Using Multi-Criteria Decision Analysis to Select Waste to Energy Technology for a Mega City: The Case of Moscow

Abstract

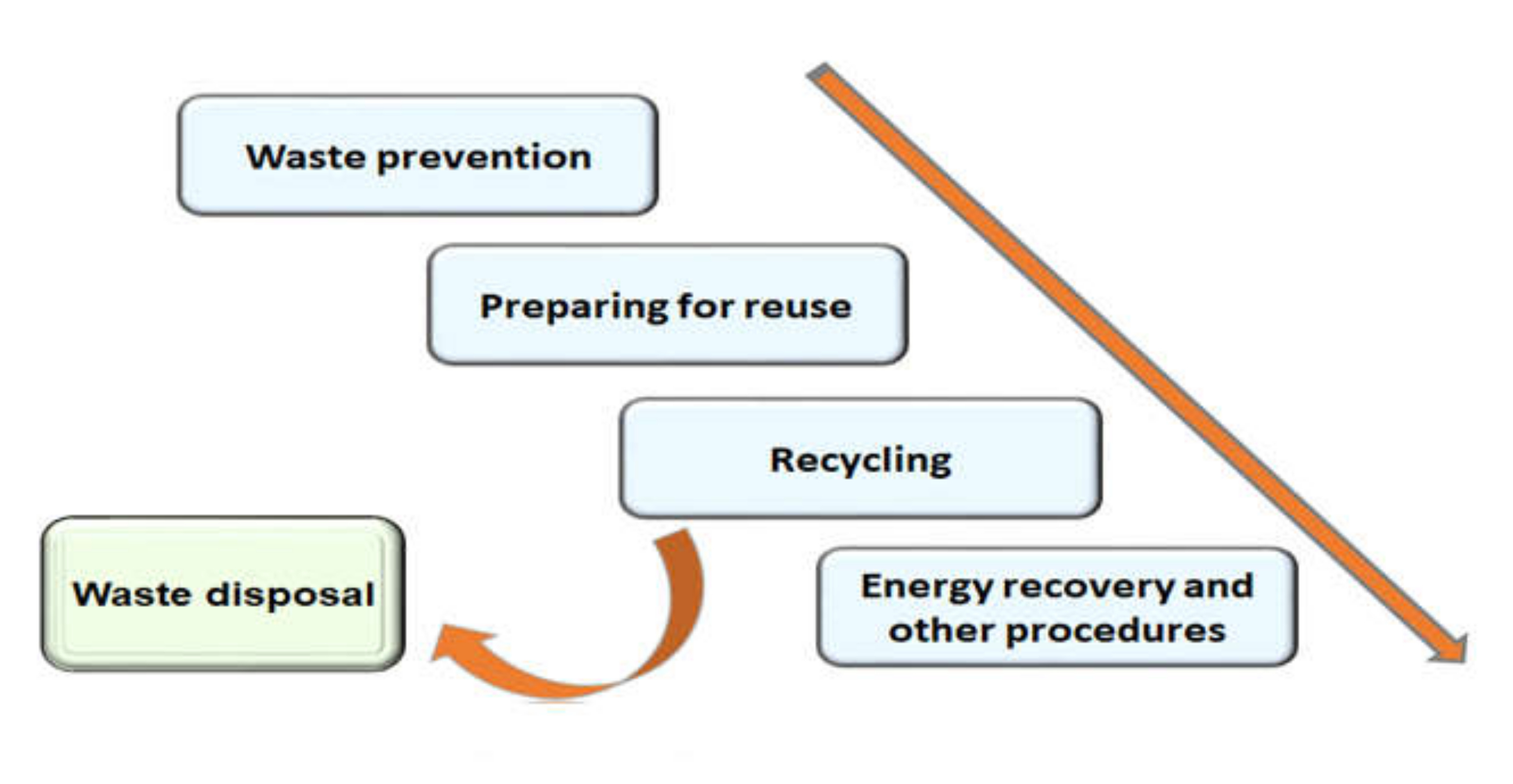

:1. Introduction

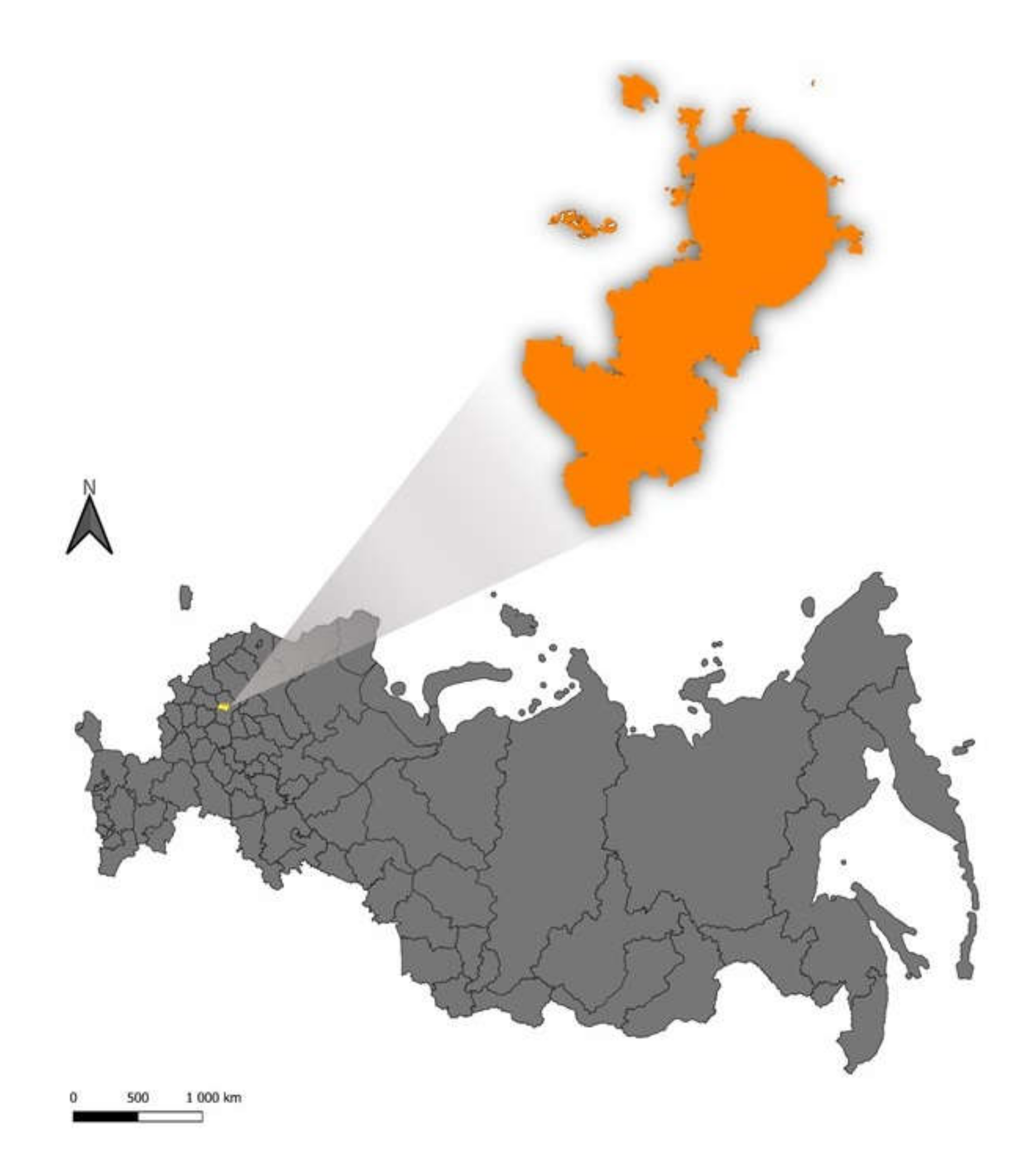

1.1. Study Area

1.2. Solid Waste Management in Moscow

