Understanding the Key Quality Factors in Construction Projects—A Systematic Literature Review

Abstract

1. Introduction

- What are the quality-related factors identified covering issues of quality management in construction projects?

- What are the relations between factors of organisation, project and product?

- Identification of quality-related factors in construction projects present in the literature and their grouping.

- Comparison of the obtained results by reviewing the literature and previous studies of the authors.

- Construction of the preliminary model showing assumed relations between groups of factors.

2. Sources and Methods

2.1. Systematic Literature Review

2.2. Research Procedure

- identification of studies,

- title, abstract and keywords screening,

- full-text screening,

- analysis of included papers,

- definition of a null SEM model,

- discussion of the results and their comparison with previous research.

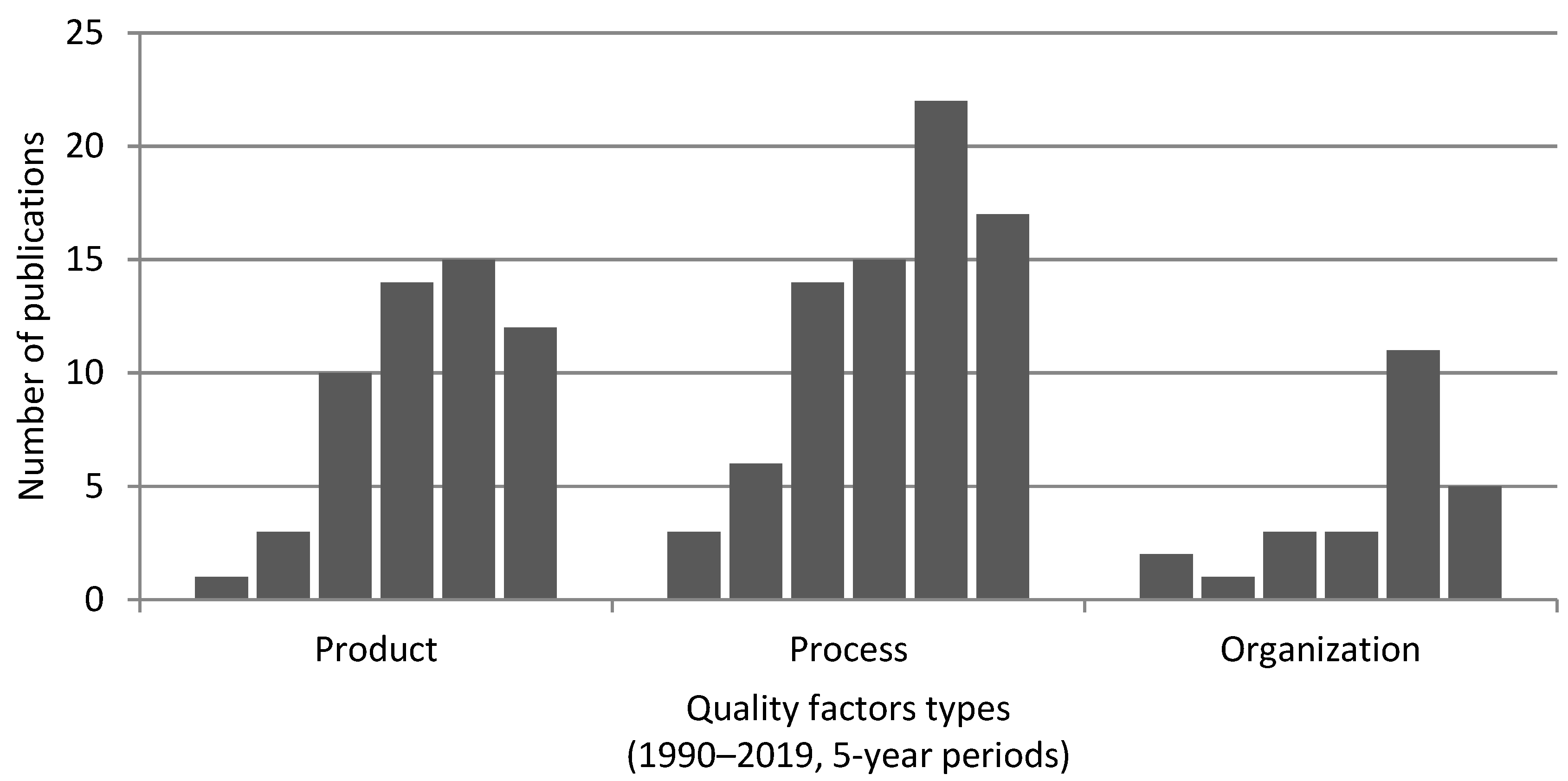

2.3. Descriptive Analysis

3. Results

3.1. Selection of the Papers

3.2. Phases of Construction Projects

3.3. Identification of Quality-Related Factors

3.4. Quantitative Description of Quality-Related Factors

- O1 “quality department”—permanent manager or department that covers quality issues in multiple projects with own budget,

- O2 “long-term partnering”—developing long-term cooperation with selected suppliers,

- O3 “quality audit”—monitoring of the project from the company point of view,

- O4 “clear responsibilities”—an unequivocal division of tasks, powers and responsibilities,

- O5 “quality culture”—systematic actions to build an organisational culture based on quality and continuous improvement,

- O6 “formalisation”—recurrent procedures used in many projects, project methodologies.

