Cell-Based Meat and Firms’ Environmental Strategies: New Rationales as per Available Literature

Abstract

1. Introduction

2. Theoretical Framework

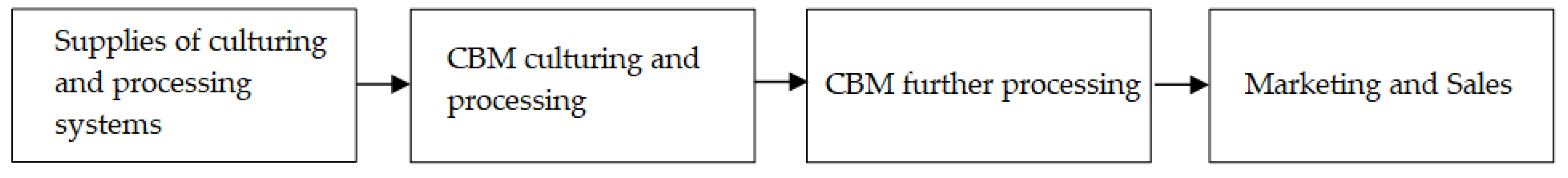

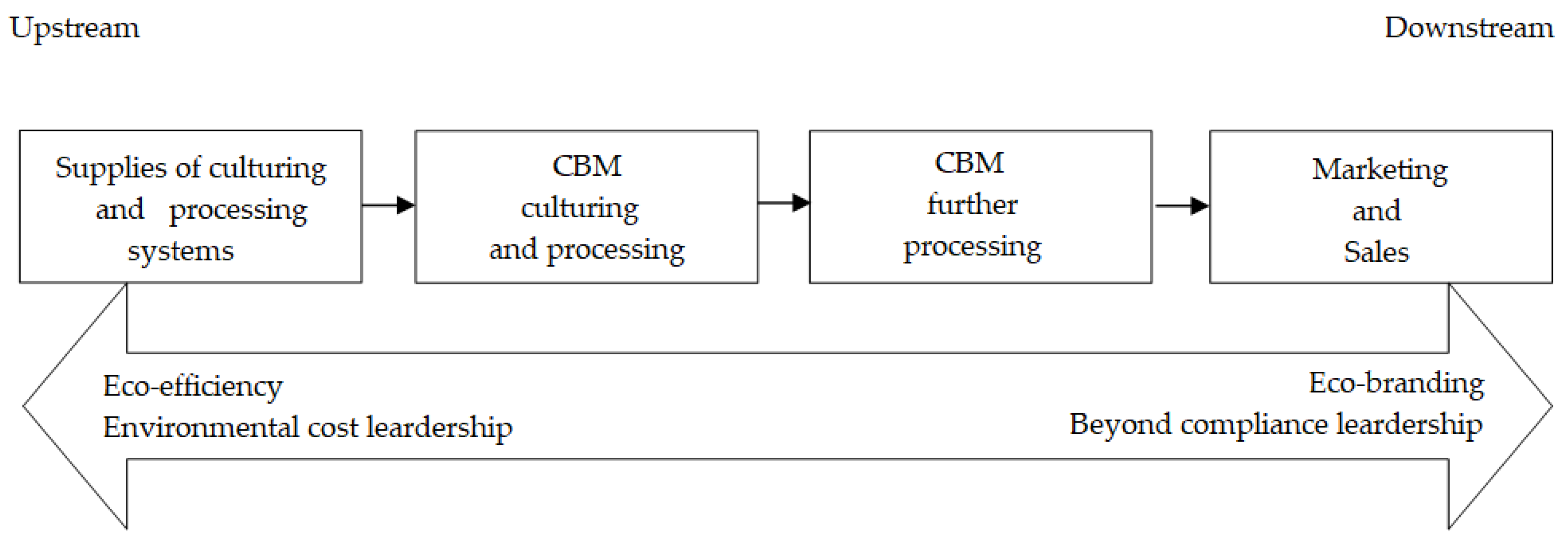

2.1. Competitive Environmental Strategies

2.2. Conventional Meat Chain, Environmental Implications, and the (Cell-Based) Meat of the Future

3. Method

4. Results

4.1. Expected Environmental Improvements

4.2. Cell-Based Meat and Possible Cost Reductions in the Meat Value Chain

4.3. Consumer Acceptance and Differentiation Potential

5. Discussion

Suggestions for Future Research and Contributions

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Vinnari, M.; Tapio, P. Future images of meat consumption in 2030. Futures 2009, 41, 269–278. [Google Scholar] [CrossRef]