1.3. Energy System and Waste to Energy in Moscow

2. Methodology

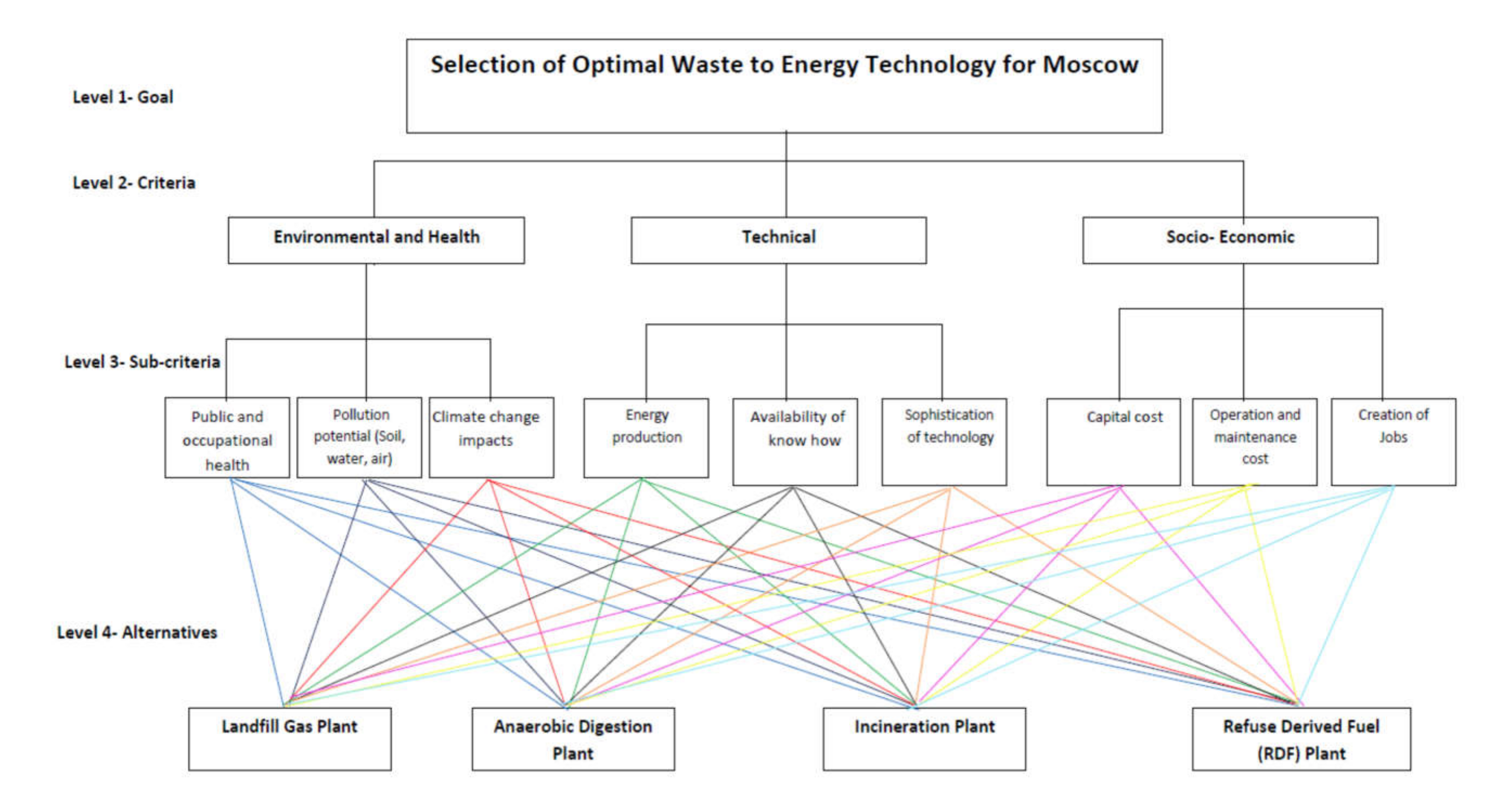

2.1. Identification of the Goal and Criteria

2.2. AHP Model Construction

2.3. Pairwise Comparison by Solicitation of Experts Opinions

2.4. Priorities Assessment

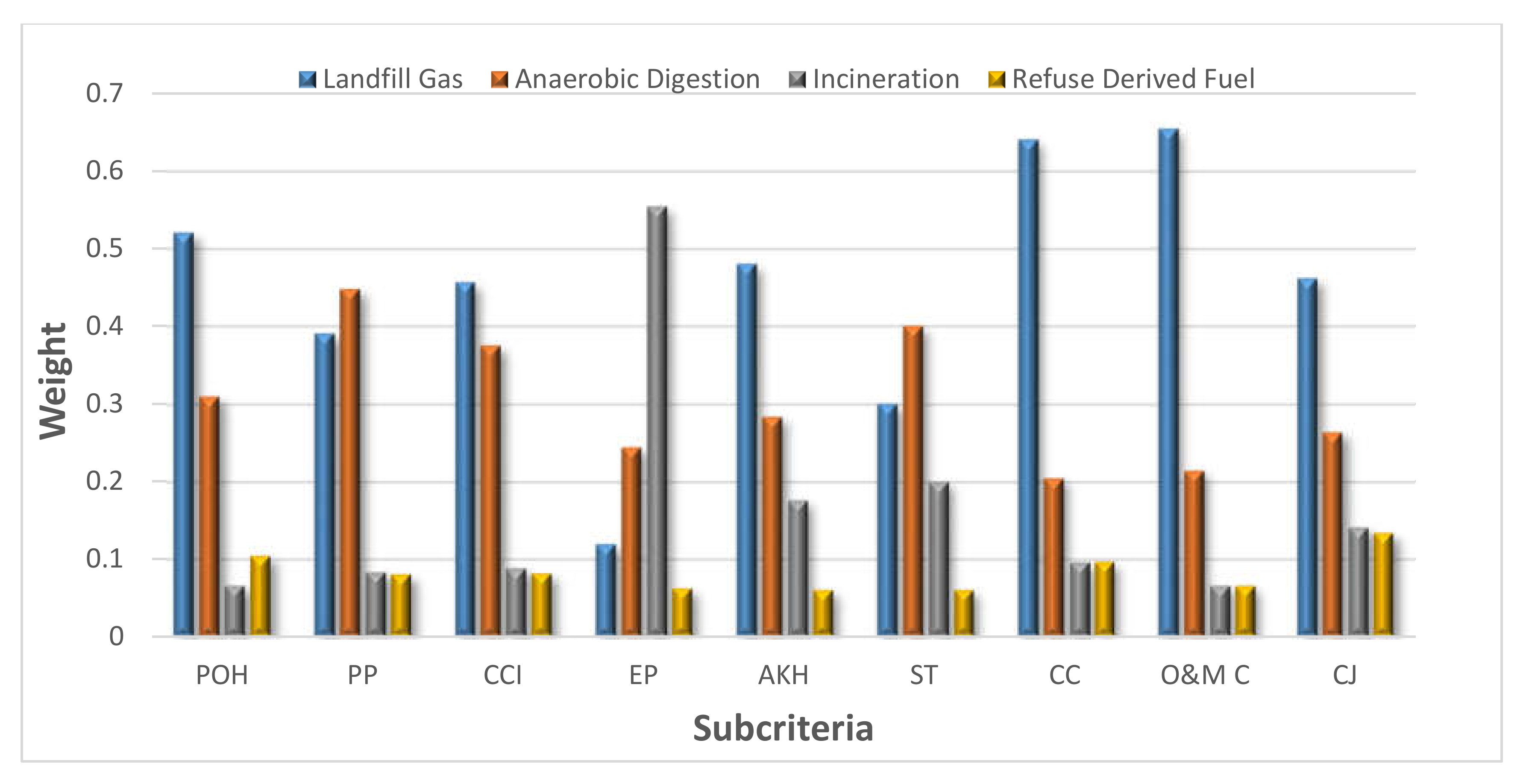

