Abstract

The mining industry is facing sustainable development challenges, among which the energy efficiency issues seem to be of major importance. As transport of the mined ore is considered as one of the most energy intensive operations, the improvement of its energy efficiency is a key indicator in terms of sustainable actions taken by mining companies. In open-pit mines, the material handling operations are mostly performed with trucks. Their electrified version—truck trolley systems—surpass diesel trucks’ efficiency while comparing the increased production capacity and the reduction of maintenance cost and fuel consumption. The paper analyzes the opportunities and benefits of the replacement of an ore transport system based on hauling trucks with a regenerative belt conveying in an open-pit mine. Presented case study has been analyzed from energy consumption and environmental impact reduction perspectives. Generally, conception of a regenerative conveyor is based on recuperation of energy or continuous braking needed while a conveyor is running downhill. Energy generated during the braking process (converted from the potential gravitational energy of the conveyed material) is fed back to the electrical grid. Then the regenerative conveyor can be considered as a machine that mines energy as an additional by-product of an exploited deposit. It was shown that difference in transportation cost between haul trucks and energy efficient regenerative conveyors is around 95%. The paper points the conditioning elements to allow the implementation of a regenerative belt conveyor system.

1. Introduction

Nowadays, the mining industry is forced to shift from conventional mining to a sustainable one, which makes sense for economic, environmental and social reasons. These three factors are considered to be of fundamental importance to balance mining operations within the whole mine life cycle [1,2]. Growing concerns about mining companies’ impact on their surroundings call for sustainability reports to provide transparent and comprehensive information about their sustainable activities [3,4]. The Global Reporting Initiatives (GRI) Standards framework is considered to be the most practical guideline for sustainable reporting (SR), as it reflects the positive and negative contributions of sustainable development in the company. Although the usefulness of the reports and quality of contained information have been the subject of criticism [5,6,7], SR improves corporate image as well as the social and environmental performance of the company. Since the Polish mining industry is amongst the strongest in the European Union—the top 10 producers of primary aggregates [8], the leader of phasing out European hard coal production [9] and finally the leading country in copper production [10]—the necessity of implementing sustainable solutions in Polish mines is crucial in order to meet the international standards for responsible mining activities. The aggregates production in Poland for the last 30 years has boosted to match the demand from the extensive infrastructure development—since 1990 in the adjacent East Germany lands and also within Poland being entered into the EU, after implementing the EU structural funds.

In the recent years, authors [4,11,12,13] have identified and evaluated sustainable practices of selected mining companies in Poland. It seems that guidelines for sustainability reporting are considered as a set of best practices that are more and more often implemented not only by large mining companies but also by small and medium-sized ones for which their public perception is essential. In accordance with [14] the most relevant and widely analyzed segment of sustainability in mining is its environmental performance. Aspects such as gas emissions, noise pollution and especially energy use are attracting widespread interest. In general, the metal ore and rock resource mining industry is considered as an energy intensive one and it is estimated to consume 6.2% of the total global energy consumption [15]. According to [16], the final energy consumption of the Polish mining industry accounted for 12.30% of the final consumption of the European Union mining in 2017. Such an energy intensive industry sector needs to be scrutinized from a sustainability and energy-related policy perspective.

The sustainable development concept of the energy issues in the mining industry is aimed at initiatives for the improvement of operations’ energy efficiency and the use of clean energy. The implementation of technologies that minimize the energy consumption of comminution processes [17,18], loading and hauling operations [19,20] or mine ventilation [21,22] are key actions dedicated to the sustainable use of energy. Moreover, renewable energy use, energy management systems and strategies are becoming increasingly important for energy savings [23,24,25]. Comprehensively designed energy systems and deployment of renewable energy systems enables model energy demand, control on electricity consumption and finally, leads to cleaner production.

Furthermore, as current European Union policy in the field of Energy and Environment is aimed at energy efficient and environmentally friendly operations, directives and regulations for energy efficiency were put in force by the EU Energy Efficiency Directive [26] and amending Directive on Energy Efficiency [27] which constitutes the policy framework and measures for efficient use of energy in the EU. The noteworthy part of government legislation is energy labeling and eco-design regulations [28]. The main objective of energy labeling is to provide an accurate information about energy efficiency of a product and some features of its usage, including noise emissions. This means that users may compare energy-related products and choose those that are better-performing. Next, eco-design requirements set the mandatory minimum standards for products’ energy consumption to enhance its environmental performance over its entire lifecycle. Considering these trends energy-consuming mining equipment, e.g. belt conveyors, should no longer be designed and built to the outdated and conservative standards. That is the reason for which, the proposal of new standards for belt conveyors has been presented in [29]. The idea of standardization assumes to create energy labels and take a holistic perspective on designing conveying systems.

