Capital Intensity and Labour Productivity in Waste Companies

Abstract

:1. Introduction

2. Literature Review

- Y is the output,

- A is the level of technology,

- K is the capital stock,

- L is the quantity of labour.

- (TFA + IFA) are tangible + intangible fixed assets,

- R is operating revenues,

- CE is Cost of employees,

- LP is labour productivity,

- c.l. ratio is the capital–labour ratio,

- FAT is the Fixed Assets Turnover.

3. Materials and Methods

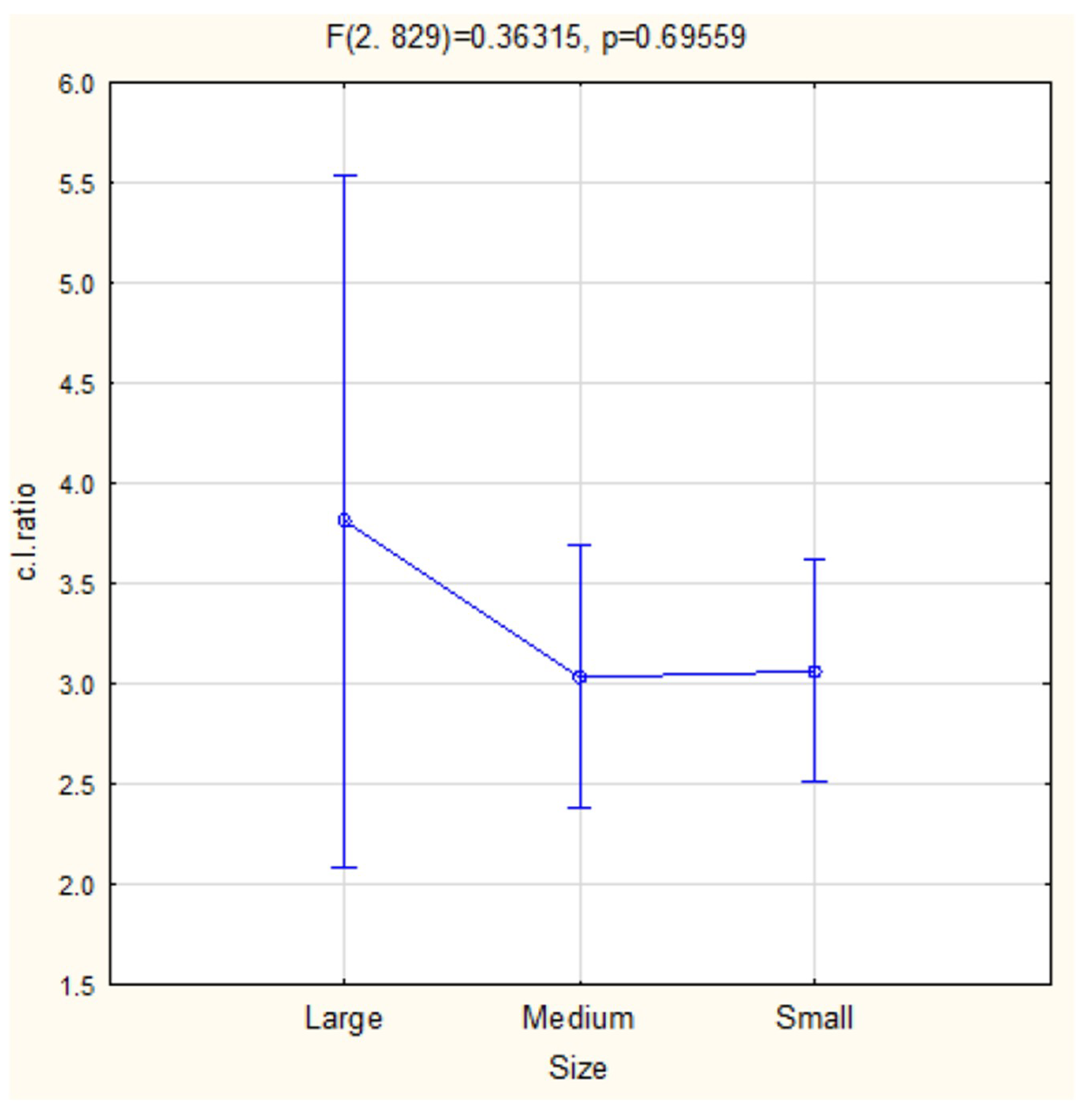

- H: Xl = X2 = … = Xk = 0 X (groups of companies according to size) = 1, …,3;

