impacts of weather and other emergencies. Besides, it can also significantly protect the environment with low carbon, alleviate congestion and provide energy efficiency. Thus, it is an effective way to construct an urban sustainable logistics distribution system [

10]. The feasibility study of the urban underground logistics network is presented in the construction of Xiong’an New Area, in China.

However, the current research is still mainly about the evaluation and feasibility of the underground logistics system and the analysis of the socio-economic benefits, while little research has been conducted on the optimization and design of the sustainable urban underground logistics network system framework considering the environmental and economic factors. The latter is important enough to determine the sustainable development of urban transportation logistics, especially during the outbreak of the pandemic, when the roads were closed. The question of how to make a reasonable layout to guarantee urban residents’ and enterprises’ demands for material circulation highlights the importance and urgency of a reasonable urban stereoscopic distribution network based on the underground logistics system.

Considering the environmental and economic factors in urban logistics, this paper conducts comprehensive design and optimization research on the network nodes and passages of urban underground logistics and proposes a relatively complete framework of sustainable underground logistics network. At first, this paper observes the congestion in different areas of the city, performs the first location of urban underground logistics nodes through the set cover model and classifies the located logistics nodes into first-level and second-level nodes via fuzzy clustering; secondly, for the purpose of the minimum construction and operation cost of underground logistics, this paper builds an optimization and design model of an underground logistics passage considering freight volume, congestion and other constraints on the located logistics nodes. Besides, an ant colony algorithm is used to solve the aforementioned model to design optimal passages for every underground logistics node, thus forming a sustainable underground logistics network framework including all-levels logistics nodes and passages. Finally, the effectiveness of the proposal is validated by analyzing and discussing the cases in a subdistrict of Nanjing. It provides support for decisions in the design and development of urban sustainable underground logistics networks.

2. Literature Review

Recent years have witnessed an economic boom, surging vehicles on the ground and consequently worse environmental pollution and urban traffic congestion, which seriously hampered urban development. Therefore, people look to pay more attention to the utilization of underground space. Such utilization in China is in the stage of networking where various underground facilities are gradually networking, such as underground shopping malls, rail transit, utility tunnels, etc. [

11]. Based on the database of the Web of Science, Taylor and Francis, CNKI and so on, this paper analyzes the research literature in related fields, including the feasibility evaluation and impact of the ULS, the construction of the ULS and the ULS in an integrated transportation system and the planning of underground logistics system and network, based on the following literature review.

Despite the rapid growth of infrastructure construction in underground space in China, there is still a lack of systematic evaluation indicators to evaluate the development degree of underground space [

12]. Some scholars began to create indicators for the development of underground space and evaluate the degree of underground space construction in various regions based on these indicators [

13]. One of the proposals is the construction of the logistics of underground space. This logistics system, capable of storage and freight transportation, has been the solution of choice to ease the shortage of urban space and has attracted more attention in recent years due to its economic and environmentally friendly characteristics.

The underground logistics system (ULS) originated in England. In 1927, an underground transportation system was built by the Royal Mail in London. The priority of the research was how to deal with the massive transport volume and ease the traffic congestion. The early research on the underground logistics system mainly focused on the feasibility of this system. Sinfield proved the feasibility of the pipeline transportation system by calculating the cost of network construction in the actual urban environment [

14]. However, Rijsenbrij proposed the creative combination of freight transportation with urban underground technology and analyzed the freight capacity of the underground [

15]. Some scholars replaced the concept of supplementing logistics transportation with an idle underground transport capacity and evaluated the important indicators of underground stations through a complex network. They assessed the importance of each station via the TOPSIS model and located the candidate distribution hubs and stations [

16]. Favoring other perspectives, some scholars investigated the economic advantages of electrically driven underground transportation over traditional transportation [

9], while other scholars analyzed the quantitative relation between the implementation of the strategy of the urban rail transit system and the sustainability of urban transportation logistics in real-world simulations by means of system dynamics [

3]. Moreover, the impact of the ULS from the perspective of the urban transportation system has been studied, for example, using highway toll data, traffic flow data and traffic survey data to build a model to calculate the emissions and the number of containers carried along the ULS from Waigaoqiao Port to the Jiading area [

17].

From a macro-level perspective, scholars elaborated in 2017 on the policies of ULS construction and application in China with the aid of the PEST-SWOT model and offered some suggestions on its development [

18]. The traditional logistics network has reached its limit in China’s cities due to urban traffic congestion. Compared with traditional railways and special expressways, the underground logistics system has its unique edges, such as fast transportation and less impact on the environment and roads. As supporting technologies grow and mature, the future logistics system will gradually shift to underground logistics, producing an underground logistics network. The urban underground logistics system will become the new direction toward which urban logistics will evolve in the new century.