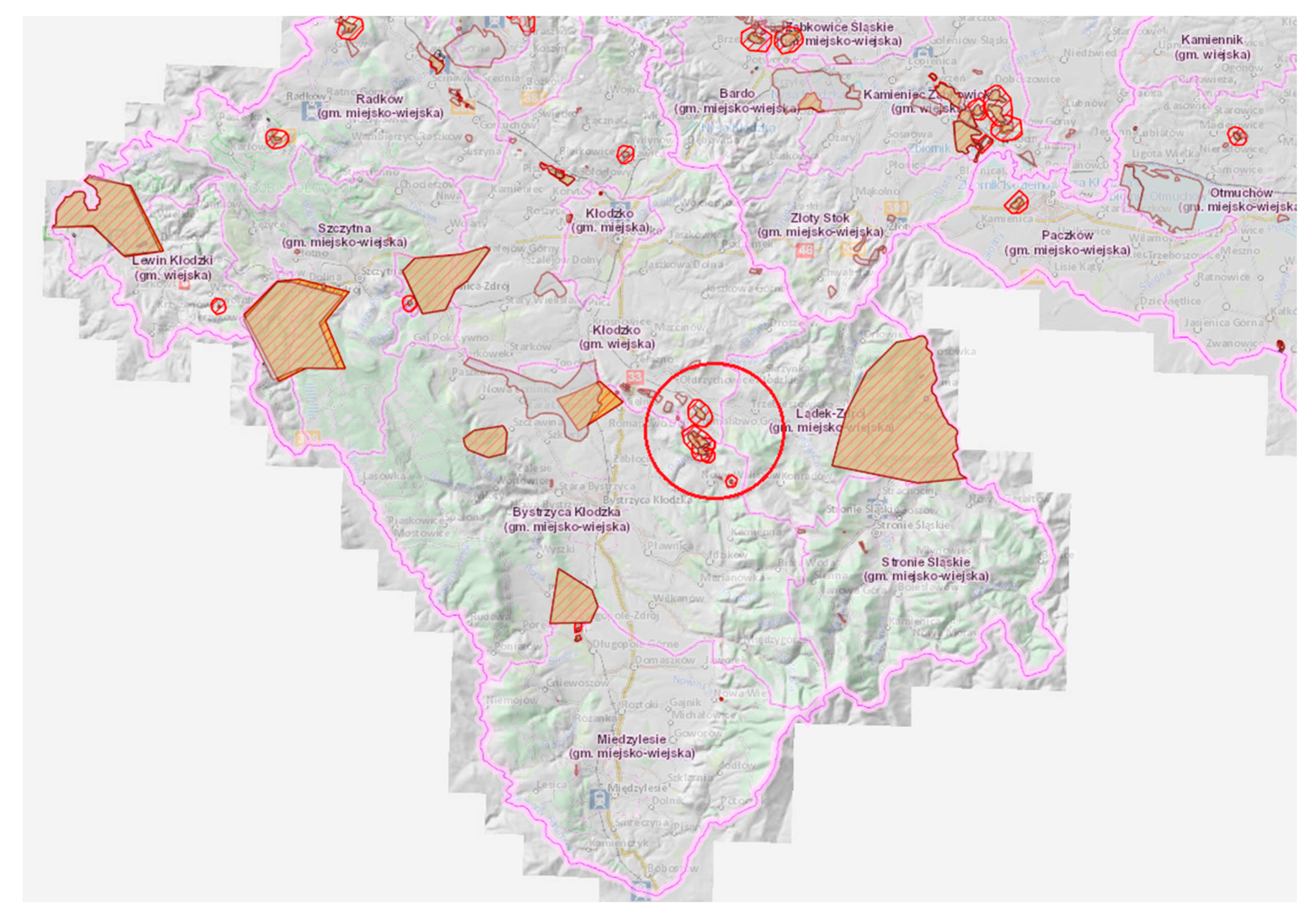

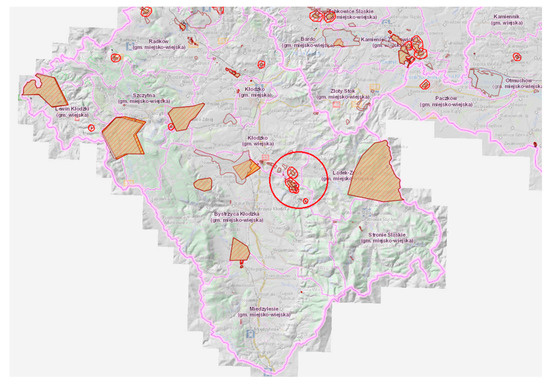

Taking the above into consideration, the sustainability concept is in line with energy-related policy framework. Thus, the efficient use of energy seems not to be a matter of choice but an absolute necessity, especially for energy-intensive mining operations, amongst which material handling is of great importance. The aforementioned massive aggregates production in Poland is located mostly in the southern, mountainous part of the country (see Figure 1). Such location gives an opportunity to recover the potential gravitational energy of tons of run-of-mine material in the case of transporting it downhill. The sustainable approach assumes that apart from a deposit of aggregates, a deposit of potential gravitational energy (a sort of by-product) should be evaluated and effectively “mined” with the use of appropriate equipment—a regenerative belt conveyor.

Figure 1.

Active aggregate mines and prospective deposits in the Klodzko Valley in Lower Silesia (Southwest Poland at the Czech Republic border) [30].

2. Materials and Methods

2.1. Materials Handling—Energy Intensive Operation

In accordance with Soofastaei et al. [31], the energy consumption due to material handling constitutes around 20% of the total energy usage in the mining industry. The mostly used mode of transport in open-pit mines are haul trucks, for which the main source of energy is diesel fuel [32]. When it comes to diesel fuel consumption, it is estimated to account for 40% of the total energy use and to generate even up to 50% of maintenance costs in open-pit mines [20,32]. Additionally, the environmental impact of haul trucks is recognized as negative and the reason is twofold. Firstly, consumed fuel causes greenhouse gas (GHG) emissions. Secondly, haul truck operations are the source of noise, dust, vibrations and local roads deterioration.

The energy efficiency of hauling operations depends on operating conditions, equipment unit efficiency and operator skills and practice [19]. Since various parameters influence fuel consumption, a neural network model was implemented to predict specific fuel consumption and maximum truck velocity was recognized as the most influential parameter [31]. Peralta et al. [33] showed that truck reliability, distance and weight are important for fuel consumption and a truck maintenance plan is vital for energy consumption and GHG emissions reduction. Another research proved that a 10% decrease in engine load factors results in significant CO2 emission and fuel consumption reductions, as well as associated potential savings [34]. Moreover, hybrid electric vehicles are becoming an alternative for conventional haul trucks. Although the hybrid electric powertrain technology may improve fuel efficiency, the essential elements are drive cycle profile, constantly changing conditions and hybrid control system [35]. The relevant constraint of dump trucks energy performance are operator’s skills, which directly influence parameters such as vehicle speed and cycle time during operation [36]. Some research has compared the traditional shovel-hauling truck system with in-pit crushing and conveying systems while analyzing the optimal transportation system in surface mines [32,37]. Truck haulage is flexible and may be well suited on an ongoing basis. On the other hand, belt conveyors operate at a lower decibel level (70 dB at 5 m distance) than trucks (90 dB at a distance of 10 m), minimize amount of emitted dust, reduce overall auxiliary equipment requirements and finally their (valuable) operating time is 25% higher than for haul trucks.

2.2. Trolley Trucks and Belt Conveyors Developments

Advancements in haul truck transportation are aimed at energy consumption reduction which directly lessens environmental impact. Therefore, the idea of mining haul trucks powered with diesel-electric engines and operating on trolley systems has been proposed. The general idea is to implement the trolley truck concept for hauling operations on ramps and diesel-powered ones for the remaining haul cycle [38,39]—such a solution is considered as the most effective one. It is worth to note that, in a situation where trolley assist systems work on downhill routes, the energy feedback to the grid is possible. It is observed that an important effort has been made for mining haul trucks operated on trolley systems, especially in the development of an integrated electric-mechanical model of a diesel-electric truck [40,41]. Valenzuela Cruzat and Aníbal Valenzuela [41] modelled and evaluated advantages of truck trolley systems for uphill and downhill paths for a copper mine. Obtained results show the increase in truck’s speed (44%), reduction of its travel time (16%) and fuel savings (85%) on each up-down cycle. Another study points that diesel-trolley trucks are a beneficial opportunity for open-pit mines, because they tend to reduce the cost of rock mass transportation by 15–20% [42]. Another benefit is the reduction of fuel consumption by 50–60% and up to 1.7–2.0 times of pollution emission in comparison to diesel haul trucks. Advantages of a truck trolley system implementation are the increase of production capacity and the reduction of maintenance cost and fuel consumption. Generally, the solution enables production level requirements to be met and reduces the cost per ton of hauled material.

Alternative belt conveying systems are largely used as a technology for material transportation in the mining industry—high efficiency, reliability and durability make them competitive with haul trucks [19,20,43]. However, conveyors consume the significant proportion of power supply and contributes considerable part of costs in mines. In a Polish continuous-surface lignite mine, it was estimated that 50% of the total energy consumption was consumed by the over 120-km belt conveyor system [44]. Belt conveyor system cost is up to 40% of an operational cost and 12–15% of a mining production manufacturing cost [45,46]. Therefore, both theoretical and experimental research is aimed at new energy efficient solutions for conveying systems [47,48].

The majority of research on energy savings in belt conveyors operations is focused on equipment and operational level. When it comes to idlers, optimized space intervals [49], decreasing of rolling resistance [50] and idler intelligent garlands [51] have been analyzed. In the case of conveyor belts, the main attention has been put on its indentation resistance [52] and improvement of its structure and rubber compounds [53]. For drive systems, a selection diagram for an efficient drive configuration and design approach for multiple drive belt conveyors have been developed [54,55]. The operation efficiency of a belt conveyor is improved by adjusting the belt speed to the quantities of transported material. However, to optimize feed rate and belt speed while reducing energy consumption, the energy models of belt conveyors are of great importance [46]. Modelling energy requirements of belt conveyor systems with regard to dynamic loading was evaluated by Halepoto and Khaskheli [56]. A belt conveyor analytical model for optimizing its operating parameters such as operating efficiency, load shifting and operation scheduling was proposed by Zhang and Xia [57]. The methodology for optimizing conveyor speed was established in a range of works [58,59,60] and proved that speed control systems may result in energy and environmental benefits e.g. active speed control implementation may result in hourly energy savings of 16.21% for an 8 h dual belt conveyor system operation.

2.3. Measures of Mining Transport Energy Efficiency

While comparing the energy effectiveness of various transportation systems, the specific energy consumption (SEC), expressed in amount of energy needed to move a unit of mass of transported material for a distance unit, is widely used. However, it has to be noted that for any mine site, transportation costs are generated from moving run-of-mine material between workplaces of consecutive operations—from an excavation site departure (point A) to a depot (point B). Transportation route layout for trucks, rail vehicles and belt conveyors, in accordance with the appropriate industry standards, differ from one another. The allowed inclination for a railroad is limited to only 2.5%, for a road for trucks, up to 12%, while a conveyor route can be inclined up (or down) to 25%. Considering also the relations of allowed curvature of transportation routes (which can be replaced with a transfer point in a case of belt conveyors), the following relations apply to actual routes lengths LA,B at any given mine site:

For the most inclined routes, a railroad is at least 5 times longer than a truck road and 10 times longer than a conveyors route. Therefore, apart from SEC, the site SEC (SSECA,B), expressed in amount of energy needed to move a mass unit of transported material from the point A to the point B along the transportation route that is specific for the mode of transport, should be compared.

