Green Innovation Risk Identification of the Manufacturing Industry under Global Value Chain Based on Grounded Theory

Abstract

1. Introduction

2. Literature Review

2.1. Green Innovation Risk

2.2. Related Factors of Green Innovation

2.3. Risk Identification of Green Innovation

3. Research Method and the Design of Risk Factor Identification

3.1. Research Methods

3.2. Selection of the Research Objects

3.3. Data Sources and Collections

4. Identification Process of the Green Innovation Risk Factors

4.1. Open Coding

4.2. Axial Coding

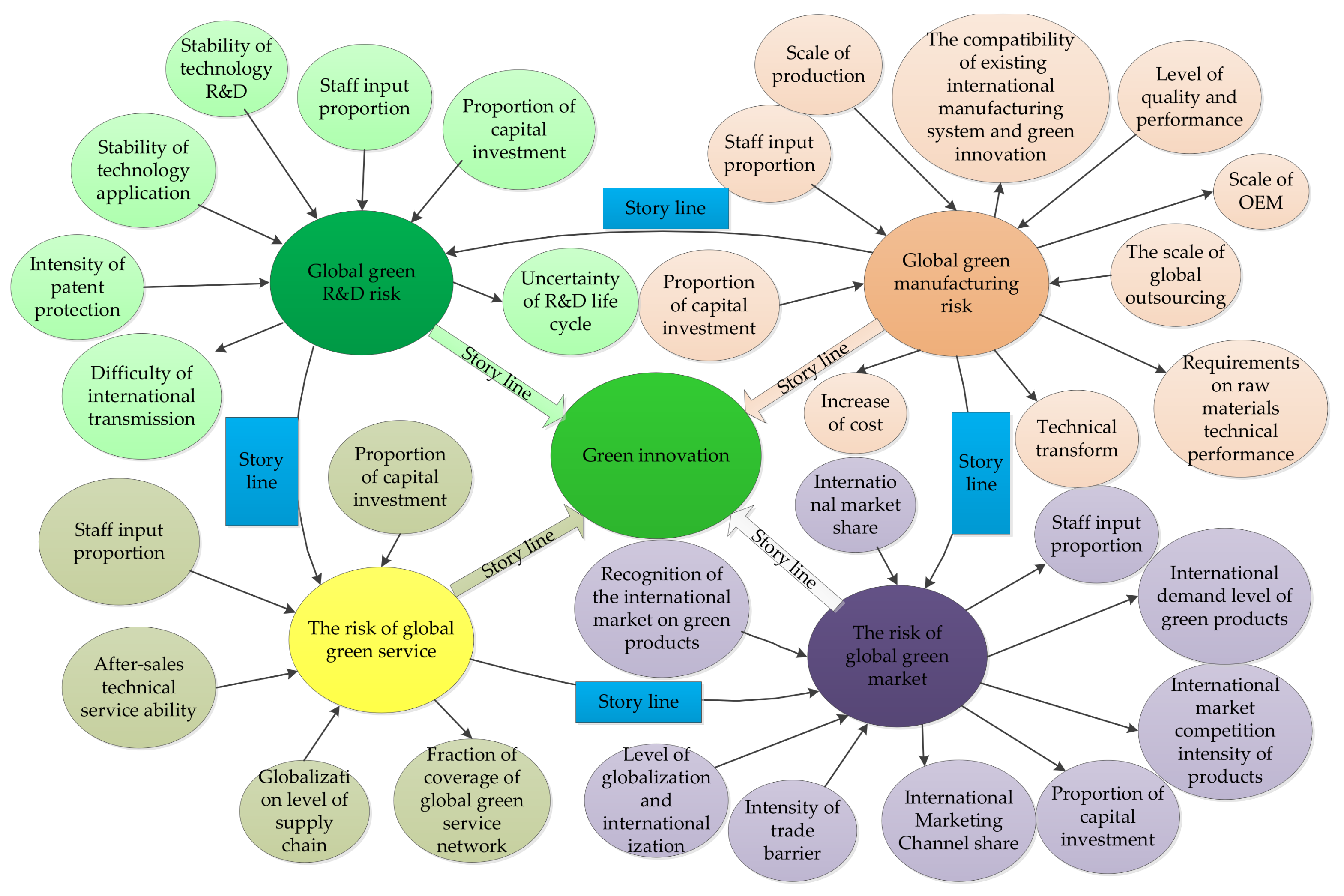

4.3. Selective Coding

4.4. Theoretical Saturation Test

5. Risk Identification Results and Model Interpretation

5.1. Green R&D Risk under the Global Value Chain

5.2. Green Manufacturing Risk under the Global Value Chain

5.3. Green Marketing Risks under the Global Value Chain

5.4. Green Service Risks under the Global Value Chain

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Number | Category | Original Data (Initial Material) |

|---|---|---|

| 1 | Proportion of global green R&D personnel investment | A3 The staff of the R&D Department of the enterprise all have bachelor’s degrees or above. Most of them have master’s degrees, and those with doctoral degrees are increasing year by year. (Human capital) A7 Last year, the enterprise recruited 17 high-end talents from “double first-class” universities and famous foreign universities with master’s degrees or above, and the enterprise provided a competitive salary and development platform for them. (Acquire innovative talents) A11 The enterprise pays attention to R&D investments and technology reserves. It has an independent R&D department and nearly 300 researchers; about one-third of them have master’s degrees or above, and all have independent R&D abilities. (Human capital investment) A19 The enterprise encourages employees to study abroad and return with more new knowledge and ideas. (Encourages employees to improve themselves) |