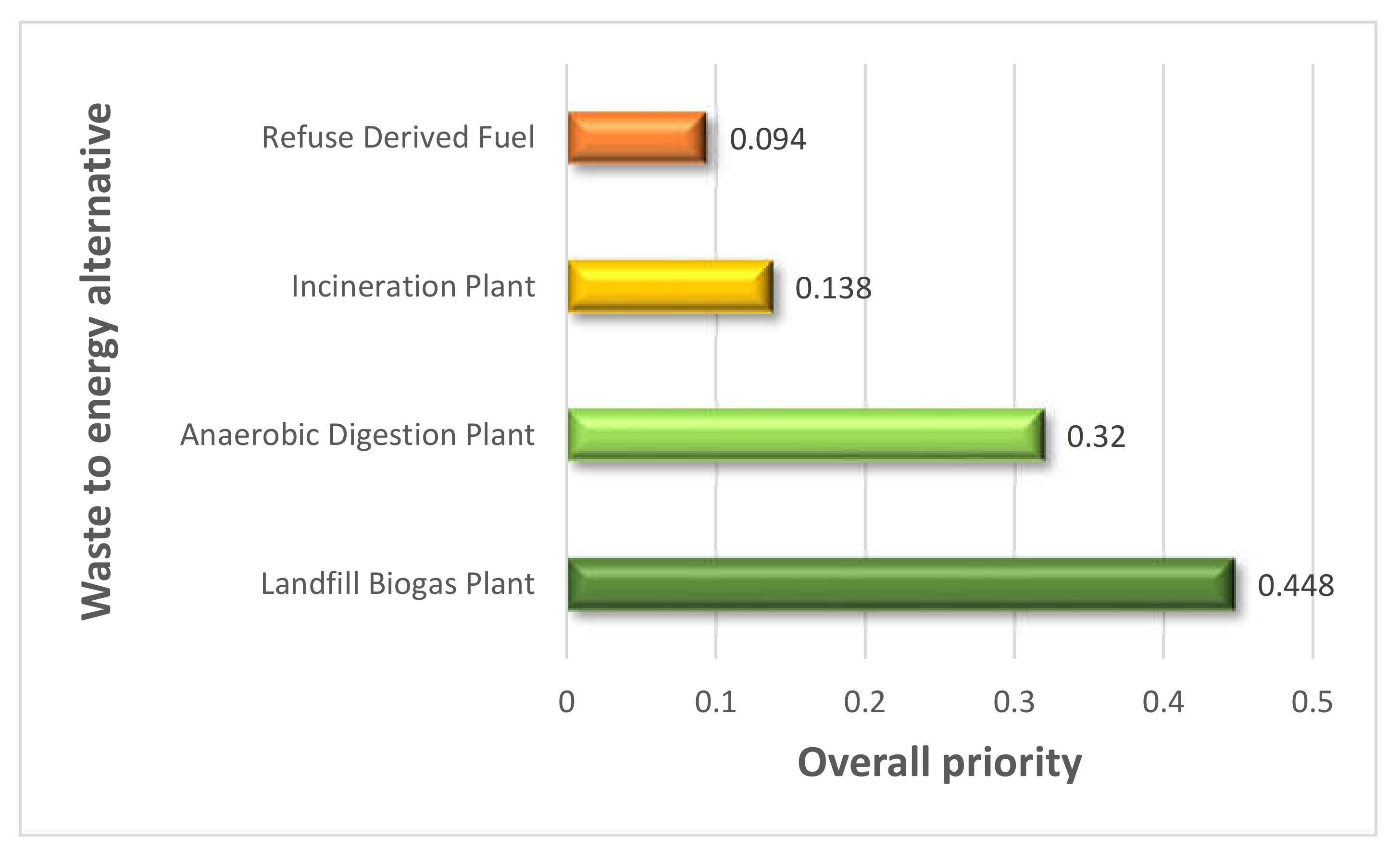

3. Results and Discussion

3.1. Application of AHP

3.2. Sensitivity Analysis

- All criteria have an equal weight of 33.3%

- One criteria having 100% weight while the other two having weights of 0%.

4. Conclusions and Recommendations

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kaza, S.; Yao, L.; Perinaz Bhada-Tata, P.B.; Van Woerden, F. What a Waste 2.0, A Global Snapshot of Solid Waste Management to 2050; World Bank: Washington, DC, USA, 2018; Available online: https://openknowledge.worldbank.org/handle/10986/30317 (accessed on 10 November 2020).

