Modern Circular Economy: Corporate Strategy, Supply Chain, and Industrial Symbiosis

Abstract

:1. Introduction

2. Literature Review

2.1. Introduction to Circular Economy and Its Implementation

- ▪

- Prolong and share: prolong product/material lifespan through proper design and maintenance; share products to provide access to the related services as well as to other customers;

- ▪

- Reuse/redistribute: use multiple times or also redistribute to new users;

- ▪

- Refurbishing/remanufacturing: implement an “aesthetic process” to repair generally without disassembling; replace bad components to bring the product at a “like new state”;

- ▪

- Recycle: reduce to basic materials and reuse at least a part of them to generate new products;

- ▪

- Cascades: implement the biological cycle until the material returns as a nutrient to the soil.

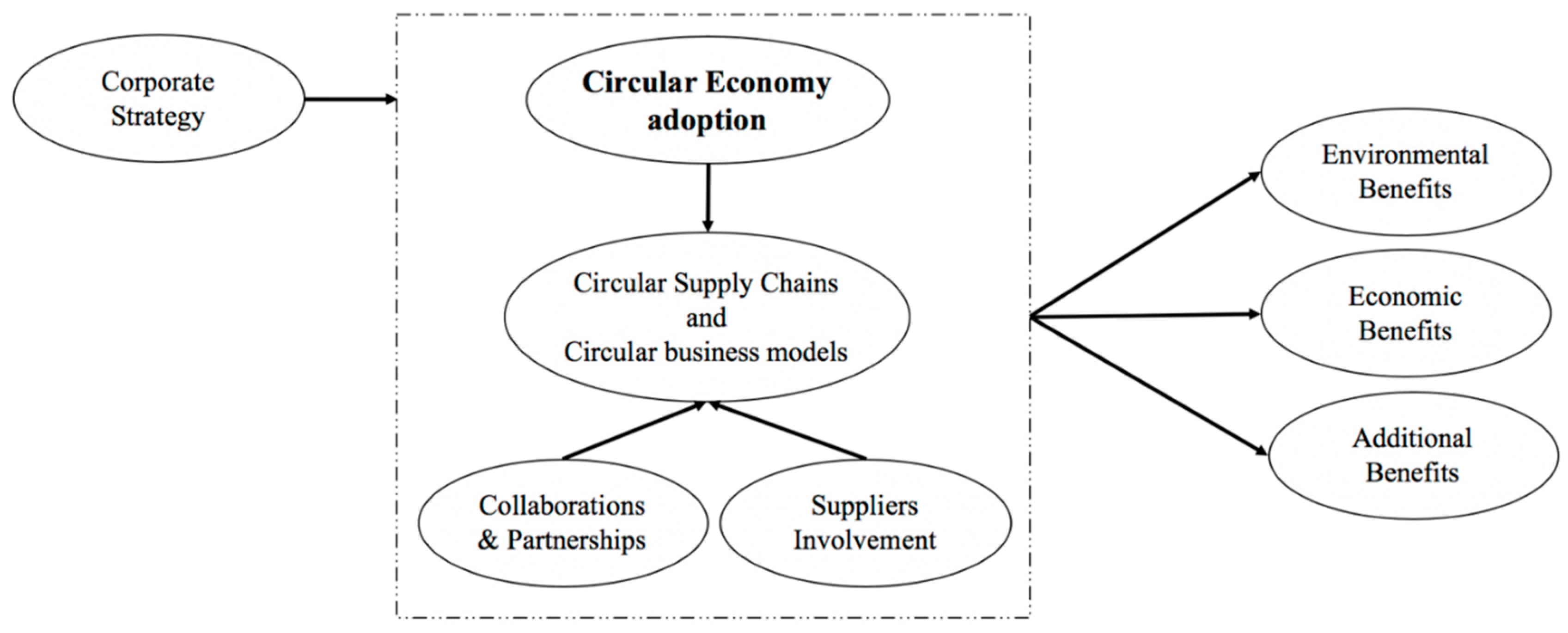

2.2. Circular Economy Role within Corporate Strategies

- ▪

- Circular inputs: use of bio-based or potentially completely recyclable material; use of renewable energy to reduce the environmental footprint;

- ▪

- Sharing platforms: collaborative models between users and owners for the use/access of goods and services to increase the usage rates;

- ▪

- Product as a service: leaving the product ownership to the producer in order to increase resource productivity;

- ▪

- Resource recovery: recover usable resources/energy from waste or products;

- ▪

- Product use extension: prolongation of product use and life through modular design, repair, upgrading, and resale.