| 2 | Proportion of global R&D investment | A2 The enterprise’s annual R&D investment accounted for more than 17% of its marketing revenue (nearly 20% last year). (R&D investment) A5 The enterprise obtains part of its financial support through financial institutions and venture capital institutions for their own energy conservation and emission reduction projects to guarantee the material basis of innovation. (Acquire innovation capital) A13 Last year, the enterprise invested two-hundred thousand yuan into the research and development of an experimental desulfurization device. (Capital investment) A21 The implementation of green innovation in the enterprise is faced with a high-cost risk, and the uncertainty of income makes it difficult to obtain the financial support of shareholders, so the R&D projects are difficult to carry out. (Capital support) |

| 3 | Stability of global green research and development | A6 In the past three years, the enterprises have been increasing their investments in green innovation, especially in the research and development of environmental protection projects. (Research and development of environmental protection products) A10 Although enterprises have invested much into green innovation in the current period, the immature level of its R&D technology and the workload and difficulty of the R&D personnel also affect the success rate of R&D. (Investment risk) A22 Enterprises have a stable long-term cooperative relationship. They often participate in conferences, exhibitions, and other exchange activities organized by industry associations, serving as the main members to establish stable social relations with other organizations. (Stable partnership) A25 The talent hunting of the headhunting company makes increases the conflicts between the superiors and the subordinates in the team continuously. The lack of good communication and coordination ability among the team members leads to instability of the development team and causes the team members to leave the product development team. It has a certain impact on the enterprise. (Unstable R&D environment) |

| 4 | Uncertainty of global green R&D life cycle | A4 Green innovation of an enterprise is a high-risk and high-cost activity, requiring great investment of resources into capital, human, and material resources. However, due to the complexity of green R&D, the R&D life cycle may be too long, resulting in losses. (R&D life cycle is too long) A17 Enterprises do not artificially maintain a product without a market. Making money is the ultimate goal of an enterprise. The key point is to ensure that the business portfolio is balanced; that is to say, there should be products at all stages of the product life cycle. (Product life cycle) A24 If a product is in trouble early in its life cycle, it must be decided quickly whether to redevelop the product or abandon it. Ensure that this step is incorporated into the product plan to maintain objectivity in subsequent operations. (Product growth period) |

| 5 | Stability of global green technology applications | A2 The strategic decision makers of green innovation activities of enterprises are the managers of the enterprises. They convene project members from all departments according to the needs of the green innovation activities. (Allocation of green innovation resources) A15 To be more scientific and provide environmental protection to deal with pollution, enterprises adopt green technology for their sewage treatment to classify the treatment of sewage. Sewage treatment can thus reach the standard of grade II and III directly. (Mature technology) A17 In recent years, a large number of safety accidents and dangerous problems have had a great influence on the stability of the whole working environment. The adoption of corresponding green mining technology will help China’s mining development become more stable and safer. (Green technology application) |

| 6 | The ease of the international transfer of green technology | A7 When transferring technology, there will be uncertainty in the international transfer of green innovation, which has a negative impact on green innovation. (Technology transfer risk) A9 Our company attaches great importance to international economic and technological cooperation. To catch up with the advanced level of the world as soon as possible, we should speed up our own scientific and technological research through the introduction, digestion, and absorption of international technology transfer. (International Economic and technological cooperation) |

| 7 | International Protection of green technology patents | A5 The innovation achievements of enterprises will obtain property rights protection through patent applications and other means. There is also the leakage of innovation information. The law of intellectual property protection in China is not perfect, which may lead to conflicts. (Intellectual property protection) A7 Due to the imperfection of technology and law, someone imitates, manufactures, and sells fake and poor-quality products to seek huge profits, leading to technical losses and the leakage trade secrets. In recent years, the infringement of intellectual property rights has been repeatedly prohibited in many countries. (Infringement Act) A16 The establishment and improvement of an intellectual property protection system is conducive to motivating the enthusiasm of R&D staff. (Policy support) |

| 8 | Proportion of global green manufacturing personnel input | A1 Enterprise production personnel are from technical secondary schools, colleges, or above, and they begin to practice in this field during their internships in the city of the production and manufacturing work, leading to skilled operation. (Human capital) A5 Enterprises determine their production personnel quota according to the positions determined in the design of the production line. For example, the rated personnel quota of a gravure machine is 3—that is to say, only 3 people can do it. (According to the equipment quota) A14 Creating a healthy and safe environment is conducive to the improvement and maintenance of the physical and mental health of employees; it will be also conducive to creating a good social environment. (Working environment) |

| 9 | Proportion of global green manufacturing investment | A3 The persons in charge and the manufacturing personnel of the enterprise participate in the manufacturing-related education and training organized by qualified training institutions, and internal education and training are carried out according to the classes, levels, and nature of the work. (Education and training) A8 In recent years, enterprises have spent a large amount of money on on-site pollution control, setting up car washing tanks, dust control, noise control, disposing of construction waste into the pool, drainage measures, and so on. (Capital investment) A12 The company invested a part of the funds into the use of safety and environmental protection, the purchase of safety protection equipment and mechanical equipment, and accessories for regular inspection. (Safety and environmental protection funds) |