After the feasibility study, a large number of scholars have put forward their own insights on the construction of the underground logistics system. Firstly, based on the analysis of individual cases, Heijden summarized and analyzed the operational characteristics of different underground logistics networks, as well as their respective cost and efficiency, by analyzing specific cases, namely the Aalsmeer flower market and Schiphol Airport [

19]. In order to cope with the increasing container transportation in the Port of Antwerp, scholars have established a special underground logistics system to solve the freight logistics problems on both sides of the port [

9].

Secondly, as regards the intermodal transportation of containerized cargo, some scholars suggested establishing a port-convergence-station of underground logistics to connect underground logistics and the port. A robust optimization model is used to deal with the uncertainty of overruning limit flow, and a case study is employed to prove that the establishment of a port-convergence-station can ease the traffic jam [

20]. Other scholars believed that in order to ensure the smooth connection between the underground and the container yard of the ground terminal in the underground container logistics system, an underground parking garage should be established to form a buffer zone for underground loading/unloading vehicles and underground guided vehicles (UGVs). The mixed-integer nonlinear programming model (MNIP) is used to build a model for the minimum waiting time of vehicles [

21]. Several scholars created a two-stage model to realize road-underground-ocean container multimodal transport. The first stage is to determine the planning layout with the 0–1 planning model, and the second stage is to build a simulation model under the current scenario to simulate the volume of goods that can be transported by transport containers within a specified time. They concluded that transportation efficiency can be improved in such a way [

22]. In addition, considering the integrated transportation of roads and the ULS, Chen et al. established a mathematical model to study the freight transportation assignment problem in the integrated transportation network composed of aboveground roads and the ULS [

23].

Finally, as for the planning of the whole urban underground logistics system, many scholars also contributed their own research methods. Some scholars designed the conceptual model of the underground logistics system with Cargo Cap as the carrier, advised pallet-size freight and carried out the network planning and terminal model design within certain areas [

24]. Other scholars have carried out the network planning of underground logistics system by using the theories of the uncertain graph and dynamic programming [

25]; when it comes to route selection, certain scholars used a genetic algorithm to plan the layout of the distribution route considering the time and investment [

26]. Other scholars, taking into account the interests of both logistics planning decision-making departments and customers, used the bi-level programming model to study the location of logistics nodes in the construction of the underground logistics system [

27]. Li and Wang took the Steiner minimal tree (SMT) as the theoretical model, based on the characteristics of the continuous expansion of large cities in China, and established an underground tree logistics network layout model for the expanding large cities in China [

28]. They also optimized the algorithm by adopting the intelligence optimization algorithm using plant phototropism growth pattern as its heuristic criterion and created a plant growth simulation algorithm (PGSA). The algorithm uses the growth process of artificial plants in the space of a given logistics node set to find the optimal layout of the urban underground logistics network. In addition, some scholars located 23 imported grain distribution nodes through the qualitative method and evaluated the importance of each node in the freight railway, roadway, and waterway network by using complex network theory [

29]. Some scholars use the improved Bat-inspired Algorithm to solve the 0–1 mixed integer programming model, in order to locate the underground logistics center, which is faster than the basic Bat-inspired Algorithm [

30].

After summarizing extensive relevant data, this paper establishes that many scholars’ models only consider single factors, for instance, location of nodes or passages, but lack cost accounting and thus a comprehensive research. This paper starts from the location of nodes to the optimization of passages, considering factors including the node location, channel connection, specification selection and channel and node optimization in the later stage. Although the fuzzy clustering method is often used in the research for the evaluation of logistics enterprises or nodes [

31], this paper employs it to classify the logistics nodes into first-level and second-level nodes, to in line with the reality, environmental protection and resource saving. Moreover, this paper elaborates on a case analysis in the Xianlin sub-district, in Nanjing, to carry out the test. Through this case, the whole analysis process is presented, and the conclusion is discussed and analyzed to show the feasibility of the approach employed in this paper.