2.3. Circular Supply Chains

2.4. The Relational Dimension of the Circular Economy

2.5. Circular Economy Main Benefits and Opportunities

2.6. Conceptual Framework

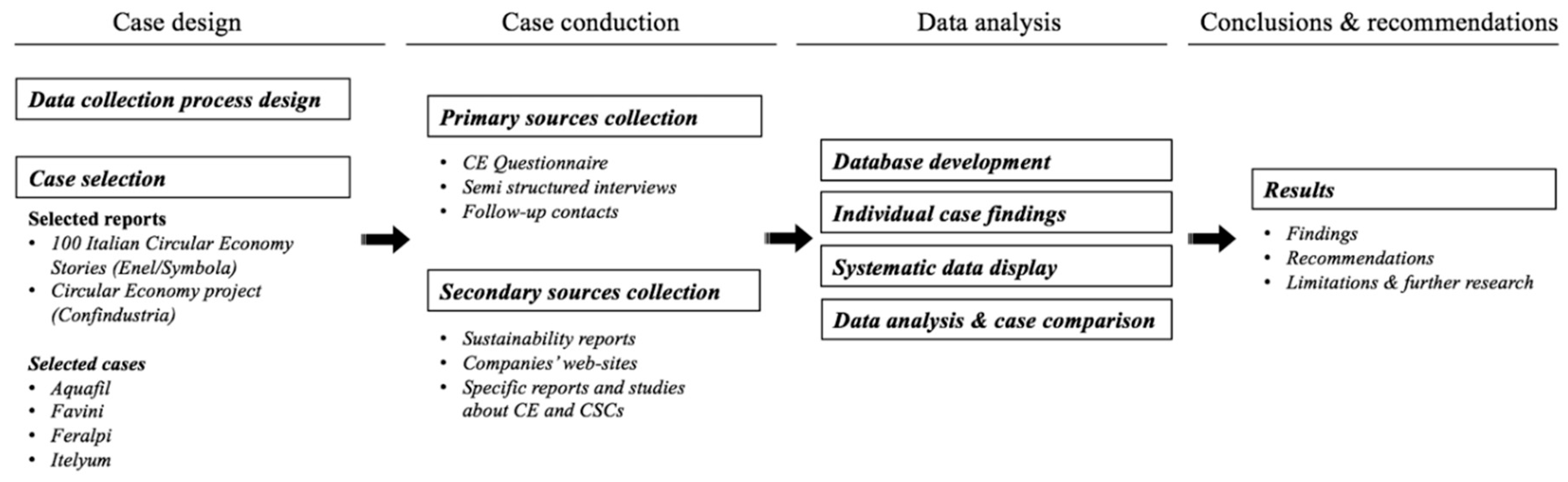

3. Methodology

3.1. Case Selection

3.2. Data Collection

3.3. Data Analysis

4. Case Description

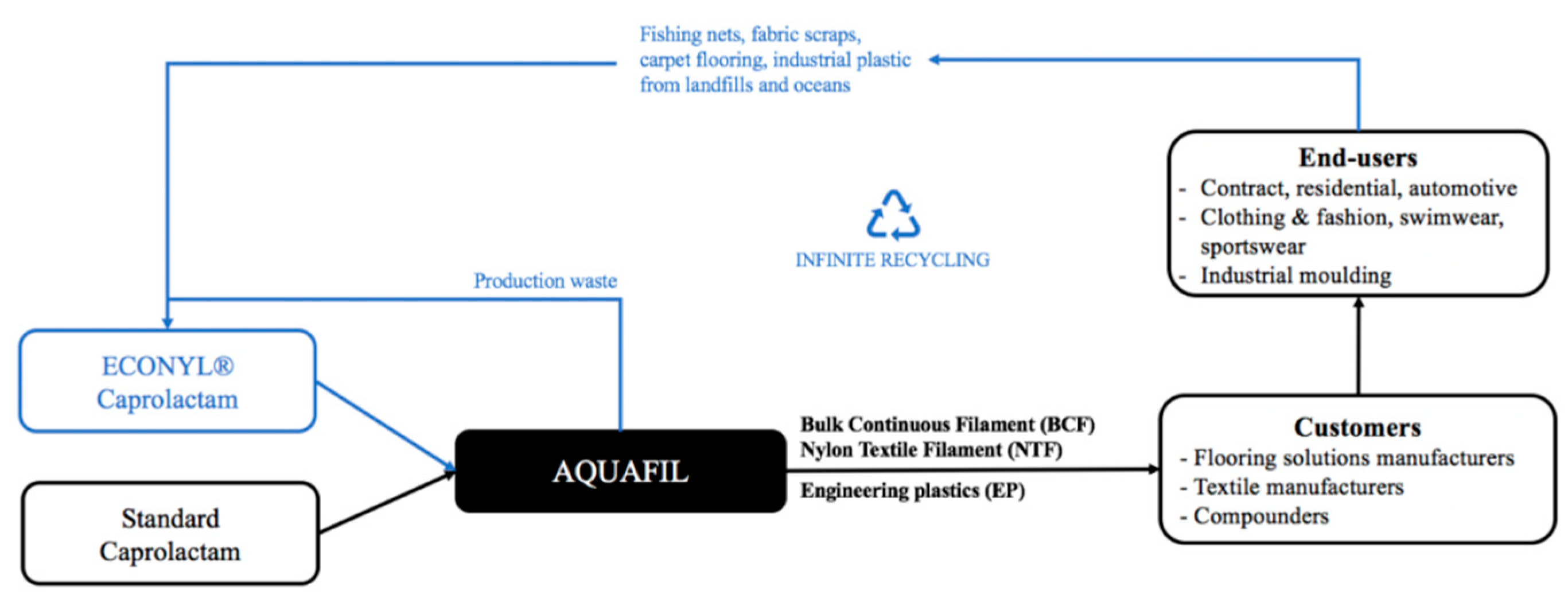

4.1. Aquafil

- -

- Bulk continuous filament (BCF): flooring solutions for contract, automotive and residential markets;

- -

- Nylon textile filament (NTF): textile solutions for clothing and fashion, swimwear and sportswear sectors;

- -

- Engineering plastics (EP): polyamide and polyester polymer plants for compounders.