| 10 | Production scale of global green manufacturing products | A4 The company’s multi-cylinder diesel engine has passed three national emission standards, and the annual production capacity of this diesel engine can reach 1.2 million. (Production capacity) A6 In the past three years, the company has replaced a quarter of its old production equipment, adding 100 advanced units of production equipment. (Amount of production equipment) A11 We planned a corresponding production plan by defining the minimum and maximum scale limits of the product and the load rate of the equipment. (Production plan) |

| 11 | Requirements of global green manufacturing for products based on the technical performance of raw materials | A3 Our company should try its best to acquire the same manufacturer, serial number, and production date for the raw materials used in the products of the unified production batch. (Product raw material requirements) A12 Enterprises use the storage of raw materials, which require relatively stable temperatures, sunlight and seasonal changes, and day to night changes will be considered as well. (Storage standards) |

| 12 | Quality and performance level of global green manufacturing products | A1 Starting last year, the company introduced the world’s leading production equipment from abroad and trained relevant technical personnel. Now this equipment has been put into use, and the utilization rate of the newly introduced equipment for raw materials is greater than 90%, thus changing the production scale of the enterprise. (Obtain advanced equipment) A7 The enterprise uses a series parallel production line. Some production links can be changed at any time as needed. The main production links are solved by parallel connection. (Production link) |

| 13 | Global outsourcing scale of green products | A5 In the process of green innovation, the manufacturing industry puts forward new requirements for processes, equipment, and raw materials. Global outsourcing is a better way to solve the problems of insufficient production conditions and low added value manufacturing links of innovation subjects. At this time, the changes in global outsourcing models will also bring risks. (Global outsourcing risk) A8 Because offshore outsourcing is global competition, although the main players in this competition are enterprises, the overall competitiveness of the country is crucial. Due to the relatively low cost, developing countries have certain advantages in global competition. (Fierce outsourcing competition) A10 Service outsourcing is an important way for countries to participate in the division of economic globalization in the development of the internet’s information, which is also an important way to enhance the status of the global value chain. (Service outsourcing) |

| 14 | International OEM scale of green manufacturing products | A6 On the other hand, the OEM scale will lead to competition for orders among agents in the international market, resulting in fierce competition among enterprises. (Competing for orders) A9 China is the world’s largest producer and has become a “world factory”, especially in the field of consumer goods such as clothing, bags, and 3C digital products. At the same time, the OEM model also supports most of the world’s famous brands. (OEM model) A13 Large-scale orders can form a relatively stable scale benefit, but we have to admit that the biggest defect of the OEM model is that it cannot control its own development direction. (Disadvantages of OEM) |

| 15 | Global green manufacturing technology transformation | A2 The enterprise has 2837 units of advanced production equipment, more than 20% of which are imported large-scale pieces of intelligent equipment. (Production equipment) A8 Enterprises consider investment in technological transformation as the breakthrough point that will drive investment and contribute to stable growth. At the same time, it will integrate information technology into R&D, production, and circulation; promote the integration of informatization and industrialization; help with transformation. (Technical transformation) A22 Enterprises actively recommend major technical transformation projects that meet the policy and market prospects for financial institutions and promote cooperation between banks and enterprises, striving for loan support. (Broaden financing channels) A24 The company guides and vigorously promotes advanced manufacturing modes, such as intelligent manufacturing, lean manufacturing, and flexible manufacturing, and seeks to use the new generation of production and manufacturing modes, such as concurrent engineering, networked manufacturing, and collaborative manufacturing. (Informatization) |

| 16 | Compatibility of existing international production system and green innovation | A7 Enterprises have begun to use information technology to compete with each other. This competition tends to be fast, flexible, automatic, and global. The information technology revolution is changing the competition modes of enterprises. (Technology change) A9 A reasonable arrangement of production sites and the implementation of different management modes are new ways for enterprises to continuously explore and improve their economic benefits. (Increasing competition) |

| 17 | The increase in global green manufacturing costs | A8 The government issues reasonable low-carbon standards and strengthens law enforcement. To implement low-carbon standards, we should treat every enterprise fairly. If some enterprises which fail to meet the standards, they should be punished correspondingly. (Low-carbon emission standards) A19 In the process of implementing green innovation, enterprises need to invest considerable human resources and funds. If the government can provide subsidies for enterprises at this time, many problems could be solved for the development of green innovation. (Government subsidy) A21 For enterprises using current traditional modes of production development, income is relatively optimistic. If the government requires enterprises to reduce their carbon emissions, then it needs to invest a large amount of funds for the implementation of green innovation. (Mandatory rules and regulations) |

| 18 | Proportion of global green marketing personnel input | A1 Enterprises should invite professionals to organize marketing personnel training courses regularly. (Organizational training) A5 The enterprise provides performance rewards to its marketing personnel. The sales champion of the week is selected at the weekly meeting, and the corresponding material rewards are awarded. (Performance Award) A13 In the past two years, the company has employed excellent sales personnel with high salaries, implementing rich material rewards and development space. (Introduction of talents) A16 Enterprises have rich Mid Year Awards every year. To maintain excellent employees, the company has implemented corresponding ladder type welfare treatment. (Prevent the brain drain) |