- Godfray, H.C.J.; Aveyard, P.; Garnett, T.; Hall, J.W.; Key, T.J.; Lorimer, J.; Pierrehumbert, R.T.; Scarborough, P.; Springmann, M.; Jebb, S.A. Meat consumption, health, and the environment. Science 2018, 361, eaam5324. [Google Scholar] [CrossRef] [PubMed]

- Food and Agriculture Organization Corporate Statistical Database (FAOSTAT). New Food Balances. Available online: http://www.fao.org/faostat/en/#data/FBS (accessed on 2 December 2019).

- Godfray, H.C.J.; Springmann, M.; Sexton, A.; Lynch, J.; Hepburn, C.; Jebb, S. Meat: The Future Series Alternative Proteins; World Economic Forum: Cologny, Switzerland, 2019; Available online: http://www3.weforum.org/docs/WEF_White_Paper_Alternative_Proteins.pdf (accessed on 5 April 2019).

- Gerber, P.J.; Steinfeld, H.; Henderson, B.; Mottet, A.; Opio, C.; Dijkman, J.; Falcucci, A.; Tempio, G. Tackling Climate Change through Livestock; A Global Assessment of Emissions and Mitigation Opportunities; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2013; Available online: http://www.fao.org/3/a-i3437e.pdf (accessed on 2 January 2020).

- Kappenthuler, S.; Seeger, S. Addressing global environmental megatrends by decoupling the causal chain through floating infrastructure. Futures 2019, 113, 102420. [Google Scholar] [CrossRef]

- Reis, G.G.; Heidemann, M.S.; Borini, F.M.; Molento, C.F.M. Livestock value chain in transition: Cultivated (cell-based) meat and the need for breakthrough capabilities. Technol. Soc. 2020, 62, 101286. [Google Scholar] [CrossRef]

- Stephens, N.; di Silvio, L.; Dunsford, I.; Ellis, M.; Glencross, A.; Sexton, A. Bringing cultured meat to market: Technical, socio-political, and regulatory challenges in cellular agriculture. Trends Food Sci. Technol. 2018, 78, 155–166. [Google Scholar] [CrossRef] [PubMed]

- Froggatt, A.; Wellesley, L. Meat Analogues; Considerations for the, EU; Research, Paper; Energy, Environment and Resources Department; The Royal Institute of International Affairs Chatham House: London, UK, 2019; Available online: https://www.chathamhouse.org/2019/02/meat-analogues (accessed on 11 March 2019).

- Good Food Institute. Company Database. 2020. Available online: https://docs.google.com/spreadsheets/d/1JUMBfHa2E4MgX7EVt5SVrSTqP2JKKwZVELYIf8wMmI0/edit?usp=sharing (accessed on 26 October 2020).

- World Economic Forum. Technology Pioneers. 2020. Available online: https://widgets.weforum.org/techpioneers-2020/ (accessed on 16 June 2020).

- Bonny, S.P.; Gardner, G.E.; Pethick, D.W.; Hocquette, J.-F. What is artificial meat and what does it mean for the future of the meat industry? J. Integr. Agric. 2015, 14, 255–263. [Google Scholar] [CrossRef]

- Specht, E.A.; Welch, D.R.; Clayton, E.M.R.; Lagally, C.D. Opportunities for applying biomedical production and manufacturing methods to the development of the clean meat industry. Biochem. Eng. J. 2018, 132, 161–168. [Google Scholar] [CrossRef]

- Tuomisto, H.L.; de Mattos, M.J.T. Environmental Impacts of Cultured Meat Production. Environ. Sci. Technol. 2011, 45, 6117–6123. [Google Scholar] [CrossRef]

- Heidemann, M.S.; Molento, C.F.M.; Reis, G.G.; Phillips, C.J.C. Uncoupling Meat From Animal Slaughter and its Impacts on Human-Animal Relationships. Front. Psychol. 2020, 11, 1824. [Google Scholar] [CrossRef]

- Cabane, O.F. The New Protein Landscape Version 2.6. 2019. Available online: https://brandfirstnj.com/wp-content/uploads/2018/08/52197-New-Proteins-Map-1d.pdf (accessed on 2 February 2019).

