Life Cycle Assessment of Biogas Production from Unused Grassland Biomass Pretreated by Steam Explosion Using a System Expansion Method

Abstract

:1. Introduction

2. Materials and Methods

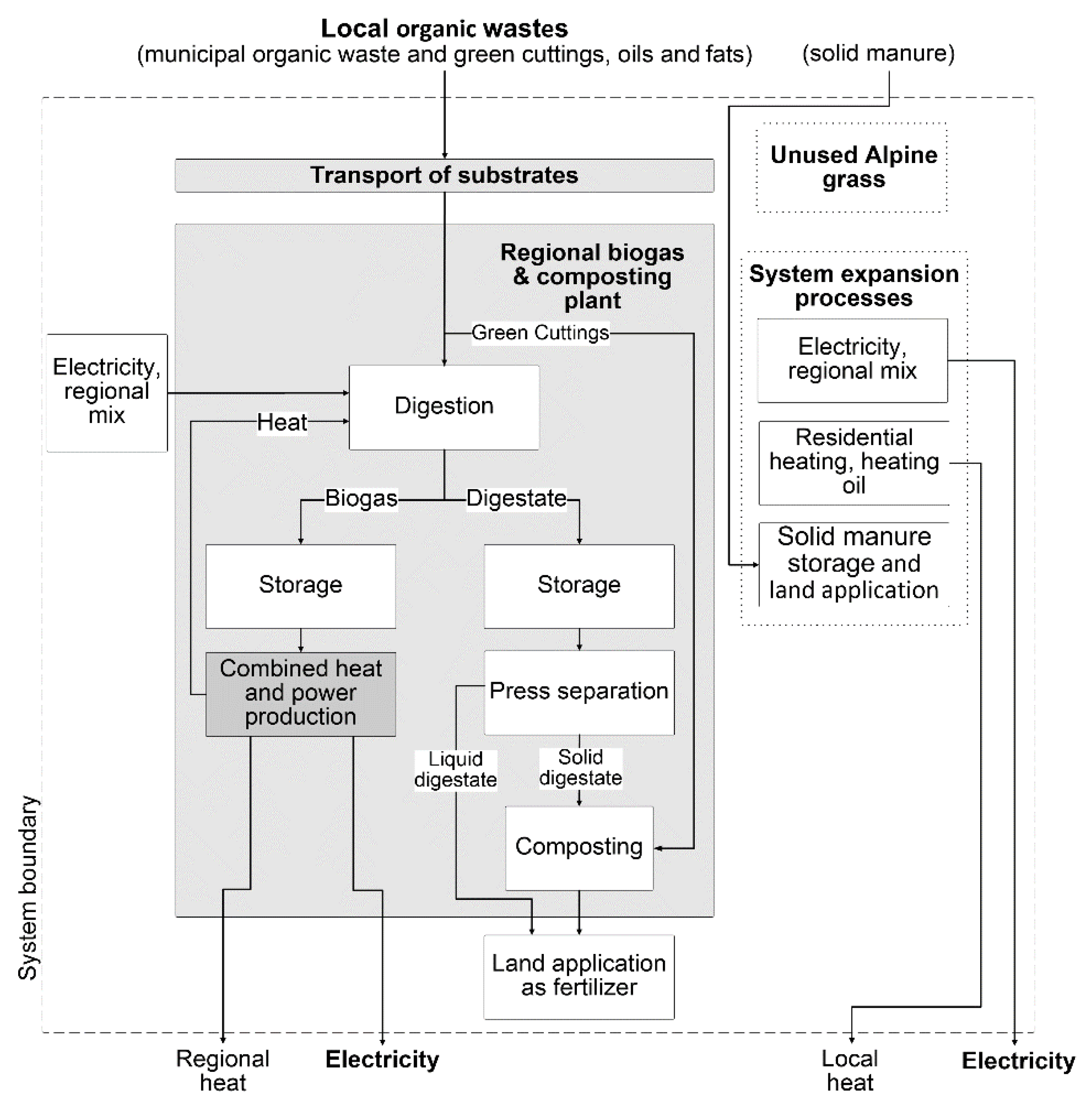

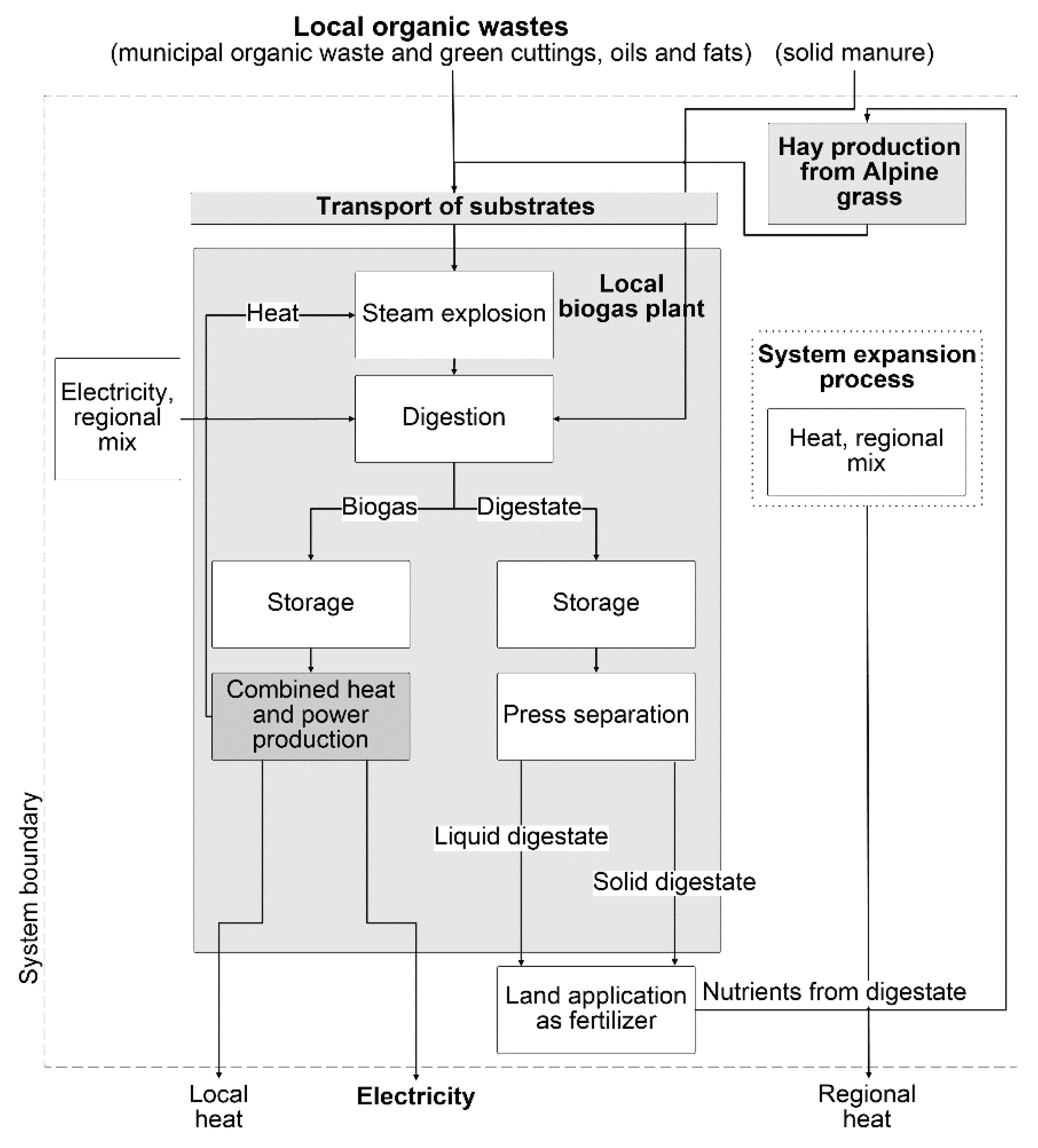

2.1. Overview of Scenarios

2.2. Biogas Substrates

2.3. System Expansion (SE) Approach and Energy Modeling

2.4. Digestate and Nutrient Modeling

2.5. Infrastructure Modeling

2.6. LCA Modeling Approach