The SSEC depends on the actual inclination of the route, operational capacity and parameters of a given transportation mode. The energy savings in mine transport can therefore be achieved either by improvements of haulage equipment or by appropriate delineation of its transportation route.

2.4. Accurate Modeling of Belt Conveyors

The calculations of the amount of energy needed for belt conveying should be based upon advanced calculation methods of resistances to motion and required drive power rather than simplified and conservative standards—CEMA, DIN, ISO [29]. The main resistances to motion methods are developed on both the theoretical analysis of physical phenomena that occur in the running belt conveyor (with the use of physical equations of loads, tensions, displacements and deformations rather than dimensionless, controlled by empirical constants, equations adopted in simplified standard methods) and the laboratory tests and in-situ measurements [61]. Such approach allows to evaluate the impact of a belt conveyor route layout, mechanical properties of a belt, idlers and transported material volumes on the actual resistances to motion. The theoretically proven and verified calculation methods of belt conveyor resistances to motion are capable to deal with any belt conveyor installation. These methods with the object methodology—inheritance of objects and virtual methods [62]—have been implemented in the in-house software QNK-TT by the domestic engineering software company Entertech, which is successfully used for the accurate modeling of a belt conveyor operation [63,64].

The QNK-TT software was used in this paper for digital experiments to model and analyze the actual energy demand by a belt conveyor in the given operating conditions.

2.5. Opportunities of Recuperation of a Potential Gravitational Energy of Hauled Tonnages of Mined Material by Belt Conveyors

Optimization of belt conveyor construction as well as organizational and technical improvements of bulk material transportation are vital for reducing energy consumption. Nevertheless, it seems that not only solutions which generate energy savings are relevant but also these which generate energy itself. This means that the development of an energy recovery system for belt conveyors is of great importance with regard to sustainable development rules. The idea for using regenerative drives for downhill conveyors and optimal scheduling models was proposed by Mathaba and Xia [65]. Generally, the conception of a regenerative conveyor is based on regenerative or continuous braking needed while conveyors are running downhill. Energy generated during the braking process is fed back to electrical network when using an AC drive or to other driving motors while connecting their AC drive and DC busbars together [34]. This solution seems to be a beneficial improvement in existing downhill conveyors. However, the replacement of an existing haul truck transportation technology with a belt conveyor, especially the regenerative one, provides an improvement of material handling operation in both energy and environmental performances.

Following trends of sustainable development, the solution of recovering the energy can be used in some open-pit mines, in which aggregates are excavated from the ground. The average annual production of aggregates in Polish mines is around 300 million tons [8,66]. In Poland, open-pit mines are often located in hilly terrain and mineral deposits are excavated using hillside excavations. As a consequence, aggregates are transported from extraction site downhill to an aggregate storage area. However, the most commonly used types of transport are haul trucks [67], because of their flexibility and outsourced maintenance. The replacement of such transportation systems with conveyors would result in energy and environmental improvements in mines, which is analyzed below.

3. Results and Discussion

The presented case study examines the possible replacement of a hauling truck with the regenerative belt conveyor in the actual, chosen aggregates (here: dolomites) open-pit mine, where material is transported from the pit (opened typically on the peak of the hill) to the storage area located 43 m below. In Figure 2 the regular dump truck road is presented by a blue line while the analyzed alternative way of transportation is marked in red. The length of the existing truck road is 1500 m whilst the length of the conveyor is 645 m with an inclination angle of −3.83°. The annual production is around 100,000 (metric) tons and the optional storage bunker at the pit departure station is taken into account. The created map of the drive power range for a decline conveyor (presented in 3.1. subchapter) shows the optimal areas for recovery of energy. Then, the analysis of energy recovering was performed for two alternative conveyors: an energy efficient conveyor and a typical conveyor. Finally, the environmental impact of the proposed deployment has been calculated.

Figure 2.

Visualization of the alternative haulage route for trucks (blue line) and for conveyor (red line) for the chosen, actual aggregates mine site (marked by the red circle in the Figure 1) [30].