- Caiado, R.G.G.; Dias, R.D.F.; Mattos, L.V.; Quelhas, O.L.G.; Filho, W.L. Towards sustainable development through the perspective of eco-efficiency—A systematic literature review. J. Clean. Prod. 2017, 165, 890–904. [Google Scholar] [CrossRef]

- Orsato, R.J. Competitive environmental strategies: When does it pay to be green? Calif. Manag. Rev. 2006, 48, 127–143. [Google Scholar] [CrossRef]

- Orsato, R.J. Sustainability Strategies; When does it pay to be green; Palgrave Mcmillan: Basingstoke, UK, 2009. [Google Scholar]

- De Marchi, V.; di Maria, E.; Micelli, S. Environmental Strategies, Upgrading and Competitive Advantage in Global Value Chains. Bus. Strat. Environ. 2012, 22, 62–72. [Google Scholar] [CrossRef]

- Dahlin, K.B.; Behrens, D.M. When is an invention really radical? Res. Policy 2005, 34, 717–737. [Google Scholar] [CrossRef]

- Toldrá, F.; Reig, M. Innovations for healthier processed meats. Trends Food Sci. Technol. 2011, 22, 517–522. [Google Scholar] [CrossRef]

- Ash, A.; Hunt, L.; McDonald, C.; Scanlan, J.; Bell, L.W.; Cowley, R.; Watson, I.; McIvor, J.; MacLeod, N. Boosting the productivity and profitability of northern Australian beef enterprises: Exploring innovation options using simulation modelling and systems analysis. Agric. Syst. 2015, 139, 50–65. [Google Scholar] [CrossRef]

- Bourreau, M.; Gensollen, M.; Moreau, F. The Impact of a Radical Innovation on Business Models: Incremental Adjustments or Big Bang? Ind. Innov. 2012, 19, 415–435. [Google Scholar] [CrossRef]

- Buysse, K.; Verbeke, A. Proactive environmental strategies: A stakeholder management perspective. Strat. Manag. J. 2003, 24, 453–470. [Google Scholar] [CrossRef]

- Yang, D.; Wang, A.X.; Zhou, K.Z.; Jiang, W. Environmental Strategy, Institutional Force, and Innovation Capability: A Managerial Cognition Perspective. J. Bus. Ethics 2018, 159, 1147–1161. [Google Scholar] [CrossRef]

- Post, M.J. Cultured meat from stem cells: Challenges and prospects. Meat Sci. 2012, 92, 297–301. [Google Scholar] [CrossRef]

- Porter, M. Techniques for Analyzing Industries and Competitors; The Free Press: New York, NY, USA, 1980. [Google Scholar]

- Huppes, G.; Ishikawa, M.A. Framework for Quantified Eco-efficiency Analysis. J. Ind. Ecol. 2005, 9, 25–41. [Google Scholar] [CrossRef]

- Lowe, M.; Gereffi, G. A Value Chain Analysis of the U.S. Beef and Dairy Industries; Report Prepared for Environmental Defense Fund; Duke University: Durham, NC, USA, 2009; p. 55. Available online: https://gvcc.duke.edu/wp-content/uploads/CGGC_BeefDairyReport_2-16-09.pdf (accessed on 16 June 2020). [CrossRef]

- Steinfeld, H.; Gerber, P.; Wassenaar, T.D.; Castel, V.; Rosales, M.; Rosales, M.; de Haan, C. Livestock’s Long Shadow; Environmental Issues and Options; FAO: Rome, Italy, 2006. [Google Scholar]