| 19 | Proportion of global green marketing investment | A3 Enterprises will regularly invite professionals to give relevant lectures, thus training their employees. (Talent training mode) A12 Due to the commodity sales, business indicators, and other reasons, it is necessary to achieve the expected business objectives through various marketing means, such as advertising, price reduction, bundling, purchases and gifts, rebates, gift distributions, free trials, and other marketing means. (Promotional activities) A15 Enterprises take 3% off their annual planned turnover as their marketing capital investment. (Budget standard) A18 Formulate a marketing fund use plan, effectively control all the investment funds, and make full use of (and determine) the flow direction of each fund. (Fund use plan) |

| 20 | International demand level for green products | A7 Now consumers pay more attention to energy conservation and environmental protection. When they buy products, they also pay more attention to this aspect of performance. Therefore, green products represent an opportunity. (Green market demand) A12 At present, enterprises offer both traditional innovative products and new green products. Given the changing trends of sales in the last three months, the demand for green products is gradually increasing. (Demand for green products) A18 In recent years, the haze problem has become increasingly more serious, environmental problems are increasingly focused on by the public, China’s per capita consumption level has improved, and the public’s awareness of low-carbon life is becoming stronger. (Public awareness of environmental protection) |

| 21 | International market recognition of green products in the manufacturing industry | A3 Using the results of the customer’s purchase information feedback, the company’s new green products can better meet the needs of consumers than the original traditional innovative products. (Consumer satisfaction) A4 To improve public awareness of environmental protection, the news media actively report and promote the concept of green innovation. (Media publicity) A11 Increasingly more consumers tend to buy green products when they buy products, and their awareness of energy conservation and emission reduction is becoming stronger. (Environmental awareness of consumers) A14 In recent years, the emergence of green products, such as electric vehicles and wind power generation, has embodied enterprises’ R&D, and managers are paying more attention to the green development of enterprises. (Green development strategy) |

| 22 | International market share of green products | A1 The international competitiveness of an industry is ultimately reflected in the share of its products in the international market. (International market share) A3 The company adheres to the business philosophy of focusing on foreign trade supplemented by domestic trade, continuously expanding its market share in the international market; the market in China is also increasing. (Expanding market share) A10 Teamwork develops the international market; at the same time, it expands the international market share and gradually establishes a company image of “quality first, service first”. (Developing international market) |

| 23 | Competition intensity of green products in the international market | A6 Now, the profits of traditional BX products have been squeezed to their limits, and other competitors have begun to save energy. Low energy consumption products are a bright spot when looking for new business opportunities, but they will be gradually eliminated if they do not transform in time. (Fierce market competition) A9 When enterprises hold a seminar, they mention that they should regard green innovation from a strategic perspective. Managers always remind employees that green innovation has become the development trend of the whole industry. (Industry development trend) |

| 24 | Green products’ share of existing international marketing channels | A7 The international market for manufacturing green products (processes, services) requires changes; its recognition is not high enough, and the international market share of manufactured green products (processes, services) is too small. Moreover, international market competition is fierce, and it is difficult to use existing international marketing channels. (International market channel) A13 The high proportion of existing marketing channels is an important area for the success of new product marketing. (Marketing Channel) |

| 25 | Commercialization and internationalization of green technology | A1 Since entering the 21st century, international management has become the future development goal of enterprises; this will be the result of the rapid development of economic globalization and production internationalization. (International operation) A11 We investigated the internationalization degree of chess enterprises at the micro level, including the financing ability, asset utilization ability, internationalization of science and technology enterprises, technological innovation ability, and human capital. (Degree of internationalization) A17 After the development of recent years, the commercialization, industrialization, and internationalization of green technology of our enterprises have made great progress. (Commercialization and internationalization of green technology) |

| 26 | The intensity of green technical barriers to trade in the international community | A6 Technical barriers to trade (TBTs) are the most effective means to establish trade barriers and promote trade protectionism. (Trade protection) A16 Many countries have formulated a series of laws and regulations on their packaging and labeling to prevent the waste generated by packaging machinery from posing a threat to the ecological environment, human beings, animals, and plants. From the perspective of environmental protection and energy conservation, this has a positive effect, but it forces the exporters to change their packaging constantly, so they lose many trade opportunities. (Label rules) |

| 27 | Proportion of global green service personnel input | A1 Our service staff are all undergraduates or above. They have a strong sense of customer service and good communication skills. (Staff requirements) A8 After-sales service is actually the beginning of the second stage of sales. After-sales service personnel positions are specifically set up by the marketing department to serve the last link of marketing. (After-sales service personnel) A12 We seek excellent talents in domestic and foreign markets, introduce a large number of high-level talents that can guide the development of enterprises, and recruit excellent graduates from major universities across the country to facilitate large-scale talent introduction. (Talent introduction) |

| 28 | Proportion of global green service investments | A2 The enterprise’s annual service capital investment accounts for more than 10% of the total sales revenue. (Service investment) A7 Since last year, we have increased a part of our funds in after-sales services, which are used for product installation, introduction, debugging, customer training, loss reporting, and maintenance for a period of time after sales. (Service fee) A16 The percentage control method of the after-sales service cost refers to the percentage of each after-sales service cost in terms of sales volume. This percentage can be based on the current amount in the budget or that in the past. (Percentage control method) |