3.5. Relations between the Factors

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A. List of Papers Used in The Analysis by Group and Category

Appendix A.1. Organisation Quality Management Related

Appendix A.1.1. Quality Culture

- Acikara, T., Kazaz, A., Ulubeyli, S. Evaluations of construction Project Participants’ Attitudes toward Quality Management in Turkey. Procedia Engineering 2017, 196, 203–210.

- Atkinson, A. Human error in the management of building projects. Construction Management and Economics 1998, 16(3), 339–349.

- Cheetham, D.W., Carter, D.J. The challenge of assuring quality on site British construction site quality assurance case study. Building Research & Information 1993, 21(2), 85–98.

- Collier, P., Corbett, M., Lundrigan, B. Quality performance in a design-build mega-project. Annual Quality congress Transactions 2001, 17–26.

- Jawaharnesan, L., Price, ADF Assessment of the role of the client’s representative for quality improvement. Total Quality Management 1997, 8(6), 375–389.

- Lee, S.H., Peña-Mora, F. Understanding and managing iterative error and change cycles in construction. System Dynamics Review 2007, 23(1), 35–60.

- Mahmood, W.Y.W., Mohammed, A.H. A conceptual framework for the development of quality culture in the construction industry. Proceedings of the 24th Annual conference. Association of Researchers in construction Management, 2008, 247–256.

- Tang, S.L., Aoieong, R.T., Tsui, C.S.L. Quality Culture Auditing for construction Contractors. HKIE Transactions Hong Kong Institution of Engineers 2010, 17(1), 26–35.

- Yng Ling, F.Y., Nga, Tran H. Undesirable project management practices adopted to achieve project outcomes a case study of Vietnam. International Journal of Project Organisation and Management 2012, 4(2), 153–170.

Appendix A.1.2. Process vs. Organisation

- Basu, R. Managing quality in projects: An empirical study. International Journal of Project Management 2014, 31(1), 178–187.

- Wu, Y., Huang, Y., Zhang, S., Zhang, Y. Quality self-control and co-supervision mechanism of construction agent in public investment project in China. Habitat International 2012, 36(4), 471–480.

Appendix A.1.3. Design Phase

- Abdul-Rahman, H., Rahim, F.A.M., Danuri, M.S.M., Wah, L.W. A study on quality management during the pre-construction stage of design-and-build projects. CME 2007 conference—Construction Management and Economics: ‘Past, Present and Future’ 2007, 753–764.

- Anderson, S.D., Cook, E.L. TQM implementation strategy for capital projects. Journal of Management in Engineering 1995, 11(4), 39–47.

- Chang, A.-P., Chou, C.-C., Lin, J.-D. To enhance quality control by using PDRI to define scope of project procurement. Journal of Quality 2014, 21(4), 269–282.

- Chase, G.W., Federle, MOO Implementation of TQM in building design and construction. Journal of Management in Engineering 1992, 8(4), 329–339.

- Fisher, D., Miertschin, S., Pollock, D.R., Jr. Benchmarking in construction industry. Journal of Management in Engineering 1995, 11(1), 50–57.

- Kurdziel, J.M., Nelson, C.R., Nystrom, J.A., Peterson, D.L. Intelligent construction systems; the convergence of computing, communication, and construction. Joint conference on Water Resource Engineering and Water Resources Planning and Management 2000: Building Partnerships 2004.

- Shen, Y.J., Walker, D.H.T. Integrating OHS, EMS and QM with constructability principles when construction planning—A design and construct project case study. TQM Magazine 2001, 13(4), 247–259.

- Toakley, A.R., Marosszeky, M. Towards total project quality—A review of research needs. Engineering, construction and Architectural Management 2003, 10(3), 219–228.

Appendix A.2. Quality Management System

Appendix A.2.1. QMS

- Abdul-Rahman, H. Some observations on the management of quality among construction professionals in the UK. Construction Management and Economics 1996, 14(6), 485–495.

- Battikha, M.G. QUALICON: Computer-based system for construction quality management. Journal of construction Engineering and Management 2002, 128(2), 164–173.

- Battikha, M.G., Russell, A.D. Construction quality management—Present and future. Canadian Journal of Civil Engineering 1998, 25(3), 401–411.

- Burati, J.L., Jr., Matthews, M.F., Kalidindi, S.N. Quality management in construction industry. Journal of construction Engineering and Management 1991, 117(2), 341–359.

- Chen, J., Yang, G. Stuty on improving quality management of construction by information technology. Applied Mechanics and Materials 2012, 174–177, 3471–3474.

- Chileshe, N. PHD in construction management research: What is original contribution to knowledge? The case of TQM. In: Proceedings of the 21st Annual conference. Association of Researchers in construction Management, 2005, 1267–1278.

- Chini, A.R., Valdez, H.E. ISO 9000 and the USS construction industry. Journal of Management in Engineering 2003, 19(2), 69–77.

- Jiang, L., Chen, X., Zhang, X. Virtual organisation of construction project based on project life cycle. Communications in Computer and Information Science 2011, 209, 47–53.

- Kiwus, C.H., Williams, T.P. Application of TQM to environmental construction. Journal of Management in Engineering 2001, 17(3), 176–184.

- Lam, K.C., Ng, ST. A cooperative Internet-facilitated quality management environment for construction. Automation in construction 2006, 15(1), 1–11.

- Leong, T.K., Zakuan, N., Saman, MZM Review of quality management system research in construction industry. International Journal of Productivity and Quality Management 2014, 13(1), 105–123.

- Olafsdottir, A.H., Sverdrup, H., Stefansson, G., Ingason, H.T. Using system dynamics to better understand quality management in the construction industry. International Journal of Productivity and Quality Management 2019, 26(2), 223–245.