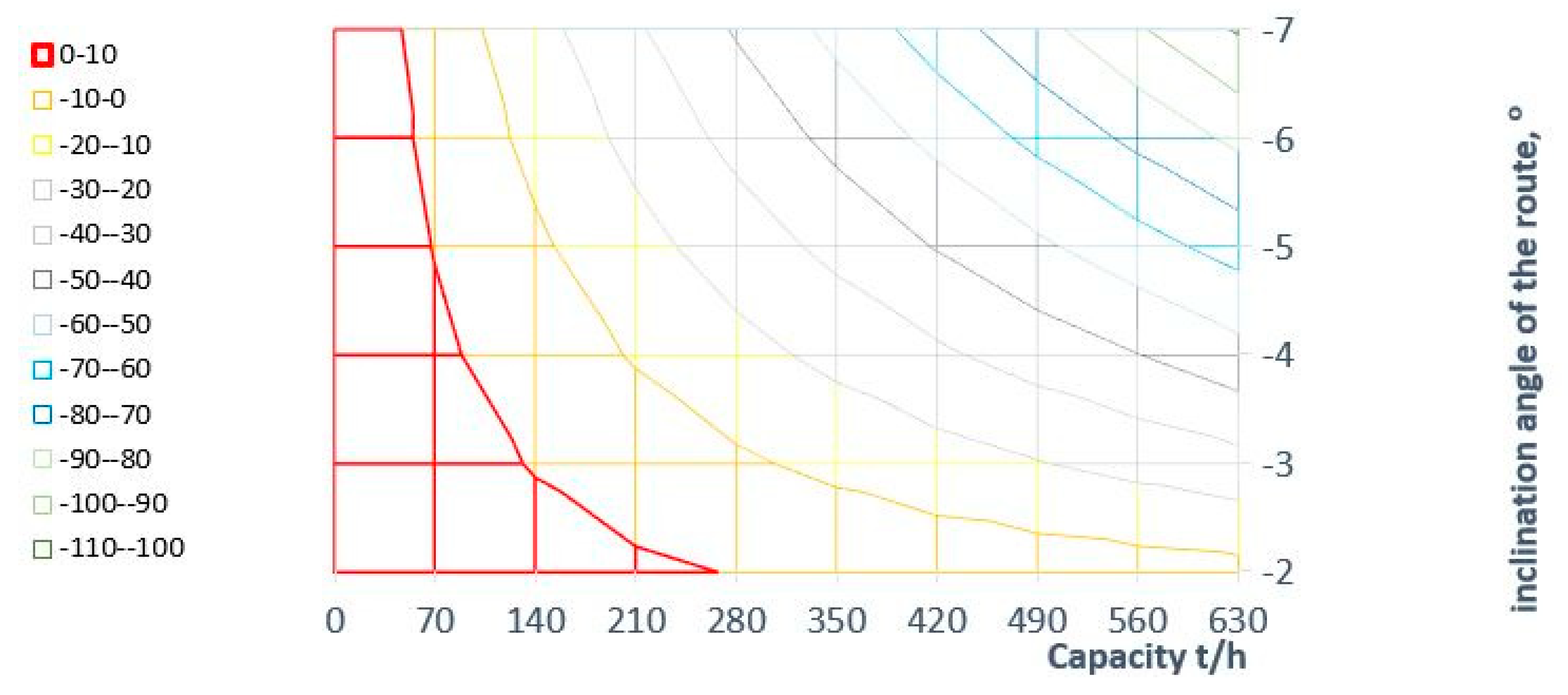

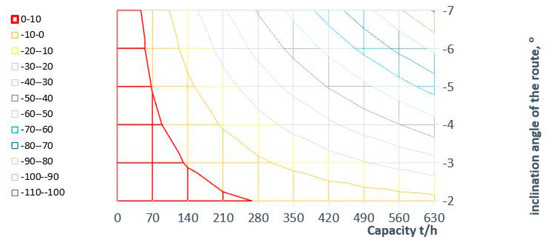

3.1. Map of Drive Power Range

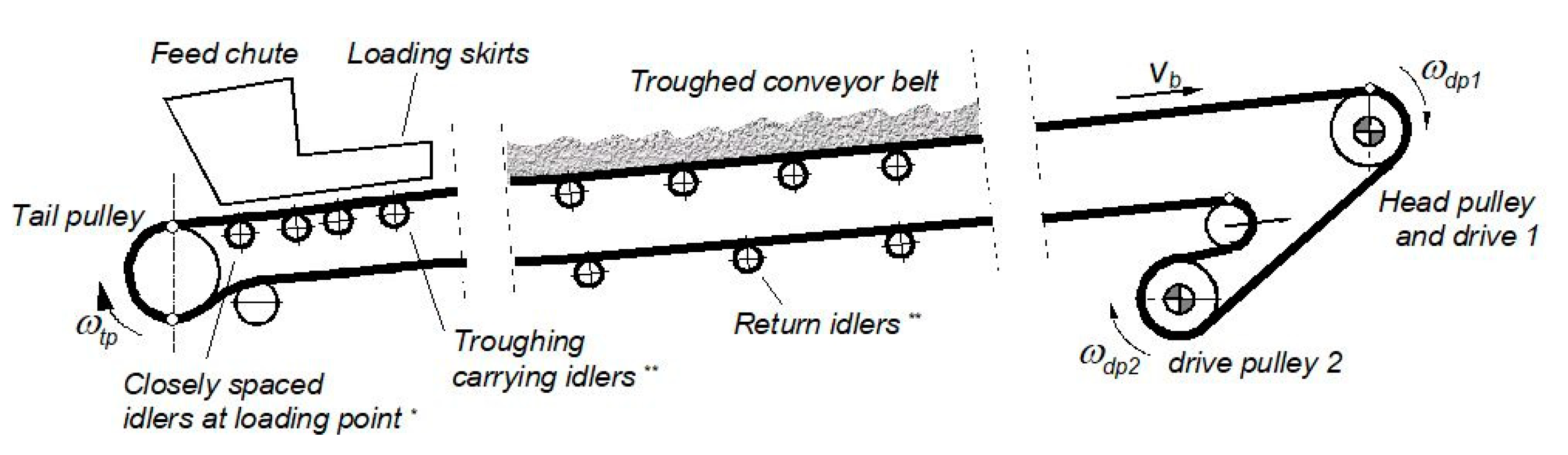

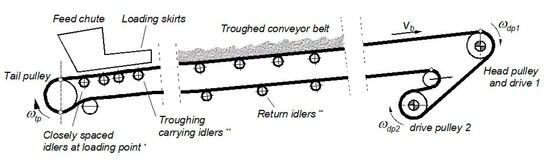

Belt conveyor drive power is a function of belt speed multiplied by the total belt conveyor resistances to motion, which is the sum of primary (main—acting along the whole conveyor route), secondary (occurring at specific points only—pulleys, cleaning devices, etc.) and gradient resistances (see Figure 3). It is worth noting that in the case of the downhill conveyor, the component which represents gravity force influences mostly the total motional resistance and the required power. Therefore, the effectiveness of energy recovery solution in belt conveyors depends on the belt conveyor inclination angle and tonnage of transported material. However, to indicate the areas of belt conveyor work, for which the implementation of the solution is justified, theoretical analyses of belt conveyor drive power range have been carried out. The assumptions for calculations made in the aforementioned QNK-TT software are presented in Table 1.

Figure 3.

Layout of the main conveyor objects generating motion resistances [61].

Table 1.

Parameters of analyzed energy efficient belt conveyor.

As it is presented in Figure 4, positive values of power indicate that even an energy efficient conveyor at the small inclination angle of −2° cannot be used for energy recovery purposes. In the case of the conveyor, where the angle route profile equals −3°, the problem with achieving the average conveyor capacity (400 t/h) occurs in open-pit mines. In the case of the route angle values being between −4° and −7° recovery of energy operation is possible in a sufficiently large range of conveyor capacity.

Figure 4.

Drive power map for downhill conveyor (exerting at drive pulley shaft); power contours every 10 kW, red grid—no energy recovery area, negative values represent recovered power (calculations: QNK-TT software).

Taking above into consideration, there are two conditions for the use of the regenerative belt conveyor implementation:

- Mineral deposits located in a hilly terrain and the run-of-mine material is transported downhill—a declining belt conveyor route can be laid out;

- The gravity forces work of the conveyed material significantly surpasses the conveyor motion resistances, which usually can be achieved with the help of a storage bunker at the loading point to maintain the actual high capacity.

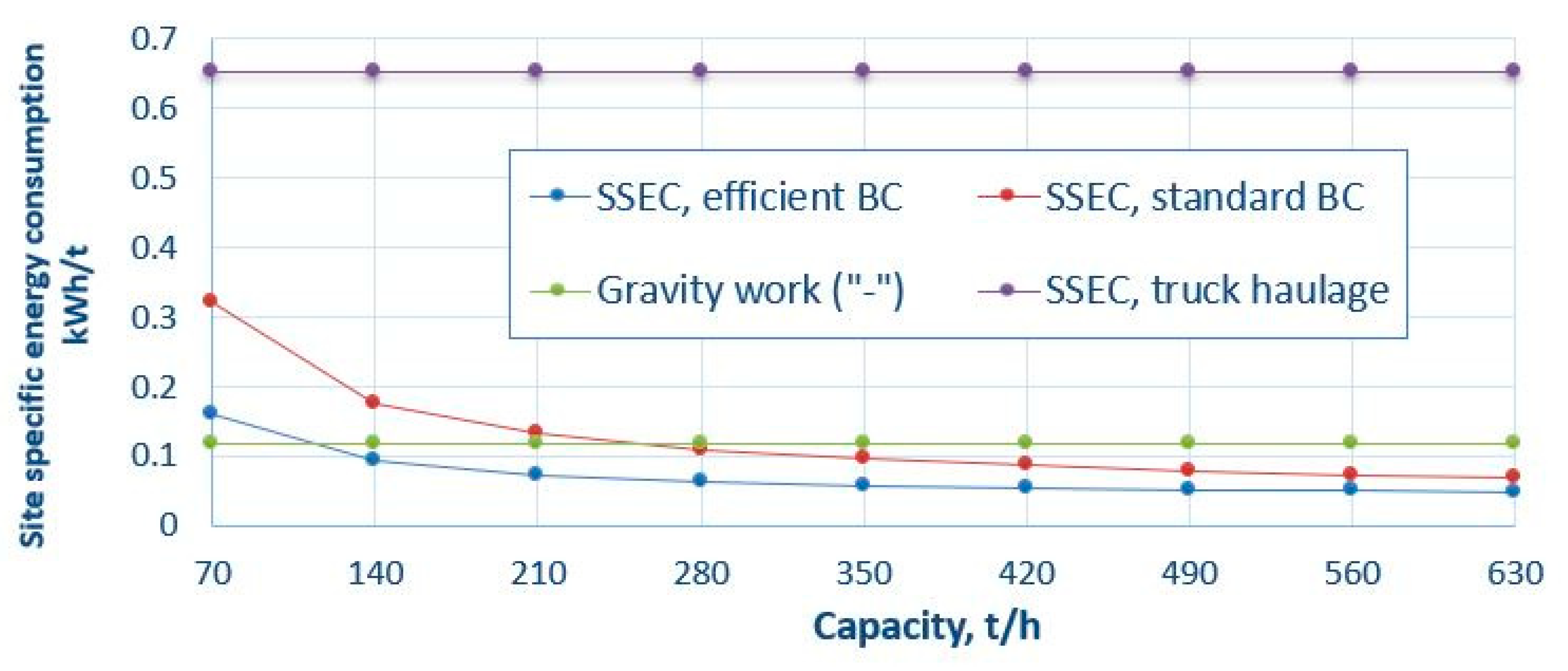

3.2. Recovery of Energy—The Comparison of an Energy Efficient and a Typical Belt Conveyor

In order to indicate a conveyor system, which enables the recovery of energy, the comparison of two alternative conveyors was performed. The first is an energy efficient belt conveyor (Table 1) and the second is a typical belt conveyor, for which idler rotational resistance equals 3 N and the textile conveyor belt parameters are EP1000/4 (8 + 3) and mass is 13.3 kg/m.

