Review and Meta-Analysis of EVs: Embodied Emissions and Environmental Breakeven

Abstract

:1. Introduction

2. Materials and Methods

2.1. EV LCA Review

2.1.1. Selection of Review Material

- Published in the last ten years (the most dated study was 2012).

- Included the production (material extraction and manufacturing) phase and use phase of the vehicle.

- Included greenhouse gas emissions within the analysis.

- Used empirical data.

- Included a BEV case.

- Included a medium-sized passenger vehicle.

2.1.2. Review Approach

2.2. Analysis

2.2.1. The Distance of Intersection Point Calculations

2.2.2. Emission Disparity

2.2.3. Maximum Production Emissions

2.2.4. Monte Carlo Simulation

2.2.5. GHG Emission Intensity of Electricity Supply

3. Review

3.1. Overview of the Reviewed Studies

3.2. Methodologies, Goals, and Scopes

3.2.1. Inclusion of Battery Replacement

3.2.2. Inclusion of End of Life

3.2.3. Inclusion of Maintenance and Differing Sub-Process Inclusion within the Maintenance Phase

3.2.4. LCA Methods

3.2.5. Databases Used for Background Data

3.2.6. Drive Cycle Selection

3.3. Contextual Variability and Assumptions

3.3.1. Electricity Source

3.3.2. Production Location and Carbon Intensity of the Electrical Grid at the Production Facility