- Abu Qdais, H.A. Techno Economic Analysis of Municipal Solid Waste Management in Jordan. Waste Manag. 2007, 27, 1666–1672. [Google Scholar] [CrossRef] [PubMed]

- Jeevahan, J.; Anderson, A.; Sriram, V.; Durairaj, R.B.; Britto, G.; Mageshwaran, G. Waste to energy conversion technologies and conversion of food waste into potential products: A review. Int. J. Ambient Energy 2018. [Google Scholar] [CrossRef]

- Abu Ashoor, J.; Abu Qdais, H.A.; Al Widyan, M. Estimation of Animal and Olive Solid Wastes in Jordan and Their Potential as A Supplementary Energy Source: An Overview. Renew. Sustain. Energy Rev. 2010, 14, 2227–2231. [Google Scholar] [CrossRef]

- Tulokhanova, A.; Ulanova, O. Assessment of municipal solid waste management scenarios in Irkutsk (Russia) using a life cycle assessment-integrated waste management model. Waste Manag. Res. 2013, 31, 475–484. [Google Scholar] [CrossRef] [PubMed]

- International Finance Corporation (IFC). Waste in Russia, Garbage or Resource: Development of Scenarios for Municipal Solid Waste Management; World Bank Group: Moscow, Russia, 2014. [Google Scholar]

- Dzhamalova, R.G.; Medovara, Y.A.; Yushmanova, I.O. Principles of MSW landfill sites’ placement depending on geological and hydrogeological conditions of territories (based on Moscow region). Water Resour. 2019, 46 (Suppl. 2), 51–58. [Google Scholar] [CrossRef]

- Chandel, M.K.; Kwok, G.; Jackson, R.B.; Pratson, L.F. The potential of waste-to-energy in reducing GHG emissions. Carbon Manag. 2012, 3, 133–144. [Google Scholar] [CrossRef] [Green Version]

- Almanaseer, N.; Abbassi, B.; Dunlop, C.; Friesen, K.; Seminiw, E.N. Multi-Criteria Analysis of Waste-to-Energy Technologies in Developed and Developing Countries. J. Environ. Res. Eng. Manag. 2020, 76, 32–43. [Google Scholar] [CrossRef]

- CEWEP. Confederation of the Waste to Energy Plants. 2018. Available online: https://www.cewep.eu/wp-content/uploads/2020/01/CEWEP-Municipal-waste-treatment-2018.pdf (accessed on 20 September 2020).

- Thabit, Q.; Nassour, A.; Nelles, M. Potentiality of Waste-to-Energy Sector Coupling in the MENA Region: Jordan as a Case Study. Energies 2020, 13, 2786. [Google Scholar] [CrossRef]

- Levaggi, L.; Levaggi, R.; Marchiori, C.; Trecroci, C. Waste-to-Energy in the EU: The effects of plant ownership, waste mobility, and decentralization on environmental outcomes and welfare. Sustainability 2020, 12, 5743. [Google Scholar] [CrossRef]

- Pralata, L.B.; Morales, M.V.; Rodrigus RCDe Menna, F.; Vittuari, M. Decision-Making Process in the Circular Economy: A Case Study on University Food Waste-to-Energy. Energies 2020, 13, 2291. [Google Scholar] [CrossRef]

- Drljaca, M. The transition from linear to circular economy (concept of efficient waste management). In Proceedings of the International Conference on Quality for Successful Business and Competitiveness, Vrnjacka Banja, Serbia, 9–11 December 2015; pp. 35–44. [Google Scholar]

- Tugov, A.N. Prospects for the Use of Municipal Solid Wastes as Secondary Energy Resources in Russia. Therm. Eng. 2013, 60, 663–668. [Google Scholar] [CrossRef]

- Bratanova, A.; Robinson, J.; Wagner, L. New technology adoption for Russian energy generation: What does it cost? A case study for Moscow. Appl. Energy 2016, 162, 924–939. [Google Scholar] [CrossRef] [Green Version]

- Shipelov, A. A Russian Revolution in Waste Management. 2019. Available online: https://w2e.ru/upload/medialibrary/07b/Russian_Revolution_waste_management.pdf (accessed on 12 September 2020).

- Proskuryakova, L.N.; Ermolenko, G.V. The future of Russia’s renewable energy sector: Trends, scenarios and policies. Renew. Energy 2019, 143, 1670–1686. [Google Scholar] [CrossRef]

- Rahman, S.M.; Azeem, A.; Ahmmed, F. Selection of an appropriate waste to energy conversion technology for Dhaka City, Bangladesh. Int. J. Sustain. Eng. 2017, 10, 99–104. [Google Scholar] [CrossRef]

- Cristobal San, J.R. Multi-criteria decision-making in the selection of a renewable energy project in spain: The Vikor method. Renew. Energy 2011, 36, 498–502. [Google Scholar] [CrossRef]

- Hwang, C.L.; Yoon, K. Multiple Attribute Decision Making: Methods and Applications a State-of-the-Art Survey; Springer Science and Business Media: Berlin/Heidelberg, Germany, 2012; Volume 186. [Google Scholar]

- Abdullah, L.; Najib, L. Sustainable energy planning decision using the intuitionistic fuzzy analytic hierarchy process: Choosing energy technology in Malaysia. Int. J. Sustain. Energy 2016, 35, 360–377. [Google Scholar] [CrossRef]

- Algarin, C.R.; Llanos, A.P.; Castro, A.O. An Analytic Hierarchy Process Based Approach for Evaluating Renewable Energy Sources. Int. J. Energy Econ. Policy 2017, 7, 38–47. [Google Scholar]

- Khoshand, A.; Kamalan, H.; Rezaeli, H. Application of analytical hierarchy process (AHP) to assess options of energy recovery from municipal solid waste: A case study in Tehran, Iran. J. Mater. Cycles Waste Manag. 2018, 20, 1689–1700. [Google Scholar] [CrossRef]

- ROSSTAT. Russian Federal State Statistics Service. 2020. Available online: https://rosstat.gov.ru/ (accessed on 10 October 2020).