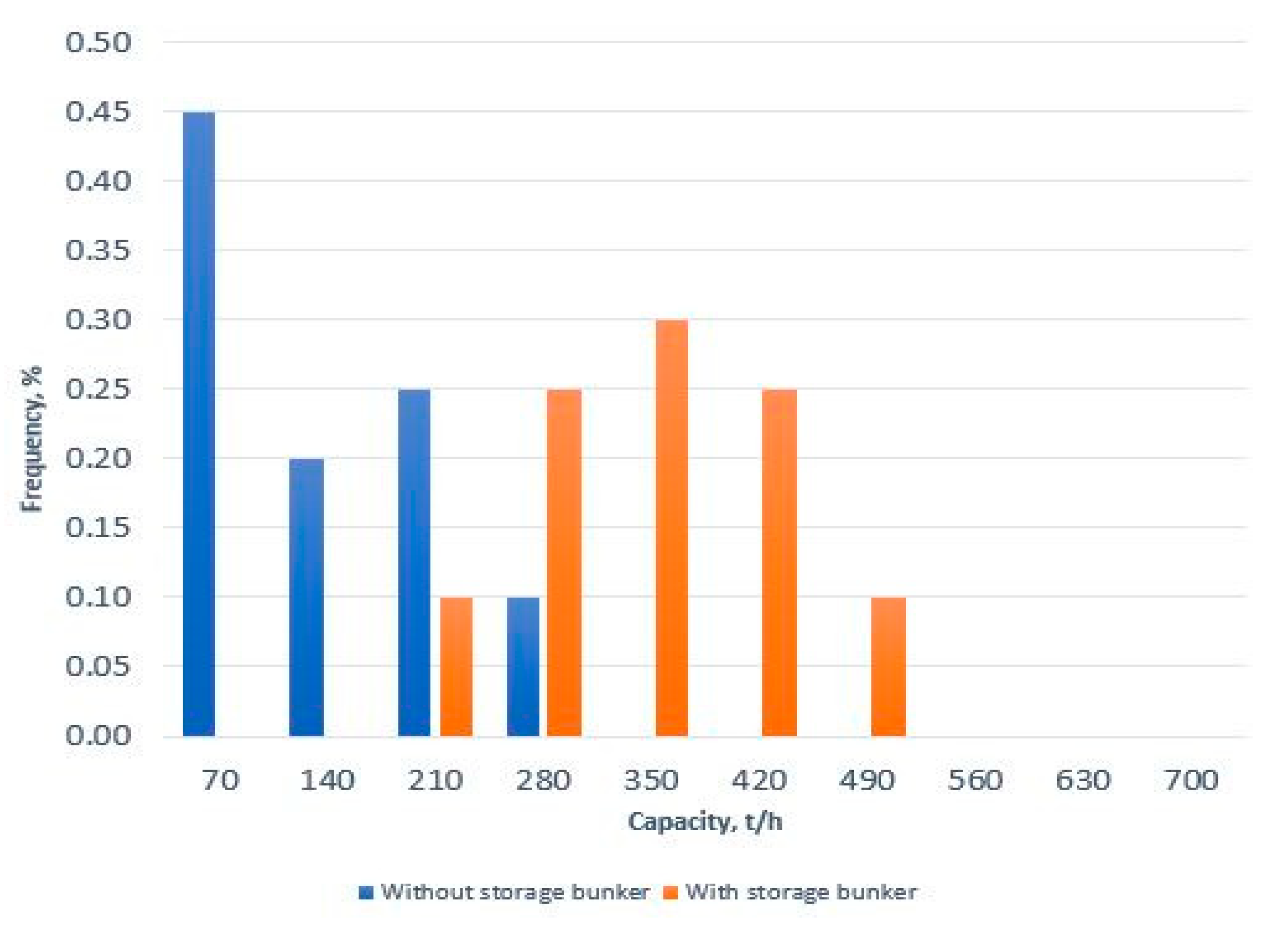

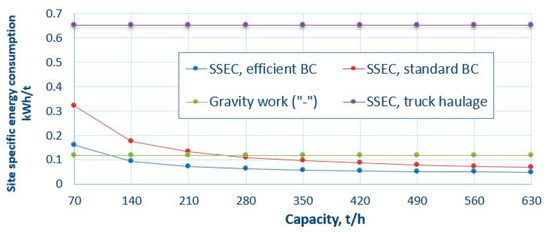

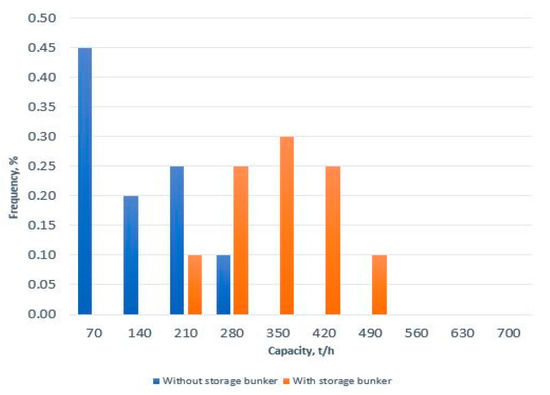

The site-specific energy consumption of these conveyors has been presented as a function of amount of transported material and compared with the SSEC of the actual truck (see Table 2 and Table 3) and with the gravity force work (Figure 5). It is shown that energy savings may be achieved by using the efficient belt conveyor or increasing conveyor capacity. The higher values of capacity may be achieved by using a storage bunker. The analysis of the conveyor capacity distribution with and without the bunker is presented in Figure 6. The change in the amount of transported material caused by the storage bunker enables a more effective management of the belt filling ratio (the ratio of the actual to the maximum conveyor capacity).

Table 2.

Parameters of analyzed energy efficient belt conveyor.

Table 3.

Parameters of alternative haul truck transportation for the analyzed site.

Figure 5.

Comparison of the site-specific energy consumption needed to overcome resistance to motion and gravitation forces calculated on 1 metric ton of transported material from the mine departure to the depot (see: Figure 1).

Figure 6.

Capacity distribution of transported aggregate by a conveyor for two operational loading scenarios: with and without a storage bunker.

To evaluate the possibility of recovery energy during downhill transportation, four different alternatives have been compared (Table 2). As it occurred, the system storage bunkers with efficient belt conveyors are the most effective solution when it comes to the amount of recovered energy (6MWh).

The comparison of the energy efficiency of the standard belt conveyor and the efficient one indicates that energy efficient components of belt conveyors can significantly reduce the site-specific energy consumption (SSEC) value (Figure 5). The typical conveyor would not recover the energy unlike the efficient one. Furthermore, the storage bunker on the entrance to a conveyor system enables a more effective distribution of mass flowrate. High average capacity of a running conveyor directly influences the energy efficiency of a belt conveyor transportation system. In works [50,51,68], it was proven that the implementation of energy efficient components or conveyor-bunker-conveyor transportation systems result in energy consumption reduction.

For the analyzed case, only the implementation of these two solutions combined (energy efficient conveyor elements and the storage bunker to maintain the high average capacity) would lead to the real possibility of generating the electric energy.