3.3.3. Battery Capacity

3.3.4. Vehicle Lifetime

3.3.5. Energy Efficiency

3.3.6. Vehicle Weight

3.4. Granularity and Access to Data

3.4.1. Aggregated Emissions

3.4.2. Battery Pack Production Emissions

3.4.3. Lack of Supplementary Data

3.4.4. Missing or Excluded Key Data Points

4. Operationalization of Extracted Meta-Data

4.1. Aggregation of Results from All Studies

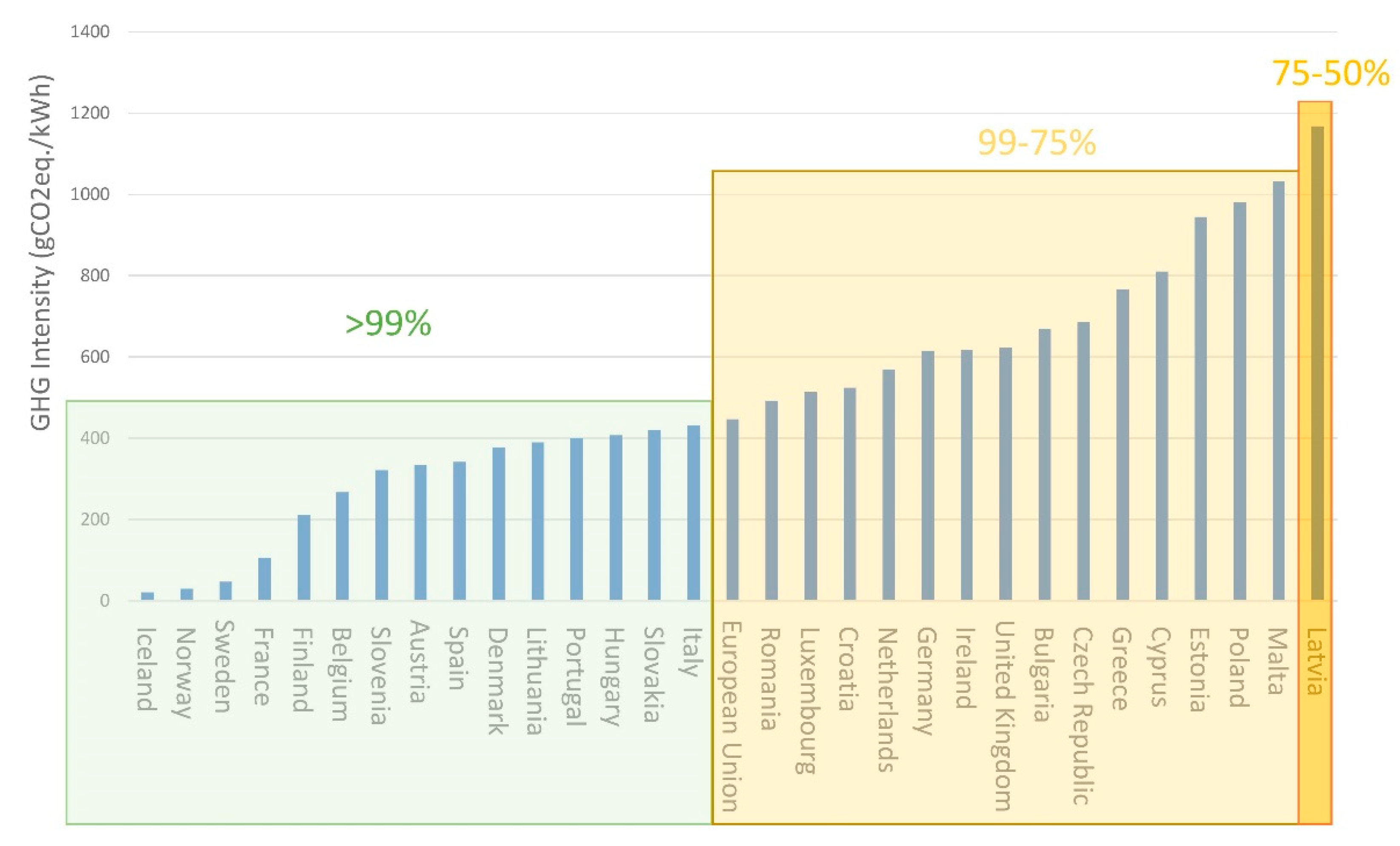

4.2. Electrical Grid Intensities

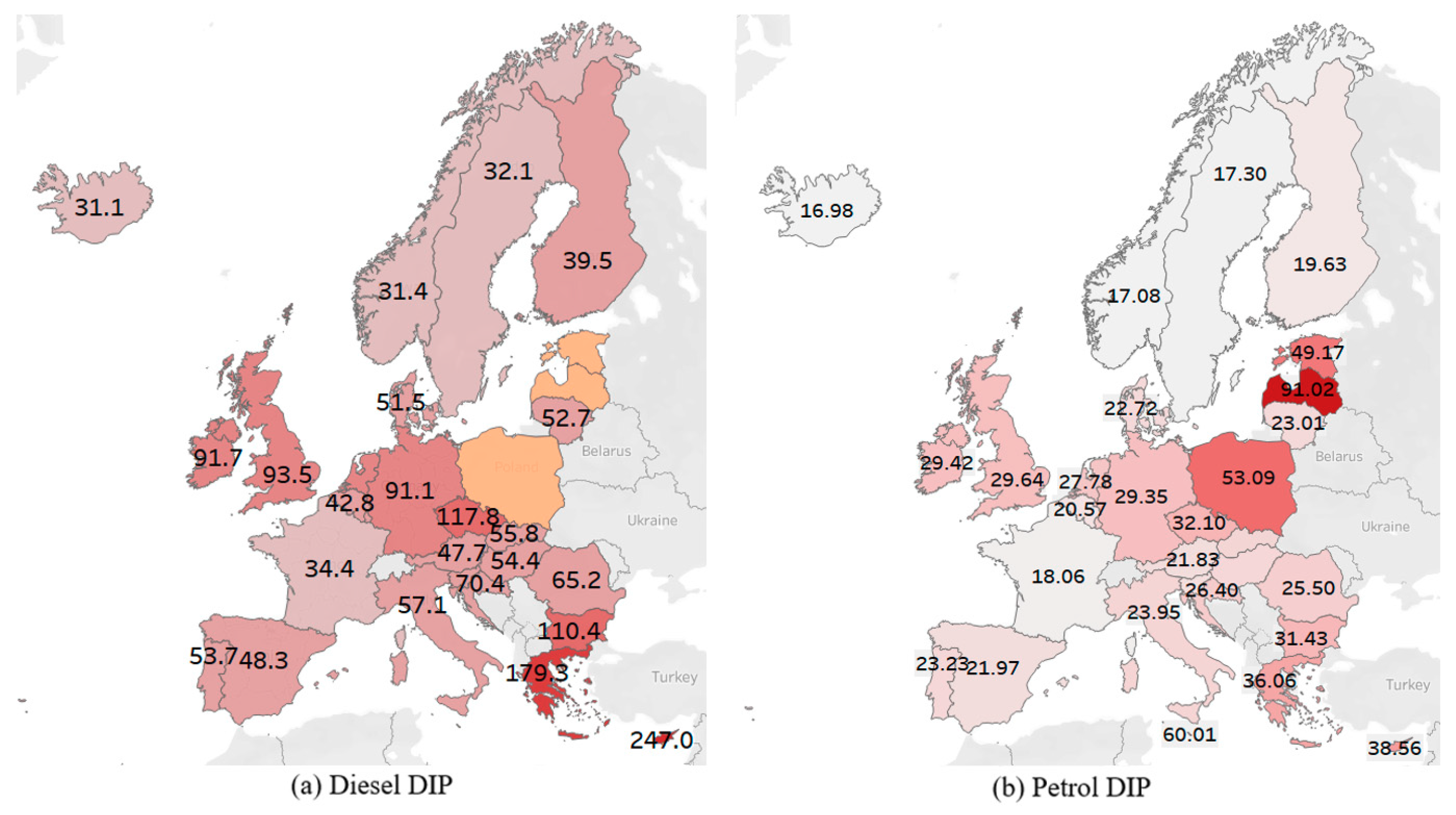

4.3. The Distances of Intersection Points (DIPs)

4.4. Emissions Disparity (ED)

4.5. Maximum Production Emissions (MPEs)

4.6. Monte Carlo Simulation (MCS)

5. Discussion and Conclusions

5.1. Discussion on the Review

5.2. Discussion on the Operationalization of the Extracted Meta-Data

5.3. Limitations and Further Study

5.4. Policy Implications

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Study and Year | Vehicle Type | Lifetime (km) | Battery Capacity (kWh) | Country of Study | EV Fuel Efficiency (kWh/100 km) | ICEV Fuel Efficiency (l/100 km) | Total (g CO2/km) |

|---|---|---|---|---|---|---|---|

| Gao, L., and Winfield, Z. C. (2012) | Petrol | 256,000 | US. | 6.821235 | 265 | ||

| Gao, L., and Winfield, Z. C. (2012) | BEV | 256,000 | 24 | US. | 21.15178 | 231 | |