3. Research Method for the Network Design

The comprehensive design and optimization methods for the sustainable urban underground logistics network proposed by this paper are shown in

Figure 3, which contains three parts: the logistics nodes location, nodes classification and logistics passage design. The location of logistics nodes is the key to the whole underground logistics network, which determines the pattern and scale of the whole logistics network and directly affects the construction cost and the service level of the whole logistics system. However, considering that the number and location of the candidate nodes are unknown, and the logistics nodes need to be located to cover all freight logistics areas, this paper introduces congestion indexes to determine the areas to be covered and establishes a set cover model to determine the location of the nodes. In order to maximize resource savings, the nodes located above are further classified by the fuzzy clustering method, that is, by the classification of the first-level node and the second-level node. Then, a mixed integer programming model is proposed to optimize and design the logistics passage between nodes, and an ant colony algorithm is designed to solve this model. Based on these three parts, a complete sustainable urban underground logistics network can be constructed. Each area is included in the underground logistics network through the logistics nodes in that region. In this network, the first level-nodes are interconnected, while the second-level nodes are connected with the first-level nodes outside the area via the first-level nodes inside the area. Moreover, the first-level nodes can be connected with the logistics park and transfer cargo across areas. All the nodes are connected by the logistics passages designed above.

3.1. Location of Underground Logistics Nodes Based on the Cover Model

The Set Cover problem is a classical problem in combinatorial optimization and theoretical computer science. It requires a set to be covered with certain subsets at a minimum cost.

Let be areas; the complete set covering these areas is , and nodes are set as ; where is the logistics park, stands for the first-level nodes of underground logistics, stands for the second-level nodes of underground logistics, is the supply location and is the demand location. Let be one of the subsets of ; if and , then is called as a set cover of ; is the distance between nodes and ; is the set of logistics nodes that can serve demand point , such that , in order to find the minimum size of a set cover that can cover all congested areas after considering the realities of each region.

Given a decision variable

for each

:

The 0–1 model of the set cover problem can be formulated as follows:

For the above functions, Function (1) states whether or not the -th logistics node is selected. The objective Function (2) minimizes the number of facility nodes located as the objective of the model. Function (3) ensures that the radius of service from the point to the point is no more than 3 km. Function (4) ensures that the area nodes in the set are covered by at least one set. The decision variable (5) refers to the demand nodes which are located as the facility nodes.

3.2. Classification of Underground Logistics Node

The set cover model can only locate the nodes which can cover all areas. But in practical applications, in order to maximize resource savings, nodes should be classified, and the cover model cannot classify these nodes into the different levels. This paper will divide nodes into two levels: the first-level nodes are interconnected with each other, while the second-level nodes are connected with the first-level nodes outside the area via the first-level nodes inside the area. The first-level nodes are connected with the logistics park and can transfer cargo across areas. In contrast, cluster analysis can classify research objects automatically under certain rules through mathematical methods. The traditional clustering analysis uses a hard classification approach to classify each research object, to be strictly identified into a certain class, which is an either-or analysis method with the classification decision boundary. However, in reality, most of the research objects have no boundary; instead, they have certain probability estimations. Hence, a soft classification approach, namely fuzzy clustering analysis, emerged.

3.2.1. Fuzzy Clustering Analysis Model Building

The purpose of fuzzy clustering analysis is to partition samples into clusters to minimize the sum of squared error (SSE) of mean value between each sample and its cluster. The basic method to obtain the minimum SSE is the C-means method. Therefore, this paper uses the fuzzy C-means clustering, whose model is formulated as follows:

Let sample set be and the -th cluster be , while for element , let be a membership index, which means the degree of membership of elements belonging to the cluster .

Assume that for a given integer

, it satisfies

Then, the fuzzy matrix

is a fuzzy C-partition, which is formulated as follows:

Based on the above, the model of fuzzy

C-means clustering analysis can be shown as follows:

where

is the number of sample indicators of

;

is the cluster centroid of the fuzzy

C-partition of cluster

.

3.2.2. Solution of the Fuzzy Clustering Model

The fuzzy clustering model can be solved by many methods. In this paper, the fuzzy C-means clustering model is solved by using the method of the fuzzy equivalent matrix, as described below:

- (1)

Step 1: The standard deviation method is used to standardize the original data:

where

is the raw value of the

-th indicator of the sample

;

is the average value of the

-th indicator,

is the standard deviation of the

-th indicator and

is the standardized value of the

-th indicator of the sample

.

- (2)

Step 2: The fuzzy similarity matrix is formulated with the Euclidean distance method.

where

is the number of sample indicators;

is a constant that can make sense;

,

and

are the number of samples.

- (3)

Step 3: Based on the fuzzy similarity relation matrix, the fuzzy equivalent matrix can be solved. The max-min composition of relations is calculated for the fuzzy similarity relation matrix. The stopping criterion is , and the fuzzy matrix satisfying the stopping criterion is the fuzzy equivalent matrix.

