Sustainable Engineering: Load Transfer Characterization for the Structural Design of Thinner Concrete Pavements

Abstract

:1. Introduction

2. Materials and Methods

2.1. Practical Laboratory Test

2.2. Agregate Properties

2.3. Sustainability Comparison of Traditional Slab and Short Slab Jointed Plain Concrete Pavements

3. Results and Discussions

3.1. Laboratory Test Results

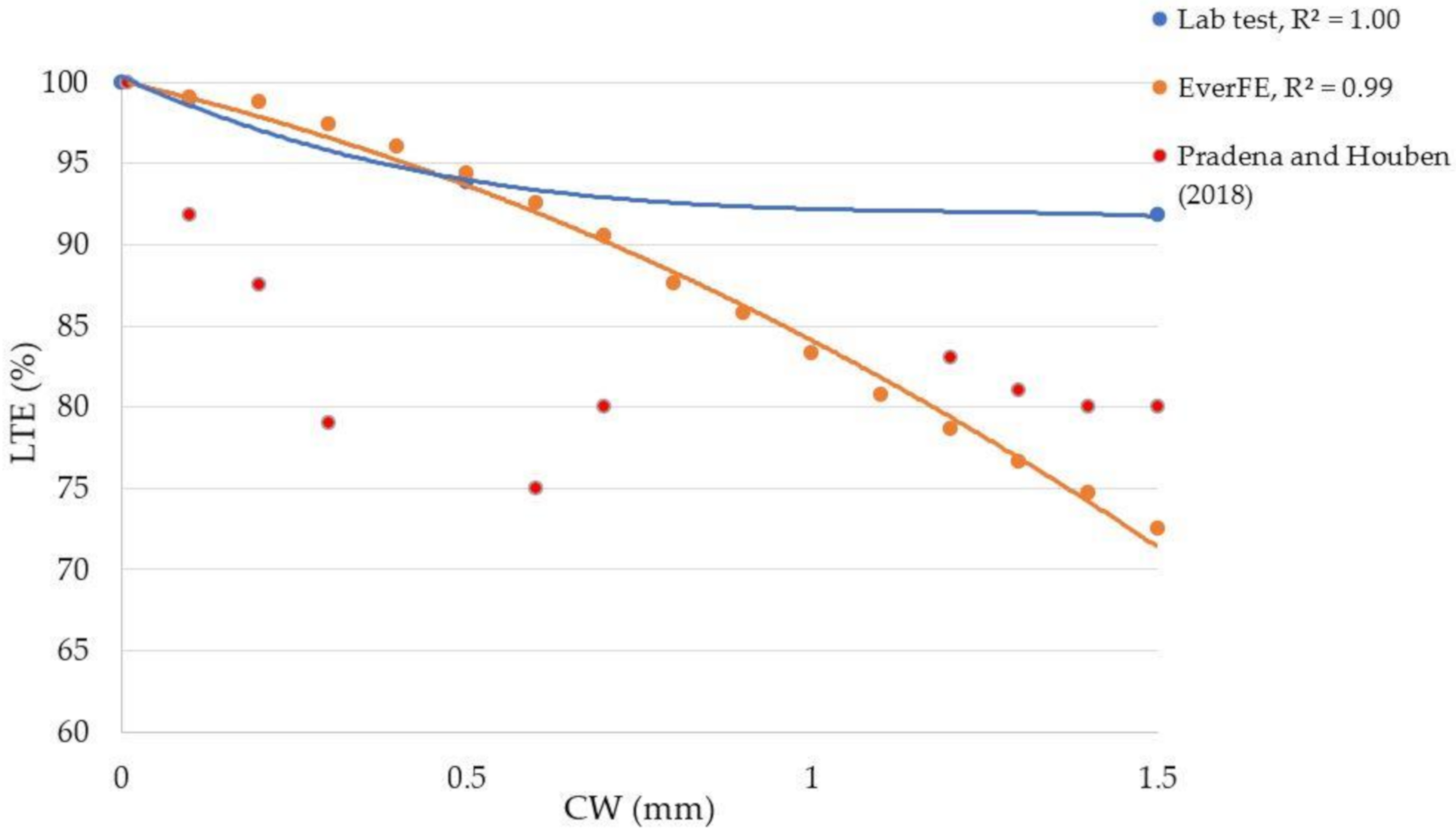

3.2. The LTE–CW Relation

3.3. Sustainability Analysis Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, H. Life-cycle analysis of repair of concrete pavements. In Eco-Efficient Repair and Rehabilitation of Concrete Infrastructures; Woodhead Publishing: Cambridge, UK, 2018; pp. 723–738. [Google Scholar]