- Ben-Arye, T.; Levenberg, S. Tissue Engineering for Clean Meat Production. Front. Sustain. Food Syst. 2019, 3. [Google Scholar] [CrossRef]

- Grandin, T. Animal welfare and society concerns finding the missing link. Meat Sci. 2014, 98, 461–469. [Google Scholar] [CrossRef] [PubMed]

- Heikkurinen, P.; Forsman-Hugg, S. Strategic Corporate Responsibility in the Food Chain. Corp. Soc. Responsib. Environ. Manag. 2011, 18, 306–316. [Google Scholar] [CrossRef]

- Swaffield, S.R.; Corry, R.C.; Opdam, P.; McWilliam, W.; Primdahl, J. Connecting business with the agricultural landscape: Business strategies for sustainable rural development. Bus. Strat. Environ. 2019, 28, 1357–1369. [Google Scholar] [CrossRef]

- Croney, C.C.; Muir, W.; Ni, J.-Q.; Widmar, N.O.; Varner, G. An Overview of Engineering Approaches to Improving Agricultural Animal Welfare. J. Agric. Environ. Ethics 2018, 31, 143–159. [Google Scholar] [CrossRef]

- Cassidy, L. Clean Meat. 2018. Available online: https://www.aocs.org/stay-informed/inform-magazine/featured-articles/clean-meat-february-2018 (accessed on 10 January 2019).

- Weinrich, R. Opportunities for the Adoption of Health-Based Sustainable Dietary Patterns: A Review on Consumer Research of Meat Substitutes. Sustainability 2019, 11, 4028. [Google Scholar] [CrossRef]

- Bryant, C.J.; Barnett, J.C. What’s in a name? Consumer perceptions of in vitro meat under different names. Appetite 2019, 137, 104–113. [Google Scholar] [CrossRef]

- Bhat, Z.F.; Fayaz, H. Prospectus of cultured meat—Advancing meat alternatives. J. Food Sci. Technol. 2011, 48, 125–140. [Google Scholar] [CrossRef]

- Bhat, Z.F.; Kumar, S.; Fayaz, H. In vitro meat production: Challenges and benefits over conventional meat production. J. Integr. Agric. 2015, 14, 241–248. [Google Scholar] [CrossRef]

- Datar, I.; Betti, M. Possibilities for an in vitro meat production system. Innov. Food Sci. Emerg. Technol. 2010, 11, 13–22. [Google Scholar] [CrossRef]

- Post, M.J. An alternative animal protein source: Cultured beef. Ann. N. Y. Acad. Sci. 2014, 1328, 29–33. [Google Scholar] [CrossRef]

- Rubio, N.; Datar, I.; Stachura, D.; Kaplan, D.; Krueger, K. Cell-Based Fish: A Novel Approach to Seafood Production and an Opportunity for Cellular Agriculture. Front. Sustain. Food Syst. 2019, 3. [Google Scholar] [CrossRef]

- Stephens, N.; King, E.; Lyall, C. Blood, meat, and upscaling tissue engineering: Promises, anticipated markets, and performativity in the biomedical and agri-food sectors. BioSocieties 2018, 13, 368–388. [Google Scholar] [CrossRef]

- Van der Weele, C.; Tramper, J. Cultured meat: Every village its own factory? Trends Biotechnol. 2014, 32, 294–296. [Google Scholar] [CrossRef]

- Van Vuuren, D.P.; Stehfest, E.; Gernaat, D.E.H.J.; Berg, M.V.D.; Bijl, D.L.; de Boer, H.S.; Daioglou, V.; Doelman, J.C.; Edelenbosch, O.Y.; Harmsen, M.; et al. Alternative pathways to the 1.5 °C target reduce the need for negative emission technologies. Nat. Clim. Chang. 2018, 8, 391–397. [Google Scholar] [CrossRef]

- Mattick, C.S.; Landis, A.E.; Allenby, B.R.; Genovese, N.J. Anticipatory Life Cycle Analysis of In Vitro Biomass Cultivation for Cultured Meat Production in the United States. Environ. Sci. Technol. 2015, 49, 11941–11949. [Google Scholar] [CrossRef] [PubMed]

