Abstract

The objective of this study is to verify the relationships between orientation, collaboration and performance for supply chain management (SCM) of Korean foreign direct investment (FDI) firms for sustainable growth. To achieve the objective, this study created the research model, and the research hypotheses came from prior research. The questionnaire was sent to Korean FDI firms, and the collected data were analyzed by various analytical methods such as a factor analysis, a Cronbach’s alpha coefficient, structural equation modeling (SEM) and a moderated regression analysis. The results are as follows. First, orientation for SCM has a positive effect on collaboration for SCM. Global SCM is regarded as an essential part in the era in which a value chain is globalized, and as a result, it is globally performed in the procurement of raw materials, production of goods and sales of final goods. To perform global SCM, staff of manufacturers should have recognition of SCM from the internal viewpoint of a firm, they should create strategy and structure for SCM from the whole viewpoint of a firm, and they should disseminate it to suppliers and customers. Second, collaboration for SCM has a positive effect on supply chain performance. The key factors are collaboration with international logistics service providers as well as inter-departmental collaboration. The collaboration is based on attaining efficiency and effectiveness, and as a result, firms achieve superior supply chain performance.

1. Introduction

Sustainability of firms based on the globalization of value chains is important from external as well as internal viewpoints of firms. From these viewpoints, Korean manufacturing firms collaborate with suppliers and customers as well as with departments. In particular, firms that perform foreign direct investment (FDI) on the basis of globalization of value chains make an effort to attain sustainable growth through global supply chain management (SCM). FDI is performed for various reasons. For instance, Korean FDI firms go abroad for buying raw materials, producing goods and selling the goods, and this is explained by market-oriented knowledge and technology- and material-oriented FDI. Collaboration with customers and suppliers as well as internal collaboration in a firm is important in FDI to attain efficiency and effectiveness on the basis of globalization of a value chain. In this regard, the study on global SCM and FDI of Korean manufacturing firms is required from the viewpoint of enhancing the competitiveness of Korean FDI firms.

If FDI by Korean manufacturers requires market-oriented knowledge, researchers need to identify how they manage their supply chains after entering into the country. In particular, there is doubt about how Korean manufacturers perform localization strategy in the overseas market if it is a market-oriented FDI. The study on localization strategy of Korean firms was performed by Seo and Kim in Indonesia [1] and India [2]. Lee [3] confirmed product localization for advancing into the Indian market. Shin [4] analyzed localization strategy and its implementation by Korean subsidiaries in the North American Free Trade Agreements (NAFTA) region. Zhang et al. [5] studied FDI performance factors of Korean firms in China. They analyzed localization strategy of Korean FDI firms using a case study. Lee and Kim [6] also studied how to adjust in Chinese market based on changes to its FDI policy. In addition, research on collaboration for SCM was started by Stevens [7], and there are various viewpoints concerned with the collaboration. For example, collaboration for SCM is divided into a vertical viewpoint [8,9] and a horizontal viewpoint [10,11]. The former means collaboration that includes suppliers, focal firms and demanders, and on the other hand, the latter means collaboration that includes competitors (common logistics) as well as logistics service providers and information technology (IT) and information systems (IS) service providers. Therefore, collaboration for SCM includes various viewpoints.

There is a lack of prior research on Korean FDI firms. In particular, almost all prior research papers are case studies concerned with service firms such as banking, information and communication technology, and distribution. In this regard, prior research has limitations as follows. First, research on collaboration for SCM in Korean FDI firms is needed. Collaboration for SCM should be investigated from an inter-corporate viewpoint as well as from an inter-departmental viewpoint concerned with procurement, production, sales and services of Korean FDI firms. However, prior research analyzed localization strategy through case studies, and as a result, empirical tests are needed.

Second, almost all prior research on supply chain collaboration investigated the relationships between suppliers, manufacturers and customers. However, there is no research for the relationships between manufacturers and logistics firms in supply chains. Korean FDI firms prefer that they procure raw materials from overseas, produce goods in low cost countries, and sell goods to the world market. In this regard, research on collaboration for SCM between Korean FDI firms and international logistics firms is regarded as one of the methods to enhance the international competitiveness of Korean FDI firms.

Third, there is a lack of research to verify precedent factors on collaboration for SCM of Korean FDI firms. Prior research focuses on the motivation or entry modes of FDI firms. However, research on precedent factors of collaboration for SCM is not active. For instance, Bae [12] identified perceived environmental uncertainty as a precedent factor of supply chain collaboration. In addition, Iyer [13] and Rodrigues et al. [14] confirmed that logistics information systems have positive effect on supply chain collaboration. Despite the prior research, there is still a lack of research on precedent factors of collaboration for SCM. In this regard, this study needs to verify cause and effect variables of collaboration for SCM of Korean FDI firms. Therefore, the objective of this study is to empirically analyze the effects of orientation and collaboration for SCM on supply chain performance of Korean FDI firms.

2. Literature Review

SCM is based on various theoretical viewpoints. In particular, the viewpoint of value is useful to explain the relationships in supply chains [15]. The relationships are changed by value, which firms pursue. If firms focus on cost leadership as value, they concentrate on internal efficiency based on inter-departmental collaboration. On the other hand, if differentiation as a value is important to firms, they are immersed in external effectiveness based on collaboration with partners in supply chains. In this regard, the relationships in supply chains are created by value. The relationships are reinforced by supply chain collaboration on the basis of supply chain orientation. Moreover, the relationships are started from supply chain orientation, and performance in supply chains is increased when supply chain collaboration is enhanced. From the viewpoint, supply chain collaboration is regarded as adding value in whole supply chains. Therefore, this study investigates cause and effect factors of supply chain collaboration on the basis of value from the viewpoint of the relationships in supply chains.