| 29 | Coverage of global green service outlets | A3 The after-sale service outlets of the enterprise are all above the prefecture-level cities in China. In the next three years, the enterprise will strive to increase the number of its after-sale service outlets in county-level cities. (After-sale service outlets) A5 The enterprise will provide tracking services, that is, a regular follow-up or telephone follow-up. These follow-ups will solve all kinds of problems found by users in the process of use and avoid further deterioration of the problems. (Tracking service) A6 The enterprise will place spare equipment in the after-sale outlet according to the situation. Users can use this equipment when accidents occur to not affect the normal work of users. (Spare equipment service) |

| 30 Thirty | Global level of green product supply chain | A2 In the background of economic globalization, the level of the national supply chain determines its resource allocation ability, coordination, and service support. Especially in the process of promoting “one belt, one road” construction, we need to improve our overall planning capabilities by improving the level of the supply chain. (The level of the supply chain) A20 The integration ability of the supply chain and collaborative efficiency have become the core areas of competitiveness in enterprises, industries, and even the national economy. (The integration and collaboration of the supply chain) |

| 31 | Global after-sale technical service ability of green products | A4 The system service ability of the enterprise is very strong. It has an experienced engineering service team that can provide after-sale and engineering services, and they can quickly solve on-site problems. (Service ability) A6 The enterprise arranges technical personnel to introduce the product function to the users before delivery. After delivery, these personnel conduct centralized training for users. This training service will ensure that users are fully aware of and familiar with the operation of the products, even allowing them to carry out simple maintenance themselves. (Operation instruction) A12 The enterprise requires after-sale service staff to fill in the maintenance report promptly after a repair. The maintenance report should include the cause of the failure, the handling situation, and the user’s opinions. Each party retains one copy of the maintenance report as a record. (Maintenance report) |

References

- Tong, J.D.; Xie, D.Y.; Bao, Q.; Huang, Q.H.; Li, X.Y.; Liu, Z.B.; Jin, B.; Yu, M.J.; Wang, X.S. “Anti Globalization” and the Transformation and Upgrading of the Real Economy. Chin. Ind. Econ. 2017, 6, 5–59. [Google Scholar]

- Zhang, F.; Gallagher, K.S. Innovation and technology transfer through global value chains: Evidence from china’s pv industry. Energy Policy 2016, 94, 191–203. [Google Scholar] [CrossRef]

- Yin, S.; Zhang, N.; Li, B.Z.; Dong, H.M. Enhancing the effectiveness of multi-agent cooperation for green manufacturing: Dynamic co-evolution mechanism of a green technology innovation system based on the innovation value chain. Environ. Impact Assess. Rev. 2021, 86, 106475. [Google Scholar] [CrossRef]

- Müller, J.M.; Voigt, K.I. Sustainable industrial value creation in SMEs: A comparison between industry 4.0 and made in China 2025. Int. J. Precis. Eng. Manuf. Green Technol. 2018, 5, 659–670. [Google Scholar] [CrossRef]

- Saunila, M.; Ukko, J.; Rantala, T. Sustainability as a driver of green innovation investment and exploitation. J. Clean. Prod. 2018, 179, 631–641. [Google Scholar] [CrossRef]

- Gupta, H.; Barua, M.K. A grey DEMATEL-based approach for modeling enablers of green innovation in manufacturing organizations. Environ. Sci. Pollut. Res. 2018, 25, 9556–9578. [Google Scholar] [CrossRef] [PubMed]

- Köhler, A.R.; Som, C. Risk preventative innovation strategies for emerging technologies the cases of nano-textiles and smart textiles. Technovation 2014, 34, 420–430. [Google Scholar] [CrossRef]

- Song, M.; Fisher, R.; Kwoh, Y. Technology challenges of green innovation and sustainable resource management with large scale data. Technol. Forecast. Soc. Chang. 2019, 144, 361–368. [Google Scholar] [CrossRef]

- Meroño-Cerdán, A.L.; López-Nicolás, C.; Molina-Castillo, F.J. Risk aversion, innovation and performance in family firms. Econ. Innov. New Technol. 2018, 27, 189–203. [Google Scholar] [CrossRef]

- Mercado-Caruso, N.; Segarra-Oña, M.; Ovallos-Gazabon, D.; Peiró-Signes, A. Identifying Endogenous and Exogenous Indicators to Measure Eco-Innovation within Clusters. Sustainability 2020, 12, 6088. [Google Scholar] [CrossRef]

- Bernauer, E.; Kammerer, S. Explaining Green Innovation. In Center for Comparative and International Studies; Working Paper; University of Zurich: Zurich, Switzerland, 2006; pp. 1–16. [Google Scholar] [CrossRef]

- Gang, Z.; Zhang, X.J. Review and Prospect of foreign green innovation research. Foreign Econ. Manag. 2011, 33, 25–32. [Google Scholar]

- Zhao, Y. Innovation Economics; China Economic Press: Beijing, China, 2006; p. 30. [Google Scholar]

- Otway, H.J.; Von Winterfeldt, D. Beyond acceptable risk: On the social acceptability of technologies. Policy Sci. 1982, 14, 247–256. [Google Scholar] [CrossRef]

- Sun, Y.Y.; Bi, K.X.; Yin, S. Measuring and integrating risk management into green innovation practices for green manufacturing under the global value chain. Sustainability 2020, 12, 545. [Google Scholar] [CrossRef]

- George, C.; Hartmann, M.; Mvers, B. Technical Risk, Produet Specifications and Market Risk; The MIT Press: Cambridge, MA, USA, 2003; pp. 178–186. Available online: https://www.mendeley.com/catalogue/5b79699d-faa5-3bd7-81ca-715b44c8e433/ (accessed on 17 November 2020).