- Alexander, P.; Brown, C.; Arneth, A.; Dias, C.; Finnigan, J.; Moran, D.; Rounsevell, M.D. Could consumption of insects, cultured meat or imitation meat reduce global agricultural land use? Glob. Food Secur. 2017, 15, 22–32. [Google Scholar] [CrossRef]

- Sun, Z.C.; Yu, Q.L.; Han, L. The environmental prospects of cultured meat in China. J. Integr. Agric. 2015, 14, 234–240. [Google Scholar] [CrossRef]

- Lynch, J.; Pierrehumbert, R. Climate Impacts of Cultured Meat and Beef Cattle. Front. Sustain. Food Syst. 2019, 3, 1–11. [Google Scholar] [CrossRef]

- Smetana, S.; Mathys, A.; Knoch, A.; Heinz, V. Meat alternatives: Life cycle assessment of most known meat substitutes. Int. J. Life Cycle Assess. 2015, 20, 1254–1267. [Google Scholar] [CrossRef]

- Bhat, Z.F.; Kumar, S.; Bhat, H.F. In vitro meat: A future animal-free harvest. Crit. Rev. Food Sci. Nutr. 2015, 57, 782–789. [Google Scholar] [CrossRef] [PubMed]

- Kadim, I.T.; Mahgoub, O.; Baqir, S.; Faye, B.; Purchas, R. Cultured meat from muscle stem cells: A review of challenges and prospects. J. Integr. Agric. 2015, 14, 222–233. [Google Scholar] [CrossRef]

- FAO. Sustainability Assessment of Food and Agriculture Systems; Guidelines v. 3.0.; FAO: Rome, Italy, 2014; Available online: http://www.fao.org/3/a-i3957e.pdf (accessed on 23 November 2019).

- Sergelidis, D. Lab Grown Meat: The Future Sustainable Alternative to Meat or a Novel Functional Food? Biomed. J. Sci. Tech. Res. 2019, 17, 12440–12444. [Google Scholar] [CrossRef]

- Langelaan, M.L.; Boonen, K.J.; Polak, R.B.; Baaijens, F.P.; Post, M.J.; van der Schaft, D.W. Meet the new meat: Tissue engineered skeletal muscle. Trends Food Sci. Technol. 2010, 21, 59–66. [Google Scholar] [CrossRef]

- Specht, L. Medium Costs and Production Volumes for Cell-Based Meat. 2019. Available online: https://www.gfi.org/files/sci-tech/clean-meat-production-volume-and-medium-cost.pdf (accessed on 3 March 2020).

- Laestadius, L.I.; Caldwell, M.A. Is the future of meat palatable? Perceptions of in vitro meat as evidenced by online news comments. Public Health Nutr. 2015, 18, 2457–2467. [Google Scholar] [CrossRef]

- Pandurangan, M.; Kim, D.H. A novel approach for in vitro meat production. Appl. Microbiol. Biotechnol. 2015, 99, 5391–5395. [Google Scholar] [CrossRef]

- Allan, S.J.; de Bank, P.A.; Ellis, M.J. Bioprocess Design Considerations for Cultured Meat Production with a Focus on the Expansion Bioreactor. Front. Sustain. Food Syst. 2019, 3, 5391–5395. [Google Scholar] [CrossRef]

- Li, X.; Zhang, G.; Zhao, X.; Zhou, J.; Du, G.; Chen, J. A conceptual air-lift reactor design for large scale animal cell cultivation in the context of in vitro meat production. Chem. Eng. Sci. 2020, 211, 115269. [Google Scholar] [CrossRef]

- Post, M. Cultivated Meat Webinar with Prof. Mark Post; The Good Food Institute Israel. 2020. Available online: https://www.youtube.com/watch?v=R8P_5REK5Do&feature=youtu.be&t=2533 (accessed on 29 October 2020).

- Aleph Farms. Nature & Design. 2020. Available online: https://aleph-farms.com/nature-design/ (accessed on 28 October 2020).