3.3. Energy Efficiency and Environmental Improvements Impact Benefits

Nowadays, the analysis of environmental impact of proposed solutions for belt conveyor transportation system, presented for instance in [47,69], is considered as an essential part of a research. The implementation of regenerative conveyor results in energy and environmental benefits. Firstly, the replacement of the haul truck with the conveyor is an activity oriented on energy efficiency improvement. Therefore, the company may obtain the energy efficiency certificate (white certificate) if the project yields a total energy savings amount equivalent to at least 10 tons (ton of oil equivalent) per year on average [70]. Sum of annual savings of diesel fuel (5.04-5.61 tons—Table 3) and recovered energy (1 ton—estimated based on Table 2) is not enough for the white certificate but may be used for an energy efficiency audits. Secondly, the conveyor operation leads to a lower value of cost per ton of transported material. As an average cost of 1MWh is around EUR 109.27 [71], the total cost of 2 MWh of consumed energy is around EUR 2018.56. Taking into account the annual production, the average cost for belt conveyor transportation is EUR 0.0022 per ton*meter. When it comes to haul truck transportation, its cost of EUR 0.054 per ton*meter was assumed following Zajączkowski et al. [72]. The difference in transportation cost between the haul truck and energy efficient conveyor is estimated at around 95%. The similar result of 93% difference in costs for conveyors and haul trucks was achieved in [73] for 762 m transportation length and production capacity of 630 t/h. Last but not least, in comparison to haul trucks which are directly responsible for emissions because they burn diesel fuel, belt conveyors are an indirect source of emissions. Furthermore, the regenerative conveyor enables to reduce air pollutant emissions, because some part of needed electricity is not generated in fossil fuels power plants but by conveyors themselves. Comparing the environmental aspect of transportation system substitutions, it appears that total CO2 emissions for the mining truck equals 15.73 tons annually (CO2 factor emission is 2.622 kg/l [74]). The value of CO2 emissions for efficient conveyors with a storage bunker is 1584 kg (Table 4). It is noteworthy that for downhill conveyors, energy consumption is estimated only for idle operation. Given these points, we can finally focus on the evaluation of reduction of emissions while using recovery of energy for downhill efficient conveyors with a storage bunker. Calculations for annual value of 6 MWh of recovered energy were prepared in accordance with [75] and presented in Table 5. It shows that the implementation of the proposed solution may result in nearly 5 tons of CO2 reduction annually.

Table 4.

CO2 emission comparison.

Table 5.

Reduction of gas emissions due to energy recovered by downhill transportation.

It must be also noted that regardless of the actual electric energy mix, the replacement of mining trucks with belt conveyors enables a decrease in fossil fuel consumption because electricity is consumed instead of oil or gas, such as compressed natural gas (CNG), liquefied natural gas (LNG), liquefied petroleum gas (LPG). Taking into account the growing share of “green” sources of energy in the national energy mix, this advantage of belt conveyors over diesel trucks grows as well.

4. Conclusions

Currently, the mining industry has to respond to the challenge of energy-related requirements for sustainable development and policy framework. Belt conveying transportation systems have been recognized as a possible direction for an energy efficient implementation. For the comparison of an alternative mode of transportation, the presented site-specific energy consumption (SSEC) indicator should be analyzed with regard to differences of standards compliant routes layout designed for trucks, conveyors or rail vehicles.

While analyzing the replacement dump trucks by belt conveyors, it has been proven that downhill belt conveyor systems can generate energy from the potential gravitational energy accumulated in mined deposits. A mine that implements such solution increases the overall recovery of the mined raw material which follows the sustainable development challenges.

Recovery of energy is possible by implementing a regenerative belt conveyor. However, such transportation system needs to be precisely designed with special focus on:

- conveyor route profile (the inclination angle above 5° is recommended),

- energy efficient components of belt conveyor (the accurate, object-oriented calculations of a belt conveyor resistances to motion are necessary to select the best suited technical solution)

- a storage bunker with a belt conveyor system to keep high capacity and avoid low loading or empty operations (where the regenerative conveyor needs driving).

The presented case study has proven that a regenerative conveyor brings savings in both the overall energy and fossil fuel consumption, transportation costs reduction and gas emissions, noise, vibration and road damage reduction.

All things considered, regenerative belt conveyors, because of their positive influence on pro-environmental performance of an open-pit may become a trademark for sustainable open-pit mines located in hilly terrains and help the mining company to receive social acceptance.

Author Contributions

Conceptualization, W.K., N.S. and R.K.; methodology, W.K.; validation, R.K.; data curation, N.S.; writing—original draft preparation, R.K., W.K. and N.S.; writing—review and editing, N.S.; supervision, R.K.; project administration, R.K.; funding acquisition, R.K. All authors have read and agreed to the published version of the manuscript.

Funding

The research work cofounded with the research subsidy of the Polish Ministry of Science and Higher Education granted for 2020.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Asr, E.T.; Kakaie, R.; Ataei, M.; Mohammadi, M.R.T. A review of studies on sustainable development in mining life cycle. J. Clean. Prod. 2019, 229, 213–231. [Google Scholar]

- Hilson, G.; Murck, B. Sustainable development in the mining industry: Clarifying the corporate perspective. Resour. Policy 2000, 26, 227–238. [Google Scholar] [CrossRef]

- Orazalin, N.; Mahmood, M. Determinants of GRI-based sustainability reporting: Evidence from an emerging economy. J. Account. Emerg. Econ. 2019, 10, 140–164. [Google Scholar] [CrossRef]

- Wozniak, J.; Pactwa, K. State of non-financial reporting of polish representatives of the mining industry in a sustainable social dimension. In Proceedings of the IOP Conference Series: Earth and Environmental Science; Institute of Physics Publishing: Bristol, UK, 2019; Volume 362. [Google Scholar]

- Boiral, O.; Heras-Saizarbitoria, I.; Brotherton, M.C. Assessing and Improving the Quality of Sustainability Reports: The Auditors’ Perspective. J. Bus. Ethics 2019, 155, 703–721. [Google Scholar] [CrossRef]

- Boiral, O.; Heras-Saizarbitoria, I.; Brotherton, M.C.; Bernard, J. Ethical Issues in the Assurance of Sustainability Reports: Perspectives from Assurance Providers. J. Bus. Ethics 2019, 159, 1111–1125. [Google Scholar] [CrossRef]

- Fonseca, A.; McAllister, M.L.; Fitzpatrick, P. Sustainability reporting among mining corporations: A constructive critique of the GRI approach. J. Clean. Prod. 2014, 84, 70–83. [Google Scholar] [CrossRef]

- European Aggregates Association. Annual Review: 2018–2019; European Aggregates Association: Brussels, Belgium, 2020. [Google Scholar]

- European Association for Coal and Lignite. Annual Report 2018; European Association for Coal and Lignite: Brussels, Belgium, 2018. [Google Scholar]

- Mininstry Republic of Austria. World Mining Data 2019; Federal Mininstry Republic of Austria: Vienna, Austria, 2019. [Google Scholar]

- Kaźmierczak, U.; Strzałkowski, P. Environmentally Friendly Rock Mining—Case Study of the Limestone Mine “Górażdże”, Poland. Appl. Sci. 2019, 9, 5512. [Google Scholar] [CrossRef]

- Kopacz, M.; Kryzia, D.; Kryzia, K. Assessment of sustainable development of hard coal mining industry in Poland with use of bootstrap sampling and copula-based Monte Carlo simulation. J. Clean. Prod. 2017, 159, 359–373. [Google Scholar] [CrossRef]

- Pactwa, K.; Woźniak, J.; Strempski, A. Sustainable mining—Challenge of Polish mines. Resour. Policy 2018, 1–9. [Google Scholar] [CrossRef]

- Aznar-Sánchez, J.A.; Velasco-Muñoz, J.F.; Belmonte-Ureña, L.J.; Manzano-Agugliaro, F. Innovation and technology for sustainable mining activity: A worldwide research assessment. J. Clean. Prod. 2019, 221, 38–54. [Google Scholar] [CrossRef]

- Holmberg, K.; Kivikytö-Reponen, P.; Härkisaari, P.; Valtonen, K.; Erdemir, A. Global energy consumption due to friction and wear in the mining industry. Tribol. Int. 2017, 115, 116–139. [Google Scholar] [CrossRef]

- Odyssee Database. Available online: https://odyssee.enerdata.net/database/ (accessed on 27 April 2020).