- Sánchez, R.F.; Meseguer, A.G. Pavimentos de hormigón en vías urbanas. Inf. Constr. 1971, 23, 61–73. (In Spanish) [Google Scholar]

- Smith, T.; Maillard, P. Sustainable Benefits of Concrete Pavement. In Proceedings of the 42e Congres Annuel de l’AQTR-Defi, Transport Durable, Montréal, OC, Canada, 2–4 April 2007. [Google Scholar]

- Delatte, N. Concrete Pavement Design, Construction, and Performance, 1st ed.; Taylor & Francis: New York, NY, USA, 2008. [Google Scholar]

- Díaz-Minguela, J.; Hacar, F. Estudio de los pavimentos de túneles carreteros: Ventajas de los pavimentos de hormigón frente a los bituminosos. Obras y Proyectos 2018, 23, 87–95. (In Spanish) [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Effectiveness of hair and wave polypropylene fibers for concrete roads. Constr. Build. Mater. 2018, 166, 581–591. [Google Scholar] [CrossRef]

- Mohod, M.V.; Kadam, K.N. A comparative study on rigid and flexible pavement: A review. IOSR JMCE 2016, 13, 84–88. [Google Scholar]

- Kline, J.; Barcelo, L. Cement and CO2, a victim of success! In Proceedings of the IEEE-IAS/PCA 54th Cement Industry Technical Conference, San Antonio, TX, USA, 14–17 May 2012; pp. 1–14. [Google Scholar]

- Monteiro, P.J.M.; Miller, S.A.; Horvath, A. Towards sustainable concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef]

- Mindess, S. Sustainability of concrete. In Developments in the Formulation and Reinforcement of Concrete, 2nd ed.; Woodhead Publishing: Vancuver, BC, Canada, 2019; pp. 3–17. [Google Scholar]

- Fernandez, A.; Leung, Y. Technology Roadmap-Low-Carbon Transition in the Cement Industry. 2018. International Energy Agency. Available online: https://webstore.ie.org/technologyroadmap-low-carbon-transition-in-the-cement-industry (accessed on 6 May 2020).

- Lepech, M.D.; Keoleian, G.A.; Li, V.C.; Qian, S. Design of green engineered cementitious composites for pavement overlay applications. In Proceedings of the 1st International Sympoium on Life Cycle Civil Engineering, Varenna, Italy, 10–14 June 2008; pp. 837–842. [Google Scholar]

- Potgieter, J.H. An Overview of Cement production: How “green” and sustainable is the industry? Environ. Manag. Sustain. Dev. 2012, 1, 14. [Google Scholar] [CrossRef] [Green Version]

- Opoku, A.; Ahmed, V. Embracing sustainability practices in UK construction organizations. Built Environ. Proj. Asset Manag. 2014, 4, 90–107. [Google Scholar] [CrossRef]

- World Commission on Environment and Development. Our Common Future: Report of the World Commission on Environment and Development; Oxford University Press: Oxford, UK, 1987. [Google Scholar]

- Rosen, M.A. Engineering Sustainability: A Technical Approach to Sustainability. Sustainability 2012, 4, 2270–2292. [Google Scholar] [CrossRef] [Green Version]

- Brunatti, C.; Fernandez, L. El Pavimento de Hormigón. Un Camino Sustentable. In Proceedings of the I Congreso Hormigón Premezclado de las Américas, Mar del Plata, Argentina, 8–10 November 2010. (In Spanish). [Google Scholar]

- Plati, C. Sustainability factors in pavement materials, design, and preservation strategies: A literature review. Constr. Build. Mater. 2019, 211, 539–555. [Google Scholar] [CrossRef]

- Van Dam, T.; Taylor, P.; Fick, G.; Gress, D.; VanGeem, M.; Lorenz, E. Sustainable Concrete Pavements: A Manual of Practice; National Concrete Pavement Technology Center, Iowa State University: Ames, IA, USA, 2012. [Google Scholar]