3. Results and Discussion

3.1. Overall Scenario Comparison

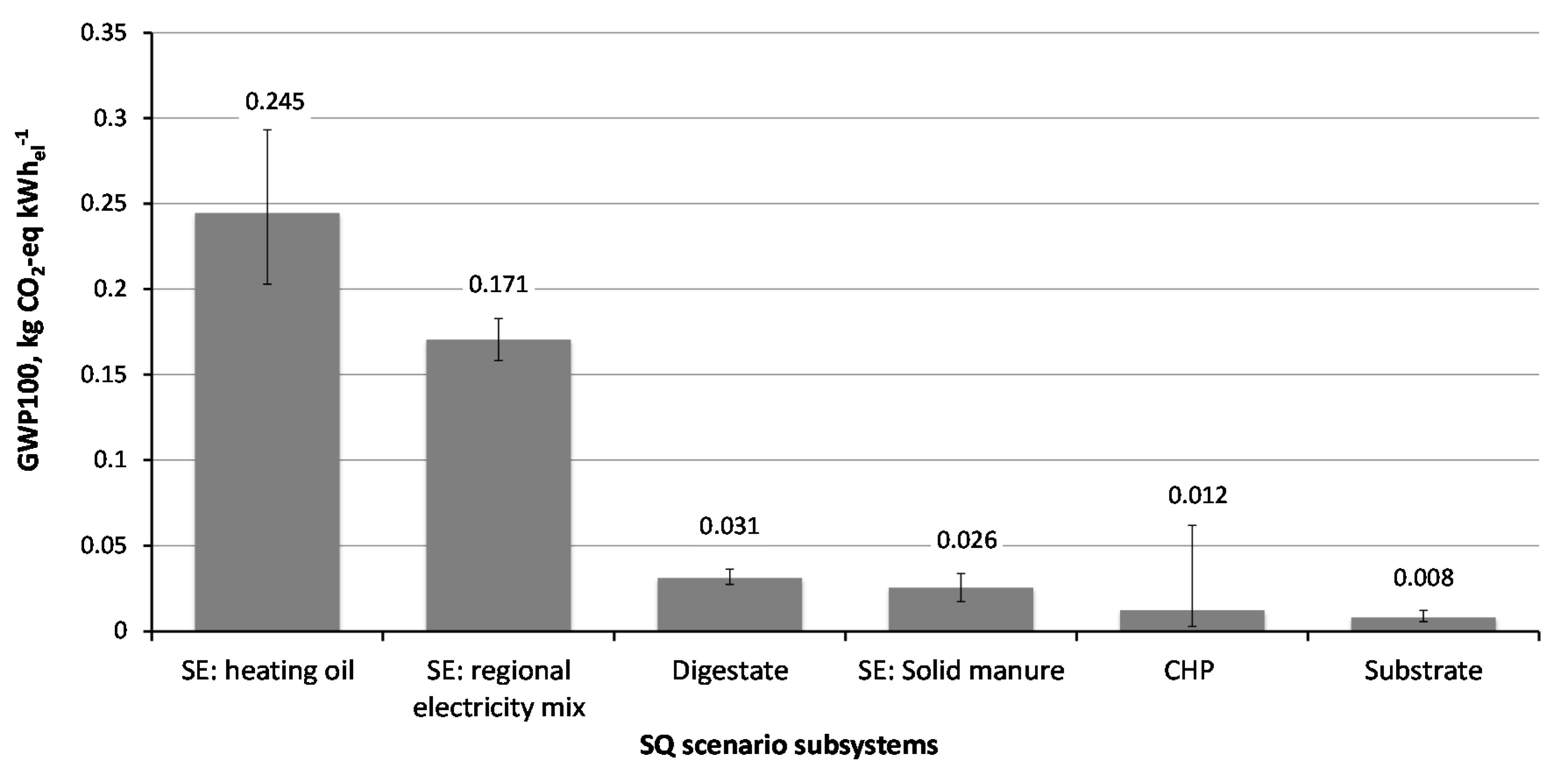

3.2. SQ Contribution Analysis

3.2.1. Climate Change Impacts

3.2.2. Other Impact Categories

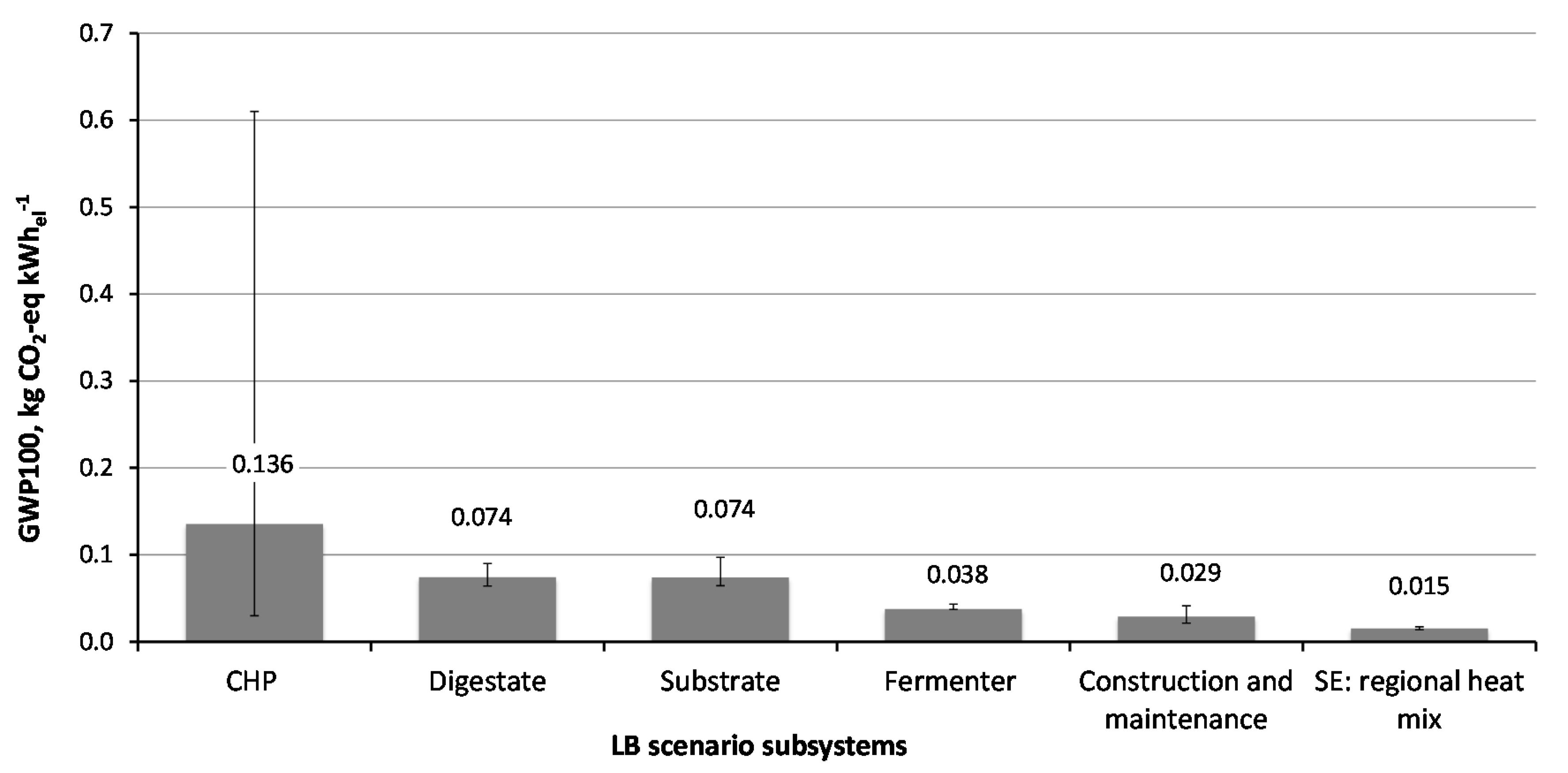

3.3. LB Contribution Analysis

3.3.1. Climate Change Impacts

3.3.2. Other Impact Categories

3.4. Sensitivity Analyses

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Schermer, M. REsilience of Marginal GrAssland and Biodiversity Management Decision Support—REGARDS; Department of Sociology, University Innsbruck: Innsbruck, Austria, 2015. [Google Scholar]

- Kral, I.; Piringer, G.; Saylor, M.; Gronauer, A.; Bauer, A. Environmental effects of steam explosion pretreatment on biogas from maize-case study of a 500-kW Austrian biogas facility. Bioenergy Res. 2016, 9, 198–207. [Google Scholar] [CrossRef]

- Bauer, A.; Lizasoain, J.; Theuretzbacher, F.; Agger, J.W.; Rincón, M.; Menardo, S.; Saylor, M.K.; Enguídanos, R.; Nielsen, P.J.; Gronauer, A.; et al. Steam explosion pretreatment for enhancing biogas production of late harvested hay. Bioresour. Technol. 2014, 166, 403–410. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, L.C.; Donoso-Bravo, A.; Nilsen, P.J.; Fdz-Polanco, F.; Perez-Elvira, S.I. Influence of thermal pretreatment on the biochemical methane potential of wheat straw. Bioresour. Technol. 2013, 143, 251–257. [Google Scholar] [CrossRef] [PubMed]