- (4)

Step 4: Setting the critical value of the cluster in the fuzzy equivalent matrix, the samples can be clustered.

3.3. Network Design of the Underground Passages

The establishment of the underground logistics network requires underground passages to connect every node located by the method shown in

Section 3.2. Therefore, the main work of this section is the establishment and optimization of underground passages for network nodes connecting. In this section, firstly, the assumptions and objectives of designing the passages among nodes are put forward. Secondly, the mixed integer programming model with a minimum total cost object for the optimal design of underground logistics passages is constructed. Finally, the solution method of the model is given. The details are as follows:

3.3.1. Assumption on the Construction of the Passage Network

Before building the model, this paper makes the following assumptions. First of all, the construction of the underground logistics system network should be located on the logistics network node located on

Section 3; secondly, this paper proposes four specifications of underground tunnel available as the standard, which are: two-way four-track (10 tons), two-way double track (10 tons), two-way four-track (5 tons) and two-way double track (5 tons). The construction cost and transported vehicles vary with the types of tunnels. The goal of tunnel design is to meet the traffic capacity and minimize the logistics cost in the network. Thirdly, the logistics cost in this paper is composed of transportation cost and depreciation of underground logistics tunnels and nodes. Finally, because the freight in the underground nodes and passageways has to be daily cleared, those parts entering the underground must be transported to the demand location every day. Except for the underground passage from the logistic park to the first-level nodes, other underground passages admit underground transportation vehicles with a capacity of 5 tons. After considering the supply and demand between the nodes, the cargo-carrying capacity of vehicles and the road capacity, the location of first-level and second-level nodes should be adjusted appropriately to determine the tunnel route and build the underground logistics network.

3.3.2. Model of Passage Network Design

When constructing the underground passage, an important part of the logistics network, it is necessary to not only consider the freight flow between nodes and select the track with appropriate road capacity, but also examine the cost of different types of tracks. Aiming at the minimum cost, on the basis of the underground logistics node group located in

Section 3.1, the logistics passage is designed and the underground logistics network model is built.

Let be the freight volume from node to node ; be the freight volume of ground transportation from node to node ; be the freight volume of underground transportation from node to node ; be the number of vehicles dispatched from node to node , where , ; is the congestion index at node ; be the maximum congestion coefficient; be the annual comprehensive depreciation rate; be the freight transportation cost per ton-kilometer from node to node , in which ; is the cargo supply of node , wherein ; be the cargo demand of node , where ; is the freight volume per transportation vehicle of node , where ; indicates the connection between node ij and indicates the type tunnel route selected from to , where ; be the construction cost of different types of tunnel, where is 1, 2, 3, 4 to represent four types of track, namely a two-way four-track (10 tons), two-way double track (10 tons), two-way four rails (5 tons) and two-way double track (5 tons), respectively; be the construction cost of the first-level logistics nodes and the second-level nodes, respectively.

The model is formulated as follows:

In the above formula, the objective Function (4-1) indicates the construction cost of the logistics network, including transportation cost , the construction cost of node and the construction cost of the tunnel , where the construction cost of the node and the tunnel is included in the total cost in the form of depreciation per day. The constraint (17) restricts the congestion in the area to control the freight volume of ground transportation. Constraints (18) and (19) specify the volume of goods in the supply location and the demand location to meet all demands; (20) restricts the volume of goods transported by the vehicles, which cannot exceed the carrying capacity of conveyance; and (21) restricts the freight flow between nodes and defines zero freight flow when the nodes are disconnected; (22) restricts the connection between different nodes; (23) defines the non-negativity of the decision variables.

3.3.3. Solution to the Model of Passage Network Design

Based on the above models and assumptions, this paper gives the following parameters: assume that the average transportation cost per ton-kilometer is kept at about 1 yuan/ton-km (including the depreciation of vehicles and equipment), independent of the tunnel size. The construction costs of the underground logistics tunnel and node is the following: the two-way four-track (two independent tracks) (10 tons) tunnels and nodes cost 500 million yuan km, the two-way double track (two independent tracks) (10 tons) tunnels and nodes cost 400 million yuan/km, the two-way four-track (two independent tracks) (5 tons) tunnels and nodes cost 350 million yuan/km, the two-way double track (two independent tracks) (5 tons) tunnels and nodes cost 300 million yuan/km and the construction cost of a first-level node and a second-level node is about 150 million and 100 million yuan, respectively; the design life of the passages and the node lasts 100 years, and the annual comprehensive depreciation rate is 1%.