On the basis of the relationships in supply chains, firms can have resources through hierarchy or the market based on vertical integration [16]. If the market is stable, transaction mechanism dominates the market. However, participants in the market want stable transactions through hierarchy if environmental uncertainty is high and there is transaction cost in the market. In contrast, the relationships in supply chains can provide value for firms operated in supply chain networks if the environment in the market is between stable and uncertain.

Networks in supply chains consist of participants and relationships. The former is composed of departments of focal firms and supply chain participants such as suppliers and customers. The latter means collaboration among the participants as well as the departments. Networks in supply chains are divided into vertical and horizontal. Vertical networks mean participants in the networks from suppliers of raw materials to final customers, and supply chain collaboration manages the flow of supplementary resources. In contrast, horizontal networks include competitors and collaborators, and supply chain collaboration manages the flow of mutual substitute resources [17]. In this regard, value is created by collaboration among supply chain participants. On the other hand, there is a different viewpoint to collaboration in supply chains which is the servitization capacity of firms such as sensing, seizing, reconfiguring, digitization, customization, network management, management values, management behavior, employee values and employee behavior [18,19].

The basic supposition of networks in supply chains is that firms depend on resources controlled by their partners. Approaches to resources are achieved by collaboration with participants in supply chains. The participants make an investment in the relationships with other participants, and as a result, they acquire information, knowledge and technology from partners. Hence, they make collaborative relationships in supply chains and this is connected with value creation. From this viewpoint, the key function of networks in supply chains is to create value on the basis of achieving supply chain collaboration. To create value, firms enhance the relationships with partners through collaboration from the viewpoint of whole supply chains. This means that they strengthen supply chain performance through the collaboration. Consequentially, they create value through collaboration in supply chain networks.

The management of the relationships in supply chain networks is achieved through close collaboration among functional departments and by efficient connection on the basis of external operations among supply chain partners [20]. Collaboration among partners in supply chains enhances performance, which is shared with participants in supply chains. Supply chain efficiency is kept in the best efficient conditions through collaboration with partners. Relationship-based supply chain collaboration is a part of integrated relationships with suppliers and customers and it provides firms with an opportunity of performance improvement [21,22]. The collaboration helps with implementing customer needs such as low-cost and high-quality goods and services, which have an effect on the choice of customers. The reason is that firms can understand customers’ long-term needs, expectation and preference [23]. The collaboration is similar to product–service innovation in an innovation portfolio [24]. Therefore, firms that want to achieve customer needs through the collaboration need to focus on internal collaboration, attain customer needs through collaboration with suppliers, and respond to customer expectation very well [25].

Supply chain collaboration is expanded to the viewpoint of suppliers and customers as well as the viewpoint of inter-functional areas in a firm. In this regard, collaboration is started from internal efficiency and it is developed to efficient relationships with partners [26]. It improves efficiency and productivity as well as cost saving, and as a result, there are benefits such as correct plans, market prediction, improved logistics efficiency and enhanced customer service. Therefore, successful collaboration creates value in a supply chain process, and it is connected with operational performance like cost saving and superior services.

3. Research Model and Methodology

3.1. Research Model

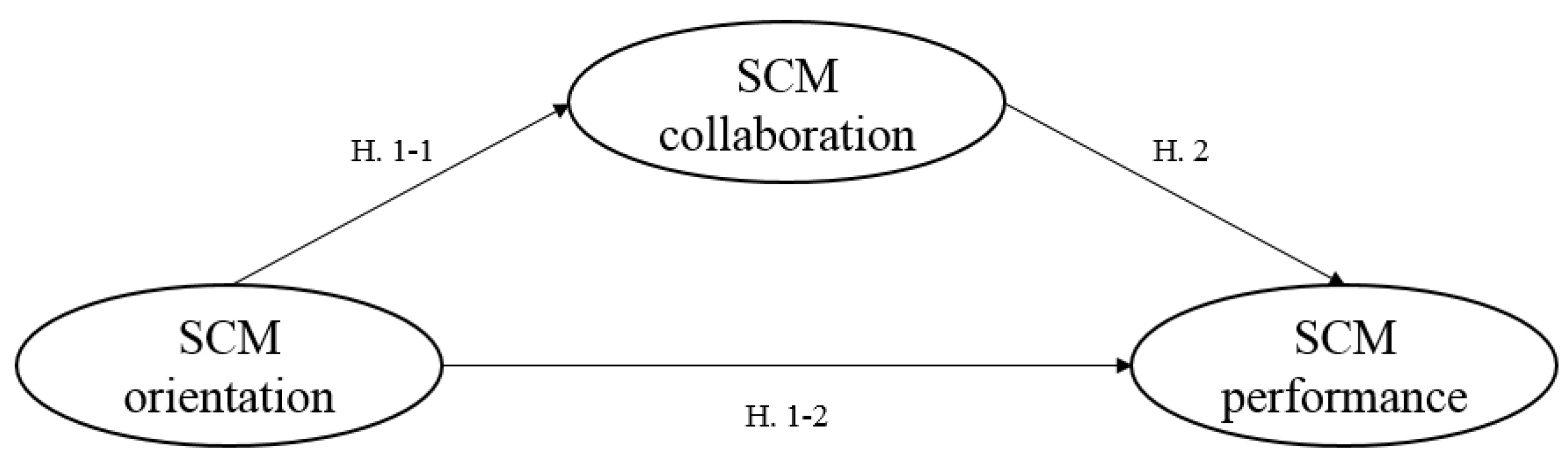

The theoretical relationships between orientation, collaboration and performance for SCM are discussed above and this is represented as the research model as follows.

Figure 1 shows the theoretical relationships between the variables. This means that collaboration for SCM mediates the relationship between orientation for SCM and performance for SCM, and orientation for SCM is a precedent variable of performance for SCM. Next is the supporting details to the hypotheses.