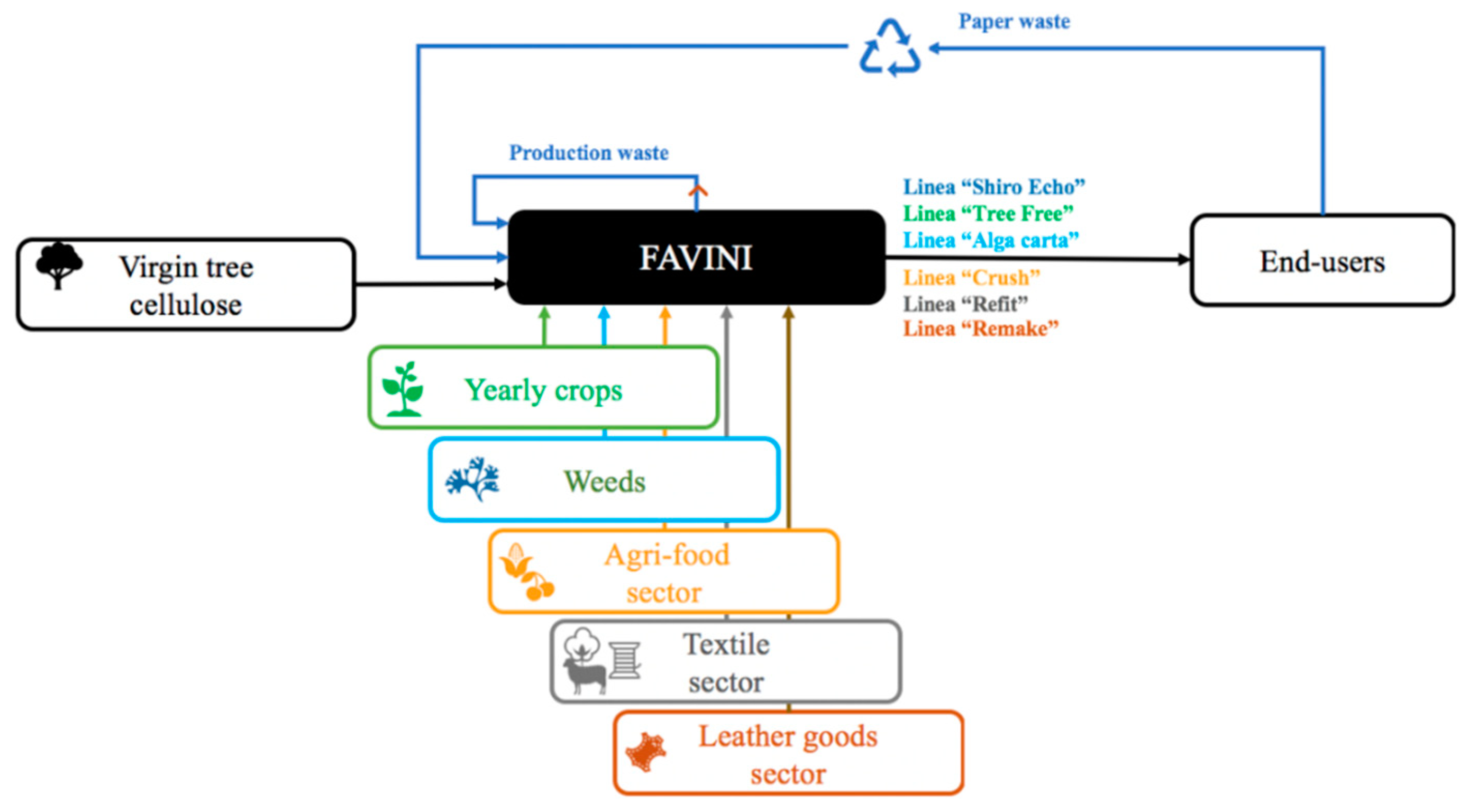

4.2. Favini

- -

- Shiro Echo: produced with 100% recycled fibers;

- -

- Tree Free: made with fibers from annual plants such as bamboo and cotton linters;

- -

- Alga Carta: produced with algae coming from at-risk lagoon environments;

- -

- Crush: produced with 15% cellulose from agro-industrial by-products (corn, citrus, kiwi, olives, almonds, hazelnuts, coffee, lavender, cherry and grapes);

- -

- Refit: made with 15% by-products from wool and cotton textile processing;

- -

- Remake: containing 25% of leather offcuts and shavings.

4.3. Feralpi

- -

- Building construction industry: bars and rolls for reinforced concrete used in the construction of load-bearing structures, as well as spacers and pylons used in the formation of walls and prefabricated structures.

- -

- Manufacturing industry and industrial applications: pre-worked steel products, premium quality steel intermediate products and services concerning the pre-processing of steel products.