- George, S.D.; Shoemaker, P.J.H. Wharton on Managing Emerging Technologies; Xuaxia Publishing House: Beijing, China, 2002; pp. 185–190. [Google Scholar]

- Peter, L. The importance of integtating risk in retrospective evaluations of research and development. Res. Eval. 2012, 21, 152–165. [Google Scholar]

- Miorando, R.; Ribeiro, J.L.D.; Cortimiglia, M.N. An economic–probabilistic model for risk analysis in technological innovation projects. Technovation 2014, 34, 485–498. [Google Scholar] [CrossRef]

- Gong, C. Risk Management and Risk Sharing of Scientific and Technological Innovation. Chin. Mark. 2011, 29, 27. [Google Scholar]

- Fan, H.; Xu, X. Risk Analysis of Technological Innovation. Innov. Entrep. Manag. 2017, 2, 1–10. [Google Scholar]

- Yang, C.; Bi, K.; Hu, R. Transmission Mechanism of Green Innovation Power of Industrial Enterprises in an Open Economy. Syst. Eng. 2018, 36, 79–90. [Google Scholar]

- Horbach, J.; Rammer, C.; Rennings, K. Determinants of eco-innovations by type of environmental impact—The role of regulatory push pull, technology push and market pull. Ecol. Econ. 2012, 78, 112–122. [Google Scholar] [CrossRef]

- El-Kassar, A.N.; Singh, S.K. Green innovation and organizational performance: The influence of big data and the moderating role of management commitment and HR practices. Technol. Forecast. Soc. Chang. 2019, 144, 483–498. [Google Scholar] [CrossRef]

- Fernando, Y.; Jabbour CJ, C.; Wah, W.X. Pursuing green growth in technology firms through the connections between environmental innovation and sustainable business performance: Does service capability matter? Resour. Conserv. Recycl. 2019, 141, 8–20. [Google Scholar] [CrossRef]

- Trott, A.H. Innovation risks of strategic outsourcing. Technovation 2006, 26, 672–681. [Google Scholar]

- Baryannis, G.; Validi, S.; Dani, S.; Antoniou, G. Supply chain risk management and artificial intelligence: State of the art and future research directions. Int. J. Prod. Res. 2019, 57, 2179–2202. [Google Scholar] [CrossRef]

- Ma, X.M.; Li, J. Research on Risk Identification of Harbin Mudanjiang Railway Passenger Dedicated Line Construction Project Based on Fault Tree. Sci. Technol. Manag. 2016, 18, 82–86. [Google Scholar]

- Xiaodong, L.; Kexin, B.; Hui, Y. Research on Risk Management of Low Carbon Technology Breakthrough Innovation under Global Value Chain: A Case Study of Chinese Manufacturing Industry. Chin. Soft Sci. 2016, 11, 152–166. [Google Scholar]

- Glaser, B.G.; Strauss, A.L. The Discovery of Grounded Theory: Strategies for Qualitative Research; Aldine Publishing Company: Chicago, IL, USA, 1967. [Google Scholar]

- Wenhui, Z. Knowledge Service, Value Co-creation and Innovation Performance: A Multi Case Study Based on Grounded Theory. Sci. Res. 2015, 33, 567–573. [Google Scholar]

- Zhang, B.; Zhang, Q. Research on Influencing Factors of Members Willingness to Cooperate based on Grounded Theory. J. Manag. 2015, 8, 1224–1229. [Google Scholar]

- Goldkuhl, G.; Cronholm, S. Multi-grounded theory-Adding theoretical grounding to grounded theory. Int. J. Qual. Methods 2015, 2, 187–205. [Google Scholar] [CrossRef]

- Su, Y.; Wu, N.; Zhou, X. Entrepreneurial Process Model from Institutional Perspective: A Multi Case Study based on Grounded Theory. Nankai Manag. Rev. 2017, 2, 181–192. [Google Scholar] [CrossRef]

- Fassinger, R.E. Paradigms, praxis, problems and promise: Grounded theory in counseling psychologyresearch. J. Couns. Psychol. 2005, 52, 156–166. [Google Scholar] [CrossRef]

- Xu, Y.; Qi, L.; Lv, X. Identification of Key Drivers of Low Carbon Innovation Performance of Manufacturing Enterprises based on Grounded Theory. Chin. Sci. Technol. Forum 2018, 3, 81–90. [Google Scholar]

- Xu, J.; Qu, X. Qualitative Research on Driving Factors of Environmental Technology Innovation Behavior of Equipment Manufacturing Enterprises based on Grounded Theory. Manag. Rev. 2014, 26, 90–101. [Google Scholar]