- Covarrubias, T.J.P.; Covarrubias, J.P. TCP design for thin concrete pavements. In Proceedings of the 9th International Conference on Concrete Pavements, San Francisco, CA, USA, 17–21 August 2008. [Google Scholar]

- Covarrubias, J.P. Design of concrete pavement with optimized slab geometry. Rev. Ing. Constr. 2012, 27, 181–197. [Google Scholar]

- Roesler, J.R.; Cervantes, V.G.; Amirkhanian, A. Accelerated performance testing of concrete pavement with short slabs. Int. J. Pavement Eng. 2012, 13, 494–507. [Google Scholar] [CrossRef]

- ICH. Available online: https://ich.cl/pavimentando/noticias-pavimentando/experiencia-de-chile-con-los-pavimentos-de-losas-cortas/ (accessed on 14 June 2020).

- Revista EMB Construcción. Available online: http://www.emb.cl/construccion/articulo.mvc?xid=3280&edi=154&xit=augusto-holmberg-gerente-general-ich-el-repunte-del-hormigon-en-la-industria-de-pavimentos (accessed on 14 June 2020). (In Spanish).

- Skrzypczak, I.; Radwański, W.; Pytlowany, T. Durability vs technical—The usage properties of road pavements. E3S Web Conf. 2018, 45, 00082. [Google Scholar] [CrossRef] [Green Version]

- Chávez, O. Losas Cortas: Una experiencia en Nicaragua. In Proceedings of the VII Congreso Nacional de Ingeniería Civil, Managua, Nicaragua, 17–18 October 2013. (In Spanish). [Google Scholar]

- Salsilli, R.; Wahr, C.; Delgadillo, R.; Huerta, J.; Sepúlveda, P. Field performance of concrete pavements with short slabs and design procedure calibrated for Chilean conditions. Int. J. Pavement Eng. 2014, 16, 363–379. [Google Scholar] [CrossRef]

- Pradena, M.; Houben, L. Load Transfer-Crack Width Relation of Non-Dowelled Jointed Plain Concrete Short SLABS. Balt. J. Road Bridge Eng. 2018, 13, 40–45. [Google Scholar] [CrossRef] [Green Version]

- Covarrubias, J.P. Design of concrete slabs with optimized geometry. In Proceedings of the 2nd International Conference on Best Practices for Concrete Pavements, Florianopolis, Brazil, 2–4 November 2011. [Google Scholar]

- Bordelon, A.C.; Roesler, J.; Hiller, J.E. Mechanistic-Empirical Design Concepts for Jointed Plain Concrete Pavements in Illinois; Illinois Center for Transportation (ICT): Urbana, IL, USA, 2009. [Google Scholar]

- Wadkar, A.; Mehta, Y.; Cleary, D.; Guo, E.; Musumeci, L.; Zapata, A.; Kettleson, W. Load-Transfer Efficiencies of Rigid Airfield Pavement Joints Based on Stresses and Deflections. J. Mater. Civ. Eng. 2011, 23, 1171–1180. [Google Scholar] [CrossRef]

- Snyder, M.B. Guide to Dowel Load Transfer System for Jointed Concrete Roadway Pavements; Institute for Transportation at Iowa State University; National Concrete Consortium: Ames, IA, USA, 2011. [Google Scholar]

- Maitra, S.R.; Reddy, K.S.; Ramachandra, L.S. Load Transfer Characteristics of Aggregate Interlocking in Concrete Pavement. J. Transp. Eng. 2010, 136, 190–195. [Google Scholar] [CrossRef]

- Nowlen, W.J. Influence of Aggregate Properties on Effectiveness of Interlock Joints in Concrete Pavements. J. PCA Res. Dev. Lab. 1968, 10, 2–8. [Google Scholar]

- Walraven, J.C. Aggregate Interlock: A Theoretical and Experimental Analysis. Ph.D. Thesis, The Delft University of Technology, Delft, The Nederlands, October 1980. [Google Scholar]

- Wattar, S.W. Aggregate Interlock Behavior of Large Crack Width Concrete Joints in PCC Airport Pavements. Ph.D. Thesis, The University of Illinois at Urbana-Champaign, Champaign County, IL, USA, 2002. [Google Scholar]