Figure 1.

Research model. SCM, supply chain management.

3.2. Hypotheses

3.2.1. Orientation and Collaboration for SCM

Despite various research papers on collaboration for SCM, there is a lack of research papers on antecedents of collaboration for SCM. The antecedents that have been shown to have an effect on collaboration are environmental uncertainty [15], trust and technology [27], IT [13,28], inter-organizational IT use and cooperative attitude [29], security, trust and readiness [30] and compatibility [31]. The variables reflect the inter-corporate viewpoint or exist outside firms. On the other hand, this study needs to investigate the relationship between orientation and collaboration for SCM from the internal viewpoint of firms.

SCM is divided into a perceived viewpoint and an implemented viewpoint [32]. From the perceived viewpoint, SCM reflects the recognition of staff in SCM from the internal viewpoint of a firm. From the implemented viewpoint, SCM includes inter-corporate collaboration, which contains suppliers and customers as well as inter-departmental collaboration. SCM from the perceived viewpoint means orientation for SCM, and this is divided into strategic orientation and structural orientation for SCM.

There are many debates on strategy and structure in prior research, and research on strategy and structure in SCM is also performed. According to contingency theory, environmental uncertainty affects firms as opportunities and threats and it has a negative effect on firm performance. However, firms find opportunities in environmental uncertainty and would change the negative effect into the positive effect [12]. Orientation for SCM means that staff recognizes SCM, and then they strategically and structurally change firms to fit in the direction of SCM to perform SCM. The strategic and structural changes of firms are performed as the direction to have a positive influence on performance on the basis of the variance of environment concerned with SCM. Therefore, this study suggests the hypothesis on the relationships between orientation, collaboration and performance for SCM as follows.

Hypothesis 1 (H1).

Orientation for SCM of Korean FDI firms has a positive effect on collaboration for SCM (H. 1–1) and supply chain performance (H. 1–2).

3.2.2. Collaboration and Performance for SCM

There are many prior research papers on collaboration for SCM. Prior research investigated inter-departmental collaboration from the internal viewpoint [33,34,35,36] and inter-corporate collaboration from the external viewpoint [13,37,38,39,40,41,42]. In addition, research on the direction of collaboration in supply chains also has been performed [38,43,44,45,46]. Collaboration for SCM is performed from internal to external [35,47,48,49,50], and external collaboration is also based on internal collaboration [42,51]. This means that firms perform inter-departmental collaboration to internally achieve efficiency, and effectiveness is attained by collaboration with suppliers and customers for SCM. On the other hand, firms that recognize the need of SCM through external collaboration can perform collaboration with supply chain participants through internal preparation for SCM. In this regard, firms attain internal collaboration by way of external collaboration.

Firms perform external collaboration as well as internal collaboration for SCM. Collaboration has a positive effect on supply chain performance as well as on the firm performance of supply chain participants. For example, collaboration in supply chains is the cause of superior performance because of preventing misconception and collision from occurring between firms and minimizing overlap and inefficiency existing in supply chains. Therefore, collaboration for SCM has a positive effect on supply chain performance and this is shown in the hypothesis as follows.

Hypothesis 2 (H2).

Collaboration for SCM between Korean FDI firms and international logistics firms has a positive effect on supply chain performance.

3.3. Context of the Study

3.3.1. Definitions of Variables

To analyze the relationships between orientation, collaboration and performance for SCM of Korean FDI firms, this study extracted variables in various methods. First, this study identified orientation and collaboration for SCM as the factors that have a positive effect on supply chain performance. Second, this study developed the measuring items that explain the variables extracted by prior research. Third, this study verified a possibility of measurement on the measuring items by interviews with experts. The contents are follows.

First, the factors that have an effect on supply chain performance can be approached from various viewpoints. In particular, the factors concerned with strategy and marketing viewpoints are important variables that have an influence on performance. However, this study should grasp the present conditions of SCM in Korean FDI firms. In this regard, this study needs to identify plans, performance, estimation and feedback of SCM in the firms. This is based on management theory usually used in strategic management research. Therefore, this study will analyze the relationships between orientation, collaboration and performance for SCM in Korean FDI firms.

Second, there are the conceptual definitions of orientation, collaboration and performance for SCM identified by above processes. Orientation for SCM means that staff recognizes and performs the directions of SCM in an organization [32]. SCM is not simple practical behavior, but it includes strategic characteristics that firms have. When supply chain participants understand the whole strategy and then perform SCM, they can attain superior performance on the basis of mutual understanding among the participants. Therefore, orientation for SCM can be divided into a perceived viewpoint and an implemented viewpoint. The former is connected with strategic orientation for SCM and the latter is concerned with structural orientation for SCM. Collaboration for SCM means degree of smooth cooperation of human and physical resources in a firm and dissemination of the cooperation to international logistics firms [52]. It is divided into inter-departmental collaboration and collaboration with international logistics firms. Supply chain performance means effectiveness and efficiency created by the introduction of SCM [53]. It is divided into quality performance, reliability performance, flexibility and responsiveness performance and cost performance. All items were measured as the perception of respondents on a seven-point Likert scale. Operational definitions are shown in Appendix A.

3.3.2. Sampling Methods and Data Collection

The population of this study was Korean FDI firms. The sampling frame was a membership list of Korea Trade-Investment Promotion Agency (KOTRA) and samples were extracted from the list. In all, 1000 firms were extracted by a random sampling method in the population. The survey was administered to the sample firms. The firms had a phone call from the researcher concerned with whether or not they answered the questionnaire, and the survey was administered only to firms that answered to responding to the survey.