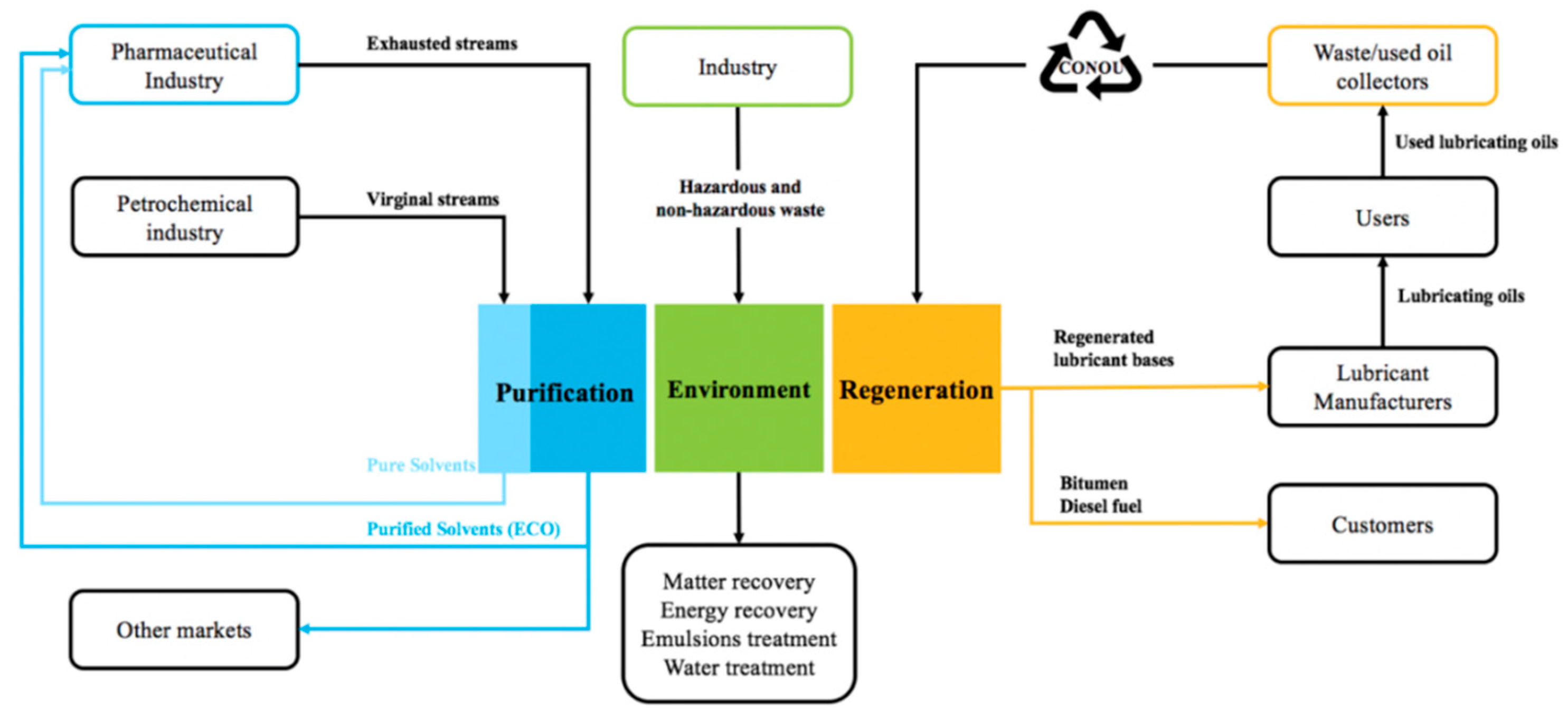

4.4. Itelyum

- -

- The regeneration of waste oils. Starting from used lubricating oils and recycling processes, Itelyum produces new lube-based oils and other valuable fractions to be returned to industrial cycles (Itelyum Regeneration Solutions);

- -

- The recovery of spent solvent streams from pharmaceutical chemistry that, after advanced distillation phases, are returned to the same company in a close partnership (Itelyum Purification Solutions);

- -

- The valorization of organic waste streams from different sources to engineer products for other markets (Itelyum Environment Solution).

5. Analysis and Comparison of the Cases

5.1. Circular Economy Role within Corporate Strategies

5.2. Circular Supply Chains, Innovation, and Suppliers’ Selection

5.3. Circular Economy Benefits and Opportunities

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| How is CE concretely implemented by companies? | Industrial sector: - Textile industry | Industrial sector: - Paper industry | Industrial sector: - Steel industry | Industrial sector: - Materials regeneration and industrial waste management industry |

| CE implementation: - Regenerated and infinitely recyclable nylon (ECONYL®) obtained from an innovative patented regeneration process of pre- and post-consumer waste | CE implementation: - Creative reuse of industrial residues/scraps and development of new specific ecological paper product lines: Shiro, Crush, Refit, Remake | CE implementation: - Steel from scrap - By-products and additives (Green Stone, Green Iron) from production waste valorization for the construction industry | CE implementation: - Regenerated waste oil - Recovered exhausted pharmaceutical streams - Hazardous and organic waste valorization - Wastewater depuration - Responsible waste management | |

| How does CE relate to the corporate strategy? | - Multiyear path supported by all the shareholders and guided by specific internal sustainability principles (ECO PLEDGE) | - CE is fully integrated in the corporate strategy and enables them to be the first movers in the paper industry | - Sustainability is a pillar of their business strategy with a dedicated company organization unit reporting to the Chairman | - Sustainability and implementation of an advanced CE model with a circular supply chain are at the core of their creation |

| Which are the sustainability programs in the circular supply chains? | Resource recovery - Nylon from carpets and rugs for ECONYL® | Resource recovery - Wool, cotton, seaweeds, leather and agro-industry production scraps (upcycling) | Resource recovery - Steel scraps - Production waste (black slag, refractory materials, non-ferrous metals, dust/flue gases, rolling scale) - Plastic/polymers materials from various sources - Recovered heat for buildings inside and outside the plant | Resource recovery - Used lubricating oils - Spent solvent streams from the pharmaceutical industry - Industrial waste |

| Circular input - Organic material for Bio-Nylon production - Energy self-generation from photovoltaic system | Circular input - Algae and annual plants for Shiro paper - Energy self-generation from hydroelectric system and new aeolic system | Circular input - Energy self-generation from renewable systems | Circular input - Energy self-generation from high-performance co-generation - Energy from fuels recovered from waste streams - Energy self-generation from photovoltaic system | |

| Specific reclaiming program - Reclaiming Program for waste containing nylon - Take-back programs with big fashion players | Specific reclaiming program NO | Specific reclaiming program NO | Specific reclaiming program - Wasted oil from automotive and spent solvents from pharmaceutical | |

| Industrial symbiosis—materials NO | Industrial symbiosis—materials - Creative reuse of agro-industrial, leather and textile scraps | Industrial symbiosis—materials NO | Industrial symbiosis—materials - Recovery of spent solvent from/for pharmaceutical industry - Recovery of waste oils | |

| Industrial symbiosis—energy - AqualifSLO excess thermal energy to Atlantis water park in Ljubljana | Industrial symbiosis—energy NO | Industrial symbiosis—energy - Recovered heat to buildings inside the plant, to Goodyear Dunlop Tires and to public and residential buildings | Industrial symbiosis—energy NO | |

| Process and product innovation: - Bio-Nylon from only renewable materials (e.g., plants) - New materials and innovative processes | Process and product innovation: - New fine paper from agro-industry (Carta Crusca, Crush Cacao, Crush Grape, Crush Fagiolo) - Post-consumer absorbent hygienic products | Process and product innovation: - First intermediate products obtained from the combined recovery of white and black slag (Ecocemento, Green Concrete) - Re-use of fluff from car demolition - Recycling of plastic packaging - product quality and process optimization - Increase energy efficiency and reduce impact and emissions, in line with an Industry 4.0 approach | Process and product innovation: - Improvement of plants flexibility, making them suitable for receiving and handling variable and different charges - Increase in process transformation efficiency, optimizing raw materials and waste management | |