- Pheng, L.S., Wee, D. Improving maintenance and reducing building defects through ISO 9000. Journal of Quality in Maintenance Engineering 2001, 7(1), 6–24.

Appendix A.2.2. QMS Implementation

- Pheng, L.S., Teo, J.A. Implementing total quality management in construction firms. Journal of Management in Engineering 2004, 20(1), 8–15.

- Rashed, A., Othman, M. Implementing quality management in construction projects. IEOM 2015—5th International conference on Industrial Engineering and Operations Management, Proceeding 2015.

- Song, X.-H., Niu, D.-X., Ye, C.-Q., Lu, D.-L. Survey on the quality management system of power distribution projects based on the theory of TQM. Applied Mechanics and Materials 2012, 108, 30–34.

Appendix A.3. Satisfaction/Customer Satisfaction

- Albert P.C. Chan, C.M. Tam Factors affecting the quality of building projects in Hong Kong. International Journal of Quality & Reliability Management 2000, 17(4/5), 423–442.

- Al-Momani, A.H. Examining service quality within construction processes. Technovation 2000, 20(11), 643–651.

- Williams, P., Ashill, N.J., Naumann, E., Jackson, E. Relationship quality and satisfaction: Customer-perceived success factors for on-time projects. International Journal of Project Management 2015, 33(8), 1836–1850.

Appendix A.4. Performance-Related

Appendix A.4.1. Performance

- Arditi, D., Lee, D.-E. Assessing the corporate service quality performance of design-build contractors using quality function deployment. Construction Management and Economics 2003, 21(2), 175–185.

- Bassioni, H.A., Price, A.D.F., Hassan, T.M. Performance measurement in construction. Journal of Management in Engineering 2004, 20(2), 42–50.

- Din, S., Abd-Hamid, Z., Bryde, D.J. ISO 9000 certification and construction project performance: The Malaysian experience. International Journal of Project Management 2011, 29(8), 1044–1056.

- Haponava, T., Al-Jibouri, S. Influence of process performance during the construction stage on achieving end-project goals. Construction Management and Economics 2010, 28(8), 853–869.

- Ke, H., Yue, L., Hu, Z.P. Research on grading standard of the project quality management system under comprehensive evaluation method. Applied Mechanics and Materials 2014, 638–640, 2332–2337.

- Ledbetter, W.B. Quality performance on successful project. Journal of construction Engineering and Management 1994, 120(1), 34–46.

- Leong, T.K., Zakuan, N., Mat Saman, MZZ, Ariff, M.S.M., Tan, C.S. Using project performance to measure effectiveness of quality management system maintenance and practices in construction industry. The Scientific World Journal 2014, 591361.

- Luu, V.T., Kim, S.-Y., Huynh, T.-A. Improving project management performance of large contractors using benchmarking approach. International Journal of Project Management 2008, 26(7), 758–769.

- Miao, Y.H. Construction project quality evaluation system from lean construction perspective. Applied Mechanics and Materials 2014, 687–691, 4438–4441.

- Olafsdottir, A.H., Ingason, H.T., Stefansson, G. Defining the variables for a dynamic model of quality management in the construction industry. Results from stakeholder group model-building sessions. International Journal of Productivity and Quality Management 2016, 19(2), 187–208.

- Palaneeswaran, E., Ng, T., Kumaraswamy, M. Client satisfaction and quality management systems in contractor organisations. Building and Environment 2006, 41(11), 1557–1570.

- Shanmugapriya, S., Subramanian, K. Structural equation model to investigate the factors influencing quality performance in Indian construction projects. Sadhana – Academy proceedings in Engineering Sciences 2015, 40(6), 1975–1987.

- Stevens, J.D. Blueprint for measuring project quality. Journal of Management in Engineering 1996, 12(2), 34–39.

- Zavadskas, E.K., Vilutienė, T., Turskis, Z., Šaparauskas, J. Multi-criteria analysis of Projects’ performance in construction. Archives of Civil and Mechanical Engineering 2014, 14(1), 114–121.

- Zulu, S. Impact of project management on project performance: A structural equation modelling approach. In: Proceedings of 23rd Annual ARCOM Conference, 2007, 651–660.

Appendix A.4.2. Critical Success Factors

- Ceptureanu, E.-G., Ceptureanu, S.-I., Luchian, C.-E., Luchian, I. Quality management in project management consulting. A case study in an international consulting company. Amfiteatru Economic 2017, 19(44), 215–230.

- Collins, A., Baccarini, D. Project success—A survey. Journal of construction Research 2004, 5(2), 211–231.

- Doloi, H. Analysis of pre-qualification criteria in contractor selection and their impacts on project success. Construction Management and Economics 2009, 27(12), 1245–1263.

- Kululanga, G.K., Kuotcha, W., McCaffer, R., Edum-Fotwe, F. Construction contractors’ claim process framework. Journal of construction Engineering and Management 2001, 127(4), 309–314.

- Rahman, H.A., Wang, C., Jackson, C. CTM 4 model using Ishikawa diagram for quality management in design-and-build projects. Scientific Research and Essays 2011, 6(25), 5442–5456.

Appendix A.4.3. Quality Factors

- Chen, H.Z., Wu, A.J., Shen, L. Research on quality management system of Wuxi Taihu international expo center project. Applied Mechanics and Materials 2012, 226–228, 2268–2272.

- Hamzah, N., Ramly, A., Salleh, H., Tawil, N.M., Khoiry, M.A., Che Ani, AI. The importance of design process in housing quality. Procedia Engineering 2011, 20, 483–489.