- respectively,

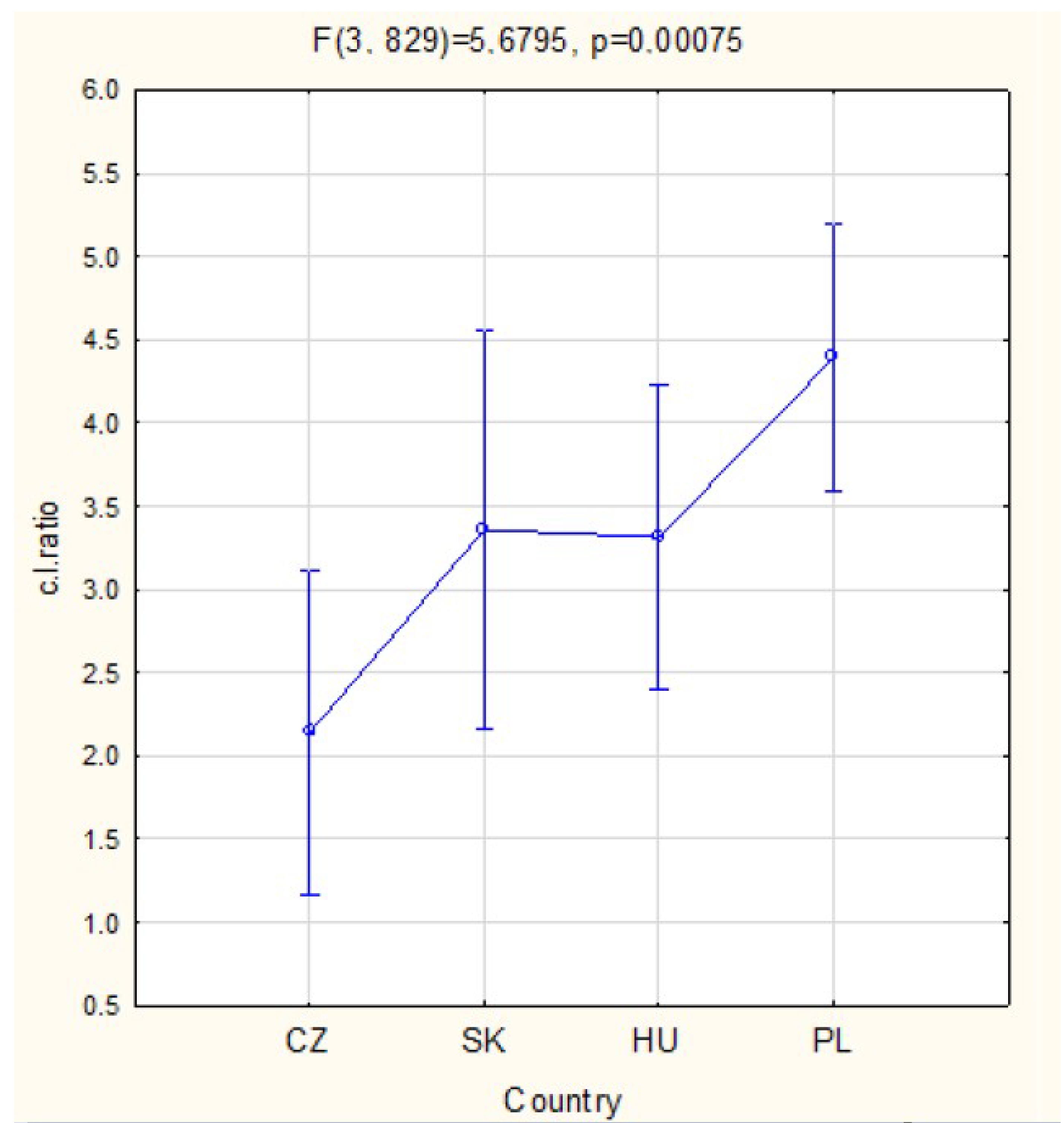

- H: Yl = Y2 = … = Yk = 0, Y (groups of companies by V4 countries) = 1, …,4;

- respectively,

- H: Zl = Z2 = … = Zk = 0, Z (groups of companies by economic activities) = 1, …, 3.