| Which are the main stakeholders that contribute to CSC implementation? | Suppliers selection - Environmental qualification protocol for supplier selection (ECONYL® Qualified Programme) | Suppliers selection - No specific program but requirement for no use of metals, chrome and pollutants | Suppliers selection - Scrap purchases only from authorized national and foreign suppliers - Use of Sustainable Supply Chain Self-Assessment Platform (TenP) | Suppliers selection - Internal criteria - Sustainable Supply Chain Self-Assessment Platform (TenP) being implemented |

| Partnerships and collaborations - Tarkett for an innovative technology to recover carpet tiles - Genomatica Inc. to use only renewable plant-based materials in the Bio-Nylon production | Partnerships and collaborations - Industrial collaborations for fiber processing - Fashion industry (Benetton, Vivienne Westwood, Louis Vuitton) to create ecological packaging for specific product lines | Partnerships and collaborations - Partnership for the co-development of the slag treatment process for the Greenstone product - University R&D | Partnerships and collaborations - Axens for an innovative process to regenerate the used lube oil with high quality and performance levels - Chemicals and lubricants industrial sectors | |

| Which are the main environmental benefits generated by the CE implementation? | Environmental benefits: - Waste regeneration and exploitation (used carpets/rugs) - Reduction in water consumption (internal water recycling) - Reduced CO2 emissions - Electric energy from renewable sources | Environmental benefits: - Industrial scraps regeneration and exploitation (from agro and fashion industries) - Reduction in water consumption (internal water recycling) - Reduced CO2 emissions - Electric energy from hydroelectric and new Aeolic project to compensate CO2 emissions | Environmental benefits: - Waste regeneration and exploitation (metal waste) - Reduction in water consumption - Reduced CO2 emissions - Energy self-generation from photovoltaic source | Environmental benefits: - Waste regeneration and exploitation (used oil) - Reduced water withdrawal - Reduced CO2 emissions and prevented tons of air pollutants - 700 tons of dangerous waste responsibly managed - Lower land consumption/pollution |

| Which are the main economic benefits generated by the CE implementation? | Economic benefits: - Risk mitigation thanks to lower raw material cost volatility - Revenues from new market segments through new eco-products (ECONYL ®) - EU-funded projects | Economic benefits: - Cost reduction for certain raw materials - Revenues from new market segments (fashion, food, stationary) through new premium paper (Crush, Refit, Remake) - EU-funded projects | Economic benefits: - Cost reduction for landfilling - Access to new green financial tools and EU funded projects - Compliance with national regulations | Economic benefits: - Internalized socio-economic value (sustainable approach provides success levers for improvement of turnover and economic margins, mitigation of enterprise risk, the attraction of capital and investors and the consolidation of the brand) |

Appendix B

| Core Questions | Question Items | AQUAFIL | FAVINI | FERALPI | ITELYUM |

|---|---|---|---|---|---|

| How is CE concretely implemented by companies? | Product innovation | ✓ | ✓ | ||

| Process innovation | ✓ | ✓ | ✓ | ✓ | |

| Business model innovation | ✓ | ✓ | ✓ | ||

| How does CE relate to the corporate strategy? | CE as a key element in the corporate strategy | ✓ | ✓ | ✓ | ✓ |

| Which are the sustainability programs in the Circular Supply Chains? | Resource recovery | ✓ | ✓ | ✓ | ✓ |

| Circular inputs | ✓ | ✓ | ✓ | ✓ | |

| Specific reclaiming programs | ✓ | ✓ | |||

| Industrial symbiosis—materials | ✓ | ✓ | ✓ | ||

| Industrial symbiosis—energy | ✓ | ✓ | |||

| R&D for product/process innovation | ✓ | ✓ | ✓ | ✓ | |

| Which are the main stakeholders that contribute to CSC implementation? | Supplier selection program | ✓ | ✓ | ✓ | |

| Partnerships | ✓ | ✓ | ✓ | ✓ | |

| Which are the main environmental benefits generated by the CE implementation? | Waste regeneration and exploitation | ✓ | ✓ | ✓ | ✓ |

| Reduced water consumption | ✓ | ✓ | ✓ | ✓ | |

| Reduced CO2 emissions | ✓ | ✓ | ✓ | ✓ | |

| Self-production of energy from renewable sources | ✓ | ✓ | ✓ | ✓ | |

| Reduced land consumption | ✓ | ||||

| Which are the main economic benefits generated by the CE implementation? | Cost reduction for raw materials | ✓ | ✓ | ✓ | ✓ |

| Cost reduction for landfilling | ✓ | ✓ | ✓ | ||

| Cost reduction for water and energy consumption | limited | limited | limited | ✓ | |

| Risk mitigation | ✓ | ✓ | |||

| New market segments penetration | ✓ | ✓ | ✓ | ||

| Increased revenues/turnover improvements | ✓ | ✓ | limited | ✓ | |

| Access to green financial tools | ✓ | ✓ | ✓(*) | ✓ | |

| Brand consolidation and competitiveness improvement | ✓ | ✓ | ✓ | ✓ |

References

- Borowski, P.F. Nexus between water, energy, food and climate change as challenges facing the modern global, European and Polish economy. AIMS Geosci. 2020, 6, 397–421. [Google Scholar] [CrossRef]

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; Urban Development; World Bank: Washington, DC, USA, 2018. [Google Scholar]

- Vanalle, R.M.; Ganga, G.M.D.; Godinho Filho, M.; Lucato, W.C. Green supply chain management: An investigation of pressures, practices, and performance within the Brazilian automotive supply chain. J. Clean. Prod. 2017, 151, 250–259. [Google Scholar] [CrossRef]

- De Giovanni, P.; Zaccour, G. A selective survey of game-theoretic models of closed-loop supply chains. 4OR 2019, 17, 1–44. [Google Scholar] [CrossRef]