| Ma, Hongrui, et al. (2012) | Petrol | 180,000 | UK. | 6.4 | 201.2 | ||

| Ma, Hongrui, et al. (2012) | Petrol | 289,500 | US. | 12.9 | 282.9 | ||

| Ma, Hongrui, et al. (2012) | BEV | 180,000 | 35 | UK. | 14 | 109.2 | |

| Ma, Hongrui, et al. (2012) | BEV | 289,500 | 35 | US. | no data | 130.6 | |

| Sharma, R., et al. (2013) | Diesel | 150,000 | Australia | 4.5 | 173.4 | ||

| Sharma, R., et al. (2013) | BEV | 150,000 | 19.2 | Australia | 12 | 208.3 | |

| Sharma, R., et al. (2013) | Petrol | 150,000 | Australia | 12.5 | 410 | ||

| Szczechowicz, E., Dederichs, T., and Schnettler, A. (2012) | Petrol | 150,000 | Germany | 7.5 | 252.7 | ||

| Szczechowicz, E., Dederichs, T., and Schnettler, A. (2012) | BEV | 150,000 | 34.3 | Germany | 17.15 | 163.9 | |

| Bartolozzi, I., Rizzi, F., and Frey, M. (2013) | BEV | no lifetime given, only emissions per km | 34.2 | Italy | 17 | 110.35 | |

| Bartolozzi, I., Rizzi, F., and Frey, M. (2013) | BEV | no lifetime given, only emissions per km | 34.2 | Italy | 17 | 121.2 | |

| Bartolozzi, I., Rizzi, F., and Frey, M. (2013) | BEV | no lifetime given, only emissions per km | 34.2 | Italy | 17 | 178.25 | |

| Hawkins, Troy R., et al. (2013) | Diesel | 150,000 | EU | 6.85 | 228.439 | ||

| Hawkins, Troy R., et al. (2013) | Petrol | 150,000 | EU | 5.35 | 259.732 | ||

| Hawkins, Troy R., et al. (2013) | BEV | 150,000 | 24 | EU | 17.31 | 194.017 | |

| Hawkins, Troy R., et al. (2013) | BEV | 150,000 | 24 | EU | 17.31 | 225.31 | |

| Hawkins, Troy R., et al. (2013) | BEV | 150,000 | 24 | EU | 17.31 | 309.801 | |

| Hawkins, Troy R., et al. (2013) | BEV | 150,000 | 24 | EU | 17.31 | 206.534 | |

| Chatzikomis, C. I., Spentzas, K. N., and Mamalis, A. G. (2014) | Petrol | 150,000 | Greece | 7.13 | 228.9 | ||

| Chatzikomis, C. I., Spentzas, K. N., and Mamalis, A. G. (2014) | BEV | 150,000 | 30 | Greece | 21 | 198.7 | |

| Messagie et al. (2014) | Diesel | 230,500 | no data | EU | 5.3 | 189 | |

| Messagie et al. (2014) | Diesel | 230,500 | no data | EU | 5.9 | 195 | |

| Messagie et al. (2014) | Petrol | 230,500 | no data | EU | 7.2 | 267 | |

| Messagie et al. (2014) | Petrol | 230,500 | no data | EU | 7.1 | 270 | |

| Messagie et al. (2014) | Petrol | 230,500 | no data | EU | 13.1 | 288 | |

| Messagie et al. (2014) | BEV | 230,500 | no data | EU | 17 | 95 | |

| Bauer, Christian, et al. (2015) | Petrol | 240,000 | EU | no data | 301.33 | ||

| Bauer, Christian, et al. (2015) | Diesel | 240,000 | EU | no data | 253.48 | ||

| Bauer, Christian, et al. (2015) | BEV | 240,000 | 25 | EU | no data | 66.86 | |

| Bauer, Christian, et al. (2015) | BEV | 240,000 | 25 | EU | no data | 67.94 | |

| Bauer, Christian, et al. (2015) | BEV | 240,000 | 25 | EU | no data | 70.36 | |

| Bauer, Christian, et al. (2015) | BEV | 240,000 | 25 | EU | no data | 87.14 | |

| Bauer, Christian, et al. (2015) | BEV | 240,000 | 25 | EU | no data | 185.94 | |

| Bauer, Christian, et al. (2015) | BEV | 240,000 | 25 | EU | no data | 213.94 | |

| Bauer, Christian, et al. (2015) | BEV | 240,000 | 25 | EU | no data | 370.94 | |

| Girardi, P., Gargiulo, A., and Brambilla, P. C. (2015) | Petrol | 150,000 | Italy | 6.83 | 308.0599 | ||

| Girardi, P., Gargiulo, A., and Brambilla, P. C. (2015) | BEV | 150,000 | 24 | Italy | 19 | 155.0967 | |

| Onat et al. (2015) | Petrol | 240,000 | US. | 7.6 | 263.4052 | ||

| Onat et al. (2015) | BEV | 240,000 | 24 | US. | no data | 195.22 | |

| Tagliaferri at al. (2016) | BEV | 150,000 | 24 | EU | 15.56 | 117.7 | |

| Tagliaferri at al. (2016) | Diesel | 150,000 | 24 | EU | 5 | 170 | |

| Burchart-Korol, Dorota, et al. (2018) | BEV | 150,000 | 29.9 | Czech Republic | 19.9 | 220.38 | |

| Burchart-Korol, Dorota, et al. (2018) | BEV | 150,000 | 29.9 | Poland | 19.9 | 282.71 | |