The objects of the survey were marketing managers or production managers performing SCM in the sample firms because the objective of this study is to identify the relationships between orientation, collaboration and performance of global SCM. They were considered suitable for the survey because they understood the objective of this study and performed global SCM. The survey was performed from June 2020 to August 2020, and 75 firms responded. There were three questionnaires that had problems such as single responses or many non-responses, and as a result, 72 questionnaires were used for analyses.

3.3.3. Analytical Methods

To achieve the objective of this study, the data were analyzed by various methods. The data stability should be tested before analyzing causal relationships between the variables. This study used various analytical methods to verify the data stability. First, content validity was tested. It means whether measuring items reflect the contents of the variables. There are two methods to do this. One is to extract measuring items on the basis of prior research. Conceptual and operational definitions of the variables used in this study came from prior research. The other is that the fitness of measuring items is tested by experts. The measuring items of the variables were tested by three professors who have over three research papers concerned with international logistics, three researchers who are performing research on international logistics and three workers who worked over ten years in the field. As a result, there were no problems in the measuring items but there were problems such as unrealistic and vague items. The items were clearly changed according to experts’ comments.

Second, reliability and validity of the data should be tested, and the former can be identified by a Cronbach’s alpha coefficient and the latter can be verified by fitness indices of the measuring model such as chi-square (P > 0.05), Q (<2.0), goodness of fit index (GFI: >0.9), adjusted goodness of fit index (AGFI: >0.9), comparative fit index (CFI: >0.9), normal fit index (NFI: >0.9), incremental fit index (IFI: >0.9), Tucker–Lewis index (TLI: >0.9), root mean square error of approximation (RMSEA: <0.08) and a factor loading coefficient (>0.5).

Third, a correlation analysis and multicollinearity should be tested. There is not the exact criterion in correlation coefficients, but these explain the relationship between variables. This means that the result explains correlations between the variables. If correlation coefficients between independent variables are high, multicollinearity is doubted. There are two kinds of criteria for multicollinearity: tolerance and maximum level of variance influence factors (MAX-VIF). The former should be over 0.1 and the latter should be below 10.0. If there are no problems in the above results, the hypotheses can be tested.

There are two methods to test the hypotheses. Applying the first, this study identified the relationships between orientation, collaboration and performance of SCM. The relationships between the variables were confirmed by theoretical background and analyzed by a measurement model and a structural model. It can verify whether the characteristics of the sample firms are the same as the characteristics of the population and perform the path analysis among the variables, and as a result, the results are more informative than the results of a multiple regression analysis. In addition, the moderation effect of collaboration on the relationship between orientation and performance for SCM is identified by a moderated regression analysis (MRA). It has three models: One is to analyze the effect of an independent variable (orientation for SCM) on a dependent variable (supply chain performance), another is to identify the effects of an independent variable and a moderation variable (collaboration for SCM) on a dependent variable, and the third is to prove the effects of an independent variable, a moderation variable and an additional variable (an independent variable × a moderation variable) on a dependent variable. If the effects are significant and R square of model III is higher than R squares of model I and II, there is a moderation effect of the moderation variable. This means that a moderation variable enhances the relationship between an independent variable and a dependent variable. The results are as follows.

4. Results

4.1. The Information on Respondents

Table 1 shows the general characteristics of responding firms. The highest number of firms was in machine, transport and equipment, which had 12 firms. Three firms were involved in metal and non-metal and timber, paper and furniture, which had the lowest number of firms. There were 15 firms with over US$ 50 million in annual turnover and five firms with below US$ 1 million. In addition, there were 15 firms between 1998 and 2008 and after 2008 in relation to the foundation year of firms. Described next are the results of reliability and validity of the data.

Table 1.

The general characteristics of responding firms.

4.2. Reliability and Validity Results

This study used measuring items such as orientation, collaboration and performance for SCM. The results of validity and reliability are as follows.

Table 2 shows the result of reliability and validity on orientation for SCM. It is divided into strategic orientation and structural orientation. The former shows over 0.5 in factor loading coefficients and it has three items. There is no problem in validity because the Cronbach’s alpha coefficient is 0.900. The latter has four measuring items and shows over 0.5 in factor loading coefficients. In addition, the Cronbach’s alpha coefficient is 0.897 and that is why there are no problems in the results. However, the fitness indices show that there are problems because these are not passed in the criteria.

Table 2.

The results of reliability and validity on orientation for SCM.

Table 3 is the result of reliability and validity on collaboration for SCM. It is divided into inter-departmental collaboration and collaboration with international logistics firms. The former has four measuring items, and the Cronbach’s alpha coefficient is 0.882. The latter has six measuring items, and the Cronbach’s alpha coefficient is 0.907. As a result, there is good reliability and validity. However, there are problems in the results of fitness indices.

Table 3.

The results of reliability and validity on collaboration for SCM.

Table 4 shows the result of reliability and validity of supply chain performance. There are four variables, namely, quality, reliability, flexibility and responsiveness, and cost. The first has three items, factor loading coefficients are over 0.5, and the Cronbach’s alpha coefficient is 0.913. The second has three items, factor loading coefficients are over 0.5, and the Cronbach’s alpha coefficient is 0.946. The third has three items, factor loading coefficients are over 0.5, and the Cronbach’s alpha coefficient is 0.825. The fourth has two items, factor loading coefficients are over 0.5, and the Cronbach’s alpha coefficient is 0.838. As a result, there are no problems in the results. However, the fitness indices are lower than the criteria, and therefore, the results of this study can be only applied to the sample firms. Next is the result of a correlation analysis.

Table 4.

The results of reliability and validity on performance for SCM.

Table 5 shows the result of a correlation analysis. There are two results. One is the relationship between independent variables. The high levels of correlation coefficients can be doubted in multicollinearity. The other is the relationship between independent variables and dependent variables. This means that there are the high levels of correlation between independent variables and dependent variables. Next is the result of multicollinearity.