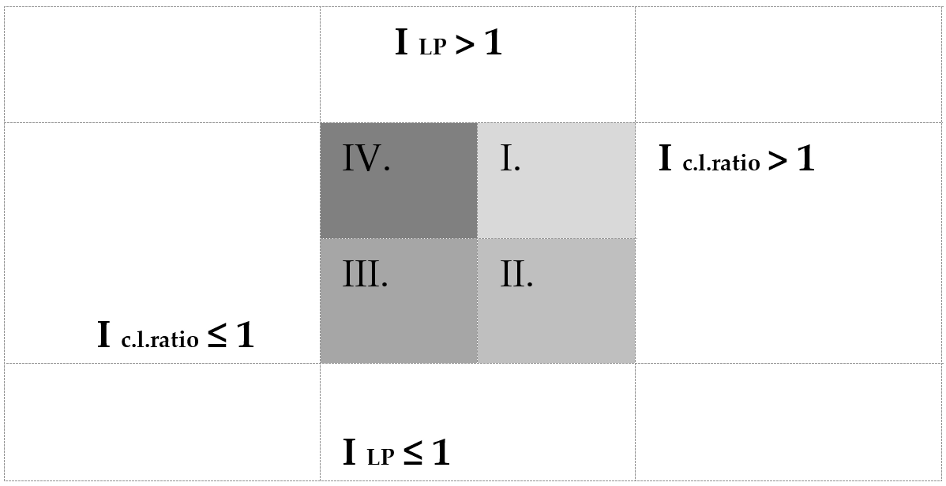

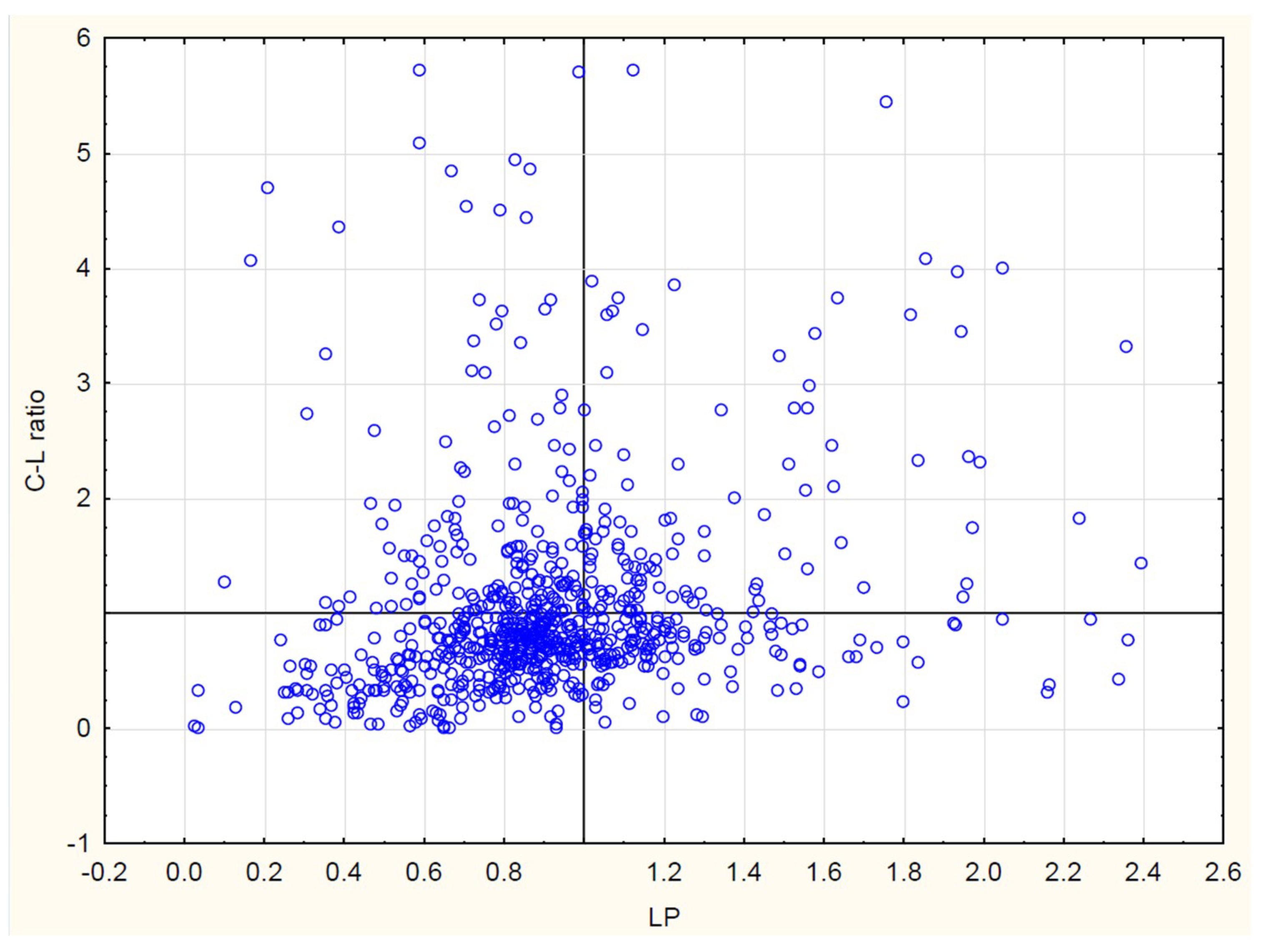

- Quadrant I: I c.l. ratio > 1 ∧ I LP > 1;

- Quadrant II: I c.l. ratio > 1 ∧ I LP ≤ 1;

- Quadrant III: I c.l. ratio ≤ 1 ∧ I LP ≤ 1;

- Quadrant IV: I c.l. ratio ≤ 1 ∧ I LP > 1.

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- EC. Impact Assessment Guidelines. SEC(2009)92/1. Available online: https://ec.europa.eu/transparency/regdoc/rep/2/2009/EN/2-2009-92-EN-1-1.PDF (accessed on 1 June 2020).

- Sandhu, K.; Burton, P.; Dedekorkut-Howes, A. Between hype and veracity; privatisation of municipal solid waste management and its impacts on the informal waste sector. Waste Manag. 2017, 59, 545–556. [Google Scholar] [CrossRef]

- Bartolacci, F.; Paolini, A.; Quaranta, A.G.; Soverchia, M. Assessing factors that influence waste management financial sustainability. Waste Manag. 2018, 79, 571–579. [Google Scholar] [CrossRef] [PubMed]

- Agovino, M.; Matricano, D.; Garofalo, A. Waste management and competitiveness of firms in Europe: A stochastic frontier approach. Waste Manag. 2020, 102, 528–540. [Google Scholar] [CrossRef] [PubMed]

- D’Onza, G.; Greco, G.; Allegrini, M.J. Full cost accounting in the analysis of separated waste collection efficiency: A methodological proposal. Environ. Manag. 2016, 167, 59–65. [Google Scholar] [CrossRef] [PubMed]