- Yung, P. Yip, B. Construction quality in China during transition: A review of literature and empirical examination. International Journal of Project Management 2010, 28(1), 79–91.

Appendix A.4.4. Costs of Quality

- Al-Tmeemy, S.M.H., Rahman, H.A., Harun, Z. Contractors’ perception of the use of costs of quality system in Malaysian building construction projects. International Journal of Project Management 2012, 30(7), 827–838.

- Duttenhoeffer, R. Cost and quality management. Journal of Management in Engineering 1992, 8(2), 167–175.

- Hall, M., Tomkins, C. A cost of quality analysis of building project: Towards a complete methodology for design and build. Construction Management and Economics 2001, 19(7), 727–740.

- Mashwama, N., Aigbavboa, C., Thwala, D. An Assessment of the Critical Success factor for the Reduction of Cost of Poor Quality in construction Projects in Swaziland. Procedia Engineering 2017, 196, 447–453.

- Pollack-Johnson, B., Liberatore, M.J. Incorporating quality considerations into project time/cost tradeoff analysis and decision making. IEEE Transactions on Engineering Management 2006, 53(4), 534–542.

- Rounce, G. Quality, waste and cost considerations in architectural building design management. International Journal of Project Management 1998, 16(2), 123–127.

- Shao, B., Wang, F., Chen, Z. Research on applying the total quality management to implicit cost control in construction projects. Advanced Materials Research 2012, 368–373, 3150–3154.

- Tam, V.W.Y., Le, K.N. Quality improvement in construction by using a Vandermonde interpolation technique. International Journal of Project Management 2007, 25(8), 815–823.

- Tang, S.L., Aoieong, R.T., Ahmed, S.M. The use of Process Cost Model (PCM) for measuring quality costs of construction projects: Model testing. Construction Management and Economics 2004, 22(3), 263–275.

- Titov, S., Nikulchev, E., Bubnov, G. Learning Practices as a Tool for Quality Costs Reduction in construction Projects. Quality—Access to Success 2015, 16(149), 68–70.

Appendix A.5. Quality Assurance Related

Appendix A.5.1. Improvement

- Kazaz, A., Birgonul, M.T. The evidence of poor quality in high rise and medium rise housing units: A case study of mass housing projects in Turkey. Building and Environment 2005, 40(11), 1548–1556.

- McNary, L.D. Quality management in the public services department of a city government: Streamlining the street cave-in repair process. Quality Engineering 2001, 13(3), 485–500.

- Nyborg, A., Bjorlo, A. Hibernia GBS: construction schedule recovery applying total quality management principles. Proceedings of the Annual Offshore Technology conference 1997, 2, 8399.

- Soares, J., Anderson, S. Modeling process management in construction. Journal of Management in Engineering 1997, 13(5), 45–53.

- Stewart, R.A., Spencer, C.A. Six-sigma as a strategy for process improvement on construction projects: A case study. Construction Management and Economics 2006, 24(4), 339–348.

Appendix A.5.2. Quality Inspection

- Al-Ani, R., Al-Adhmawi, F.I. Implementation of quality management concepts in managing engineering project site. Jordan Journal of Civil Engineering 2011, 5(1), 89–106.

- Hedayatnasab, A., Majrouhisardroud, J., Limbachiya, M. Improving construction quality control and management using automated data collection technologies. IMCIC 2011—2nd International Multi-conference on Complexity, Informatics and Cybernetics, proceedings 2011, 24–29.

- Kraft, E., Molenaar, K. Fundamental project quality assurance organisations in highway design and construction. Journal of Management in Engineering 2014, 30(4), 04014015.

- Leu, S.-S., Tzeng, B.-R. A CPM-based construction quality inspection and decision-aid system. Computer-Aided Civil and Infrastructure Engineering 2000, 15(3), 233–239.

- Minchin, R.E., Hammons, M.I., Ahn, J. A construction quality index for highway construction. Construction Management and Economics 2008, 26(12), 1313–1324.

Appendix A.5.3. Rework

- Balouchi, M., Gholhaki, M., Niousha, A. Reworks causes and related costs in construction: case of Parand mass housing project in Iran. International Journal of Quality and Reliability Management 2019, 36(8), 1392–1408.

- Josephson, P.-E., Larsson, B., Li, H. Illustrative benchmarking rework and rework costs in Swedish construction industry. Journal of Management in Engineering 2002, 18(2), 76–83.

- Love, P.E.D., Smith, J. Benchmarking, benchaction, and benchlearning: Rework mitigation in projects. Journal of Management in Engineering 2003, 19(4), 147–159.

Appendix A.5.4. BIM

- Gökçe, K.U., Scherer, R.J., Dikbas, H.A. Integrated construction project management system based on IFC and ISO 9001:2000. IFIP International Federation for Information Processing 2007, 243, 513–520.

- Ma, Z., Cai, S., Mao, N., Yang, Q., Feng, J., Wang, P. Construction quality management based on a collaborative system using BIM and indoor positioning. Automation in construction 2018, 92, 35–45.

- Nguyen, P.T., Vo, K.D., Phan, P.T., Huynh, V.D.B., Nguyen, T.A., Cao, T.M., Nguyen, QLHTT, Le, L.P. Construction project quality management using building information modeling 360 field. International Journal of Advanced Computer Science and Applications 2018, 9(10), 228–233.

- Pasquire, C., Pennanen, A., Ballard, G., Haahtela, Y. Target costing and designing to targets in construction. Journal of Financial Management of Property and construction 2011, 16(1), 52–63.