- Landrum, N.E.; Ohsowski, B. Identifying worldviews on corporate sustainability: A content analysis of corporate sustainability reports. Bus. Strategy Environ. 2018, 27, 128–151. [Google Scholar] [CrossRef] [Green Version]

- D’Amato, D.; Droste, N.; Allen, B.; Kettunen, M.; Lähtinen, K.; Korhonen, J.; Toppinen, A. Green, circular, bio economy: A comparative analysis of sustainability avenues. J. Clean. Prod. 2017, 168, 716–734. [Google Scholar] [CrossRef]

- Farooque, M.; Zhang, A.; Thürer, M.; Qu, T.; Huisingh, D. Circular supply chain management: A definition and structured literature review. J. Clean. Prod. 2019, 228, 882–900. [Google Scholar] [CrossRef]

- Brown, P.; Bocken, N.; Balkenende, R. Why do companies pursue collaborative circular oriented innovation? Sustainability 2019, 11, 635. [Google Scholar] [CrossRef] [Green Version]

- Luciano, B.; Bourlakis, M.; Maull, R. Business Models in the Circular Economy and the Enabling Role of Supply Chains. In Proceedings of the 23rd European Operations Management Association (EurOMA), Trondheim, Norway, 17–22 June 2016. [Google Scholar]

- Rockström, J.; Steffen, W.; Noone, K.; Persson, A.; Chapin, F.S., III; Lambin, E.; Lenton, T.M.; Scheffer, M.; Folke, C.; Schellnhuber, H.J.; et al. Planetary Boundaries: Exploring the safe operating space for humanity. Ecol. Soc. 2009, 14, 32. [Google Scholar] [CrossRef]

- Meadows, D.H.; Randers, J.; Meadows, D.L. The Limits to Growth. The 30-Year Update; Routledge: London, UK, 2004. [Google Scholar]

- Reeves, M.; Deimler, M. Adaptability: The new competitive advantage. In Harvard Business Review; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, July–August 2011; pp. 135–141. Available online: https://hbr.org/2011/07/adaptability-the-new-competitive-advantage (accessed on 24 July 2020).

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Jalali, H.; Ansaripoor, A.H.; De Giovanni, P. Closed-loop supply chains with complementary products. Int. J. Prod. Econ. 2020, 229, 107757. [Google Scholar] [CrossRef]

- Rajeev, A.; Pati, R.K.; Padhi, S.S.; Govindan, K. Evolution of sustainability in supply chain management: A literature review. J. Clean. Prod. 2017, 162, 299e314. [Google Scholar] [CrossRef]

- De Giovanni, P. Dynamic Quality Models and Games in Digital Supply Chains; Springer Nature: Cham, Switzerland, 2020; To appear. [Google Scholar]

- Meredith, J. Building operations management theory through case and field research. J. Oper. Manag. 1998, 16, 439–452. [Google Scholar] [CrossRef]

- Bressanelli, G.; Perona, M.; Saccani, N. Challenges in supply chain redesign for the Circular Economy: A literature review and a multiple case study. Int. J. Prod. Res. 2019, 57, 7395–7422. [Google Scholar] [CrossRef] [Green Version]

- Voon-Hsien, L.; Ooi, K.-B.; Chong, A.Y.-L.; Lin, B. A Structural Analysis of Greening the Supplier, Environmental Performance and Competitive Advantage. Prod. Plan. Control 2015, 26, 116–130. [Google Scholar]

- Dan, D.; Dobrotӑ, G. An Innovative Method in the Regeneration of Waste Rubber and the Sustainable Development. J. Clean. Prod. 2018, 172, 3591–3599. [Google Scholar]

- Lacy, P.; Rutqvist, J. Waste to Wealth: The Circular Economy Advantage; Springer: London, UK, 2016. [Google Scholar]

- De Giovanni, P.; Ramani, V. Product cannibalization and the effect of a service strategy. J. Oper. Res. Soc. 2018, 69, 340–357. [Google Scholar] [CrossRef]

- Hervani, A.; Helms, M.; Sarkis, J. Performance measurement for green supply chain management. Benchmark. Int. J. 2005, 12, 330–353. [Google Scholar] [CrossRef] [Green Version]

- Cui, H.; Song, X. The Study on Countermeasures of Promoting Energy-Saving and Emissions-Reducing Based on Circular Economy Theory. In Proceedings of the 2009 IITA International Conference on Services Science, Management and Engineering, Zhangjiajie, China, 11–12 July 2009; pp. 333–335. [Google Scholar]

- Hussain, M.; Malik, M. Organizational enablers for circular economy in the context of sustainable supply chain management. J. Clean. Prod. 2020, 256, 120375. [Google Scholar] [CrossRef]

- Dhakal, M.; Smith, M.H.; Newbery, R. Secondary market: A significant aspect in reverse logistics and sustainability. Int. J. Soc. Sustain. Econ Soc. Cult. Con. 2016, 12, 24–35. [Google Scholar] [CrossRef]

- Genovese, A.; Acquaye, A.A.; Figueroa, A.; Koh, S.C.L. Sustainable supply chain management and the transition towards a circular Economy: Evidence and some applications. Omega 2017, 66, 344e357. [Google Scholar] [CrossRef]

- Genc, T.S.; De Giovanni, P. Optimal return and rebate mechanism in a closed-loop supply chain game. Eur. J. Oper. Res. 2018, 269, 661–681. [Google Scholar] [CrossRef] [Green Version]

- Lovins, A.; Braungart, M. A New Dynamic—Effective Business in a Circular Economy, 2nd ed.; Ellen MacArthur Foundation Publishing: Cowes, UK, 2014. [Google Scholar]

- Weetman, C. A Circular Economy Handbook for Business and Supply Chains: Repair, Remake, Redesign, Rethink; Kogan Page: New York, NY, USA, 2017. [Google Scholar]

- Lombardi, D.R.; Laybourn, P. Redefining industrial symbiosis: Crossing academic–practitioner boundaries. J. Ind. Ecol. 2012, 16, 28–37. [Google Scholar] [CrossRef]