- Schumacher, B.; Wedwitschka, H.; Hofmann, J.; Denysenko, V.; Lorenz, H.; Liebetrau, J. Disintegration in the biogas sector—Technologies and effects. Bioresour. Technol. 2014, 168, 2–6. [Google Scholar] [CrossRef]

- Sapci, Z.; Morken, J.; Linjordet, R. An Investigation of the Enhancement of Biogas Yields from Lignocellulosic Material using Two Pretreatment Methods: Microwave Irradiation and Steam Explosion. BioResources 2013, 8, 1976–1985. [Google Scholar] [CrossRef]

- Risberg, K.; Sun, L.; Leven, L.; Horn, S.J.; Schnurer, A. Biogas production from wheat straw and manure—impact of pretreatment and process operating parameters. Bioresour. Technol. 2013, 149, 232–237. [Google Scholar] [CrossRef]

- Pérez-Elvira, S.I.; Fdz-Polanco, F. Continuous thermal hydrolysis and anaerobic digestion of sludge. Energy integration study. Water Sci. Technol. 2012, 65, 1839–1846. [Google Scholar] [CrossRef]

- Li, A.; Antizar-Ladislao, B.; Khraisheh, M. Bioconversion of municipal solid waste to glucose for bio-ethanol production. Bioprocess Biosyst. Eng. 2007, 30, 189–196. [Google Scholar] [CrossRef]

- Sargalski, W.; Solheim, O.E.; Fjordside, C. Treating Organic Waste with CAMBI® THP. In Proceedings of the 12th European Biosolids and Organic Resources Conference, Manchester, UK, 12–14 November 2007. [Google Scholar]

- Shafiei, M.; Kabir, M.M.; Zilouei, H.; Horváth, I.S.; Karimi, K. Techno-economical study of biogas production improved by steam explosion pretreatment. Bioresour. Technol. 2013, 148, 53–60. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Inaba, A.; Tan, R.; Christiansen, K.; Klüppel, H.-J. The New International Standards for Life Cycle Assessment: ISO 14040 and ISO 14044. Int. J. Life Cycle Assess. 2006, 11, 80–85. [Google Scholar] [CrossRef]

- Bedoić, R.; Čuček, L.; Ćosić, B.; Krajnc, D.; Smoljanić, G.; Kravanja, Z.; Ljubas, D.; Pukšec, T.; Duić, N. Green biomass to biogas—A study on anaerobic digestion of residue grass. J. Clean. Prod. 2019, 213, 700–709. [Google Scholar] [CrossRef]

- Vo, T.T.Q.; Rajendran, K.; Murphy, J.D. Can power to methane systems be sustainable and can they improve the carbon intensity of renewable methane when used to upgrade biogas produced from grass and slurry? Appl. Energy 2018, 228, 1046–1056. [Google Scholar] [CrossRef]

- Wang, L.; Littlewood, J.; Murphy, R.J. Environmental sustainability of bioethanol production from wheat straw in the UK. Renew. Sustain. Energy Rev. 2013, 28, 715–725. [Google Scholar] [CrossRef] [Green Version]

- Prasad, A.; Sotenko, M.; Blenkinsopp, T.; Coles, S.R. Life cycle assessment of lignocellulosic biomass pretreatment methods in biofuel production. Int. J. Life Cycle Assess. 2015, 21, 44–50. [Google Scholar] [CrossRef] [Green Version]

- Schumacher, B.; Oechsner, H.; Senn, T.; Jungbluth, T. Life cycle assessment of the conversion of Zea mays and x Triticosecale into biogas and bioethanol. Eng. Life Sci. 2010, 10, 577–584. [Google Scholar] [CrossRef]

- Ingrao, C.; Bacenetti, J.; Adamczyk, J.; Ferrante, V.; Messineo, A.; Huisingh, D. Investigating energy and environmental issues of agro-biogas derived energy systems: A comprehensive review of Life Cycle Assessments. Renew. Energy 2019, 136, 296–307. [Google Scholar] [CrossRef]

- Frühauf, S. Potentialanalyse Biogener Roh-, Rest-und Abfallstoffe für die Einbringung in eine Biogasanlage in der Gemeinde Lech am Arlberg. Master’s Thesis, University of Natural Resources and Life Sciences, Vienna, Austria, 2013. [Google Scholar]

- Bayerische Landesanstalt für Landwirtschaft (2014) Biogasausbeuten verschiedener Substrate. Available online: http://www.lfl.bayern.de/iba/energie/049711/ (accessed on 20 October 2020).