- Yin, B.; Xiao, W.; Liu, Y. Green R&D investment and the Rise of “made in China” in Global Value Chain. Sci. Res. 2018, 36, 1395–1403. [Google Scholar]

- Wu, D.D.; Kefan, X.; Hua, L. Modeling technological innovation risks of an entrepreneurial team using system dynamics: An agent-based perspective. Technol. Forecast. Soc. Chang. 2010, 776, 857–869. [Google Scholar] [CrossRef]

- Wu, J.; Wu, Z. Integrated risk management and product innovation in China: The moderating role of board of directors. Technovation 2013, 11, 1–11. [Google Scholar] [CrossRef]

- Su, Y.; Li, T.C. Simulation analysis of knowledge transfer in a knowledge alliance based on a circular surface radiator model. Complexity 2020, 2020, 4301489. [Google Scholar] [CrossRef]

- Gao, X.; Ye, H.; Kang, Y. Research on Enterprise Technology Innovation Risk Management based on Risk Matrix. Sci. Technol. Manag. Res. 2014, 34, 8–11. [Google Scholar]

- Lu, X. Enterprise’s Low Carbon Innovation Collaborative Model based on Urban Green Transformation. Sci. Technol. Prog. Countermeas. 2015, 4, 67–71. [Google Scholar]

- Chen, Y.; Liu, J.; Xie, K. Risk in integrated leapfrogging mode of technological innovation. Kybernetes 2012, 4110, 1423–1439. [Google Scholar] [CrossRef]

- Mao, J.; Huo, B. Risk and Evaluation of Technological Innovation. Research on Quantitative Economy. Technol. Econ. 2002, 2, 1–5. [Google Scholar]

- Yin, S.; Zhang, N.; Li, B. Improving the Effectiveness of Multi-Agent Cooperation for Green Manufacturing in China: A Theoretical Framework to Measure the Performance of Green Technology Innovation. Int. J. Environ. Res. Public Health 2020, 17, 3211. [Google Scholar] [CrossRef] [PubMed]

- Xiao, T.; Liu, H.; Ye, P. Research on the Influencing Factors of Service Innovation of Manufacturing Enterprises. J. Manag. 2014, 4, 591–598. [Google Scholar]

- Jiang, G. On the Relationship between After-Sales Technical Support and After-Sales Technical Support and Customer Satisfaction. Silicon Val. 2013, 1, 159–181. [Google Scholar]

- Yin, S.; Zhang, N.; Dong, H.M. Preventing COVID-19 from the perspective of industrial information integration: Evaluation and continuous improvement of information networks for sustainable epidemic prevention. J. Ind. Inf. Integr. 2020, 19, 100157. [Google Scholar] [CrossRef]

| Main Categories | Corresponding Categories | The Connotations of Categories |

|---|---|---|

| Green R&D risk under the global value chain | Proportion of global green R&D personnel investments | In the process of global green R&D, the proportion of relevant R&D personnel to the total number of employees in the world. |

| Proportion of global green R&D investments | In the process of global green R&D, the proportion of R&D investment in operating revenue. | |

| Stability of global green R&D | In the global green R&D process of the manufacturing industry, due to the complex, advanced, and mature characteristics of green technology, green technology and its changes are uncertain. | |

| Life cycle uncertainty of global green R&D | In addition to personnel and capital investment, R&D also needs time to invest. Due to the high complexity of green R&D, the length of time for new green technology to replace the green technology under development is uncertain. | |

| Stability of global green technology applications | The possibility that the low-orbit green technology being developed will be replaced by other, more advanced, high-orbit green technology. | |

| The difficulty of the international transfer of green technology | Green innovation technology can be transferred from one party to another. The success or failure of green technology diffusion and the achievement of transformation in different regions is mainly limited by the supply capacity of the technology providers. Another reason is the maturity of the technology itself. | |

| International protection of green technology patents | To limit the abuse of intellectual property rights, relatively uniform international laws will be produced through the coordination of international intergovernmental organizations in accordance with the relevant provisions of various countries’ intellectual property rights to protect green technology patents. | |

| Green manufacturing risks under the global value chain | Proportion of global green manufacturing personnel investments | In the global green manufacturing process of the manufacturing industry, the number of manufacturing personnel accounts for the proportion of global employees in the enterprise. |

| Proportion of global green manufacturing investments | In the global green manufacturing process of the manufacturing industry, the amount of manufacturing capital investment accounts for the proportion of the enterprise’s global operating income. | |

| Production scale of global green manufacturing products | In the global green manufacturing process of the manufacturing industry, the number of land resources, human resources, machines, and equipment resources invested in manufacturing green products. | |

| Requirements of global green manufacturing products on the technical performance of raw materials | To produce green products, the material and performance indexes of raw materials must meet the requirements of the process. | |

| Quality and performance levels of global green manufacturing products | The quality and performance of green products produced in the global green manufacturing process of the manufacturing industry are good or bad. | |

| Global outsourcing scale of green products | Enterprises in other countries complete the processing and manufacturing activities assigned by their own countries to complete a certain link or process, and in this process, the number of manufacturing contracts undertaken by enterprises in other countries provides the scale of global outsourcing. | |