- Stransky, M., Matejka, P. Digital quality management in construction industry within BIM projects. Engineering for Rural Development 2019, 18, 1707–1718.

- Wang, K.-C., Wang, S.-H., Kung, C.-J., Weng, S.-W., Wang, W.-C. Applying BIM and visualisation techniques to support construction quality management for soil and water conservation construction projects. 35th International Symposium on Automation and Robotics in construction and International AEC/FM Hackathon: The Future of Building Things. ISARC, 2018.

Appendix A.6. External Relations

Appendix A.6.1. Procurement

- Dozzi, P., Hartman, F., Tidsbury, N., Ashrafi, R. More-stable owner-contractor relationships. Journal of construction Engineering and Management 1996, 122(1), 30–35.

- Erickson, J. Meeting the quality management issue on highway construction. Journal of Professional Issues in Engineering Education and Practice 1989, 115(2), 162–167.

- Gransberg, D.D., Molenaar, K. Analysis of owner’s design and construction quality management approaches in design/build projects. Journal of Management in Engineering 2004, 20(4), 162–169.

- Molenaar, K.R., Bogus, S.M., Priestley, J.M. Design/build for water/wastewater facilities: State of the industry survey and three case studies. Journal of Management in Engineering 2004, 20(1), 16–24.

- Pongpeng, J., Liston, J. Constractor ability criteria: A view from the Thai construction industry. Construction Management and Economics 2003, 21(3), 267–282.

- Yean Yng Ling, F. Models for predicting quality of building projects. Engineering, construction and Architectural Management 2005, 12(1), 6–20.

Appendix A.6.2. Partnering

- Gransberg, D.D., Dillon, W.D., Reynolds, L., Boyd, J. Quantitative analysis of partnered project performance. Journal of construction Engineering and Management 1999, 125(3), 161–166.

- Tang, W., Duffield, C.F., Young, D.M. Partnering mechanism in construction: An empirical study on the chinese construction industry. Journal of construction Engineering and Management 2006, 132(3), 217–229.

- Tang, W., Qiang, M., Duffield, C.F., Young, D.M., Lu, Y. Enhancing total quality management by partnering in construction. Journal of Professional Issues in Engineering Education and Practice 2009, 135(4), 129–141.

- Wilson, R.A., Jr., Songer, A.D., Diekmann, J. Partnering More than a workshop, a catalyst for change. Journal of Management in Engineering 1995, 11(5), 40–45.

Appendix A.6.3. Suppliers QM

- AlMaian, R.Y., Needy, K.L., Walsh, K.D., Alves, TDCL. A qualitative data analysis for supplier quality-management practices for engineer-procure-construct projects. Journal of construction Engineering and Management 2016, 142(2), 04015061.

- Koch, C., Larsen, C.S. Quality in construction: A supply chain perspective. In: Proceedings 22nd Annual ARCOM conference. Association of Researchers in construction Management, 2006, 459–469.

- Yousef, R., La Scola Needy, K., Walsh, K.D., Da Alves, T.C.L. Supplier quality management inside and outside the construction industry. EMJ – Engineering Management Journal 2015, 27(1), 11–22.

- Yu, T., Man, Q., Wang, Y., Shen, G.Q., Hong, J., Zhang, J., Zhong, J. Evaluating different stakeholder impacts on the occurrence of quality defects in offsite construction projects A Bayesian-network-based model. Journal of Cleaner Production 2019, 241, 118390.

- Zeng, S.X.X., Lou, G.X., Tam, V.W.Y. Managing information flows for quality improvement of projects. Measuring Business Excellence 2007, 11(3), 30–40.

Appendix A.7. Other Management Systems

Appendix A.7.1. Environment

- Khadour, L., Darkwa, J. TQEM in the UK construction industry: Some key findings from a survey. In: Proceedings of the 24th Annual conference. Association of Researchers in construction Management 2008, 239–246.

- Khadour, L., Ramsay-Dawber, P., Morledge, R. Case studies on the implementation of TQEM in the UK building contractors. Proceedings of the 25th Annual conference. Association of Researchers in construction Management, 2009, 1051–1058.

Appendix A.7.2. Safety

- Loushine, T.W., Hoonakker, P.L.T., Carayon, P., Smith, M.J. Quality and Safety Management in construction. Total Quality Management 2006, 17(9), 1171–1212.

- Ogwueleka, A.C. A Review of Safety and Quality Issues in the construction Industry. Journal of construction Engineering and Project Management 2013, 3(3), 42–50.

- Husrul, N.H., Hamimah, A., Kamaruzaman, J. Management of Safety for Quality construction. Journal of Sustainable Development 2008, 1(3), 41–47.

Appendix A.8. Methods

- Basu, R. Quality management tools and techniques in major infra-structure projects. 2017 6th International conference on Reliability, Infocom Technologies and Optimisation: Trends and Future Directions 2018, 114–126.

- Delgado-Hernandez, D.J., Aspinwall E. A framework for building quality into construction projects – Part I. Total Quality Management 2008, 19(10), 1013–1028.

- Delgado-Hernandez, D.J., Aspinwall, E.M. Improvement tools in the UK construction industry. Construction Management and Economics 2005, 23(9), 965–977.

- Delgado-Hernandez, D.J., Bampton, K.E., Aspinwall, E. Quality function deployment in construction. Construction Management and Economics 2007, 25(6), 597–609.

- Delgado-Hernandez, D.J., Cruz-Cruz, C.C., Vences-García, P.Y. Improvement Management Tools in the construction Industry: Case Study of Mexico. Journal of construction Engineering and Management 2017, 143(4), 05016024.