| Gawron, James H., et al. (2018) | Petrol | 257,495 | US. | 266.5721 | |||

| Gawron, James H., et al. (2018) | BEV | 257,495 | 23 | US. | 19.57 | 138.725 | |

| Gawron, James H., et al. (2018) | BEV | 257,495 | 23 | US. | 19.57 | 153.0942 | |

| Wu et al. (2018) | Petrol | 150,000 | no data | China | 8.3 | 233.73 | |

| Wu et al. (2018) | Petrol | 150,000 | no data | China | 8.9 | 268.27 | |

| Wu et al. (2018) | BEV | 150,000 | no data | China | 19.4 | 218.8 | |

| Wu et al. (2018) | BEV | 150,000 | no data | China | 23.8 | 288.4 | |

| Bekel, K., and Pauliuk, S. (2019) | Petrol | 150,000 | Germany | no data | 326.4 | ||

| Bekel, K., and Pauliuk, S. (2019) | BEV | 150,000 | 35.8 | Germany | 17.53 | 139.7 | |

| Kawamoto et al. (2019) | Petrol | 200,000 | EU | 5.102041 | 170.33 | ||

| Kawamoto et al. (2019) | Petrol | 200,000 | Australia | 5.813953 | 182.83 | ||

| Kawamoto et al. (2019) | Petrol | 200,000 | China | 6.21118 | 195.33 | ||

| Kawamoto et al. (2019) | Petrol | 200,000 | US. | 7.575758 | 245.33 | ||

| Kawamoto et al. (2019) | Diesel | 200,000 | EU | 3.802281 | 140.33 | ||

| Kawamoto et al. (2019) | Diesel | 200,000 | Japan | 4.62963 | 170.33 | ||

| Kawamoto et al. (2019) | BEV | 200,000 | 35.8 | EU | 12.70648 | 146.57 | |

| Kawamoto et al. (2019) | BEV | 200,000 | 35.8 | Japan | 12.40695 | 171.57 | |

| Kawamoto et al. (2019) | BEV | 200,000 | 35.8 | U.S. | 17.3913 | 202.01 | |

| Kawamoto et al. (2019) | BEV | 200,000 | 35.8 | China | 12.70648 | 204.9 | |

| Kawamoto et al. (2019) | BEV | 200,000 | 35.8 | Australia | 12.70648 | 213.23 | |

| Li, Y., Ha, N., and Li, T. (2019) | Petrol | 260,000 | China | 359.6 | |||

| Li, Y., Ha, N., and Li, T. (2019) | Petrol | 260,000 | China | 386.9 | |||

| Li, Y., Ha, N., and Li, T. (2019) | Petrol | 260,000 | China | 418.1 | |||

| Li, Y., Ha, N., and Li, T. (2019) | BEV | 260,000 | 17.7 | China | 11.67 | 456.7 | |

| Li, Y., Ha, N., and Li, T. (2019) | Petrol | 260,000 | China | 437.7 | |||

| Li, Y., Ha, N., and Li, T. (2019) | BEV | 260,000 | 24.4 | China | 13.71 | 487.8 | |

| Li, Y., Ha, N., and Li, T. (2019) | BEV | 260,000 | 42.1 | China | 14.98 | 518.9 | |

| Li, Y., Ha, N., and Li, T. (2019) | BEV | 260,000 | 59.9 | China | 16.77 | 565.9 | |

| Xiong, S., Ji, J., and Ma, X. (2019) | BEV | 160,000 | 47.5 | China | 15.3 | 201.93 | |

| Xiong, S., Ji, J., and Ma, X. (2019) | BEV | 120,000 | 60.5 | China | 15.2 | 237.57 |

References

- European Commission. A European Strategy for Low-Emission Mobility. In Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committeee and the Committee of the Regions; European Commission: Brussels, Belgium, 2016. [Google Scholar]

- IPCC. Transport. In Climate Change: Mitigation of Climate Change: Contribution of Working Group III to the Fifth Assessment Report of the IPCC; Intergovernmental Panel on Climate Change, Cambridge University Press: Cambridge, UK, 2014. [Google Scholar]

- Woo, J.; Choi, H.; Ahn, J. Well-to-wheel analysis of greenhouse gas emissions for electric vehicles based on electricity generation mix: A global perspective. Transp. Res. Part D Transp. Environ. 2017, 51, 340–350. [Google Scholar] [CrossRef]

- International Organization for Standardizaiton (ISO). Environmental Management—Life Cycle Assessment—Principles and Framework; ISO 14040:2006; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Egede, P.; Dettmer, T.; Herrmann, C.; Kara, S. Life Cycle Assessment of Electric Vehicles—A Framework to Consider Influencing Factors. Procedia CIRP 2015, 29, 233–238. [Google Scholar] [CrossRef]

- Nordelöf, A.; Messagie, M.; Tillman, A.M.; Söderman, M.L.; Van Mierlo, J. Environmental impacts of hybrid, plug-in hybrid, and battery. Int. J. Life Cycle Assess. 2014, 19, 1866–1890. [Google Scholar] [CrossRef] [Green Version]

- Brandao, M.; Heath, G.; Cooper, J. What Can Meta-Analyses Tell Us About the Reliability of Life Cycle Assessment for Decision Support? J. Ind. Ecol. 2012, 16, S3–S7. [Google Scholar] [CrossRef]

- Hawkins, T.R.; Gausen, O.M.; Strømman, A.H. Environmental impacts of hybrid and electric vehicles—A review. Int. J. Life Cycle Assess. 2012, 17, 997–1014. [Google Scholar] [CrossRef]