- Moscow City Environmental Profile. Available online: http://leadnet.ru/mep/english/chapter1.htm (accessed on 14 September 2020).

- State of the Environment Report (2017) State Reports Concerning the State and Protection of the Environment of the Russian Federation in 2017. Available online: http://www.mnr.gov.ru/docs/gosudarstvennye_doklady/o_sostoyanii_i_ob_okhrane_okruzhayushchey_sredy_rossiyskoy_federatsii (accessed on 12 September 2020).

- Plastinina, I.; Teslyuk, L.; Dukmasova, N.; Pikalova, E. Implementation of Circular Economy Principles in Regional Solid Municipal Waste Management: The Case of Sverdlovskaya Oblast (Russian Federation). Resources 2019, 8, 90. [Google Scholar] [CrossRef] [Green Version]

- Volakova, A.V. Waste Utilization Market; National Research University, Higher School of Economics: Moscow, Russia, 2018. (In Russian) [Google Scholar]

- Moscow Register of MSW (2029); Department of Housing and Communal Services of Moscow (2019). Territorial Scheme of Solid Waste Management in the City of Moscow. Available online: https://www.mos.ru/dgkh/documents/view/232950220/ (accessed on 5 August 2020).

- Ermolaeva Yu, V. Zero-waste megacities in Russia: Implementing an effective waste management scheme in Russia according to the expert survey on the example of Moscow and Kazan. Res. Result Sociol. Manag. 2019, 5, 96–108. [Google Scholar] [CrossRef] [Green Version]

- Ministry of Ecology and Nature Management. 2020. Available online: http://mep.mosreg.ru (accessed on 18 August 2020).

- Agiamoh, R.G. From bureaucracy to market? Ongoing reform and performance challenges of solid waste administration in Moscow. Public Adm. Issues 2020, 5, 149–170. [Google Scholar] [CrossRef]

- Aleshina, T.A.; Chernyshev, S.N. Sovremennoe geoekologicheskoe sostoyanie svalok i poligonov tverdykh bytovykh otkhodov moskovskoy oblasti i puti resheniya [The Present-Day Geo-Ecological Status of Landfi lls in the Moscow Region and Solutions to the Problem in Question]. Vestnik MGSU 2012, 9, 185–190. [Google Scholar] [CrossRef]

- Medvedkov, A.; Tkachev, A.A. Actual priorities of nature protection in the Moscow region. Bull. Mosc. State Reg. Univ. Series Nat. Sci. 2018. (In Russian) [Google Scholar] [CrossRef] [Green Version]

- Alexandrov, G.G.; Ginzburg, A.S. Anthropogenic impact of Moscow district heating system on urban environment, 16th International Symposium on District Heating and Cooling, 9–12 September 2018, Hamburg, Germany. Energy Procedia 2018, 149, 161–169. [Google Scholar] [CrossRef]

- Gasho, E.G. Energetic and climatic strategy of Moscow. Energy Sav. 2018, 2, 4–10. [Google Scholar]

- Ramanov, D.; Pelda, J.; Holler, S. Technical, economic and ecological effects of lowering temperatures in the Moscow district heating system. Energy 2020, 211. [Google Scholar] [CrossRef]

- Polygalov, S.; Ilinykh, G.; Sliusar, N.; Korotaev, V.; Rukavishnikova, I. Challenges and opportunities for energy recovery from municipal solid waste in the Russian Federation. WIT Trans. Ecol. Environ. 2019, 222, 131–143. [Google Scholar] [CrossRef]

- Govor, I.L.; Gitarski, M.L. An Analytical Review of the Potential Contribution of Solid Waste Management Industry Contribution in the Climate Policy of Russia; GIZ report; GIZ: Eschborn, Germany, 2020. (In Russian) [Google Scholar]

- Abu Qdais, H.A.; Alsharaideh, H.A. Selection of Management Option for Solid Waste from Olive Oil Industry Using the Analytical Hierarchy Process. J. Mater. Cycles Waste Manag. 2016, 18, 177–185. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision making with the analytic hierarchy process. Int. J. Serv. Sci. 2008, 1, 82–93. [Google Scholar] [CrossRef] [Green Version]

- Saaty, T.L. The Analytic Hierarchy Process: Planning, Priority Setting, Resource Allocation; McGraw-Hill: New York, NY, USA, 1980; Volume 287. [Google Scholar]

- Lootsma, F.A. Multi-Criteria Decision Analysis via Ratio and Difference Judgement; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1999. [Google Scholar]

- Lanshina, T.A.; Laitner, J.A.; Potshinkov, V.Y.; Barinova, V.A. The slow expansion of renewable energy in Russia: Competitiveness and regulation issues. Energy Policy 2018, 120, 600–609. [Google Scholar] [CrossRef]