| International OEM scale of green manufacturing products | In the global green manufacturing process of the manufacturing industry, OEM enterprises can provide the scale of green products according to the requirements of the client. | |

| The transformation of global green manufacturing technology | To better produce green products, an enterprise transforms its existing equipment according to the presence of higher technology. | |

| Compatibility of the existing international production system and green innovation | The integration degree of the existing international manufacturing system and green technology in the manufacturing industry. | |

| Global green manufacturing cost increases | In the global manufacturing process of the manufacturing industry, due to the influence of the carbon emission system, carbon taxes, and other factors in various countries, the enterprise faces considerable extra expenses to increase the production costs of its green products. | |

| Green marketing risks under the global value chain | Proportion of global green marketing staff investments | In the global green marketing process of the manufacturing industry, the number of marketing staff accounts for the proportion of the total number of employees in the enterprise. |

| Proportion of global green marketing investments | In the process of global green marketing of the manufacturing industry, the proportion of marketing funds in operating revenue. | |

| International demand level of green products | In the international market, the total amount of green products in the manufacturing industry for which consumers have purchase intentions that can be realized. | |

| International market recognition of green products | In the international market, consumers’ affection for and satisfaction with the green products in the manufacturing industry. | |

| International market share of green products | The proportion of manufacturing green products in the international market sales of similar products. | |

| Competition intensity of green products in the international market | The total quantity, ability, and unfair competition of competitors producing green innovative products on the global market. | |

| Green products’ share of existing international marketing channels | The utilization of existing marketing outlets in the sales process of green products in the manufacturing industry. | |

| Commercialization and internationalization of green technology | The enterprise transforms green R&D achievements into green products and makes full use of various resources at home and abroad in cross-border economic cooperation. | |

| The intensity of green technical barriers to trade in the international community | The extent to which trade protection in the international community hinders the sale of green products on the international market. | |

| Green services under the global value chain | Proportion of global green service staff investments in the manufacturing industry | When enterprises provide green services on the international market, the number of their service staff accounts for the proportion of the total number of employees. |

| Proportion of global green service investments in the manufacturing industry | When enterprises provide green services on the international market, the amount of service funds accounts for the proportion of business income. | |

| Coverage of global green service outlets in the manufacturing industry | The proportion of the number of outlets provides green services based on the total number in all market areas. | |

| Global level of the green product supply chain in the manufacturing industry | The degree of the cross circulation of business flow, logistics, information flow, and capital flow from a global perspective in the process of enterprises purchasing raw materials and parts of green products (manufacturing intermediates, to products, to final products) and delivering green products to consumers through sales channels. | |

| Global after-sale technical service ability of green products in the manufacturing industry | The service quality and efficiency of the installation configuration, use guidance, and fault handling. The service quality and efficiency of information inquiry, customer information acquisition, consultation, and technical training provided by the enterprises. |

| Typical Relational Structure | Connotations of the Relational Structure |

|---|---|

| Green R&D risk under the global value chain → Green Innovation | The proportion of R&D personnel investments, R&D capital investments, the stability of R&D, uncertainty of the R&D life-cycle, the difficulty of the international transfer of technology, and international protection of the technology patents have an important impact on the green innovation of the manufacturing industry. |

| Green manufacturing risk under the global value chain → Green Innovation | The proportion of manufacturing personnel investment, the proportion of manufacturing capital investment, the production scale, the degree of technical performance requirements of raw materials, the quality and performance level of manufactured products, the scale of global outsourcing, the scale of OEM, the degree of technological transformation, existing international production systems, the compatibility of green innovation, and the increase rate of costs play an important role in the green innovation of the manufacturing industry. |

| Green marketing risk under the global value chain → Green Innovation | The proportion of marketing staff investment, the proportion of marketing capital investment, the level of international demand, the recognition degree of green products on the international market, the international market share, the competitive intensity of the international market, the share of green products in the existing international marketing channels, the level of technological commercialization and internationalization, and the intensity of technical trade barriers within international society play an important role in the green innovation of the manufacturing industry. |

| Green service risk under the global value chain → Green Innovation | The proportion of service staff investment, the proportion of service capital investment, the coverage of the service outlets, product supply chain globalization, and global after-sale technical service capacity play an important role in the green innovation of the manufacturing industry. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Wu, L.; Yin, S. Green Innovation Risk Identification of the Manufacturing Industry under Global Value Chain Based on Grounded Theory. Sustainability 2020, 12, 10270. https://doi.org/10.3390/su122410270

Sun Y, Wu L, Yin S. Green Innovation Risk Identification of the Manufacturing Industry under Global Value Chain Based on Grounded Theory. Sustainability. 2020; 12(24):10270. https://doi.org/10.3390/su122410270

Chicago/Turabian StyleSun, Yingying, Lei Wu, and Shi Yin. 2020. "Green Innovation Risk Identification of the Manufacturing Industry under Global Value Chain Based on Grounded Theory" Sustainability 12, no. 24: 10270. https://doi.org/10.3390/su122410270

APA StyleSun, Y., Wu, L., & Yin, S. (2020). Green Innovation Risk Identification of the Manufacturing Industry under Global Value Chain Based on Grounded Theory. Sustainability, 12(24), 10270. https://doi.org/10.3390/su122410270