- Byrum, C.R.; Barton, P.J.; Rollings, R.S.D.; Ioannides, A.M.; Gemayel, C.A.; Tayabji, S. Joint Load Transfer in Concrete Airfield Pavements: Final Report; Innovative Pavement Research Foundation Report IPRF-01-G-002-05-2; IPRF: Rosemont, IL, USA, 2011. [Google Scholar]

- Söderqvist, J. Design of Concrete Pavements: Design Criteria for Plain and Lean Concrete. Ph.D. Thesis, Royal Institute of Technology, Stockholm, Sweden, November 2006. [Google Scholar]

- Stet, M.J.A.; Leest, A.; Frénay, J.W. Dutch design tool for jointed and continuously reinforced concrete road pavements. In Proceedings of the 10th International Symposium on Concrete Roads, Brussels, Belgium, 18–22 September 2006. [Google Scholar]

- Houben, L.J.M. Structural Design of Pavements. Part IV: Design of Concrete Pavements; Lecture Notes CT4860; The Delft University of Technology: Delft, The Netherlands, 2006. [Google Scholar]

- Hiller, J.E. Development of Mechanistic-Empirical Principles for Jointed Plain Concrete Pavement Fatigue Design. Ph.D. Thesis, University of Illinois at Urbana-Champaign, Champaign, IL, USA, October 2007. [Google Scholar]

- Chilean Highway Agency. Difusión Nuevas Tecnologías y Especificaciones Técnicas Manual Anexo N°1: Método de Diseño de Pavimento de Hormigón con Losas de Espesor Optimizado; Ministerio de Obras Públicas: Santiago, Chile, 2012. (In Spanish) [Google Scholar]

- Revista Obras Públicas. Resultados observados en nuevas tecnologías de pavimentos de hormigón. Rev. Obras Públicas 2020, 53, 34–37. [Google Scholar]

- Colley, B.E.; Humphrey, H.M. Aggregate Interlock at Joints in Concrete Pavements; Highway Research Record 189; HRB National Research Council: Washington, DC, USA, 1967; Volume 189, pp. 1–18. [Google Scholar]

- Jensen, E.A. Mechanism of load transfer-crack width relation in JPCP: Influence of coarse aggregate properties. In Proceedings of the 7th International Conference on Concrete Pavements. The Use of Concrete in Developing Long-Lasting Pavement Solutions for the 21st Century, International Society for Concrete Pavements, Orlando, FL, USA, 9–13 September 2001. [Google Scholar]

- Pradena, M.; Houben, L.; César, A. Laboratory Characterization of the Load Transfer-Crack Width Relation for Innovative Short Concrete Slabs Pavements. Balt. J. Road Bridge Eng. 2020, 15, 232–250. [Google Scholar] [CrossRef]

- Abraham, M.A.; Nguyen, N. “Green engineering: Defining the principles”—Resdts from the sandestin conference. Environ. Prog. 2003, 22, 233–236. [Google Scholar] [CrossRef]

- Allen, D.T.; Shonnard, D.R. Sustainable Engineering: Concepts, Design, and Case Studies; Prentice Hall: Upper Saddle River, NJ, USA, 2012. [Google Scholar]

- ASTM. Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading); ASTM C78; ASTM: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Ramirez, L.C. Concrete Mixer Properties Affecting the Aggregate Interlock Mechanism of Joints and Cracks for Rigid Pavement Systems. MSc Thesis, University of Pittsburgh, Pittsburgh, PA, USA, November 2010. [Google Scholar]

- Thompson, I. Use of Steel Fibres to Reinforce Cement Bound Roadbase. Ph.D. Thesis, The University of Nottingham, Nottingham, UK, May 2001. [Google Scholar]

- Arnold, S.; Fleming, P.R.; Austin, S.; Robins, P. A test method and deterioration model for joints and cracks in concrete slabs. Cem. Concr. Res. 2005, 35, 2371–2383. [Google Scholar] [CrossRef] [Green Version]

- Pradena, M.; Houben, L.; César, A. Experimental evaluation of load transfer efficiency of non-dowelled concrete pavements. Gradevinar. accepted.