Table 5.

The results of correlation analysis.

As shown in Table 6, tolerance is over 0.1, and MAX-VIF is below 10.0. This means that there are no problems in multicollinearity among independent variables. Next is the result of identifying the hypotheses.

Table 6.

The results of multicollinearity.

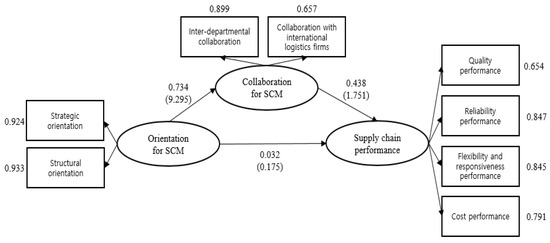

4.3. Path Analysis Result

The objective of this study is to verify the relationships between orientation, collaboration and performance for SCM of Korean FDI firms. The results are as follows.

Table 7 shows the results of causality between the variables. Orientation for SCM of Korean FDI firms has a positive effect on collaboration for SCM (H. 1–1 is supported). Collaboration for SCM of Korean FDI firms has a positive effect on supply chain performance (H. 2 is supported). However, the relationship between orientation for SCM and supply chain performance is not supported (H. 1–2 is rejected). Therefore, this study analyzes the moderation effect of collaboration on the relationship between orientation and performance. The details of the result are shown in Appendix B.

Table 7.

Hypotheses tests.

Table 8 shows the moderation effect of orientation and collaboration on performance of SCM. The result explains that the effects are significant, and adj R square of model III is higher than the R squares of model I and II. This means that collaboration of SCM enhances the relationship between orientation and performance of SCM. The discussions of the results are as follows.

Table 8.

The moderation effect.

4.4. Discussion

The results of the above analyses are explained as follows. First, orientation for SCM has a positive effect on collaboration for SCM. Global SCM is regarded as the essential part in the era in which a value chain is globalized, and as a result, procurement of raw materials, production of goods and sales of final goods are globally performed. Korean FDI firms would attain supply chain performance on the basis of planning, performing and estimating of global SCM. However, the firms cannot achieve whole supply chain goals when they just perform global SCM. To perform global SCM, staff should have recognition of SCM from the internal viewpoint of a firm, they should make strategy and structure for SCM from the whole viewpoint of a firm, and they should disseminate it to suppliers and customers. The internal recognition and application of SCM are a useful resource to achieve firm performance and a rare resource, which is not easily bought by competitors in the market. In addition, the capabilities cannot be substituted by other resources and be perfectly imitated by competitors. Orientation and collaboration for SCM as a resource of firms has causal ambiguity and social complexity on the relationship with supply chain performance, and as a result, they can enjoy sustainable competitive advantages in the market.

Korean FDI firms internally perform the structure and strategy of SCM on the basis of orientation for SCM, and as a result, inter-departmental collaboration is performed. In addition, they enhance the level of collaboration for SCM based on collaboration with international logistics service providers. The orientation and collaboration for SCM are connected with development stages of SCM by Stevens [7]. The development stages are started from the internal viewpoint of a firm, and supply chain performance is achieved by inter-corporate collaboration. Therefore, the result of this study like the positive effect of orientation for SCM (internal recognition) on collaboration for SCM (inter-departmental collaboration and collaboration with international logistics firms) is the same result with the viewpoint of Stevens [7]; that is, the stages are developed to the recognition of SCM, internal integration and external integration.

Second, collaboration for SCM has a positive effect on supply chain performance. To attain supply chain performance, firms should achieve inter-departmental collaboration and collaboration with international logistics firms. Prior research for the relationships between collaboration and performance had been performed in various viewpoints, but there is no research concerned with the relationship between global SCM and supply chain performance. In addition, the relationships between collaboration and performance are based on various theoretical backgrounds. For instance, the relationship between inter-corporate collaboration and performance is explained by social exchange theory and resource-based theory. In addition, the relationship between inter-departmental collaboration and performance is explained by strategic choice theory and information processing theory. Similarly, internal collaboration has a positive effect on performance by way of external collaboration and vice versa. Therefore, collaboration for SCM enhances supply chain performance, and the key factors are collaboration with international logistics firms as service providers as well as inter-departmental collaboration. The collaboration is based on attaining efficiency and effectiveness, and as a result, firms achieve superior supply chain performance.

Korean manufacturers invest in overseas countries based on various reasons. They buy raw materials at cheap prices, produce goods in low-cost countries and sell the goods to the global market. In this regard, global SCM is necessary, and they should make internal processes fitted in global SCM based on inter-departmental collaboration. If they make the most efficient global logistics network through collaboration with international logistics service providers, they can attain superior supply chain performance. This is connected with core competence management; that is, manufacturers focus on manufacturing, and international logistics firms focus on logistics. Therefore, firms can achieve efficiency and effectiveness when they focus on their core competence and outsource the other parts to experts. Moreover, manufacturers and logistics firms should collaborate with each other, and as a result, they can attain superior supply chain performance. However, the results cannot be generalized to all firms because the sample size is too small in relation to the whole population.

5. Conclusions

The objective of this study is to verify the relationships between orientation, collaboration and performance for SCM of Korean FDI firms. To achieve the objective, this study created the research model and the research hypotheses based on prior research. Conceptual and operational definitions of the variables were confirmed by prior research, and the questionnaire was sent to Korean FDI firms. Collected data were analyzed by various analytical methods.

This study used various analytical methods to identify the stability of the data. Reliability and validity of measuring items were verified by a confirmatory factor analysis and a Cronbach’s alpha coefficient. To test the hypotheses, this study analyzed a measurement model and a structural model and performed MRA. The theoretical implications are shown in the discussion part, and managerial implications, limitations and future research directions are as follows.