- Marmiroli, B.; Messagie, M.; Dotelli, G.; Van Mierlo, J. Electricity Generation in LCA of Electric Vehicles: A Review. Appl. Sci. 2018, 8, 1384. [Google Scholar] [CrossRef] [Green Version]

- Moro, A.; Lonza, L. Electricity carbon intensity in European Member States: Impacts on GHG emissions of electric vehicles. Transp. Res. Part D Transp. Environ. 2018, 64, 5–14. [Google Scholar] [CrossRef]

- Ellingsen, L.A.W.; Singh, B.; Strømman, A.H. The size and range effect: Lifecycle greenhouse gas emissions of electric vehicles. Environ. Res. Lett. 2016, 11, 054010. [Google Scholar] [CrossRef]

- Zamagni, A.; Masoni, P.; Buttol, P.; Raggi, A.; Buonamici, R. Finding Life Cycle Assessment Research Direction with the Aid of Meta-Analysis. J. Ind. Ecol. 2012, 16, S39–S52. [Google Scholar] [CrossRef]

- Kawamoto, R.; Mochizuki, H.; Moriguchi, Y.; Nakano, T.; Motohashi, M.; Sakai, Y.; Inaba, A. Estimation of CO2 Emissions of Internal Combustion Engine Vehicle and Battery Electric Vehicle Using LCA. Sustainability 2019, 11, 2690. [Google Scholar] [CrossRef] [Green Version]

- Zumsteg, J.M.; Cooper, J.S.; Noon, M.S. Systematic Review Checklist: A Standardized Technique for Assessing and Reporting Reviews of Life Cycle Assessment Data. J. Ind. Ecol. 2012, 16, S12–S21. [Google Scholar] [CrossRef] [Green Version]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; The PRISMA Group. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef] [Green Version]

- Hawkins, T.R.; Singh, B.; Majeau-Bettez, G.; Strømman, A.H. Comparative Environmental Life Cycle Assessment of Conventional and Electric Vehicles. J. Ind. Ecol. 2013, 17, 53–64. [Google Scholar] [CrossRef]

- Gao, L.; Winfield, Z.C. Life Cycle Assessment of Environmental and Economic Impacts of Advanced Vehicles. Energies 2012, 5, 605–620. [Google Scholar] [CrossRef]

- Ma, H.; Balthasar, F.; Tait, N.; Riera-Palou, X.; Harrison, A. A new comparison between the life cycle greenhouse gas emissions of battery electric vehicles and internal combustion vehicles. Energy Policy 2012, 44, 160–173. [Google Scholar] [CrossRef]

- Szczechowicz, E.; Dederichs, T.; Schnettler, A. Regional assessment of local emissions of electric vehicles using traffic simulations for a use case in Germany. Int. J. Life Cycle Assess. 2012, 17, 1131–1141. [Google Scholar] [CrossRef]

- Bartolozzi, I.; Rizzi, F.; Frey, M. Comparison between hydrogen and electric vehicles by life cycle assessment: A case study in Tuscany, Italy. Appl. Energy 2013, 101, 103–111. [Google Scholar] [CrossRef]

- Sharma, R.; Manzie, C.; Bessede, M.; Crawford, R.H.; Brear, M.J. Conventional, hybrid and electric vehicles for Australian driving conditions. Part 2: Life cycle CO2-e emissions. Transp. Res. Part C Emerg. Technol. 2013, 28, 63–73. [Google Scholar] [CrossRef]

- Chatzikomis, C.I.; Spentzas, K.N.; Mamalis, A.G. Environmental and economic effects of widespread introduction of electric vehicles in Greece. Eur. Transp. Res. Rev. 2014, 6, 365–376. [Google Scholar] [CrossRef]

- Messagie, M.; Boureima, F.S.; Coosemans, T.; Macharis, C.; Mierlo, J.V. A Range-Based Vehicle Life Cycle Assessment Incorporating Variability in the Environmental Assessment of Different Vehicle Technologies and Fuels. Energies 2014, 7, 1467–1482. [Google Scholar] [CrossRef]

- Bauer, C.; Hofer, J.; Althaus, H.J.; Del Duce, A.; Simons, A. The environmental performance of current and future passenger vehicles: Life cycle assessment based on a novel scenario analysis framework. Appl. Energy 2015, 157, 871–883. [Google Scholar] [CrossRef]

- Girardi, P.; Gargiulo, A.; Brambilla, P.C. A comparative LCA of an electric vehicle and an internal combustion engine vehicle using the appropriate power mix: The Italian case study. Girardi, Pierpaolo, Gargiulo, Alessia and Brambilla, Paola Cristina. Int. J. Life Cycle Assess. 2015, 20, 1127–1142. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M.; Tatari, O. Conventional, hybrid, plug-in hybrid or electric vehicles? State-based comparative carbon and energy footprint analysis in the United States. Appl. Energy 2015, 150, 36–49. [Google Scholar] [CrossRef]

- Tagliaferri, C.; Evangelisti, S.; Acconcia, F.; Domenech, T.; Ekins, P.; Barletta, D.; Lettieri, P. Life cycle assessment of future electric and hybrid vehicles: A cradle-to-grave systems engineering approach. Chem. Eng. Res. Des. 2016, 112, 298–309. [Google Scholar] [CrossRef]