- Ecoinvent Centre. Ecoinvent Data v 2.2. Swiss Centre for Life Cycle Inventories, Dübendorf. 2014. Available online: https://www.ecoinvent.org/database/older-versions/ecoinvent-version-2/ecoinvent-version-2.html (accessed on 22 October 2020).

- Amon, B.; Amon, T.; Boxberger, J.; Alt, C. Emissions of NH3, N2O and CH4 from dairy cows housed in a farmyard manure tying stall (housing, manure storage, manure spreading). Nutr. Cycl. Agroecosystems 2001, 60, 103–113. [Google Scholar] [CrossRef]

- Energie, A.d.V.L.-B. Energie-zukunft Vorarlberg—Ergebnisse aus dem Visionsprozess. In Schritt für Schritt zur Energieautonomie. Quantifizierungen und Zukunftsentwürfe; Amt der Vorarlberger Landesregierung: Bregenz, Austria, 2010; pp. 1–22. [Google Scholar]

- Landesregierung, A.d.V. Energiebericht 2013 auf Basis der Energieverbrauchsdaten 2012; Amt der Vorarlberger Landesregierung: Bregenz, Austria, 2013; pp. 1–18. [Google Scholar]

- Kaltschmitt, M.; Streicher, W. Regenerative Energien in Österreich: Grundlagen, Systemtechnik, Umweltaspekte, Kostenanalysen, Potenziale, Nutzung, 1st ed.; Vieweg + Teubner: Wiesbaden, Germany, 2009. [Google Scholar]

- Biermayr, P.; Eberl, M.; Ehrig, R.; Fechner, H.; Kristöfel, C.; Neuhauser, P.E.; Prüggler, N.; Sonnleitner, A.; Strasser, C.; Weiss, W.; et al. Innovative Energietechnologien in Österreich- Marktentwicklung 2011. Biomasse, Photovoltaik, Solarthermie und Wärmepumpen; Federal Ministry of Agriculture, Forestry, Environment and Water Management: Vienna, Austria, 2012; p. 171.

- Döhler, H.; Eckel, H.; Fröba, N.; Grebe, S.; Hartmann, S.; Häußermann, U.; Klages, S.; Sauer, N.; Nakazi, S. Faustzahlen Biogas, 2nd ed.; Kuratorium für Technik und Bauwesen in der Landwirtschaft e.V. (KTBL): Darmstadt, Germany, 2009; p. 236. [Google Scholar]

- Frühauf, S.; Saylor, M.K.; Lizasoain, J.; Gronauer, A.; Bauer, A. Potential Analysis of Agro-Municipal Residues as a Source of Renewable Energy. BioEnergy Res. 2015, 8, 1449–1456. [Google Scholar] [CrossRef]

- Laaber, M. Gütesiegel Biogas. Evaluierung Der Technischen, ökologischen und Sozioökonomischen Rahmenbedingungen für eine Ökostromproduktion aus Biogas. Ph.D. Thesis, University of Natural Resources and Life Sciences, Vienna, Austria, 2011. [Google Scholar]

- Cuhls, C.; Mähl, D.B.; Berkau, S.; Clemens, P.D.J. Ermittlung der Emissionssituation bei der Verwertung von Bioabfällen; Gewitra-Ingenieurgesellschaft für Wissenstransfer mbH: Bonn, Germany, 2008; pp. 1–172. [Google Scholar]

- Lampert, C.; Tesar, M.; Thaler, P. Klimarelevanz und Energieeffizienz der Verwertung biogener Abfälle; 9783990041567; Umweltbundesamt GmbH: Vienna, Austria, 2011; pp. 3–76. [Google Scholar]

- Wulf, S.; Maeting, M.; Clemens, J. Application technique and slurry co-fermentation effects on ammonia, nitrous oxide, and methane emissions after spreading: II. Greenhouse gas emissions. J. Environ. Qual. 2002, 31, 1795–1801. [Google Scholar] [CrossRef]

- Amon, B.; Kryvoruchko, V.; Amon, T.; Zechmeister-Boltenstern, S. Methane, nitrous oxide and ammonia emissions during storage and after application of dairy cattle slurry and influence of slurry treatment. Agric. Ecosyst. Environ. 2006, 112, 153–162. [Google Scholar] [CrossRef]