- Halpin, D.W., Kueckmann, M. Lean construction and simulation. Winter Simulation conference proceedings 2002, 1697–1703.

- Jia, W. Application of quality control techniques in construction projects. Advanced Materials Research 2012, 433–440, 1513–1518.

- Page, W.A., Teague, R.D. Mobile Bay Project quality management program. Proceedings of the Annual Offshore Technology conference 1994, 287–296.

- Ren, M.-M., Ling, N., Wei, X., Fan, S.-H. The application of PDCA cycle management in project management. International conference on Computer Science and Applications 2017, 268–272.

- Su, Z.G. Research on construction quality control content and method. Applied Mechanics and Materials 2014, 687–691, 4511–4514.

Appendix A.9. Others (Without a Category)

- Keeling, D. Channel Tunnel Rail Link Quality management. Proceedings of the Institution of Civil Engineers: Civil Engineering 2003.

- Liu, A.M.M. The quest for quality in public housing projects: A behaviour-to-outcome paradigm. Construction Management and Economics 2003, 21(2), 147–158.

- Love, P.E.D., Josephson, P.-E. Role of error-recovery process in projects. Journal of Management in Engineering 2004, 20(2), 70–79.

- Pheng, L.S., Hong, S.H. Strategic quality management for the construction industry. TQM Magazine 2005, 17(1), 35–53.

- Walker, D.H.T., Keniger, M. Quality management in construction: An innovative advance using project alliancing in Australia. TQM Magazine 2002, 14(5), 307–317.

Appendix B. Interpretation of Quality-Related Factors

Appendix B.1. Process Quality Factors

- F1 Planning and control—use of methods, techniques, and technologies for planning and control in project implementation;

- F2 Involvement and teamwork—project participants involved in the project, and an efficient team;

- F3 Expertise and knowledge—people involved in the project are qualified, possess competencies, know and apply techniques, methods for the work they perform;

- F4 Customer satisfaction—focus on understanding and customer expectations and fulfilling them;

- F5 Top management commitment—managers available, responsible and involved in the project, contribute to the quality;

- F6 Communication—effective transmission of information, lack of misunderstanding, conflict management;

- F7 Continuous improvement—effects of improvement visible in the project, employees involved in the implementation of new methods or technologies;

- F8 Coordination between project participants—work performed by different contractors or employees is coordinated in time;

- F9 Quality policy—the formal quality policy was described and implemented; employees act according to the policy;

- F10 Availability of resources—resources are well planned, controlled and adequately utilised;

- F11 Supplier quality management—quality management practices extend to suppliers, including at least supplies control and effective information exchange;

- F12 Quality supervision—team members were assigned to monitor and control quality; quality monitoring procedures are present;

- F13 Requirements management—elicitation, documentation, change management, configuration management.

- F14 Health and safety—team members were assigned to monitor health and safety; H&S procedures present and implemented; absence of unsafe behaviours among employees;

Appendix B.2. Organisation Quality Factors

- O1 Quality department—a permanent department in the organisation that coordinates quality management throughout the company and projects;

- O2 Long-term partnering—cooperation with suppliers and partners is not limited to one project only, but it is based on long-term relations, which allows continuous improvement;

- O3 Quality audit—quality management system is regularly monitored; quality audits results in change requests;

- O4 Clear responsibilities—the responsibilities of all employees in the organisation and project are precisely described and well known;

- O5 Quality culture—pro-quality attitude is present among managers and employees even before the project begins.

- O6 Formalisation—all quality-related processes are described in procedures or other documentation; employees act according to the documentation; document change management process implemented;

Appendix B.3. Product Quality Factors

- S1 Accuracy of specifications—initial specifications are precise and accurate;

- S2 Transfer without errors and shortcomings—no rework or delays during transfer between phases;

- S3 Downtime—the downtime, if necessary, is planned and optimised (e.g., brownfield projects);

- D1 Complete technical documentation—documentation includes all necessary information and takes into account known limitations (e.g., space, technology, resources);

- D2 Permits acquired—all permits before the execution phase acquired on time;

- D3 Difference between predicted and planned budgets—planned over-budget not higher than admissible by project management frameworks;

- E1 Customer satisfaction at the end phase—the delivered result consistent with customer requirements;

- E2 The viability of the project—the profitability of the project is consistent with the initial assumptions;

- E3 Compliance with scope—the project delivered according to time, cost and scope;

- E4 Contribution for future projects—good practices and lessons learned can be transferred to the organisation or the following projects;

- E5 Completion of inspection and use permit—all permits after the execution phase acquired on time;

- E6 Transfer without errors and shortcomings—no rework or delays during the transfer of the final result;

- E7 Initial budget change—final over-budget not higher than admissible by project management frameworks;

References

- Standish Group. The Standish Group Report Chaos; Standish Group International Inc.: Boston, MA, USA, 2018. [Google Scholar]

- AXELOS. Managing Successful Projects with PRINCE2®, 6th ed.; TSO: London, UK, 2017; ISBN 978-0-11-331533-8. [Google Scholar]

- AXELOS. Managing Successful Programmes; TSO: London, UK, 2020; ISBN 978-0-11-331676-2. [Google Scholar]

- Project Management Institute. Construction Extension to the PMBOK Guide; Project Management Institute: Newtown Square, PA, USA, 2016; ISBN 978-1-62825-090-9. [Google Scholar]

- Morris, P.W.G. Reconstructing Project Management; Wiley-Blackwell: Hoboken, NJ, USA, 2013; ISBN 978-1-118-53691-9. [Google Scholar]