- Burchart-Korol, D.; Jursova, S.; Folęga, P.; Korol, J.; Pustejovska, P.; Blaut, A. Environmental life cycle assessment of electric vehicles in Poland and the Czech Republic. J. Clean. Prod. 2018, 202, 476–487. [Google Scholar] [CrossRef]

- Gawron, J.H.; Keoleian, G.A.; De Kleine, R.D.; Wallington, T.J.; Kim, H.C. Life cycle assessment of connected and automated vehicles: Sensing and computing subsystem and vehicle level effects. Environ. Sci. Technol. 2018, 52, 3249–3256. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, M.; Zheng, J.; Sun, X.; Zhao, M.; Wang, X. Life cycle greenhouse gas emission reduction potential of battery electric vehicle. J. Clean. Prod. 2018, 190, 462–470. [Google Scholar] [CrossRef]

- Bekel, K.; Pauliuk, S. Prospective cost and environmental impact assessment of battery and fuel cell electric vehicles in Germany. Int. J. Life Cycle Assess. 2019, 24, 2220–2237. [Google Scholar] [CrossRef]

- Li, Y.; Ha, N.; Li, T. Research on Carbon Emissions of Electric Vehicles throughout the Life Cycle Assessment Taking into Vehicle Weight and Grid Mix Composition. Energies 2019, 12, 3612. [Google Scholar] [CrossRef] [Green Version]

- Xiong, S.; Ji, J.; Ma, X. Comparative Life Cycle Energy and GHG Emission Analysis for BEVs and PhEVs: A Case Study in China. Energies 2019, 12, 834. [Google Scholar] [CrossRef] [Green Version]

- Crawford, R.H.; Bontinck, P.A.; Stephan, A.; Wiedmann, T.; Yu, M. Hybrid life cycle inventory methods—A review. J. Clean. Prod. 2018, 172, 1273–1288. [Google Scholar] [CrossRef]

- Pomponi, F.; Lenzen, M. Hybrid life cycle assessment (LCA) will likely yield more accurate results than process-based LCA. J. Clean. Prod. 2018, 176, 210–215. [Google Scholar] [CrossRef]

- Säynäjoki, A.; Heinonen, J.; Junnonen, J.M.; Junnila, S. Input–output and process LCAs in the building sector: Are the results compatible with each other? Carbon Manag. 2017, 8, 155–166. [Google Scholar] [CrossRef]

- Lenzen, M. Errors in Conventional and Input-Output—Based Life—Cycle Inventories. J. Ind. Ecol. 2008, 4, 127–148. [Google Scholar] [CrossRef]

- Romare, M.; Dahllöf, L. The Life Cycle Energy Consumption and Greenhouse Gas Emissions from Lithium-Ion Batteries; IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2017; Volume 23. [Google Scholar]

- Emami, N.; Heinonen, J.; Marteinsson, B.; Säynäjoki, A.; Junnonen, J.M.; Laine, J.; Junnila, S. A Life Cycle Assessment of Two Residential Buildings Using Two Different LCA Database-Software Combinations: Recognizing Uniformities and Inconsistencies. Buildings 2019, 9, 20. [Google Scholar] [CrossRef] [Green Version]

- The International Council on Clean Transportation. Effects of Battery Manufacturing on Electric Vehicle Life-Cycle Greenhouse Gas Emissions; International Council Clean Transportation: Washington, DC, USA, 2018. [Google Scholar]

- Pryshlakivsky, J.; Searcy, C. An uncertainty analysis of the energy intensity of 37 materials used in automobile manufacturing: Statistical methods and recommendations. Sustain. Prod. Consum. 2020, 24, 12–25. [Google Scholar] [CrossRef]

- Skrúcaný, T.; Kendra, M.; Stopka, O.; Milojević, S.; Figlus, T.; Csiszár, C. Impact of the Electric Mobility Implementation on the Greenhouse Gases Production in Central European Countries. Sustainability 2019, 11, 4948. [Google Scholar]

- Weidema, B.P.; Frees, N.; Nielsen, A.M. Marginal production technologies for life cycle inventories. Int. J. Life Cycle Assess. 1999, 4, 48–56. [Google Scholar] [CrossRef]

- Tranberg, B.; Corradi, O.; Lajoie, B.; Gibon, T.; Staffell, I.; Andresen, G.B. Real-time carbon accounting method for the European electricity markets. Energy Strategy Rev. 2019, 26, 100367. [Google Scholar] [CrossRef]

- Millard-Ball, A.; Schipper, L. Are We Reaching Peak Travel? Trends in Passenger Transport in Eight Industrialized Countries. Transp. Rev. 2011, 31, 357–378. [Google Scholar] [CrossRef]

- Burkhardt, J.J., III; Heath, G.; Cohen, E. Life cycle greenhouse gas emissions of trough and tower concentrating solar power electricity generation: Systematic review and harmonization. J. Ind. Ecol. 2012, 16, S93–S109. [Google Scholar] [CrossRef]

- Weiss, M.; Haufe, J.; Carus, M.; Brandão, M.; Bringezu, S.; Hermann, B.; Patel, M.K. A review of the environmental impacts of biobased materials. J. Ind. Ecol. 2012, 16, S169–S181. [Google Scholar] [CrossRef]

- Teehan, P.; Kandlikar, M. Sources of variation in life cycle assessments of desktop computers. J. Ind. Ecol. 2012, 16, S182–S194. [Google Scholar] [CrossRef]

- Bousquin, J.; Gambeta, E.; Esterman, M.; Rothenberg, S. Life cycle assessment in the print industry: A Critical Review. J. Ind. Ecol. 2012, 16, S195–S205. [Google Scholar] [CrossRef]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations: Copenhagen, Denmark, 2015. [Google Scholar]

- European Environment Agency. National emissions reported to the UNFCCC and to the EU Greenhouse Gas Monitoring Mechanism. Reykjavik: S.n., 6, 16. 2020. Available online: https://www.eea.europa.eu/data-and-maps/data/national-emissions-reported-to-the-unfccc-and-to-the-eu-greenhouse-gas-monitoring-mechanism-16 (accessed on 16 June 2020).