- Zhang, G.; Zhao, X.; Li, X.; Du, G.; Zhou, J.; Chen, J. Challenges and possibilities for bio-manufacturing cultured meat. Trends Food Sci. Technol. 2020, 97, 443–450. [Google Scholar] [CrossRef]

- Bryant, C.; Barnett, J. Consumer acceptance of cultured meat: A systematic review. Meat Sci. 2018, 143, 8–17. [Google Scholar] [CrossRef]

- Hartmann, C.; Siegrist, M. Consumer perception and behaviour regarding sustainable protein consumption: A systematic review. Trends Food Sci. Technol. 2017, 61, 11–25. [Google Scholar] [CrossRef]

- O’Keefe, L.; McLachlan, C.; Gough, C.; Mander, S.; Bows-Larkin, A. Consumer Responses to a Future UK Food System. Br. Food J. 2016, 118, 412–428. [Google Scholar] [CrossRef]

- Wilks, M.; Phillips, C.J.C. Attitudes to in vitro meat: A survey of potential consumers in the United States. PLoS ONE 2017, 12, e0171904. [Google Scholar] [CrossRef] [PubMed]

- Valente, J.D.P.S.; Fiedler, R.A.; Heidemann, M.S.; Molento, C.F.M. First glimpse on attitudes of highly educated consumers towards cell-based meat and related issues in Brazil. PLoS ONE 2019, 14, e0221129. [Google Scholar] [CrossRef] [PubMed]

- Mancini, M.C.; Antonioli, F. Exploring consumers’ attitude towards cultured meat in Italy. Meat Sci. 2019, 150, 101–110. [Google Scholar] [CrossRef]

- Verbeke, W.; Sans, P.; van Loo, E.J. Challenges and prospects for consumer acceptance of cultured meat. J. Integr. Agric. 2015, 14, 285–294. [Google Scholar] [CrossRef]

- Weinrich, R.; Strack, M.; Neugebauer, F. Consumer acceptance of cultured meat in Germany. Meat Sci. 2020, 162, 107924. [Google Scholar] [CrossRef]

- Hocquette, A.; Lambert, C.; Sinquin, C.; Peterolff, L.; Wagner, Z.; Bonny, S.P.F.; Lebert, A.; Hocquette, J.F. Educated consumers don’t believe artificial meat is the solution to the problems with the meat industry. J. Integr. Agric. 2015, 14, 273–284. [Google Scholar] [CrossRef]

- Slade, P. If you build it, will they eat it? Consumer preferences for plant-based and cultured meat burgers. Appetite 2018, 125, 428–437. [Google Scholar] [CrossRef]

- Verbeke, W.; Marcu, A.; Rutsaert, P.; Gaspar, R.; Seibt, B.; Fletcher, D.; Barnett, J. ‘Would you eat cultured meat?’: Consumers’ reactions and attitude formation in Belgium, Portugal and the United Kingdom. Meat Sci. 2015, 102, 49–58. [Google Scholar] [CrossRef]

- Marcu, A.; Gaspar, R.; Rutsaert, P.; Seibt, B.; Fletcher, D.; Verbeke, W.; Barnett, J. Analogies, metaphors, and wondering about the future: Lay sense-making around synthetic meat. Public Underst. Sci. 2014, 24, 547–562. [Google Scholar] [CrossRef] [PubMed]

- Bekker, G.A.; Fischer, A.R.; Tobi, H.; van Trijp, H.C. Explicit and implicit attitude toward an emerging food technology: The case of cultured meat. Appetite 2017, 108, 245–254. [Google Scholar] [CrossRef] [PubMed]

- Bryant, C.; Dillard, C. The Impact of Framing on Acceptance of Cultured Meat. Front. Nutr. 2019, 6, 103. [Google Scholar] [CrossRef] [PubMed]

- Siegrist, M.; Hartmann, C. Perceived naturalness, disgust, trust and food neophobia as predictors of cultured meat acceptance in ten countries. Appetite 2020, 155, 104814. [Google Scholar] [CrossRef]

- Gómez-Luciano, C.A.; de Aguiar, L.K.; Vriesekoop, F.; Urbano, B. Consumers’ willingness to purchase three alternatives to meat proteins in the United Kingdom, Spain, Brazil and the Dominican Republic. Food Qual. Prefer. 2019, 78, 103732. [Google Scholar] [CrossRef]