- Kapur, S. Financial viability and problems of manufacturers dealing in waste based business. Indian J. Econ. Dev. 2015, 11, 751–754. [Google Scholar]

- Moktadir, M.A.; Kumar, A.; Ali, S.M.; Paul, S.K.; Sultana, R.; Rezaei, J. Critical success factors for a circular economy: Implications for business strategy and the environment. Bus. Strategy Environ. 2020. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Chiaroni, D.; Del Vecchio, P.; Urbinati, A. Designing business models in circular economy: A systematic literature review and research agenda. Bus. Strategy Environ. 2020, 29, 1734–1749. [Google Scholar] [CrossRef]

- Jabbour, A.; Luiz, J.V.R.; Luiz, O.R.; Jabbour, C.J.C.; Ndubisi, N.O.; de Oliveira, J.H.C.; Horneaux, F. Circular economy business models and operations management. J. Clean. Prod. 2019, 235, 1525–1539. [Google Scholar] [CrossRef]

- Pieroni, M.P.P.; McAloone, T.C.; Pigosso, D.C.A. Configuring new business models for circular economy through product–service systems. Sustainability 2019, 11, 3727. [Google Scholar] [CrossRef] [Green Version]

- Griffith, R.; Huergo, E.; Mairesse, J.; Peters, B. Innovation and productivity across four European countries. Oxf. Rev. Econ. Policy 2006, 22, 483–498. [Google Scholar] [CrossRef]