- Zivin, J.S.G.; Kotchen, M.J.; Mansur, E.T. Spatial and temporal heterogeneity of marginal emissions: Implications for electric cars and other electricity-shifting policies. J. Econ. Behav. Organ. 2014, 107, 248–268. [Google Scholar] [CrossRef] [Green Version]

- Heinonen, J.; Laine, J.; Pluuman, K.; Säynäjoki, E.S.; Soukka, R.; Junnila, S. Planning for a Low Carbon Future? Comparing Heat Pumps and Cogeneration as the Energy System Options for a New Residential Area. Energies 2015, 8, 9137–9154. [Google Scholar] [CrossRef] [Green Version]

- Holden, E.; Banister, D.; Gössling, S.; Gilpin, G.; Linnerud, K. Grand Narratives for sustainable mobility: A conceptual review. Energy Res. Soc. Sci. 2019. [Google Scholar] [CrossRef]

- Creutzig, F.; Roy, J.; Lamb, W.F.; Azevedo, I.M.; De Bruin, W.B.; Dalkmann, H.; Edelenbosch, O.Y.; Geels, F.W.; Grubler, A.; Hepburn, C.; et al. Towards demand-side solutions for mitigating climate change. Nat. Clim. Chang. 2018, 8, 260. [Google Scholar] [CrossRef] [Green Version]

- García-Olivares, A.; Solé, J.; Osychenko, O. Transportation in a 100% renewable energy system. Energy Convers. Manag. 2018, 158, 266–285. [Google Scholar] [CrossRef]

- García-Olivares, A. Substitutability of Electricity and Renewable Materials for Fossil Fuels in a Post-Carbon Economy. Energies 2015, 8, 13308–13343. [Google Scholar] [CrossRef] [Green Version]

- Polish Ministry of Energy. Electromobility Development Plan in Poland: Energy for the Future. Polish Ministry of Energy, 2016. Available online: https://www.gov.pl/web/klimat/elektromobilnosc (accessed on 16 June 2020).

- Keskkonnaministri Määruse. Täiselektriliste Sõidukite Ostutoetuse Andmise Tingimused ja Kord. 2020. Available online: https://www.riigiteataja.ee/akt/113122019018 (accessed on 30 October 2020).

- Polish Ministry of Energy. National Energy and Climate Plan for the Years 2021–2030; Polish Ministry of Energy: Warsaw, Poland, 2019.

- Ministerstwo Klimatu. Program “Zielony Samochód”. Ministerstwo Klimatu, 2020. Available online: https://www.gov.pl/web/klimat/program-zielony-samochod (accessed on 16 June 2020).

- European Alternative Fuels Observatory. Finland—Incentives and Legislation. European Alternative Fuels Observatory. 2020. Available online: https://www.eafo.eu/countries/finland/1732/incentives (accessed on 16 June 2020).

- Ministry of Economic Affairs and Employment. Finland’s Integrated Energy and Climate Plan; Ministry of Economic Affairs and Employment: Helsinki, Finland, 2019.

- European Alternative Fuels Observatory. Malta—Incentives and Legislation. European Alternative Fuels Observatory. 2020. Available online: https://www.eafo.eu/countries/malta/1744/incentives (accessed on 16 June 2020).

| Methodological Characteristics | Contextual/Vehicle Characteristics | Results |

|---|---|---|

| Included life-cycle processes | Electricity mix | Battery production |

| Life-cycle assessment (LCA) type (process, hybrid, or input–output (IO)) | Country of study | Vehicle production |

| Background database | Vehicle make/model | Total production |

| Other data sources | Powertrain (ICEV, BEV, PHEV) | Well-to-Tank |

| Vehicle weight | Tank-to-Wheels | |

| Fuel efficiency (l/100 km and kWh/100 km) | Well-to-Wheels | |

| Battery capacity | End of life | |

| Vehicle lifetime | Maintenance (including battery replacement) | |

| Vehicle classification (LDV, SUV, etc.) | Total life-cycle emissions |

| Study & Year | LCA Method | Materials | Manuf-Acturing | Shipping | Use Phase | Mainte-Nance | Battery Replacement | EOL | Lifetime (km) |

|---|---|---|---|---|---|---|---|---|---|

| Gao et al. (2012) [17] | Process | x | x | x | x | x | x | 256,000 | |

| Ma et al. (2012) [18] | Process | x | x | x | x | x | x | 180,000 | |

| Szczechowicz et al. (2012) [19] | Process | x | x | x | x | x | 150,000 | ||

| Bartolozzi et al. (2013) [20] | Process | x | x | x | x | x | x | LT not disclosed | |