- Osman, O.; El Ghazolly, M.; Mousa, R. Impact of increasing legal axle loads on truck factor in Egypt; Taylor & Francis Group: London, UK, 2009; pp. 709–718. [Google Scholar]

- Macea, L.F.; Fuentes, L.G.; Alvarez, A.E. Evaluación de factores camión de los vehículos comerciales de carga que circulan por la red vial principal colombiana. Rev. Fac. Ing. 2016, 66, 57–69. (In Spanish) [Google Scholar]

- Hanekom, A.C.; Horak, E.; Visser, A.T. Comparison of South African and American Aggregate Interlock Efficiency at Concrete Pavement Joints. In Proceedings of the 16th ASCE Engineering Mechanics Conference, Seattle, WA, USA, 16–18 July 2003. [Google Scholar]

- Neville, A.M. Properties of Concrete; Longman: London, UK, 1995; Volume 4. [Google Scholar]

- Tunc, E.T.; Alyamac, K.E. A preliminary estimation method of Los Angeles abrasion value of concrete aggregates. Constr. Build. Mater. 2019, 222, 437–446. [Google Scholar] [CrossRef]

- ASTM. Resistance to Degradation of Large Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine; ASTM C535; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM. Standard Test Method for Compressive Strength and Elastic Moduli of Intact Rock Core Specimens Under Varying States of Stress and Temperatures; ASTM D7012; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Deere, D.U.; Miller, R.P. Engineering Classifications and Index Properties for Intact Rock; Technical Report No. AFWL-TR 65-116; Air Force Weapons Laboratory, Kirtland Air Force Base: Albuquerque, NM, USA, 1966. [Google Scholar]

- Chilean Highway Agency. Highways Manual; Ministry of Publics Works: Santiago, Chile, 2019. (In Spanish) [Google Scholar]

- Salsilli, R.; Wahr, C. Trends in Concrete Pavements. In Proceedings of the Seminar New Challenges and Trends in Concrete Pavements, Santiago, Chile, 9 November 2010. (In Spanish). [Google Scholar]

- Salgado, M. Analysis and Prediction of the Behaviour of Semi-Rigid Short Slabs Concrete Pavements. In Proceedings of the International Seminar Latest Advances in Design and Construction of Concrete Pavements, Buenos Aires, Argentina, 9–10 May 2011. (In Spanish). [Google Scholar]

- ISO. ISO 14040: Environmental management—Life Cycle Assessment—Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- ISO. ISO 14044: Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Harvey, J.; Meijer, J.; Ozer, H.; Al-Qadi, I.L.; Saboori, A.; Kendall, A. Pavement Life Cycle Assessment Framework (No. FHWA-HIF-16-014); Federal Highway Administration: Washington, DC, USA, 2016. [Google Scholar]

- Cebrián, D.; Garraín, D.; Vidal, R.; Abad, J.; París, A. Free LCA: The use of ELCD in the design stage. In Proceedings of the 13th International Congress on Project Engineering, Bajadoz, Spain, 8–10 July 2009. [Google Scholar]

- ÖKOBAUDAT Database. Available online: https://oekobaudat.de/ (accessed on 16 May 2020).

- EN 15804. Sustainability of Construction Work—Environmental Product Declarations—Core Rules for the Product Category of Construction Products; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- EPA 2002 U.S. Exhaust and Crankcase Emissions Factors for Nonroad Engine Modelling—Compression-Ignition; Report No. NR-009b; Assessment and Standards Division, Office of Transportation and Air Quality: Washington, DC, USA, 2002. [Google Scholar]

- GreenDelta. Available online: http://www.openlca.org/download/ (accessed on 5 April 2020).

- Bare, J.C.; Norris, G.A.; Pennington, D.W.; McKone, T. TRACI: The tool for the reduction and assessment of chemical and other environmental impacts. JIE 2003, 6, 49–78. [Google Scholar] [CrossRef]

- Shi, X.; Mukhopadhyay, A.; Zollinger, D.; Grasley, Z. Economic input-output life cycle assessment of concrete pavement containing recycled concrete aggregate. J. Clean. Prod. 2019, 225, 414–425. [Google Scholar] [CrossRef]

- Harvey, J.; Wang, T.; Lea, J. Application of LCA results to network-level highway pavement management. In Climate Change, Energy, Sustainability and Pavements; Springer: Berlin/Heidelberg, Germany, 2014; pp. 41–73. [Google Scholar]