- Hashi, I.; Stojcic, N. The impact of innovation activities on firm performance using a multi-stage model: Evidence from the Community Innovation Survey 4. Res. Policy 2013, 42, 353–366. [Google Scholar] [CrossRef] [Green Version]

- Gogokhia, T.; Berulava, G. Business environment reforms, innovation and firm productivity in transition economies. Eurasian Bus. Rev. 2020, 1–25. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Hult, G.T.M.; Ketchen, D.J.; Calantone, R.J. Effects of firm-, industry-, and country-level innovation on firm performance. Mark. Lett. 2020, 31, 231. [Google Scholar] [CrossRef]

- Henriques, A.A.; Camanho, A.S.; Amorim, P.; Silva, J.G. Performance benchmarking using composite indicators to support regulation of the Portuguese wastewater sector. Util. Policy 2020, 66. [Google Scholar] [CrossRef]

- Jain, N.K.; Panda, A.; Choudhary, P. Institutional pressures and circular economy performance: The role of environmental management system and organisational flexibility in oil and gas sector. Bus. Strategy Environ. 2020. [Google Scholar] [CrossRef]

- Tortorella, G.; Silva, G.; Campos, L.M.S.; Pizzeta, C.; Latosinski, A.; Soares, A. Productivity improvement in solid waste recycling centres through lean implementation aided by multi-criteria decision analysis. Benchmarking 2018, 25, 1480. [Google Scholar] [CrossRef]

- Cobb, C.W.; Douglas, P.H. A theory of production. Am. Econ. Rev. 1928, 8, 139–1965. [Google Scholar]

- Barro, R.J. Notes on growth accounting. J. Econ. Growth 1999, 4, 119–137. [Google Scholar] [CrossRef]

- Kojic, V.; Lukac, Z. An alternative approach to solving cost minimisation problem with Cobb–Douglas technology. Cent. Eur. J. Oper. Res. 2018, 26, 629. [Google Scholar] [CrossRef]

- Stijepic, D. An argument against Cobb-Douglas production functions (in multi-sector-growth modeling). SSRN 2015. [Google Scholar] [CrossRef] [Green Version]

- Kleyn, J.; Arashi, M.; Bekker, A.; Millard, S. Preliminary testing of the Cobb–Douglas production function and related inferential issues. Commun. Stat. Simul. Comput. 2017, 46, 469. [Google Scholar] [CrossRef]

- Hossain, M.M.; Basak, T.; Majumder, A.K. Application of non-linear Cobb-Douglas production function with autocorrelation problem to selected manufacturing industries in Bangladesh. Open J. Stat. 2013, 3, 173–178. [Google Scholar] [CrossRef] [Green Version]

- Elburz, Z.; Cubukcu, K.M. Spatial effects of transport infrastructure on regional growth: The case of Turkey. Spat. Inf. Res. 2020. [Google Scholar] [CrossRef]

- Smirnov, R.G.; Wang, K. The Cobb-Douglas production function revisited. arXiv 2019, arXiv:1910.06739. [Google Scholar]

- Cysneiros, F.J.A.; Leiva, V.; Liu, S.; Marchant, C.; Scalco, P. A Cobb–Douglas type model with stochastic restrictions: Formulation, local influence diagnostics and data analytics in economics. Qual. Quant. 2019, 53, 1693–1719. [Google Scholar] [CrossRef]

- Lin, L.; Yuan, G.X.; Wang, H.; Xie, J. The stochastic incentive effect of venture capital in partnership systems with the asymmetric bistable Cobb–Douglas utility. Commun. Nonlinear Sci. Numer. Simul. 2019, 66, 109–128. [Google Scholar] [CrossRef]

- Ishikawa, A.; Fujimoto, S.; Mizuno, T. why does production function take the Cobb-Douglas form? Direct observation of production function using empirical data. Evol. Inst. Econ. Rev. 2020. [Google Scholar] [CrossRef]

- Concha, F.J.M. The general urban system. In Microeconomic Modeling in Urban Science, 1st ed.; Academic Press: Cambridge, MA, USA, 2018; pp. 157–199. [Google Scholar] [CrossRef]

- Gajdzik, B.; Gawlik, R. Choosing the production function model for an optimal measurement of the restructuring efficiency of the Polish metallurgical sector in years 2000–2015. Metals 2018, 8, 23. [Google Scholar] [CrossRef] [Green Version]