- De Giovanni, P. Blockchain and smart contracts in supply chain management: A game theoretic model. Int. J. Prod. Econ. 2020, 228, 107855. [Google Scholar] [CrossRef]

- Kouhizadeh, M.; Zhu, Q.; Sarkis, J. Blockchain and the circular economy: Potential tensions and critical reflections from practice. Prod. Plan. Control 2020, 31, 950–966. [Google Scholar] [CrossRef]

- De Giovanni, P. Eco-Digital Supply Chains Through Blockchains. SSRN Electron. J. 2019. [Google Scholar] [CrossRef]

- Prosman, E.J.; Sacchi, R. New environmental supplier selection criteria for circular supply chains: Lessons from a consequential LCA study on waste recovery. J. Clean. Prod. 2018, 172, 2782–2792. [Google Scholar] [CrossRef]

- De Giovanni, P. Smart Supply Chain with Vendor Managed Inventory, Coordination, and Environmental performance. Eur. J. Oper. Res. 2020, 282. in press. [Google Scholar] [CrossRef]

- Withers, P.J.; Doody, D.G.; Sylvester-Bradley, R. Achieving sustainable phosphorus use in food systems through circularisation. Sustainability 2018, 10, 1804. [Google Scholar] [CrossRef] [Green Version]

- Italian Circular Economy Stakeholder Platform. Strumenti per la Misurazione Dell’economia Circolare. 2018. Available online: https://www.icesp.it/sites/default/files/DocsGdL/REPORT_GdL3%20Strumenti%20per%20la%20misurazione%20dell%E2%80%99economia%20circolare_0.pdf (accessed on 30 September 2020).

- EU. Waste Prevention and Management—Environment—European Commission. 2020. Available online: https://ec.europa.eu/environment/green-growth/waste-prevention-and-management/index_en.htm (accessed on 24 July 2020).

- De Luca, A.I.; Iofrida, N.; Leskinen, P.; Stillitano, T.; Falcone, G.; Strano, A.; Gulisano, G. Life cycle tools combined with multi-criteria and participatory methods for agricultural sustainability: Insights from a systematic and critical review. Sci. Total Environ. 2017, 595, 352e370. [Google Scholar] [CrossRef]

- ISO. ISO 14040 International Standard. In Environmental Management—Life Cycle Assessment—Principles and Framework; International Organisation for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Sala, S.; Beylot, A.; Corrado, S.; Crenna, E.; Sanyé-Mengual, E.; Secchi, M. Indicators and Assessment of the Environmental Impact of EU Consumption. 2020. Available online: https://publications.jrc.ec.europa.eu/repository/bitstream/JRC114814/science_for_policy_report_final_on_line.pdf (accessed on 24 July 2020).

- Guinee, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Rydberg, T. Life cycle assessment: Past, present, and future. Environ. Sci. Technol. 2011, 45, 90–96. [Google Scholar] [CrossRef]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Suh, S. Recent developments in life cycle assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Leising, E.; Quist, J.; Bocken, N. Circular Economy in the building sector: Three cases and a collaboration tool. J. Clean. Prod. 2018, 176, 976–989. [Google Scholar] [CrossRef]

- Domenech, T.; Bleischwitz, R.; Doranova, A.; Panayotopoulos, D.; Roman, L. Mapping Industrial Symbiosis Development in Europe_ typologies of networks, characteristics, performance and contribution to the Circular Economy. Resour. Conserv. Recycl. 2019, 141, 76–98. [Google Scholar] [CrossRef]

- De Giovanni, P.; Vinzi, V.E. The benefits of the emissions trading mechanism for Italian firms: A multi-group analysis. Int. J. Phys. Distrib. Logist. Manag. 2014, 44, 305–324. [Google Scholar] [CrossRef]

- Mirzaee, H.; Naderi, B.; Pasandideh, S.H.R. A preemptive fuzzy goal programming model for generalized supplier selection and order allocation with incremental discount. Comput. Ind. Eng. 2018, 122, 292e302. [Google Scholar] [CrossRef]

- Caniels, M.C.; Gehrsitz, M.H.; Semeijn, J. Participation of suppliers in greening supply chains: An empirical analysis of German automotive suppliers. J. Purch. Supply Manag. 2013, 19, 134–143. [Google Scholar] [CrossRef]

- Cao, M.; Zhang, Q. Supply chain collaboration: Impact on collaborative advantage and firm performance. J. Oper. Manag. 2011, 29, 163–180. [Google Scholar] [CrossRef]

- Kopfer, H.; Kotzab, H.; Corsten, D.; Felde, J. Exploring the performance effects of key-supplier collaboration. Int. J. Phys. Distrib. Logist. Manag. 2005, 35, 445–461. [Google Scholar]

- Hartmann, J.; Moeller, S. Chain liability in multitier supply chains? Responsibility attributions for unsustainable supplier behavior. J. Oper. Manag. 2014, 32, 281–294. [Google Scholar] [CrossRef] [Green Version]

- Konys, A. Green supplier selection criteria: From a literature review to a comprehensive knowledge base. Sustainability 2019, 11, 4208. [Google Scholar] [CrossRef] [Green Version]

- De Giovanni, P.; Cariola, A. Process innovation through industry 4.0 technologies, lean practices and green supply chains. Res. Transp. Econ. 2020, 100869. [Google Scholar] [CrossRef]

- Taghikhah, F.; Voinov, A.; Shukla, N. Extending the supply chain to address sustainability. J. Clean. Prod. 2019, 229, 652–666. [Google Scholar] [CrossRef]

- De Giovanni, P. State-and control-dependent incentives in a closed-loop supply chain with dynamic returns. Dyn. Games Appl. 2016, 6, 20–54. [Google Scholar] [CrossRef]

- EIO (Eco-Innovation Observatory). The Eco-Innovation Challenge: Pathways to a Resource-Efficient Europe. Brussels, Belgium: European Commission, Directorate-General for the Environment; EIO: Brussels, Belgium, 2011. [Google Scholar]