- Svejvig, P.; Andersen, P. Rethinking project management: A structured literature review with a critical look at the brave new world. Int. J. Proj. Manag. 2015, 33, 278–290. [Google Scholar] [CrossRef]

- Brocke, J.v.; Lippe, S. Managing collaborative research projects: A synthesis of project management literature and directives for future research. Int. J. Proj. Manag. 2015, 33, 1022–1039. [Google Scholar] [CrossRef]

- Picciotto, R. Towards a ‘New Project Management’ movement? An international development perspective. Int. J. Proj. Manag. 2020, 38, 474–485. [Google Scholar] [CrossRef]

- Bergmann, T.; Karwowski, W. Agile project management and project success: A literature review. In Advances in Human Factors, Business Management and Society; Kantola, J.I., Nazir, S., Barath, T., Eds.; Springer: Cham, Switzerland, 2019; Volume 783, pp. 405–414. ISBN 978-3-319-94708-2. [Google Scholar]

- Olafsdottir, A.H.; Ingason, H.T.; Stefansson, G. Defining the variables for a dynamic model of quality management in the construction industry: Results from stakeholder group model-building sessions. Int. J. Prod. Qual. Manag. 2016, 19, 187. [Google Scholar] [CrossRef]

- Ingason, H.; Olafsdottir, A.H.; Sverdrup, H.; Stefansson, G. Using system dynamics to better understand quality management in the construction industry. Int. J. Prod. Qual. Manag. 2019, 26, 1. [Google Scholar] [CrossRef]

- Ren, M.-M.; Ling, N.; Wei, X.; Fan, S.-H. The application of PDCA cycle management in project management. In Proceedings of the 2015 International Conference on Computer Science and Applications (CSA), Wuhan, China, 20–22 November 2015; pp. 268–272. [Google Scholar]

- Mashwama, N.; Aigbavboa, C.; Thwala, D. An assessment of the critical success factor for the reduction of cost of poor quality in construction projects in Swaziland. Procedia Eng. 2017, 196, 447–453. [Google Scholar] [CrossRef]

- Watt, A. Project Management; BCampus: Victoria, BC, USA, 2014; ISBN 978-1-77420-013-1. [Google Scholar]

- Basu, R. Managing quality in projects: An empirical study. Int. J. Proj. Manag. 2014, 32, 178–187. [Google Scholar] [CrossRef]

- Dolaček-Alduk, Z.; Mikulić, D.; Radujković, M. Quality management in project-oriented construction processes. Građevinar 2007, 59, 209–218. [Google Scholar]

- Ogwueleka, A.C. A review of safety and quality issues in the construction industry. J. Constr. Eng. Proj. Manag. 2013, 3, 42–48. [Google Scholar] [CrossRef]

- Doskočil, R.; Lacko, B. Risk Management and knowledge management as critical success factors of sustainability projects. Sustainability 2018, 10, 1438. [Google Scholar] [CrossRef]

- Wu, X.; Zhao, W.; Ma, T. Improving the impact of green construction management on the quality of highway engineering projects. Sustainability 2019, 11, 1895. [Google Scholar] [CrossRef]

- Wang, G.; Liu, H.; Li, H.; Luo, X.; Liu, J. A building project-based industrialised construction maturity model involving organisational enablers: A multi-case study in China. Sustainability 2020, 12, 4029. [Google Scholar] [CrossRef]

- Vukomanovic, M.; Radujkovic, M.; Nahod, M.M. EFQM excellence model as the TQM model of the construction industry of South-eastern Europe. J. Civ. Eng. Manag. 2014, 20, 70–81. [Google Scholar] [CrossRef]

- Ljevo, Ž.; Vukomanović, M.; Džebo, S. Assessing the influence of project management on quality during the early phases of construction projects. Organ. Technol. Manag. Constr. 2018, 9, 1584–1592. [Google Scholar] [CrossRef][Green Version]

- Biedenbach, T.; Müller, R. Paradigms in project management research: Examples from 15 years of IRNOP conferences. Int. J. Manag. Proj. Bus. 2011, 4, 82–104. [Google Scholar] [CrossRef]

- Fink, A. Conducting Research Literature Reviews: From Paper to the Internet; SAGE Publications: Thousand Oaks, CA, USA, 1998; ISBN 978-0-7619-0904-0. [Google Scholar]

- Denyer, D.; Tranfield, D. Producing a systematic review. In The Sage Handbook of Organizational Research Methods; Buchanan, D.A., Bryman, A., Eds.; SAGE Publications: Thousand Oaks, CA, USA, 2009; pp. 671–689. ISBN 978-1-4129-3118-2. [Google Scholar]

- Denyer, D.; Tranfield, D.; van Aken, J.E. Developing design propositions through research synthesis. Organ. Stud. 2008, 29, 393–413. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. The PRISMA group preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef]

- Ljevo, Z.; Vukomanović, M.; Rustempašić, N. Analysing significance of key quality factors for management of construction projects. Građevinar 2017, 2017, 359–366. [Google Scholar] [CrossRef]

- Byrne, B.M. Structural Equation Modeling with AMOS: Basic Concepts, Applications, and Programming, 3rd ed.; Lawrence Erlbaum Associates: Mahwah, NJ, USA, 2016; ISBN 978-1-138-79702-4. [Google Scholar]

- Hair, J.F., Jr.; Anderson, R.E.; Tatham, R.L.; Black, W.C. Multivariate Data Analysis; Prentice Hall: Upper Saddle River, NJ, USA, 1998; ISBN 978-0-13-813263-7. [Google Scholar]