On the basis of the results, this study suggests various managerial implications as follows. First, managers of Korean FDI firms need to recognize that orientation for SCM has a positive effect on collaboration for SCM. Global SCM is a strategy that FDI firms should perform. Managers should make recognition of staff concerned with global SCM by training and encouraging the staff, and the recognition can be applied to the structural and strategic viewpoints. If staff gets the recognition, managers need to think about how to use it. SCM is not easily attained by the introduction of systems or amendment to processes. If they want to apply the recognition to global SCM, they need to sustainably train staff and bring about a change of process for global SCM, followed by performing global SCM from the structural and strategic viewpoints. Orientation for SCM is to enhance standardization and collaboration and to minimize overlap and inefficiency, followed by improvement of whole performance. In addition, it is one of methods that disseminate the base if they structure reward systems concerned with global SCM. Moreover, the attention and encouragement of a chief executive officer and directors are also one of methods for successful global SCM. Firms that have a high level of the orientation achieve a high level of performance by way of collaboration for SCM.

Second, managers of Korean FDI firms need to recognize that collaboration for SCM has a positive effect on supply chain performance. The collaboration can be divided into inter-departmental collaboration and collaboration with international logistics firms. Managers have generally thought that departments in firms collaborate with each other to attain their goals. However, inefficiency caused by a lack of inter-departmental collaboration obstructs the achievement of their goals in practice. In particular, information among departments is distorted when they compete to acquire resources, and as a result, it is difficult for them to attain the goals. To overcome this, managers need to educate staff regarding corporate strategy, business unit strategy and functional level strategy, and then they need to create recognition for staff on strategy, tactics and operations. To achieve goals of firms, whole departments should abandon the selfishness of their department and need to attain efficiency and effectiveness based on smooth information exchange (collaboration). In this regard, managers should stimulate achievement of their goals on the basis of encouragement to staff and proper reward systems. Therefore, inter-departmental collaboration is based on achieving supply chain performance.

Collaboration between Korean FDI firms and international logistics firms is based on achieving supply chain performance. Manufacturers should focus on manufacturing as their core competence, and logistics service providers should focus on management of international logistics processes as their core competence. Managers of manufacturers should transact with international logistics firms that have high-quality logistics services. They need to obtain a flexible capability for information sharing, and as a result, they can make the most efficient international logistics processes. The managers should deliver their requirements to international logistics firms by sustainable communication, and as a result, international logistics firms should responsibly perform international logistics. Moreover, international logistics firms should develop new services on the basis of cooperating with manufacturers as customers. As a result, manufacturers are provided with superior international logistics services, and international logistics firms achieve high profits on the basis of high quality of services. Therefore, Korean FDI firms attain high levels of supply chain performance affected by collaboration for SCM with international logistics firms. However, the results cannot be generalized to all firms because the sample size is too small in relation to the whole population.

Despite the above implications, there are limitations. First, there are small-sized sample firms. This study performed the analyses on the basis of 72 firms. The population is a membership list of KOTRA. To collect the data, this study performed a survey to the Korean FDI firms but the response rate was low. Researchers need to gather more data to identify the strict results. Second, item 4 of orientation for SCM was classified in strategic orientation and as a result, it was deleted. All items were extracted by prior research, but the item was not classified in structural orientation. The in-depth study on the items is required in the future. Third, there are just 72 firms to analyze the hypotheses. The lack of data is connected with the reliability of the results. However, the model of this study is based on prior research, and the results of this study show the same trend as prior research. In addition, the relationships between small- and medium-sized enterprises (SMEs) are more problematic than the relationship between conglomerates and SMEs. The limitations indicate future research directions.

Funding

This work was supported by the Ministry of Education of the Republic of Korea and the National Research Foundation of Korea (NRF-2019S1A5A8033609).

Conflicts of Interest

The author declares no conflict of interest.

Appendix A

Table A1.

The details of questionnaire.

Table A1.

The details of questionnaire.

| Variables | Sub-Variables | Items |

|---|---|---|

| Orientation for SCM | Strategic orientation |

|

| Structural orientation |

| |

| Collaboration for SCM | Inter-departmental collaboration |

|

| Collaboration with international logistics firms |

| |

| Supply chain performance | Quality performance |

|

| Reliability performance |

| |

| Flexibility and responsiveness performance |

| |

| Cost performance |

|

Appendix B

Figure A1.

The details of the result.

Figure A1.

The details of the result.

References

- Seo, M.K.; Kim, H.J. A Study on Case for Localization of Korean Enterprise in Indonesia. Int. Commer. Inf. Rev. 2013, 15, 481–508. [Google Scholar]

- Seo, M.K.; Kim, H.J. A Study on Case for Localization of Korean Enterprise in India. Int. Commer. Inf. Rev. 2014, 16, 409–437. [Google Scholar]

- Lee, H.S. Product Localization for Advancing into the Indian Market. Korean J. Area Stud. 2017, 35, 33–60. [Google Scholar]

- Shin, M.S. Localization Strategy and its Performance of Korean Subsidiaries in NAFTA Region. Int. Commer. Rev. 2003, 8, 245–274. [Google Scholar]

- Zhang, H.; Park, K.A.; Kim, C.K. A Study on the FDI Performance Factors: Focused on the Korean Firms in China. Korean J. Int. Bus. 2005, 16, 27–64. [Google Scholar]

- Lee, S.W.; Kim, H.M. Impact of China Logistics Market based on Changing of Enterprise Policy in China due to Growth of International Trade of China. Ocean Policy Res. 2007, 22, 67–96. [Google Scholar]