- Jarchow, C.E.; Morehouse, M.D.; Patrick, R.B.; Pois, J.; Vatter, W.J.; Ketchum, M.D.; Solomon, E. Capital sources and uses. J. Bus. 1954, 27, 33–37. [Google Scholar] [CrossRef]

- Ben Hassine, H.; Boudier, F.; Mathieu, C. The two ways of FDI R&D spillovers: Evidence from the French manufacturing industry. Appl. Econ. 2017, 49, 2395–2408. [Google Scholar] [CrossRef]

- Ngundu, M.; Ngepah, N. Growth effects of Foreign Direct Investment (FDI) from China and other sources in Africa: The role of institutional quality. J. Econ. Bus. 2019, 2. [Google Scholar] [CrossRef] [Green Version]

- Doytch, N.; Narayan, S. Does FDI influence renewable energy consumption? An analysis of sectoral FDI impact on renewable and non-renewable industrial energy consumption. Energy Econ. 2016, 54, 291–301. [Google Scholar] [CrossRef]

- Elfakhani, S.; Mackie, W. An analysis of net FDI drivers in BRIC countries. Compet. Rev. 2015, 25, 98–132. [Google Scholar] [CrossRef]

- Apostolov, M. Cobb–Douglas production function on FDI in Southeast Europe. Econ. Struct. 2016, 5, 10. [Google Scholar] [CrossRef] [Green Version]

- Winnicka-Popczyk, A. Capital sources of innovation financing in polish family businesses (the report of own research). In Proceedings of the New Challenges Of Economic And Business Development—2018; Productivity Economic Growth, Riga, Latvia, 10–12 May 2018; p. 790. [Google Scholar]

- Mura, L.; Kljucnikov, A.; Tvaronaviciene, M.; Androniceanu, A. Development trends in human resource management in small and medium enterprises in the visegrad group. Acta Polytech. Hung. 2017, 14, 105–122. [Google Scholar]

- Verderame, P.M.; Elia, J.A.; Li, J.; Floudas, C.A. Planning and scheduling under uncertainty: A review across multiple sectors. Ind. Eng. Chem. Res. 2010, 49, 3993–4017. [Google Scholar] [CrossRef]

- Chakraborty, A.; Malcolm, A.; Colberg, R.D.; Linninger, A.A. Optimal waste reduction and investment planning under uncertainty. Comput. Chem. Eng. 2004, 28, 1145–1156. [Google Scholar] [CrossRef]

- Butun, H.; Kantor, I.; Marechal, F. An optimisation approach for long-term industrial investment planning. Energies 2019, 12, 4076. [Google Scholar] [CrossRef] [Green Version]

- Ghosal, V. Demand uncertainty and the capital-labor ratio: Evidence from the US manufacturing sector. Rev. Econ. Stat. 1991, 73, 157–161. [Google Scholar] [CrossRef]

- Takahashi, H.; Mashiyama, K.; Sakagami, T. Does the capital intensity matter? Evidence from the postwar Japanese economy and other OECD countries. Macroecon. Dyn. 2012, 16, 103–116. [Google Scholar] [CrossRef]

- Gilje, E.P.; Taillard, J.P. Do private firms invest differently than public firms? Taking cues from the natural gas industry. J. Financ. 2016, 71, 1733–1778. [Google Scholar] [CrossRef]

- Berends, P.A.J.; Romme, A.G.L. Cyclicality of capital-intensive industries: A system dynamics simulation study of the paper industry. Omega Int. J. Manag. Sci. 2001, 29, 543–552. [Google Scholar] [CrossRef]

- Mason, G.; Osborne, M. Productivity, Capital-Intensity and Labour Quality at Sector Level in New Zealand And The UK (No. 07/01); New Zealand Treasury Working Paper; The Treasury: Wellington, New Zealand, 2007. [Google Scholar]

- Bjuggren, C.M. Employment protection and labor productivity. J. Public Econ. 2018, 157, 138–157. [Google Scholar] [CrossRef]

- Střeleček, F.; Lososová, J. An evaluation of the types of technical development in agriculture in the year 1995–2000. Agric. Econ. Czech 2003, 49, 151–165. [Google Scholar] [CrossRef] [Green Version]