Since

Section 3 locates four first-level nodes and nine s-level nodes, and has fixed the service range of these nodes, the first step of the solving process is to determine the connectivity between nodes according to the service range. According to the supply-demand relationship of regional nodes, combined with the idea of an ant colony algorithm, the shortest feasible path between nodes is obtained (the process shown in

Figure 4). According to the freight flow between nodes, the freight flow of each route in the network is calculated. On the basis of the freight flow along the route and with the aim of the minimum cost, a suitable tunnel is built while the freight flow is met. The specific steps are as follows:

- (1)

Step1: Calculate first-level nodes and second-level nodes serving supply location and divide the area where the nodes are located.

- (2)

Step2: Define the connectivity between nodes by their area.

- (3)

Step3: Find the shortest path selection by the connectivity and the supply-demand relation between and .

- (4)

Step4: If the freight flow from to passes path , add up the part where the freight flow from o to d passes path , and then the freight flow along each route is obtained through this cycle.

- (5)

Step 5: Solve the model based on freight logistics after meeting the constraints of road capacity and the vehicle’s carrying capacity at minimum cost and obtain the final result.

5. Conclusions

In order to solve the problem of environmental pollution and transportation cost increase caused by urban traffic congestion, the underground logistics transportation system has been widely studied and discussed by scholars. This paper proposes a relatively complete systematic method for underground logistics nodes and structural components of passage logistics, designs the framework of sustainable urban underground logistics network considering environmental and economic factors and verifies the method by studying the Xianlin sub-district, in Nanjing, as an example. This paper first considers local congestion in different areas. With the help of a reasonable set cover model, the first urban underground logistics nodes are selected to locate 13 underground logistics nodes. Then, the located nodes are classified by the fuzzy clustering method to locate four first-level nodes and nine s-level nodes. Secondly, with the aim of the minimum cost of underground logistics construction and operation, with the constraints of traffic volume and congestion factored in, the optimization and design model of the underground logistics passage is constructed, and an ant colony algorithm is employed to solve the model, in order to find the optimal parameters for the passage at each node, thus forming a sustainable underground logistics network structure framework including all levels of logistics nodes and passages. Through the analysis of the underground logistics network structure in the Xianlin sub-district, in Nanjing, the underground logistics system built by following the method presented in this paper can effectively reduce the cost of urban traffic congestion and logistics emission pollution, and has good environmental and economic benefits.

This paper analyzes the cost of congestion and exhaust emission of the transportation system and draws the following conclusions:

First, in terms of exhaust emission reduction, greenhouse gas emissions are still more dominant than air pollutant gas emissions; however, only limited greenhouse gas emissions can be reduced by easing traffic congestion. In a freight transportation cycle, only about 7 tons of CO2 emissions can be reduced, while the reduction of CO, HC and NOx amounts to about 0.1–0.5 tons. Therefore, solving the problem of traffic congestion can alleviate exhaust gas emissions to a certain extent, but the effect is not significant. It is a more effective solution to replace the current truck with new energy vehicles or trains as the means of transport.

Second, when it comes to the reduction in the cost of congestion, the cost of time of freight accounts for the largest proportion of the total costs of congestion (nearly over 90%), followed by costs of fuel, with the lowest proportion in exhaust treatment costs. Therefore, in the road section with large freight flow, establishing an underground logistics system for the purpose of reduction in freight time caused by traffic congestion is extremely effective, greatly cutting down the congestion-caused loss. In addition, the cost of fuel and exhaust treatment can also be cut by the underground logistics system, but the benefits generated from cost reduction are less than those obtained by the reduction in the cost of time. Hence, during the actual planning, all those cost reduction methods can be employed mainly in the section with large freight flow to obtain the maximum benefit.

Focusing on the three keywords economy, environment and society, which are related to the sustainable development of urban logistics, this paper puts forward an effective method and scheme for the construction of an integrated underground logistics system by grasping the core element of congestion alleviation, which provides a meaningful decision-making reference for the planning and construction of an underground logistics system in congested cities. However, there are also some research limitations. For example, this paper only considers the underground passage for freight transportation. However, with the fluctuation of the freight flow, the passage will either lay idle or require a queue. Therefore, the questions of how to calculate the cost of idling for the passage and whether it can be used for vehicles other than the specified ones should be considered, although they were not covered in this paper. In future research, the measures for an emergency in the underground logistics system will be studied to improve the research on the network.