| Hawkins et al. (2013) [16] | Process | x | x | x | x | x | x | 150,000 | |

| Sharma et al. (2013) [21] | Process | x | x | x | x | 150,000 | |||

| Chatzikomis et al. (2014) [22] | Process | x | x | x | 150,000 | ||||

| Messagie et al. (2014) [23] | Process | x | x | x | x | x | x | 230,500 | |

| Bauer et al. (2015) [24] | Process | x | x | x | x | x | x | Vehicle: 240,000 Battery: 150,000 | |

| Girardi et al. (2015) [25] | Process | x | x | x | x | x | 150,000 | ||

| Onat et al. (2015) [26] | Hybrid | x | x | x | x | 240,000 | |||

| Tagliaferri at al. (2016) [27] | Process | x | x | x | x | 150,000 | |||

| Burchart-Korol et al. (2018) [28] | Process | x | x | x | x | x | x | 150,000 | |

| Gawron et al. (2018) [29] | Process | x | x | x | x | 257,495 | |||

| Wu et al. (2018) [30] | Process | x | x | x | x | 150,000 | |||

| Bekel et al. (2019) [31] | Process | x | x | x | x | x | 150,000 | ||

| Kawamoto et al. (2019) [13] | Process | x | x | x | x | x | x | 200,000 | |

| Li et al. (2019) [32] | Hybrid | x | x | x | x | x | 260,000 | ||

| Xiong et al. (2019) [33] | Process | x | x | x | x | x | x | 160,000; 120,000 |

| Approach | Number of Studies | Studies |

|---|---|---|

| Not discussed and not included | 6 | [20,21,22,29,31,32] |

| Out of scope—identified as a limitation | 1 | [18] |

| Battery life considered longer than or equal to vehicle life | 7 | [16,19,25,26,27,28,30,33] |

| Battery replacement included with unclear methodology | 2 | [17,24] |

| Included with clear methodology—Ratio of battery lifetime versus EV lifetime | 1 | [23] |

| Included with clear methodology—one-time battery replacement | 1 | [13] |

| Approach | Additional Comments | Number of Studies | Studies |

|---|---|---|---|

| Not discussed and not Included | 1 | [22] | |

| Out of scope—identified as a limitation | Limitations often mention lack of precedence due to mass-market EVs not having reached EOL or citing relative impact being less than 2% of total life-cycle emissions in studies that have included EOL. | 3 | [21,26,30] |

| Included with an unclear methodology | Aggregated EOL emissions into other processes, making the environmental impact associated with EOL unclear. Because EOL often includes recycling materials, uncertainty increases because recycling can lead to positive or negative GHG emissions depending on methodology. | 4 | [17,24,28,31] |

| Included with clear methodology—positive environmental impact | Positive environmental impact in terms of reducing GHG emissions due to material recycling. | 2 | [23,27] |

| Included with clear methodology—negative environmental impact |

| 9 |

|

| Approach | Additional Comments | Number of Studies | Studies |

|---|---|---|---|

| Not discussed and not included | 3 | [22,27,29] | |

| Out of scope—identified as limitation | 1 | [19] | |

| Included with an unclear methodology |

| 7 |

|

| Included with clear methodology |

| 8 |

| Database/Data Source | Number of Studies | Studies |

|---|---|---|

| Ecoinvent | 7 | [19,20,24,25,27,28,31] |

| GREET | 5 | [16,17,21,26,29] |

| Collection of published data and/or country-specific databases, Other | 6 | [13,18,22,23,30,32] |

| GaBi | 1 | [33] |

| Production (tCO2 eq.) | Energy Efficiency (EV: kWh/100 km ICEV: L/100 km) | WTW Emissions (gCO2eq/km) | Maintenance (gCO2eq/km) | EOL (tCO2eq) | ||

|---|---|---|---|---|---|---|

| BEV | Mean | 10.8 | 16.7 | 132.2 | 10.1 | 0.2 |

| SD | 2.38 | 3.15 | 107.1 | 5.06 | 1.55 | |

| n | 24 | 23 | 40 | 14 | 13 | |

| Petrol | Mean | 6.6 | 7.6 | 237.1 | 12 | 0.4 |

| SD | 2.01 | 2.12 | 63.64 | 5.55 | 1.05 | |

| n | 18 | 17 | 23 | 12 | 14 | |

| Diesel | Mean | 6.1 | 5.2 | 154.3 | 10.1 | −0.6 |

| SD | 1.25 | 1.03 | 32.7 | 4.82 | 1.06 | |

| n | 6 | 5 | 8 | 4 | 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dillman, K.J.; Árnadóttir, Á.; Heinonen, J.; Czepkiewicz, M.; Davíðsdóttir, B. Review and Meta-Analysis of EVs: Embodied Emissions and Environmental Breakeven. Sustainability 2020, 12, 9390. https://doi.org/10.3390/su12229390

Dillman KJ, Árnadóttir Á, Heinonen J, Czepkiewicz M, Davíðsdóttir B. Review and Meta-Analysis of EVs: Embodied Emissions and Environmental Breakeven. Sustainability. 2020; 12(22):9390. https://doi.org/10.3390/su12229390

Chicago/Turabian StyleDillman, Kevin Joseph, Áróra Árnadóttir, Jukka Heinonen, Michał Czepkiewicz, and Brynhildur Davíðsdóttir. 2020. "Review and Meta-Analysis of EVs: Embodied Emissions and Environmental Breakeven" Sustainability 12, no. 22: 9390. https://doi.org/10.3390/su12229390