- Stevens, G.C. Integrating the Supply Chain. Int. J. Phys. Distrib. Logist. Manag. 1989, 9, 3–8. [Google Scholar] [CrossRef]

- Li, J.; Chen, C.W.; Wu, C.H.; Hung, H.C.; Lin, C.T. How do Partners Benefit from IT Use in Supply-Chain Management: An Empirical Study of Taiwan’s Bicycle Industry. Sustainability 2020, 12, 3888. [Google Scholar] [CrossRef]

- Vanichchinchai, A. The Effect of Lean Manufacturing on a Supply Chain Relationship and Performance. Sustainability 2019, 11, 5751. [Google Scholar] [CrossRef]

- Isaksson, M.P.; Hulthen, H.; Forslund, H. Environemntally Sustainable Logistics Performance Management Process Integration between Buyers and 3PLs. Sustainability 2019, 11, 3061. [Google Scholar] [CrossRef]

- Bae, H.S.; Park, D.J. Gaps in Performance between the Levels of Inter-Corporate Relationships in Port Logistics Processes. Asian J. Shipp. Logist. 2018, 34, 209–217. [Google Scholar] [CrossRef]

- Bae, H.S. Empirical Relationships between Perceived Environmental Uncertainty, Supply Chain Integration and Operational Performance: Analyses of Direct, Indirect and Total Effects. Asian J. Shipp. Logist. 2017, 33, 263–272. [Google Scholar] [CrossRef]

- Iyer, K.N.S. Demand Chain Collaboration and Operational Performance: Role of IT Analytic Capability and Environmental Uncertainty. J. Bus. Ind. Mark. 2011, 26, 81–91. [Google Scholar] [CrossRef]

- Rodrigues, A.M.; Stank, T.P.; Lynch, D.F. Linking Strategy, Structure, Process and Performance in Integrated Logistics. J. Bus. Logist. 2004, 25, 65–94. [Google Scholar] [CrossRef]

- Bae, H.S. Investigating the Effect of Environmental Uncertainty on Supply Chain Collaboration and Operational Performance. Ph.D. Thesis, University of Hull, Hull, UK, 2014. [Google Scholar]

- O’Donnell, A.A.; Rinehart, L.M.; Wells, M.V. The Network Concept in Entrepreneurship Research: A Review and Critique. Manag. Decis. 2001, 39, 749–760. [Google Scholar] [CrossRef]

- Elg, U.; Johansson, U. Networking when National Boundaries Dissolve: The Swedish Food Sector. Eur. J. Mark. 1996, 30, 61–74. [Google Scholar] [CrossRef]

- Galera-Zarco, C.; Opazo-Basáez, M.; Marić, J.; García-Feijoo, M. Digitalization and the Inception of Concentric Strategic Alliances: A Case Study in the Retailing Sector. Strateg. Chang. 2020, 29, 165–177. [Google Scholar] [CrossRef]

- Opazo-Basáez, M.; Cantín, L.N.; Campos, J.A. Does Distance Really Matter? Assessing the Impact of KIBS Proximity on Firms’ Servitization Capacity: Evidence from the Basque Country. Investig. Reg. J. Reg. Res. 2020, 48, 51–68. [Google Scholar]

- Vendrell-Herrero, F.; Bustinza, O.F.; Opazo-Basáez, M. Information Technologies and Product-Service Innovation: The Moderating Role of Service R&D Team Structure. J. Bus. Res. 2020. [Google Scholar] [CrossRef]

- Opazo-Basáez, M.; Vendrell-Herrero, F.; Bustinza, O.F. Uncovering Productivity Gains of Digital and Green Servitization: Implications from the Automotive Industry. Sustainability 2018, 10, 1524. [Google Scholar] [CrossRef]

- Bustinza, O.F.; Vendrell-Herrero, F.; Gomes, E.; Lafuente, E.; Opazo-Basáez, M.; Rabetino, R.; Vaillant, Y. Product-Service Innovation and Performance: Unveiling the Complexities. Int. J. Bus. Environ. 2018, 10, 95–111. [Google Scholar] [CrossRef]

- Lai, K.; Ngai, E.W.T.; Chen, T.C.E. Measures for Evaluating Supply Chain Performance in Transport Logistics. Transp. Res. Part E Logist. Transp. Rev. 2002, 38, 439–456. [Google Scholar] [CrossRef]

- Seclen-Luna, J.P.; Opazo-Basáez, M.; Narvaiza, L.; Fernández, P.J.M. Assessing the Effects of Human Capital Composition, Innovation Portfolio and Size on Manufacturing Firm Performance. Compet. Rev. Int. Bus. J. 2020. [Google Scholar] [CrossRef]

- Sánchez-Montesinos, F.; Opazo-Basáez, M.; Aranda, D.; Bustinza, O.F. Creating Isolating Mechanisms through Digital Servitization: The Case of Covirán. Strateg. Chang. 2018, 27, 121–128. [Google Scholar] [CrossRef]

- Bowersox, D.J.; Daugherty, P.J. Logistics Paradigms: The Impact of Information Technology. J. Bus. Logist. 1995, 16, 65–80. [Google Scholar]

- Salam, M.A. The Mediating Role of Supply Chain Collaboration on the Relationship between Technology, Trust and Operational Performance: An Empirical Investigation. Benchmarking Int. J. 2017, 24, 298–317. [Google Scholar] [CrossRef]

- Jimenez-Jimenez, D.; Martinez-costa, M.; Rodrigues, C.S. The Mediating Role of Supply Chain Collaboration on the Relationship between Information Technology and Innovation. J. Knowl. Manag. 2019, 23, 548–567. [Google Scholar] [CrossRef]