- Coelho, L.G.; Lange, L.C.; Coelho, H. Multi-criteria decision making to support waste management: A critical review of current practices and methods. Waste Manag. Res. 2017, 35, 3–28. [Google Scholar] [CrossRef] [PubMed]

- Schlifter, G.; Madlener, G. AHP-based risk analysis energy performance contracting projects in Russia. Energy Policy 2016, 97, 559–581. [Google Scholar] [CrossRef]

- Geller, F. Assessing the energy security in Russia: The AHP approach. J. Res. Bus. Econ. Manag. 2018, 10, 2002–2015. [Google Scholar]

- Zaychenko, I.; Gutman, S.; Kalinina, O. Adjustment of Energy Strategy of Russia to Specific Nature of Far North: Analytic Hierarchy Process. In International Scientific Conference Energy Management of Municipal Transportation Facilities and Transport EMMFT 2017; Murgul, V., Popovic, Z., Eds.; Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2017; Volume 692. [Google Scholar] [CrossRef]

- Vershinina, K.; Dorokhov, V.; Romanov, D.; Nyashina, G.; Kuznetsov, G. Multi-criteria efficiency analysis of using waste-based fuel mixtures in the power industries of China, Japan, and Russia. Appl. Sci. 2020, 10, 2460. [Google Scholar] [CrossRef] [Green Version]

- Kokorin, A. Russia’s Post-Paris climate policy: Slow progress and problems. Russ. Anal. Dig. 2016, 185, 9–12. [Google Scholar]

- Qazi, W.A.; Abushammala, M.; Azam, M.H. Multi-criteria decision making of waste-to energy technologies for municipal solid waste management in Sultanate of Oman. Waste Manag. Res. 2018, 36, 594–605. [Google Scholar] [CrossRef]

- Statista. 2020. Available online: https://www.statista.com/statistics/263712/unemployment-in-russia/ (accessed on 10 October 2020).

- Fan, Y.V.; Klemesa, J.J.; Leeb, C.T.; Perryc, S. GHG emissions of incineration and anaerobic digestion: Electricity mix. Chem. Eng. Trans. 2019, 72, 145–150. [Google Scholar] [CrossRef]

- Bilitewski, B.; Wunsch, C. WTE: Greenhouse gas benefits. In Encyclopedia of Sustainability Science and Technology; Meyers, R., Ed.; Springer: New York, NY, USA, 2019. [Google Scholar] [CrossRef]

- Yi, S.; Jang, Y.-C.; An, K. Potential for energy recovery and greenhouse gas reduction through waste-to-energy technologies. J. Clean. Prod. 2018, 176, 503–511. [Google Scholar] [CrossRef]

- Arkharov, I.A.; Simakova, E.N.; Navasardyan, E.S. Landfill gas as feedstock for energy and industrial processes. Chem. Pet. Eng. 2016, 52, 547–551. [Google Scholar] [CrossRef]

- Ishizaka, A.; Labib, A. Analytical hierarchy process and expert choice: Benefits and limitations. Oper. Res. Insight 2009, 22, 201–220. [Google Scholar] [CrossRef] [Green Version]

- Gilmundinov, V.M.; Tagaeva, T.O. Assessment of the potential of municipal solid waste processing in Siberian Region. Reg. Res. Russ. 2019, 9, 236–244. [Google Scholar] [CrossRef]

- Tugov, A.N. Experience of using municipal solid waste in the energy industry (An Overview). Therm. Eng. 2015, 62, 853–861. [Google Scholar] [CrossRef]

- Papineschi, J.; Hoog, D.; Chowdhury, T.; Durrant, C.; Thomson, A. Analysis of Nordic Regulatory Framework and Its Effect on Waste Prevention and Recycling, Nordic Council of Ministers. 2019. Available online: http://norden.divaportal.org/smash/get/diva2:1304371/FULLTEXT01.pdf (accessed on 4 October 2020).

- Istrate, I.R.; Galvez-Martos, J.L.; Dufour, J. The impact of incineration phase-out on municipal solid waste landfilling and life cycle environmental performance: Case study of Madrid, Spain. Sci. Total Environ. 2020. [Google Scholar] [CrossRef]

| Main Criteria | Subcriteria | Description |

|---|---|---|

| Environmental and Health | Public and occupational health (POH) | Capability of the selected technology to minimize the risks on public and workers’ health |

| Pollution potential (PP) | Minimal adverse environmental impacts on water, soil and air | |

| Climate change impact (CCI) | Carbon footprint of the selected technology that has less emissions of carbon dioxide and other greenhouse gases | |

| Technical | Energy production (EP) | The selected technology with the highest energetic potential |

| Availability of know how (AOH) | The existence of practical knowledge and skills regarding running and maintaining the selected waste to energy technology | |

| Sophistication of technology (SOT) | Refers to high and advanced technology that requires skillful human resources | |

| Socioeconomic | Capital cost (CC) | The selected waste to energy technology that has the least initial investment cost (CAPEX) |

| Operation and maintenance cost (OMC) | The selected waste to energy technology that has the least running and maintenance costs (OPEX) | |

| Job creation (JC) | The potential of the selected technology to create employment opportunity |