- Hoffmann, V. Introduction to Business Economics: Director’s Analysis II; Czech Committee for Scientific-Management: Prague, Czech Republic, 1992; pp. 1–89. [Google Scholar]

- Volek, T.; Novotna, M. Labour productivity and technological intensities of small and medium enterprises in manufacturing. In Proceedings of the 12th International Days Of Statistics And Economics, Prague, Czech Republic, 6–8 September 2018; Loster, T., Pavelka, T., Eds.; Melandrium: Slany, Czech Republic, 2018; pp. 1884–1893. [Google Scholar]

- Pérez-López, G.; Prior, D.; Zafra-Gómez, J.L. Temporal scale efficiency in DEA panel data estimations. An application to the solid waste disposal service in Spain. Omega 2018, 76, 18–27. [Google Scholar] [CrossRef]

- Campos-Alba, C.M.; de la Higuera-Molina, E.J.; Perez-Lopez, G.; Zafra-Gomez, J.L. Measuring the efficiency of public and private delivery forms: An Application to the waste collection service using order-M data panel frontier analysis. Sustainability 2019, 11, 2056. [Google Scholar] [CrossRef] [Green Version]

- Perez-Lopez, G.; Prior, D.; Luis Zafra-Gomez, J.; Maria Plata-Diaz, A. Cost efficiency in municipal solid waste service delivery. Alternative management forms in relation to local population size. Eur. J. Oper. Res. 2016, 255, 583–592. [Google Scholar] [CrossRef]

- Montgomery, D.C.; Runger, G.C. Applied Statistics and Probability for Engineers, 4th ed.; Wiley: Hoboken, NJ, USA, 2007. [Google Scholar]

- Commission recommendation. Off. J. Eur. Union 2003, L 124, 0036–0041. Available online: http://eur-lex.europa.eu/eli/reco/2003/361/oj (accessed on 17 July 2020).

- Eurostat. Annual Enterprise Statistics by Size Class for Special Aggregates of Activities (NACE Rev. 2). Available online: https://ec.europa.eu/eurostat/web/products-datasets/-/sbs_sc_sca_r2 (accessed on 20 July 2020).

- Fischer, C.J. The development and achievements of EU waste policy. Mater. Cycles Waste Manag. 2011, 13. [Google Scholar] [CrossRef]

- Tausova, M.; Mihalikova, E.; Culkova, K.; Stehlikova, B.; Taus, P.; Kudelas, D.; Strba, L. Recycling of communal waste: Current state and future potential for sustainable development in the EU. Sustainability 2019, 11, 2904. [Google Scholar] [CrossRef] [Green Version]

- Posta, V. A statistical analysis of productivity and compensation of labor in the EU. Stat. Stat. Econ. J. 2018, 98, 338–351. [Google Scholar]

- Simões, P.; Marques, R.C. How does the operational environment affect utility performance? A parametric study on the waste sector. Resour. Conserv. Recycl. 2011, 55, 695–702. [Google Scholar] [CrossRef]

- Banai, A.; Lang, P.; Nagy, G.; Stancsics, M. Waste of money or growth opportunity: The causal effect of EU subsidies on Hungarian SMEs. Econ. Syst. 2020, 44. [Google Scholar] [CrossRef]

- Leitmanová, I. Vývoj trhu práce z regionálního hlediska [The development of labour market from regional point of view]. Politická Ekon. 2000, 48. [Google Scholar] [CrossRef]

- Mankins, M. Great companies obsess over productivity, not efficiency. Harvard Business Review, 1 March 2017. [Google Scholar]

- Schmidt-Traub, G. Investment Needs to Achieve the Sustainable Development Goals: Understanding the Billions and Trillions; Sustainable Development Solutions Network: Paris, France, 2015. [Google Scholar]