- Hall, D.J.; Skipper, J.B.; Hazen, B.T.; Hanna, J.B. Inter-organizational IT Use, Cooperative Attitude, and Inter-organizational Collaboration as Antecedents to Contingency Planning Effectiveness. Int. J. Logist. Manag. 2012, 23, 50–76. [Google Scholar] [CrossRef]

- Panahifar, F.; Byrne, P.J.; Salam, M.A.; Heavey, C. Supply Chain Collaboration and Firm’s Performance: The Critical Role of Information Sharing and Trust. J. Enterp. Inf. Manag. 2018, 31, 358–379. [Google Scholar] [CrossRef]

- Rajaguru, R.; Matanda, M. Role of Compatibility and Supply Chain Process Integration in Facilitating Supply Chain Capabilities and Organizational Performance. Supply Chain Manag. Int. J. 2019, 24, 301–316. [Google Scholar] [CrossRef]

- Esper, T.L.; Defee, C.C.; Mentzer, J.T. A Framework of Supply Chain Orientation. Int. J. Logist. Manag. 2010, 21, 161–179. [Google Scholar] [CrossRef]

- Daugherty, P.J.; Chen, H.; Mattioda, D.D.; Grawe, S.J. Marketing/Logistics Relationships: Influence on Capabilities and Performance. J. Bus. Logist. 2009, 30, 1–18. [Google Scholar] [CrossRef]

- Ellinger, A.C. Improving Marketing/Logistics Cross-functional Collaboration in the Supply Chain. Ind. Mark. Manag. 2000, 29, 85–96. [Google Scholar] [CrossRef]

- Gimenez, C.; Ventura, E. Logistics-production, Logistics-marketing and External Integration: Their Impact on Performance. Int. J. Oper. Prod. Manag. 2005, 25, 231–249. [Google Scholar] [CrossRef]

- Kahn, K.B.; Mentzer, J.T. Marketing’s integration with other departments. J. Bus. Res. 1998, 42, 53–62. [Google Scholar] [CrossRef]

- Boon-Itt, S.; Wong, C.Y. The Moderating Effects of Technological and Demand Uncertainties on the Relationship between Supply Chain Integration and Customer Delivery Performance. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 253–276. [Google Scholar] [CrossRef]

- Flynn, B.B.; Huo, B.; Zhao, X. The Impact of Supply Chain Integration on Performance: A Contingency and Configuration Approach. J. Oper. Manag. 2010, 28, 58–71. [Google Scholar] [CrossRef]

- Kim, J.S.; Shin, N. The Impact of Blockchain Technology Application on Supply Chain Partnership and Performance. Sustainability 2019, 11, 6181. [Google Scholar] [CrossRef]

- Scannell, T.V.; Vickery, S.K.; Dröge, C.L. Upstream Supply Chain Management and Competitive Performance in the Automotive Supply Industry. J. Bus. Logist. 2000, 21, 23–48. [Google Scholar]

- Shin, N.; Park, S.H.; Park, S. Partnership-based Supply Chain Collaboration: Impact on Commitment, Innovation and Firm Performance. Sustainability. 2019, 11, 449. [Google Scholar] [CrossRef]

- Stank, T.P.; Keller, S.B.; Closs, D.J. Performance Benefits of Supply Chain Logistical Integration. Transp. J. 2001, 41, 32–46. [Google Scholar]

- Boon-itt, S.; Wong, C.Y. The Interactions between Internal and External Integration and their Combined on Operational Performance. In Proceedings of the POMS 22nd Conference, Reno, NV, USA, 29 April–2 May 2011; Paper No. 020-0296. pp. 1–20. [Google Scholar]

- Danese, P.; Romano, P. Supply Chain Integration and Efficiency Performance: A Study on the Interactions between Customer and Supplier Integration. Supply Chain Manag. Int. J. 2011, 16, 220–230. [Google Scholar] [CrossRef]

- Dröge, C.; Jayaram, J.; Vickery, S.K. The Effects of Internal versus External Integration Practices on Time-based Performance and Overall Firm Performance. J. Oper. Manag. 2004, 22, 557–573. [Google Scholar] [CrossRef]

- Germain, R.; Iyer, K.N.S. The Interaction of Internal and Downstream Integration and its Association with Performance. J. Bus. Logist. 2006, 27, 29–51. [Google Scholar] [CrossRef]

- Braunscheidel, M.J.; Suresh, N.C. The organizational antecedents of a firm’s supply chain agility for risk mitigation and response. J. Oper. Manag. 2009, 27, 119–140. [Google Scholar] [CrossRef]

- Chen, H.; Daugherty, P.J.; Roath, A.S. Defining and Operationalizing Supply Chain Process Integration. J. Bus. Logist. 2009, 30, 63–84. [Google Scholar] [CrossRef]

- Gimenez, C. Logistics Integration Processes in the Food Industry. Int. J. Phys. Distrib. Logist. Manag. 2006, 36, 231–249. [Google Scholar] [CrossRef]

- Schoenherr, T.; Swink, M. Revisiting the Arcs of Integration: Cross-validations and Extensions. J. Manag. 2012, 30, 99–115. [Google Scholar] [CrossRef]

- Salvador, F.; Forza, C.; Rungtusantham, M.; Choi, T.Y. Supply Chain Interactions and Time-related Performances. Int. J. Oper. Prod. Manag. 2001, 21, 461–476. [Google Scholar] [CrossRef]

- Bae, H.S.; Grant, D.B. Investigating Effects of Organizational Culture and Learning on Environmental Collaboration and Performance of Korean Exporting Firms. Int. J. Logist. Res. Appl. 2018, 21, 614–630. [Google Scholar] [CrossRef]

- Flynn, B.B.; Flynn, E.J. An Exploratory Study of the Nature of Cumulative Capabilities. J. Oper. Manag. 2004, 22, 439–457. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).