- Mouat, M.J.; Prince, R.; Roche, M. Making Value Out of Ethics: The Emerging Economic Geography of Lab-grown Meat and Other Animal-free Food Products. Econ. Geogr. 2018, 95, 136–158. [Google Scholar] [CrossRef]

- Tubb, C.; Seba, T. Rethinking Food and Agriculture 2020–2030: The Second Domestication of the Cow, and the Collapse of Industrial Livestock Farming. 2019. Available online: https://www.rethinkx.com/food-and-agriculture (accessed on 21 December 2019).

- De Chiara, A. Eco-labeled Products: Trend or Tools for Sustainability Strategies? J. Bus. Ethics 2015, 137, 161–172. [Google Scholar] [CrossRef]

- Orzechowski, A. Artificial meat? Feasible approach based on the experience from cell culture studies. J. Integr. Agric. 2015, 14, 217–221. [Google Scholar] [CrossRef]

- Bryant, C.; Szejda, K.; Parekh, N.; Deshpande, V.; Tse, B. A Survey of Consumer Perceptions of Plant-Based and Clean Meat in the USA, India, and China. Front. Sustain. Food Syst. 2019, 3, 217–221. [Google Scholar] [CrossRef]

- Del Giudice, T.; Stranieri, S.; Caracciolo, F.; Ricci, E.C.; Cembalo, L.; Banterle, A.; Cicia, G. Corporate Social Responsibility certifications influence consumer preferences and seafood market price. J. Clean. Prod. 2018, 178, 526–533. [Google Scholar] [CrossRef]

- Weinrich, R. Cross-Cultural Comparison between German, French and Dutch Consumer Preferences for Meat Substitutes. Sustainability 2018, 10, 1819. [Google Scholar] [CrossRef]

- D’Souza, C.; Taghian, M.; Brouwer, A.R. Ecolabels information and consumer self-confidence in decision making: A strategic imperative. J. Strat. Mark. 2019, 1–17. [Google Scholar] [CrossRef]

- Lopes, E.L.; Veiga, R.T. Increasing purchasing intention of eco-efficient products: The role of the advertising communication strategy and the branding strategy. J. Brand Manag. 2019, 26, 550–566. [Google Scholar] [CrossRef]

- Gereffi, G.; Humphrey, J.; Sturgeon, T. The governance of global value chains. Rev. Int. Political Econ. 2005, 12, 78–104. [Google Scholar] [CrossRef]

- Poulsen, R.T.; Ponte, S.; Lister, J. Buyer-driven greening? Cargo-owners and environmental upgrading in maritime shipping. Geoforum 2016, 68, 57–68. [Google Scholar] [CrossRef]

- Aleph Farms. Sustainability. 2020. Available online: https://aleph-farms.com/sustainability/ (accessed on 28 October 2020).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reis, G.G.; Heidemann, M.S.; Matos, K.H.O.d.; Molento, C.F.M. Cell-Based Meat and Firms’ Environmental Strategies: New Rationales as per Available Literature. Sustainability 2020, 12, 9418. https://doi.org/10.3390/su12229418

Reis GG, Heidemann MS, Matos KHOd, Molento CFM. Cell-Based Meat and Firms’ Environmental Strategies: New Rationales as per Available Literature. Sustainability. 2020; 12(22):9418. https://doi.org/10.3390/su12229418

Chicago/Turabian StyleReis, Germano Glufke, Marina Sucha Heidemann, Katherine Helena Oliveira de Matos, and Carla Forte Maiolino Molento. 2020. "Cell-Based Meat and Firms’ Environmental Strategies: New Rationales as per Available Literature" Sustainability 12, no. 22: 9418. https://doi.org/10.3390/su12229418

APA StyleReis, G. G., Heidemann, M. S., Matos, K. H. O. d., & Molento, C. F. M. (2020). Cell-Based Meat and Firms’ Environmental Strategies: New Rationales as per Available Literature. Sustainability, 12(22), 9418. https://doi.org/10.3390/su12229418