- Buchgraber, K.; Gindl, G. Zeitgemäße Grünlandbewirtschaftung; Stocker Verlag: Graz, Austria, 2004. [Google Scholar]

- Gmb, H.G.D. OpenLCA 1.8; Green Delta GmbH: Berlin, Germany, 2014. [Google Scholar]

- Goedkoop, M.J.; Reinout, H.; Huijbregts, M.; De Schryver, A.; Struijs, J.; Van Zelm, R. ReCiPe 2008, a Life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and Endpoint Level, 1st ed.; Report I: Characterisation; Ministerie van VROM: Den Haag, The Netherlands, 2008. [Google Scholar]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.D.M.; Hollander, A.; Van Zelm, R. ReCiPe2016: A Harmonized Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. RIVM Report 2016-0104; National Institute for Public Health and the Environment: Bilthoven, The Netherlands, 2016. [Google Scholar]

- Frischknecht, R.; Jungbluth, N.; Althaus, H.-J.; Bauer, C.; Doka, G.; Dones, R.; Hirschier, R.; Hellweg, S.; Humbert, S.; Köllner, T.; et al. Implementation of Life Cycle Impact Assessment Methods. Ecoinvent Report No. 3, v2.0; Frischknecht, R., Jungbluth, N., Eds.; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2007; p. 151. [Google Scholar]

- IBM Corp. IBM SPSS Statistics for Windows, Version 21.0; IBM: New York, NY, USA, 2012. [Google Scholar]

- Siegl, S. Öko-Strom aus Biomasse. Vergleich der Umweltwirkungen verschiedener Biomasse-Technologien zur Stromerzeugung Mittels Lebenszyklusanalysen. Ph.D Thesis, University of Natural Resources and Life Sciences, Vienna, Austria, 2010. [Google Scholar]

- Bachmaier, J. Treibhausgasemissionen Und Fossiler Energieverbrauch Landwirtschaftlicher Biogasanlagen. Eine Bewertung auf Basis von Messdaten mit Evaluierung der Ergebnisunsicherheit mittels Monte-Carlo-Simulation. Ph.D. Thesis, University of Natural Resources and Life Sciences, Vienna, Austria, 2012. [Google Scholar]

- Pucker, J.; Jungmeier, G.; Siegl, S.; Potsch, E.M. Anaerobic digestion of agricultural and other substrates—implications for greenhouse gas emissions. Animal 2013, 7 (Suppl. 2), 283–291. [Google Scholar] [CrossRef] [PubMed]

- Gerin, P.A.; Vliegen, F.; Jossart, J.M. Energy and CO2 balance of maize and grass as energy crops for anaerobic digestion. Bioresour. Technol. 2008, 99, 2620–2627. [Google Scholar] [CrossRef] [PubMed]

- Bacenetti, J.; Sala, C.; Fusi, A.; Fiala, M. Agricultural anaerobic digestion plants: What LCA studies pointed out and what can be done to make them more environmentally sustainable. Appl. Energy 2016, 179, 669–686. [Google Scholar] [CrossRef] [Green Version]

- Evangelisti, S.; Lettieri, P.; Borello, D.; Clift, R. Life cycle assessment of energy from waste via anaerobic digestion: A UK case study. Waste Manag. 2014, 34, 226–237. [Google Scholar] [CrossRef]

| Substrate Inputs | Substrate | DM Content | Organic DM Content | Annual CH4 yield | Annual Energy from CH4 |

