Sustainability of Extraction of Raw Material by a Combination of Mobile and Stationary Mining Machines and Optimization of Machine Life Cycle

Abstract

:1. Introduction

2. Materials and Methods

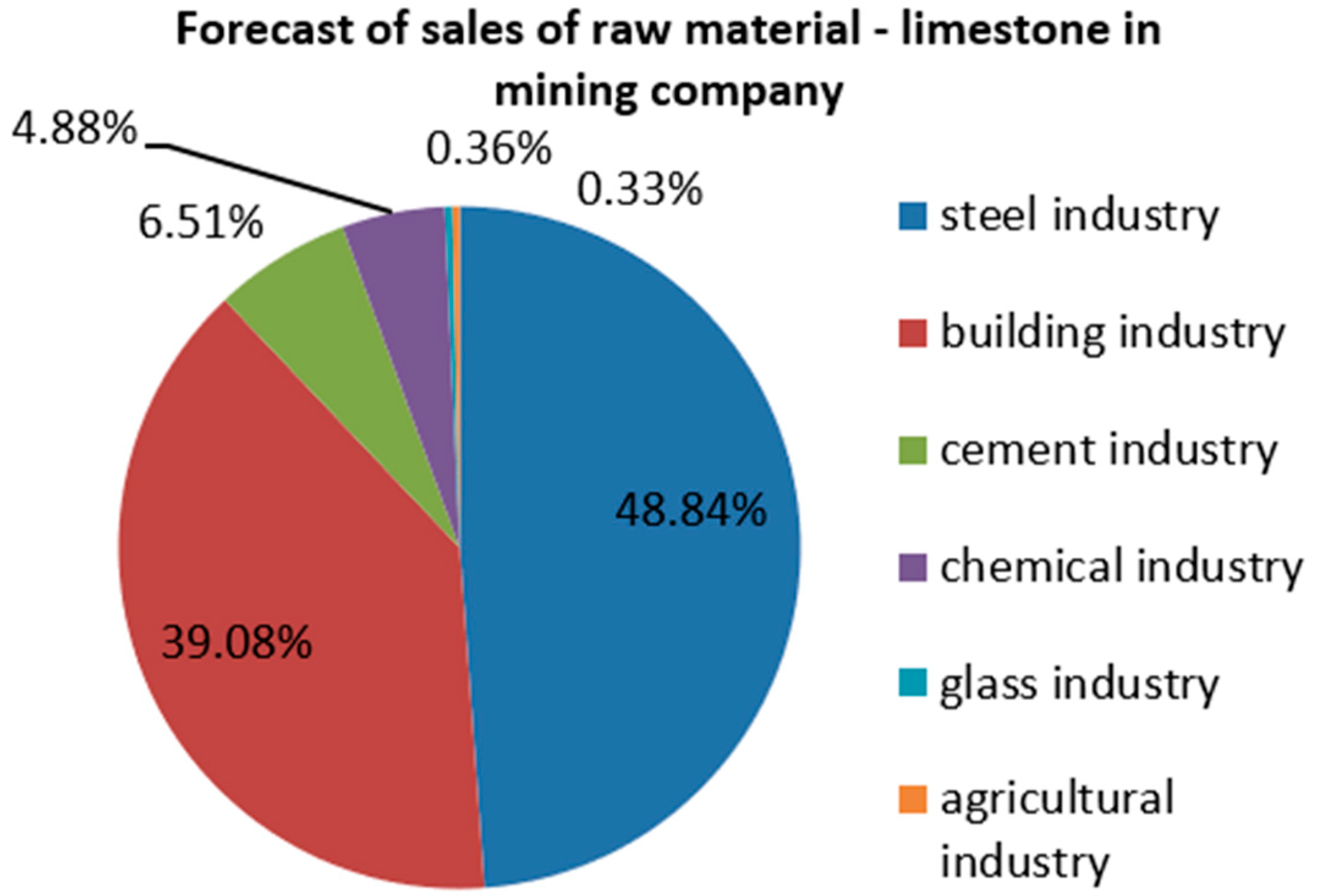

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cehlár, M.; Čulková, K.; Pavolová, H.; Khouri, S. Sustainability of Business with Earth Sources in V4. In 4th International Innovative Mining Symposium. Bristol, Great Britain, Edition Diffusion Presse Sciences. E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2019; Volume 105, pp. 1–7. [Google Scholar] [CrossRef]

- Teplická, K. Operational Analysis in the Practice of Industrial Enterprises; Technical University of Ostrava: Ostrava, Czech Republic, 2019; 114p, ISBN 978-80-248-4316-2. [Google Scholar]

- Cehlár, M.; Mihók, J.; Engel, J.; Rybár, R. Surface Mining; ES/AMS F BERG, TU: Košice, Slovakia, 2005; 328p. [Google Scholar]