- Yang, R.Y. Development and Implementation of Comprehensive Regionalized Pavement Life-Cycle Assessment. Ph.D. Thesis, University of Illinois at Urbana-Champaign, Champaign, IL, USA, April 2017. [Google Scholar]

- Brink, A.; Horak, E.; Visser, A. Improvement of aggregate interlock equation used in mechanistic design software. Int. J. Concr. Pavements 2005, 1, 1–22. [Google Scholar]

- Barman, M. Joint Performance Characterization of Bonded Whitetopping Overlays. Ph.D. Thesis, University of Pittsburgh, Pittsburgh, PA, USA, 2014. [Google Scholar]

- Hu, C.H.; Ma, X.Z. Load Transfer Behavior of Cracking for Cement Concrete Pavement. Adv. Mater. Res. 2015, 1120, 1496–1500. [Google Scholar] [CrossRef]

- Buch, N.; Frabizzio, M.A.; Hiller, J.E. Impact of coarse aggregates on transverse crack performance in jointed concrete pavements. ACI Mater. J. 2000, 97, 325–332. [Google Scholar]

- Mulyono, A.T.; Parikesit, D.; Antameng, M.; Rahim, R. Analysis of loss cost of road pavement distress due to overloading freight transportation. J. East Asia Soc. Transp. Stud. 2009, 8, 19–30. [Google Scholar]

- Macea-Mercado, L.F.; Morales, L.; Márquez-Díaz, L.G. Un sistema de gestión de pavimentos basado en nuevas tecnologías para países en vía de desarrollo. Ing. Investig. Tecnol. 2016, 17, 223–236. [Google Scholar] [CrossRef] [Green Version]

- Achurra, S. Procedure to Measure and Control of the Superficial Friction in Chilean Pavements. Master’s Thesis, Catholic University of Chile, Santiago, Chile, July 2009. (In Spanish). [Google Scholar]

- Slaper, H.; Velders, G.J.; Daniel, J.S.; De Gruijl, F.R.; Van der Leun, J.C. Estimates of ozone depletion and skin cancer incidence to examine the Vienna Convention achievements. Nature 1996, 384, 256–258. [Google Scholar] [CrossRef]

| Load Test (kN) | Vehicle Axle (kN) | Stress Produced (kPa) |

|---|---|---|

| 8 | 80 | 224 |

| 10 | 100 | 266 |

| 12 | 120 | 320 |

| Properties | Aggregate 1 | Aggregate 2 |

|---|---|---|

| LA (%) | 12 | 27 |

| UCS (MPa) | 104.83 | 58.94 |

| CP (%) | 75 | 100 |

| Route | Traditional JPCP | Short Slabs JPCP |

|---|---|---|

| 1 | 220 | 170 |

| 2 | 220 | 160 |

| 3 | 180 | 150 |

| 4 | 180 | 100 |

| 5 | 150 | 100 |

| 6 | 180 | 130 |

| 7 | 220 | 150 |

| 8 | 300 | 220 |

| 9 | 250 | 180 |

| 10 | 260 | 200 |

| 11 | 240 | 180 |

| 12 | 250 | 200 |

| 13 | 165 | 125 |

| 14 | 260 | 180 |

| 15 | 180 | 150 |

| 16 | 250 | 180 |

| 17 | 200 | 150 |

| 18 | 280 | 200 |

| Properties | Traditional Pavement | Short Slab Pavement |

|---|---|---|

| Portland Cement | 80.57 | 88.66 |

| Gravel | 5.75 | 6.35 |

| Sand | 2.84 | 3.13 |

| Diesel | 0.46 | 1.44 |

| Joint seal | 9.99 | - |

| Others | 0.38 | 0.42 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

César, A.; Pradena, M. Sustainable Engineering: Load Transfer Characterization for the Structural Design of Thinner Concrete Pavements. Sustainability 2020, 12, 9153. https://doi.org/10.3390/su12219153

César A, Pradena M. Sustainable Engineering: Load Transfer Characterization for the Structural Design of Thinner Concrete Pavements. Sustainability. 2020; 12(21):9153. https://doi.org/10.3390/su12219153

Chicago/Turabian StyleCésar, Andrés, and Mauricio Pradena. 2020. "Sustainable Engineering: Load Transfer Characterization for the Structural Design of Thinner Concrete Pavements" Sustainability 12, no. 21: 9153. https://doi.org/10.3390/su12219153