- Hussain, S.; Fangwei, Z.; Siddiqi, A.; Ali, Z.; Shabbir, M. Structural equation model for evaluating factors affecting quality of social infrastructure projects. Sustainability 2018, 10, 1415. [Google Scholar] [CrossRef]

- Kitchenham, B.; Charters, S. Guidelines for Performing Systematic Literature Reviews in Software Engineering; Keele University: Keele, UK; Durham University: Durham, UK, 2007. [Google Scholar]

- Project Management Institute. A Guide to the Project Management Body of Knowledge, 6th ed.; Project Management Institute: Newton Square, PA, USA, 2017; ISBN 978-1-62825-184-5. [Google Scholar]

- Wawak, S.; Rogala, P.; Dahlgaard-Park, S.M. Research trends in quality management in years 2000–2019. Int. J. Qual. Serv. Sci. 2020. [Google Scholar] [CrossRef]

- Ceptureanu, E.-G.; Ceptureanu, S.-I.; Luchian, C.-E.; Luchian, I. Quality management in project management consulting. A case study in an international consulting company. Amfiteatru Econ. J. 2017, 19, 215. [Google Scholar]

- Acıkara, T.; Kazaz, A.; Ulubeyli, S. Evaluations of construction project participants’ attitudes toward quality management in Turkey. Procedia Eng. 2017, 196, 203–210. [Google Scholar] [CrossRef]

- Koskela, L.J.; Howell, G. The underlying theory of project management is obsolete. In Proceedings of the PMI Research Conference (PMI), Seattle, WA, USA, 14–17 July 2002; pp. 293–302. [Google Scholar]

- Melgrati, A.; Damiani, M. Rethinking the project management framework: New epistemology, new insights. In Proceedings of the PMI Research Conference (PMI), Seattle, WA, USA, 14–17 July 2002; pp. 371–380. [Google Scholar]

| Journal Title | Papers |

|---|---|

| Journal of Management in Engineering | 17 |

| Construction Management and Economics | 14 |

| Journal of Construction Engineering and Management | 9 |

| International Journal of Project Management | 8 |

| Applied Mechanics and Materials | 6 |

| International Journal of Productivity and Quality Management | 3 |

| Procedia Engineering | 3 |

| Total Quality Management | 3 |

| TQM Magazine | 3 |

| Advanced Materials Research | 2 |

| Automation in Construction | 2 |

| Building and Environment | 2 |

| Engineering, Construction and Architectural Management | 2 |

| Journal of Professional Issues in Engineering Education and Practice | 2 |

| Others | 50 |

| Group | Category | N | 1990 | 1995 | 2000 | 2005 | 2010 | 2015 | 2020 | ||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Organisation quality management related | Quality culture | 9 | |||||||||||||||||||||||||||||||||||

| Process vs. organisation | 2 | ||||||||||||||||||||||||||||||||||||

| Design phase | 8 | ||||||||||||||||||||||||||||||||||||

| Quality Management System | QMS | 13 | |||||||||||||||||||||||||||||||||||

| QMS implementation | 3 | ||||||||||||||||||||||||||||||||||||

| Satisfaction | Customer satisfaction | 3 | |||||||||||||||||||||||||||||||||||

| Performance related | Performance | 15 | |||||||||||||||||||||||||||||||||||

| Critical Success Factors | 5 | ||||||||||||||||||||||||||||||||||||

| Quality factors | 3 | ||||||||||||||||||||||||||||||||||||

| Costs of quality | 10 | ||||||||||||||||||||||||||||||||||||

| Quality Assurance related | Improvement | 5 | |||||||||||||||||||||||||||||||||||

| Quality inspection | 5 | ||||||||||||||||||||||||||||||||||||

| Rework | 3 | ||||||||||||||||||||||||||||||||||||

| BIM | 6 | ||||||||||||||||||||||||||||||||||||

| External relations | Procurement | 6 | |||||||||||||||||||||||||||||||||||

| Partnering | 4 | ||||||||||||||||||||||||||||||||||||

| Suppliers QM | 5 | ||||||||||||||||||||||||||||||||||||

| Other management systems | Environment | 2 | |||||||||||||||||||||||||||||||||||

| Safety | 3 | ||||||||||||||||||||||||||||||||||||

| Methods | Methods | 11 | |||||||||||||||||||||||||||||||||||

| Process Quality Factors | Organisation Quality Factors | Product Quality Factors |

|---|---|---|

|

| Phase 1. Initiation

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wawak, S.; Ljevo, Ž.; Vukomanović, M. Understanding the Key Quality Factors in Construction Projects—A Systematic Literature Review. Sustainability 2020, 12, 10376. https://doi.org/10.3390/su122410376

Wawak S, Ljevo Ž, Vukomanović M. Understanding the Key Quality Factors in Construction Projects—A Systematic Literature Review. Sustainability. 2020; 12(24):10376. https://doi.org/10.3390/su122410376

Chicago/Turabian StyleWawak, Sławomir, Žanesa Ljevo, and Mladen Vukomanović. 2020. "Understanding the Key Quality Factors in Construction Projects—A Systematic Literature Review" Sustainability 12, no. 24: 10376. https://doi.org/10.3390/su122410376

APA StyleWawak, S., Ljevo, Ž., & Vukomanović, M. (2020). Understanding the Key Quality Factors in Construction Projects—A Systematic Literature Review. Sustainability, 12(24), 10376. https://doi.org/10.3390/su122410376