| Waste to Energy Alternative | Description |

|---|---|

| Landfill gas (LFG) | A sanitary landfill with a gas plant erected on the landfill to recover the gas generated as a result of anaerobic degradation of the organic fraction to produce heat or electric energy. |

| Anaerobic digestion (AD) | Forwarding the biodegradable organic fraction of the municipal solid waste to a specially constructed plant where the waste is subjected to anaerobic degradation and producing methane gas for energy production. The digestate and residue after digestion need to be disposed. |

| Incineration plant (IP) | A thermal treatment process, where the solid waste is combusted in a solids chamber at high temperature. The heat is recovered from the system where it is used for heating purposes or electricity generation. While the gases are burned in a secondary chamber. The emitted gases may contain harmful emissions while the ash requires disposal. |

| Refuse derived fuel (RDF) | Combustible fraction of municipal solid waste including paper, plastic, organics, and wood are densified into pellets that can be utilized by different industries for energy production. |

| Importance Scale | Definition of the Importance Scale |

|---|---|

| 1 | Equal importance of the row criterion over the column criterion |

| 2 | Between equal and weak importance of the row criterion over the column criterion |

| 3 | Weak importance of the row criterion over the column criterion |

| 4 | Between weak and strong importance of the row criterion over the column criterion |

| 5 | Strong importance of the row criterion over the column criterion |

| 6 | Between strong and demonstrated importance of the row criterion over the column criterion |

| 7 | Demonstrated importance of the row criterion over the column criterion |

| 8 | Between demonstrated and absolute importance of the row criterion over the column criterion |

| 9 | Absolute importance of the row criterion over the column criterion |

| No. | Experts Category | Profession | Number |

|---|---|---|---|

| 1. | Academics | Lecturers and researchers with environmental background | 4 |

| 2. | Waste Professionals | Solid waste treatment plants operators | 2 |

| 3. | Decision Makers of Federal and Local Authorities | Specialist of the natural resources protection and management | 3 |

| 4. | Energy Specialist | Operators and researchers in the field of energy | 3 |

| 5. | Members of International donating agencies in Moscow | Head of Department | 1 |

| 6. | Graduate Researchers | PhD researchers in integrated solid waste management | 3 |

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| RC | 0 | 0 | 0.58 | 0.90 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 |

| Criteria | Environmental and Health | Technical | Socioeconomic | Priority Vector |

|---|---|---|---|---|

| Environmental and Health | 1 | 6 | 5 | 0.729 |

| Technical | 0.167 | 1 | 2 | 0.162 |

| Socioeconomic | 0.20 | 0.5 | 1 | 0.109 |

| Criteria | Environmental- Health | Technical | Socioeconomic | Priority Vector | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Subcriteria | POH | PP | CCI | EP | AKH | SOT | CC | OMC | JC | |

| POH | 1 | 4 | 5 | - | - | - | - | - | - | 0.683 |

| PP | 0.25 | 1 | 2 | - | - | - | - | - | - | 0.20 |

| CCI | 0.20 | 0.50 | 1 | - | - | - | - | - | - | 0.117 |

| EP | - | - | - | 1 | 5 | 5 | - | - | - | 0.709 |

| AKH | - | - | - | 0.20 | 1 | 2 | - | - | - | 0.178 |

| SOT | - | - | - | 0.20 | 0.50 | 1 | - | - | - | 0.113 |

| CC | - | - | - | - | - | - | 1 | 3 | 4 | 0.615 |

| O&MC | - | - | - | - | - | - | 0.33 | 1 | 3 | 0.268 |

| JC | - | - | - | - | - | - | 0.25 | 0.33 | 1 | 0.117 |

| Scenario | Criteria | Criteria Weight | Alternative | Alternative Ranking |

|---|---|---|---|---|

| Scenario No. 1 |

| 33.33% 33.33% 33.33% |

| 2 3 1 4 |

| Scenario No. 2. a |

| 100% 0% 0% |

| 1 2 3 4 |

| Scenario No. 2. b |

| 0% 100% 0% |

| 3 2 1 4 |

| Scenario No. 2. c |

| 0% 0% 100% |

| 1 2 3 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurbatova, A.; Abu-Qdais, H.A. Using Multi-Criteria Decision Analysis to Select Waste to Energy Technology for a Mega City: The Case of Moscow. Sustainability 2020, 12, 9828. https://doi.org/10.3390/su12239828

Kurbatova A, Abu-Qdais HA. Using Multi-Criteria Decision Analysis to Select Waste to Energy Technology for a Mega City: The Case of Moscow. Sustainability. 2020; 12(23):9828. https://doi.org/10.3390/su12239828

Chicago/Turabian StyleKurbatova, Anna, and Hani Ahmed Abu-Qdais. 2020. "Using Multi-Criteria Decision Analysis to Select Waste to Energy Technology for a Mega City: The Case of Moscow" Sustainability 12, no. 23: 9828. https://doi.org/10.3390/su12239828

APA StyleKurbatova, A., & Abu-Qdais, H. A. (2020). Using Multi-Criteria Decision Analysis to Select Waste to Energy Technology for a Mega City: The Case of Moscow. Sustainability, 12(23), 9828. https://doi.org/10.3390/su12239828