- Jeswiet, J.; Szekeres, A. Energy Consumption in Mining Comminution. Procedia CIRP 2016, 48, 140–145. [Google Scholar] [CrossRef]

- Klein, B.; Wang, C.; Nadolski, S. Energy-efficient comminution: Best practices and future research needs. In Green Energy and Technology; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Awuah-Offei, K. Energy efficiency in mining: A review with emphasis on the role of operators in loading and hauling operations. J. Clean. Prod. 2016, 117, 89–97. [Google Scholar] [CrossRef]

- Soofastaei, A.; Karimpour, E.; Knights, P.; Kizil, M. Energy-efficient loading and hauling operations. In Green Energy and Technology; Springer: Cham, Switzerland, 2018; pp. 121–146. [Google Scholar]

- Bunko, T.; Shyshov, M.; Bokii, O.; Belikov, A.; Zhalilov, O.; Kokoulin, I. Increase of energy efficiency of mine fans work on a mine vent network. E3S Web Conf. 2019, 109, 00012. [Google Scholar] [CrossRef]

- Nel, A.J.H.; Arndt, D.C.; Vosloo, J.C.; Mathews, M.J. Achieving energy efficiency with medium voltage variable speed drives for ventilation-on-demand in South African mines. J. Clean. Prod. 2019, 232, 379–390. [Google Scholar] [CrossRef]

- Lee, D.; Cheng, C.C. Energy savings by energy management systems: A review. Renew. Sustain. Energy Rev. 2016, 56, 760–777. [Google Scholar] [CrossRef]

- Moreno-Leiva, S.; Haas, J.; Junne, T.; Valencia, F.; Godin, H.; Kracht, W.; Nowak, W.; Eltrop, L. Renewable energy in copper production: A review on systems design and methodological approaches. J. Clean. Prod. 2020, 246, 118978. [Google Scholar] [CrossRef]

- Numbi, B.P.; Zhang, J.; Xia, X. Optimal energy management for a jaw crushing process in deep mines. Energy 2014, 68, 337–348. [Google Scholar] [CrossRef]

- European Environment Agency (EEA). Directive 2012/27/EU of the European Parliament and of the Council of 25 October 2012 on Energy Efficiency, Amending Directives 2009/125/EC and 2010/30/EU and Repealing Directives 2004/8/EC and 2006/32/EC Text with EEA Relevance; European Environment Agency (EEA): Copenhagen, Denmark, 2012.

- European Environment Agency (EEA). Directive (EU) 2018/2002 of the European Parliament and of the Council-of 11 December 2011—Amending Directive 2012/27/EU on Energy Efficiency; European Environment Agency (EEA): Copenhagen, Denmark, 2011.

- European Environment Agency (EEA). Directive 2009/125/EC of the European Parliament and of the Council of 21 October 2009 Establishing a Framework for the Setting of Ecodesign Requirements for Energy-Related Products (Recast) (Text with EEA Relevance); European Environment Agency (EEA): Copenhagen, Denmark, 2009.

- Kawalec, W.; Król, R. Sustainable Development Oriented Belt Conveyors Quality Standards. In Proceedings of the 14th International Scientific Conference Computer Aided Engineering, Wroclaw, Poland, 20–23 June 2018; Rusiński, E., Pietrusiak, D., Eds.; Springer: Cham, Switzerland, 2019; Volume 1, pp. 327–336. ISBN 978-3-030-04974-4. [Google Scholar]

- Państwowy Instytut Geologiczny—Państwowy Instytut Badawczy Portal Geologia—Mapy Geologiczne. Available online: http://geologia.pgi.gov.pl/arcgis/apps/MapSeries/index.html?appid=8d14826a895641e2be10385ef3005b3c (accessed on 22 October 2020).

- Soofastaei, A.; Aminossadati, S.M.; Arefi, M.M.; Kizil, M.S. Development of a multi-layer perceptron artificial neural network model to determine haul trucks energy consumption. Int. J. Min. Sci. Technol. 2016, 26, 285–293. [Google Scholar] [CrossRef]

- Dzakpata, I.K.; Knights, P.; Kizil, M.S.; Nehring, M. Truck and Shovel Versus In-Pit Conveyor Systems: A Comparison of the Valuable Operating Time Open Pit Mine Production Scheduling View Project; University of Wollongong: Wollongong, NSW, Australia, 2016. [Google Scholar]

- Peralta, S.; Sasmito, A.P.; Kumral, M. Reliability effect on energy consumption and greenhouse gas emissions of mining hauling fleet towards sustainable mining. J. Sustain. Min. 2016, 15, 85–94. [Google Scholar] [CrossRef]

- Kecojevic, V.; Komljenovic, D.; Kecojevic, V.; Komljenovic, D. Haul truck fuel consumption and CO2 emission under various engine load conditions. Min. Eng. 2010, 62, 44–48. [Google Scholar]

- Esfahanian, E.; Meech, J.A. Hybrid Electric Haulage Trucks for Open Pit Mining; IFAC Proceedings Volumes (IFAC-PapersOnline); Elsevier: Amsterdam, The Netherlands, 2013; Volume 15, pp. 104–109. [Google Scholar]

- Sahoo, L.K.; Bandyopadhyay, S.; Banerjee, R. Benchmarking energy consumption for dump trucks in mines. Appl. Energy 2014, 113, 1382–1396. [Google Scholar] [CrossRef]

- Nehring, M.; Knights, P.F.; Kizil, M.S.; Hay, E. A comparison of strategic mine planning approaches for in-pit crushing and conveying, and truck/shovel systems. Int. J. Min. Sci. Technol. 2018, 28, 205–214. [Google Scholar] [CrossRef]

- Mazumdar, J. Performance improvement of mining haul trucks operating on trolley systems. In Proceedings of the Conference Record—IAS Annual Meeting, Orlando, FL, USA, 9–13 October 2011; IEEE Industry Applications Society: New York, NY, USA, 2011. [Google Scholar]

- Mazumdar, J.; Koellner, W.; Moghe, R. Interface issues of mining haul trucks operating on trolley systems. In Proceedings of the Conference Proceedings—IEEE Applied Power Electronics Conference and Exposition—APEC, Palm Springs, CA, USA, 21–25 February 2010; pp. 1158–1165. [Google Scholar]

- Mazumdar, J. All electric operation of ultraclass mining haul trucks. In Proceedings of the Conference Record—IAS Annual Meeting, Lake Buena Vista, FL, USA, 6–11 October 2013; IEEE Industry Applications Society: New York, NY, USA, 2013. [Google Scholar]

- Cruzat, J.V.; Valenzuela, M.A. Integrated Modeling and Evaluation of Electric Mining Trucks during Propel and Retarding Modes. IEEE Trans. Ind. Appl. 2018, 54, 6586–6597. [Google Scholar] [CrossRef]

- Khazin, M.; Tarasov, A. Ecological and economic evaluation of quarry trolley trucks. Perm. J. Pet. Min. Eng. 2018, 17, 166–180. [Google Scholar] [CrossRef]

- Norgate, T.; Haque, N. Energy and greenhouse gas impacts of mining and mineral processing operations. J. Clean. Prod. 2010, 18, 266–274. [Google Scholar] [CrossRef]

- Fajer, R.; Idziak, E.; Konieczka, Z.; Mrówka, A.; Orzechowski, L.; Szczepaniak, T. Optymalizacja rozwiązań technicznych przenośników taśmowych w PGE GiEK SA Oddział KWB Bełchatów. Gór. Geoinż. 2011, 35, 81–89. [Google Scholar]