- Teplická, K.; Čulková, K. Permanent improving in engineering industry through improvement suggestion. Ann. Fac. Eng. Hunedoara Int. J. Eng. 2013, 11, 219–222. [Google Scholar]

- Teplická, K.; Čulková, K. Optimization of processes for machinery and equipment renovation through models of operation analysis. Ann. Fac. Eng. Hunedoara Int. J. Eng. 2011, 9, 327–329. [Google Scholar]

- Šofranko, M.; Wittenberger, G.; Škvareková, E. Optimisation of technological transport in quarries using application software. Int. J. Min. Miner. Eng. 2015, 6, 1–13. [Google Scholar]

- Čech, J.; Šofranko, M. Economic Projection and Evaluation of Mining Venture. Econ. Manag. 2018, 21, 38–52. [Google Scholar] [CrossRef]

- Koščo, J.; Tauš, P.; Beer, M.; Rybár, R.; Kudelas, D. Forecast Trends and New Possibilities of Using Some of Selected Earth Resources. In Proceedings of the 17th SGEM Science and Technologies in Ecology, Exploration and Mining: Exploration and Mining: International Multidisciplinary Scientific Geoconference, Sofia, Bulgaria, 29 June–5 July 2017; pp. 343–350. [Google Scholar]

- Mayton, A.G.; Demich, B.; Nasarwanji, M.F. Investigation of machine mounted area lighting to reduce risk of injury from slips-trips-falls for operators of mobile surface mining equipment. Min. Metall. Explor. 2020. [Google Scholar] [CrossRef]

- Adebayo, B.; Mukoya, J.G.M. Rock properties and machine parameters evaluation at rossing uranium mine for optimum drill performance. J. S. Afr. Inst. Min. Mettargy 2019, 119, 459–464. [Google Scholar] [CrossRef]

- Eshchin, E.K. Calculations of dynamic operating modes of electric drives of self-propelled mining machines. J. Min. Inst. 2018, 233, 534–538. [Google Scholar] [CrossRef]

- Qi, C.C.; Chen, Q.S.; Kim, S.S. Integrated and intelligent design framework for cemented paste backfill: A combination of robust machine learning modeling and multi-objective optimalization. Miner. Eng. 2020, 155, 106422. [Google Scholar] [CrossRef]

- Kuczaj, M.; Sitek, W. Experimental and Theoretical Assessment of Functional and Operational Qualities of Mechanical Protection Mechanisms Used in Safety Couplings of Drive Systems of Mining Machines. In Proceedings of the IOP Conference Series-Earth and Environmental Science Poland, Krakow, Poland, 16–18 October 2019; Volume 261. [Google Scholar] [CrossRef]

- Krupnik, L.; Yelemessov, K.; Beisenov, B.; Baskanbayeva, D. Substantiation and process design to manufacture polymer-concrete transfer cases for mining machines. Min. Miner. Depos. 2020, 14, 103–109. [Google Scholar] [CrossRef]

- Gerike, B.L.; Klishin, V.I.; Mokrushev, A.A. Availability assessment of mouting groups of mining machines. J. Min. Sci. 2019, 55, 954–961. [Google Scholar] [CrossRef]

- Varga-Machuca, J.; Garcia, F.; Coronado, A.M. Detailed comparison of methods for classifying bearing failures using noisy measurements. J. Fail. Anal. Prev. 2020. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, S.M.; Qiao, S.Y. Study on Safety Monitoring System of Mine Machine. In Proceedings of the Progress in Mine Safety Science and Engineering II, 2nd International Symposium on Mine Safety Science and Engineering, Beijing, China, 21–23 September 2013; pp. 487–490. [Google Scholar]

- Deng, Q.G.; Wei, J.P.; Cao, Q.G. Management and assessment of coal mine safety based on man-machine-environment system. Int. Symp. Saf. Sci. Technol. Prog. Saf. Sci. Technol. 2008, 7, 98–101. [Google Scholar]

- Karlinski, J.; Ptak, M.; Dzialak, P.; Rusinski, E. The approach to mining safety improvement: Accident analysis of an underground machine operator. Arch. Civil Mech. Eng. 2016, 16. [Google Scholar] [CrossRef]

- Gerike, B.L.; Klishin, V.I.; Gerike, P.B. Highly Efficient Hard Rock-Breaking tool for Mining Machines. In Proceedings of the IOP Conference Series Earth and Environmental, Novosibirsk, Russia, 1–5 October 2018; Volume 262. [Google Scholar] [CrossRef]

- Krunic, D.J.; Vujic, S.; Tanaijevic, M.; Dimitrijevic, B.; Subaranovic, T.; Ilic, S.; Maksimovic, S. Model approaches to life cycle assessment of auxiliary machines based on an example of a coal mine in Serbia. J. Min. Sci. 2018, 54, 404–413. [Google Scholar] [CrossRef]

- McNinch, M.; Parks, D.; Jacksha, R.; Miller, A. Leveraging IOT to improve machine safety in the mining industry. Min. Metall. Explor. 2019, 36, 675–681. [Google Scholar] [CrossRef]