- Sinha, A.; Sengupta, T.; Alvarado, R. Interplay between technological innovation and environmental quality: Formulating the SDG policies for next 11 economies. J. Clean Prod. 2020, 242. [Google Scholar] [CrossRef]

| Short Form | Indicator Name | Definition | 2013 | 2018 | ||

|---|---|---|---|---|---|---|

| Average | Median | Average | Median | |||

| c.l. ratio | Capital–Labour Ratio in Euro | Tangible and intangible fixed assets/Costs of employees | 3.832 | 1.770 | 3.410 | 1.645 |

| LP | Labour Productivity in Euro | Operating revenues/Costs of employees | 6.049 | 4.683 | 5.582 | 4.293 |

| FAT | Fixed Assets Turnover in Euro | Operating revenues/Tangible + intangible fixed assets/ | 1.579 | 2.927 | 1.637 | 2.808 |

| ROS | Return on Sales in Euro | Profit/loss before Taxes/Operating revenues | 0.046 | 0.033 | 0.050 | 0.035 |

| LCR | Labour Cost Ratio in Euro | Costs of employees/Operating revenues | 0.165 | 0.214 | 0.179 | 0.233 |

| Country | Size | Total | ||

|---|---|---|---|---|

| Large | Medium | Small | ||

| Czech Republic (CZ) | 10 | 74 | 97 | 181 |

| Hungary (HU) | 9 | 73 | 138 | 220 |

| Poland (PL) | 21 | 140 | 111 | 272 |

| Slovakia (SK) | 4 | 34 | 74 | 112 |

| Total | 44 | 321 | 420 | 785 |

| Quadrant | Indicator | Average Value in | Index | |

|---|---|---|---|---|

| 2013 | 2018 | |||

| Quadrant I (125 companies) | Return on Sales—ROS | 0.062 | 0.065 | 1.055 |

| Labour Cost Ratio—LCR | 0.182 | 0.145 | 0.800 | |

| Labour Productivity—LP | 5.506 | 6.880 | 1.250 | |

| Capital–Labour ratio—c.l. ratio | 2.213 | 3.970 | 1.794 | |

| Fixed Assets Turnover—FAT | 2.488 | 1.733 | 0.696 | |

| Quadrant II (170 companies) | Return on Sales—ROS | 0.066 | 0.050 | 0.759 |

| Labour Cost Ratio—LCR | 0.171 | 0.213 | 1.244 | |

| Labour Productivity—LP | 5.840 | 4.696 | 0.804 | |

| Capital–Labour Ratio—c.l. ratio | 2.249 | 3.148 | 1.400 | |

| Fixed Assets Turnover—FAT | 2.597 | 1.492 | 0.574 | |

| Quadrant III (350 companies) | Return on Sales—ROS | 0.041 | 0.051 | 1.225 |

| Labour Cost Ratio—LCR | 0.152 | 0.190 | 1.256 | |

| Labour Productivity—LP | 6.594 | 5.250 | 0.796 | |

| Capital–Labour Ratio—c.l. ratio | 3.735 | 2.401 | 0.643 | |

| Fixed Assets Turnover—FAT | 1.766 | 2.187 | 1.238 | |

| Quadrant IV (140 companies) | Return on Sales—ROS | 0.022 | 0.034 | 1.571 |

| Labour Cost Ratio—LCR | 0.189 | 0.155 | 0.823 | |

| Labour Productivity—LP | 5.296 | 6.432 | 1.214 | |

| Capital–Labour Ratio—c.l. ratio | 7.596 | 6.212 | 0.818 | |

| Fixed Assets Turnover—FAT | 0.697 | 1.035 | 1.485 | |

| Quadrant | Inequalities | Investment Development |

|---|---|---|

| Quadrant I | Intensive | |

| Quadrant II | Intensive | |

| Quadrant III | Modest | |

| Quadrant IV | Modest |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Novotná, M.; Leitmanová, I.F.; Alina, J.; Volek, T. Capital Intensity and Labour Productivity in Waste Companies. Sustainability 2020, 12, 10300. https://doi.org/10.3390/su122410300

Novotná M, Leitmanová IF, Alina J, Volek T. Capital Intensity and Labour Productivity in Waste Companies. Sustainability. 2020; 12(24):10300. https://doi.org/10.3390/su122410300

Chicago/Turabian StyleNovotná, Martina, Ivana Faltová Leitmanová, Jiří Alina, and Tomáš Volek. 2020. "Capital Intensity and Labour Productivity in Waste Companies" Sustainability 12, no. 24: 10300. https://doi.org/10.3390/su122410300

APA StyleNovotná, M., Leitmanová, I. F., Alina, J., & Volek, T. (2020). Capital Intensity and Labour Productivity in Waste Companies. Sustainability, 12(24), 10300. https://doi.org/10.3390/su122410300