- Bajda, M.; Jurdziak, L.; Konieczka, Z. Comparison of electricity consumption by belt conveyors in a brown coal mine: Pt 1, Study of statistical significance of differences and correlations. Gór. Odkryw. 2018, 26, 263–274. [Google Scholar]

- Luo, J.; Huang, W.; Zhang, S. Energy cost optimal operation of belt conveyors using model predictive control methodology. J. Clean. Prod. 2015, 105, 196–205. [Google Scholar] [CrossRef]

- He, D.; Pang, Y.; Lodewijks, G. Green operations of belt conveyors by means of speed control. Appl. Energy 2017, 188, 330–341. [Google Scholar] [CrossRef]

- Krol, R.; Kawalec, W.; Gladysiewicz, L. An Effective Belt Conveyor for Underground Ore Transportation Systems. IOP Conf. Ser. Earth Environ. Sci. 2017, 95, 42047. [Google Scholar] [CrossRef]

- Gładysiewicz, L.; Kawalec, W.; Król, R. Selection of carry idler spacing of belt conveyor taking into account random stream of transported bulk material. Eksploat. Niezawodn. Maint. Reliab. 2016, 18, 32–37. [Google Scholar] [CrossRef]

- Kisielewski, W.; Król, R. Wpływ krążników na energochłonność przenośnika taśmowego. Min. Sci. 2014, 21, 61–72. [Google Scholar] [CrossRef]

- Katterfeld, A.; Richter, C. Reducing the Energy Consumption of Belt Conveyors by the Use of Intelligent Garlands. In Proceedings of the 12th International Conference on Bulk Materials Storage, Handling and Transportation (ICBMH 2016), Darwin, NT, Australia, 11–14 July 2016; pp. 600–605. [Google Scholar]

- Gładysiewicz, L.; Konieczna-Fuławka, M. Influence of idler set load distribution on belt rolling resistance. Arch. Min. Sci. 2019, 64, 251–259. [Google Scholar]

- Jansen, M. The development of energy-optimized conveyor belts—A joint project of the Conveyor Belt Group of ContiTech AC and RWE Power AG. World Min. Surf. Undergr. 2008, 60, 83. [Google Scholar]

- Masaki, M.S.; Zhang, L.; Xia, X. A design approach for multiple drive belt conveyors minimizing life cycle costs. J. Clean. Prod. 2018, 201, 526–541. [Google Scholar] [CrossRef]

- Schützhold, J.; Benath, K.; Müller, V.; Hofmann, W. Design criteria for energy efficient belt conveyor drives. In Proceedings of the 2014 International Symposium on Power Electronics, Electrical Drives, Automation and Motion, SPEEDAM 2014, Ischia, Italy, 18–20 June 2014; IEEE Computer Society: Washington, DC, USA, 2014; pp. 1256–1263. [Google Scholar]

- Halepoto, I.A.; Khaskheli, S. Modeling of an Integrated Energy Efficient Conveyor System Model using Belt Loading Dynamics. Indian J. Sci. Technol. 2016, 9. [Google Scholar] [CrossRef]

- Zhang, S.; Xia, X. A new energy calculation model of belt conveyor. In Proceedings of the IEEE AFRICON Conference, Nairobi, Kenya, 23–25 September 2009. [Google Scholar]

- He, D.; Pang, Y.; Lodewijks, G. Speed control of belt conveyors during transient operation. Powder Technol. 2016, 301, 622–631. [Google Scholar] [CrossRef]

- Hiltermann, J.; Lodewijks, G.; Schott, D.L.; Rijsenbrij, J.C.; Dekkers, J.A.J.M.; Pang, Y. A Methodology to Predict Power Savings of Troughed Belt Conveyors by Speed Control. Part. Sci. Technol. 2011, 29, 14–27. [Google Scholar] [CrossRef]

- Zhang, S.; Xia, X. Optimal control of operation efficiency of belt conveyor systems. Appl. Energy 2010, 87, 1929–1937. [Google Scholar] [CrossRef]

- Gładysiewicz, L. Belt Conveyors. Theory and Calculations; Wroclaw University of Technology Publishing House: Wroclaw, Poland, 2003. (In Polish) [Google Scholar]

- Gładysiewicz, L.; Kawalec, W. Object modeling of a belt conveyor. In Mine Planning and Equipment Selection 2000, Proceedings of the Ninth International Symposium on Mine Planning and Equipment Selection, Athens, Greece, 6–9 November 2000; A.A. Balkema: Roterdam, The Netherlends, 2004; pp. 811–814. [Google Scholar]

- Kawalec, W.; Kulinowski, P. Computations of belt conveyors. Transp. Przem. Masz. Rob. 2007, 1, 6–11. [Google Scholar]

- Kulinowski, P.; Kawalec, W. Program Komputerowy QNK-TT do Wspomagania Projektowania Przenośników Taśmowych. Available online: http://www.EnterTECH.com.pl/QNK (accessed on 24 August 2020).

- Mathaba, T.; Xia, X. Optimal and energy efficient operation of conveyor belt systems with downhill conveyors. Energy Effic. 2017, 10, 405–417. [Google Scholar] [CrossRef]

- Państwowy Instytut. Geologiczny Zestawienie Geologicznych Zasobów Bilansowych i Wydobycia Ważniejszych Kopalin w Polsce w 2018 r. Available online: http://geoportal.pgi.gov.pl/css/surowce/images/2018/pdf/zasoby_i_wydobycie_kopalin_2018.pdf (accessed on 20 April 2020).

- Borcz, A.; Kozioł, W. Machine systems in surface mining. Part 1. Machines in polish mining. Nowocz. Bud. Inż. 2015, 4, 102–107. [Google Scholar]

- Kiriia, R.; Shyrin, L. Reducing the energy consumption of the conveyor transport system of mining enterprises. E3S Web Conf. 2019, 109, 00036. [Google Scholar] [CrossRef]

- Kawalec, W.; Suchorab, N.; Konieczna-Fuławka, M.; Król, R. Specific Energy Consumption of a Belt Conveyor System in a Continuous Surface Mine. Energies 2020, 13, 5214. [Google Scholar] [CrossRef]

- Polish Government. Energy Efficiency Act of May 20, 2016; Polish Government: Warsav, Poland, 2016. [Google Scholar]

- Grupa Kapitałowa Energa. Cennik Standardowy dla Przedsiębiorstw. Available online: https://www.energa.pl/dam/jcr:127d671c-818e-4675-a7c0-06ede63b7683/Cennikstandardowydlaprzedsiębiorstw_01112019_.pdf (accessed on 28 April 2020).

- Zajączkowski, M.; Czerniak, A.; Adamski, P. Wydobywanie Kopalin ze Złóż Położonych na Gruntach w Zarządzie PGL LP-Zasady i Tryb Ubiegania się o Koncesję Przez Jednostki PGL LP; Lasy Państwowe: Warsaw, Poland, 2017. [Google Scholar]

- Superior Industries. Long Distance Conveying—Long Term Savings. Conveyor vs Haul Trucks. Available online: https://superior-ind.com/portfolio-items/savings-conveyors-vs-haul-trucks/ (accessed on 2 October 2020).

- Abbaspour, H.; Drebenstedt, C. Environmental Comparison of Different Transportation Systems—Truck-Shovel and IPCCs—In Open-Pit Mines by System Dynamic Modeling. In Proceedings of the 27th International Symposium on Mine Planning and Equipment Selection—MPES 2018; Springer International Publishing: Cham, Switzerland, 2019; pp. 287–305. [Google Scholar]

- National Centre for Emissions Management (KOBiZE). Emission Indexes CO2, SO2, NOx, COi, Total Particulates for Electric Energy; KOBiZE: Warsaw, Poland, 2019. (in Polish) [Google Scholar]

- CEMA: Conveyor Equipment Manufacturers Association. Belt Conveyors for Bulk Materials, 6th ed.; CEMA: Conveyor Equipment Manufacturers Association: Naples, FL, USA, 2009. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).