- Sütőová, A.; Zgodavová, K.; Lajczyková, M. Quality and effectiveness evaluation of the geological services using CEDAC method. Acta Montan. Slovaca 2018, 23, 18–25. [Google Scholar]

- Teplická, K.; Čulková, K. Evaluation of maintenance process through controlling. Ann. Fac. Eng. Hunedoara 2009, 7, 77–82. [Google Scholar]

- Teplická, K.; Hurná, S.; Kádárová, J.; Čulková, K. Competitiveness increasing in mining companies through application of operation research methods. Tem J. 2020, 9, 393–401. [Google Scholar] [CrossRef]

- Zavadsky, J.; Korenkova, V.; Zavadska, Z.; Kadarova, J.; Tucek, D. Competences in the quality management system evaluation based on the most worlwide used key performance indicators. Qual. Access Success 2020, 20, 29–41. [Google Scholar]

- Rosová, A.; Behun, M.; Khouri, S.; Cehlar, M.; Ferencz, V.; Sofranko, M. Case study: The simulation modeling to improve the efficiency and performance of production process. Wirel. Netw. 2020. [Google Scholar] [CrossRef]

- Potkány, M.; Škultétyová, M. Research into customer preferences of potential buyers of simple wood based houses for the purpose of using the target costing. Open Eng. 2019, 9, 390–396. [Google Scholar] [CrossRef]

- Pavolová, H.; Šimková, Z.; Seňová, A.; Wittenberger, G. Macroeconomic indicators of raw material policy in Slovakia. In Proceedings of the First Interregional Conference Sustainable Development of Eurasian Mining Regions, Kemerovo, Russia, 25–27 November 2019; Edition Diffusion Presser Sciences: London, UK, 2019; pp. 1–12. [Google Scholar]

- Šimková, Z.; Seňová, A.; Divoková, A.; Očenášová, M.; Varga, P. Possibilities of Using Brownfields after Mining and Processing of Mineral Resources in Slovakia. In Proceedings of the 14th International Innovative Mining Symposium, London, UK, 16–19 November 2019; pp. 1–6. [Google Scholar] [CrossRef]

| Machinery used in mining and quarrying | Wheel loaders, tracked excavators, dozers, trucks, drilling rigs, compressors, mills, crushers, conveyors |

| Mining equipment | Mining combines, mining complexes |

| Excavation of mining works | Punching combines, drilling rigs, drilling rigs, punching complexes, punching machines |

| Transport machines | Trackless conveyor loaders, rail locomotives, suspended locomotives, belt and rake conveyors |

| Lifting machines | Hoists, mobile hoists, cranes, mobile work platforms, construction lifts, rack stackers |

| Wheel Loader | Machine Weight (kg) | Bucket Capacity (m3) | Number of Loads (x) | Conversion (ton) |

|---|---|---|---|---|

| DOSAN DL250 | 14,000 | 2.5 | 6 | 4 |

| VOLVOL120 E | 19,000 | 3.3 | 4.55 | 5.28 |

| CAT 966 M | 23,200 | 4.4 | 3.41 | 7.04 |

| CAT 972 M | 24,900 | 4.8 | 3.13 | 7.68 |

| Tracked Excavator | Machine Weight (kg) | Bucket Capacity (m3) |

|---|---|---|

| DOSAN DX 225 | 23,600 | 1.7 |

| VOLVOEC290CNL | 31,000 | 1.7 |

| CAT 329 E | 30,500 | 1.8 |

| CAT 336 F | 27,200 | 2.2 |

| Mobile Crusher | Fraction (0–36 mm) | Fraction (0–100 mm) |

|---|---|---|

| HARTL 12/65 J | 150 ton/h | 200 ton/h |

| SANDVIK QJ341+ | 250 ton/h | 330 ton/h |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teplická, K.; Straka, M. Sustainability of Extraction of Raw Material by a Combination of Mobile and Stationary Mining Machines and Optimization of Machine Life Cycle. Sustainability 2020, 12, 10454. https://doi.org/10.3390/su122410454

Teplická K, Straka M. Sustainability of Extraction of Raw Material by a Combination of Mobile and Stationary Mining Machines and Optimization of Machine Life Cycle. Sustainability. 2020; 12(24):10454. https://doi.org/10.3390/su122410454

Chicago/Turabian StyleTeplická, Katarína, and Martin Straka. 2020. "Sustainability of Extraction of Raw Material by a Combination of Mobile and Stationary Mining Machines and Optimization of Machine Life Cycle" Sustainability 12, no. 24: 10454. https://doi.org/10.3390/su122410454

APA StyleTeplická, K., & Straka, M. (2020). Sustainability of Extraction of Raw Material by a Combination of Mobile and Stationary Mining Machines and Optimization of Machine Life Cycle. Sustainability, 12(24), 10454. https://doi.org/10.3390/su122410454