|---|---|---|---|---|---|

| [t FM a−1] | [% of FM] | [% of DM] | [Nm3 a−1] | [kWh a−1] | |

| Status Quo (SQ) Scenario | |||||

| To biogas without SEP | |||||

| Municipal organic waste mixture | 894 | 39% | 52% | 55,772 | 555,492 |

| Oils and fats | 36 | 95% | 92% | 21,396 | 213,099 |

| Direct to composting | |||||

| Green cuttings | 60 | 15% | 89% | n/a | n/a |

| Direct to field application | |||||

| Solid manure | 2630 | 25% | 80% | n/a | n/a |

| Total SQ Scenario (biogas only) | 930 | 77,168 | 768,591 | ||

| Local Biogas (LB) Scenario | |||||

| To biogas with SEP | |||||

| Hay | 3371 | 87% | 94% | 762,663 | 7,596,119 |

| Municipal organic waste mixture | 894 | 39% | 52% | 71,108 | 708,234 |

| Oils and fats | 36 | 95% | 92% | 21,396 | 213,099 |

| Green cuttings | 60 | 15% | 89% | 2217 | 22,084 |

| To biogas without SEP | |||||

| Solid manure | 2630 | 25% | 80% | 129,459 | 1,289,410 |

| Total LB Scenario (biogas only) | 6991 | 986,842 | 9,828,947 | ||

| Energy [kWh a−1] | Status Quo (SQ) Scenario | Local Biogas (LB) Scenario |

|---|---|---|

| Electricity | ||

| CHP electricity, total output | 292,065 | 3,735,000 |

| SE electricity | 3,442,935 a | n/a |

| Expanded system electricity output (CHP electricity output plus SE electricity) | 3,735,000 | 3,735,000 |

| Heat | ||

| CHP heat, total output | 322,808 | 4,128,158 |

| CHP heat used on-site | 37,123 | 549,239 |

| CHP heat used off-site | 258,247 b | 2,807,147 |

| CHP heat output not used | 27,439 | 276,392 |

| SE heat | 2,807,147 c | 258,247 d |

| Expanded system heat used off-site (CHP heat used off-site plus SE heat) | 3,065,394 | 3,065,394 |

| SQ Scenario | LB Scenario | LB Impacts in % of SQ Impacts | ||||||

|---|---|---|---|---|---|---|---|---|

| Impact Category | Reference Unit | Point Estimate | 5th-Percentile | 95th-Percentile | Point Estimate | 5th-Percentile | 95th-Percentile | |

| Climate change | kg CO2-eq kWh−1 | 5.01 × 10−1 | 4.56 × 10−1 | 5.69 × 10−1 | 3.67 × 10−1 | 2.63 × 10−1 | 8.55 × 10−1 | 73% |

| Non-renewable energy resources | MJ-eq kWh−1 | 5.53 | 4.85 | 6.30 | 2.22 | 1.93 | 2.68 | 40% |

| Freshwater ecotoxicity | kg 1,4-DCB-eq kWh−1 | 1.26 × 10−4 | 6.16 × 10−5 | 2.36 × 10−4 | 5.33 × 10−5 | 2.89 × 10−5 | 9.44 × 10−5 | 42% |

| Human toxicity | kg 1,4-DCB-eq kWh−1 | 1.88 × 10−2 | 1.18 × 10−2 | 3.01 × 10−2 | 1.99 × 10−2 | 1.34 × 10−2 | 3.09 × 10−2 | 106% |

| Terrestrial acidification | kg SO2-eq kWh−1 | 3.78 × 10−3 | 1.89 × 10−3 | 5.71 × 10−3 | 1.48 × 10−2 | 5.03 × 10−3 | 2.47 × 10−2 | 393% |

| Particulate matter formation | kg PM10-eq kWh−1 | 7.26 × 10−4 | 4.78 × 10−4 | 9.81 × 10−4 | 2.69 × 10−3 | 1.41 × 10−3 | 3.99 × 10−3 | 371% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kral, I.; Piringer, G.; Saylor, M.K.; Lizasoain, J.; Gronauer, A.; Bauer, A. Life Cycle Assessment of Biogas Production from Unused Grassland Biomass Pretreated by Steam Explosion Using a System Expansion Method. Sustainability 2020, 12, 9945. https://doi.org/10.3390/su12239945

Kral I, Piringer G, Saylor MK, Lizasoain J, Gronauer A, Bauer A. Life Cycle Assessment of Biogas Production from Unused Grassland Biomass Pretreated by Steam Explosion Using a System Expansion Method. Sustainability. 2020; 12(23):9945. https://doi.org/10.3390/su12239945

Chicago/Turabian StyleKral, Iris, Gerhard Piringer, Molly K. Saylor, Javier Lizasoain, Andreas Gronauer, and Alexander Bauer. 2020. "Life Cycle Assessment of Biogas Production from Unused Grassland Biomass Pretreated by Steam Explosion Using a System Expansion Method" Sustainability 12, no. 23: 9945. https://doi.org/10.3390/su12239945

APA StyleKral, I., Piringer, G., Saylor, M. K., Lizasoain, J., Gronauer, A., & Bauer, A. (2020). Life Cycle Assessment of Biogas Production from Unused Grassland Biomass Pretreated by Steam Explosion Using a System Expansion Method. Sustainability, 12(23), 9945. https://doi.org/10.3390/su12239945