- OECD (Organization for Economic Co-operation and Development). Eco-Innovation in Industry: Enabling Green Growth; OECD: Paris, France, 2009. [Google Scholar]

- Bowen, F.E.; Cousins, P.D.; Lamming, R.C.; Faruk, A.C. Horses for courses: Explaining the gap between the theory and practice of green supply. In Greener Management International Autumn; Greenleaf Publishing: London, UK, 2001; pp. 41–60. [Google Scholar]

- Zhang, H.; Yang, F. On the drivers and performance outcomes of green practices adoption. Ind. Manag. Data Syst. 2016, 116, 2011–2034. [Google Scholar] [CrossRef]

- Liu, B.; De Giovanni, P. Green process innovation through Industry 4.0 technologies and supply chain coordination. Ann. Oper. Res. 2019, 1–36. [Google Scholar] [CrossRef]

- Paquin, R.L.; Busch, T.; Tilleman, S.G. Creating economic and environmental value through industrial symbiosis. Long Range Plan. 2015, 48, 95–107. [Google Scholar] [CrossRef]

- Lehr, C.B.; Thun, J.H.; Milling, P.M. From waste to value—A system dynamics model for strategic decision- making in closed-loop supply chains. Int. J. Prod. Res. 2013, 51, 4105–4116. [Google Scholar] [CrossRef]

- El Hachem, W.; De Giovanni, P. Accelerating the transition to alternative fuel vehicles through a Distributive Justice perspective. Transp. Res. Part D Transp. Environ. 2019, 75, 72–86. [Google Scholar] [CrossRef]

- Firnkorn, J.; Müller, M. Selling mobility instead of cars: New business strategies of automakers and the impact on private vehicle holding. Bus. Strategy Environ. 2012, 21, 264–280. [Google Scholar] [CrossRef]

- Leandro, A.; Paixao, S. Corporate Social Responsibility and Circular Economy: Two ways, same destinations? An outlook on both concepts and cases from Portugal. In Proceedings of the Congrès avniR, Lille, Portugal, 7 November 2018. [Google Scholar]

- Vollero, A.; Conte, F.; Siano, A.; Covucci, C. Corporate social responsibility information and involvement strategies in controversial industries. Corp. Soc. Responsib. Environ. Manag. 2019, 26, 141–151. [Google Scholar] [CrossRef]

- Bhattacharya, C.B.; Sen, S. Doing better at doing good: When, why, and how consumers respond to corporate social initiatives. Calif. Manag. Rev. 2004, 47, 9–24. [Google Scholar] [CrossRef]

- Du, S.; Battacharya, C.B.; Sen, S. Maximizing business returns to corporate social responsibility (CSR): The role of CSR communication. Int. J. Manag. Rev. 2010, 12, 8–19. [Google Scholar] [CrossRef]

- McWilliams, A.; Siegel, D.S.; Wright, P.M. Corporate social responsibility: Strategic implications. J. Manag. Stud. 2006, 43, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Muñoz-Torres, M.J.; Fernández-Izquierdo, M.Á.; Rivera-Lirio, J.M.; Ferrero-Ferrero, I.; Escrig-Olmedo, E.; Gisbert-Navarro, J.V.; Marullo, M.C. An Assessment Tool to Integrate Sustainability Principles into the Global Supply Chain. Sustainability 2018, 10, 535. [Google Scholar] [CrossRef] [Green Version]

- European Commission. The EU Environmental Implementation Review 2019 Country Report—ITALY. 2019. Available online: https://ec.europa.eu/environment/eir/pdf/report_it_en.pdf (accessed on 30 September 2020).

- Kotzab, H.; Seuring, S.; Müller, M.; Reiner, G. (Eds.) Research Methodologies in Supply Chain Management; Springer Science & Business Media: Berlin, Germany, 2006. [Google Scholar]

- Preeker, T.; De Giovanni, P. Coordinating innovation projects with high tech suppliers through contracts. Res. Policy 2018, 47, 1161–1172. [Google Scholar] [CrossRef]

- ENEL and Symbola Foundation. 100 Italian Circular Economy Stories. 2018. Available online: http://www.symbola.net/assets/files/100storie_DEF_Web_pag%20singole_25-05-18_1527247969.pdf (accessed on 30 September 2020).

| AQUAFIL | FAVINI | FERALPI | ITELYUM | |

|---|---|---|---|---|

| Industrial sector | Textile industry | Paper industry | Steel industry | Materials regeneration and industrial waste management industries |

| Type | Manufacturer | Manufacturer | Manufacturer | Manufacturer |

| Revenues | 549 million € | 160 million € | 1302 million € | 300 million € |

| Main CE ouput | Regenerated and infinitely recyclable nylon | Ecological paper from the creative reuse of industrial waste | Steel from scrap, by-products and additives from production waste | Regenerated waste oil, recovered exhausted pharmaceutical streams, hazardous waste valorization |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maranesi, C.; De Giovanni, P. Modern Circular Economy: Corporate Strategy, Supply Chain, and Industrial Symbiosis. Sustainability 2020, 12, 9383. https://doi.org/10.3390/su12229383

Maranesi C, De Giovanni P. Modern Circular Economy: Corporate Strategy, Supply Chain, and Industrial Symbiosis. Sustainability. 2020; 12(22):9383. https://doi.org/10.3390/su12229383

Chicago/Turabian StyleMaranesi, Cristina, and Pietro De Giovanni. 2020. "Modern Circular Economy: Corporate Strategy, Supply Chain, and Industrial Symbiosis" Sustainability 12, no. 22: 9383. https://doi.org/10.3390/su12229383

APA StyleMaranesi, C., & De Giovanni, P. (2020). Modern Circular Economy: Corporate Strategy, Supply Chain, and Industrial Symbiosis. Sustainability, 12(22), 9383. https://doi.org/10.3390/su12229383